Page 1

Oscillating spindle sander

Model

38160

asseMbly and Operating instructiOns

Visit our website at: http://www.harborfreight.com

read this material before using this product.

Failure to do so can result in serious injury.

saVe this Manual.

Copyright© 1998 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork contained

herein may be reproduced in any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing improvements, actual product may

differ slightly from the product described herein. Tools required for assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

revised Manual 10c

Page 2

saVe this Manual

Keep this manual for the safety warnings

and precautions, assembly, operating,

inspection, maintenance and cleaning

procedures. Write the product’s serial number

in the back of the manual near the assembly

diagram (or month and year of purchase if

product has no number). Keep this manual

and the receipt in a safe and dry place for

future reference.

iMpOrtant saFety

inFOrMatiOn

in this manual, on the labeling, and

all other information provided with

this product:

this is the safety alert

symbol. it is used to alert

you to potential personal

injury hazards. Obey all

safety messages that follow

this symbol to avoid possible

injury or death.

danger indicates a

hazardous situation

which, if not avoided, will result

in death or serious injury.

Warning indicates a

hazardous situation

which, if not avoided, could

result in death or serious injury.

nOtice is used to

address practices not

related to personal injury.

cautiOn, without the

safety alert symbol, is

used to address practices not

related to personal injury.

general tool safety Warnings

Warning read all safety warnings

and instructions. Failure to follow the

warnings and instructions may result

in electric shock, re and/or serious

injury.

save all warnings and instructions

for future reference.

KEEP GUARDS IN PLACE and in 1.

working order.

REMOVE ADJUSTING KEYS AND 2.

WRENCHES. Form habit of checking to

see that keys and adjusting wrenches

are removed from tool before turning it

on.

KEEP WORK AREA CLEAN. Cluttered 3.

areas and benches invite accidents.

DON’T USE IN DANGEROUS 4.

ENVIRONMENT. Don’t use power tools

in damp or wet locations, or expose them

to rain. Keep work area well lighted.

KEEP CHILDREN AWAY. All visitors 5.

should be kept safe distance from work

area.

cautiOn, used with

the safety alert

symbol, indicates a hazardous

situation which, if not avoided,

could result in minor or moderate

injury.

Page 2 For technical questions, please call 1-800-444-3353. SKU 38160

MAKE WORKSHOP KID PROOF 6.

with padlocks, master switches, or by

removing starter keys.

DON’T FORCE TOOL. It will do the job 7.

better and safer at the rate for which it

was designed.

reV 10e

Page 3

USE RIGHT TOOL. Don’t force tool or 8.

attachment to do a job for which it was

not designed.

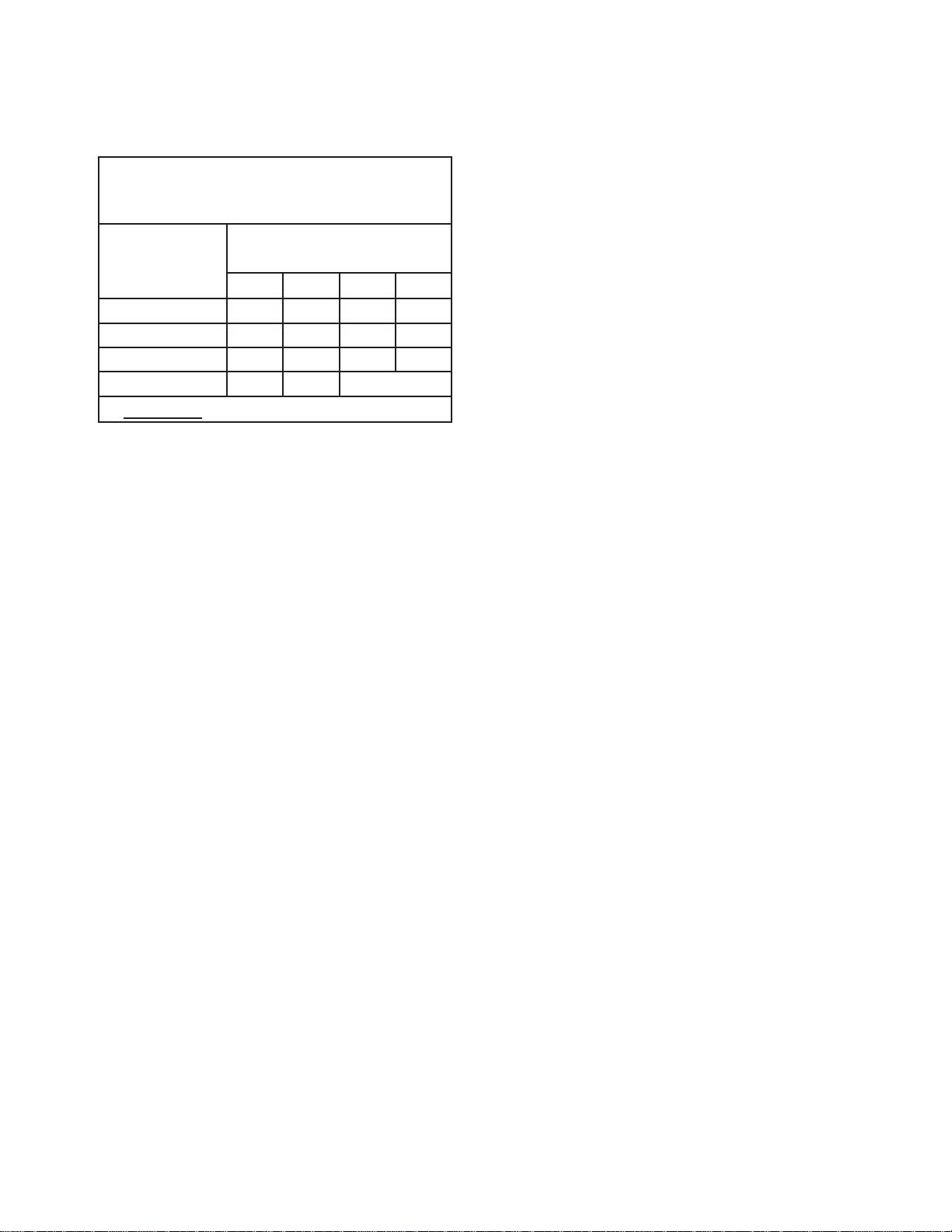

recOMMended MiniMuM Wire

gauge FOr eXtensiOn cOrds

(120 VOlt)

naMeplate

aMperes

(at full load)

0 – 6 18 16 16 14

6.1 – 10 18 16 14 12

10.1 – 12 16 16 14 12

12.1 – 16 14 12

eXtensiOn cOrd

length

25’ 50’ 100’ 150’

do not use.

table a

13.

DON’T OVERREACH. Keep proper

footing and balance at all times.

14.

MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for best and safest

performance. Follow instructions for

lubricating and changing accessories.

DISCONNECT TOOLS before servicing;

15.

when changing accessories, such as

blades, bits, cutters, and the like.

REDUCE THE RISK OF 16.

UNINTENTIONAL STARTING. Make

sure switch is in off position before

plugging in.

USE PROPER EXTENSION CORD. 9.

Make sure your extension cord is in good

condition. When using an extension

cord, be sure to use one heavy enough

to carry the current your product will

draw. An undersized cord will cause a

drop in line voltage resulting in loss of

power and overheating. Table A shows

the correct size to use depending on

cord length and nameplate ampere

rating. If in doubt, use the next heavier

gauge. The smaller the gauge number,

the heavier the cord.

WEAR PROPER APPAREL. Do not wear 10.

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Nonslip footwear

is recommended. Wear protective hair

covering to contain long hair.

ALWAYS USE SAFETY GLASSES. Also 11.

use face or dust mask if cutting operation

is dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT

safety glasses.

SECURE WORK. Use clamps or a vise 12.

to hold work when practical. It’s safer

than using your hand and it frees both

hands to operate tool.

reV 10e

USE RECOMMENDED ACCESSORIES. 17.

Consult the owner’s manual for

recommended accessories. The use of

improper accessories may cause risk of

injury to persons.

NEVER STAND ON TOOL. Serious 18.

injury could occur if the tool is tipped

or if the cutting tool is unintentionally

contacted.

CHECK DAMAGED PARTS. Before 19.

further use of the tool, a guard or other

part that is damaged should be carefully

checked to determine that it will operate

properly and perform its intended

function – check for alignment of moving

parts, binding of moving parts, breakage

of parts, mounting, and any other

conditions that may affect its operation.

A guard or other part that is damaged

should be properly repaired or replaced.

DIRECTION OF FEED. Feed work into 20.

a blade or cutter against the direction of

rotation of the blade or cutter only.

NEVER LEAVE TOOL RUNNING

21.

UNATTENDED. TURN POWER OFF.

Don’t leave tool until it comes to a

complete stop.

Page 3For technical questions, please call 1-800-444-3353.SKU 38160

Page 4

grOunding instructiOns

tO preVent

electric shOck

and death FrOM incOrrect

grOunding Wire

cOnnectiOn

read and FOllOW these

instructiOns:

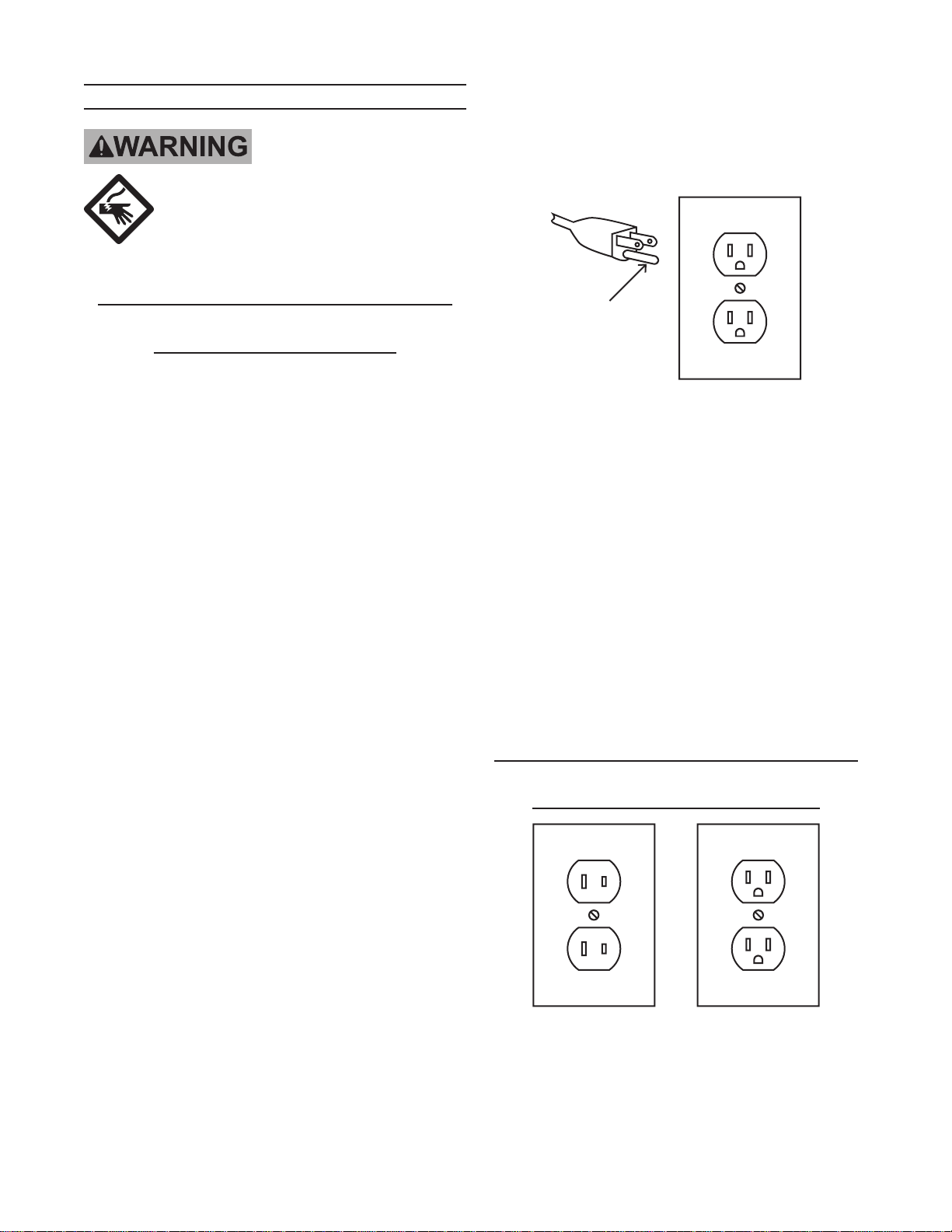

3-pole receptacles that accept the tool’s

plug.

6.

Repair or replace damaged or worn cord

immediately.

110-120 V~ grounded tools: tools

with three prong plugs

In the event of a malfunction or 1.

breakdown, grounding provides a path

of least resistance for electric current

to reduce the risk of electric shock.

This tool is equipped with an electric

cord having an equipment-grounding

conductor and a grounding plug. The

plug must be plugged into a matching

outlet that is properly installed and

grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided – if it will 2.

not t the outlet, have the proper outlet

installed by a qualied electrician.

Improper connection of the equipment-3.

grounding conductor can result in a risk

of electric shock. The conductor with

insulation having an outer surface that

is green with or without yellow stripes is

the equipment-grounding conductor. If

repair or replacement of the electric cord

or plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

grounding

pin

125 V~ 3-prong plug and Outlet

(for up to 125 V~ and up to 15 a)

This tool is intended for use on a circuit 7.

that has an outlet that looks like the one

illustrated above in 125 V~ 3-prong

plug and Outlet. The tool has a

grounding plug that looks like the plug

illustrated above in 125 V~ 3-prong

plug and Outlet.

The outlet must be properly installed and 8.

grounded in accordance with all codes

and ordinances.

Do not use an adapter to connect this 9.

tool to a different outlet.

110-120 V~ double insulated tools:

tools with two prong plugs

Check with a qualied electrician or 4.

service personnel if the grounding

instructions are not completely

understood, or if in doubt as to whether

the tool is properly grounded.

Use only 3-wire extension cords that 5.

have 3-prong grounding plugs and

Page 4 For technical questions, please call 1-800-444-3353. SKU 38160

Outlets for 2-prong plug

To reduce the risk of electric shock, 1.

double insulated equipment has a

polarized plug (one blade is wider than

reV 10e

Page 5

the other). This plug will t in a polarized

outlet only one way. If the plug does not

t fully in the outlet, reverse the plug.

If it still does not t, contact a qualied

electrician to install the proper outlet. Do

not change the plug in any way.

Double insulated tools may be used in 2.

either of the 120 volt outlets shown in the

preceding illustration. (see Outlets for

2-prong plug.)

sander safety Warnings

For your Own safety read instruction

Manual before Operating sander

Wear eye protection.1.

Only use safety equipment that has been 8.

approved by an appropriate standards

agency. Unapproved safety equipment

may not provide adequate protection.

Eye protection must be ANSI-approved

and breathing protection must be

NIOSH-approved for the specic hazards

in the work area.

9.

Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the inuence

of drugs, alcohol or medication. A

moment of inattention while operating

power tools may result in serious

personal injury.

Support workpiece with miter gauge, 2.

backstop, or worktable.

The backstop is a fence near the surface 3.

that helps the operator maintain control

of the workpiece and prevents the

workpiece from being pulled into the

machine. For safety, it must be adjusted

very close to the sanding surface.

The worktable is the surface mounted 4.

close to the sanding surface that the

operator rests the workpiece against

to prevent it from being pulled by the

sanding surface. For safety, it must

be adjusted very close to the sanding

surface.

dO nOt Operate With any 5.

guard disabled, daMaged, Or

reMOVed. Moving guards must

move freely and close instantly.

The use of accessories or attachments 6.

not recommended by the manufacturer

may result in a risk of injury to persons.

When servicing use only identical 7.

replacement parts.

Industrial applications must follow OSHA 10.

guidelines.

Maintain labels and nameplates on 11.

the tool. These carry important safety

information. If unreadable or missing,

contact Harbor Freight Tools for a

replacement.

Avoid unintentional starting. Prepare to 12.

begin work before turning on the tool.

People with pacemakers should 13.

consult their physician(s) before use.

Electromagnetic elds in close proximity

to heart pacemaker could cause

pacemaker interference or pacemaker

failure.

WARNING: Some dust created by power 14.

sanding, sawing, grinding, drilling, and

other construction activities, contains

chemicals known [to the State of

California] to cause cancer, birth defects

or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and

cement or other masonry products

• Arsenic and chromium from chemically

reV 10e

Page 5For technical questions, please call 1-800-444-3353.SKU 38160

Page 6

treated lumber

Your risk from these exposures varies,

depending on how often you do this type

of work. To reduce your exposure to

these chemicals: work in a well ventilated

area, and work with approved safety

equipment, such as those dust masks

that are specially designed to lter out

microscopic particles. (California Health

& Safety Code § 25249.5, et seq.)

WARNING: Handling the cord on this 15.

product will expose you to lead, a

chemical known to the State of California

to cause cancer, and birth defects or

other reproductive harm. Wash hands

after handling. (California Health &

Safety Code § 25249.5, et seq.)

16.

The warnings, precautions, and

instructions discussed in this instruction

manual cannot cover all possible

conditions and situations that may occur.

It must be understood by the operator

that common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

unpacking

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353 as soon as

possible.

saVe these

instructiOns.

speciFicatiOns

Electrical Input 120 V~ / 60 Hz / 11 A

Motor No Load Speed 1787 RPM

Oscillations per

Minute

Oscillation Travel 7/8”

Sanding Belt Capacity 3/4” - 2”

Sanding Belt Height 4-1/2”

Sanding Thickness 3/16 - 11/16”

Dust Collection Port 2”

Table Tilt Angle 0 - 45°

Page 6 For technical questions, please call 1-800-444-3353. SKU 38160

58 OPM

rev 00c; 10c

Page 7

to change/install sand belts

(see parts diagram and parts list on pages 8 and 9)

place switch in “OFF” position, and unplug the sander before performing any of the steps below.

The Oscillating Sander has been shipped completely assembled with a 2” sand belt (#49) and regular core board

installed. Change sand belts as follows:

tO reMOVe sand belt

1. Grasp and hold sand belt (#49) on rotating axle (#46). Loosen nut (#51). If nut is too tight and rotating axle

spins inside sand belt, secure the rotating axle with a wrench and loosen nut.

2. Remove nut, big washer (#50), and sand belt. Unscrew rotating axle clockwise and remove core board (#36) also see instructions below describing how to remove core board.

3. Remove big washer (#50) and clean sawdust accumulation.

tO install sand belt

1. Replace big washer (#50). Fin side of washer should always be installed down. The ns help push sawdust

through the dust exhaust port opening, preventing buildup of sawdust. Sawdust buildup in this area may cause

the oscillating motion to stop. The big washer must be used with all sanding sleeves.

2. Select and install the desired rotating axle.

3. Install appropriate sand belt on the rotating axle. (Note: If sanding sleeve becomes difcult to install or remove,

apply talcum powder on the inside of the sand belt before installing on axle).

4. Install big washer (#50) and nut.

5. Grasp and hold sand belt and tighten nut. Do not overtighten.

replacing core boards

The Oscillating Sander comes with two core boards. The core board with the circular opening is for sanding when the working

table (#34) is level. The core board with the oblong opening is to be used when the working table is set at an angle.

to remove core boards

Push rmly from underneath the working table until core board is removed.

to insert core boards

1. Align the notch in the core board with the spring dowel (#35) located on the inner rim of the core board insert area.

2. Push down rmly until the core board is fully inserted and ush with the surface of the working table.

Page 7For technical questions, please call 1-800-444-3353.SKU 38160

Page 8

preparing For Operation

note:

√ this sander is designed for use on plastic and wood surfaces only. do not use this sander for sanding

metals. sanding metals will cause sparks that will ignite wood and dust particles on sander, in the dust

collector, or in workshop.

√ it is recommended that this tool not be used for extended work on any berglass or abrasive materials.

it has been found that those materials are subject to accelerated wear and possible premature failure,

as the berglass chips and grindings are highly abrasive to bearings, brushes, commutator, etc. During

any sanding of these materials, it is important the tool be cleaned frequently by blowing with an air

jet.

√ do not use sander without a sand belt. doing so will damage the rotating axle.

√ Make sure nut on the top of the rotating axle is tightened securely - but not overtightened.

sand belt selectiOn

Selecting the correct size diameter, type of grit and sanding sleeve is an extremely important step in achieving a

high quality nish:

√ Aluminum oxide, silicon carbide, and other synthetic abrasives are best for power sanding.

√ Natural abrasives, such as int and garnet are too soft for use in power sanding.

Select and install the desired sand belt for the particular application. Sand belts from 3/4”- 2” can be used with this

sander. Choose one that is close in size to the material you are sanding.

grit selectiOn

The condition of the surface to be sanded will determine which grit will do the proper job. In general, coarse grit will

remove the most material. Finer grit will produce the best nish in all sanding operations. If the surface is rough,

start with a coarse grit and sand until the surface is uniform. Medium grit may then be used to remove scratches

left by the coarser grit and ner grit used for nishing of the surface. Always continue sanding with each grit until

the surface is uniform.

Warning! Do not use water with this sander. It is for dry

sanding only. Wet sanding will damage the machine,

and may present a shock hazard. Use only in dry

locations.

reV 10c

Page 8 For technical questions, please call 1-800-444-3353. SKU 38160

Page 9

Operation

Exercise caution! Never force the material into the sander. You will become familiar with the sander’s features from

practice and use. If possible, practice sanding with a scrap piece of wood.

adJusting table angle

1. If working table is to be used at an angle, make sure to install the angle core board (with the oblong-shaped

opening) before sanding.

2. Loosen dial knob (#32) and adjust working table to the desired angle using the numbers on the rotating plate

(#31) as a guide.

3. Tighten dial knob securely so that the working table will not move during operation.

sanding

1. Turn sander on.

2. Let the motor build to its full speed, then gradually feed material against sanding sleeve. Do not let the material

contact sanding sleeve before turning on sander and allowing it to develop full speed.

Feed directiOn

When sanding, the sanding sleeve rotates counterclockwise. Therefore, feed the material against the sanding

sleeve from right to left. When fed from right to left, the rotation of the sanding sleeve sands against the material.

If fed in the opposite direction, the rotation forces of the spinning sanding sleeve will tend to throw or bounce the

material away from the sanding sleeve. This could cause loss of control of the material.

dust cOllectiOn capability

A standard 2-1/4” dust collect cover (#40) has been provided to make dustless sanding possible. The dust collection

port is located under the working top on the rear side of the sander. The pickup adapter end of a vacuum hose (not

included) will t inside the dust collect cover.

Even with a dust collection system, it is necessary to periodically clean sanding dust from the core board and big

washer areas. Sanding dust buildup in this area may cause the core board surface to rise above the working table

surface.

Maintenance

cleaning: Regularly clean the work surface with dry brush or clean cloth. Clean sawdust accumulations from core

board, big washers and rotating axle after each use.

lubricatiOn: No lubrication is required. All of the bearings in this tool are lubricated with a sufcient amount of

high grade lubricant for the life of the machine under normal operating conditions.

pOWer cOrd: Inspect the power cord periodically, and if damaged, have it repaired by an authorized technician.

replaceMent parts: When servicing, use only identical replacement parts. Use of any other parts will void the

warranty.

Page 9For technical questions, please call 1-800-444-3353.SKU 38160

Page 10

parts list

no. name Quantity no. name Quantity

1 stand 1 29 hexagon-headed bolt M8x20 6

2 switch 1 30 stand 1 of working table 1

3 Vertical Motor 1 31 rotating plate 1

4 key of Motor 1 32 parts of dial knob 2

5 clamp nail 2 33 crossed disc nail M5 x 8 7

6 Worm 1 34 Working table 1

7 spring ring for hole 55 1 35 spring dowel 3 x 8 1

8 bearing 80106 1 36 core board 2

9 spring ring for axle 32 1 37 hexagonn socket head cap

10 cross head disc nail M5 x 55 2 screw M6 x 20 2

11 screw Washer 5 holee 55 11 38 dust cover 1

12 rocker arm 2 39 hexagon-headed bolt M8 x 25 7

13 nut M5 4 40 dust collect cover 1

14 hexagon socket head cap 41 pointer 1

screw M4 x 30 2 42 stand ii of Working table 1

15 left core axle of Worm Wheel 1 43 stand board 1

16 Worm Wheel 1 44 dial 1

17 stand of Worm Wheel 1 45 key 5 x 50 1

18 screw M8 x 65 1 46 rotating axle of sand belt 1

19 right core axle of Worm Wheel 1 47 big Washer i 1

20 guide pole 1 48 rubber cylinder 1

21 shuttle axle cover 1 49 sand belt 1

22 shuttle axle 1 50 big Washer ii 1

23 spring dowel 4 x 30 1 51 left nut M8 1

24 bearing 61804 1 52 board of switch 1

25 hexagon socket head cap 53 nut M8 4

screw Mg x 16 5 54 Washer nut M8 4

26 spring Washer 8 7 55 rubber Washer 4

27 Frame to Fix Motor 1

28 screw Washer 14

Page 10 For technical questions, please call 1-800-444-3353. SKU 38160

Page 11

assembly diagram

Page 11For technical questions, please call 1-800-444-3353.SKU 38160

Page 12

liMited 1 year / 90 day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality

and durability standards, and warrants to the original purchaser that for a period of ninety

days from date of purchase that the engine/motor, the belts (if so equipped), and the blades

(if so equipped) are free of defects in materials and workmanship. Harbor Freight Tools also

warrants to the original purchaser, for a period of one year from date of purchase, that all other

parts and components of the product are free from defects in materials and workmanship (90

days if used by a professional contractor or if used as rental equipment). This warranty does

not apply to damage due directly or indirectly, to misuse, abuse, negligence or accidents,

repairs or alterations outside our facilities, normal wear and tear, or to lack of maintenance.

We shall in no event be liable for death, injuries to persons or property, or for incidental,

contingent, special or consequential damages arising from the use of our product. Some states

do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation of exclusion may not apply to you.

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection veries the defect, we will either repair or

replace the product at our election or we may elect to refund the purchase price if we cannot

readily and quickly provide you with a replacement. We will return repaired products at our

expense, but if we determine there is no defect, or that the defect resulted from causes not

within the scope of our warranty, then you must bear the cost of returning the product.

THIS WARRANTY IS EXPRESSLY IN LIEU OF

This warranty gives you specic legal rights and you may also have other rights which

vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

reV 10c

Page 12 For technical questions, please call 1-800-444-3353. SKU 38160

Loading...

Loading...