Page 1

Model 43242

MINI AIR FILTER

With Pressure Gauge and Pressure Regulator

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright © 2000 by Harbor Freight Tools. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express

written consent of Harbor Freight Tools.

For technical questions please call 1-800-444-3353

UNPACKING

When unpacking, check to make sure all parts shown on the back of this instruction

sheet are included. If any parts are missing or broken, please call Harbor Freight Tools

at the number shown on the front of this instruction sheet as soon as possible.

OPERATING INSTRUCTIONS

NOTE:All parts mentioned below refer to parts shown on the reverse side of this

instruction sheet.

1. For ease of use, and to avoid damage to the Mini Air Filter, it is recommended that the unit be

mounted in a convenient location on the workbench or in the work area. This can be done by

attaching the Mounting Bracket (part #22) to the side of the workbench or wall, using two

wood or metal screws (not provided). (Figure A)

2. Once the Mounting Bracket has been attached to a desired location, unscrew and remove the

Retaining Ring (part #23) from the top of the Mini Air Filter.

3. Insert the top of the Mini Air Filter through the Mounting Bracket and secure by replacing the

Retaining Ring.

4. Attach a 1/4” NPT Female hose connector to the air compressor supply hose. Then, wrap the

threads of the 1/4” NPT Female hose connector with approximately 3” of Teflon tape. Next,

connect the 1/4” NPT Female hose connector to the inlet side of the Mini Air Filter.

5. Attach a 1/4” NPT Male hose connector to one end of the outlet extension hose (to which you

will connect a tool). Check to make sure the other end of the outlet extension hose is fitted

with a quick coupler. Then, wrap the threads of the 1/4” NPT Male hose connector with

approximately 3” of Teflon tape. Next, connect the 1/4” NPT Male hose connector to the outlet

side of the Mini Air Filter.

6. Connect the quick coupler of the air outlet extension hose to the tool you are using. Turn on

the air compressor and regulate the desired PSI to the tool by pulling up and turning the

Pressure Adjustment Knob (part #1) on the Mini Air Filter clockwise for reduced air pressure,

or counterclockwise for increased air pressure. Press down on the knob to lock.

7. The Mini Air Filter is now ready for use. NOTE: Depending on usage, periodically examine

the Drain Cup (part #11) for accumulated water that is being separated from the compressed

air system. See Step one for instructions on draining the excess fluid from the Drain Cup.

SEE REVERSE SIDE OF THIS INSTRUCTION FLYER FOR PRODUCT

WARNINGS, PRECAUTIONS, PARTS LIST, AND ASSEMBLY DIAGRAM.

FIGURE A

1

23

9

14

CLEANING AND MAINTENANCE

1. When the water level rises to the bottom edge of the

Filter Mesh Mounting (part #9) within the Drain Cup (part

#11) it is necessary to remove the excess fluid. To drain

the fluid slowly turn the Water Valve Drain (part #14)

counterclockwise until the fluid begins to flow from the

Drain Cup. When all of the fluid has been drained turn

the Water Valve Drain clockwise to tighten.

2. To clean, wipe with a clean, damp cloth, using a mild

soap with water if necessary. Then, dry.

22

AIR OUTLET

11

REV 01d; 07g

Page 2

SAFETY WARNINGS AND PRECAUTIONS

1. KEEP PRODUCT USAGE AREA CLEAN. Cluttered

areas invite injuries.

2. KEEP CHILDREN AWAY FROM PRODUCT USAGE

AREA. Do not allow children to handle this product.

22

1

3. DO NOT USE THIS PRODUCT IF UNDER THE

INFLUENCE OF ALCOHOL OR DRUGS. Read

warning labels on prescriptions to determine if your

judgement or reflexes are impaired while taking

drugs. If there is any doubt, do not attempt to use

this product.

4. USE EYE PROTECTION. Wear ANSI-approved

safety impact eye goggles. The ANSI-approved

safety impact goggles are available from Harbor

Freight Tools.

5. CHECK FOR DAMAGED PARTS. Before us ing

this product, carefully check that it will operate

properly and perform its intended function. Check

for damaged parts and any other conditions that may

affect its operation. Replace or repair damaged or

worn parts immediately.

6. REPLACEMENT PARTS AND ACCESSORIES.

When servicing, use only identical replacement

parts. Only use accessories intended for use with

this product. Approved accessories are available

from Harbor Freight Tools.

7. MAINTENANCE: Service and maintenance should

be performed regularly by a qualified technician.

10

11

12

13

2

3

15

16

17

4

23

5

6

18

19

20

7

8

9

21

14

NOTE: Some parts are listed and shown for

illustration purposes only, and are not available

individually as replacement parts.

8. USE THE RIGHT PRODUCT FOR THE RIGHT

JOB. There are certain applications for which this

product was designed. Do not use a smaller tool to

do the work required by a larger industrial size tool.

Do not use this product for a purpose for which it was

not intended.

9. THE BRASS COMPONENTS OF THIS PRODUCT

CONTAIN LEAD, A CHEMICAL KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE BIRTH

DEFECTS (OR OTHER REPRODUCTIVE HARM).

(California Health & Safety code § 25249.5, et seq.)

SAVE THIS INSTRUCTION SHEET

You will need this instruction sheet for the

Operating, Maintenance Procedures, and

Safety Warnings and Precautions. Keep

your invoice with this instruction sheet. Write

the invoice number on the the front of this

instruction sheet. Keep this instruction sheet

and invoice in a safe and dry place for future

reference.

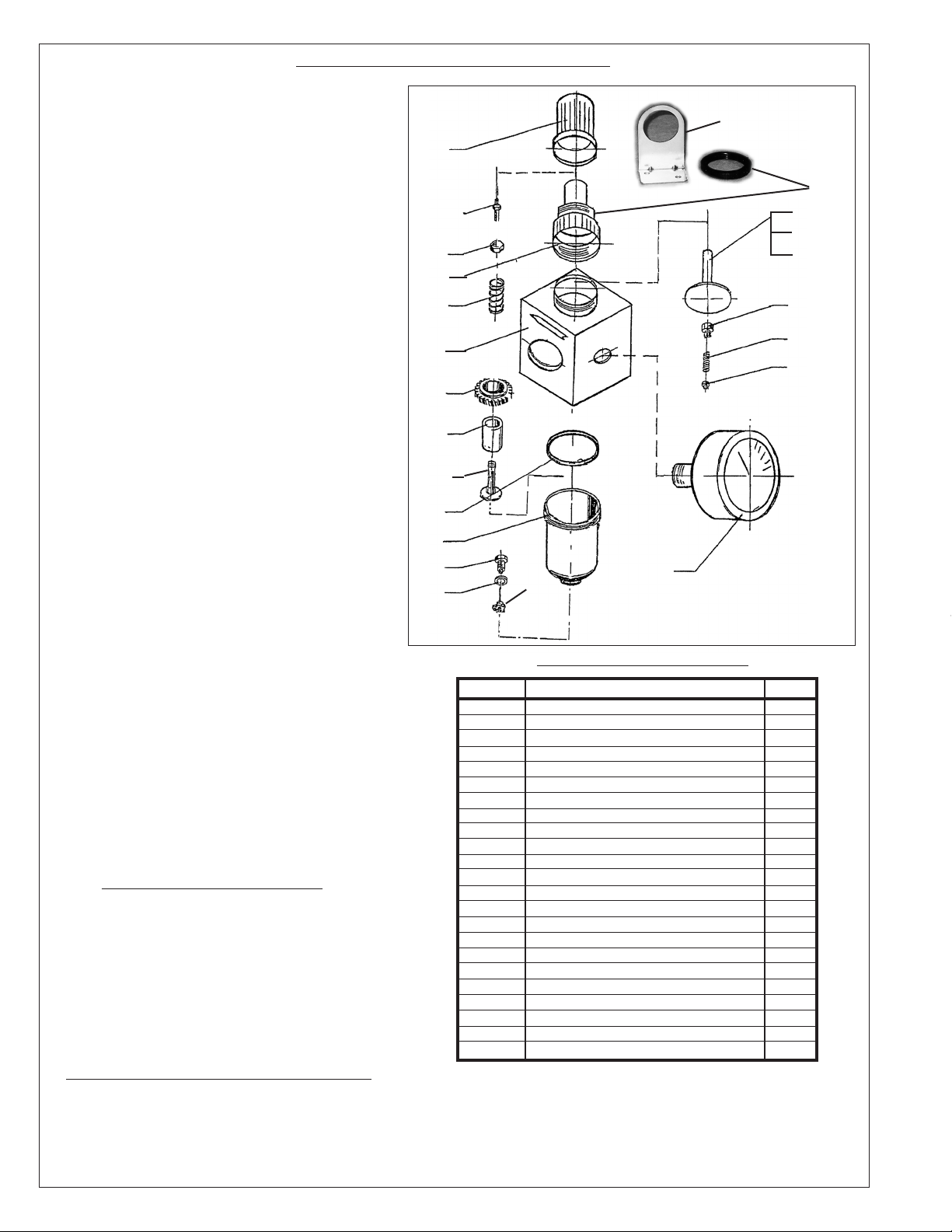

PARTS LIST / ASSEMBLY DIAGRAM

PART # DESCRIPTION QTY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Pressure Adjustment Knob

Sinistral Screw

Sinistral Nut

Pressure Adjustment Mounting

Spring

Body

Air Distributor

Filter Mesh

Filter Mesh Mounting

“O” Ring

Drain Cup

Adjustment Screw

Gasket

Water Valve Drain

Filter Valve Screw

Brass Gasket

Rubber Cover

Rubber Screw

Spring

Rubber Gasket

Pressure Gauge

Mounting Bracket

Retainer Ring

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL AS A REFERENCE

THER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE

OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR

PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND

LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT

OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS

SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE

TOOL ONLY. NEI-

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Loading...

Loading...