Harbor Freight Tools 37999 Product manual

20 TON SHOP PRESS

37999

SET UP AND OPERATING INSTRUCTIONS

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2009 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual Revised 09g

SAVE THIS MANUAL

Keep this manual for the safety

warnings and precautions, assembly,

operating, inspection, maintenance and

cleaning procedures. Write the product’s

serial number in the back of the manual

near the assembly diagram (or month

and year of purchase if product has no

number). Keep this manual and the

receipt in a safe and dry place for future

reference.

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling,

and all other information

provided with this product:

not avoided, could result in

minor or moderate injury.

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

WARNING Read all safety

warnings and instructions.

Failure to heed these markings

may result in personal injury

and/or property damage.

Save all warnings and

instructions for future

reference.

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

The warnings, precautions,

and instructions discussed

in this manual cannot cover

all possible conditions and

situations that may occur.

The operator must understand

that common sense and

caution are factors, which

cannot be built into this

product, but must be supplied

by the operator.

Work area

Keep the work area clean and a.

well lit. Cluttered benches and dark

areas increase the risks of electric

shock, re, and injury to persons.

Do not operate the tool in b.

explosive atmospheres, such

as in the presence of ammable

liquids, gases, or dust. Air and

hydraulic tools create sparks which

may ignite the dust or fumes.

Page 2

For technical questions, please call 1-800-444-3353.

SKU 37999

Personal safety

Stay alert. Watch what you are a.

doing and use common sense

when operating the tool. Do not

use the tool while tired or under

the inuence of drugs, alcohol, or

medication. A moment of inattention

while operating the tool increases the

risk of injury to persons.

Dress properly. Do not wear loose b.

clothing or jewelry. Contain long

hair. Keep hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

increases the risk of injury to persons

as a result of being caught in moving

parts.

Do not overreach. Keep proper c.

footing and balance at all times.

Proper footing and balance

enables better control of the tool in

unexpected situations.

Use safety equipment.d. Wear

heavy-duty work gloves during use.

Non-skid safety shoes and a hard

hat must be used for the applicable

conditions.

Store the tool when it is idle out b.

of reach of children and other

untrained persons. A tool is

dangerous in the hands of untrained

users.

Check for misalignment or binding c.

of moving parts, breakage of

parts, and any other condition

that affects the tool’s operation.

If damaged, have the tool serviced

before using. Many accidents are

caused by poorly maintained tools.

There is a risk of bursting if the tool is

damaged.

Use only accessories that are d.

identied by the manufacturer for

the specic tool model. Use of an

accessory not intended for use with

the specic tool model, increases the

risk of injury to persons.

Service

Tool service must be performed a.

only by qualied repair personnel.

When servicing a tool, use only b.

identical replacement parts. Use

only authorized parts.

Always wear eye protection.e. Wear

ANSI-approved safety goggles,

heavy-duty work gloves, and steeltoe work boots during set up and/or

use.

Tool use and care

Do not force the tool.a. Use the

correct tool for the application. The

correct tool will do the job better and

safer at the rate for which the tool is

designed.

SKU 37999

For technical questions, please call 1-800-444-3353.

Use only the lubricants supplied c.

with the tool or specied by the

manufacturer.

Specic Safety Rules

Maintain labels and nameplates 1.

on the Shop Press. These carry

important safety information. If

unreadable or missing, contact

Harbor Freight Tools for a

replacement.

Keep hands away from arbor plates 2.

and press rod during use.

Page 3

Do not move workpiece while 3.

compressed.

Release load before service or 4.

maintenance.

the “Inspection, Maintenance, And

Cleaning” section of this manual.

Use of unauthorized parts or failure to

follow maintenance instructions may

create a risk of injury.

Bolt to oor before use.5.

Keep area under arbor plates clear. 6.

If arbor plates rest on obstruction

(i.e., bolt, debris, etc.), it creates an

uneven press, causing excess stress

and possible breakage.

Do not stand directly in front of the 7.

press when loaded. Do not leave the

press unattended when loaded.

Avoid off-center loads. Do not 8.

operate if workpiece tilts or binds

during compression.

STOP and release compression 9.

if you suspect imminent structural

failure. If safe, inspect thoroughly and

reposition before proceeding.

Do not compress springs or other 10.

elastic objects. They could disengage

hazardously.

Keep bystanders out of work area.11.

Only use with accessories rated to 16.

handle the forces exerted by this tool

during operation. Other accessories

not designed for the forces generated

may break and forcefully launch

pieces.

Use only with bottle jack provided,17.

Industrial applications must follow 18.

OSHA requirements.

This product is not a toy. Keep it out 19.

of reach of children.

The warnings, precautions, 20.

and instructions discussed in

this instruction manual cannot

cover all possible conditions and

situations that may occur. It must

be understood by the operator that

common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

20 Ton Limit. Do not operate the 12.

hydraulic jack beyond rated capacity.

Inspect before every use; do not use 13.

if parts are loose or damaged.

Jack service must be performed 14.

only by qualied repair personnel.

Service or maintenance performed by

unqualied personnel could result in

a risk of injury.

When servicing a jack, use only 15.

identical replacement parts - refer to

attached, product-specic parts list

and diagram. Follow instructions in

Page 4

For technical questions, please call 1-800-444-3353.

SAVE THESE

INSTRUCTIONS.

SKU 37999

SPECIFICATIONS

OPERATING INSTRUCTIONS

Maximum

Capacity

Oil Type Hydraulic Jack Oil

20 Tons

(40,000 pounds)

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Unpacking

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353 as soon

as possible.

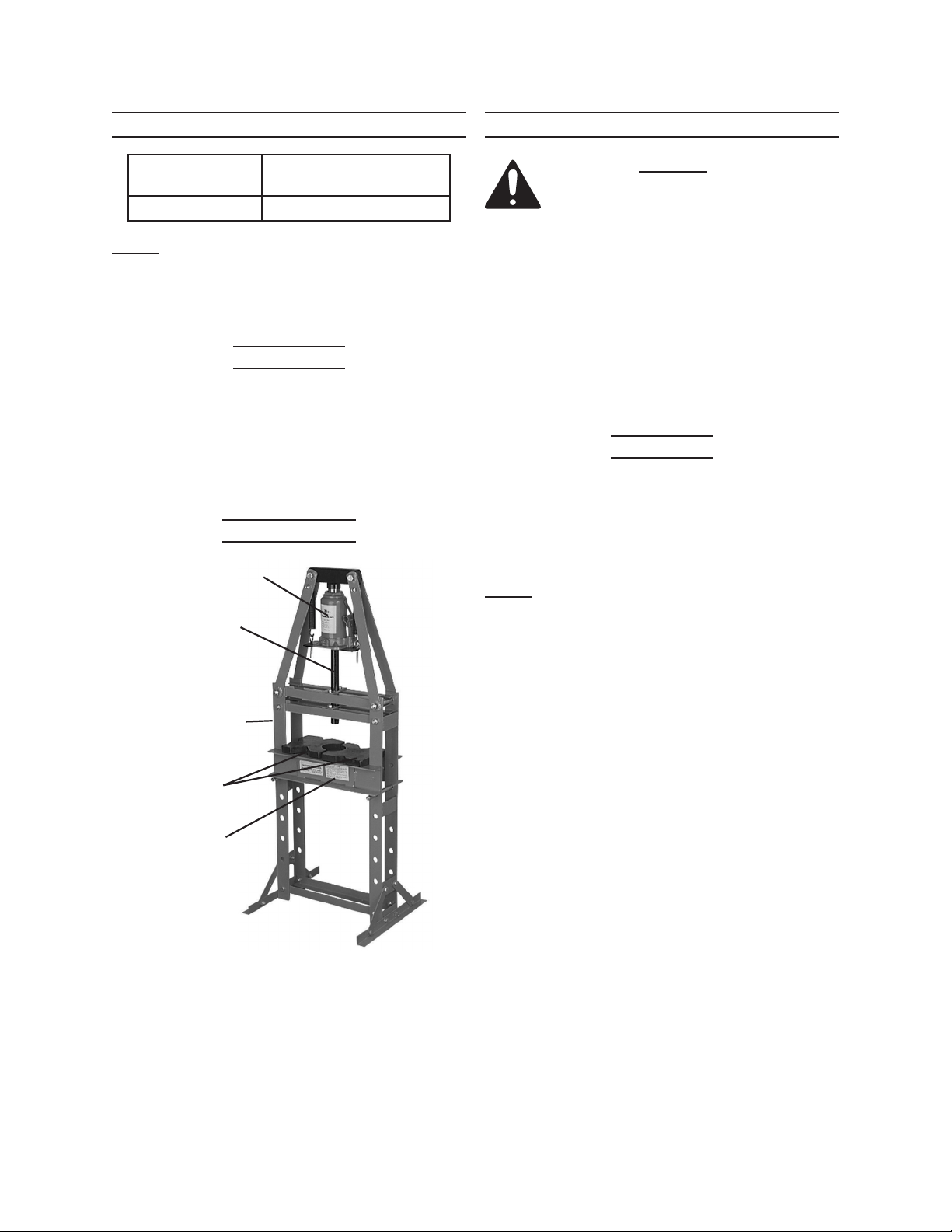

Components

Bottle Jack (1)

Press Rod (24)

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Inspect tool before use, looking

for damaged, loose, and

missing parts. If any problems

are found, do not use tool until

repaired.

Assembly

Using the Components photo (left) 1.

and the Parts List and Diagram near

the end of the manual, lay out and

identify all pieces before assembly.

Note: All threaded ends of the fasteners

should face the interior of the press

or the back of the press, with the boltheads on the outside or front of the

press.

Uprights (18)

Arbor Plates (20)

Press Apron (12)

Figure 1

SKU 37999

Have someone help you hold pieces

in place during assembly.

Finger tighten all nuts in step 2. Then

adjust the unit so that it is square,

and tighten all nuts and bolts before

bolting to the oor.

Finger tighten all nuts for the

remainder of the assembly. Then

adjust the unit so that it is square

and the Press Rod (24) has smooth

vertical travel. Securely tighten all

nuts and bolts.

For technical questions, please call 1-800-444-3353.

Page 5