Page 1

FINISHING SANDER

®

42864

ASSEMBLY AND OPERATION INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY, READ AND UNDERSTAND

ALL WARNINGS AND INSTRUCTIONS BEFORE USE.

Copyright© 2006 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

SPECIFICATIONS

Electrical Requirements 120 V~, 60 Hz, 1 A (loaded)

Speed 12,000 OPM (Orbits Per Minute)

Dust Chute 1-1/4” OD

Dimensions 4” W x 4-3/4” L x 5-3/4” H

Dimensions: 3-1/2” W x 7-3/8” L

Finishing Sander Pads

Weight 2.5 lb.

Sold separately as Item 91063 - a 15 pack

with 5 each of 80, 150, & 240 grit

E194601

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Keep this manual and invoice in a safe and dry place for future reference.

GENERAL SAFETY RULES

1.

2.

3.

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in

electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS

WORK AREA

Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents. Make sure there is adequate surrounding workspace.

Do not operate power tools in explosive atmospheres, such as in the pres-

ence of flammable liquids, gases, or dust. Power tools create sparks which may

ignite the dust or fumes.

Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control. Protect others in the work area from

debris such as chips and sparks. Provide barriers or shields as needed.

ELECTRICAL SAFETY

1.

Grounded tools must be plugged into an outlet properly installed and grounded

in accordance with all codes and ordinances. Never remove the grounding

prong or modify the plug in any way. Do not use any adapter plugs. Check with

For technical questions, please call 1-800-444-3353.

Page 2SKU 42864

Page 3

a qualified electrician if you are in doubt as to whether the outlet is properly

grounded. If the tools should electrically malfunction or break down, grounding

provides a low resistance path to carry electricity away from the user.

2.

3.

4.

5.

6.

Double insulated tools are equipped with a polarized plug (one blade is wider

than the other). This plug will fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If it still does not fit, contact

a qualified electrician to install a polarized outlet. Do not change the plug

in any way. Double insulation eliminates the need for the three wire grounded

power cord and grounded power supply system.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges,

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

Do not abuse the Power Cord. Never use the Power Cord to carry the tools or

pull the Plug from an outlet. Keep the Power Cord away from heat, oil, sharp

edges, or moving parts. Replace damaged Power Cords immediately. Dam-

aged Power Cords increase the risk of electric shock.

When operating a power tool outside, use an outdoor extension cord marked

“W-A” or “W”. These extension cords are rated for outdoor use, and reduce the

risk of electric shock.

1.

2.

3.

4.

5.

PERSONAL SAFETY

Stay alert. Watch what you are doing, and use common sense when operat-

ing a power tool. Do not use a power tool while tired or under the influence

of drugs, alcohol, or medication. A moment of inattention while operating power

tools may result in serious personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

Avoid accidental starting. Be sure the Power Switch is off before plugging

in. Carrying power tools with your finger on the Power Switch, or plugging in power

tools with the Power Switch on, invites accidents.

Remove adjusting keys or wrenches before turning the power tool on. A

wrench or a key that is left attached to a rotating part of the power tool may result

in personal injury.

Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the power tool in unexpected situations.

For technical questions, please call 1-800-444-3353.

Page 3SKU 42864

Page 4

6.

Use safety equipment. Always wear eye protection. Dust mask, nonskid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions. Al-

ways wear ANSI approved safety goggles and a dust mask/respirator when using

or performing maintenance on this tool.

TOOL USE AND CARE

1.

2.

3.

4.

5.

6.

Use clamps (not included) or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body

is unstable and may lead to loss of control.

Do not force the tool. Use the correct tool for your application. The correct

tool will do the job better and safer at the rate for which it is designed. Do not force

the tool and do not use the tool for a purpose for which it is not intended.

Do not use the power tool if the Power Switch does not turn it on or off. Any

tool that cannot be controlled with the Power Switch is dangerous and must be

replaced.

Disconnect the Power Cord Plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally. Always unplug the tool

from its electrical outlet before performing any inspection, maintenance, or

cleaning procedures.

Store idle tools out of reach of children and other untrained persons. Tools

are dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly main-

tained tools with a sharp cutting edge are less likely to bind and are easier to control.

Do not use a damaged tool. Tag damaged tools “Do not use” until repaired.

7.

8.

1.

2.

Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool may become hazardous

when used on another tool.

SERVICE

Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

When servicing a tool, use only identical replacement parts. Follow instruc-

tions in the “Inspection, Maintenance, And Cleaning” section of this manual.

Use of unauthorized parts or failure to follow maintenance instructions may create

a risk of electric shock or injury.

For technical questions, please call 1-800-444-3353.

Page 4SKU 42864

Page 5

SPECIFIC SAFETY RULES

1.

2.

3.

4.

5.

6.

7.

Maintain labels and nameplates on the Sander. These carry important informa-

tion. If unreadable or missing, contact Harbor Freight Tools for a replacement.

When using a handheld power tool, always maintain a firm grip on the tool

with both hands to resist starting torque.

Avoid unintentional starting. Make sure you are prepared to begin work before

plugging in the Sander.

Never lay the tool down until it has come to a complete stop. Moving parts can

grab the surface and pull the tool out of your control.

Never leave the Sander unattended when it is plugged into an electrical outlet.

Turn off the tool, and unplug it from its electrical outlet before leaving.

Take caution as some woods contain preservatives such as copper chromium

arsenate (CCA) which can be toxic. When cutting these materials extra care should

be taken to avoid inhalation and minimize skin contact.

WARNING! Exposure to aluminum oxide (a dust generated from material removing

processes) can result in eye, skin, and respiratory irritation. Always use a NIOSH

(National Institute for Occupational Safety and Health) approved respirator and

ANSI approved safety goggles. Avoid skin exposure. Proper ventilation in the work

area is required.

8.

9.

WARNING! Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities, contain chemicals known (to the State of California)

to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

Lead from lead-based paints.

•

Crystalline silica from bricks and cement or other masonry products.

•

Arsenic and chromium from chemically treated lumber.

•

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area,

and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

(California Health & Safety Code § 25249.5, et seq.)

WARNING! People with pacemakers should consult their physician(s) before

using this product. Electromagnetic fields in close proximity to a heart pacemaker

could cause interference to or failure of the pacemaker.

In addition, people with pacemakers should adhere to the following:

Avoid operating power tools alone.

•

For technical questions, please call 1-800-444-3353.

Page 5SKU 42864

Page 6

If powered via a power cord be certain that the tool is properly grounded. A ground

•

fault interrupt (GFCI) system is also a good precaution. This inexpensive device

is a good safety measure because it prevents a sustained electrical shock.

Properly maintain and inspect all tools before use to avoid electrical shock.

•

10.

Note: Performance of this tool (if powered by line voltage) may vary depending on varia-

WARNING! The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur. It must

be understood by the operator that common sense and caution are factors which

cannot be built into this product, but must be supplied by the operator.

tions in local line voltage. Extension cord usage may also affect tool performance.

GROUNDING

WARNING!

Improperly connecting the grounding wire can result in the risk of electric shock.

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the power cord plug provided with the tool.

Never remove the grounding prong from the plug. Do not use the tool if the

power cord or plug is damaged. If damaged, have it repaired by a service facility before use. If the plug will not fit the outlet, have a proper outlet installed by

a qualified electrician.

1.

2.

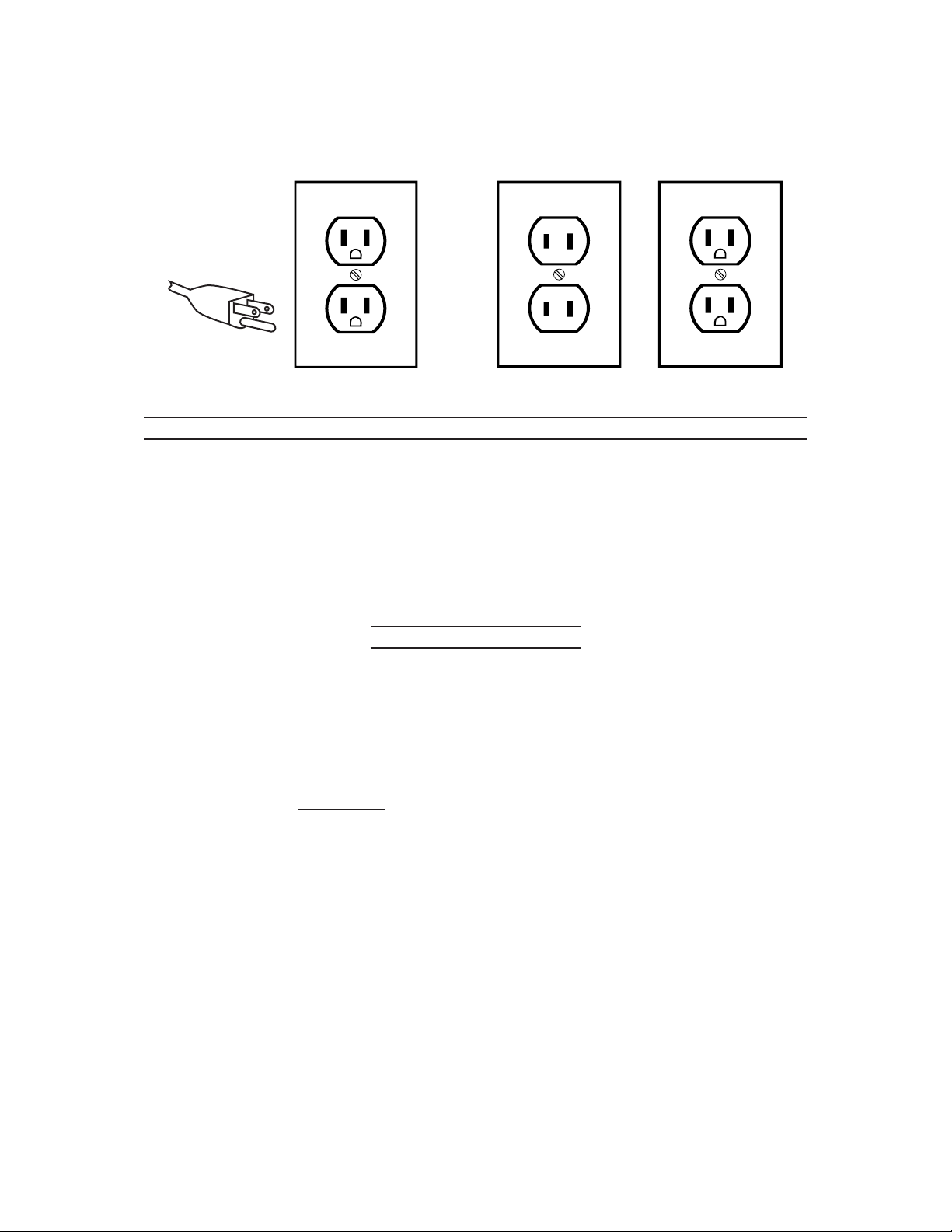

GROUNDED TOOLS: TOOLS WITH THREE PRONG PLUGS

Tools marked with “Grounding Required” have a three wire cord and three prong

grounding plug. The plug must be connected to a properly grounded outlet. If

the tool should electrically malfunction or break down, grounding provides a low

resistance path to carry electricity away from the user, reducing the risk of electric

shock. (See Figure A.)

The grounding prong in the plug is connected through the green wire inside the

cord to the grounding system in the tool. The green wire in the cord must be the

only wire connected to the tool’s grounding system and must never be attached to

an electrically “live” terminal. (See Figure A.)

For technical questions, please call 1-800-444-3353.

Page 6SKU 42864

Page 7

3.

Your tool must be plugged into an appropriate outlet, properly installed and grounded

in accordance with all codes and ordinances. The plug and outlet should look like

those in the following illustration. (See Figure A.)

FIGURE A

FIGURE B

DOUBLE INSULATED TOOLS: TOOLS WITH TWO PRONG PLUGS

1.

2.

Tools marked “Double Insulated” do not require grounding. They have a special

double insulation system which satisfies OSHA requirements and complies with

the applicable standards of Underwriters Laboratories, Inc., the Canadian Standard

Association, and the National Electrical Code. (See Figure B.)

Double insulated tools may be used in either of the 120 volt outlets shown in the

preceding illustration. (See Figure B.)

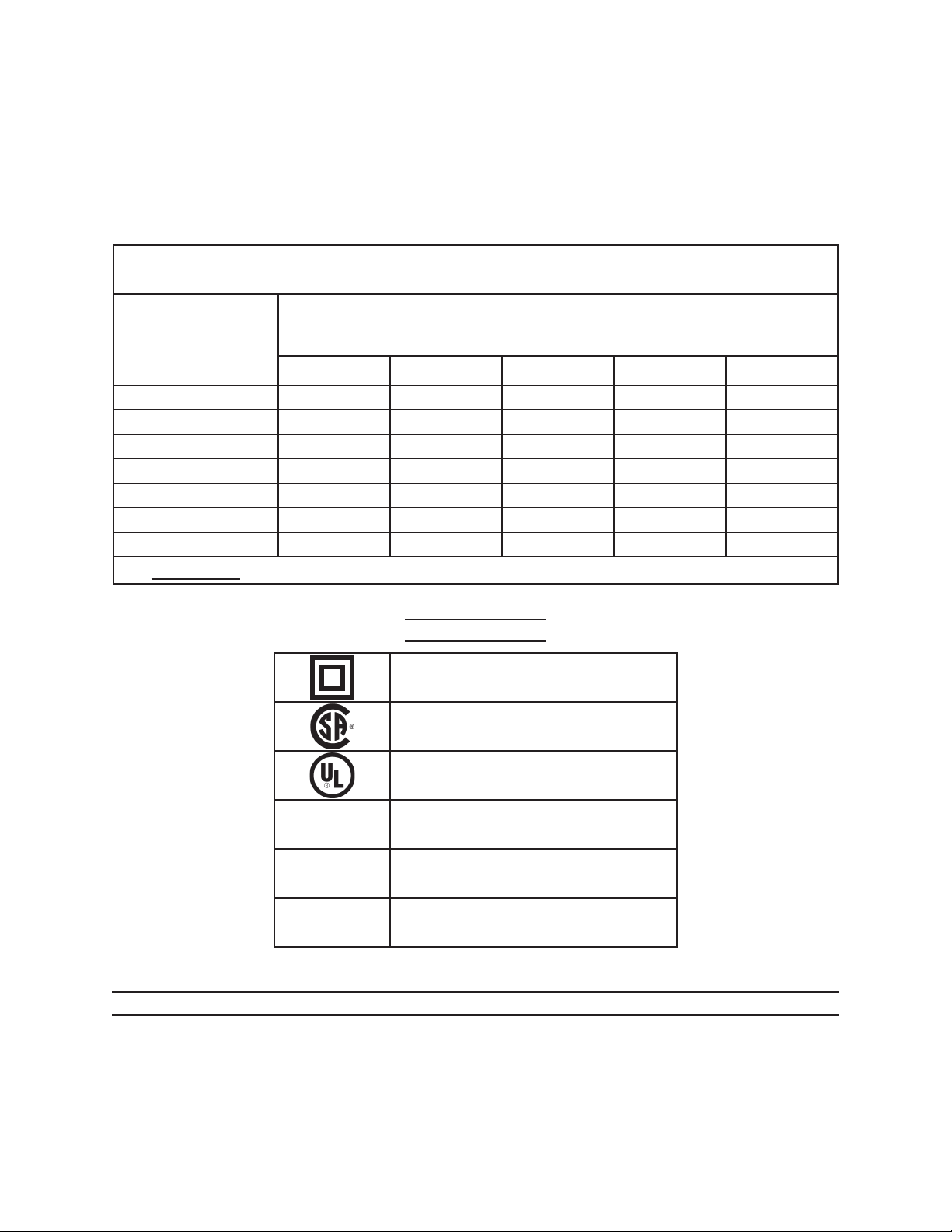

EXTENSION CORDS

1.

2.

Grounded tools require a three wire extension cord. Double Insulated tools can

use either a two or three wire extension cord.

As the distance from the supply outlet increases, you must use a heavier gauge

extension cord. Using extension cords with inadequately sized wire causes a serious drop in voltage, resulting in loss of power and possible tool damage.

(See Figure C, next page.)

3.

4.

5.

6.

The smaller the gauge number of the wire, the greater the capacity of the cord. For

example, a 14 gauge cord can carry a higher current than a 16 gauge cord.

(See Figure C.)

When using more than one extension cord to make up the total length, make sure

each cord contains at least the minimum wire size required. (See Figure C.)

If you are using one extension cord for more than one tool, add the nameplate am-

peres and use the sum to determine the required minimum cord size.

(See Figure C.)

If you are using an extension cord outdoors, make sure it is marked with the suffix

“W-A” (“W” in Canada) to indicate it is acceptable for outdoor use.

For technical questions, please call 1-800-444-3353.

Page 7SKU 42864

Page 8

7.

Make sure your extension cord is properly wired and in good electrical condition.

Always replace a damaged extension cord or have it repaired by a qualified electrician before using it.

8.

Protect your extension cords from sharp objects, excessive heat, and damp or wet

areas.

RECOMMENDED MINIMUM WIRE GAUGE FOR EXTENSION CORDS*

(120 OR 240 VOLT)

NAMEPLATE

EXTENSION CORD LENGTH

AMPERES

(at full load)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

FIGURE C

25 Feet 50 Feet 75 Feet 100 Feet 150 Feet

* Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

SYMBOLOGY

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

V~

A

n0 xxxx/min.

Volts Alternating Current

Amperes

No Load Revolutions per Minute (RPM)

UNPACKING

When unpacking, check to make sure that the item is intact and undamaged. If any

parts are missing or broken, please call Harbor Freight Tools at the number shown on the

cover of this manual as soon as possible.

For technical questions, please call 1-800-444-3353.

Page 8SKU 42864

Page 9

ASSEMBLY INSTRUCTIONS

Note: For additional information regarding the parts listed in the following pages, refer to

the Assembly Diagram at the end of this manual.

CAUTION: Always make sure the Power Cord (17) of the Sander is unplugged from its

electrical outlet prior to making any adjustments or assembling to the tool.

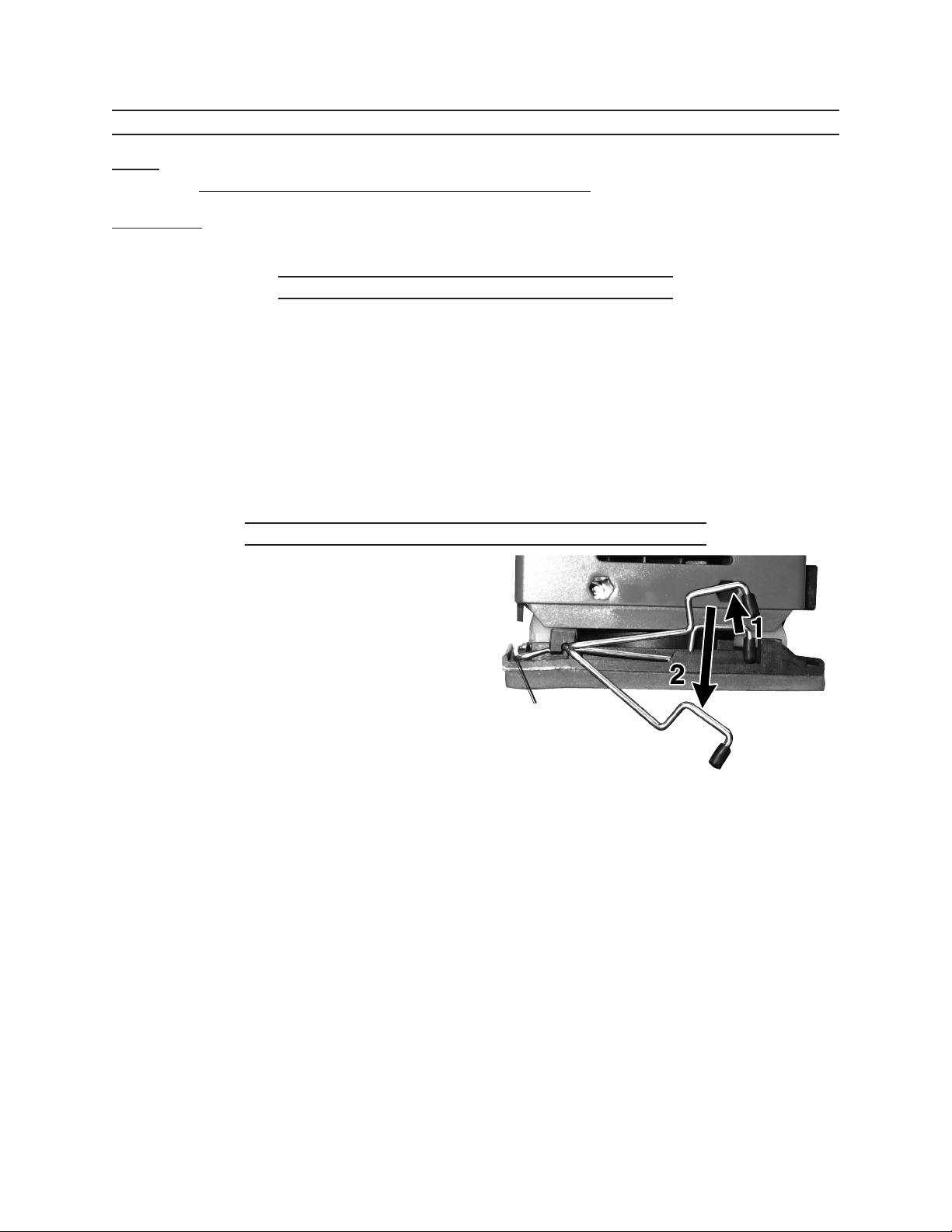

Attaching the dust collection chute (0)

1.

2.

3.

1.

2.

Turn the Chute (0) so that the tab on top of the rectangular end faces up. Snap it

in place into the rectangular shaft at the back of the Sander.

Connect a 1-1/4” dust collection hose from the Chute to your dust collection system

(hose and system not included).

The Dust Collection Chute (0) will only work if the sandpaper has holes that line up

with the 6 dust collection holes in the Backing Pad (28). (There are 4 other holes in

the Backing Pad for the Screws (29).)

Attaching sandpaper to the Backing Pad (28)

Press the tab on the Clamps (6) inward

on both sides of the unit and swing

the clamps on both sides up, out, and

down. See 1 & 2, right.

Cut the sandpaper to fit the 3-1/2” W

x 7-3/8” L Sander Pad (28), with a

little extra to overlap and fit under the

Clamps (6). Do not use torn or frayed

sandpaper.

Sandpaper

Sandpaper

goes under

goes under

here

here

3.

After wrapping the overlapped edges of sandpaper under the Clamps (6), snap the

Clamps (6) back into place.

For technical questions, please call 1-800-444-3353.

Page 9SKU 42864

Page 10

OPERATING INSTRUCTIONS

Note: For additional information regarding the parts listed in the following pages, refer to

the Assembly Diagram at the end of this manual.

1.

2.

3.

4.

5.

6.

Note: All orbital sanders leave sanding marks on the workpiece. To minimize sanding

7.

CAUTION: Always make sure the Power Cord (17) of the Sander is unplugged from

its electrical outlet prior to making any adjustments to the tool.

Clamp your workpiece down, or insert it in a vise. Make sure the wood you are

sanding does not have any nails or metal of any kind in it, or you will ruin the sand-

paper and damage the Pad (28).

After donning the appropriate safety gear covered on page 2 of this manual, plug

in the Sander.

Turn on the Sander by turning on the Switch (2).

Always run the Sander for a few seconds before contacting the workpiece.

Contact the workpiece with minimal pressure. If the Sander is not removing enough

material, try a grittier piece of sandpaper. If you want to remove a lot of material

fast, use a belt sander.

marks, always try to sand with the grain of the wood.

Occasionally check the sandpaper for tears, wear, or fraying. Replace if neces-

sary.

8.

When you are finished, turn off the Switch (2).

For technical questions, please call 1-800-444-3353.

Page 10SKU 42864

Page 11

INSPECTION, MAINTENANCE, AND CLEANING

1.

WARNING! Make sure the Power Switch (2) of the Sander is in its “OFF” posi-

tion and that the tool is unplugged from its electrical outlet before performing any

inspection, maintenance, or cleaning procedures.

2.

BEFORE EACH USE, inspect the general condition of the Sander. Check for loose

screws, misalignment or binding of moving parts, cracked or broken parts, dam-

aged electrical wiring, and any other condition that may affect its safe operation. If

abnormal noise or vibration occurs, have the problem corrected before further use.

Do not use damaged equipment.

3.

4.

5.

Wipe the unit down after each use with a dry, lint free cloth.

Make sure the vents on the top are clear of dust and debris.

Periodically, have a qualified service technician clean or replace the Carbon Brushes

(4).

Part Description

1 Right Housing

2 Switch

3 Carbon Brush Spring

4 Carbon Brush

5 Pedestal Bearing

6 Circuit Board

7 Electric Cord

8 Cord Protector

9 Power Cord Holder

10 Screw

11 Label

PARTS LIST

Part Description

12 Dust Chute Gasket

13 Left Housing

14 Stator

15 Backing Pad

16 Armature

17 Base Plate

18 Tapered Sleeve

19 Dust Chute

20 Dust Port

21 Screw

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN

THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE

IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO

REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN

BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES

ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT

OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

For technical questions, please call 1-800-444-3353.

Page 11SKU 42864

Page 12

ASSEMBLY DIAGRAM

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

For technical questions, please call 1-800-444-3353.

Page 12SKU 42864

Page 13

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser for a period of ninety days from date of purchase that the motor, the belts

(if so equipped), and the blades (if so equipped) are free of defects in materials and workmanship. Harbor Freight

Tools also warrants to the original purchaser, for a period of one year from date of purchase, that all other parts

and components of the product are free from defects in materials and workmanship. This warranty does not apply

to damage due directly or indirectly to misuse, abuse, negligence or accidents; repairs or alterations outside our

facilities; or to lack of maintenance. We shall in no event be liable for death, injuries to persons or property, or for

incidental, contingent, special or consequential damages arising from the use of our product. Some states do

not allow the exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion

may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid.

Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection

verifies the defect, we will either repair or replace the product at our election or we may elect to refund the purchase

price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our

expense, but if we determine there is no defect, or that the defect resulted from causes not within the scope of

our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Limited

90 day/1 year

warranty

WARRANTY

For technical questions, please call 1-800-444-3353.

Page 13SKU 42864

Page 14

PONCEUSE DE FINITION

Modèle

42864

®

ASSEMBLAGE ET MODE D’EMPLOI

IMPORTANT!

Cette édition de langue

française est une traduction

du manuel anglais original

accompagnant ce produit. Si

une partie du manuel anglais

original est inconsistante

avec cette traduction, le

manuel anglais original

gouvernera.

En raison des améliorations continuantes, le produit réel peut différer légèrement du produit décrit ici.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visitez notre site Internet à http://www.harborfreight.com

POUR ÉVITER LA BLESSURE SÉRIEUSE, LISEZ

ET COMPRENEZ TOUS LES AVERTISSEMENTS

ET LES INSTRUCTIONS AVANT L’UTILISATION.

Le Copyright© 2006 par le Harbor Freight Tools®. Tous droits réservés. Aucune portion de ce

manuel ou de n’importe quel travail d’art contenu ici ne peut être reproduite dans aucune

forme ou forme sans le consentement écrit explicite de Harbor Freight Tools.

Pour les questions techniques et les pièces détachées,

appelez-vous s’il vous plaît 1-800-444-3353.

Page 15

SPÉCIFICATIONS

Spécifications électriques 120 V~, 60 Hz, 1 A (chargé)

Vitesse 12,000 OPM (Orbites par minute)

Conduit de poussière 1-1/4” OD

Dimensions 4” Long x 4-3/4” Large x 5-3/4” Haut

E194601

Tampons pour ponceuse de

finition

Poids 2,5 lb.

Dimensions : 3-1/2” Large x 7-3/8” Long

Vendu séparément Item 91063 paquet de 15 (5

chacun de 80, 159, & 240 grains)

GARDER CE MANUEL

Vous aurez besoin de ce manuel pour les avertissements et les mesures de sécurité,

les instructions d’assemblage et de fonctionnement, les inspections, l’entretien, les pro- les inspections, l’entretien, les pro-les inspections, l’entretien, les procédures de nettoyage et le schéma d’assemblage. Gardez votre facture avec ce manuel. Gardez votre facture avec ce manuel.

Écrire le numéro de facture à l’intérieur de la couverture avant. Conserver ce manuel et laavant. Conserver ce manuel et laConserver ce manuel et la

facture dans un endroit sécuritaire et sec pour référence future.

RÈGLES DE SÉCURITÉ GÉNÉRALES

Aire de Travail

1.

Garder votre aire de travail propre et bien éclairée. Les banquettes chargées

et les endroits sombres invitent les accidents. Assurez-vous d’avoir un espace de

travail environnant adéquat.

2.

3.

1.

Ne pas faire fonctionner des outils électriques dans une atmosphère explo-

sive, tel qu’en présence de liquides inflammables, de gaz ou de poussière.

Les outils électriques créent des étincelles qui peuvent mettre le feu à la poussière

et aux émanations.

Garder les passants, les enfants et les visiteurs à l’écart lorsque vous faites

fonctionner un outil électrique. Des distractions peuvent vous faire perdre le

contrôle. Protéger les autres dans votre aire de travail de tous débris tels que les

fragments et les étincelles. Mettre des barrières ou des écrans si besoin.

Règles de sécurité électriques

Les outils mis à la terre doivent être branchés dans une prise installée cor-

rectement et mise à la terre selon tous les codes et règlements. Ne jamais

enlever la broche mise à la terre ou modifier la fiche d’aucune façon. Ne pas utiliser

d’adaptateur de fiches. Vérifier avec un technicien qualifié en cas de doute, à savoir

si la prise est mise à la mise à la terre correctement. S’il arrive que les outils ont un

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 2SKU 42864

Page 16

mauvais fonctionnement électrique ou un bris, la mise à la terre fournit un chemin

à faible résistance pour éloigner l’électricité de l’usager.

2.

3.

4.

5.

Les outils à double isolation sont équipés d’une fiche polarisée (une lame

est plus large que l’autre). Cette fiche entre dans une prise polarisée seulement

d’une façon. Si la fiche n’entre pas complètement dans la prise, tournez-la. Si elle

n’entre toujours pas, communiquez avec un électricien qualifié pour installer une

prise polarisée. Ne changez pas la prise d’aucune façon. La double isolation élimine

le besoin d’avoir un cordon d’alimentation à trois pôles avec prise de terre et un

système d’alimentation électrique mis à la terre.

Éviter tout contact avec les surfaces conductrices telles que les tuyaux, les

radiateurs, les cuisinières, et les réfrigérateurs. Il y a un risque plus élevé de

choc électrique si votre corps est conducteur.

Ne pas exposer les outils électriques à la pluie ou à des conditions humides.

L’eau qui pénètre dans un outil électrique augmentera le risque de choc électri-

que.

Éviter de malmener le cordon d’alimentation. Ne jamais utiliser le cordon

d’alimentation pour transporter les outils ou tirer la fiche d’une prise. Éloigner le

cordon d’alimentation des sources de chaleur, de l’huile, des bords coupants, ou

des pièces en mouvement. Remplacer les cordons d’alimentation endommagés

immédiatement. Les cordons d’alimentation endommagés augmentent le risque

de choc électrique.

6.

1.

2.

3.

Si vous vous servez d’un outil électrique à l’extérieur, utilisez une rallonge

pour l’extérieur identifiée W-A or W. Ces rallonges sont cotées pour usage exté-

rieur, et réduisent le risque de choc électrique.

Sécurité personnelle.

Restez vigilant. Portez attention à ce que vous faites, et utilisez un gros bon sens

lorsque vous faites fonctionner un outil électrique.Ne pas utiliser un outil électrique vous faites fonctionner un outil électrique.Ne pas utiliser un outil électriquevous faites fonctionner un outil électrique. Ne pas utiliser un outil électrique Ne pas utiliser un outil électriqueNe pas utiliser un outil électrique

lorsque vous êtes fatigué ou sous l’influence de drogues, d’alcool ou de médica- de drogues, d’alcool ou de médica-de drogues, d’alcool ou de médica-

ments. Un moment d’inattention en travaillant avec un outil électrique peut causer Un moment d’inattention en travaillant avec un outil électrique peut causerUn moment d’inattention en travaillant avec un outil électrique peut causer

de sérieuses blessures corporelles.

Habillez-vous correctement. Ne portez pas des vêtements amples ou des bijoux.

Retenez les cheveux longs. Gardez vos cheveux, vêtements et gants éloignés des

pièces en mouvement. Les vêtements amples, les bijoux et les cheveux longs peu-

vent se prendre dans les pièces en mouvement.

Évitez les démarrages accidentels. Assurez-vous que l’interrupteur est en po-

sition arrêt (off) avant de brancher. Transporter des outils électriques avec le doigt

sur l’interrupteur ou brancher des outils électriques avec l’interrupteur en position

marche (on), invite les accidents.

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 3SKU 42864

Page 17

4.

Retirez les clés d’ajustement ou toutes clés avant de démarrer l’outil électri-

que. Une clé d’ajustement ou toute clé qui reste attachée à une pièce tournante

de l’outil électrique peut causer des blessures corporelles.

5.

6.

1.

2.

3.

Ne pas essayer d’atteindre des objets éloignés. Gardez une bonne prise et un

bon équilibre en tout temps. Une bonne prise et un bon équilibre permet de mieux

contrôler l’outil électrique dans des situations inattendues.

Utilisez de l’équipement de sécurité. Portez toujours une protection pour les yeux.

Masques anti-poussières, des souliers de sécurité antidérapants, casque de protec-

tion, ou un serre-tête antibruit doivent être utilisés pour les conditions appropriées.

Portez toujours des lunettes protectrices approuvées par ANSI ainsi qu’un masque

de poussière/respiratoire lors de l’utilisation ou de l’entretien de cet outil.

Utilisation Et Entretien Des Outils

Utilisez des étaux (non inclus) ou d’autres façons pratiques pour sécuriser

et supporter la pièce sur une plate-forme stable. la pièce sur une plate-forme stable.la pièce sur une plate-forme stable. Tenir la pièce par la main ou

contre vous est très instable et peut mener à une perte de contrôle. est très instable et peut mener à une perte de contrôle.est très instable et peut mener à une perte de contrôle.

Ne forcez pas l’outil. Utilisez l’outil approprié pour vos besoins. L’outil appropriéapproprié

fera un meilleur travail ainsi qu’un travail plus sécuritaire à la vitesse pour laquelle il

a été conçu. Ne forcez pas l’outil et ne vous servez pas de l’outil dans un but autre Ne forcez pas l’outil et ne vous servez pas de l’outil dans un but autreNe forcez pas l’outil et ne vous servez pas de l’outil dans un but autre l’outil et ne vous servez pas de l’outil dans un but autrel’outil et ne vous servez pas de l’outil dans un but autre

que celui pour lequel il a été conçu.

N’utilisez pas l’outil électrique si l’interrupteur refuse de se mettre en position

marche (on) ou arrêt (off). Tout outil qui ne peut pas être contrôlé par l’interrupteuroutil qui ne peut pas être contrôlé par l’interrupteur

est un outil dangereux et doit être remplacé. remplacé.remplacé.

4.

5.

6.

7.

Débranchez la fiche du cordon électrique de source d’alimentation électrique

avant de faire tout ajustement, de changer des accessoires, ou de remiser ajustement, de changer des accessoires, ou de remiserajustement, de changer des accessoires, ou de remiser

l’outil. De telles mesures préventives de sécurité réduisent le risque de démarrer de sécurité réduisent le risque de démarrerde sécurité réduisent le risque de démarrer

l’outil accidentellement. Débranchez toujours l’outil de sa prise électrique avant Débranchez toujours l’outil de sa prise électrique avantDébranchez toujours l’outil de sa prise électrique avant de sa prise électrique avantde sa prise électrique avant

d’exécuter toute inspection, entretien, ou procédures de nettoyage. procédures de nettoyage.

Remisez les outils non utilisés hors de portée des enfants et des personnes

novices. Les outils dangereux dans les mains d’utilisateurs novices. dangereux dans les mains d’utilisateurs novices.dangereux dans les mains d’utilisateurs novices.

Entretenez vos outils avec soin. Gardez les outils de découpage aiguisés et

propres. Des outils avec des bords tranchants entretenus correctement sont moins Des outils avec des bords tranchants entretenus correctement sont moinsDes outils avec des bords tranchants entretenus correctement sont moins avec des bords tranchants entretenus correctement sont moinsavec des bords tranchants entretenus correctement sont moins

aptes à se coincer et sont plus faciles à contrôler. N’utilisez pas un outil endommagé. N’utilisez pas un outil endommagé.

Étiquetez les outils endommagés : Ne pas utiliser avant d’être réparé.

Vérifiez les alignements ou les arrimages des pièces en mouvement, les bris

de pièces, et toute autre condition qui pourrait affecter le bon fonctionnement toute autre condition qui pourrait affecter le bon fonctionnementtoute autre condition qui pourrait affecter le bon fonctionnement

de l’outil. Si endommagé, faites réparer l’outil avant de vous en servir. Plusieurs réparer l’outil avant de vous en servir. Plusieursréparer l’outil avant de vous en servir. Plusieurs PlusieursPlusieurs

accidents sont causés par outils mal entretenus.

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 4SKU 42864

Page 18

8.

Utilisez seulement des accessoires recommandés par le fabricant du mo- mo-

dèle. Des accessoires qui conviennent pour un outil peuvent devenir dangereux dangereuxdangereux

lorsqu’utilisés sur un autre outil.

Service

1.

2.

1.

2.

3.

Le service des outils doit être effectué par du personnel qualifié. Le service

ou l’entretien effectué par du personnel non qualifié peut causer un risque de bles-

sures.

Lorsque vous faites l’entretien d’un outil, utilisez seulement des pièces de

remplacement identiques. Suivez les directives dans la section «Inspection, En-

tretien et Nettoyage» de ce manuel. L’utilisation de pièces non autorisées ou défaut

de suivre les instructions d’entretien peuvent créer un risque de choc électrique ou

de blessures.

RÈGLES DE SÉCURITÉ SPÉCIFIQUES

Gardez les étiquettes et les plaques signalétiques sur la ponceuse. Celles-ci

contiennent des informations importantes.Si illisiblesou manquantes,communiquez Si illisibles ou manquantes, communiquezSi illisibles ou manquantes, communiquez

avec Harbor Freight Tools pour un remplacement. Lorsque vous utilisez un outil

électrique à main, maintenez toujours une poigne solide sur l’outil avec les deux avec les deuxavec les deux

mains afin de pouvoir bien résister au démarrage du torque.

Évitez les démarrages accidentels. Assurez-vous d’être prêt à commencer le

travail avant de brancher la ponceuse. avant de brancher la ponceuse.avant de brancher la ponceuse.

Ne jamais déposer l’outil avant qu’il ne soit complètement arrêté. Les pièces

en mouvement peuvent s’accrocher à la surface et entraîner l’outil hors de votre s’accrocher à la surface et entraîner l’outil hors de votres’accrocher à la surface et entraîner l’outil hors de votre

contrôle.

4.

5.

6.

7.

Ne laisser jamais l’outil sans surveillance lorsqu’il est branché dans une prise

électrique. Arrêter le fonctionnement, et débrancher le de sa prise électrique avant

de quitter.

Soyez vigilants puisque certains bois contiennent de l’arséniate de cuivre et etet

de chrome (CCA) qui peut être toxique. Lors de la coupe de ces matériaux, il faut

faire très attention de ne pas inhaler et de minimiser le contact avec la peau. de ne pas inhaler et de minimiser le contact avec la peau.de ne pas inhaler et de minimiser le contact avec la peau.

AVERTISSEMENT! L’exposition à l’oxyde d’aluminium (une poussière générée

par le processus de ponçage) peut causer une irritation aux yeux, à la peau ou de ponçage) peut causer une irritation aux yeux, à la peau oude ponçage) peut causer une irritation aux yeux, à la peau ou

respiratoire.Utiliser toujours un masque respiratoire approuvé par NIOSH (National Utiliser toujours un masque respiratoire approuvé par NIOSH (NationalUtiliser toujours un masque respiratoire approuvé par NIOSH (National respiratoire approuvé par NIOSH (NationalNational

Institute for Occupational Safety and Health) et des lunettes étanches approuvées) et des lunettes étanches approuvées des lunettes étanches approuvées

par ANSI. Éviter toute exposition à la peau. Une ventilation appropriée dans votre Éviter toute exposition à la peau. Une ventilation appropriée dans votreÉviter toute exposition à la peau. Une ventilation appropriée dans votre Une ventilation appropriée dans votreUne ventilation appropriée dans votre

aire de travail est requise. de travail est requise.

AVERTISSEMENT! La poussière créée par le sablage électrique, le sciage,

le broyage, le perçage, et toute autre activité de construction, contient des et toute autre activité de construction, contient deset toute autre activité de construction, contient des

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 5SKU 42864

Page 19

chimiques reconnus (par l’état de Californie) comme pouvant causer des can- l’état de Californie) comme pouvant causer des can-l’état de Californie) comme pouvant causer des can-

cers, des anomalies congénitales ou autres dommages reproductifs. Des DesDes

exemples de ces produits chimiques: - Le plomb provenant des peintures à base - Le plomb provenant des peintures à baseLe plomb provenant des peintures à base

de plomb. - La silice cristallisée qui provient des briques et du ciment ou - La silice cristallisée qui provient des briques et du ciment ouLa silice cristallisée qui provient des briques et du ciment ou

autres produits de maçonnerie. - L’arsenic et le chrome qui proviennent du bois - L’arsenic et le chrome qui proviennent du boisL’arsenic et le chrome qui proviennent du bois

traité chimiquement.

Votre risque d’exposition varie, dépendant du temps que vous consacrez à ce type typetype

de travail.Pour réduire votre exposition à ces produits chimiques: travaillez dans un Pour réduire votre exposition à ces produits chimiques: travaillez dans unPour réduire votre exposition à ces produits chimiques:travaillez dans un travaillez dans untravaillez dans un

environnement bien aéré, et travaillez avec de l’équipement de sécurité, tels que et travaillez avec de l’équipement de sécurité, tels queet travaillez avec de l’équipement de sécurité, tels que

les masques anti-poussières qui sont spécialement conçus pour filtrer les particules qui sont spécialement conçus pour filtrer les particulesqui sont spécialement conçus pour filtrer les particules

microscopiques. (California Health & Safety Code § 25249.5, et seq.)

8.

AVERTISSEMENT! Les personnes ayant un stimulateur cardiaque devraient consul-

ter leur médecin avant d’utiliser ce produit. Les champs électromagnétiques dans un

espace restreint peuvent causer de l’interférence ou un bris du stimulateur cardiaque.

De plus, les personnes qui ont un stimulateur cardiaque devraient respecter ce qui

suit : - Éviter de se servir d’outils électriques seuls. - Si l’outil fonctionne avec le

cordon d’alimentation, s’assurer que l’outil est bien mis à la terres. Un disjoncteur

de fuite à la terre (GFCI) est aussi une bonne précaution. Ce dispositif peu coûteux

est une bonne mesure de sécurité car il prévient les chocs électriques. - Entretenir

et vérifier tous les outils avant utilisation pour éviter les chocs électriques.

9.

AVERTISSEMENT! Les avertissements, les mesures de sécurité et les instructions

discutés dans ce manuel d’instructions ne peuvent pas couvrir toutes les conditions

et les situations qui pourraient se produire. L’opérateur doit bien comprendre que

le gros bon sens et la vigilance sont des facteurs qui ne peuvent pas être intégrés

à ce produit, mais doivent venir de l’opérateur lui-même.

Remarque: La performance de cet outil (s’il fonctionne avec une ligne de tension) peut

varier selon les fluctuations de la ligne de tension locale. L’usage d’une rallonge

peut aussi affecter la performance de l’outil.

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 6SKU 42864

Page 20

MISE À LA TERRE

AVERTISSEMENT!

Une mauvaise connexion du fil de terre de l’outil peut entraîner un risque de choc

électrique. En cas de doutes, consultez un électricien qualifié ou une personne

affectée à l’entretien. Ne modifiez pas la fiche de l’outil. Ne modifiez pas la fiche

mise à la terre à trois broches. N’utilisez pas l’outil si le cordon d’alimentation

ou la fiche est endommagé. S’il est endommagé le faites réparer dans un centre

de service avant de l’utiliser.

LES OUTILS MISE À LA TERRE : LES OUTILS FICHE À TROIS BROCHES

1.

2.

3.

Les outils étiquetés «Mise à la terre requis» sont munis d’un cordon tri filaire mise

à la terre et une prise de mise à la terre. La fiche doit être branché à un cordon mis

à la terre. En cas de fonctionnement défectueux ou de panne, la mise à la terre

assure un parcours sécuritaire de faible résistance pour le courant électrique, ce

qui réduit les risques de choc électrique. (Voir L’IMAGE A.)

La broche de mise à la terre à l’intérieur de la fiche est raccordée à travers le fil

vert à l’intérieur du cordon au conducteur de mise à la terre de l’outil. Le fil vert à

l’intérieur du cordon doit être le seul fil raccordé au conducteur de mise à la terre

de l’outil et ne devrait jamais être raccordé à une lame sous tension.

(Voir L’IMAGE A.)

L’outil doit être branché dans une prise de courant correctement installée et mise

à terre conformément à tous les codes et règlements locaux. La fiche et la prise de

courant semblable à celles l’illustrée ci-après. (Voir L’IMAGE A.)

1.

L’IMAGE A L’IMAGE B

LES OUTILS À DOUBLE ISOLATION: LES OUTILS AVEC

FICHE À DEUX BROCHES

La double isolation élimine le besoin d’un cordon tri filaire mis à la terre et d’un

système d’alimentation mise à la terre. Ils ont un système spécial double isolation

qui se conforme aux exigences de OSHA et conforme aux normes de Underwri-

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 7SKU 42864

Page 21

ters Laboratories, Inc., de L’Association Canadienne de Normalisation et du Code

Électrique National. (Voir L’IMAGE B.)

2.

1.

2.

3.

4.

5.

6.

Les outils à double isolation peuvent être utilisé dans l’un ou l’autre de la prise de

courant d’un circuit de 120 volts comme le montre l’illustration ci-dessus.

(Voir L’IMAGE B.)

CORDONS DE RALLONGE

L’outil avec mise à la terre doit utiliser une rallonge à trois fils. Les outils a double

isolation peuvent utiliser une rallonge à deux ou trois fils.

L’utilisation d’un cordon de calibre inférieur occasionne une baisse de tension en-

traînant une perte de puissance et la surchauffe. (Voir L’IMAGE C.)

Le calibre du fil est inversement proportionnel à sa grosseur. (Voir L’IMAGE C.)

Lorsque vous utilisez plus d’un cordon de rallonge pour longueur, assurez-vous

que le calibre des fils des cordons convient à l’intensité du courant consommé par

l’outil. (Voir L’IMAGE C.)

Si vous utilisez un cordon de rallonge pour multiples outils, mettez l’intensité no-

minale de la plaque signalétique et utiliser le somme de déterminer le calibre de

cordon minimum requis. (Voir L’IMAGE C.)

Lorsque vous utilisez un outil électrique à l’extérieur, vous devez vous servir d’une

rallonge électrique portant le symbole « W-A » ou « W ».au Canada. Ces cordons

ont une tolérance appropriée à un usage extérieur.

7.

8.

Assurez-vous que la rallonge est bien câblée et en bon état. Si la rallonge est en-

dommagée, remplacez-la ou faites-la réparer par un électricien qualifié avant de

vous en servir.

La rallonge ne doit pas venir en contact avec des objets tranchants, être exposée

à de la chaleur excessive ni être utilisée dans un endroit mouillé ou humide.

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 8SKU 42864

Page 22

CALIBRE MINIMUM DES RALLONGES *

(COURANT DE 120 OU 240 V SEULEMENT)

L’INTENSITÉ

Longueur de la rallonge en pieds

NOMINALE

(au maximum)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

L’IMAGE C

25 pieds 50 pieds 75 pieds 100 pieds 150 pieds

*Basé sur limitant le volt du cordon, baissez à cinq volts à

150 % de l’intensité nominale.

SYMBOLES

Construction de Classe 2

Association Canadienne de Normalisation

Underwriters Laboratories Inc.

V~

A

n0 xxxx/min.

Volts

Ampères

Sous Vide xxxx/tours à la minute

DÉBALLAGE

Lors du déballage, assurez-vous que le produit est intact et non endommagé. Si

des pièces sont manquantes ou brisées, veuillez appeler Harbor Freight Tools au numéro

affiché sur la couverture de ce manuel aussitôt que possible.

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 9SKU 42864

Page 23

INSTRUCTIONS D’ASSEMBLAGE

REMARQUE: Pour plus d’information au sujet des pièces listées dans les prochainesPour plus d’information au sujet des pièces listées dans les prochaines

pages, consultez les illustrations d’assemblage à la fin de ce manuel. illustrations d’assemblage à la fin de ce manuel.

Avertissement: Toujours s’assurer que le cordon d’alimentation (17) de la ponceuse estToujours s’assurer que le cordon d’alimentation (17) de la ponceuse est

débranché de sa prise électrique avant de faire tout ajustement à l’outil. sa prise électrique avant de faire tout ajustement à l’outil.sa prise électrique avant de faire tout ajustement à l’outil.

Attacher le conduit de poussière

1.

2.

3.

Tourner le conduit (0) pour que l’onglet sur le haut du bout rectangulaire soit di-

rigé vers le haut. Le cliquer en place dans le conduit rectangulaire à l’arrière de la

ponceuse.

Brancher un boyau de collection de poussière 1 1/4» à partir de la chute jusqu’au

système de collection de poussière (boyau et système non inclus).

Le conduit de poussière (0) fonctionnera seulement si le papier sablé a des trous

qui s’alignent avec les 6 trous de collection de poussière dans le tampon arrière

(28). (Il y a 4 autres trous dans le tampon arrière pour les vis (29).

Attacher le papier sablé au tampon arrière (28)

Le papier

abrasif

coule ici

1.

2.

3.

Presser l’onglet sur les serre-joints (6) vers l’intérieur des deux côtés de l’unité

et tourner sur les deux côtés vers le haut, l’extérieur et vers le bas. Voir 1 et 2, à

droite.

Couper le papier sablé pour qu’il soit de la même dimension que le tampon de la

ponceuse (28) soit 31/2» de large par 73/8» de long, avec un peu plus pour dé-

border et aller en dessous des serre-joints (6). Ne pas utiliser de papier sablé

déchiré ou effiloché.

Après avoir ajusté les bords du papier sablé sous les serre-joints (6), cliquer les serre-joints

(6) en place.

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 10SKU 42864

Page 24

DIRECTIVES POUR LE FONCTIONNEMENT

REMARQUE: Pour plus d’information au sujet des pièces listées dans les prochainesPour plus d’information au sujet des pièces listées dans les prochaines

pages, consultez les illustrations d’assemblage à la fin de ce manuel.

1.

2.

3.

4.

5.

6.

REMARQUE: Toutes les ponceuses de finition laissent des marques sur la pièce de travail.Toutes les ponceuses de finition laissent des marques sur la pièce de travail.

Avertissement: Toujours s’assurer que le cordon d’alimentation (17) de la ponceuseToujours s’assurer que le cordon d’alimentation (17) de la ponceuse

est débranché de sa prise électrique avant de faire tout ajustement à l’outil. sa prise électrique avant de faire tout ajustement à l’outil.sa prise électrique avant de faire tout ajustement à l’outil.

Bien immobiliser la pièce de travail, ou l’insérer dans un étau. S’assurer que le bois S’assurer que le boisS’assurer que le bois

à poncer ne contient aucun clou ou métal de toute sorte, pour éviter de ruiner la poncer ne contient aucun clou ou métal de toute sorte, pour éviter de ruiner la

ponceuse ou le tampon (28).

Après avoir pris les précautions décrites à la page 2 de ce manuel, brancher la la

ponceuse.

Mettre la ponceuse en marche en actionnant l’interrupteur (2).

Toujours faire fonctionner la ponceuse pour quelques secondes avant de la mettre

en contact avec la pièce de travail.

Appliquer une pression minimale sur la pièce de travail. Si la ponceuse n’enlève Si la ponceuse n’enlèveSi la ponceuse n’enlève

pas assez de matériel, essayer un morceau de papier sablé plus granuleux. Pour matériel, essayer un morceau de papier sablé plus granuleux. Pourmatériel, essayer un morceau de papier sablé plus granuleux. Pour PourPour

enlever plus de matériel de façon rapide, utiliser une ponceuse à courroie. rapide, utiliser une ponceuse à courroie.rapide, utiliser une ponceuse à courroie.

Pour minimiser les marques de ponçage, toujours essayer de poncer dans le sens

du grain du bois.

7.

8.

À l’occasion, vérifier la dégradation ou l’effilochage de la ponceuse. Remplacer RemplacerRemplacer

si nécessaire.

Lorsque le travail est terminé, arrêter la ponceuse en actionnant l’interrupteur (2).

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 11SKU 42864

Page 25

INSPECTION, ENTRETIEN ET NETTOYAGE

1.

AVERTISSEMENT! S’assurer que l’interrupteur de courant (2) de la ponceuse est

à la position Arrêt (OFF) et que l’outil est débranché des sa prise électrique avant

d’effectuer des toute procédure d’inspection, d’entretien, ou de nettoyage.

2.

AVANT CHAQUE UTILISATION, vérifier la condition générale de la pon-

ceuse. Vérifier les vis, les alignements et les arrimages des pièces en

mouvement, les pièces fendues ou cassées, le câblage électrique défec-

tueux, et toute autre condition qui peut affecter un fonctionnement sécu-

ritaire. Si des bruits anormaux ou des vibrations surviennent, s’assurer

que le problème soit corrigé avant la prochaine utilisation. Ne pas utiliser d’équipe-

ment endommagé.

3.

4.

5.

Essuyer l’outil avec un linge sec et exempt de charpie après chaque utilisation.

S’assurer que les évents sur le dessus sont exempts de poussière et de débris.

De façon périodique, faire nettoyer ou remplacer les brosses de carbone (4) par

un technicien qualifié.

Pièce Description

1 Droite du Boîtier

2 Interrupteur

3 Ressort brosse carbone

4 Brosse carbone

5 Coussinet de socle

6 Carte de circuit

7 Cordon électrique

8 Protecteur de cordon

9 Support de cordon électrique

10 Vis

11 Collerette

LISTE DES PIÈCES

Pièce Description

12 Joint de la conduite de poussière

13 Gauche du boîtier

14 Stator

15 Tampon arrière

16 Armature

17 Plaque de base

18 Manche fuselée

19 Conduit de poussière

20 Entrée du conduit de poussière

21 Vis

LISEZ S’IL VOUS PLAÎT LE SUIVANT SOIGNEUSEMENT

LE FABRICANT ET-OU LE DISTRIBUTEUR A FOURNI LA LISTE DE PIÈCES ET LE DIAGRAMME DE

MONTAGE DANS CE MANUEL COMME UN INSTRUMENT DE RÉFÉRENCE SEULEMENT. AUCUN LE

FABRICANT OU LE DISTRIBUTEUR FONT N’IMPORTE QUELLE REPRÉSENTATION OU GARANTIE DE

N’IMPORTE QUELLE SORTE À L’ACHETEUR QU’IL OU ELLE EST AUTORISÉ POUR FAIRE N’IMPORTE

QUELLES RÉPARATIONS AU PRODUIT, OU QU’IL OU ELLE EST AUTORISÉ POUR REMPLACER

N’IMPORTE QUELLES PIÈCES DU PRODUIT. EN FAIT, LE FABRICANT ET-OU LE DISTRIBUTEUR

DÉCLARE EXPRESSÉMENT QUE TOUTES LES RÉPARATIONS ET LES REMPLACEMENTS DE

PIÈCES DEVRAIENT ÊTRE ENTREPRIS PAR LES TECHNICIENS DIPLÔMÉS ET AGRÉÉS ET PAS PAR

L’ACHETEUR. L’ACHETEUR SUPPOSE TOUT LE RISQUE ET LA RESPONSABILITÉ SURVENANT DU

FAIT DE SES RÉPARATIONS AU PRODUIT ORIGINAL OU AUX PIÈCES DÉTACHÉES Y, OU SURVENANT

DU FAIT DE SON INSTALLATION DE PIÈCES DÉTACHÉES Y.

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 12SKU 42864

Page 26

SCHÉMA D’ASSEMBLAGE

NOTEZ: Quelques pièces sont énumérées et montrées pour les buts d’illustration seule-

ment et ne sont pas en vente individuellement comme les pièces détachées.

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 13SKU 42864

Page 27

Déférez au texte

anglais pour

l’explication de

garantie.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Pour des questions techniques, veuillez appeler au 1 800 444 3353

Page 14SKU 42864

Loading...

Loading...