Harbor Freight Tools 61257 Product manual

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference.

Visit our website at: http://www.harborfreight.com

Email our technical support at: productsupport@harborfreight.com

REV 14j

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 2013 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

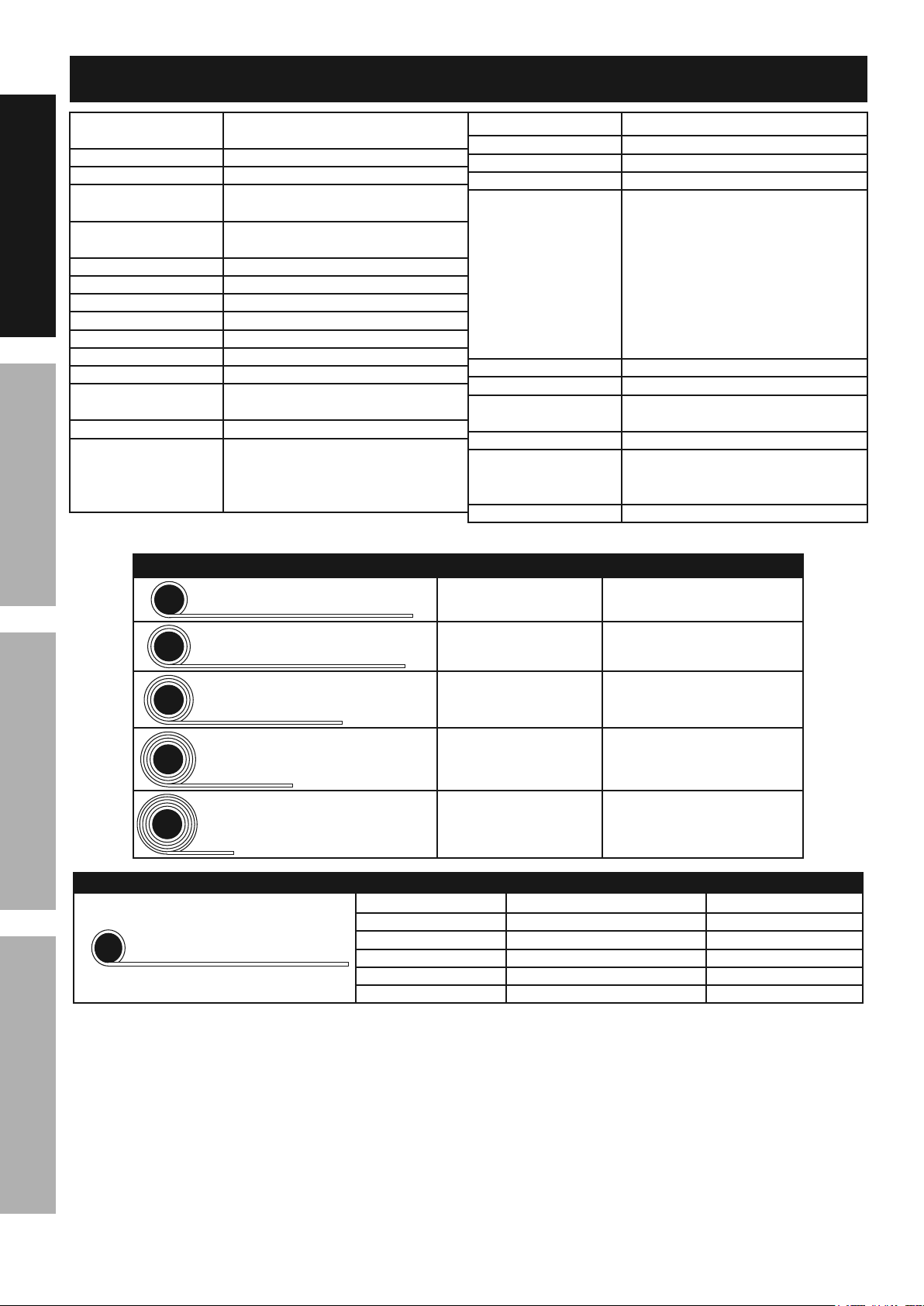

Specifications

Rated Single

Line Pull

Application ATV/UTV

SAFETY OPERATION MAINTENANCESETUP

Motor 12VDC 1.9 HP Permanent Magnet

Power IN &

Power OUT

Duty Cycle Rating 5% (45 sec at Max Rated Load;

Pendant Controller Wired, 12 ft (3.7m) long

Handlebar Controller Wired, 8 ft (2.4m) long

Geartrain 3-Stage Planetary

Gear Ratio 136:1

Freespool Cam Activated

Brake Auto. Load Holding Mechanical

Drum (Dia. X L) 2″ x 2.9″ (50mm x 74mm)

Hook 1/4″ Clevis, with Spring‑loaded

Fairlead Roller with nylon bushings

Wire Rope

Size / Type

3,500 lb. (1,588 kg.)

Yes

14 min, 15 sec Rest)

Safety Latch

Ø3/16″ x 50′ (Ø4.8mm X 15.2m)

Nominal strength=4,200 lb

7X19 Galvanized Steel

Aircraft Wire Rope

Layer Rated Line Pull Wire Rope Capacity

Battery 12VDC, Minimum 12 Ah

Battery Cables 6 gauge, 6′ (1.83m) long

Solenoid Cables 6 gauge, 3′ (0.92m) long

Mounting Pattern 3″ x 4.88″ (76.2mm x 124mm)

Mounting Hardware Winch:

4x G8, M8-1.25 X 25mm

Adaptor Plate:

2x G8, M8-1.25 X 25mm

Fairlead:

2x G8, M8-1.25 X 20mm

Socket Lead:

2x G8, ST-M4 X 30mm

Overload Protection In line Circuit Breaker

Sound Rating 85 dB

Overall Dimensions

(L X D X H)

Weight 25 lb. (11.3 kg.)

IP Rating IP 67 - Winch and Controls

Winch Certification CE

13.3″ X 4.25″ X 4.5″

(338 X 108 X 114mm)

(except remote switch,

resistant to immersion up to 3′)

1

2

3

4

5

First Layer of Wire Rope Performance

Line Pull lb. (kg.) Line Speed fpm (mpm) Amp Draw (@ 12V)

0 (0) 23 (7) 20

1

1000 (454) 14.1 (4.3) 81

2000 (907) 11 (3.4) 135

3000 (1361) 6.6 (2) 205

3500 (1588) 5.4 (1.6) 232

3500 lb. (1588 kg.) 8′ (2.4m)

2988 lb. (1355 kg.) 17.3′ (5.3m)

2606 lb. (1182 kg.) 28′ (8.5m)

2311 lb. (1048 kg.) 41′ (12.5m)

2076 lb. (942 kg.) 50′ (15.2m)

Page 2 For technical questions, please call 1-888-866-5797. Item 61257

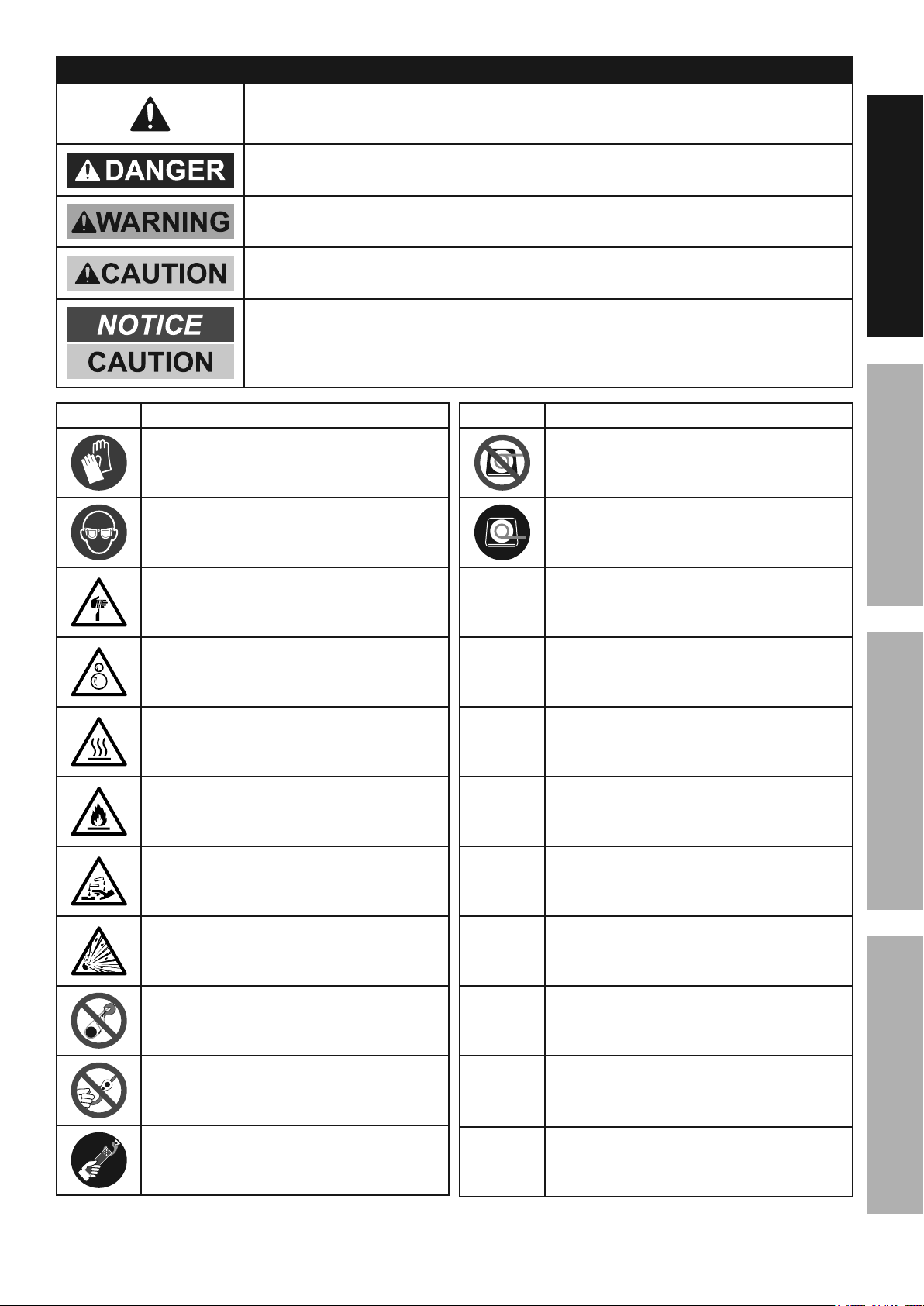

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

SAFETYOPERATIONMAINTENANCE SETUP

Symbol Property or Statement

Wear heavy-duty, cut- and

abrasion-resistant leather gloves.

Wear ANSI-approved safety glasses.

Cut or sever hazard.

Roller entanglement hazard.

Hot surface burn hazard.

Fire hazard.

Symbol Property or Statement

Do not use winch in overwind orientation.

(Wire rope enters/exits at the top.)

Use winch only in underwind orientation.

(Wire rope enters/exits at the bottom.)

VDC

A

CCA

HP

Volts Direct Current

Amperes

Cold Cranking Amperes

Horsepower

Caustic chemical (acid) hazard.

Explosion hazard.

Do not loop the wire rope around

object and hook onto itself.

Do not place finger(s) through hook.

Fingers may be caught and get

pulled into fairlead or drum.

Pull hook using strap only.

fpm

mpm

RPM

IP

G8

Feet Per Minute

Meters Per Minute

Revolutions Per Minute

International Protection rating

Classifies the degrees of protection provided

against the intrusion of solid objects,

dust, accidental contact, and water.

Grade 8

A fastener strength rating.

Page 3For technical questions, please call 1-888-866-5797.Item 61257

Important Safety Information

WARNING! Read all instructions.

Failure to follow all instructions may result in fire, serious injury and/or DEATH.

SAFETY OPERATION MAINTENANCESETUP

The warnings and precautions discussed in this manual cannot cover all possible conditions and

situations that may occur. It must be understood by the operator that common sense and caution

are factors which cannot be built into this product, but must be supplied by the operator.

Installation Precautions

1. Do not wear loose clothing or jewelry,

as they can be caught in moving parts.

Non-skid footwear is recommended.

Wear restrictive hair covering to contain long hair.

2. Wear ANSI-approved safety goggles and

heavy-duty leather work gloves during installation.

3. Before installation confirm that area is clear

of fuel lines, brake lines, electrical wires,

gas tanks or any other component which

could be damaged during drilling.

4. Mounting location and hardware

must support winch and load.

5. Use supplied power cords and wire rope listed

in manual only. Do not use thinner/longer

cables or link multiple cables together.

6. Do not route electrical cables near sharp edges

or parts that will move or become hot.

7. Ventilate area well before and while working

on battery. Explosive invisible hydrogen gas

can accumulate and then explode when ignited

by a spark from the battery connection.

8. Only connect to a clean, corrosion free battery.

9. Do not lean over or come in contact with

battery while making connections.

10. Remove all metal jewelry before

working near battery.

11. Connect red wire to positive battery terminal

and black wire to negative battery terminal.

12. Insulate all exposed wiring and

terminals after installation.

13. Install winch and fairlead in underwind orientation,

so that the wire rope enters and exits the

winch at the bottom of the drum.

Page 4 For technical questions, please call 1-888-866-5797. Item 61257

Operation Precautions

1. Do not exceed load capacity. Be aware of

dynamic loading! Sudden load movement may

briefly create excess load causing product failure.

2. Do not maintain power to the winch if the

motor stalls. Verify load is within rated capacity

for the wire rope layer, see Specifications on

page 2. Make sure the battery is fully charged.

Use double line rigging whenever possible,

see Double Line Rigging on page 11.

3. Wear ANSI-approved safety goggles and

heavy-duty leather work gloves during operation.

4. Do not disengage clutch under load.

Engage clutch before starting.

5. Keep clear of fairlead when operating.

Do not try to guide wire rope.

6. Do not place finger(s) through hook. Fingers may

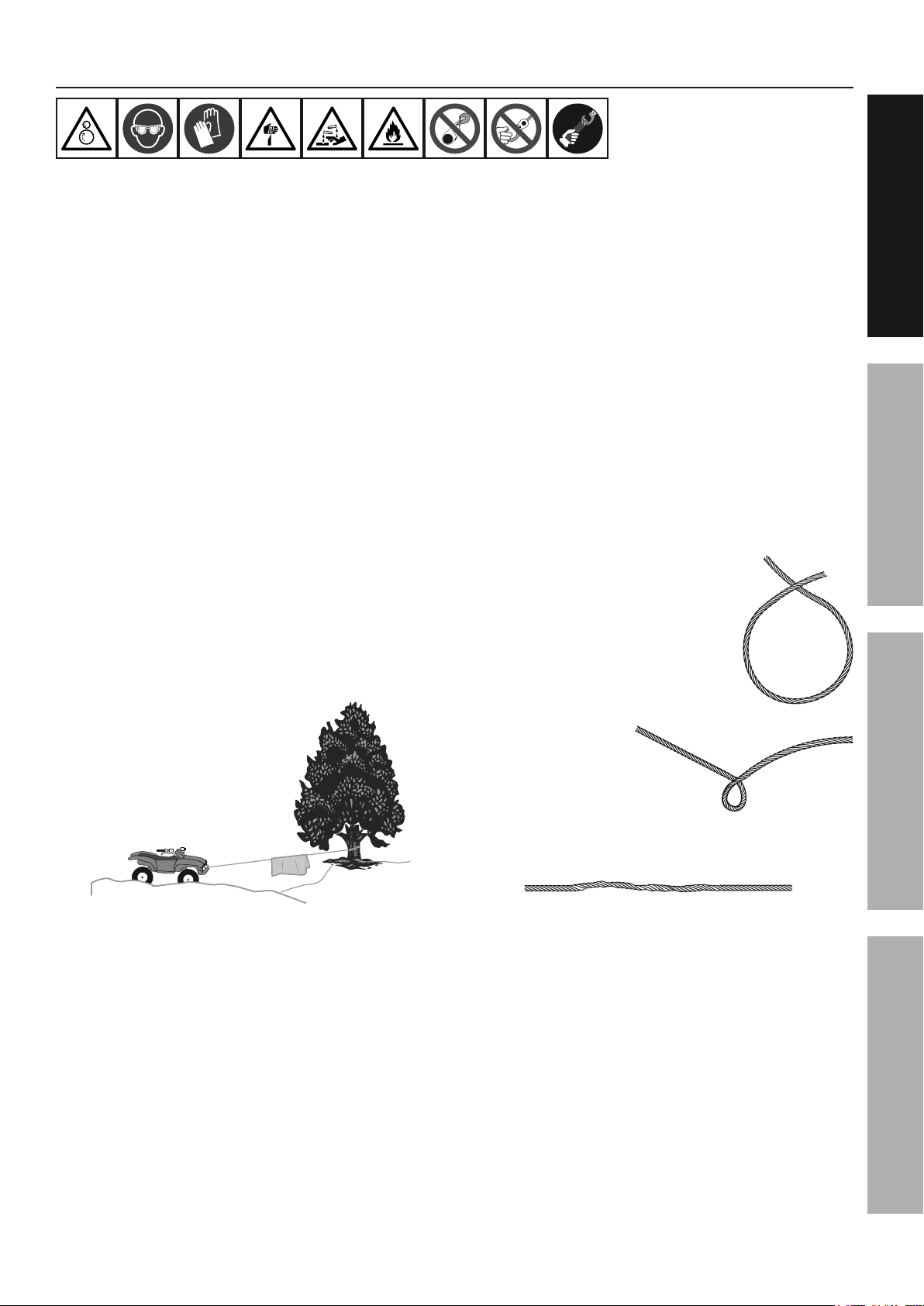

be caught and get pulled into fairlead or drum.

Use included strap to hold hook instead.

7. Stay out of the direct line that the wire rope

is pulling. If it slips or breaks, it will “whiplash”

along this line. Place heavy rag or carpet over wire

rope span 6 feet from hook to help absorb the force

released if the wire rope breaks. (See Figure A.)

13. Prevent entanglement. Do not wear loose clothing

or jewelry, as they can be caught in moving parts.

Non-skid footwear is recommended. Wear restrictive

hair covering to contain long hair.

14. Disconnect battery cables before working

near the Wire Rope, drum, fairlead or

load, to prevent accidental starting.

15. Inspect before every use; do not use if damaged or

parts loose. Examine the winch for structural cracks,

bends, damage, frayed or kinked wire rope, and any

other conditions that may affect the safe operation

of the winch. Do not use the winch even if minor

damage appears. A kink permanently weakens the

wire rope, even after it is straightened out; kinked

wire rope can fail suddenly and must not be used.

16. Keep wire rope straight to avoid

kinking the wire rope. The illustrations below show

how a kink forms and how to prevent kinking.

a. This illustration shows a kink about

to form. At this point the winch

should be stopped and the wire

rope should be straightened out

to prevent kinking.

SAFETYOPERATIONMAINTENANCE SETUP

Figure A: Whiplash Dampening Blanket or Rug

8. Do not use for lifting or moving people.

9. Use a spotter to assist you in ensuring that it

is safe to operate the winch. Make sure the

spotter is out of the way of the vehicle and

the wire rope before activating the winch.

10. Do not use the hand crank, if equipped,

to “assist” the winch.

11. Do not use vehicle to pull on the Wire Rope

and “assist” the winch.

12. Use as intended only.

Do not lift items vertically or use

for aircraft purposes.

b. This wire rope is

kinked. It is too

late

to reverse the

damage at this point, the

wire rope must be discarded.

It is permanently damaged

and must not be used.

c. This is a kinked wire rope that has been

straightened out. Even though it has been

pulled straight, some wires in the wire rope

are stretched, and others are severely bent,

if not broken. The unstretched wires will

take more load and can fail suddenly before

the rope reaches its capacity. This wire

rope must be discarded and not be used.

A kink permanently weakens the wire rope,

even after it is straightened out; kinked wire

rope can fail suddenly and must not be used.

17. Keep children and bystanders away while operating.

Distractions can cause you to lose control.

Page 5For technical questions, please call 1-888-866-5797.Item 61257

18. Stay alert, watch what you are doing and

use common sense when operating. Do not

use a winch while you are tired or under the

influence of drugs, alcohol or medication. A

moment of inattention while operating winches

may result in serious personal injury.

SAFETY OPERATION MAINTENANCESETUP

19. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the winch in unexpected situations.

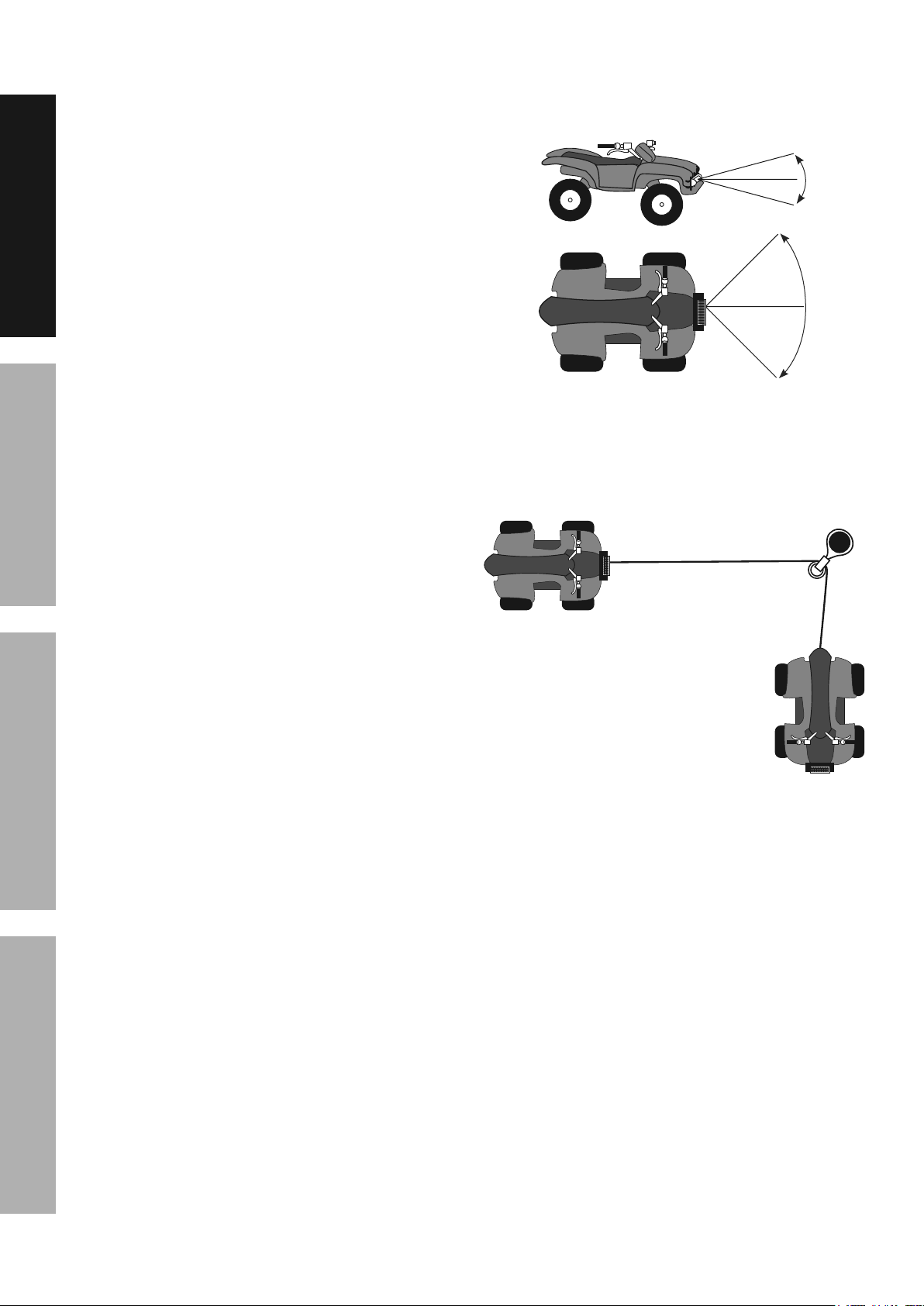

28. Do not operate the winch at extreme angles.

Do not exceed the angles shown in Figure B for

a roller fairlead. For a hawse fairlead, the angle

should be as close to straight as possible.

15°

15°

20. Hook onto the object using a pulling point,

tow strap or chain. Do not wrap the wire rope

around the object and hook onto the wire rope

itself. This can cause damage to the object

being pulled, and kink or fray the wire rope.

21. Do not use a Recovery Strap while

winching. They are designed to stretch

and can suddenly whip back towards the

operator during a winching operation.

22. Secure load after moving.

NO LOCKING MECHANISM.

23. Keep at least 5 full turns of wire rope on

drum. The wire rope’s connection to the

drum is not intended to sustain a load,

without the added support from the friction

of at least 5 full turns of wire rope.

24. Wrap wire rope under 500 lb. tension before use.

Otherwise, wire rope may bind during operation.

25. Keep clear of wire rope, hook, and load while

winching. Do not step over wire rope.

Do not push sideways against wire rope

under tension; wire rope might break under

this load and recoil back, striking the

person pushing against it or a bystander.

45°

45°

Figure B: Roller fairlead Maximum Winching Angles

29. If the object to be pulled must be pulled at an

angle in relation to the winch, use a pulley

(sold separately) and an anchor point directly

in front of the winch, as shown in Figure C,

to keep the Wire Rope pull straight.

Figure C: Pulley anchoring

26. If wire rope begins to get entangled, stop winch

immediately and release wire rope using switch.

27. Only winch with the winching vehicle′s

transmission in neutral. Winching with a vehicle′s

transmission in gear or park may damage

the transmission. A vehicle′s transmission is

not designed to handle that type of load.

30. Broken strands of wire rope will be sharp.

Wear heavy-duty work gloves when handling

the wire rope. Do not slide wire rope

through hands, even with gloves on.

31. Winch motor will be

hot during and after use. Keep clear.

32. Do not power the hook all the way

into the fairlead or winch.

33. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in

close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

Page 6 For technical questions, please call 1-888-866-5797. Item 61257

Service Precautions

1. Wear ANSI-approved safety goggles and

heavy-duty leather work gloves during service.

2. Disconnect power to winch and allow it

to cool completely before service.

3. Use supplied power cords/wire rope or cables

listed in manual only. Do not use thinner/

longer cables or link multiple cables together.

4. Have the winch serviced by a qualified repair person

using only identical replacement parts. This will

ensure that the safety of the winch is maintained.

SAVE THESE INSTRUCTIONS.

5. Maintain labels and nameplates on the winch.

These carry important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

6. WARNING: The cord of this product contains

lead and/or di (2-ethylhexyl) phthalate (DEHP),

chemicals known to the State of California

to cause cancer, and birth defects or other

reproductive harm. Wash hands after handling.

(California Health & Safety Code § 25249.5, et seq.)

SAFETYOPERATIONMAINTENANCE SETUP

Page 7For technical questions, please call 1-888-866-5797.Item 61257

Installation and Setup

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before set up or use of this product.

SAFETY OPERATION MAINTENANCESETUP

Mounting the Winch

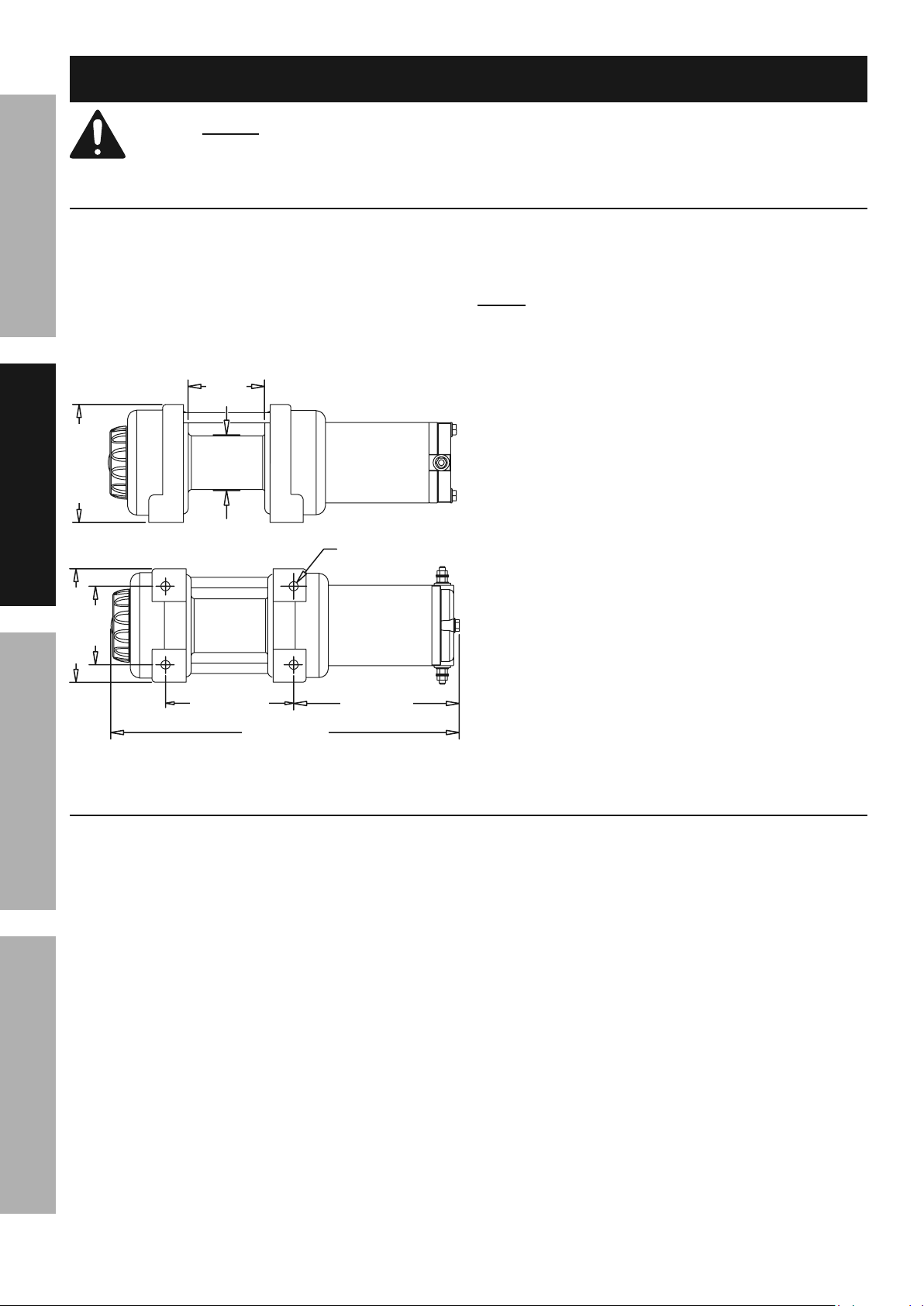

1. The plate must be rated to at

least the winch’s capacity.

2. Align the winch perpendicular to center

line of the vehicle at the desired location,

and mark the locations of the winch

base holes. Compare the dimensions

of the marked holes to Figure D.

2.83 in.

/ 72mm

2 in.

/ 51mm

4.49 in. / 114mm

4*Ø8mm

(threaded)

3 in. /

76mm

4.33 in. / 110mm

3. Before drilling, verify that the installation

surface has no hidden components or

structural pieces that will be damaged.

NOTE: This winch can generate extreme forces. Select

a location that can withstand the rated capacity without

damage or weakening. Steel reinforcement plates may

be needed or a certified welder may need to weld on

additional bracing depending on the mounting location.

4. Drill holes appropriate for the hardware

at the marked locations.

5. Install the winch using hardware

described under Specifications.

4.88 in. / 124mm 6.3 in. / 160mm

13.35 in. / 339mm

Figure D: Winch Dimensions

Mounting Winch Components

1. Mount solenoid box, switch controller, and

socket lead in proper locations so that:

a. Winch components are close enough to each

other to allow wires to be routed properly.

b. Vehicle component operation

is not interfered with.

c. Vehicle components are not damaged

by drilling or driving screws.

d. Winch components will not be damaged by

stresses caused by vehicle operation.

2. Mark the locations where the screw holes will be.

3. Verify that the installation surface has no

hidden components or structural pieces

that will be damaged before drilling.

4. Drill pilot holes for the mounting screws.

5. Secure in place with mounting screws.

Page 8 For technical questions, please call 1-888-866-5797. Item 61257

Wiring

TO PREVENT SERIOUS INJURY FROM EXPLOSION

DUE TO SPARKING AT THE BATTERY CONNECTION:

Disconnect the Battery Cables before making other wiring connections.

TO PREVENT SERIOUS INJURY FROM LEAKING BATTERY ACID:

Do not use a dirty, corroded or leaking battery.

Only use a 12V automotive (or equivalent) battery, in good condition.

SAFETYOPERATIONMAINTENANCE SETUP

1. Plan a route for the wiring from the point of

the vehicle where the winch will be mounted,

or used, to the battery. This route must be

secure, out of the way of moving parts, road

debris, or any possibility of being damaged

by operation or maintenance of the vehicle.

For example, you may wish to route the wires

under the vehicle, attaching it to the frame using

suitable fasteners. Do not attach the wires to

the exhaust system, drive shaft, emergency

brake cable, fuel line, or any other components

which may create damage the wiring through

heat or motion, or create a fire hazard.

2. If you drill through the bumper or any part

of the body to route the wires, be sure

to install a rubber grommet in the hole to

prevent fraying of the wires at that point.

3. Route the Cables from the Solenoid to the battery

and from the Solenoid to the Winch, following the

precautions discussed earlier. See Figure E.

Winch

Black

6. Attach the red Battery Cable to the Circuit Breaker.

7. Attach the black Battery Cable directly to

the negative terminal of the battery.

8. Wire in the Switch Controller

(and Socket Lead, if equipped)

according to the diagrams on the facing page.

9. The cable leading from the Switch Controller

has a red wire extending out from its

side. Connect this to an ignition circuit

(switched by the vehicle′s key) to help prevent

accidental starting. The winch will not operate

if that wire is not properly connected.

a. Use a circuit tester to find a wire that energizes

when the vehicle′s key is turned to on, and

turns off when the key is turned to off.

b. That is an ignition controlled wire.

c. Connect wire shown in Figure F to that wire.

Red

(to ignition)

Yellow

Blue

Black

White

Green

Red

(to ignition)

Red

Solenoid

Box

Black

Red

Circuit

Breaker

Battery

Handlebar

Controls

Remote

Figure E: Wiring Connections

4. Attach the wires from the solenoid to

the terminals on the Winch.

5. Attach the Circuit Breaker to the

Positive Terminal on the battery.

Preparing the Wire Rope

1. The wire rope must be properly coiled under tension

to be able to support a load without damage.

2. Uncoil the wire rope, except for 5 full wraps.

Switch

Controller

Figure F: Wiring to vehicle′s keyed ignition

Note: If not attaching the winch to a vehicle,

attach the ignition wire to the

positive battery terminal.

IF THIS IS NOT DONE,

THE WINCH WILL NOT OPERATE.

Note: The attachment of the Motor Cables

determines the operation of the Controller’s button.

After the unit is mounted and powered,

check the direction of the Power In and Power Out on

the Controller button. If you wish to change the direction

on the Controller, disconnect the Battery Cables from

the battery, switch the Motor Cable connections on the

Motor Assembly, then reconnect the Battery Cables.

3. Recoil the wire rope back into the winch

under at least 500 lb. of tension.

Page 9For technical questions, please call 1-888-866-5797.Item 61257

Operation

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before set up or use of this product.

SAFETY OPERATION MAINTENANCESETUP

The instructions that follow are basic guidelines only and cannot cover all situations encountered

during use. The operator and assistants must carefully plan usage to prevent accidents.

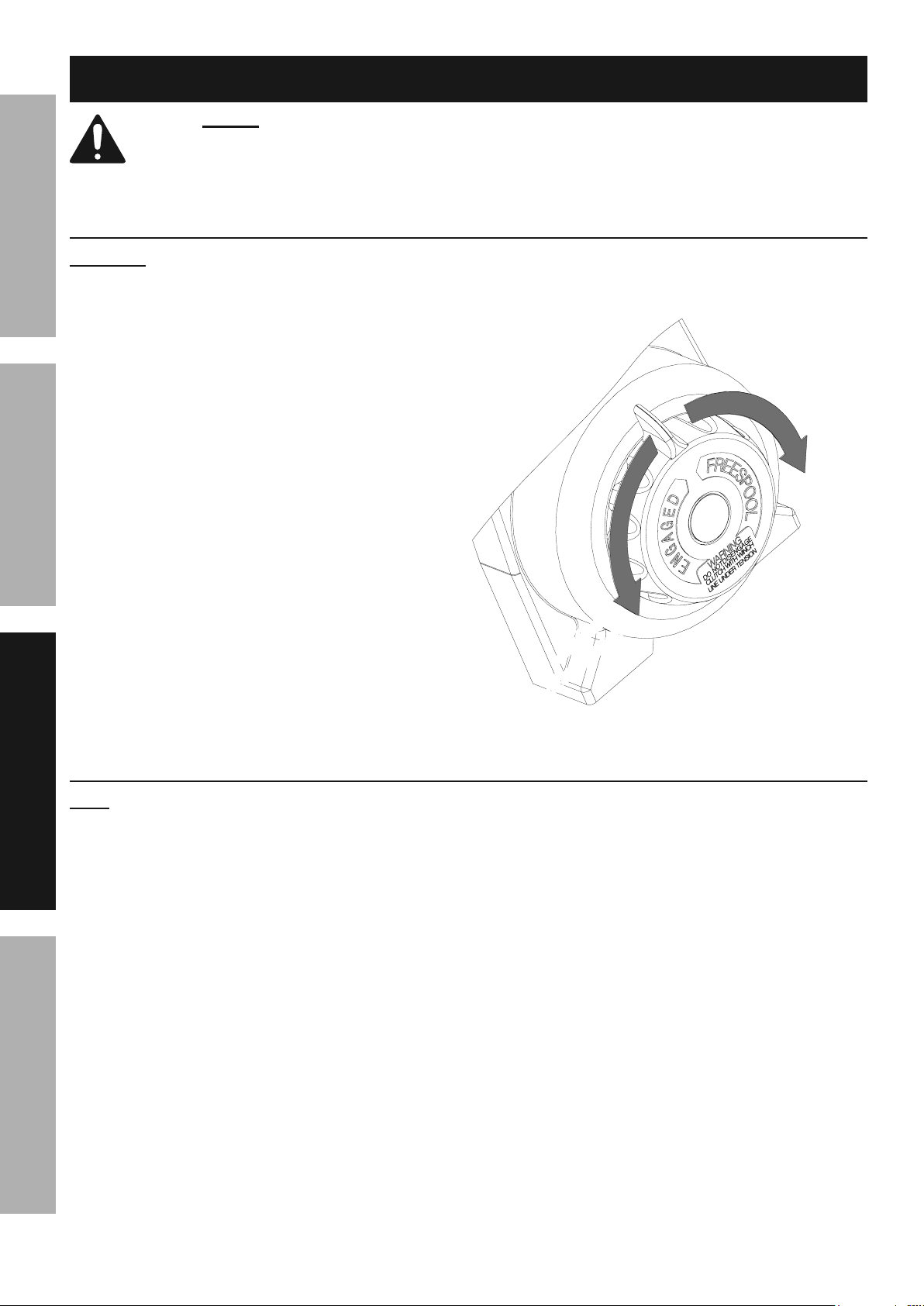

Clutch Operation

CAUTION: Do not adjust the clutch unless

there is no load on the wire rope.

1. To engage the clutch, turn the Clutch Knob

clockwise completely until it stops, see Figure G.

2. To release the clutch (freespool), turn

the Clutch Knob counterclockwise

completely until it stops, see Figure G.

Engage

Release

(freespool)

Figure G: Clutch operation

Basic Operation

Note: If a winch is to be used to pull a vehicle,

it should optimally be rated to a single line

pull at least twice the vehicle’s weight.

1. Examine the wire rope. Do not use the winch if

the wire rope is frayed, kinked or damaged.

2. Fully charge the vehicle’s battery.

3. Check the Winch’s electrical connections.

All connections must be tight and clean.

4. Put the vehicle’s transmission in Neutral.

5. If the vehicle where the winch is mounted

is not supposed to be moved, engage the

emergency brake and block the wheels

using wheel chocks (sold separately).

6. To pull out the wire rope, move the Clutch Control to

the Released position, see the instructions for your

winch model under Clutch Operation section, slide

the loop of the Hook Strap over the hook, then pull

on the Hook Strap to pull out the wire rope.

WARNING! Leave at least five full

turns of wire rope on the drum.

Page 10 For technical questions, please call 1-888-866-5797. Item 61257

Loading...

Loading...