Page 1

14” CUT OFF SAW

Model 44829

(Blade Sold Separately)

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our W eb site at http://www.harborfreight.com

Copyright © 2001 by Harbor Freight Tools. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

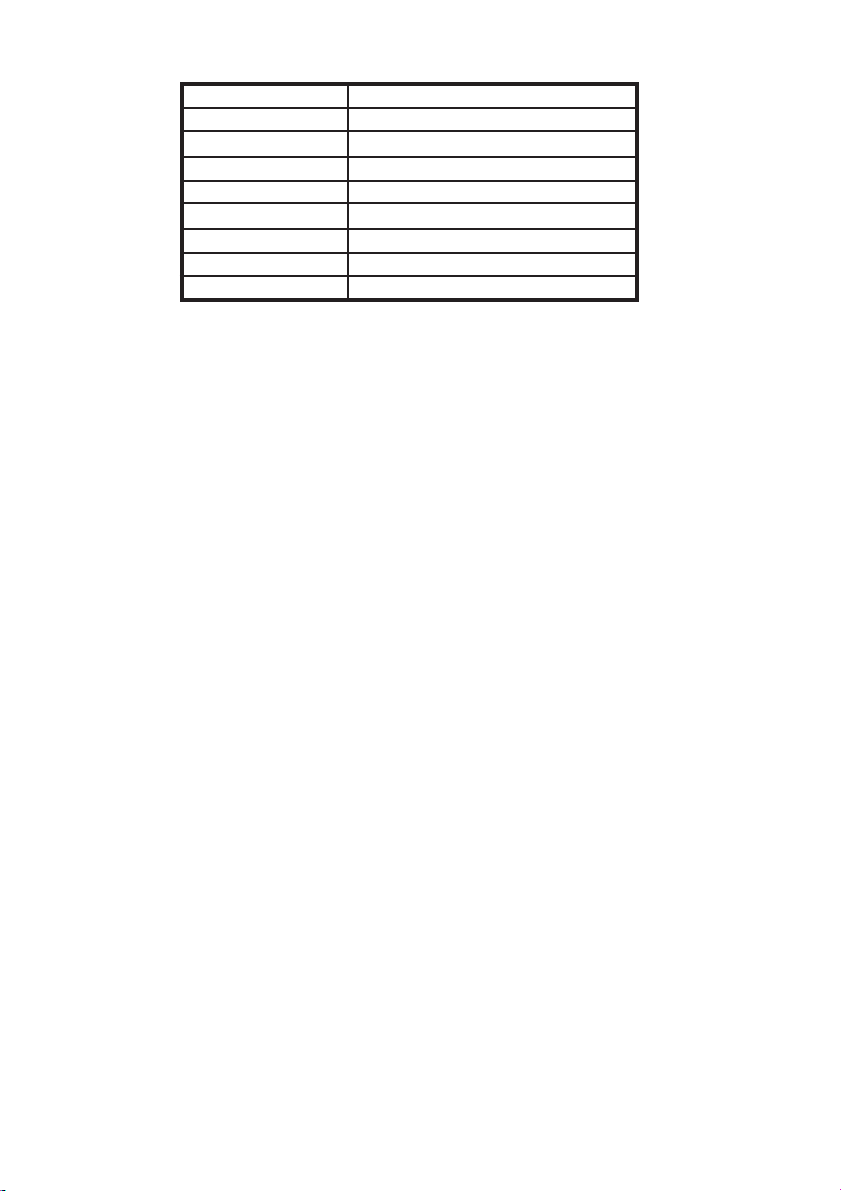

Specifications

Motor 120V Single Phase 60HZ 2HP

Watts (input) 1500 Approx.

Rpms 3400

Blade Size 14” (Not Included) 1” Arbor

Miter Angle 0-45 Degrees Rt. 0-30 Left

Weight 35.6 Lbs.

Base Dimensions 18-1/2” x 10-1/2”

Cutting Capacity Up to 4”

Table Size 9-3/4” x 10-1/4”

Vise Assembly and Spanner Wrench Included.

Recommend using #525 Cut-off Wheel (not included), 14” Diameter, 1/8” Thic kness, 30 Grit. This is an aluminum oxide wheel designed for general purpose

usage. F or cutting masonry, recommend #44815 Cut-off Wheel (not included),

14”, 1/8” Thickness.

Save This Manual

You will need the manual for the safety w arnings and precautions, assembly

instructions, operating and maintenance procedures, parts list and diagram. K eep

your inv oice with this manual. Write the invoice number on the inside of the front

cover. Keep the manual and in v oice in a safe and dry place for future reference .

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to reduce the risk of personal injury and damage to equipment.

Read all instructions before using this product!

1. Avoid working alone. If an accident happens, an assistant can bring help.

2. Keep work area clean. Cluttered areas invite injuries.

3. Observe work area conditions. Don’t e xpose to r ain. Keep work area well

lighted.

4. Keep children away. Children must never be allowed in the work area. Do

not let them handle machines, tools, or extension cords .

5. Store idle equipment. When not in use, tools must be stored in a dry

location to inhibit rust. Always lock up tools and keep out of reach of

children.

6. Dress properly. Do not w ear loose clothing or je welry as they can be caught

in moving parts. Protectiv e, electrically nonconductiv e clothes and nonskid

footwear are recommended when working. Wear restrictive hair covering to

contain long hair.

SKU 44829 Page 2 REV 09/01 REV 11/01

Page 3

7. Use eye and ear protection. Alw a ys w ear ANSI appro v ed impact saf ety

goggles. Wear an ANSI appro v ed face shield when producing metal filings .

8. Do not overreach. Keep proper footing and balance at all times. Do not

reach over or across electrical cables or frames.

9. Maintain tools with care. Inspect tool cords periodically and, if damaged,

have them repaired by an authoriz ed technician.

10. Use the right tool for the job. Do not attempt to force a small tool or

attachment to do the work of a larger industrial tool. There are certain

applications for which this tool was designed. Do not modify this tool and do

not use this tool for a purpose for which it was not intended.

11. Stay alert. Watch what you are doing, use common sense. Do not oper ate

any tool when you are tired.

12. Check for damaged parts. Before using any tool, any part that appears

damaged should be carefully checked to determine that it will operate

properly and perform its intended function. Chec k for alignment and binding

of moving parts; any broken parts or mounting fixtures; and an y other

condition that may affect proper oper ation. Any part that is damaged should

be properly repaired or replaced by a qualified technician. Do not use the tool

if any switch does not turn On and Off properly.

13. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use

accessories intended for use with this tool. Appro v ed accessories are

available from Harbor Freight Tools.

14. Do not operate tool if under the influence of alcohol or drugs. Read

warning labels on prescriptions to determine if your judgment or reflexes are

impaired while taking drugs. If there is an y doubt, do not operate the tool.

15. Use proper size and type extension cord. If an extension cord is required,

it must be of the proper size and type to supply the correct current to the

tool. Otherwise, the extension cord could melt and catch fire, or cause

electrical damage to the tool. This tool requires use of an extension cord of 0

to 12 amps capability (up to 50 feet), with wire size rated at 14 AWG. Longer

extension cords require larger size wire. If you are using the tool outdoors,

use an extension cord rated for outdoor use . (signified by “W A” on the jacket).

16. Maintenance. F or y our saf ety, maintenance should be performed regularly

by a qualified technician.

Note: Performance of this tool (if powered by line voltage) may vary depending on

variations in local line voltage. Extension cord usage may also affect tool performance.

SKU 44829 Page 3

Page 4

Warning: The warnings, cautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution

are factors which cannot be built into this product, but must be supplied by

the operator.

Unpacking

When unpacking, chec k to make sure the parts listed on page 6 are included.

If any parts are missing or broken, please call Harbor Freight T ools at the number on the cover of this manual.

Operation

Warning! Unplug the power cord while setting up the saw and workpiece. Do not

plug in until ready to cut.

Note: Steel Capacity Cutting Chart found on page 5 of this manual.

Warning: This Cut-Off Saw is designed to cut iron metal. Do not cut w ood, bric k,

aluminum, or magnesium; tool damage and/or personal injury could occur .

Before using the saw always check the following:

A. Mak e sure the b lade (not included) is securely attached.

Loosen Screw (#110) and lift Small Cover (#109) out of the w a y.

Using the Wrench (#91), remove the He x Screw (#23) - re verse thread, Stop

Washer (#22), Flat Washer #21), and the Flange (#20). Set the blade on the

arbor and replace the hardware. Do not overtighten. Move Small Cover (#109)

back in place and tighten Screw (#110).

B. Check that the Upper Shield (#12) and Lower Shield (#30) are in place.

C. The Cut Off Saw must be located on a le v el, flat, w orkbench that is solid and

able to support the weight of the tool and workpieces. The workpiece must be

secured in a vise or with clamps (vise assembly included).

D . Always wear ANSI approved impact safety goggles.

1. Disconnect the Chain (#72), allowing the blade assembly to lift. The chain is

only used for transporting the tool. Make sure the saw has cooled for 3-5 minutes

before latching or unlatching the Chain (#72), to avoid burning yourself on the hot

blade.

2. Loosen the Vise (#82) on the vise assembly and position workpiece. Tighten

the Vise (#82).

3. Make sure the blade is clear to rotate freely.

4. Press the po wer Switch (#33). Allo w b lade to reach full speed.

5. Lower the Handle (#35) slowly and contact the workpiece with very little

pressure. Let the blade do the work. If the blade begins to slow, back off as you

are ex erting too much pressure.

Caution: The Lower Shield (#30) and Small Cover (#109) must always be in

place. Both of these b lade guards m ust be in place when the tool is being used.

6. Turn off the power and unplug the tool before removing workpiece. Never leave

the tool running unattended.

SKU 44829 Page 4 REV 04/02

Page 5

Miter Cuts

For Miter Cuts, y ou must use the Vise (#82). The Vise Stop has a

Fixed Splint (#100) for this purpose. Loosen the Vise Stop by slightly loosening

each bolt and align the scale to your desired angle. Tighten the bolts. Carefully

set the workpiece into the Vise (#82) without disturbing the setting.

Steel Cutting Capacities

Steel Pipe - 4” Dia. x 1/4” Wall Thickness

Angle Iron - 4” x 4” x 1/2” Thickness

Solid Steel - 1-1/2” Dia.

Note: Use an aluminum oxide wheel for

cutting ferrous material, i.e. angle iron,

conduit pipe, etc. Use masonry wheels to

cut masonry, stone, brick, aggregate, etc.

Maintenance

Warning! Remove the electrical plug from the outlet bef ore maintaining the Sa w.

1. Wearing gloves, carefully clean any excess metal filings that accumulate on

the saw, vise assembly, or motor housing.

2. To keep looking like new, use an automotive wax to polish the metal

Base (#87).

3. Check blade for wear, replace at the first sign of any tears or crac ks.

4. Periodically check power cord for wear or tears. If necessary, have a qualified

technician replace it.

5. Ne ver use chemicals or solvents to clean the Saw.

Lubrication

1. The motor bearings are permanently lubricated at the factory. Do not attempt to

work on the motor; the tool should be serviced by a qualified technician.

2. Any mechanical part including a pivot or threaded rod ma y be lightly spra y e d

with a silicone or graphite lubricant, which will not hold or collect the metal filings

left from a job.

3. Every 500 Hrs. replace the Carbon Brush (#67). Remove the

Brush Cap (#68) and take out the Carbon Brush (#67). Replace and tighten the

Brush Cap (#68).

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER

NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO

THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE

PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE

PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN

BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER

ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS

OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 44829 Page 5 REV 04/02

Page 6

Parts List

SKU 44829 Page 6 REV 04/02

Page 7

Assembly Drawing

NOTE: Some parts are listed and shown for illustration purposes only and are not

available individually as replacement parts.

SKU 44829 Page 7 REV 04/02

Page 8

Loading...

Loading...