Page 1

Geared Head

®

Drill / Mill Machine

Model

Assembly & Operating Instructions

42827 42827

42827

42827 42827

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2005 by Harbor Freight Tools® . All rights reserved. No portion of this manual or any

artwork contained herein may be reproduced in any shape or form without the express written

consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Page 2

SPECIFICATIONS

Motor: 110V/60Hz Single Phase

1.5 HP, 15 Amps

6 Speeds (rpm): 95-175-310-450-850-1500

Motor rpm’s: 1720

Spindle Taper: R8

Spindle Collar: 1.740”

Spindle Stroke: 5”

Spindle to Table: 17-3/4”

INCLUDED ACCESSORIES

5 and 6mm Hex Wrenches

Draw Bar

R-8/JT2 Chuck

FEATURES

1. This machine may be used for surface cutting, drilling, milling, and tapping.

2. The high quality of this machine, and its ease of operation makes it suitable for use by students,

amateurs, and home hobbyists, as well as skilled technicians.

3. Drilling and milling may be done using hand operated feeding, or worm-gear feeding.

4. Many of the adjustable nuts are bronze, for adjusting thread clearance and reducing wear. These

bronze parts also allow screws to rotate smoothly and improve accuracy.

5. The vertical column is very strong and stiff, which makes the machine very stable and improves

accuracy of manufactured parts.

6. The machine head is cast steel, and has been heat-treated, stress-relieved, and precision machined.

7. Machine gears are precision ground for smooth operation.

8. Speeds can be easily changed.

9. Thread tapping operations can be done in either rotation, and working depth can be controlled using a

positive stop gauge.

Drill Cap: 1-1/4”

Face Mill Cap: 3”

End Mill Cap: 3/4”

Tapping Cap: 1/4”

Max. Y-Travel: 6-13/16”

X-Travel: 19-13/16”

Table Dimensions: 27-1/2”L x 9-1/2”W

14 / 17mm Open End Wrench

Slotted Screwdriver

Head Wrench

SAVE THIS MANUAL

You will need the manual for the safety warnings and cautions, assembly instructions, operating procedures,

maintenance procedures, trouble shooting, parts list, and diagram. Keep your invoice with this manual.

Write the invoice number on the inside of the front cover. Keep both this manual and your invoice in a safe,

dry place for future reference.

NOTICE

The Warnings, Cautions, and Instructions discussed in this instruction manual cannot

cover all possible conditions and situations that may occur. It must be understood by

the operator that common sense and caution are factors which cannot be built into this

product, but must be supplied by the operator.

Page 2 SKU # 42827

REV 11/06

Page 3

SAFETY WARNING & CAUTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL!

1. KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

2. OBSERVE WORK AREA CONDITIONS. Do not use tools in damp, wet, or poorly lit locations.

Don’t expose to rain. Keep work area well lit. Do not use electrically powered equipment in the presence

of flammable gases or liquids.

3. KEEP CHILDREN AWAY. Children must never be allowed in the work area. Do not let them handle

machines, tools, or equipment.

4. STORE IDLE EQUIPMENT. When not in use, tools must be locked up in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

5. DO NOT FORCE THE TOOL. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool’s capacities.

6. USE THE RIGHT TOOL FOR THE JOB. Do not use a tool for a purpose for which it was not

intended.

7. DRESS PROPERLY. Do not wear loose clothing or jewelry, as they can be caught in moving parts. Nonskid footwear is recommended. Wear restrictive hair covering to contain long hair. Always wear appropriate

work clothing.

8. USE EYE, EAR AND BREATHING PROTECTION. Always wear ANSI approved impact safety

goggles if you are producing metal filings or wood chips. Wear an ANSI approved dust mask or

respirator when working around metal, wood, and chemical dusts and mists. Use ANSI approved ear

protection when working in a loud or noisy environment.

9. DO NOT ABUSE THE POWER CORD. Protect the power cord from damage, either from impacts,

pulling or corrosive materials. Do not yank machine’s cord to disconnect it from the receptacle.

10. DO NOT OVERREACH. Keep proper footing and balance at all times. Do not reach over or across

running machines.

11. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories. Inspect power cord periodically and, if

damaged, have it repaired by an authorized technician. Inspect all hydraulic seals for leaks prior to use.

Control handle and power switch must be kept clean, dry, and free from oil and grease at all times.

12. REMOVE ADJUSTING KEYS AND WRENCHES. Be sure that keys and adjusting wrenches are

removed from the tool or machine work surface before operation.

13. AVOID UNINTENTIONAL STARTING. Be sure that you are prepared to begin work before turning the

start switch on.

Page 3 SKU # 42827

Page 4

14. STAY ALERT. Watch what you are doing. Do not operate this machine when you are tired.

15. DO NOT OPERATE THIS MACHINE WHILE UNDER THE INFLUENCE OF ALCOHOL, DRUGS,

OR PRESCRIPTION MEDICINES.

16. CHECK FOR DAMAGED PARTS. Before using any tool, any part that appears damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check for

alignment and binding of moving parts, any broken parts or mounting fixtures, and any other condition that may

affect proper operation. Any part that is damaged should be properly repaired or replaced by a qualified

technician. Do not use the tool if any switch does not turn on and off properly.

17. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical replacement parts

intended for use with this tool. Replacement parts are available from Harbor Freight Tools. Use of any other

parts will void the warranty.

18. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force a small tool or attachment to do the

work of a larger industrial tool. There are certain applications for which this tool was designed. Do not modify

this tool and do not use this tool for a purpose for which it was not intended.

19. MAINTENANCE. For your own safety, maintenance should be performed regularly by a qualified

technician.

SPECIAL WARNINGS WHEN USING THIS DRILLING / MILLING MACHINE

Using this machine may create special hazards.

Take particular care to safeguard yourself and those around you.

Electrical Safety. Never operate any tool if there is an electrical hazard. Never operate an electrical

tool in wet conditions. Never operate a tool with an improper electrical cord or extension cord. Never operate

an electrical tool unless you are plugged into a properly grounded outlet, which

60 Hz. We recommend you use a circuit which is protected by an appropriate circuit breaker.

Ejected Material. Use safe practices to avoid injury from ejected material. Because milling tools and

workpieces turn at high speed, there is a danger of being injured by materials that may be ejected. Always wear

ANSI-certified eye protection. Never attempt to machine any item if it is not adequately held. Always stand to

one side of the plane in which the materials are spinning, to avoid being hit if an item is ejected. Never allow

bystanders to be in the proximity of this machine while in operation.

Entanglement. Use extreme caution to prevent loose materials from being caught in the machine.

Never operate this machine with loose clothing, long hair, jewelry, or other items which may become caught in

the tools or workpieces. In case of entanglement, press the OFF switch immediately.

NOTICE: No list of warnings can be all inclusive. The operator must supply common

sense, and operate this tool in a safe manner.

supplies 110 Volts at

Page 4 SKU # 42827

Page 5

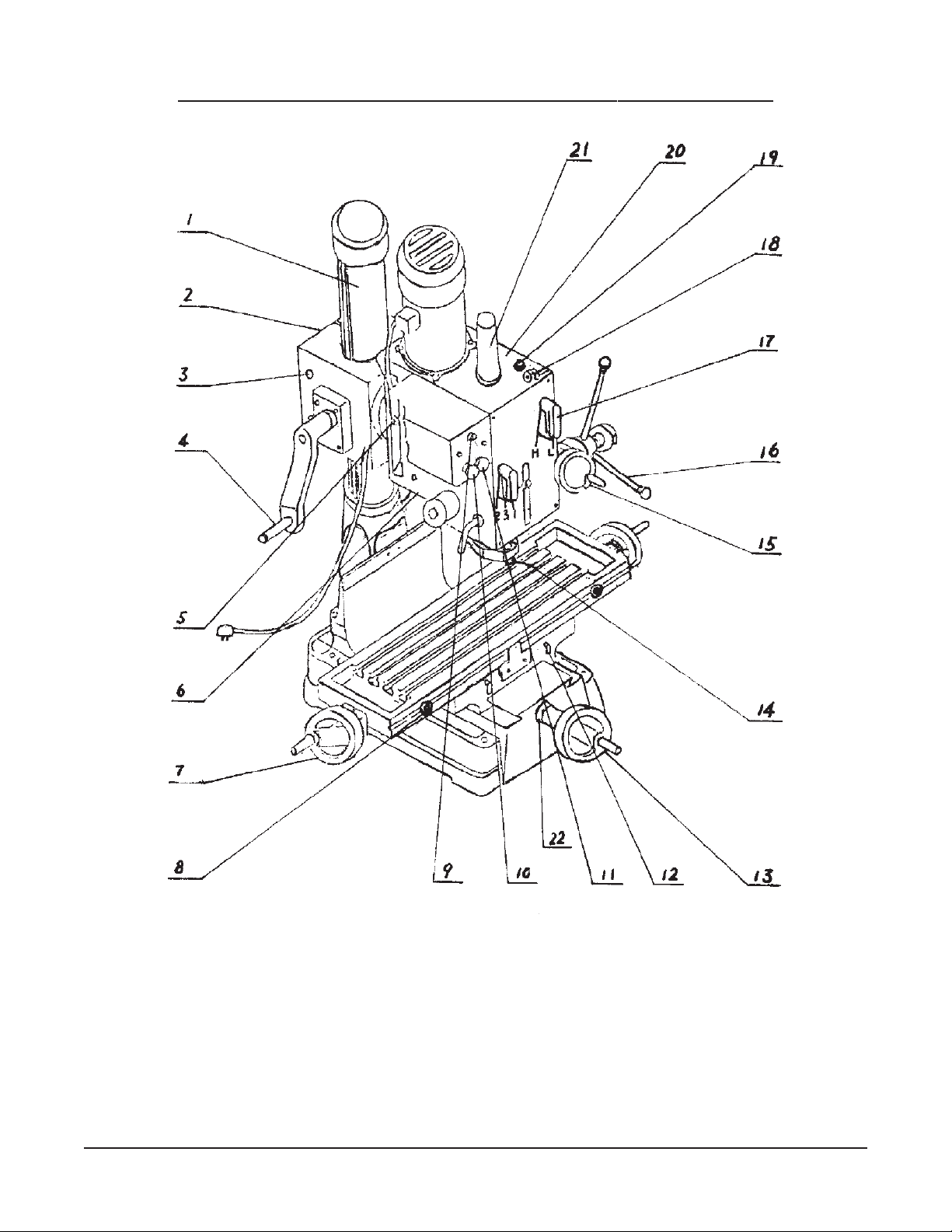

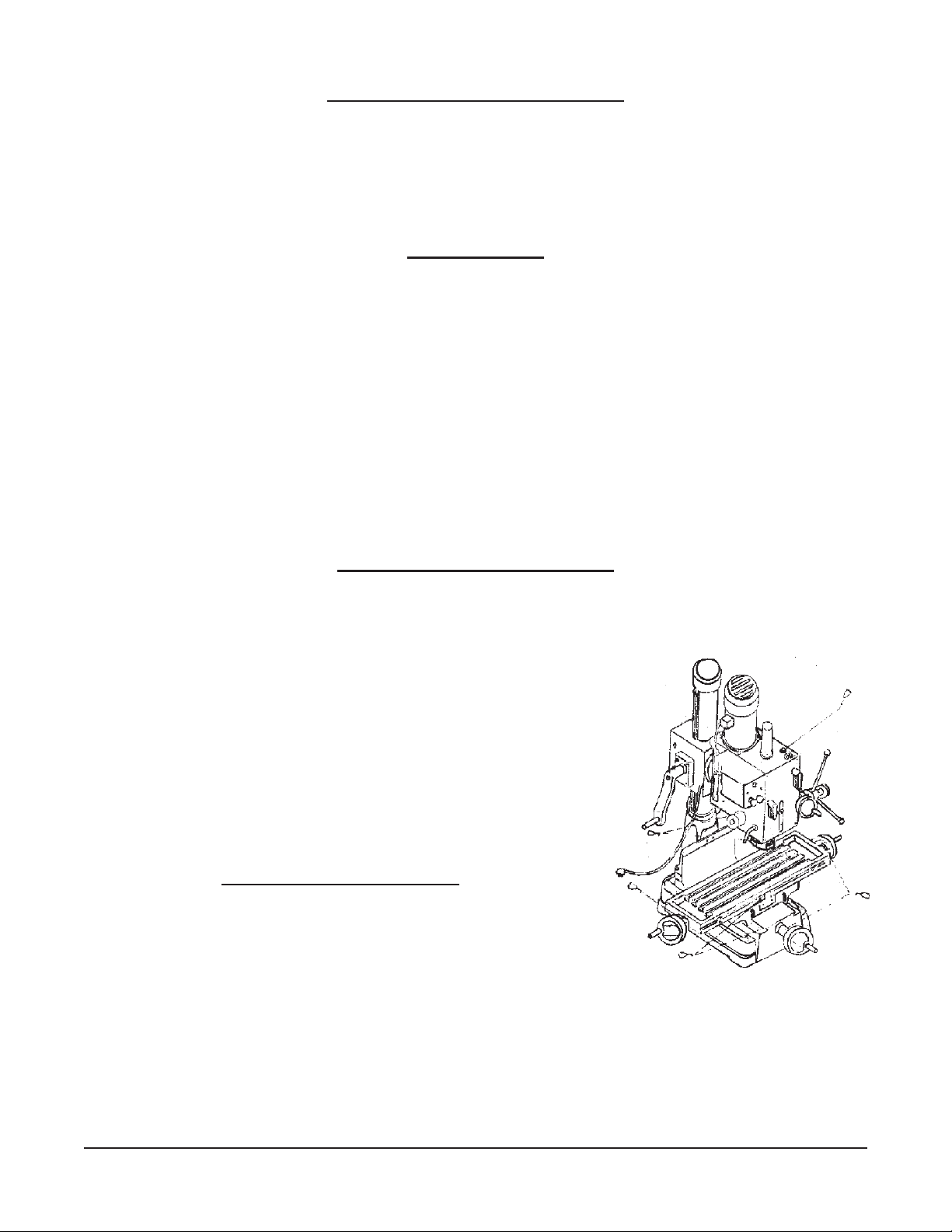

FEATURES AND CONTROLS OF THE #42827 DRILL / MILL MACHINE

Figure 1.

1. Column

2. Head Collar

3. Head Collar Lock Bolt

4. Head Crank

5. Lock Nut

6. Oil Drain Plug

7. Table Feed Wheel

8. Travel Stop

9. Knob

10. Red Bush Button

11. Green Push Button

Page 5 SKU # 42827

12. Leaf Screw

13. Cross Table Feed Wheel

14. Positive Depth Stop Gauge

15. Spindle Micro Feed Handle

16. Spindle Feed Handle

17. Speed Lever

18. Air Flow Plug

19. Oil Filler Plug

20. Head Body

21. Arbor Bolt Cover

22. Scale

Page 6

UNPACKING AND INSTALLATION

1. Remove protective crating and skids carefully. In the event of damage in transit, contact Harbor Freight

Tools immediately.

2. Read the owner’s manual and become familiar with the parts and controls on the drawings before

using this machine, as familiarity with the controls will enhance your ability and safety in using it.

INSTALLATION

1. It is important that the machine be located on a hard, solid, level floor. Find a location that

supplies easy access to 110 Volt electrical service. Make sure this machine is located in a well

lighted and well ventilated area. The floor should be resistant to vibration.

2. Before moving the machine, be sure the head is fixed on the column. Before moving the machine, lower

the head as much as possible to lower the center of gravity. When moving the machine be careful to

keep it balanced, and not allow it to topple over.

3. To set the machine on a solid concrete foundation, it’s advisable to apply a little grout to touch up

any uneveness in the concrete in order to get a solid foundation at all points.

4. When setting machine on a floor that has any surface irregularities, shims should be used to

correct this condition to the greatest extent possible.

5. There are 4 holes in the base for mounting the machine permanently to a smooth, solid, and level floor.

CLEANING AND LUBRICATION

1. Thoroughly clean the machine with a commercial degreaser.

Do not use gasoline, kerosene or other flammable liquids.

Avoid getting solvent on rubber parts, or into the electrical

controls or motor.

2. After cleaning, coat all bright metal with a light lubricant to

prevent corrosion.

3. Lubricate all points indicated in Figure 2 with a 10 weight

machine oil.

4. Remove the oil filler plug and fill the reservoir with heavy motor

oil, until the oil level reaches the middle of the oil fluid level

indicator. Replace the plug.

LEVELING THIS MACHINE

1. Before operation, it is critical to level the work surface both

lengthwise and crosswise, using a precision level. It will not be

possible to maintain accuracy of machined parts if the mill is not

properly leveled to start.

Figure 2. Lubrication Points.

Page 6 SKU # 42827

Page 7

BASIC OPERATION

Prior to Operation

1. Check the oil level, and if necessary fill to the mid point of the oil level window.

Basic Controls

Please refer to Figure 1 on page 5.

1. Raise and lower the Head by using the Head Crank (#4).

2. Feed the Spindle using Spindle Feed Handle (#16). Precise movements may be made using

the Spindle Micro Feed Handle (#15).

3. Move or feed the table from side to side by using the Table Feed Wheel (#7).

4. Move the Table front to back using the Cross Table Feed Wheel (#13).

Adjusting the Head

1. To raise or lower the head, loosen the 2 heavy

duty head lock nuts shown in the left part of

Figure 3. Use the left side head handle to raise

or lower the head on its rack and pinion

mechanism.

2. The head may be rotated 360O by loosening the

same bolts mentioned in item 1. Adjust the head

to the desired angle, then fix the heavy-duty head

lock nuts. Periodically check the tightness of

these nuts, especially during prolonged use of the

machine.

3. You may set the head at an angle by loosening

the three nuts shown in the right part of Figure

3. Retighten the nuts when you have set the angle at the desired degree.

Refer to the scale on the right side of the head to read the angle.

Figure 3. Adjusting the Head

Preparing for Drilling

Please see Figure 4.

1. Rotate the knob in the center of the spindle

feed handle (#16) counterclockwise to loosen

the spindle for vertical travel.

2. You can move the spindle vertically by

operating the spindle feed handle.

3. For more precise movement of the spindle,

operate the micro feed handle (#15).

4. For drilling blind holes (which do not pass

through the workpiece), set the positive depth

stop gauge (#14). To do so, first determine the

desired depth. Then adjust the positive stop

gauge so that the distance from the tip of the

drilling bit to the end of the gauge is equal to the

desired depth.

5. For drilling holes that pass through the workpiece, set the stop gauge in its uppermost position.

Page 7 SKU # 42827

Figure 4. Settings for Drilling

Page 8

Preparing for Milling

1. Adjust the positive stop gauge to its uppermost position.

2. Using the spindle feed handle, adjust the bit to approximately the correct height. Tighten the knob in the

center of the spindle feed handle (#16).

3. Set the final vertical adjustment using the micro feed handle.

4. Lock the rack sleeve at this height with the fixed bolt.

Preparing for Tapping

1. Adjust the positive depth gauge to the required position.

2. Loosen the knob in the center of the spindle feed handle.

Adjusting Table Slack and Compensating for Wear

1. Your machine is equipped with gib strip adjustment to

compensate for wear and excess slack on cross and

longitudinal travel.

2. Rotate the gib strip bolt slightly counterclockwise to tighten

the gib strip. Rotate it slightly clockwise to loosen the gib strip.

3. Adjust the gib strip bolt until very slight drag is felt when

moving the table.

Locking the Table Base and Machine Base

1. When milling using the longitudinal feed, it is a good idea to

lock the cross feed table to ensure the accuracy of your

work. To do this, tighten the small leaf screw located on the

right side of the table base.

2. When milling using the cross feed, lock the longitudinal travel.

Do this by tightening the two small leaf screws on the front of

the table base.

3. Adjustable travel stops are mounted on the front of the table

to limit cross travel,and therefore milling length.

Changing Machine Speed

1. Turn the power off.

2. To select the proper speed, move the speed lever to the

desired position. See Figure 6.

3. If the gears are not engaged, remove the arbor bolt cover

(#21). Rotate the spindle slightly to engage the gears, then

replace the arbor bolt cover.

4. Recheck the lever setting, and then turn the power on.

Levers L-1 L-2 L-3 H-1 H-2 H-3

rpm @ 60Hz 95 175 310 450 850 1500

Figure 6. Machine Speed Lever Settings.

Page 8 SKU # 42827

Figure 5. Adjusting the Gib Strips.

Page 9

Installing and Changing Tools

WARNING: Be sure the power is turned off and the machine unplugged before installing or changing tool bits.

Removing Face Mill or Drill Chuck Arbor

1. Remove the arbor bolt cover (#21) on the top of the head body (#20).

2. Loosen the arbor bolt at the top of the spindle shaft approximately 2 turns with a suitable wrench.

3. Rap the top of the arbor bolt with a mallet.

4. After the taper has broken loose, hold the chuck arbor with one hand, and detach the arbor bolt with

the other hand.

5. Replace the arbor bolt cover.

Installing a Face Mill or Cutter Arbor

1. Remove the arbor bolt cover (#21) on the top of the head body (#20).

2. Insert the cutter and cutter abor into the taper of the spindle.

3. Tighten the arbor bolt securely, but do not overtighten.

4. Replace the arbor bolt cover.

Additional Tools and Accessories You Will Find Helpful

Your Drill Mill machine is equipped with an R-8 spindle taper. Many tools, bits, and acessories are

available for this standard.

1. Taper Drills

2. Reamers

3. End Mills

4. Cutter Arbors

5. Taps

6. Collets

7. Adapters and Sleeves.

8. Table Power Feed

Page 9 SKU # 42827

REV 06/01

Page 10

Additional Safety Rules for Drilling and Milling

1. Be sure the drill bit or cutting tool is securely locked in the chuck.

2. Be sure the chuck key is removed from the chuck before turning on the power.

3. Adjust the table or depth stop to avoid drilling into the table.

4. Shut off the power, remove the drill bit or cutting tool, and clean the table before leaving the machine.

5. Always use clamps or a vise to hold the workpiece, to prevent it from moving, rotation or flying off

while being machined.

6. Never wear gloves when machining, as they can become entangled in the bit, causing injury.

Specification of the T-Slot.

Please refer to Figure 7. Purchase or make T-bolts and

other table top fixtures to fit these dimensions.

NOTE: These dimensions are in millimeters

TROUBLE SHOOTING

The machine doesn’t run when the power switch is turned ON.

1. The knob (#9) is in the STOP position.

2. A fuse has burned out. Check in the switch box, and replace

if necessary.

3. If there is a surge in the current, the circuit breaker may have

opened. Press the circuit breaker back in, if it is in the open

position.

4. The gears may not be engaged. Adjust the speed lever to be sure it is engaged.

Figure 7. T-Slot Dimensions.

The motor overheats, or there is insufficient power.

1. The machine is overloaded. Reduce the feed rate, and/or increase the spindle speed.

2. The voltage supply is too low. If you have an unreliable power supply, check with a qualified electrician

to repair it.

3. The magnetic switch may have a burned or broken contact point. Replace the switch.

4. The contactor relay may be broken. Replace it.

5. The motor carbon brushes may be worn or cracked. Check them and replace if needed.

6. There may be a poor electrical connection. Have a qualified electrician check the wiring and power

supply.

7. The motor may be burned out. After a long period of heavy use, the motor may burn out. If so, replace

the motor.

8. The drill bit or cutting blade may be worn. Sharpen or replace the bits as needed.

The spindle bearing is very hot.

1. There is insufficient lubrication. Turn off the power, and check the bearing for lubrication. If necessary,

apply a medium weight bearing grease.

2. The spindle bearing is worn, or is fixed too tight. Turn off the power, unplug the electrical connection,

and rotate the spindle by hand.

Be sure it turns freely. If not, check the bearing adjustment. If you feel uneveness in the bearing, you will

have to replace it.

3. The spindle has been turning at high speed for a long time. After long use, turn the machine off for a

while to give it a rest, and allow it to cool off.

Page 10 SKU # 42827

Page 11

The Table Travel is not Balanced

1. The spindle taper gap is too wide. Adjust the arbor bolt properly.

2. One of the leaf bolts may be loose. Check and tighten them if necessary.

3. The feed is too deep. Reduce the depth of the cut, and make several passes to reach the required

depth.

4. The gib strip may be out of adjustment. Check it and adjust it if necessary.

There is a vibration,and the cut is not smooth

1. The spindle bearing may be improperly adjusted or is worn. Check it and adjust or replace as

necessary.

2. The spindle is loose up and down. Check the adjustment of the two inner bearing covers. Adjust them

so there is no free play in the taper bearing, and the bearing turns freely. Tighten them against each other

to save this adjustment.

3. The gap of the taper sliding plate is too wide. Adjust the bolt tension.

4. The chuck is loose. Tighten the chuck.

5. The drill bit or cutter is dull. Sharpen or replace it. Be sure to use cutting fluid to preserve tool life.

6. The workpiece is not held firmly. Check the clamps or vise you are using, and assure that the workpiece

cannot move.

The micro feed does not work smoothly

1. The clutch may be loose. Check this and tighten if necessary.

2. The worm or worm shaft may be worn. Check these and replace if necessary.

3. The handwheel fixed screw may be loose. Check it and tighten if necessary.

The workpiece is not machined accurately

1. A heavy workpiece may be out of balance. Check to see that heavy workpieces are held in balance.

Out of balance pieces may shift when being machined.

2. A hammer has been used on the workpiece. Never strike the workpiece with a hammer.

3. The table may not be level. Check the table with a spirit level to be sure it is level both side to side and

front to back.

4. The machine may not be stable in the floor. Check to be sure the machine is firmly mounted to the floor.

Page 11 SKU # 42827

Page 12

ELECTRICAL WIRING

NOTE: This machine is designed to operate on 110 Volt/60 Hz Single Phase power supply only.

This machine is supplied with a 3-prong grounded plug. Use only a power supply which is

grounded, and which is protected by an appropriate circuit breaker. Check with a qualified

electrician before using this machine.

Serious injury or damage to property can result from improper electrical connection.

NOTICE: 110 Volt systems deliver highly energetic currents which are

capable of causing lethal injury.

Do not operate this machine without first obtaining professional installation

and safety inspection to prevent operator injury.

WIRING DIAGRAM

WIRING DIAGRAM KEY

102

L1-V1 X - L1-Z2 - - X

L2-Z2 X - L2-V1 - - X

L1-U1 X - X

L2-U2 X - X

Page 12 SKU # 42827

Figure 8. Wiring Diagram.

Page 13

MAINTENANCE

After each use:

1. Turn off the power switch and unplug the machine from its power source.

2. Remove any tool bits, clean and lubricate them, and return them to their storage case.

3. Using a stiff bristle brush, brush off all chips and shavings left from the machining operation.

4. Using a rag, wipe off any excess or dirty oil or cutting fluid left on the machine.

5. Lubricate the points indicated in Figure 2. Apply light grease or oil to all unpainted metal to prevent

corrosion.

6. Cover the machine to prevent dust or dirt contamination when not in use.

Daily Maintenance:

1. Fill the oil reservoir to the proper level before each use.

2. Check the tightness of the bolts holding the head in place.

3. If overheating is observed, or unusual noises are produced, stop the machine immediately to check for

lack of lubrication, faulty adjustments, dull tool bits, or other deficiencies. Correct any problems before

resuming work.

4. Keep the work area clean. If chips or shavings accumulate on the table or fixtures, shut off the power

and clean the chips away with a stiff bristle brush. Re-check the lubrication before continuing.

Weekly Maintenance:

1. Clean and coat the lead screw with oil.

2. Check the lubrication of the sliding parts of the table. Apply light grease if needed.

Monthly Maintenance:

1. Adjust the accuracy of the slides on both the cross and longitudinal feeds.

2. Lubricate the bearings, worm gear and worm shaft with light grease.

Yearly Maintenance:

1. Adjust the table to assure that it is level in all directions.

2. Check the electrical cord, plug, circuit breakers and related connections to assure that they are secure

and safe.

3. Drain the lubricant from the gear box and replace it with heavy grade motor oil.

NOTE: Some parts on the following pages are listed and shown for illustration

purposes only and are not available individually as replacement parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL AS

A REFERENCE TOOL ONLY: NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT:

IN FACT THE MANUFACTURER A ND/OR DISTRIBUTOR EXPRESSLY STATES THATALL REPAIRS AND

PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT

BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO

THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 13 SKU # 42827

Page 14

GEARED HEAD DRILL MILL MACHINE, HEAD PARTS LIST

Please refer to Parts Diagrams on Page 16 and 17

P/N Description Quantity

1-01 Arbor Bolt Cover 1

1-02 Arbor Bolt 1

1-04 C-Retainer Ring 1

1-05 Ball Bearing (80108) 2

1-06 Spindle Sleeve Cover 1

1-07 Oil Seal 1

1-08 Seal Retainer 1

1-09 Cap 1

1-10 C-Retainer Ring 1

1-11 Head Body 1

1-12 Rubber Flange 2

1-13 Feed Base 1

1-14 Lock Nuts 2

1-15 Taper Roller Bearing (7206E) 1

1-16 Rack Sleeve 1

1-17 Spindle Shaft 1

1-18 Taper Roller Bearing (7207E) 1

1-19 Bearing Cap 1

1-20 Gear Shaft 1

1-21 Gear 1

1-22 Grip 4

1-23 Ring 1

1-24 Handle Rod 1

1-25 Fixed Tight Collar 1

1-26 Fixed Tight Collar (thread) 1

1-27 Screw Key 1

1-28 Oil Seal 1

1-29 Gear 1

1-30 Spring and Ball 3

1-31 Gear Shaft 1

1-32 Key 1

1-33 Ring 1

1-34 Gear 1

1-35 Bearing Spacer 1

1-36 Sleeve 1

1-37 Gear 1

1-38 Key 1

1-39 Handle Rod 1

1-40 Knob 3

1-41 Ball Bearing (80202) 3

1-42 Inner Ring 1

P/N Description Quantity

1-43 Shaft 1

1-44 Micro Adjusting Indicator 1

1-45 Worm Cover 1

1-46 Ball Bearing (202G) 2

1-47 Worm Shaft 1

1-48 Key 2

1-49 Gear 1

1-50 Oil Seal 1

1-51 Ball Bearing (80107) 1

1-52 Head Body Fix Bolt 2

1-53 Oil Drain Plug 1

1-54 Graduated Rod 1

1-56 Switch Box 1

1-57 Main Cable 1

1-58 Head Handle 1

1-59 Worm Shaft 1

1-60 Worm 1

1-61 Shaft 1

1-62 Handwheel 1

1-63 Nuts 3

1-64 Spring Washer 3

1-65 Bolt 3

1-66 Lever Bracket 2

1-67 Lever (Left) 1

1-68 Lever (Right) 1

1-69 Screw 2

1-70 Lever Shaft (Right) 1

1-71 Lever Shaft (Left) 1

1-72 Name Plate 1

1-73 Screw 4

1-74 Screw 4

1-75 Speed Lever 2

1-76 Degree-Meter 1

1-77 Rivet 2

1-79 Head Collar 1

1-80 Motor Cable 1

1-81 Oil Filler Plug 2

1-82 Bolt 6

1-83 Pin 2

1-84 Head Body Cover 1

1-85 Screw with Plum Knob 1

Page 14 SKU # 42827

Page 15

DRILL MILL MACHINE, PARTS LIST

Please refer to Parts Diagrams on Page 16 and 17

P/N Description Quantity

1-86 Motor 1

1-87 Fluid Level Indicator 1

1-89 Airflow Plug 1

1-90 C-Ring 2

1-91 Set Distance Nut 1

1-92 Set Position Block 1

1-93 Lock Nut 1

1-94 Support Base 1

1-95 Handle 1

1-96 Oil Seal 2

1-101 Head Raise Bracket 1

1-102 Limit Plate 4

1-103 Spring Cover 1

1-104 Spring 1

1-105 Spring Base 1

1-106 Pinion Shaft 1

1-107 Worm Gear 1

1-108 Feed Cover 1

1-110 Spring Base 1

1-111 Lock Bolt with Knob 1

1-115 Spring 1

1-134 Hex Head Bolt 1

1-135 Hex Nut 1

1-136 Spring Pin 1

1-137 Lock Washer 1

1-139 Phillips recessed round head screw 3

1-140 Travel Switch 2

1-141 Hex Nut 1

1-142 Key 1

1-143 Hex Socket Head Screw 2

1-145 Hex Set Screw 3

1-146 Hex Set Screw 1

1-147 Hex Set Screw 2

1-148 C-Retainer Ring 1

1-153 Hex Set Screw 1

1-154 C-Retainer Ring 2

1-155 Hex Set Screw 4

1-156 Rod 1

1-157 Retainer 1

1-158 Knob 1

1-184 Screw 1

1-185 Washer 1

1-187 Washer 1

1-188 Phillips Head Recessed Screw 1

1-189 Travel Switch Base A 1

1-190 Travel Switch Base B 1

Page 15 SKU # 42827

P/N Description Quantity

2-01 Table Handle with Wheel 3

2-02 Dial Clutch 2

2-03 Thrust Bearing (8103) 4

2-04 Square Flange 1

2-05 Table Screw 1

2-06 Base 1

2-07 Gib Strip 1

2-08 Column Base 1

2-09 Column Base Ring 1

2-10 Rack 1

2-11 Column Head 1

2-12 Gib Strip Bolt 2

2-13 Leaf Screw 2

2-13-2 Knob 2

2-14 Moveable Fixed Bock 2

2-15 Table Base Nut 1

2-16 Center Base 1

2-17 Antidust Plate 1

2-18 Antidust Plate 1

2-19 Antidust Plate 1

2-20 Table Clutch 1

2-22 Left Flange 1

2-23 Table Nut 1

2-24 Table Screw 1

2-26 Right Flange 1

2-27 Gib Strip 1

2-28 Table 1

2-29 Fixed Block 2

2-30 Moveable Fixed Ring 2

2-37 Base Screw Collar 1

2-121 Meter Indicator 4

2-131 Hex Head Bolt 4

2-143 Hex Set Screw 10

2-145 Hexagon 1

2-166 Spring Pin 3

2-167 Indicated Zero with Screw 2

2-168 Oil Ball 5

2-169 Hex Head Bolt 4

2-170 Washer 4

2-171 Hex Set Screw 10

2-172 Hex Head Bolt 4

2-173 Spring Washer 4

2-174 Hex Set Screw 2

2-175 Hex Set Screw 1

2-176 Hex Set Screw 2

Page 16

VERTICAL MILLING MACHINE, HEAD PARTS DIAGRAM

Please refer to Parts List on Pages 14 and 15.

NOTE: When ordering parts from this diagram, use prefix “1”. (example: P/N 1-01 Arbor Bolt Cover)

Page 16 SKU # 42827

Page 17

VERTICAL MILLING MACHINE, BASE PARTS DIAGRAM

Please refer to Parts List on Page 15.

NOTE: When ordering parts from this diagram, use prefix “2”.

(example: P/N 2-01 Table Handle with Wheel)

Page 17 SKU # 42827

Loading...

Loading...