Page 1

MIG WELDER 131MIG WELDER 131

MIG WELDER 131

MIG WELDER 131MIG WELDER 131

06098

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright © 2003 by Harbor Freight Tools®. All rights reser ved. No portion of

this manual or any artwork contained herein may be reproduced in any shape

or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

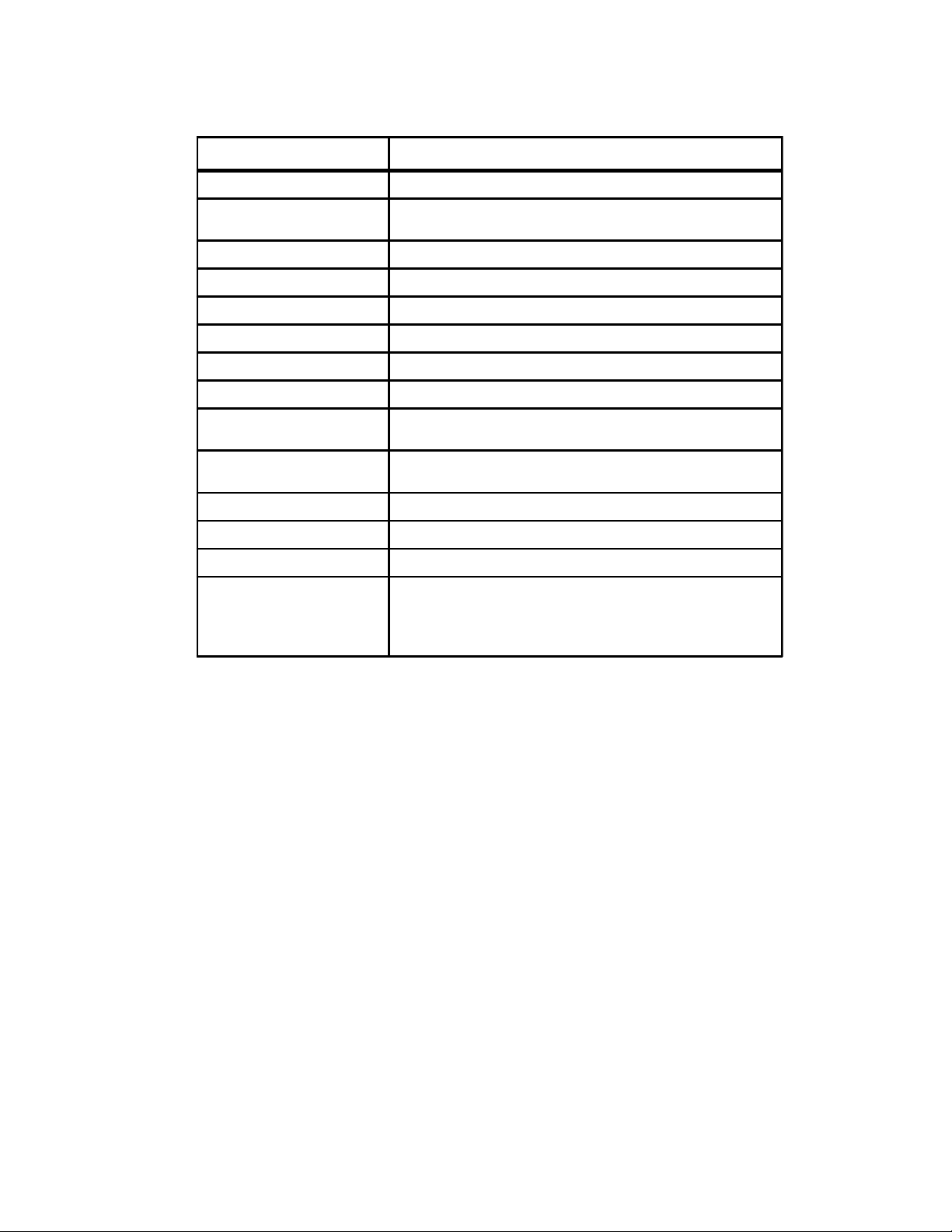

Specifications

ITEM DESCRIPTION

Welding Current 25 ~ 85 amps

Duty Cycle

Pow er Consumption 120 VAC, 21 amps at 60 Hz

Open Circuit Voltage 19 to 30 volts

Heat Control 25 ~ 85 amps, variable

Ground Cable 6 feet, 4 AWG, si ngle instu lat ion, grounding cl amp.

Torch Powe r Cable 6 feet, 8 AWG, single insulation

Power Cord 6 feet, 3-core, 14 AWG, UL

Ther m al Overload

Protection with Light

Wire Size

Welding Material Size 22 gauge to 5/32"

Wire Spool Size 4 inch spool di ameter

20% at 75 amps; 45% at 50 amps; 90% at 35 amps;

100% at 25 amps

(Peak)

®

Listed; 3-prong plug

Auto matic shutdown and rest art after cool down

0.023 to 0.035 inch steel and stainle ss steel

0.030 to 0.035 inch aluminum; 0.030 flux core

Weight 55.1 lbs.

1 - Hand held shaded face shield

Accessories

1 - Br us h H amme r

1 - Wheel Kit

1 - 2 lb. spool of flux wi re

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

3. Keep children away . Children must ne ver be allow ed in the work area. Do not let them

handle machines, tools, or extension cords.

Page 2SKU 06098

12/03

Page 3

4. Store idle equipment. When not in use , tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

5. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to e xceed the tool capacity .

6. Use the right tool for the job. Do not attempt to force a small tool or attachment to do

the work of a larger industrial tool. There are certain applications for which this tool was

designed. Do not modify this tool and do not use this tool for a purpose for which it was

not intended.

7. Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving

parts. Protective, electrically non-conductive clothes and non-skid footwear are

recommended when working. Wear restrictive hair cov ering to contain long hair.

8. Use eye and ear protection. Always wear ANSI approved, arc shaded, impact safety

full face shield when arc welding. W ear an ANSI approv ed dust mask or respirator when

working around metal, chemical dusts, fumes and mists.

9. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

10. Maintain tools with care. Keep tools sharp and clean for better and saf er performance.

Follow instructions for lubricating and changing accessories. Inspect tool cords

periodically and, if damaged, have them repaired by an authorized technician. The

handles must be kept clean, dry, and free from oil and grease at all times.

11. Disconnect power. Unplug tool when not in use.

12. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches are

removed from the tool or machine work surface before plugging it in.

13. Av oid unintentional starting. Be sure the switch is in the Off position when not in use

and before plugging in. Do not carry any tool with y our finger on the trigger , whether it is

plugged in or not.

14. Stay alert. Watch what y ou are doing, use common sense. Do not operate any tool when

you are tired.

15. Check for damaged parts. Before using any tool, an y part that appears damaged should

be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment and binding of moving parts; any brok en parts or mounting

fixtures; and any other condition that ma y affect proper operation. Any part that is damaged

should be properly repaired or replaced by a qualified technician. Do not use the tool if

any switch does not turn On and Off properly.

16. Guard against electric shock. Prevent body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerator enclosures.

17. Replacement parts and accessories. When servicing, use only identical replacement

parts. Use of any other parts will void the warranty. Only use accessories intended for

use with this tool. Approved accessories are available from Harbor Freight Tools.

18. Do not operate tool if under the influence of alcohol or drugs. Read warning labels

on prescriptions to determine if your judgment or reflexes are impaired while taking drugs.

Page 3SKU 06098

Page 4

If there is any doubt, do not operate the tool.

19. Maintenance. For your saf ety, service and maintenance should be performed regularly

by a qualified technician.

20. Use proper size and type extension cord. If an extension cord is required, it must be of

the proper size and type to supply the correct current to the tool without heating up.

Otherwise, the extension cord could melt and catch fire, or cause electrical damage to

the tool. This tool requires use of an 120 VAC extension cord of 20 amps minimum

capability (up to 30 feet), with wire size r ated at 10 AWG. Longer e xtension cords require

larger size wire. If you are using the tool outdoors, use an extension cord rated for outdoor

use (signified by “WA” on the jacket).

21. Pacemaker safety warning. People with pacemakers should consult with their

physician(s) before using this product; operation of equipment in close proximity to a

heart pacemaker could cause interference or failure of the pacemak er.

Note: Performance of this tool may vary depending on variations in local line voltage. Extension cord usage may also affect tool performance.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, b ut m ust be supplied b y the operator.

Arc Welding Safety Warnings and Precautions

Warning: This product, when used for welding and similar applications, produces chemicals known to the State of California to cause cancer and birth defects (or other reproductive harm). California Health & Safety Code 25249.5, et seq.

1. Avoid electrical shock. Do not permit electrically live par ts, cables, or electrodes to

contact skin, clothing, or gloves. Protective clothing should be free of holes, dry, and

ANSI approved.

This unit draws enough current to cause serious injury or death. Before turning the welder

on, check the electrode holder to be sure that there are no protruding screw heads, and

that all insulation is secure. Do not weld unless you are insulated from ground and the

work piece.

2. Avoid breathing fumes or gases. They can cause serious health problems. Use an

active ventilation system directly above the welding area. Keep your head out of the

fumes.

3. Av oid e ye and body damage. Arc rays and infrared radiation can injure ey es and burn

skin. Wear ANSI approved eye and body protection. Do not allow viewing by visitors

without proper eye and body protection. Use a Face Shield with arc shaded filter plate.

4. Know proper arc welding practices. Read and understand this instruction manual, as

well as your employer’s safety practices for arc welding.

5. Connect only to a code approved power source. Connect only to a grounding power

source conforming to the National Electrical Code and Local Codes.

Page 4SKU 06098

Page 5

6. Avoid fire and explosion. Remove flammable and explosive material from at least 35

feet from the welding arc to pre vent welding sparks or molten metal from starting a fire.

Keep a type ABC fire e xtinguisher within easy reach. Thoroughly clean the object being

welded of any paint, grease, or other foreign material.

7. Av oid being burned. Alwa ys wear ANSI approved welding gear: leather gloves , leather

apron, and shoes.

8. Wear pr oper clothing when welding. Use flameproof, welding type gloves . Wear cuffless

pants and pocketless shirt. Both must be free of oil and g rease. W ear high-topped, safety

to shoes with rubber soles.

Unpacking

When unpacking, check to make sure the following parts are included.

Line Cord (13)

Brush Hammer

Handheld Shaded

Face Shield

Ground Cable with Clamp

If any parts are missing or broken, please call Harbor Freight Tools at the number on the cover

of this manual as soon as possible.

Page 5SKU 06098

Welding T orch (15)

REV 05/04

Page 6

Assembly

MIG Welder Unit

1. Insert the Handle (4) into the Handle Sockets (3) and mount the Handle Soc k ets to the

Side Panel B (1) top using supplied hardware.

2. Lift Side Panel B (1) all the way to expose the wire spool and Wire Feed Mechanism

(10).

Side Panel B (1)

(C)

–

(29)

+

(D)

Wire Spool Axle (9)

Wire Spool

Wire Feed Mechanism (10)

3. Remove the Nut from the Wire Spool Axle (9). Place the Wire Spool over the Axle with

the wire exiting the spool over the top. Refer to photos above. Replace the Spool Axle

Nut.

4. Open the Wire Feed Mechanism (10) as shown in the photo (top-right).

5. Feed and guide the spool wire into the Wire Feed Mechanism, past the feed wheels

(C), and into the W elding T orch / Cab le (15).

It will help if the W elding Torch / Cable (15) is straightened out as much as possible.

Push in until the wire comes out the Welding Torch head. If it cannot be fed manually

all the way out, it can be fed automatically when the welding unit is powered up.

6. Close the Feed Mechanism (10) over the wire, and adjust the feed tension (D) if

necessary.

7. Check that +/– cables to connection Knobs (29) are correct. See photo (top-left).

When using non-flux wire and protective gas, connect wire cables as shown in photo.

For 0.9 flux cored wire, no gas is required. Reverse cable connections.

8. Close the Side Panel B (1).

Page 6SKU 06098

Page 7

Handheld Shaded Face Shield

Assemble the Handheld Shaded Face Shield as illustrated in its Assembly Drawing at the

end of this manual.

Operation

Controls and Indicators

Overload-shutdown

Indicator Lamp

Min / Max Switch

On / Off Switch

1 / 2 Pow er Level Switch

Wire Feed Speed Control

Line Cord

Ground Cable with Clamp (14)

Welding T orch Cable (15)

Welding

Caution: Bef ore ar c welding, read and understand all safety precautions and warnings

listed on pages 2 through 5.

1. If using non-flux core wire, connect and secure the Argon / CO2 gas hose to the rear of

the MIG Welder. (If using flux core wire, protective gas is not required.)

2. Attach the Ground Cable with Clamp (14) as close as possible

to the metal object to be welded, or to the metal work bench

where the object is mounted and electrically connected.

3. Set the desired welding current (30~120 amps) for the type of

metal being welded using the Min/Max Switch and 1/2 Power

Level Switch.

Refer to the power setting tab le on the next page. Thinner metals use lower current.

Heavier metals use higher current.

4. Verify that the On/Off Switch is in the OFF position, then plug the MIG Welder Line

Cord into a dedicated, 120 VAC, 20 amp line with delayed action type circuit breaker

or fuses. If an extension cord is used, it must have the following wire size: up to 30 feet,

use 10 AWG siz e wire; 30 to 50 f eet, 8 AWG wire; Over 50 feet, 6 AWG wire.

Page 7SKU 06098

Page 8

Rated DC Output Set Pow er Swi tches Amps Duty Cycle Volts

Mi n. - - 1 2 5 1 00% 15. 2

Maximum OCV 28V

Min. -- 2 35 90% 15.7

Max. -- 1 50 45% 16.5

Max. -- 2 75 20% 17.7

5. While holding the Welding Torch handle, with the electrode wire clearly out of the way

of any grounded objects, turn the On/Off Switch to the ON position.

6. Momentarily press the Welding Torch trigger switch to test the wire f eed speed.

Adjust the speed by turning the Wire F eed Speed Control knob.

7. Orient yourself on the area to be welded, then hold the Arc Shaded Face Shield over

your eyes.

Warning: Never look at the ignited arc without ANSI approved, arc shaded, eye protection in a full face shield. P ermanent eye damage or blindness can occur . Skin burns can

occur. Never breath arc fumes.

8. Press (and hold) the Torch Trigger Switch and stroke the area to be welded with the

electrode wire to ignite the arc.

Never tap the electrode wire into the welding surface to ignite the arc. This damages

its external coating on the electrode which prevents oxygen in the air from coming into

contact with the molten metal, causing it to oxidize.

9. Once the arc is ignited, tilt the electrode wire forward at an

angle of about 35°. Refer to the illustration at right.

The wire feeds automatically at a speed dependent on the

Min. or Max. current setting. The wire speed can also be

adjusted using the Wire Feed Speed Control.

Note: If too much current is dra wn from the MIG W elder, the Thermal Overload protector will activate, the red Overload indicator

will light, and the Arc W elder will turn off until it cools down. If this

happens, turn the On/Off Switch to the OFF position and wait about 3 ~ 5 minutes.

10. When the weld is complete, lift the Welding Torch handle electrode wire clearly away

from any grounded object, remov e your Face Shield, and turn the On/Off Switch to the

OFF position.

11. Unplug the power Line Cord from the electrical outlet.

Page 8SKU 06098

Page 9

Troubleshooting

Symptom Possible Cause Checks and Remedies

MIG Welder does not

work when turned on.

Wire does not feed

properly.

Reduced welding

power.

No power t o MIG W elder.

Overheated during use. In overload mode; Allow to cool down.

Insufficient wire feed spring tension. Tighten spring tension knob. See photo on page 6.

Wire guide sheath blocked. Clean or replace wire sheath.

Wire spool axle nut too tight. Loosen nut so reel moves freely .

Braking on wire reel excessive. Loosen brake using adjusting screw.

Wire reel has oxidized, poorly wound

or quali ty wire.

Ground Cable not connected or poor

connection.

Check Line Cord and plug. Check facility circuit

breaker.

Replace wire reel.

Check that the Ground Cable Clamp is secu rely

attached to the metal being welded. This area should

be cleaned down to the metal and free of paint, dirt

and grease.

Porous or spongy

welds.

Gas supply does not

switch off.

Press ing Welding Torch

trigger produces no

result.

In ternal connec tion loose on switches.

Faulty contactor. Check the state of the contacts and the me chanical

One or more rectifiers f ailed.

No gas; Litt le gas. Check presence of gas and supply line and pressure.

Clogged hole s in Welding Torch head

diffuser.

Sole noid valve bl ocked.

Poor q uality gas or wire. Gas must be very dry. Use a moisture filter. Use a

Worn or dirty solenoid valve.

Faulty Welding Torch trigger ;

Disconnected or broken control

cables.

Overload controller defective.

A qualified technician should open the unit and check

and tighten any loose connectors.

operation of the contactors.

A qualified technician should open the unit and check

for burnt rectifiers and replace.

Clear clogged holes using compressed air.

A qualified technician should open the unit and check

solenoid operation and electrical connection.

dif ferent type of wire.

A qualifi ed technic ian should open the unit and

dismantl e valve, clean orifice and seatin g element.

A qualifi ed technic ian should open the unit and

remove the torch connection plug and short-circuit

the poles. Check and repair control cables.

A qualifi ed technic ian should open the unit and

replace the overload controll er.

Maintenance

Caution: Bef ore performing any maintenance on the MIG W elder, unplug the power Line

Cord from the electrical outlet.

1. Periodically using compressed air, open the top and side panels and blow out all dust

from the interior.

Page 9SKU 06098

Page 10

2. Store the unit in a clean and dry location.

3. Periodically clean out the Torch Head.

Replacing the Wire Reel

When the wire on the Feed Reel is used up, you will need to replace it as described on

page 6, step 5 through step 9.

NOTE: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

PLEASE READ THE FOLLO WING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENT ATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS

QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO

REPLACE ANY PARTS OF THE PRODUCT. IN F A CT, THE MANUF ACTURER AND/OR DISTRIBUT OR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER

ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERET O.

Page 10SKU 06098

Page 11

Wire Feed Mechanism Assembly Drawing

Page 11SKU 06098

Page 12

MIG Welder 131 Schematic Diagram

MIG Welder 131 Assembly Drawing

Page 12SKU 06098

Page 13

Hand Held Shield Assembly Drawing

Page 13SKU 06098

Loading...

Loading...