Page 1

8 INCH DRILL PRESS

®

MODEL 44506

ASSEMBLY AND OPERATING

INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright© 2000 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Page 2

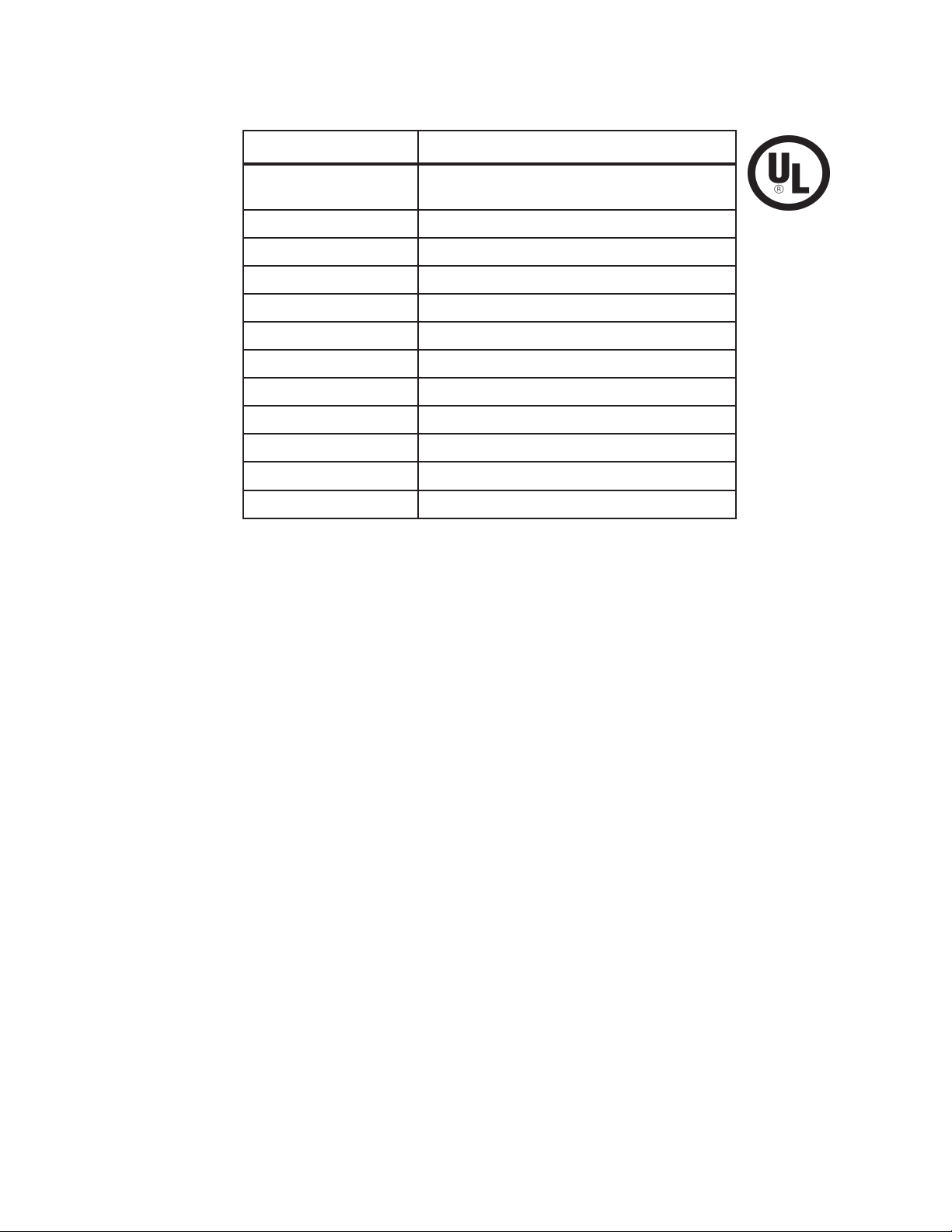

Specifications

METINOITPIRCSED

rotoM

sdeepSeldnipS.MPR0013dna,0432,0271,0011,

ekortSeldnipShcni2

nmuloCsehcni)H(4/1-51x)retemaid(98.1

snoisnemiDesaBhcni61/9:tolS;sehcni7x8/1-11

nemiDllarevOsehcni)W(2/1-7x)D(8/5-51x)H(32

htpeDtaorhT)gniwshcni8fo(sehcni4

yticapaCkcuhChcni2/1otpU

baTsehcni8/5

tolSel

noitatoRelbaT)thgirdnatfel(°54:tliT;°063

eziSelbaTsehcni8/3-6x8/5-6

thgieW.sbl04

120

snois

Save This Manual

Control

# 86PJ

;MPR0571,PH3/1,zH06,CAV011

)daolhtiw(spma6.3

026

E172674

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools, or extension cords.

4. Store idle equipment. When not in use, tools must be stored in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

5. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool

capacity.

REV 07/06

SKU 44506 For technical questions, please call 1-800-444-3353. Page 2

Page 3

6. Use the right tool for the job. Do not attempt to force a small tool or attachment to

do the work of a larger industrial tool. There are certain applications for which this tool

was designed. Do not modify this tool and do not use this tool for a purpose for which

it was not intended.

7. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically nonconductive clothes and nonskid footwear are

recommended when working. Wear restrictive hair covering to contain long hair.

8. Use eye and ear protection. Always wear ANSI approved impact safety goggles.

Wear a full face shield if you are producing metal filings or wood chips. Wear an ANSI

approved dust mask or respirator when working around metal, wood, and chemical

dusts and mists.

9. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

10. Maintain tools with care. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect tool

cords periodically and, if damaged, have them repaired by an authorized technician.

The handles must be kept clean, dry, and free from oil and grease at all times.

11. Disconnect power. Unplug when not in use.

12. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches

are removed from the tool or machine work surface before plugging it in.

13. Avoid unintentional starting. Be sure the switch is in the Off position when not in

use and before plugging in.

14. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

15. Take caution as some woods contain preservatives such as copper chromium

arsenate (CCA) which can be toxic. When cutting these materials extra care should

be taken to avoid inhalation and minimize skin contact.

16. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any

part that is damaged should be properly repaired or replaced by a qualified technician.

Do not use the tool if any switch does not turn On and Off properly.

17. Guard against electric shock. Prevent body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerator enclosures.

18. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor Freight

Tools.

SKU 44506 For technical questions, please call 1-800-444-3353. Page 3

Page 4

19. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels on prescriptions to determine if your judgment or reflexes are impaired while

taking drugs. If there is any doubt, do not operate the tool.

20. Use proper size and type extension cord. If an extension cord is required, it must

be of the proper size and type to supply the correct current to the tool without heating

up. Otherwise, the extension cord could melt and catch fire, or cause electrical

damage to the tool. This tool requires use of an extension cord of 0 to 12 amps

capability (up to 50 feet), with wire size rated at 16 AWG. Longer extension cords

require larger size wire (smaller AWG number). If you are using the tool outdoors, use

an extension cord rated for outdoor use (signified by “WA” on the jacket).

21. Secure Workpiece. Use clamps or a vise to hold workpiece, if possible. Never hold

workpiece with your hands.

22. Never leave Drill Press running unattended. Turn the power OFF.

23. Maintenance. For your safety, service and maintenance should be performed

regularly by a qualified technician.

Note: Performance of this tool may vary depending on variations in local line voltage. Extension cord usage may also affect tool performance.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, but must be supplied by the operator.

Drill Press Safety Warnings and Precautions

1. Secure the Drill Press Base to a table using Bolts (not supplied). The table must be

appropriate for use with a drill press and be located on a hard, flat, level surface.

2. Locate the Drill Press in an area where you walk around it unhampered.

3. Avoid kickback and grabbing by clamping the workpiece to the table, or use a vise that

is secured to the table. If the workpiece begins to spin, do not attempt to stop it with

your hands. Turn the motor OFF, and wait until it stops spinning before attempting to

remove it.

4. Avoid being caught and pulled into the spinning chuck. Do not wear gloves, long

sleeve shirts, ties, or jewelry. Long hair must be bundled behind the head.

5. Never place hands and arms near the workpiece to avoid the possibility of the

workpiece coming loose and striking you.

6. Before drilling, turn on the motor and check for bit wobble or machine vibration. If this

is found, correct the problem before drilling.

7. Set the proper spindle speed for the specific drilling operation.

8. When finished with the Drill Press, always press the Switch to the OFF position.

SKU 44506 For technical questions, please call 1-800-444-3353. Page 4

Page 5

9. Do not mount (or adjust) the workpiece on the Drill Press Table while the motor is

running.

10. When drilling or cutting large holes, use the slower speeds and securely fasten the

workpiece to the table using a mounted vise.

11. Do not use drill bits that extend more than six inches from the Chuck.

12. Do not use circle cutters, rotary planers, wire wheels, router bits, or shaper cutters on

this Drill Press.

Unpacking

When unpacking, check to make sure the following parts are included. Refer to the Parts

Lists and Assembly Drawings located at the end of this manual.

Locking Switch (21)

Table (C7)

Base (C4)

Head (1) Assembly

Motor (7)

Support Tube (C3)

Table Support (C1)

Bag of Loose Parts

Box of Loose Parts

If any parts are missing or broken, please call Harbor Freight Tools at the number on the

cover of this manual as soon as possible.

Assembly

Assembly hardware is located in one box and one bag. Each contains the necessary parts

for each assembly step. Remove all packing and protective material from the Drill Press

components.

1. Position the Base (C4) on a level and sturdy table for mounting.

It is recommended to bolt the Base to the table using appropriate hardware (not

supplied).

2. Place the Support Tube (C3) on the Base, aligning the mounting holes.

3. Insert three large Hex Screws (C5) into the mounting holes and tighten with a wrench.

SKU 44506 For technical questions, please call 1-800-444-3353. Page 5

Page 6

4. Install the Table Support (C1), with attached Table (C7), over the Support Tube (C3)

and slide it down. Hand Tighten the Lock Handle Support (C2).

CAUTION: Avoid injuries. The next step involves lifting the Head Assembly onto the

Support Tube. The Head Assembly is heavy. Have someone help you lift this assembly

into place.

5. Using two people, lift the Head (1) Assembly up and onto the Support Tube (C3).

Slide it down on the Column Tube as far as it will go. Align it so that it faces straight

forward, inline with the Base.

6. Screw in two Set Screws (11), into the side of the Head (1) and tighten with the Allen

wrench.

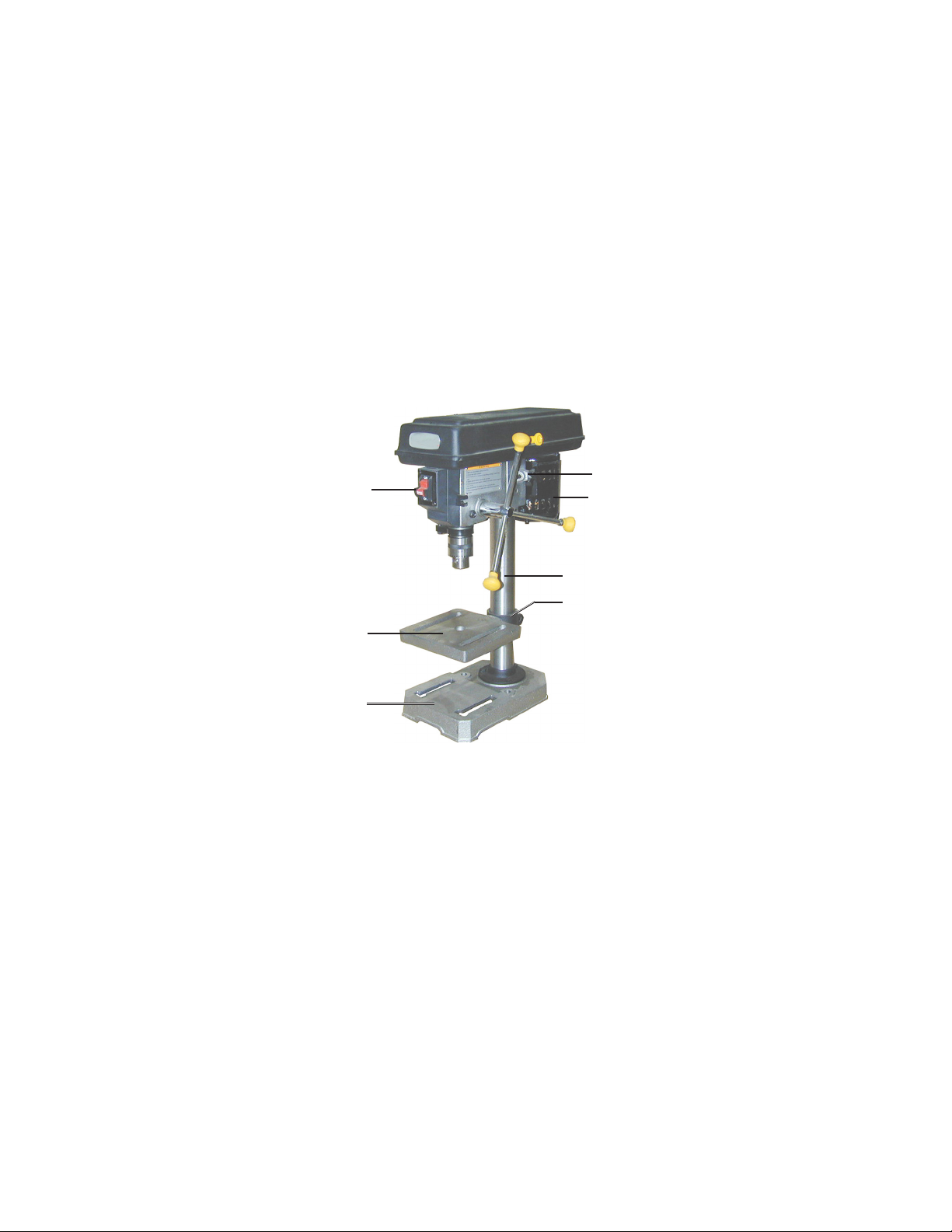

Guard (A5)

Motor Adjusting

Knob (10)

Feed Knob (12)

Hex Nuts (31)

Feed Wheel Stop

Tension Spring (28)

Chuck (B8)

Set Screws

(11)

7. Attach Knob (A2) to the (top) pulley Guard (A5) using Pan Head Screw (A3).

8. Adjust Belt (A4) tension or change speeds.

- Open the pulley Guard (A5) to expose the Belt.

- Turn the Motor Adjusting Knob (10) counterclockwise to loosen Belt Tension.

- If necessary, move the Belt up or down on the pulleys to change the drill speed.

- Push the Motor backward, tightening the Belt on the pulleys, and hold in place.

- Turn the Motor Adjusting Knob clockwise to tighten the Belt in place.

- Refer to the chart inside the Guard lid to select speed and belt locations.

Knob (A2)

Note: To test the proper belt tension, push in on the center of each belt at its center. It should

move only 1/2 inch (in or out).

Caution: overtightening the belts can cause the motor to bind, and not start. It can also

damage Motor bearings.

9. Locate the Feed Knobs (12) and Rods (13) and screw onto the Pinion Shaft (14).

10. Install the Chuck (B8).

- Thoroughly clean the tapered hole in the Chuck and the Spindle Shaft (B7) of all dirt,

grease, oil, and protective coatings (paint thinner may be necessary).

SKU 44506 For technical questions, please call 1-800-444-3353. Page 6

Page 7

- Slide the Chuck onto the Spindle Shaft.

- Turn the Chuck sleeve clockwise and open the jaws

completely.

- Tap the nose of the Chuck lightly with a piece of wood

and a hammer to securely set the Chuck.

11. Verify that the Table (C7) is square (90 degrees) to the

Head Assembly and drill bit.

Screw (C6)

- Raise the Table to within four inches of the Chuck.

- Place the long side of a combination square on the

Table.

- Align the short side of the square to the drill bit.

- If the Table is not square to the bit, loosen Screw (C6)

with a wrench.

- Rotate the Table until it is square to the bit.

- Retighten the Screw (C6).

Operation

Warning: Avoid personal injuries. Before operating this machine, review all Safety Warnings and Precautions listed on pages 2 through 5.

1. Make sure the Drill Press is OFF and the Power Cord (33) is unplugged. Loosen the

Lock Handle Support (C2) and adjust the Table height to accommodate the workpiece

being drilled. Retighten Lock Support Handle.

2. Open the Chuck (B8) and insert the drill bit in the center. Tighten with the Chuck Key.

3. Secure the workpiece (and backup material) to the Table using a vise and/or clamp.

The workpiece sits on the backup material which in typically a scrap piece of wood

used to stabilize the workpiece. It also helps the drill make a cleaner hole. To keep it

from spinning, have it touching the left side of the Column.

4. Bring the drill bit down with the Feed Knob (12) to where the hole is to be drilled.

Make minor workpiece alignment adjustments.

5. Plug the Power Cord (33) into an electrical outlet.

6. Insert the Switch Key (24) into the Locking Switch (21).

Warning: Wear an ANSI approved, full face shield while drilling any type of material.

7. Push the Switch up to turn the Motor ON.

8. Pull down on the Feed Knob and slowly drill the hole into the workpiece.

Warning: If the drill bit grabs and spins the workpiece, do not attempt to stop the spinning with your hands. Step back, and push the Switch down to the OFF position. Wait

for the spindle to stop turning before dislodging the workpiece.

9. When the drilling is complete, press the Switch to the OFF position and remove the

Switch Key (Keep the Switch Key in a safe place).

REV 10/04

SKU 44506 For technical questions, please call 1-800-444-3353. Page 7

Page 8

Setting the Depth Scale to Drill to a Specified Depth

During this procedure, refer to the left photo on page 6.

1. Make sure the Drill Press is OFF and Power Cord (33) is unplugged. Secure the

workpiece to the Table.

2. Mark the desired hole depth on the side of the workpiece.

Also view the depth indicator Pointer (32) shown on page 9.

3. Loosen the Hex Nuts (31) and screw both toward the top of Stop Rod (B12).

4. Turn the Feed Wheel counterclockwise to bring the tip of the drill bit down, next to the

hole depth mark.

5. Turn the Hex Nuts (31) down until they touch the Feed Wheel stop.

7. Turn the Drill Press ON and turn the Feed Handle counterclockwise until it drills the

hole and stops at the set depth.

8. Turn the Drill Press OFF.

Tilting the Table

1. Loosen Screw (C6) under the Table assembly with a wrench.

2. Rotate the Table to the desired angle.

The scale can be used to approximate the angle.

3. Retighten the Screw.

Maintenance

Warning: Before performing any maintenance to this machine, remove the line cord

from the electrical outlet.

Removing the Chuck and Spindle Shaft

During this procedure, refer to the Chuck and Spindle Assembly Drawing.

1. Pull the Feed Wheel counterclockwise and hold the Chuck at a depth of three inches.

2. Align the key holes in the Spindle Shaft (B7) and the Quill Tube (B3) by turning the

Chuck by hand.

3. Insert a Wedge Drift Key (not supplied) into the key holes.

4. Lightly tap the Wedge Drift Key with a rubber mallet until the Spindle Shaft falls out of

the Quill Tube.

Place a bundled cloth or basket below the Chuck to catch it when it falls.

Installing the Chuck and Spindle Shaft

1. Using a clean cloth, wipe the tapered surfaces on the Spindle Shaft (B7).

SKU 44506 For technical questions, please call 1-800-444-3353. Page 8

Page 9

2. Slide the Spindle Shaft and Chuck assembly up and into the Quill Tube (B3).

At the same time, turn the assembly until the rectangular end of the Spindle Shaft

slips into the notch on the Quill Tube.

Warning: In the previous step, if the Spindle Shaft is not properly set in the Quill Tube

notch, it may fly out during operation.

3. Loosen the Lock Handle Support (C2) and raise the Table (C7) about three inches

below the Chuck.

4. Turn the Chuck sleeve clockwise to open the jaws completely.

5. Pull the Feed Knob counterclockwise and force the Chuck against the Table until the

Spindle Shaft is secure.

Adjusting the Feed Wheel Return Tension Spring

Caution: Wear a full face shield during this procedure.

1. Move the Chuck to its uppermost position.

2. Loosen Hex Nuts (31) and move both to the lowermost position.

This will keep the Chuck from falling during this adjustment.

3. Insert a screwdriver in the lower-front notch of the Spring Cap (29).

Hold it in place and, using a wrench, remove the (outer) Hex Nut (30) only.

4. With the screwdriver still in place, loosen the (inner) Hex Nut (30) until the Spring Cap

notch disengages from the Spring Retainer (27) -- about 1/8 inch.

Pointer (32)

Spring Cap (29)

Hex Nuts (30)

Notch

Hex Nuts (31)

5. Turn the screwdriver counterclockwise and engage the next Spring Cap notch.

Leave the screwdriver in place.

6. Tighten the (inner) Hex Nut just enough to engage the notch.

If this Hex Nut is too tight, it will restrict (up and down) Chuck-Spindle movement.

7. Loosen and screw the Hex Nuts (31) to the top of the Stop Rod (B12).

SKU 44506 For technical questions, please call 1-800-444-3353. Page 9

Page 10

8. Pull the Feed Knob and check the spring tension, making sure the up movement is

smooth and complete.

From one inch down, the Chuck should return to its uppermost position. If more

tension is required, repeat steps.

9. Replace the (outer) Hex Nut and tighten on top of the (inner) Hex Nut. Do not

overtighten.

10. If the (up/down) movement is restricted, slightly loosen the (inner) Hex Nut, and

retighten the (outer) Hex Nut.

General Maintenance

1. Using compressed air, blow clean the Table, Base, and Motor cooling vents of dirt and

materials.

2. Apply paste wax to the Table and Column to enable movement and to help keep

surfaces clean.

3. All bearings are factory lubricated and need no further attention.

4. Periodically, lubricate the Tube Column, Table, and Spindle upper teeth.

5. Monthly, check the tightness of all mounting screws and bolts in the Base, Column,

and Head assemblies.

6. Check belt for wear and replace if frayed or damaged in any way.

7. Lubricate Spindle assembly with a light oil, weekly.

8. Store in a clean and dry location.

SKU 44506 For technical questions, please call 1-800-444-3353. Page 10

Page 11

Troubleshooting

MOTPMYSESUACELBISSOPNOITULOS

deepseldnipstcerrocnI-

rosnrubtibllirD

sekoms

lausunusekaM

sion

e

selbbowtibllirD

leehWdeeF

tsafoot

sdnibtibllirD

-

ro,ylwolssnruter

tibllirdlluD-

ylwolsootgnillirD-

oitacirbulgnikcaL-

n

gnorwtesnoisnettleB-

yrdeldnipS-

yellupeldnipsesooL-

yelluprotomesooL-

tibtneB-

sgniraeBeldnipSnroW-

bllirD-

noisneT

tnemtsujda

tibllirdlluD-

esoolstleB-

nitongnirpS

yltcerrockcuhCnitonti

dellatsniylreporptonkcuhC-

tibllirdgnihcnipeceipkroW-

drahooterusserpdeeF-

dA-

retsafllirD-

rbuL-

tibllirdecalpeR-

tsujdA-

noisneT

tibllirdecalpeR-

deepseldnipsegnahC-

tibwenhtiwecalpeR-

aeragnittucetacirbuL-

noisnettlebtsujdA-

eldnipsetaci

tunyellupkcehC-

swercsteSnethgiT-

sgniraebeldnipsecalpeR-

tibllirdllatsnieR-

rAdnakcuhCllatsnieR-

.ylwolseldnaHdeeFlluP-

ylbmessarob

.9egapeeS.gnirpS

ll

irdetacirbul,eceipkrownoitisopeR-

noisnettlebeldnipsdnarotomtsuj

SKU 44506 For technical questions, please call 1-800-444-3353. Page 11

Page 12

Head Assembly Parts List

#metInoitpircseD

1mirTdnaniPlloR/wdaeH

28-52.1x8M,kcoL,tuN

361/1x61/11x61/5,rehsaW

452-52.1x8M,xeH,wercS

5rotoM,

yelluP

601-0.1x6M,teS.coSxeH,wercS

7rotoM

8rotoM,potS

9potSrotoM,gnirpS

01gnitsujdArotoM,bonK

118-52.1x8M,teS.coS

21bonK

31doR

41noiniP,tfahS

5152.1x8M,xeH,tuN

#metInoitpircseD

818-8.0x5M.dHnaP,wercS

91elacShtpeD/whctiwS,xoB

0221-8.0x5M,.rCnaP,wercS

12gnikcoL,hctiwS

228-6

1x4M.dHnaP.paTfleS,wercS

32etalPhctiwS,revoC

42hctiwS,yeK

52eriW,rotcennoC

62gnirpS,taeS

72gnirpS,reniateR

xeH,wercS

82nois

neT,gnirpS

92gnirpS,paC

0342-8/3,xeH,tuN

135.1x01M,xeH,tuN

23retnioP

6152.1x8M,teS.tiS.tlF,wercS

71mm5.txE,rehsawkcoL

NOTE: Some parts are listed in these Part Lists are shown for illustration purposes only and are

not available individually as replacement parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE

IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT

BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR

HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

33rewoP,droC

43mm4,"L"xeH,hcnerW

SKU 44506 For technical questions, please call 1-800-444-3353. Page 12

Page 13

Head Assembly Drawing

SKU 44506 For technical questions, please call 1-800-444-3353. Page 13

Page 14

Pulley and Spindle Assembly Parts List

#metInoitpircseD

1ArebbuR,gnihsuB

2AbonK

3A21-8.0x5M,.dHnaP,wercS

4A62x61/5,5V,tleB

5AslebaLhtiwdrauG

6A61-01x6M,.

7AgniniateR,gniR

8Amm71,llaB,gniraeB

9ArecapS

01AyelluP,tresnI

11AeldnipS,yelluP

21AyelluP,tuN

31Adr

41A61-8.0x5M,.dHnaP,wercS

51AmaoF,rehsaW

oC,pmalC

dHrehsaw-wercS

Pulley and Spindle Assembly Drawing

When ordering a part from this drawing,

add an A- prefix to the part number.

SKU 44506 For technical questions, please call 1-800-444-3353. Page 14

Page 15

Chuck and Spindle Shaft Parts List

#metInoitpircseD

1BlliuQ,teksaG

2Bmm21,llaB,gniraeB

3BlliuQ,ebuT

4B02-8.0x5M,naP,wercS

5BpotS,ralloC

6BgniniateR,g

7BeldnipS,tfahS

8BkcuhC

9ByeKkcuhC

niR

01B0.1x6M,xeH,tuN

11B8.0x5M,xeH,tuN

21BdoR,potS

Chuck and Spindle Shaft Assembly Drawing

When ordering a part from this drawing,

add a B- prefix to the part number.

SKU 44506 For technical questions, please call 1-800-444-3353. Page 15

Page 16

Base and Table Assembly Parts List

#metInoitpircseD

1CelacShtiwelbaT,troppuS

2CeldnaHkcoL,troppuS

3CtroppuS,ebuT

4CesaB

5C02-52.1x8M,.dHxeH,wercS

6C8

7CelbaT

/7x21-2/1,.dHxeH,wercS

Base and Table Assembly Drawing

When ordering a part from this drawing,

add a C- prefix to the part number.

SKU 44506 For technical questions, please call 1-800-444-3353. Page 16

Loading...

Loading...