Page 1

COMPACT BENDER

FLOOR

38470

ASSEMBLY INSTRUCTIONS & PROJECT IDEAS

Diagrams within this manual may not be drawn proportionally.

Due to continuing improvements, actual product may differ slightly from the product described herein.

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2000 by Harbor Freight Tools®. All rights reserved. No portion of this manual

or any artwork contained herein may be reproduced in any shape or form without the

express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Rev 08/00

Page 2

THANK YOU for choosing a HARBOR FREIGHT TOOLS product. For future reference, please complete the

owner’s record below:

Model___________ Serial No._____________ Purchase Date_____________

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating

and maintenance procedures, parts list and diagram. Keep your invoice with this manual.

Write the invoice number on the inside of the front cover. Keep the manual and invoice in a

safe and dry place for future reference.

Technical Specications

Tool Name: Compact Bender-Floor

Item Number: 38470

Dimensions: 10-1/8” W x 39-3/4”H x 35-3/4”L

Stand: .325” Steel

Mounting Holes: (4) ½”

Max. Width of Stock: 1-15/16”

Max. Stock Thickness: 5/16”

Max. Bar Stock Diameter: 5/8”

Dies: 1”, 1-1/4”, 1-1/2”, 1-3/4”, 2”, 2-1/2”, 3”

Tool Weight: 44 LBS.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always

be followed to reduce the risk of personal injury and damage to

equipment.

Read all instructions before using this product!

1. Avoid working alone. If an accident happens, an assistant can bring help.

2. Keep work area clean. Cluttered areas invite injuries.

3. Observe work area conditions. Keep work area well lighted.

4. Keep children away. Children must never be allowed in the work area. Do not let them handle

machines, tools, or extension cords.

5. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit rust. Always

lock up tools and keep out of reach of children.

6. Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving parts.

Protective, electrically nonconductive clothes and nonskid footwear are recommended when working.

Wear restrictive hair covering to contain long hair.

7. Use eye and ear protection. Always wear ANSI approved impact safety goggles.

8. Do not overreach. Keep proper footing and balance at all times.

#38470 Page 2

Page 3

9. Use the right tool for the job. Do not attempt to force a small tool or attachment to do the work of a

larger industrial tool. There are certain applications for which this tool was designed. Do not modify this

tool and do not use this tool for a purpose for which it was not intended.

10. Stay alert. Watch what you are doing, use common sense. Do not operate any tool when you are tired.

11. Check for damaged parts. Before using any tool, any part that appears damaged should be carefully

checked to determine that it will operate properly and perform its intended function. Check for alignment

and binding of moving parts; any broken parts or mounting xtures; and any other condition that may

affect proper operation. Any part that is damaged should be properly repaired or replaced by a qualied

technician. Do not use the tool if any switch does not turn On and Off properly.

12. Replacement parts and accessories. When servicing, use only identical replacement parts. Use of

any other parts will void the warranty. Only use accessories intended for use with this tool. Approved

accessories are available from Harbor Freight Tools.

13. Do not operate tool if under the inuence of alcohol or drugs. Read warning labels on prescriptions

to determine if your judgment or reexes are impaired while taking drugs. If there is any doubt, do not

operate the tool.

14. Maintenance. For your safety, maintenance should be performed regularly by a qualied technician.

Warning: The warnings, cautions, and instructions discussed in this instruction manual cannot

cover all possible conditions and situations that may occur. It must be understood by the operator that

common sense and caution are factors which cannot be built into this product, but must be supplied

by the operator.

WARNING: WELDING PRECAUTIONS

If you perform any welding using the materials that have been bent by this tool, it is important that

you remember that there are additional safety precautions that must be taken. Of course, you should

follow all warnings and instructions provided by the manufacturer of the welding equipment used.

Be aware of ying sparks. Only weld in an area that does not contain any materials which can be ignited by

ying sparks. Extinguish any signicant ying sparks before continuing to weld.

Protect yourself and others around you from burns which can be caused by ying sparks.

Make certain that you have a re extinguisher accessible.

Never weld in an atmosphere which might contain ammable fumes.

Periodically during welding, and after completion of a job, inspect your area for any ignition which may have

been caused by ying sparks.

Never leave your welder unattended while it is plugged in.

Always wear electrical insulating clothing, gloves and shoes while using your welder.

Flying sparks can cause injury, and hot materials can cause burns. Please wear appropriate safety clothing,

and observe precautions to prevent burns or injury to yourself or others.

Wear protective clothing such as heavy gloves, apron and boots.

Do not look directly into the welding arc without appropriate protective eye shields.

Do not allow others to look directly into the arc without appropriate eye protection.

Wear protective gloves while welding. Welding causes the metal to become very hot, which can cause burns.

Do not touch welded areas until you are certain they have completely cooled.

#38470 Page 3

Page 4

WARNING: WELDING PRECAUTIONS (Continued)

The electrode, and especially the welding rods become very hot during welding. Exercise extreme caution to

prevent burns to yourself or others.

NOTE: Read and adhere to all warnings and instructions in the instruction manual provided by the

manufacturer of the welder being used.

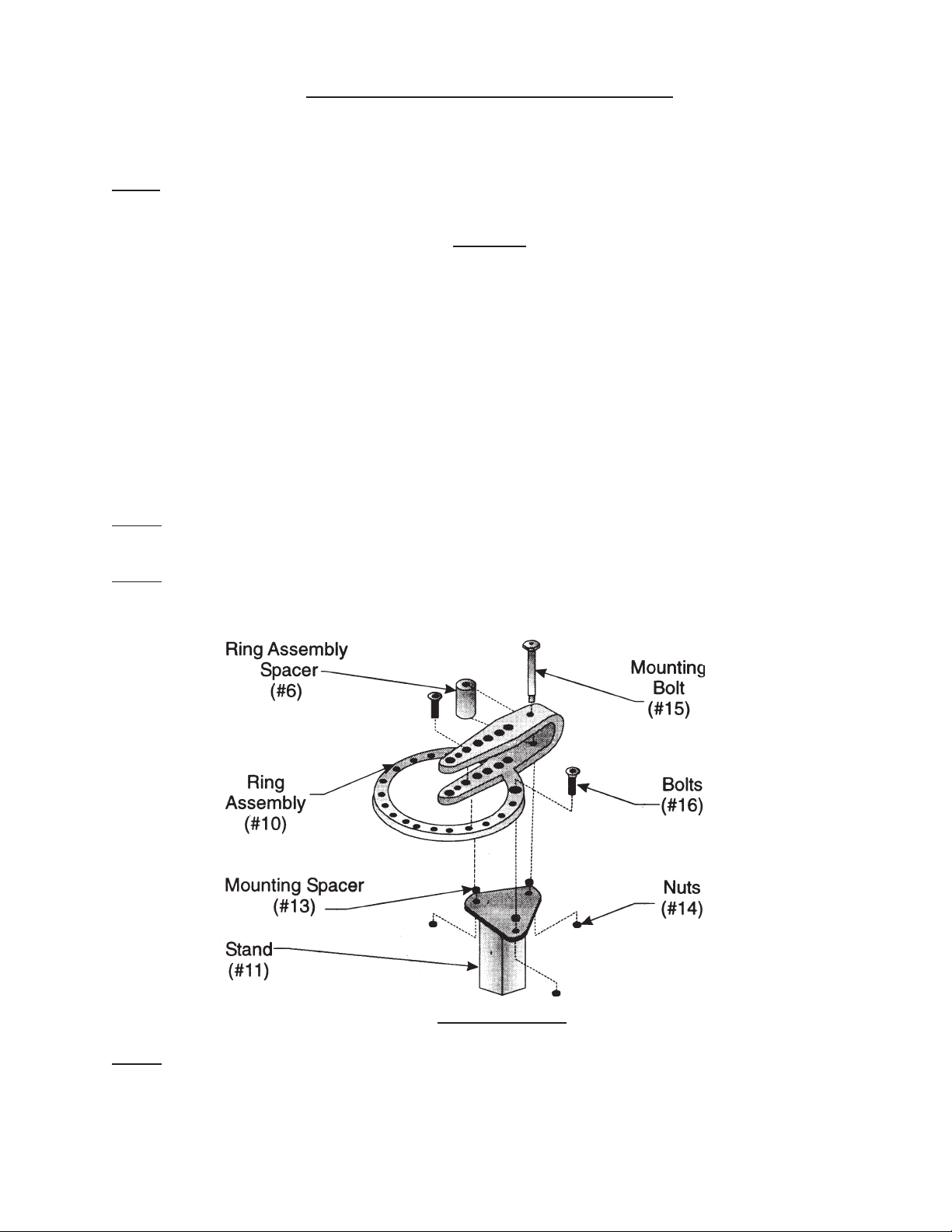

Assembly

Your Compact Bender-Floor will require complete assembly prior to operation. It is important that you read

the entire manual to become familiar with the unit BEFORE you use the Compact Bender. Before assembling

your Compact Bender be sure that you have all parts described in the Parts List on page 9.

When assembling your Compact Bender-Floor, it will be helpful to refer to each of the operational Figures as

well as to the Parts List and Assembly Diagrams on pages 9-11.

Mounting Surface: The mounting surface must be at, level and capable of supporting the weight of the

Compact Bender combined with the materials to be worked with.

Step 1) Bolt the Stand (#11) to a at, stable oor surface that is capable of supporting

the weight of this tool and the various workpieces to be used.

Step 2) Place the three (3) Mounting Spacers (#13) over each hole on the top of the Stand (#11)-see

Figure 1.

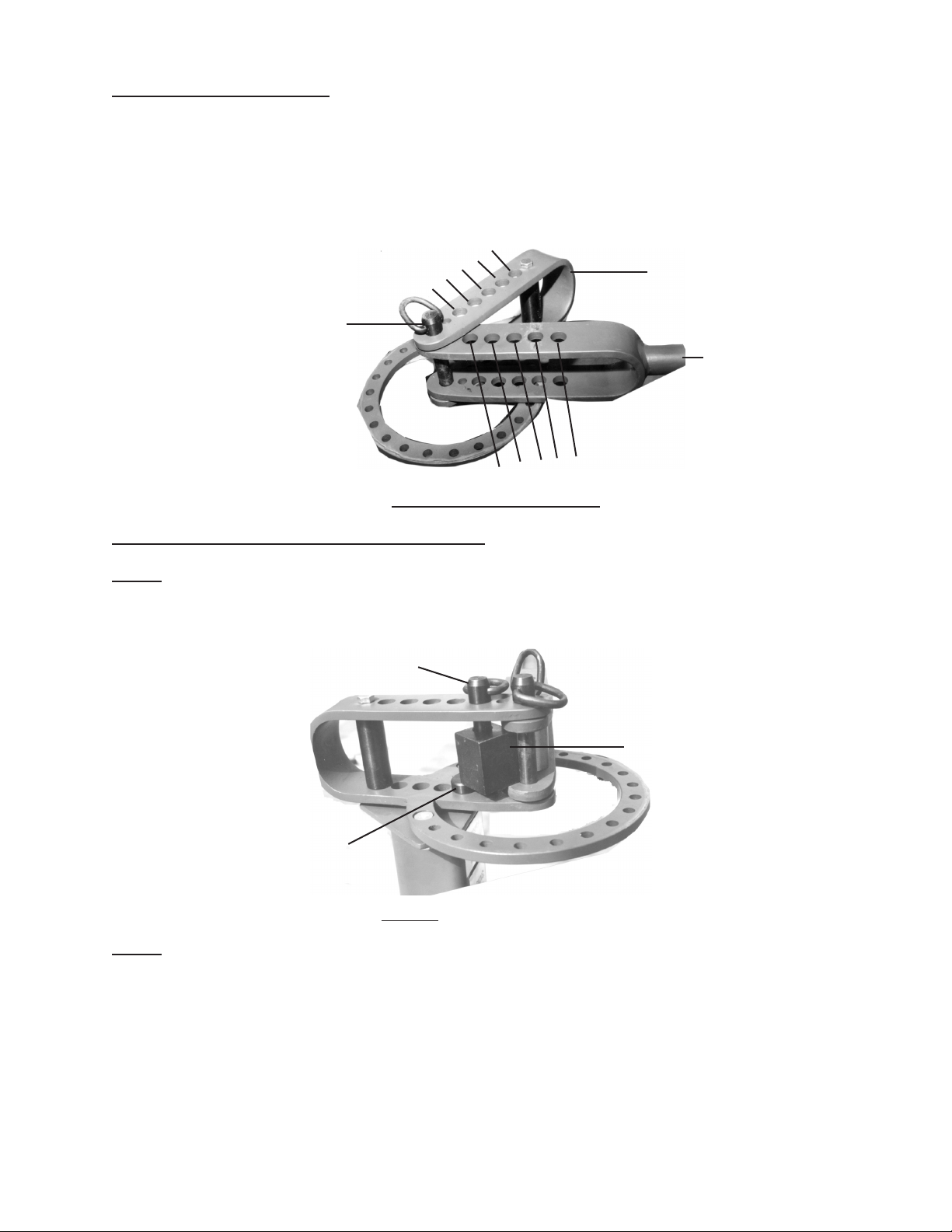

Mounting

Figure 1-Assembly

Step 3) Place the Ring Assembly/Die Receiver (#10) over the three Mounting Spacers (#13) so that

the two holes on the Ring Assembly (#10) line up with the corresponding Mounting Spacers (#13). Insert two (2) Mounting Bolts (#16) through the Ring Assembly (#10), Mounting

Spacer (#13) and Stand (#11). Tighten on Nuts (#14)-see Figure 1.

#38470 Page 4

Page 5

Step 4) Place the Ring Assembly Spacer (#6) inside the arms of the Ring Assembly/Die Receiver

(#10) between the back two holes-see Figure 1. Insert the Mounting Bolt (#15) through the

Ring Assembly/Die Receiver (#10), through the Ring Assembly Spacer (#6) and through the

bottom hole in the Ring Assembly/Die Receiver. Tighten it into place with the remaining Nut

(#14).

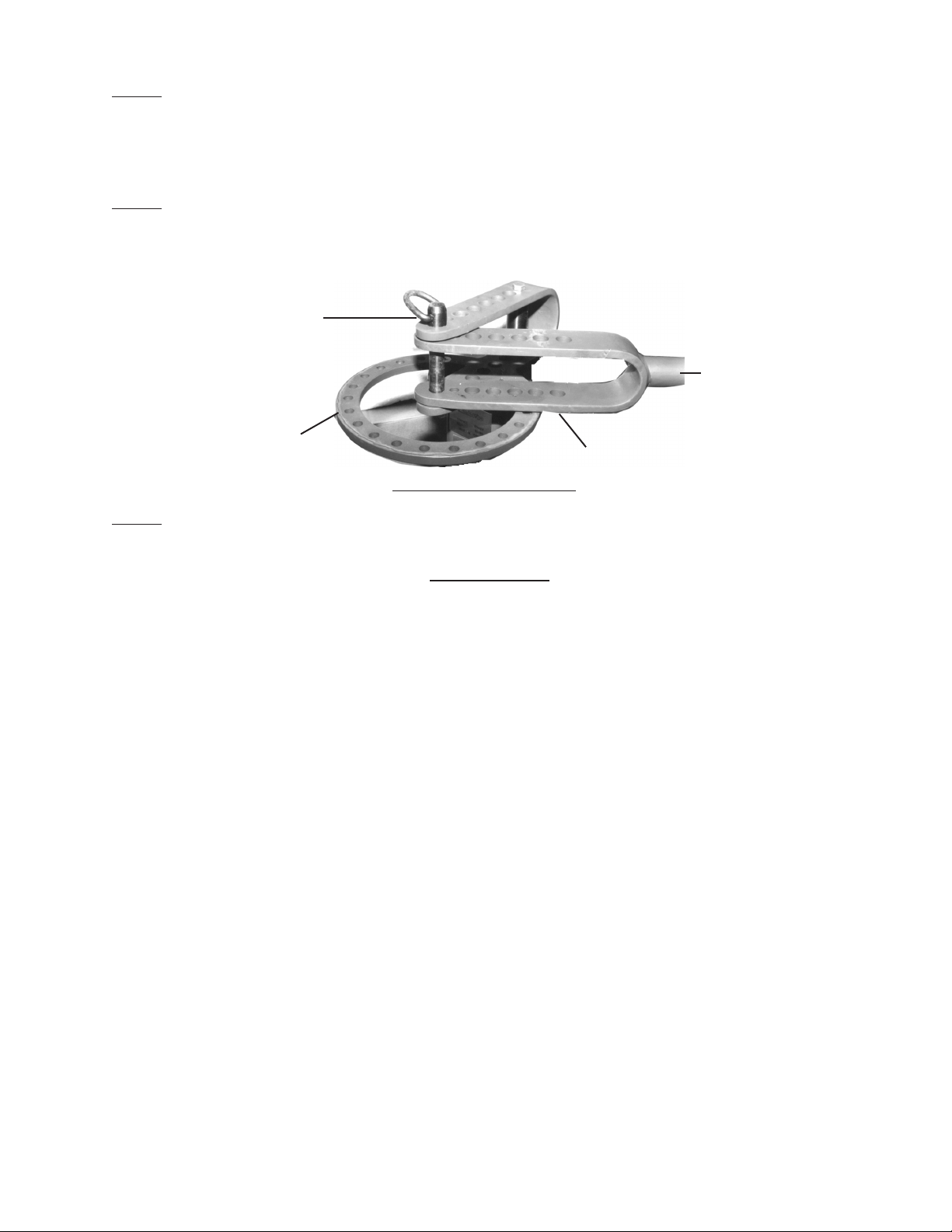

Step 5) The Inner Handle (#8) slides into the Outer Handle/ Die Receiver (#9) and is held in place by

a Handle Pin and Hair Clip (#12). The Inner Handle (#8) can be fully extended by pulling out

the Handle Pin and Hair Clip (#12) and pulling out the Inner Handle until the hole in the Outer

Handle (#9) lines up with the holes at the end of the Inner Handle (#8).

Long Hitch Pin (#1)

Inner Handle (#8)

not shown

Ring Assembly/Die Receiver (#10)

Figure 2-Assemble Handle

Step 6) Place the Outer Handle Die Receiver (#9) between the Die Receiver (#10) and secure it in

place using one of the Long Hitch Pins (#1).

Basic Operation

Following are instructions on the primary uses of your Compact Bender. Additionally, information is included

on the many ways to use your Compact Bender, along with specic examples. Becoming familiar with the

Compact Bender and its many uses will allow you to make a variety of useful items.

As the operator, you will have to decide on the way in which you will be using your Compact Bender. The following are the basic steps you will need to take when working with the Compact Bender.

Use an appropriate measuring device to measure and:

• Decide on material and measurements to be used.

• Decide on the appropriate Die. Decide on the best placement of the Die for your particular bend.

• Decide on the appropriate attachment, Stop Block or Right Angle Bend. Correct orientation of Stop

Block.

Outer Handle/Die Receiver (#9)

• Insert stock into the Bender and position it properly. Make the rst bend.

• Check the angle and direction of the bend.

• Make all consequent bends. Adjust the workpiece as needed.

Warning: Keep ngers and hands away from moving parts at all times.

#38470 Page 5

Page 6

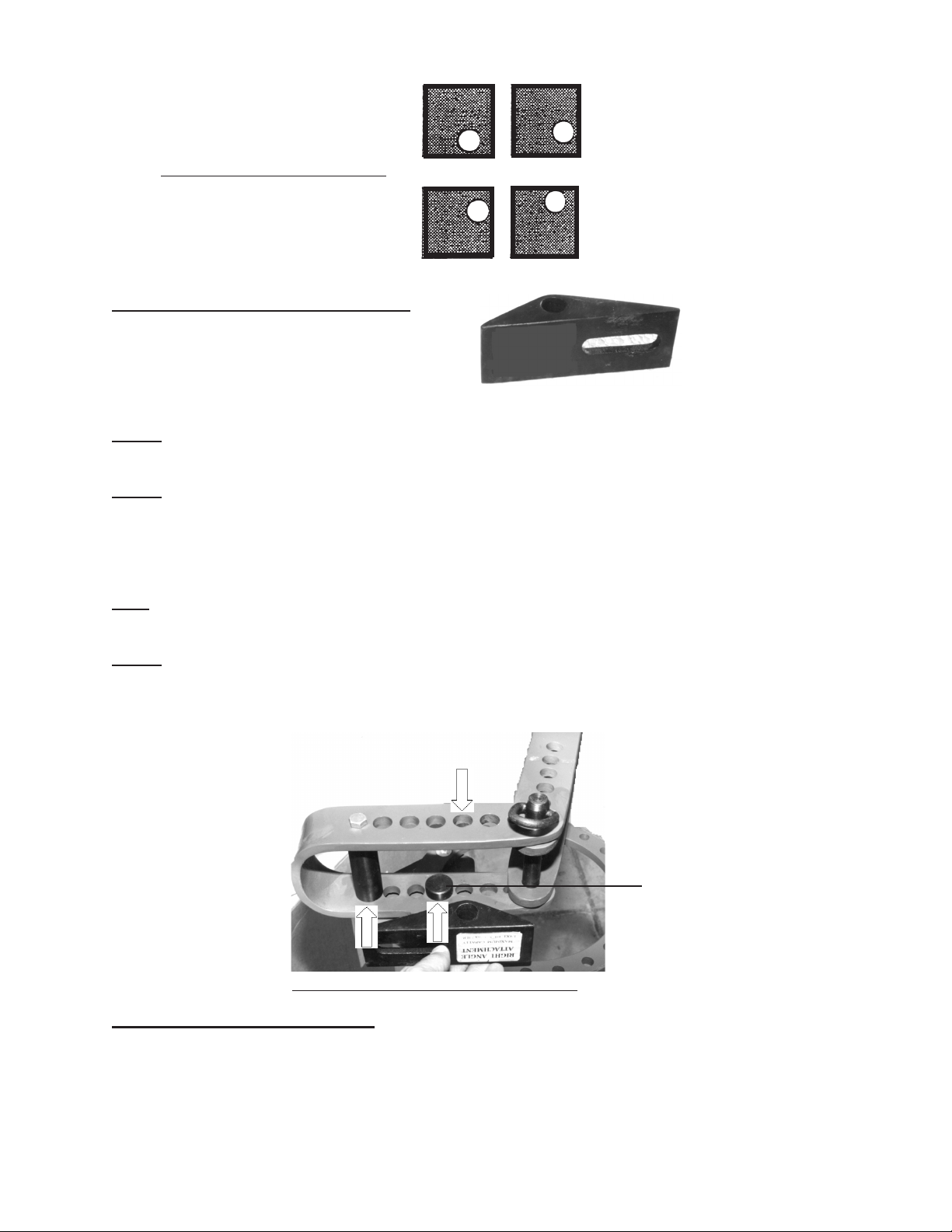

How the Holes Are Numbered

Throughout this manual, the holes are often identied by a specic number, i.e., the 3rd hole in the

Handle.There are ve (5) holes referred to in the Outer Handle/Die Receiver (#9) and 5 holes referred to

in the Ring Assembly (#10). For clarication of each hole and its corresponding number, please refer to

Figure 3 below.

5

4

3

2

1

Center Point

Figure 3 - Numbering of Holes

Use of the Support Pin with the Square Stop Block

4 5

2 3

1

Ring Assembly (#10)

Outer Handle (#9)

Step 1) Place the Support Pin (#5) into the hole under the Square Stop Block (#3) so that the Square

Stop Block (#3) will sit correctly in relation to the Ring Assembly/ Die Receiver-see Figure 4.

Long Hitch Pin (#1)

Square Stop Block (#3)

Support Pin (#5)

Figure 4

Step 2) Insert the Support Pin (#5) in the hole so that it sits under the Stop Block but does not block

the Long Hitch Pin (#1) from going through the hole in the Stop Block and into the lower hole

in the Ring Assembly (#10).

If the Stop Block is correctly placed you should not have to clamp the workpiece into place. When working

with exacting bends, however, it may be helpful to clamp the workpiece into place using vise-grip pliers.

#38470 Page 6

Page 7

Placement of Die

Dies are placed at one or two different locations depending on the bend to be made:

• A die can be used in conjunction with the Short Hitch Pin (#2) at the intersection of the Outer Handle/Die

Receiver (#9) and the Ring Assembly/Die Receiver (#10).

• The Die can also be placed on the Outer Handle/Die Receiver (#9).

• Two Dies can be placed so that one is on the Outer Handle/Die Receiver (#9) and one at the center point

where the Outer Handle/Die Receiver (#9) and Ring Assembly/Die Receiver (#10) intersect-see Figure 3.

Orientation of the Handle

The Handle is always oriented up and on the right side. The Handle is always moved clockwise

when a bend is being made.

Use of the Square Stop Block

The Stop Block is so named because it stops the workpiece from turning while the workpiece is being bent,

thus “stopping” movement of the workpiece.

When bending your workpiece, place the Square Stop Block (#3) over one of the holes in the Ring Assembly/

Die Receiver (#10). You will have to do some testing to determine placement of the Square Stop Block. You

will need to place it over the appropriate hole for the bend you desire and the Die you are using.

Step 1) There are four (4) key positions to place the Square Stop Block (#3) in while bending. The

four positions (as seen from looking down on the top of the Square Stop Block) are identied

in this manual by a letter; A, B, C, or D. See Figure 5 on the next page, for the letter and the

corresponding position of the Square Stop Block.

Warning: Always position the Stop Block so that it’s hole is oriented to the right side. Even

though another side of the Stop Block may actually face the work piece. If the hole is

oriented left instead of right, this will result in the Stop Block turning which will cause the

workpiece to move.

Step 2) Set the appropriate Die into place on the Outer Handle/Die Receiver (#9) between the upper

and lower fork. Secure the Die in place by inserting the Short Hitch Pin (#2) through the

Outer Handle/Die Receiver (#9) and the Square Stop Block. The Square Stop Block (#3) is

held in place against the stock as shown in Figure 7 on page 12.

Step 3) Set your workpiece into position. With the Handle (#9) in the starting position, set the Square

Stop Block (#3) as close to the Long Hitch Pin (#1) at the center position, as possible.

Note: To avoid large spaces between the Stop Block, the Center Pin and selected Die, orient the

Square Stop Block differently, or if possible, move it one hole closer to center.

#38470 Page 7

Page 8

Figure 5 - Stop Block Orientation

A

B

C

Use of the Right Angle Bend Attachment

You will want to use the Right Angle attachment

instead of the Stop Block when making a right angle

or sharp bend in the stock.

The Right Angle Attachment ts on the Compact Bender only one way.

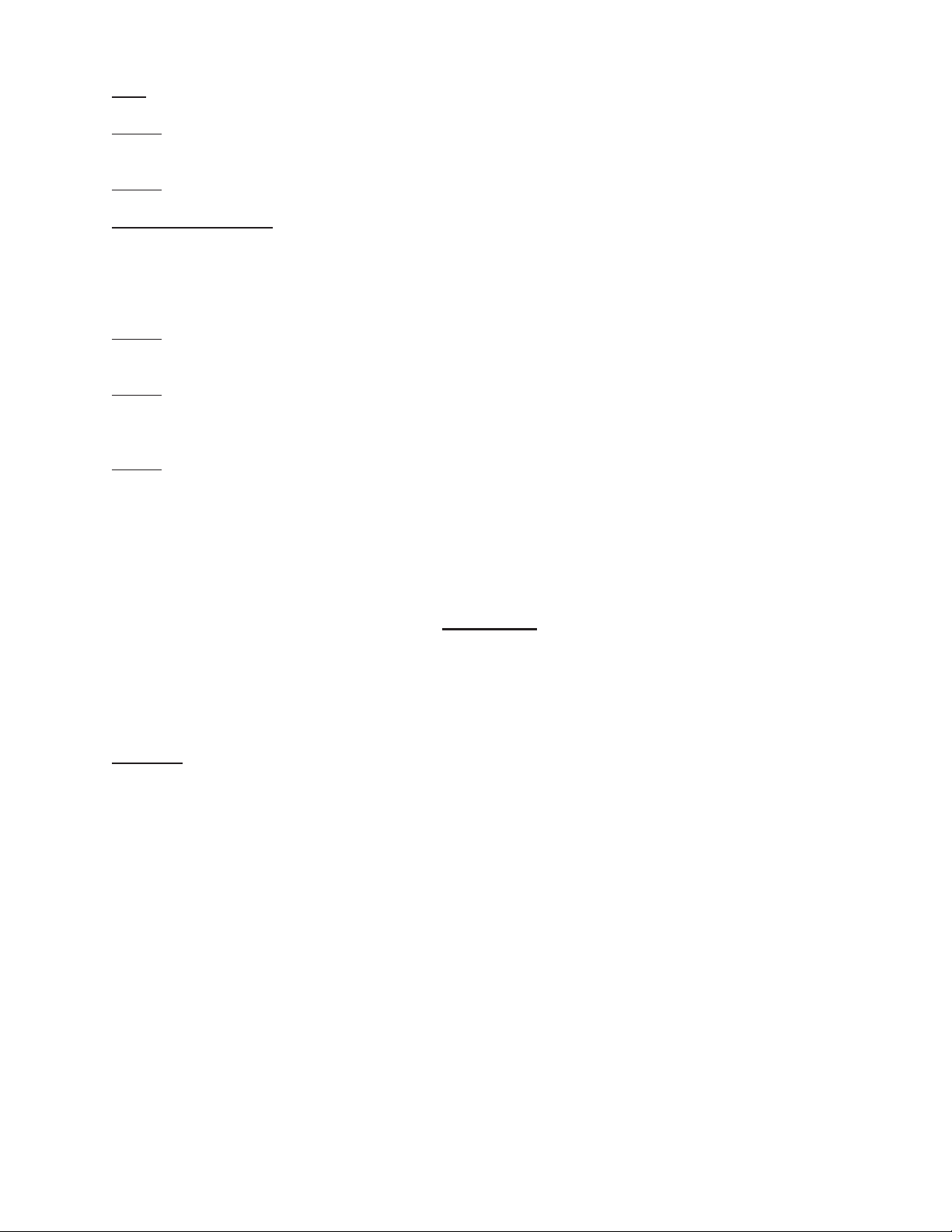

Step 1) Install the Support Pin (#5) under the Right Angle attachment. This will raise it up so that it

sits above the Ring Assembly/Die Receiver-see Figure 6.

Step 2) Set the Support Pin into the 3rd hole on the Ring Assembly/Die Receiver (#10). Line up the

hole in the top of the Right Angle Bending Attachment (#7) with hole #2 in the Ring

Assembly Die Receiver (#10)-see Figure 6. Insert the Long Hitch Pin (#1) through

the second hole in the Ring Assembly/Die Receiver(#10) to secure the Right Angle Bending

Attachment (#7) in place.

Note: Your workpiece will not need to be clamped when you are using the Right Angle

Bending Attachment (#7).

Step 3) Mark the stock at the points that you desire to make a bend. Line up the stock so that the

Right Angle Attachment hits directly at the midpoint of your mark.

D

Insert Long Hitch Pin (#1)

Support Pin (#5)

Figure 6-Right Angle Bending Attachment

The Stop and Adjustable Stop Loop

Many times while using the Bender you will need to make repeated bends of the same type and angle. In

these instances, using the Adjustable Stop Loop (#26) or the Stop (#4) will save time and allow for precisely

the same bends.

Adjust the Stop and Adjustable Stop Loop with a piece of scrap metal prior to using your actual workpiece.

This will assure accuracy and aid in obtaining ideal placement of the Stop.

#38470 Page 8

Page 9

Stop

Step 1) Test and decide the amount and distance of Handle rotation to make the desired

bend.

Step 2) Place the Stop (#4) into the next hole (clockwise) after your rotation is complete.

Adjustable Stop Loop

Use the Adjustable Stop Loop (#26) for stops where a ner adjustment is needed. The Adjustable Stop Loop

allows for more precise stops as it can be adjusted whereas the Stop (#4) is simply placed into a hole on the

Ring.

Step 1) Test and decide the amount and distance of Handle rotation to make the desired

bend.

Step 2) Place the Adjustable Stop Loop (#26) directly at the point where the rotation of the Handle

is to end. Insert Mounting Bolt (#25) through 3/8” Washer (#24) to hold the Adjustable Stop

Loop in place. Tighten on Washer (#24) and Nut (#27).

Step 3) Try a test bend and adjust the Adjustable Stop Loop (#26) as necessary to obtain a precise

bend.

Now that the basic operating instructions have been described; it is time to practice using the Compact

Bender. We are going to show you how to make several useful items such as handles and anchor bolts. We

will also show you how to make letters of the alphabet for use in making decorative signs. Once you practice

on the Compact Bender and learn its capabilities, it should be easy to come up with additional uses for the

Compact Bender based on your interests and work requirements..

Unpacking

UNPACK AND CHECK CONTENTS

When unpacking your Compact Bender check to make sure the following parts are included. If any parts are

missing or broken, please call HARBOR FREIGHT TOOLS at 1-800-444-3353.

Parts List

Part # Description Quantity Part # Description Quantity

1 Long Hitch Pin 2 15 3/8” x 5-1/4” Mounting Bolt 1

2 Short Hitch Pin 1 16 3/8” x 7/8” Mounting Bolt 2

3 Square Stop Block 1 17 1” Die 1

4 Stop 1 18 1-1/4” Die 1

5 Support Pin 1 19 1-1/2” Die 2

6 Ring Assembly Spacer 1 20 1-3/4” Die 1

7 Right Angle Bending Attachment 1 21 2” Die 1

8 Inner Handle 1 22 2-1/2” Die 1

9 Outer Handle/Die Receiver 1 23 3” Die 1

10 Ring Assembly/Die Receiver 1 24 3/8” Washer 2

11 Stand 1 25 3/8” x 1-3/8” Mounting Bolt 1

12 Handle Pin and Hair Clip 1 26 Adjustable Stop Loop 1

13 Mounting Spacer 3 27 3/8” Nut 1

14 3/8” Nut 4

Note: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

#38470 Page 9

Page 10

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE

BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT

OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN

FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL

REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK

AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT

OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION

OF REPLACEMENT PARTS THERETO.

Assembly Diagram “A”

10

#38470 Page 10

Page 11

Assembly Diagram “B”

10

#38470 Page 11

Page 12

MAKING HANDLES

Project Ideas

Round Stock

To make handles using round stock, the Square Stop Block (#3) is used rather than the Right Angle

Attachment.

Use a 10” piece of 5/8” round stock and two sections of at stock for the ends. The measurements given are

general guides only. Measurements should be adjusted according to your preferences and specic needs. If

changing stock size, you will have to experiment to obtain the best points for each bend.

Step 1) Place the Square Stop Block (#3) into place.

Square Stop Block (#3)

5/8” Round Stock

Figure 7

Step 2) With the Handle (part #8/9) in the normal position, place the 1” Die on the Center Pin. Place

the 2” Die in the 2nd hole- as in Figure 7. Insert the round stock so that the end extends 2”

down past the 1” Die - see Figure 7. Make the rst bend at 90 degrees.

Step 3) Remove the round stock from its original position. Place the second end into the

Bender in the same way as the rst bend. You want both ends to be bent in the

same direction. Make the second bend at 90 degrees. Remove from the Bender.

Step 4) Decide on how you want the round stock to t with the at stock. Drill 5/8” holes

into the at stock at the desired position. Insert the round stock into these holes.

Step 5) Weld the at stock into place from the side where the round stock exits the at

stock. Smooth away any excess weld material so that the handle sits ush in its place.

2” Die

Extend 2” past Die

1” Die

Flat Stock

To make handles using at stock, the Right Angle Bending Attachment (#7) is used rather than the Square

Stop Block (#3). Use a 10” (minimum) length of 3/4” wide x 1” thick hot-rolled at stock.

Step 1) Set the Right Angle Bending Attachment (#7) into place as previously outlined.

#38470 Page 12

Page 13

Step 2) Mark off the material as shown below. Insert the stock into the Bender to the rst mark.

Bend to 90 degrees.

1st Bend

1-3/4”

2nd 3rd

4th

1-3/4”1-3/4” 1-3/4”

Step 3) You may want to set up the Bender with the Adjustable Stop for repeated bends.

Step 4) Flip the stock around and insert the end opposite the bend. Insert it to the 2nd mark and

make a 90 degree bend.

Step 5) Reverse the stock and make the 3rd bend at the 3rd mark. Repeat for the other end and

make a bend at the 4th mark.

Step 6) With a sander or grinder remove any sharp edges or rough spots.

MAKING TUBE CLAMPS

Single Tube Clamp

Figure 8

The following instructions are for a 1” Inner Diameter tube clamp using 4-1/2” long, 3/16” thick x 1” wide at

stock. See Figure 7 as a reference.

Step 1) Place a 1” die on the center point hole and secure it in place with the Long Hitch Pin (#1).

Step 2) Using the Short Hitch Pin (#2), place a 1-1/2” die in the Outer Handle 2nd hole.

Step 3) Set the Square Stop Block (#3) into the 1st hole on the Ring Assembly (#10).

Orient it as in B (Figure 5 on page 8 of this manual).

Square Stop Block (#3)

Outer Handle (#9)

1” Die

Center Point Hole

1-1/2” Die

2”

Figure 9

Step 4) Insert the at stock into the Bender so that it extends 1-3/4” beyond the center point.

Secure the stock into position against the Square Stop Block (#3) with a clamp or vise grip.

#38470 Page 13

Page 14

Step 5) Bend the stock past 180° until the die on the Outer Handle slides off of the stock.

Step 6) Remove the Square Stop Block (#3) and the die. Put on the Right Angle Bending

Attachment (#7).

Step 7) With the workpiece as tight against the Long Hitch Pin (#1) in the center as is

possible, make a right angle bend-see Figure 10.

Figure 10

MAKING ANCHOR BOLTS-U BOLTS

Figure 11

Following the directions shown below will allow you to make a 12” Anchor Bolt from a 14-1/4” blank (see Figure 11 above).

As with all bending, you can make shorter or longer Anchor Bolts by changing the size of the blank. Use a

scrap piece to experiment with length and placement of bends.

Step 1) Place a 1” die on the center point hole and secure in place with the Long Hitch Pin (#1).

Step 2) Using the Short Hitch Pin (#2), place a 2” die in the Outer Handle 2nd hole.

Step 3) Using the Long Hitch Pin (#1) set the Square Stop Block (#3) into place. Set

the Stop Block in either position B or D (see section: Using the Square Stop Block). Position

B (3/8” or 1/2” diameter bolts) or D (5/8” diameter) according to the bolt being used.

Step 4) Place the stock into the Bender so that the unthreaded end is extended sufciently beyond

the Square Stop Block (#3) - 1/2” for 3/8” bolts; 5/8” for 1/2” bolts, and 1/4” for 5/8” bolts).

Step 5) Move the Outer Handle (#9) until you have obtained a 90 degree bend.

#38470 Page 14

Page 15

Length

Inner

Diameter

#38470 Page 15

Page 16

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality

and durability standards, and warrants to the original purchaser that this product is free from

defects in materials and workmanship for the period of 90 days from the date of purchase. This

warranty does not apply to damage due directly or indirectly, to misuse, abuse, negligence or

accidents, repairs or alterations outside our facilities, criminal activity, improper installation,

normal wear and tear, or to lack of maintenance. We shall in no event be liable for death, injuries to persons or property, or for incidental, contingent, special or consequential damages

arising from the use of our product. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation of exclusion may not apply to

you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection veries the defect, we will either repair or

replace the product at our election or we may elect to refund the purchase price if we cannot

readily and quickly provide you with a replacement. We will return repaired products at our

expense, but if we determine there is no defect, or that the defect resulted from causes not

within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specic legal rights and you may also have other rights which

vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

#38470 Page 16

Page 17

MAKING INDIVIDUAL LETTERS OF THE ALPHABET

Directions and tips for creating each letter of the alphabet are

included in the following section. The information given is based on

use of 3/16” at stock, and a 1” max. width. The letters created by using

these steps are six (6”) high and 1” deep.

When creating each letter make certain that you use hot-rolled mild steel. Aluminum can also be used.

The steps are fairly precise, but as with all bending functions you may create you own unique designs and

measurements through trial and error. Use a scrap piece of metal for practice prior to creating the actual

workpiece.

Use a protractor to measure each angle.

To make the following letters use the Right Angle Bend Attachment (#7) for each bend.

Tip: Always double check the measurements on each angle you bend.

Note: Use the Stop or Adjustable Stop for repeated bends at the same angle.

Note: After each letter has been formed, smooth away any sharp edges using a grinder or by

sanding.

The Letter “A”

Two blanks are required for this letter:

• 14” long

2nd

1st Bend

• 3-1/2” long

6” 6”2”

Step 1) Using chalk, mark off six inches (6”). Mark off two inches (2”), and then another six

inches (6”).

Step 2) Set the Right Angle Bend Attachment into place.

Step 3) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the rst

chalk mark. Bend to 76°.

Step 4) Make a bend at the second chalk mark. Bend to 76°.

Step 5) Weld the 3-1/2” blank into place about half-way between the legs to nish forming the letter

“A”.

#38470 Page 17

Page 18

The Letter “B”

Three blanks are required for this letter:

• 8-7/8” long

• 8-7/8” long

• 6” long

3rd

4th

2nd

1st Bend

2-3/4”

Step 1) Using chalk mark off 2-3/4” in from each side. Mark off one inch from the rst chalk mark on

each side.

Do the same for the second 8-7/8” blank.

Step 2) Set the Right Angle Bend Attachment into place.

Step 3) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the rst

chalk mark. Bend to 45 degrees.

Step 4) Move the stock to the second chalk mark and bend to 45°.

.

Step 5) Pull the stock out of the bender and insert the stock with the opposite end in the

bender. Make the 3rd bend at 45 degrees.

Step 6) Slide the stock to the fourth position and bend to 45°.

.

Step 7) Weld the completed two 8-7/8” pieces together, these will be the curves in the letter “B”.

Weld on the 6” piece to form the spine of the letter.

1”

2-3/4”1”

The Letter “C”

One blank is required for this letter:

• 14” long

3rd

4th

3-3/4” 3-3/4”

1-1/4”

Step 1) Using chalk, mark off 3-3/4” in from each side.

Step 2) From the inside mark, measure in another 1-1/4” and mark it off from each side.

Step 2) Set the Right Angle Bend Attachment into place.

Step 3) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the rst

chalk mark. Bend to 45°.

.

Step 4) Make a bend at your second chalk mark to 45°.

Step 5) Take the stock out of the Bender. Insert the second side. Repeat steps 3 and 4.

#38470 Page 18

1st Bend2nd

1-1/4”

Page 19

The Letter “D”

Two blanks are required for this letter:

• 12-1/2” long

• 6” long

3rd

4th

2nd

1st Bend

3”

1-1/4”

Step 1) Using long blank, mark off 3” in from each side. Then measure in and mark off 1-1/4” on

each side.

Step 2) Make a bend to 45°at the rst chalk mark. Slide the stock to the second

mark and bend to 45°.

Step 3) Pull out the stock and insert the opposite end. Repeat step 2.

Step 4) Make certain that both ends of the “D” are equal.

Step 5) Weld on the 6” piece to form the spine of the letter.

The Letter “E”

Two blanks are required for this letter:

• 14-9/16” long

• 2-1/2” long

2nd

1-1/4”

3”

1st Bend

4-1/2”4-1/2”

Step 1) Using the long blank, mark off 4-1/2” in from each side.

Step 2) Make a bend to 90° at the rst chalk mark.

Step 3) Take out the stock and insert the other end. Make a bend to 90° at the rst chalk mark.

Step 4) Make certain that the top and bottom of the “E” are parallel.

Step 5) Weld on the 2-1/2” piece at the center of the E.

Step 6) Smooth away any sharp edges using a grinder or sanding.

#38470 Page 19

Page 20

The Letter “F”

Two blanks are required for this letter:

• 10-1/2””

• 2-1/2”

Step 1) Using the long blank, mark off 4-9/16” in from one side.

Step 2) Make a bend to 90° at the rst chalk mark.

Step 3) Weld on the 2-1/2” piece at the center of the F.

The Letter “G”

Two blanks are required for this letter:

• 14” long

• 3” long

Step 1) Using chalk, mark off 3-3/4” in from each side of the long blank. Mark off one inch on each

side as shown above.

3rd 4th

3-3/4” 3-3/4”1”

1st Bend

1st Bend2nd

1”

1st Bend

1”

Step 2) Set the Right Angle Bend Attachment into place.

Step 3) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the rst

chalk mark. Bend to 45°.

.

Step 4) Make a bend at your second chalk mark to 45°.

Step 5) Take the stock out of the Bender. Insert the second side. Repeat steps 3 and 4.

Step 6) Mark off 1” on the 3” blank.

Step 7) Set the blank into the Bender at the chalk mark. Bend to 90°.

Step 8) Weld the 1” side of the 3” piece to the bottom portion of the “G” . The longer side of the 3”

blank will form the inside part of the G.

The Letter “H”

Three blanks are required for this letter:

• 6”

• 6”

• 3-3/4”

Step 1) Weld the 3-3/4” blank to the center of each 6” blank. Make certain that both 6”

blanks are even with each other.

#38470 Page 20

Page 21

The Letter “I”

Three blanks are required for this letter:

• 5”

• 5”

• 5-5/8”

Step 1) Weld the 5-5/8” blank to the center of each 5” blank. Make certain that both 5” blanks are

equally opposite each other.

The Letter “J”

One blank is required for this letter:

• 11”

Step 1) Using chalk, mark off 1-1/4” from one side. From this mark, mark off 3-1/4”.

From the second mark, mark off another 1-1/4”.

Step 2) Set the Right Angle Bend Attachment into place.

Step 3) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the rst

chalk mark. Bend to 45°.

Step 4) Move the blank to the second chalk mark. Bend to 45 degrees

Step 5) Move the blank to the third chalk mark and bend to 20 degrees.

The Letter “K”

Two blanks are required for this letter:

• 7” long

• 6” long

3-1/2” 3-1/2”

3rd

1-1/4”

1st Bend

2nd

3-1/4”

1st Bend

1-1/4”

Step 1) On the 7” blank, mark off 3-1/2”.

Step 2) Set the Right Angle Bend Attachment into place.

Step 3) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the rst

chalk mark.

Step 4) Make a bend in the 7” piece so that an angle is obvious, but so that it measures

6” when measured tip to tip. Weld the 7” blank to the center of the 6” blank.

The Letter “L”

One blank is required for this letter:

• 10-3/8” long

Step 1) Mark off 4-9/16”” in from one side.

Step 2) Make a bend to 90° at the rst chalk mark.

#38470 Page 21

1st Bend

4-9/16”

Page 22

The Letter “M”

Two blanks are required for this letter:

• 13-1/2” long

• 13-1/2” long

Step 1) For each blank, mark off 6” in from one side.

Step 2) Make a bend to 75° at the rst chalk mark.

Step 3) Move the blank to the second mark and bend to 75°. Repeat for the second

blank.

Step 4) Tack weld the two pieces together at one end. Make certain that all four tips are level with

one another.

The Letter “N”

Three blanks are required for this letter:

• 8-1/16” long

• 6” long

• 6” long

Step 1) On the 8-1/16” blank, mark off 1” in from each side.

1” 1”

6”

2nd

2nd

1st Bend

6”

1st Bend

Step 2) Make a bend to about 73° at the rst chalk mark.

Step 3) Move the blank to the second mark and bend to about 73°.

Step 4) Tack weld the one 6” piece to each end. Make certain that all three ends are

level with one another.

The Letter “O”

Two blanks are required for this letter:

• 14” long

• 3-7/8” long

1-1/4”

Step 1) Making the letter O is essentially the same as the letter C on page 17. Using chalk, mark off

1-1/4” in from each side. Then from the rst mark, mark off 2-1/2” on each side.

Step 2) From the inside mark, measure in another 1-1/4” and mark it off.

Step 3) Set the Right Angle Bend Attachment into place.

1-1/4” 1-1/4”

1st Bend234 5 6

1-1/4”2-1/2” 2-1/2”

Step 4) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the

rst chalk mark. Bend to 45°.

#38470 Page 22

Page 23

Step 5) Make a bend at your second chalk mark to 45 degrees. Repeat for the third

mark.

Step 6) Take the stock out of the Bender. Insert the second side. Repeat steps 3 and 4.

Step 7) Weld the 3-7/8” piece to the open side so that a complete circle is formed.

The Letter “P”

Two blanks are required for this letter:

• 8-7/8” long

• 6” long

Step 1) Making the top portion of the letter “P” is

essentially the same as the letter C on page 17.

Using chalk, mark off 2-3/4” in from each side of the

long blank. Mark off one inch on each side.

Step 2) Set the Right Angle Bend Attachment into place.

Step 3) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the

rst chalk mark. Bend to 45°.

Step 4) Move the stock to the second chalk mark and bend to 45°.

Step 5) Pull the stock out of the bender and insert the stock with the opposite end in the

bender. Make the 3rd bend at 45°.

Step 6) Slide the stock to the fourth position and bend to 45°.

Step 7) Weld on the 6” piece to form the spine of the letter.

3rd 4th

2-3/4”

1”

2nd

1st Bend

1”

2-3/4”

The Letter “Q”

Four blanks are required for this letter:

• 14” long

2nd

• 3-7/8” long

• 2” long

• 3/4” long

Step 1) Refer to making the letter “O” on page 21. Using chalk, mark off 1-1/4” in from each side.

Then from the rst mark, mark off 2-1/2” on each side.

Step 2) From the inside mark, measure in another 1-1/4” and mark it off.

Step 3) Set the Right Angle Bend Attachment into place.

Step 4) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the rst

chalk mark. Bend to 45°.

#38470 Page 23

4th

5th 6th

2-1/2”

1-1/4”

3rd

1-1/4”1-1/4”

1st Bend

2-1/2”

1-1/4”

Page 24

Step 5) Make a bend at your second chalk mark to 45 degrees. Repeat for the third mark.

Step 6) Take the stock out of the Bender. Insert the second side. Repeat steps 4 and 5.

Step 7) Weld the 3-7/8” piece to the open side so that a complete circle is formed.

Step 8) Weld the two short pieces to the right bottom corner of the circle you just completed. The 2”

blank should be welded to the inside, with the 3/4” blank on the outside.

The Letter “R”

Two blanks are required for this letter:

• 8-7/8”

• 6”

• 3-1/8”

Step 1) Refer to directions for making a “P” on page 22. Using chalk, mark off 2-3/4” in from each

side of the long blank. From this rst mark, mark off one inch on each side.

Step 2) Set the Right Angle Bend Attachment into place.

Step 3) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the rst

chalk mark. Bend to 45°.

2-3/4”

3rd 4th

1”

2nd

1st Bend

1”

2-3/4”

Step 4) Move the stock to the second chalk mark and bend to 45°.

Step 5) Pull the stock out of the bender and insert the stock with the opposite end in the

bender. Make the 3rd bend at 45°.

Step 6) Slide the stock to the fourth position and bend to 45°.

Step 7) Weld the loop to the top of the 6” piece to form a letter “P”.

Step 8) Weld the 3-1/8” blank opposite the leg of the “P”. You will have to weld it at a

slight outward angle to form an “R”.

The Letter “S”

One blank is required for this letter:

• 16-1/2”

Step 1) Mark off the blank as indicated above.

3-5/8”

4th

7th

1”

1-1/4”

1”

5th6th

3rd

1”

1-1/4”

8th

1st Bend2nd

3-5/8”1”

Note: The thin bend lines shown above (for bends 4, 5, 6 and 7) must be on the opposite side of

the blank from the four marks on the front side of the blank (#1, 2, 3, and 8).

Step 1) Using chalk, mark off 3-5/8” in from each side. Mark off one inch on each side-see

Figure above.

#38470 Page 24

Page 25

Step 2) Set the Right Angle Bend Attachment into place.

Step 3) Set the stock in the Bender so that the Right Angle Bend Attachment will bend at the rst

chalk mark. Bend to 45°.

Note: The 2nd and 5th bends are to 41°.

Step 4) Move the blank to the second mark and bend it to 41°.

Step 5) At the third mark bend to 45°.

Step 6) Remove the blank from the Bender. Flip it over and around and insert the other

side. At the #4 mark, bend to 45°.

Step 7) At the fth mark, bend to 41° only.

Step 8) Move the blank to the sixth mark and bend to 45°. Repeat for the seventh mark.

Step 9) Once more remove the blank from the Bender and insert the other side. This may require

moving the Right Angle Bend Attachment, inserting the blank and putting back on the Right

Angle Bend Attachment. Make certain that the stock is facing the correct way in the Bender.

At the #8 mark, bend to 45°.

The Letter “T”

Two blanks are required for this letter:

• 6” long

• 5-1/2” long (You may want to try different lengths for a different look).

Step 1) Weld the 5-1/2” blank to the center of the 6” blank.

The Letter “U”

One blank is required for this letter:

4th

• 14-3/4” long

Step 1) Mark off 5” from each side. After this, mark off another 1-1/4” from each side.

Step 2) Place the blank on the Bender at the rst chalk mark. Bend to 45. Move the blank to the

second chalk mark and bend to 45°.

Step 3) Move the blank to the 3rd chalk mark and bend to 45°.

Move the blank to the 4th mark and bend to 45 degrees.

The Letter “V”

One blank is required for this letter:

• 13-1/2” long

3rd

5” 5”

1-1/4” 1-1/4”

2nd

1st Bend

2nd

1st Bend

6”6”

Step 1) Mark off 6” in from one side.

Step 2) Make a bend to 75°at the rst chalk mark.

#38470 Page 25

Page 26

Step 3) Move the blank to the second mark and bend to 75°.

The Letter “W”

The letter “W” is formed the same way as the letter “M” on page 21.

The Letter X

Two blanks are required for this letter:

• 7-1/2” long

• 7-1/2” long

3-1/4”

Step 1) Place a mark at the center of each blank at the 3-3/4” mark.

Step 2) Make a bend in the blank so that an angle is obvious, but so that it measures

6” when measured tip to tip. Repeat for the second blank.

Step 3) Weld the two pieces together making certain that all sides are level and equidistant.

1st Bend

3-1/4”

The Letter Y

Two blanks are required for this letter:

• 9-1/2” long

• 3-3/4” long

3-1/4” 3-1/4”

Step 1) Measure 3-1/4” in from each side of the 9-1/2” blank.

Step 2) Insert the blank into the Bender and make bends short of 90°(around 80°) at each mark.

Step 3) Weld the 3-3/4” blank to the center of the bottom part of the “Y” which you have just formed.

The Letter Z

Three blanks are required for this letter:

• 7-1/2” long

• 4-1/2” long

• 4-1/2” long

Step 1) Measure 1” in from each side of the 7-1/2” blank.

2nd

1” 1”

1st Bend

1st Bend2nd

Step 2) Place the blank onto the Bender. At the rst mark, make a bend to 50°. Take out the blank

and insert the second end. At the mark, make another bend to 50°.

Step 3) Weld the 4-1/2” pieces to each side of the 7-1/2” piece. The 4-1/2” pieces should be parallel

to each other.

#38470 Page 26

Page 27

Please be aware that Harbor Freight Tools offers for sale two attachments that are used with the Compact

Bender:

Scroll Bending Attachment (SKU #36621) and Twister Attachment (SKU #36620)

We have included here the Ornamental Wrought Iron Idea and Design Booklet, which gives you some

ideas on projects that can be accomplished using the Scroll Bending Attachment and the Twister

Attachment.

#38470 Page 27

Loading...

Loading...