Page 1

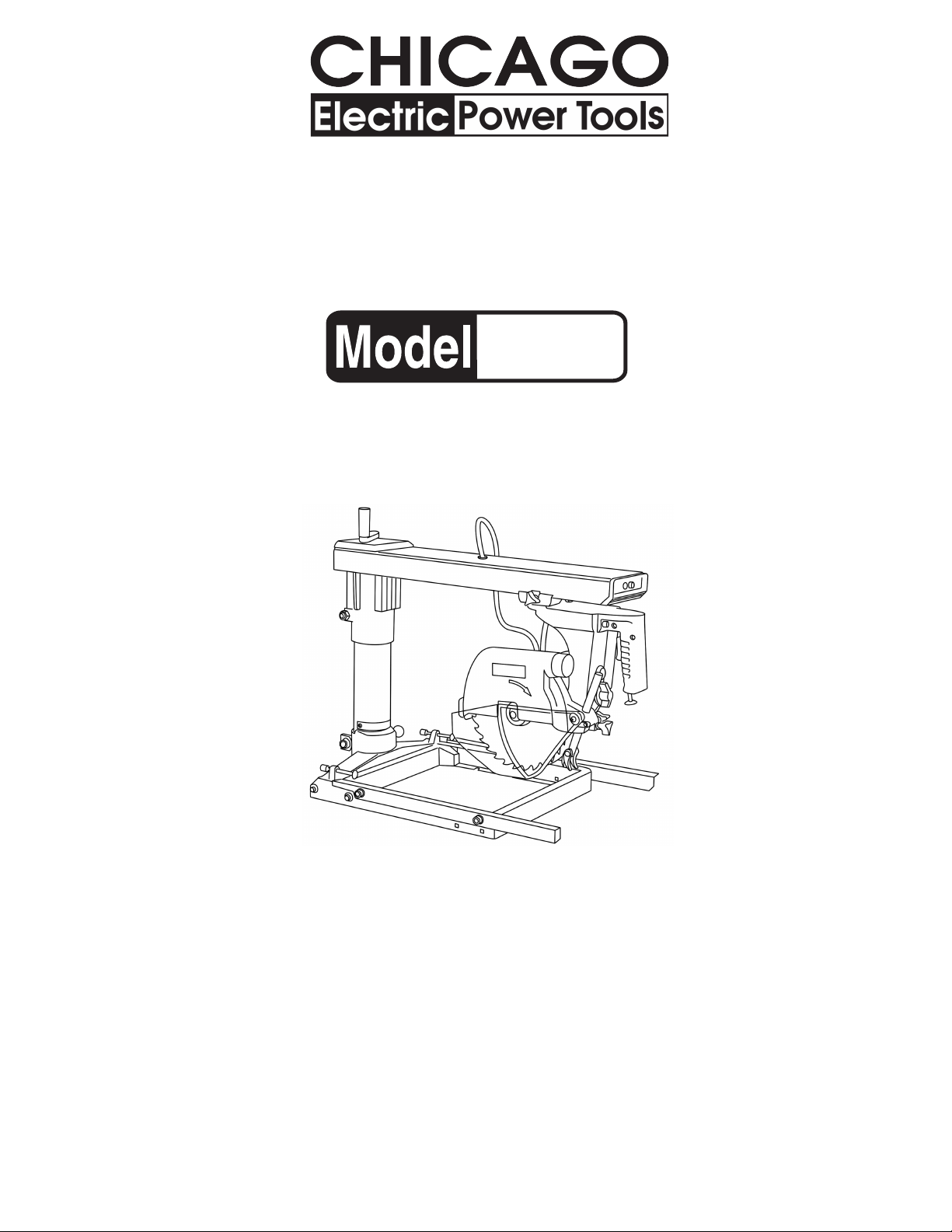

RADIAL ARM SAW

1

8-

/4 INCH

42933

ASSEMBLY AND OPERATING

INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright© 2000 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

REV 11/04; 12/06

Page 2

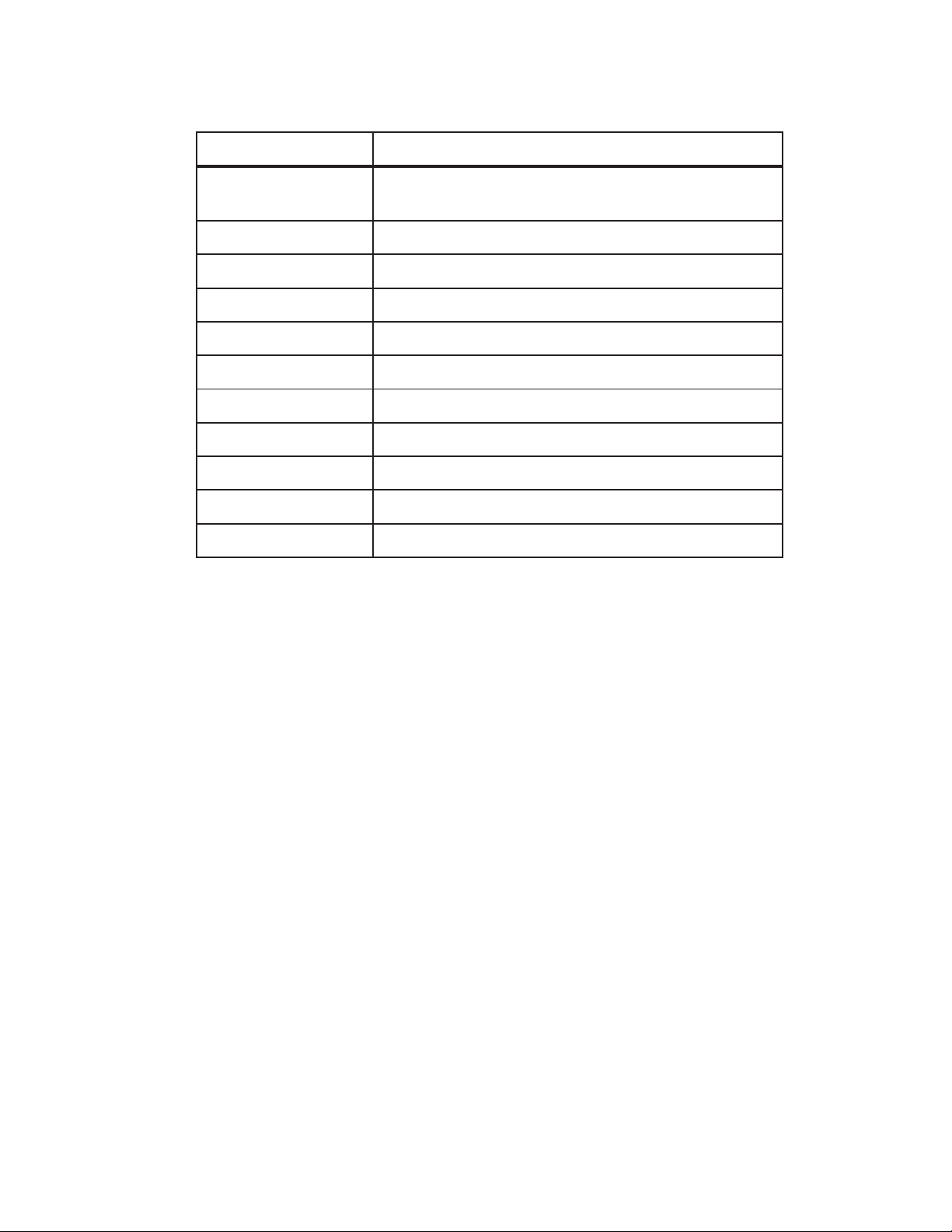

Specifications

METINOITPIRCSED

stnemeriuqeRrewoP

rotoMekarbc

edalBwaS).aid(4/1-8

robrAhcni8/5

ecnatsiDtucssorC)mumixam(sehcni11

CpiR)mumixam(sehcni02

eziSelbaTsehcni4/3x8/5-72x61/1-51

ecnatsiDtu

stuCfohtpeDsehcni8/1-2:seerged09;sehcni2:seerged54

spotSxednIleveBseerged09,54,0

SxednIertiMseerged06dna,54,03,51,0:thgirdnatfeL

spot

seirosseccA40234#metI:tn

emecalpeRedalBwaS

esahpelgnis,zH06,CAV021

Save This Manual

sttaw0331;spmadaol9.6;spmaputrats9.02

irtcele,MPReldnips0024,PH4/3-1

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools, or extension cords.

4. Store idle equipment. When not in use, tools must be stored in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

5. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool

capacity.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 2

Page 3

6. Use the right tool for the job. Do not attempt to force a small tool or attachment to

do the work of a larger industrial tool. There are certain applications for which this tool

was designed. Do not modify this tool and do not use this tool for a purpose for which

it was not intended.

7. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically nonconductive clothes and nonskid footwear are

recommended when working. Wear restrictive hair covering to contain long hair.

8. Use eye and ear protection. Always wear ANSI approved impact safety goggles.

Wear a full face shield if you are producing metal filings or wood chips. Wear an ANSI

approved dust mask or respirator when working around metal, wood, and chemical

dusts and mists.

9. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

10. Maintain tools with care. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect tool

cords periodically and, if damaged, have them repaired by an authorized technician.

The handles must be kept clean, dry, and free from oil and grease at all times.

11. Disconnect power. Unplug when not in use.

12. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches

are removed from the tool or machine work surface before plugging it in.

13. Avoid unintentional starting. Be sure the switch is in the Off position and locked

when not in use, and before plugging in. Do not carry any tool with your finger on the

trigger, whether it is plugged in or not.

14. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

15. Take caution as some woods contain preservatives such as copper chromium

arsenate (CCA) which can be toxic. When cutting these materials extra care should

be taken to avoid inhalation and minimize skin contact.

16. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any

part that is damaged should be properly repaired or replaced by a qualified technician.

Do not use the tool if any switch does not turn On and Off properly.

17. Guard against electric shock. Prevent body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerator enclosures.

18. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor Freight

Tools.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 3

Page 4

19. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels on prescriptions to determine if your judgment or reflexes are impaired while

taking drugs. If there is any doubt, do not operate the tool.

20. Use proper size and type extension cord. If an extension cord is required, it must

be of the proper size and type to supply the correct current to the tool without heating

up. Otherwise, the extension cord could melt and catch fire, or cause electrical

damage to the tool. This tool requires use of an extension cord of 0 to 10 amps

capability (up to 50 feet), with wire size rated at 18 AWG. Longer extension cords

require larger size wire. If you are using the tool outdoors, use an extension cord rated

for outdoor use (signified by “WA” on the jacket).

21. Maintenance. For your safety, service and maintenance should be performed

regularly by a qualified technician.

Safety Precautions When Using Radial Saws

1. Disconnect the line cord from the electrical outlet before servicing the Radial Arm Saw.

2. After cutting, wait until the saw blade comes to a complete stop before removing stock

from the table, reaching around the saw blade, or leaving the area.

3. Never walk away and leave the saw running.

4. When making rip cuts, feed the stock into the blade against the direction of the blade

rotation.

5. Always use a push stick when ripping small or thin stock.

6. Keep saw blade sharp and free of all rust and pitch.

7. Always use the anti-kickback finger attachment when making rip cuts. Feed stock from

the opposite end from the anti-kickback finger attachment.

8. Always use the saw blade guides and fence, and never push stock being cut by hand.

9. Tighten and lock all adjusting (saw blade positioning) screws before operating.

10. Keeps hands out of the path of the saw blade during operation.

11. Only use 8-inch saw blades with 5/8 inch arbor on this machine.

12. Always secure the stock being cut with clamps whenever possible.

13. Make sure that the Switch is in the OFF position before plugging the line cord into the

electrical outlet.

14. Many saw accidents are caused by dull, badly set, and improperly filed cutting blades;

gum or resin adhering to the cutting blade; and by saw blade misalignment with the

fence. Such conditions can cause the stock to stick, jam, stall the saw blade, or kick

back at the operator. Never use carbide blades to cut anything other than wood;

cutting hard materials can cause the carbide blade to shatter and break apart.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 4

Page 5

WARNING: Never attempt to free a stalled saw blade without first turning OFF the

saw motor.

15. Provide proper support for the stock based on its size and the type of operation to be

performed.

16. Avoid awkward hand positions (i.e., crossing arms during operation) in which a

sudden slip could cause your hand to move into the moving saw blade.

17. Before making any adjustments to the Radial Arm Saw, the Switch should be in the

OFF position and the Switch locked OFF.

18. Never turn the Radial Arm Saw ON before clearing the table and work surface of all

objects (tools, scraps of wood, etc.), except the stock to be cut.

19. Always lock the carriage arm in place before lowering the saw blade. Otherwise, when

the saw blade touches the stock, it may draw itself backward (with you) into the cutting

area.

20. Never cut more than one piece of stock at a time, for any type of cut.

21. When cross cutting, always return the carriage arm to the rear position before letting

go of the Handle.

22. Avoid Kickback of stock:

- For rip cuts, the saw blade must be exactly parallel to the fence to prevent pinching or

heeling. Use a stock separator on the output side of the stock cut.

- Only feed the stock against the rotation of the saw blade.

- Keep the stock firmly on the table while cutting.

23. When making rip cuts:

- Push only on the main section of stock, between the saw blade and the fence.

- Always use a push stick, never your hands.

- Do not release the stock before the cut is complete, and push beyond the saw blade.

- Always push the stock through the saw blade, never pull it through from the opposite

direction.

- Always use the anti-kickback claws.

- Do not rip stock that is bowed, warped, or has nonparallel edges.

24. The use of abrasive, cut off, or wire wheels can be dangerous and is not

recommended.

Note: Performance of this tool may vary depending on variations in local line voltage. Extension cord usage may also affect tool performance.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, but must be supplied by the operator.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 5

Page 6

Unpacking

When unpacking, check to make sure that all the parts are included. Refer to the Parts List

and Assembly Drawing at the end of this manual. If any parts are missing or broken, please

call Harbor Freight Tools at the number on the cover of this manual as soon as possible.

Installation

During the assembly and installation procedure, you may have to refer to the Parts List and

Assembly Drawings located at the end of this manual.

1. Secure the Radial Arm Saw to a solid bench top (or table) by bolting (or clamping) the

saw frame down to the bench top.

- The workbench must not be able to slide or tip over. Affix to floor if necessary.

- Position the Radial Arm Saw (or saw and bench) to slope slightly to the rear so the

radial arm carriage will not roll forward due to gravity.

- The workbench should be of the appropriate length and width to allow the operator

to stand aside of the saw blade, whatever position the saw blade is in.

- The work area should have adequate, overhead, non-glare lighting.

- Always lock the radial arm carriage before moving the unit.

2. Turn the Base (152) assembly upside down. Attach Table

A (127) squarely to the Base assembly using the four

cross-head Tapping Screws (165).

3. Attach the table stabilizer Stands to both sides of the

Base using four Hex Nuts (82), Washers (149), and

Round Head Bolts (148).

4. Place the Table and Base assembly on the workbench,

right side up. Secure to the workbench with nuts, bolts,

and washers (not supplied).

5. Position Table B (126) and Table C (125), and the rip

fence (guide) and secure them by partially tightening the

two screw clamps built into the Base assembly.

6. Set the Arm (118) assembly column into the Column

Base. Move the Arm slightly to the left or right until the

column index knob locks into the arm support column.

The arm support column has nine positive stops: 0, 15,

30, 45, and 60 degrees (left and right).

7. Attach the Elevating Handle assembly to the Arm using

the Allen wrench (provided).

8. Attach the Saw Blade (17) to the Gear Shaft (19) and

secure with the Outside Flange (16) and Bolt (15).

REV 03/01

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 6

Page 7

Lock the Gear Shaft with the Stopper Pin (22) located at

the front part of the Gear Case Cover (26).

Using a wrench, tighten the Bolt (15) over the Outside

Flange (16), counterclockwise.

9. Place the Safety Guard (10) over the Saw Blade and tighten

in place.

10. Install the anti-kickback pawl on the Safety Guard (10) with the

pawls facing the rear of the machine.

11. Set the height by loosening its lock knob and moving it up or

down. Retighten again when set to the proper height.

12. Verify that no play exists in the carriage, and that the arm, yoke,

and bevel locks and clamps are tight.

13. Slip the Dust Guide (4) over the exhaust stem located on the

Safety Guard.

Operating Controls

Elevating Handle (88)

Yoke Pivot Clamp Handle (88)

Safety Guard (10)

Arm Index Knob (115)

Screw Clamp (137)

ON / OFF Switch – The Switch has a built-in locking feature which

requires a key to be inserted before the saw can be turned ON.

Removing the Key and pushing the OFF button locks the saw

against unintended use. For crosscutting, press the green Switch

in, then squeeze and hold the Trigger. For rip cutting, press the

Switch (122) with Key (98)

Trigger

Bevel Index Knob (74)

Bevel Lock Knob (71)

Lock On Button

Safety Guard Lock Knob (5)

Anti-kickback Arm (13)

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 7

Page 8

green Switch in, squeeze the Trigger (motor starts), then push up on the Lock On Button (

cutting only

again will release the Lock On Button, turning the motor off.

Carriage Lock – The Carriage Lock Knob located on the left side

of the Radial Arm, permits the saw assembly to be moved in or

out, and locked at the desired position on the arm. It must be fully

released for any crosscutting, and tightly locked for all operations

in which the saw assembly is stationary. To lock turn clockwise.

To unlock turn counterclockwise.

Arm Angle – The Arm Index Knob (142) and Washer (140) are

located at the Column Base (132). They can index, release, and

secure the arm angle for various miter positions. Positive index

stops are 0, 15, 30, 45, and 60 degrees (left and right). Non-index

stops can also be set within the range of the arm assembly.

Yoke Pivot- The Yoke Index Knob, located at the top of the Yoke

(under the Carriage Arm) indexes the Yoke horizontally to 0 degree

(crosscuts) or 90 degree (for rip cuts). Loosen the Yoke Pivot Clamp

Handle and pull out the Yoke Index Knob. Turn the motor assembly

until it locks at the index position. Lock the Yoke Pivot Clamp Handle.

) to keep the motor running without holding the Trigger in. Depressing the Trigger

for rip

Blade Angle – The Bevel Index Knob (74) and the Bevel Lock Knob

(71) are used to set the Blade angle (variable or indexed). Loosen the

Bevel Index Knob (71). Turn the motor assembly clockwise or counterclockwise to the index notch of 0, 45, or 90 degrees, or to a variable

position without using the index notch. Tighten the Bevel Lock Knob

by turning clockwise.

Depth of Cut – The Elevating Handle (100) at the rear of the arm

is used to raise and lower the height of the Saw Blade. Turn the

Elevating Handle clockwise to raise the Saw Blade or counterclockwise to lower it.

Adjustments

The following checks, and possible adjustments, should be done in the order listed before

beginning operation.

WARNING: For safety, unplug the line cord to the Radial Arm Saw.

1. Tables A (127), B (126), and C (125) are checked for straightness at the factory.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 8

Page 9

However, changes in humidity can slightly alter the condition of the wood. With the

Screw Clamps (131) tightened, use a straight edge or framing square to check for

flatness and squareness. Sand down any high spots using fine sandpaper.

2. Check for Arm tightness on the Column (132). If loose, tighten Bolt (115).

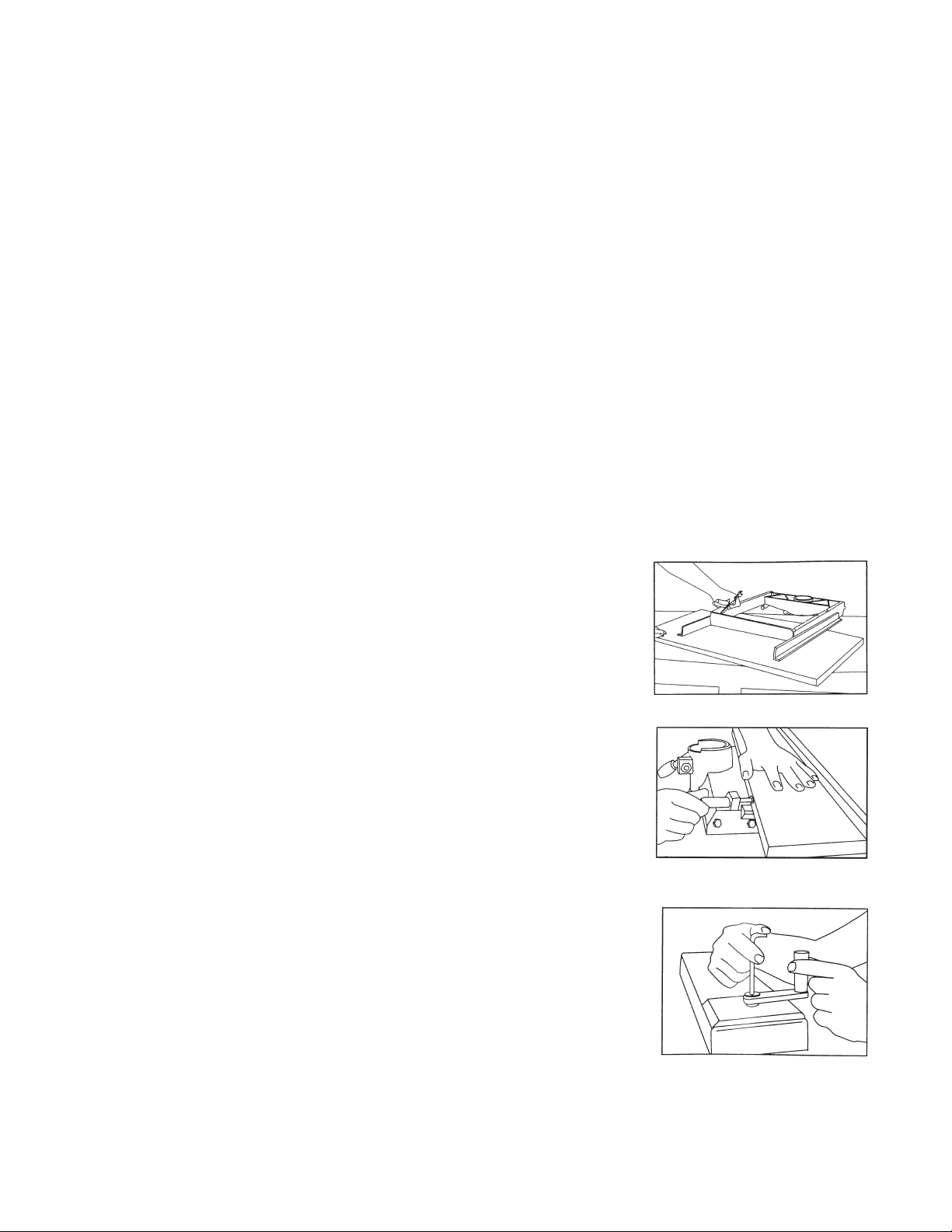

3. Check the crosscut travel of the Saw Blade for squareness.

- Lock or tighten all adjustment levers and knobs.

- Lower the Arm until it just clears the Table A front.

- Place a framing square so it just touches a tooth of the Saw

Blade.

- Mark this location with a pencil on the table and draw a straight

line using the square.

- Check that the Saw blade follows this line from front to back.

If the Saw Blade moves to the right or left side of the line as it travels the entire length

of the Arm, loosen the Screw Clamps (137) and lightly tap on the Table left or right side

until there is full travel alignment. Tighten the Screw Clamps again.

4. Check that the Saw Blade is square to Table A.

- Place a framing square on Table A so that the square is flat

on the Saw Blade (not touching teeth).

- If there is no gap between the square and the Saw Blade, no

adjustment is necessary.

- If the square does not touch the Saw Blade evenly (with the

square flat on the Table A), loosen the Bevel Lock Knob (71) and

adjust the motor until the gap between Saw Blade and the square

is eliminated.

5. Check that the Saw Blade is square to the rip fence.

- Firmly place a framing square against the rip fence and the blade

as shown to the right. The square should not touch any teeth.

- If the square is not flush with the entire blade, loosen the yoke

pivot Clamp Handle (66) and move the motor assembly until any

gaps have been eliminated. Tighten the Yoke Pivot Clamp and

recheck alignment. (This will simultaneously set both yoke indexing

positions for in and out ripping.)

Preparing the Work Table A

In order to move the Saw Blade into different cutting positions, kerf marks (or grooves) must

be cut into the worktable. It is recommended to cut grooves into a piece of 1/4 inch plywood

mounted to the surface of Table A.

1. Cut a piece of 1/4 inch plywood the same size as Table A.

2. Mount the plywood to Table A using self-tapping, countersinking screws at the four

corners of Table A.

3. Set the Carriage Arm at 0 degrees and lock in place.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 9

Page 10

4. Set the Saw Blade angle to 0 degrees index position (perpendicular to the worktable).

5. Draw out the Saw Blade to mid-range on the Carriage Arm and lock in that position.

6. Turn the Elevating Handle to lower the Saw Blade so it just touches the plywood top.

7. Place your hand on the Handle Assembly (87) and press the green ON button with the

other hand. Squeeze the Trigger (86) to start the motor.

8. With the same hand that you turned ON the machine, loosen the Carriage Lock Knob

and slowly move the Saw Blade back, cutting the rip fence; and then move it all the

way forward, cutting a groove into the entire depth of the plywood.

9. With the machine still running, turn the Elevating Handle 1/4 turn, lowering the Saw

Blade a little more. Pull the Handle back and forth again to cut the plywood groove a

little deeper. Tighten the Carriage Lock Knob again.

10. With the machine still running, loosen the yoke Clamp Handle (66) and pull out the

Yoke Index Knob and turn the yoke clockwise until it locks into the 90 degree.

This cuts a swing line into the worktable for in-ripping.

11. Once the quarter turn (swing line cut) is complete, lock the yoke Clamp Handle. With

the Saw Blade still turning, push on the Handle until the Saw Blade reaches the rip

fence, cutting the rip trough in the center of the worktable.

12. Turn the machine OFF and return the Saw Blade to the crosscut position. Lock the

Carriage Lock Knob.

13. Turn the machine ON and rotate the Yoke counterclockwise to the out-rip position. This

cuts the swing line for out-ripping. Loosen the Carriage Lock Knob.

14. Lock the yoke Clamp Handle (66) and, with the Saw Blade revolving, push the Handle

back until the new groove matches the groove cut in step 11. Turn the machine OFF.

15. Return the Saw Blade to the crosscut position. Unlock the Carriage Lock Knob (74b)

and move the motor assembly to the rear position, behind the fence. Pull out the Bevel

Index Knob (74) and lock the Saw Blade at index position 60 degrees. Turn on

machine and pull the Handle forward. This will cut a kerf mark for bevel crosscuts. Turn

the machine OFF.

16. Lock the Carriage Lock Knob and start the motor. Pull the Carriage Arm Index Lock

Knob and move the Arm to the 45 degree right-hand miter position. This will cut a

groove for miter cuts. Turn the machine OFF.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 10

Page 11

Operation

WARNING: The Radial Arm Saw can be very dangerous and cause serious injuries if not

operated properly. Review all safety precautions before operating. Always keep hands

out of the path of the moving Saw Blade.

Cross Cutting

1. Secure the stock to be cut against the table and fence.

If the stock length is short, do not hold with your hand. Use

a clamp to hold in place.

2. Adjust the Anti-kickback Arm (13) so it just clears the stock.

3. Check that the Pivot Yoke Clamp Lock and Bevel Index

Knob are set to 0 degrees and are secure in place.

4. Adjust the Elevating Handle (100) so the Saw Blade (17)

height is only 1/8 inch into the worktable.

5. Push the Handle backward so that the Saw Blade is in behind the stock to be cut.

6. Press the green Switch (122). Squeeze the Handle Trigger and slowly pull the Handle

toward you, causing the Saw Blade to cut the stock.

7. When the cut is complete, release the Trigger and push the Handle all the way back.

8. Wait for the Saw Blade to stop turning before removing the stock.

Mitre Cross Cutting

1. Loosen the yoke Clamp Handle (66) and pull out the Yoke

Index Knob.

2. Turn the motor assembly to the left or right and lock the

Yoke Index Knob at 45 degrees.

3. Tighten the yoke Clamp Handle (66).

4. Push the Handle backward so that the Saw Blade is in

behind the stock to be cut.

5. Secure the stock to be cut against the table and fence.

If the stock length is short, do not hold with your hand. Use a clamp to hold in place.

6. Adjust the Anti-kickback Arm (13) so it just clears the stock.

7. Press the green Switch (122). Depress and hold the Trigger in. Slowly pull the Handle

toward you, causing the Saw Blade to cut the stock.

8. When the cut is complete, release the Trigger and push the Handle all the way back.

9. Wait for the Saw Blade to stop turning before removing the stock.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 11

Page 12

Bevel Cross Cutting

1. Loosen the Bevel Lock Knob (71) and pull out the Bevel Index

Knob (74).

2. Turn the motor assembly clockwise or counterclockwise,

selecting the desired angle (variable or indexed, i.e., 45

degrees).

3. Tighten the Bevel Lock Knob (71) and push in the Bevel Index Knob (74).

4. Push the Handle backward so that the Saw Blade is in behind the stock to be cut.

5. Secure the stock to be cut against the table and fence. If the stock length is short, do

not hold with your hand. Use a clamp to hold in place.

6. Adjust the Anti-kickback Arm (15) so it just clears the stock.

7. Press the green Switch (122). Squeeze the Trigger and push the Handle all the way

back.

8. When the cut is complete, release the Trigger and push the Handle all the way back.

Compound Cross Cutting

Compound crosscutting combines the mitre and bevel functions. Set the Saw Blade angles

as previously described. Continue to follow steps 4 through 9, above.

In-Rip Cutting

Ripping is the process of cutting stock along the grain (or lengthwise). The stock if fed into

the Saw Blade against the blade rotation (similar to a table saw). The fence is used as a

guide to help maintain cutting width.

1. Loosen the yoke Clamp Handle (66) and pull out the

Yoke Index Knob.

2. Turn the motor assembly to the left and lock the Yoke

Index Knob at 90 degrees.

3. Tighten the yoke Clamp Handle (66).

4. Adjust the Saw Blade Safety Guard (7) so it is just above

the surface of the stock to be ripped.

5. Adjust the Anti-kickback Arm (13) so it is just above the

stock surface.

6. Adjust the Carriage Arm so that the Saw Blade is at the desired depth for the rip cut,

and securely lock the Carriage Lock Knob in place.

Note that the larger portion of the stock being ripped should be between the Fence

and the Saw Blade.

7. Adjust the Elevating Handle (100) so that the Saw Blade is 1/16 inch into the worktable.

8. Verify that the Bevel Index Knob is locked into 0 degrees.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 12

Page 13

9. Slide the stock to be ripped into the cutting area and verify that it slides easily beneath

the Safety Guard, Anti-kickback Arm, and (optional) Spreader Plate, and there is no

wobble space. Remove stock from cutting area.

10. Press the green Switch (122), squeeze the handle Trigger (93) (motor starts), and push

up on the Lock On Button.

11. From the side of the machine, feed the stock into the Saw Blade (against its rotation)

using a (long) push stick.

WARNING: Never use your hand to push the stock through the Saw Blade. Never reach

around the Saw Blade while it is running. Serious injury can occur to hands and arms.

12. When the cut is complete, and before removing the stock, squeeze the Trigger or pull

down on the Lock On Button, and press the red Switch.

Out-Rip Cutting

Out-ripping is done when the in-rip position will not permit a wide enough cut. This function

moves the Saw Blade to the front of the machine. This operation is the same as in-rip cutting (previously described), with the exception that the Pivot Yoke is turned so that the

Handle is on the right side of the machine (opposite of the in-rip position).

1. Adjust the Saw Blade for In-rip cutting as described on page 12.

2. Loosen the Bevel Lock Knob (71) and pull out the Bevel Index Knob (74).

3. Turn the motor assembly clockwise or counterclockwise, selecting the desired angle

(variable or indexed, i.e., 45 degrees).

4. Tighten the Bevel Lock Knob (71) and push in the Bevel Index Knob (74).

5. Press the green Switch (122), squeeze the handle Trigger (motor starts), and push up

on the Lock On Button.

6. From the side of the machine, feed the stock into the Saw Blade (against its rotation)

using a (long) push stick.

WARNING: Never use your hand to push the stock through the Saw Blade. Never reach

around the Saw Blade while it is running. Serious injury can occur to hands and arms.

7. When the cut is complete, and before removing the stock, squeeze the Trigger or pull

down on the Lock On Button, and press the red Switch.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 13

Page 14

Maintenance

CAUTION: Before performing any maintenance, remove the Line Cord from the electrical outlet.

1. Yoke Tightness – Periodically check and tighten the yoke Clamp Handle (66).

Over time this handle may become loose and not tighten entirely. To correct this condition,

tighten the large Nut (64) at the base of the Handle using the 5/8 inch arbor wrench.

2. Cleaning – After each use, apply compressed air to blow clean all the parts of the Radial

Arm Saw.

3. Saw Blades – Never use a replacement blade rated lower than 5,000 RPM, and larger

than 8 inches diameter.

4. Motor Brushes – Inspect the two motor Brushes (55) after the first 50 hours of saw use.

After that, check every 10 hours. Replace if necessary by a qualified technician.

Improper Brush maintenance can cause motor failure. The Brush Caps (56) are located

on each side of the motor housing.

5. Lubrication – The Radial Arm Saw does not require initial lubrication. Periodically,

however, check all moving parts (i.e., knobs, levers, column shaft, Elevating Handle,

shafts) to make sure that they move smoothly. If lubrication is required, use a small amount

of light oil. Do not oil the Carriage Arm bearings because they are sealed and do not

require lubrication.

6. Motor Preventative Maintenance – In addition to worn motor Brushes, the following are

major causes of motor failure:

- Using a dull or sticking Saw Blade

- Feeding the stock through the Saw Blade too fast

- Starting the cut before the Saw Blade has reached full speed

- Abnormal friction caused by improper alignment of the motor assembly, especially when

ripping

- Low current or voltage supplied to the machine

- Buildup of dust in the motor housing, which prevents proper cooling.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 14

Page 15

Troubleshooting

MELBORPESUACNOITULOS

imrA

erauqsaekamtonlliwwaS

ertimeerged06doogarotucssorc

.tuc

etaruccatontuceerged06

klawotycnednetasaheceipkroW

rnehwecnefehtmorfyawa

gnippi

revoecnavdaotsdnetedalBwaS

tsafootkcotseht

tpedtuC

rehtoeht

tmra

skcar

edalB

gnittuc-ssorc

dalBwaS

rewop

otdneenomorfseiravh

niylhtoomslevarttonseodwaS

nehwspilseldnaHgnitavelE

waSehtgnirewolrognitavele

rotomdlohtonodsbonkgnipmalC

)s(noitisoptesehtotylbmessa

ton,eceipkrowserocsedalBwaS

tucdehsinifdoogagnivig

otd

netsedalbodadroedalBwaS

nehwedisenootkcotshsup

gnippirnehwsllatSe

rodeepsllufhcaertonlliwrotoM

edalBwaSlluD

waSehtgnilluptoN

stcartytriD

sgniraeBdaB

alBwaS

deeftoN

derised

edalBwaSlluD

esooltuNrobrA

edalBwaSlluD

noitacilppa

rotomdedaolrevO

mrah

tiwlellaraptonsielbaT

.thgiartstonsiecneFpiR

esoolsibonKkcoLleveB

mrahtiwlellaraptonsielbaT

onknodeppirtssdaerT)s(bonkecalpeR

)s(b

lludrotnebedalBwaS

ylreporpwasgni

gnileehsiedalBwaS

thgiartstonecnefpiR

ecnefotlellaraptonedalBwaS

hctiwSFFO/NOytluaF

tuo

denrubsgnidniwrotoM

ecnefpirehtotralucidnepreptons

nmulocdnamraehtneewtebyalphcumooT

egairracotdepmalcnehwesoolootekoY

ecnefpirdnakcotsneewtebtsuD

thgiartstonAelbatfoegderaeR

elbatkrowotralucidnepreptonedalBwaS

nmulocdnamraneewtebyalphcumooT

egairracotdepmalcnehwesoolootsiekoY

.ecnefehthtiwlellaraptonsiedalBwaS

.ecnefpirehtotralucidnepreptonsimrA

ylreporpedalB

nmulocdnamraehtneewtebyalphcumooTtlobeveelsnmulocnethgiT

eldnaHgnitavelEnoesoolwercSwercSnethgiT

edisenootgninaelsied

nmulocdnamraneewtebyalphcumooT

egairracotdepmalcnehwesoolootekoY

tuchsinifrofedalBwaSreporpmignisU

nmulocdnamraneewtebyalphcumooT

egairracotdepmalcnehwesoolootekoY

secnailpparehtohtiwdedaolrevotiucriC

sihtrofdetarrednusidesutiucriC

ttsujdA

tlobeveelsnmulocehtnethgiT

eldnahpmalcekoYtsujdA

elbatkrownaelC

AelbaTtsujdA

.ecnefpirecalpeR

Aelba

TecalperrodnaS

edalBwaStsujdA

elsnmulocnethgiT

AelbaTtsujdA

jdA

nethgiT

daesU

edalBwaStsu

llupydaetsdna

stcartnaelC

sgniraeBecalpeR

ecnefpirecalpeR

lBwaStsujdA

naicinhcet

rotomecalpeR

enihcamsihtrof

tlobeve

eldnaHpmalCekoYtsujdA

bonKkcoLleveBtsujdA

edalbneprahsroecalpeR

tlobeveelsnmulocnethgiT

ldnaHpmalCekoYtsujdA

e

edalBwaSecalpeR

llupydaetsdnawols

edalBwaSecalpeR

tlobeveelsnmulocnethgiT

eldnaHpmalCekoYtsujdA

edalBwaSneprahsroecalpeR

neprahsroecalpeR

de

kcehctinuhctiwSehtevaH

ecnefpirehthtiwlevarttucssorceh

ecnefpirhtiwlevarttucssorctsujdA

wolsahtiwkcotsssorcaedalBwaSwarD

ecnefpiroterauqsedalBwaStsujdA

ahtiwkcotsssorcaedalBwaSehtwarD

ecnefpirehtoterauqsedalBwaStsujdA

lellarapotecnefroeda

deifilauqayb

enihcamehtroftlucrictnereffidaesU

rewoptneiciffushtiwtlucrictnereffi

ylwolseromedalBwaSotnikcotsdeeF

ehtspirt,sllats,staehrevorotoM

sesufrosrekaerbtiucric

acgniloocreporpmI

ecruosrewoP

yticapacrewoptneiciffus

evissecxeybdesu

rotomehtdnuoranoitalumuccatsudwas

neporotuodenrubgnidniwrotoM

evahtonodsrekaerbtiucric

ahc

riadesserpmochtiwgnisuohrotomnaelC

icinhcetdeifilauqagnisurotomecalpeR

na

rosrekaerbtiucricezisreporpllatsnI

yticapaceromhtiwenootstiucricegn

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 15

Page 16

Parts List

traPnoitpircseDyt'QtraPnoitpircseDyt'QtraPnoitpircseDyt'Q

1etalpemaN175tloBpotStliT1011wercSdeeF1

28×5MwercS285)2(gnirpSeru

35rehsaW195revoCeldnaH1211esaBmrA1

4ediuGtsuD10621×9.3tSwercSgnippaT231121rehsaW1

5bonKxednIekoY3165.6×9.2tSwerc

66MtuN9626revoCeldnaH151106×21MtloB1

7wercSgnipmalCdrauG13602×4niPgnirpS1611eceiPreffuB2

8drau

9lebaL1568×5MwercS1811revoCelbaC1

01drauGytefaS166eldnaHpmalC1911)5(gnirpSerusserP1

11etalPdrau

215rehsaWgnirpS186draoBlebaLelacS1121redniBelbaC1

31y'ssAmrAkcabkcik-itnA196csiDlaiD1221hcti

41tloBdutS10761×8.4tSwercSgnippaT6321esaChctiwS1

51)tfel(41×8MtloB117bonKkcoLleveB1421yeK1

61egnalFedistuO127)1(gnirpSeru

71edalBwaS137pilc-C1621BelbaT1

81egnalFedisnI1a47bonKkcoLleveB1721CelbaT1

91tfahSraeG1b47bonKkcoLegairraC1821tuNts

02)1(gnirpSerusserP157niPbonK1921pilc-C1

126gniRgniniateR167tfahSgniraeB403121×6niPgnirpS2

22niPreppotS17792006gnira

3222×4ByeK187tfahSreppotS1231liaRediuG1

4283×8.4tSwercSgnippaT29761rehsaWnihT233101×5MwercS1

5202×5MwercS108egairr

62revoCesaCraeG1188rehsaWgnirpS85314rehsaW2

728×4MwercS2288MtuN8631eguaG1

8240108gniraeB1386rehsaW5731pmalCwercS2

92rehs

03raeGtuptuO158tloBdaeH.xeH193121×5MwercS1

1302gniRgniniateR168elffaB

23014101KgniraeBeldeeN178AeldnaH114156×21MtloBkcoLmrA1

3307×5wercSdooW288)4(gnirpSerusserP1241bonKxedn

4321rehsaWnihT298elffaBssorC1341)3(gnirpSerusserP1

53tfahSelddiM109recapS1441pilc-C1

63316121KgniraeBeldeeN119)4(gnirpS

73raeGelddiM129nottuBnOkcoL1641pmalCelbaT2

8323×8.4tSwercSgnippaT439reggirT174141×8MtloB4

93revoCesaC

0420108gniraeB2596rehsaW29418MrehsaW4

14ediuGnaF1696rehsaWgnirpS2051dnatS2

24naF179BeldnaH11

34rotoR18921×6MwercS5251esaB1

44rotatS1996rehsaWgnirpS5351)tfeL(esaBdexiF1

54lioCelbaC5001eldnaHgnitavelE145

64pilCelbaC1101paCmrA156161x6MwercS4

745.9×5.3tSwercSgnippaT120121×4MwercS2661gnisuoH1

84revoCelbaC130141

9461×9.3tSwercSgnippaT240141rehsaW1

0501×4MwercS2501pmalCdroC1

15paCdnE1601eriWdaeL1

25tuNpirG1701)tfeL(l

35kcuhCtelloClacinoC1801mrA1

45redloHhsurB21-801wercSdaeHtalFknusretnuoC8

55hsurBnobraC22-801liaR2

65paChsurB2901)

GelbixelF146tuNtelloC171121MtuN2

G176draoBgnirpS2021retsloBdexiF1

aWreppotS148faeLgnirpSdexiF1831rehsaWgnipmalCnmuloC1

raeG14961×6MwercS284161×8MtloBdaeHdnuoR4

sserP1111elbaC1

SgnippaT2411)5(gnirpSerusserP2

wS1

sserP1521AelbaT1

oPediuG1

eB4131nmuloC1

aC1431recapS1

hctiwS104121rehsaW1

ImrA1

erusserP1541esaBnmuloC1

51)thgiR(esaBdexiF1

161×6MtloBdaeHdnuoR4

MtuNtelloC1761gnihsuB1

ebaLelacS1

thgiR(lebaLelacS1

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 16

Page 17

Assembly Diagram (1-97)

NOTE: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 17

Page 18

Assembly Diagram

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 18

Page 19

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL

AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS

OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT

ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED

TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING

OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO,

OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 42933 For replacement parts, please call 1-800-444-3353. Page 19

Loading...

Loading...