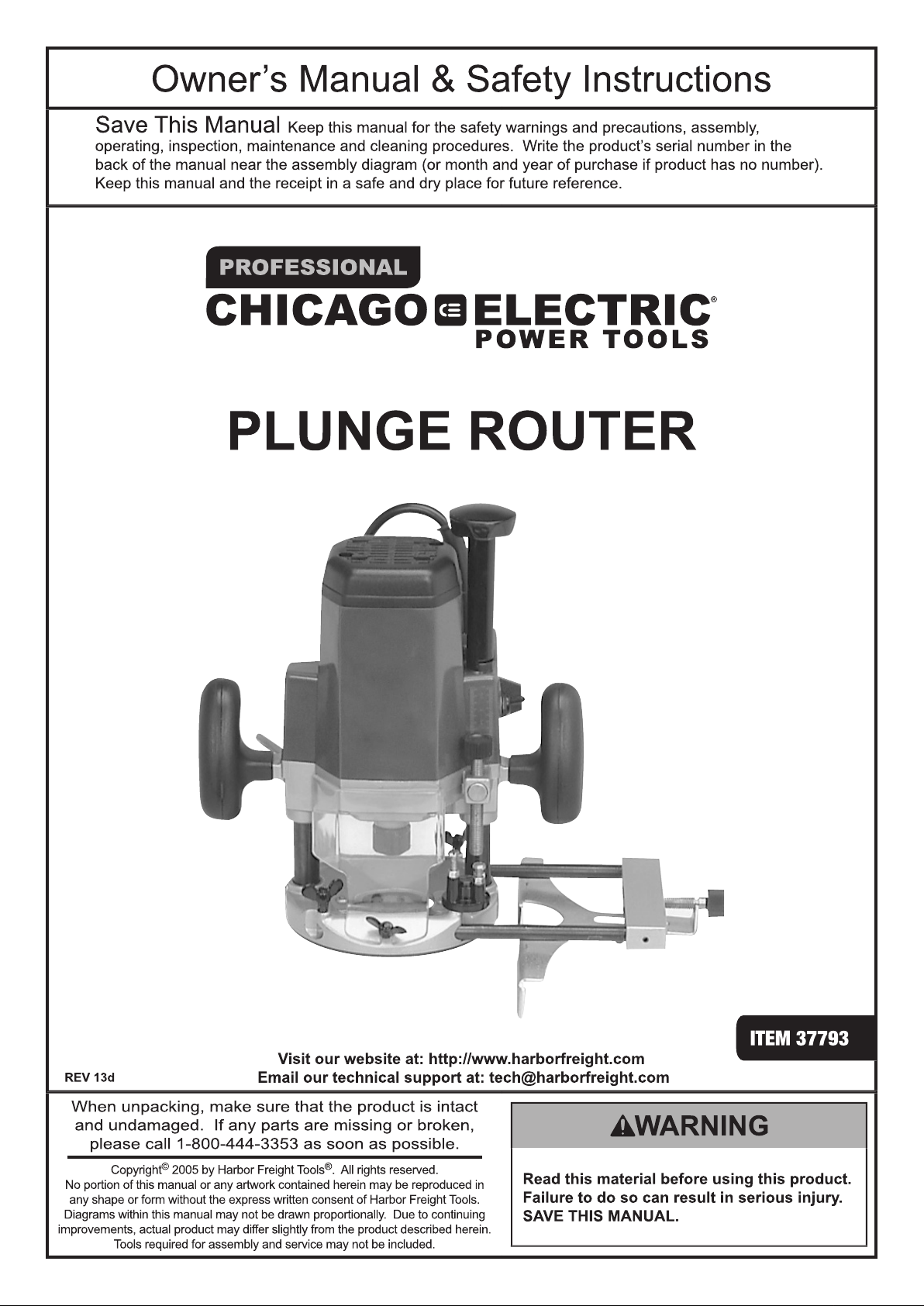

Page 1

Page 2

SAFETY OPERATION MAINTENANCESETUP

.........................................................

....................................................

..............................................

follow this symbol to avoid possible injury or death.

will result in death or serious injury.

Addresses practices not related to personal injury.

Warnings

power tool.

Work Area Safety

WARNING SYMBOLS AND DEFINITIONS

IMPORTANT SAFETY INFORMATION

Page 3

SAFETYOPERATIONMAINTENANCE SETUP

Unmodified plugs and matching

Avoid body contact with grounded surfaces

Water entering a power tool

When operating a power tool outdoors,

Use of a cord suitable for outdoor

A

Always

wear eye protection.

Safety

is in the off

or energizing power tools that

on invites accidents.

A

This enables better control

jewelry. Keep your hair, clothing and gloves

Loose clothes, jewelry

parts.

protection

ANSI

Page 4

SAFETY OPERATION MAINTENANCESETUP

power tool will do the job better and

Any

power

preventive safety measures reduce the

with the power tool or these instructions

Power tools are

Many accidents

Properly

Use of the

power tool for operations different from those

Warnings

when performing an operation where cutting

parts of the tool ″live″ and shock the operator.

Removal of

Avoid unintentional starting.

it is plugged

before leaving.

locked

– it

Page 5

SAFETYOPERATIONMAINTENANCE SETUP

dust created by power sanding,

contain

chemicals known [to the State

Your risk from these exposures varies, depending

which cannot be built into this product,

Vibration Safety

Anyone using vibrating tools regularly or for

women or people who have impaired blood

feel

when there is a

SAVE THESE INSTRU

Page 6

SAFETY OPERATION MAINTENANCESETUP

SHO

WIRE

C

tool

Do not use the

tool

if the power cord or plug is damaged.

from the user, reducing the risk of electric

with all codes and ordinances. The plug and outlet

Association, and the National Electrical Code.

Grounding

Page 7

SAFETYOPERATIONMAINTENANCE SETUP

C

tools require a three wire

tools can use either

As the distance from the supply outlet increases,

A.)

A.)

wire size required.

A.)

A.)

ABLE

A:

VOLT)

AMPERES

V

Volts

Alternating Current

A

Amperes

xxxx/min.

ANSI

flammable objects away.

Page 8

SAFETY OPERATION MAINTENANCESETUP

INFORMATION

section at the beginning of this

For additional information regarding the parts listed in the

For additional information regarding the parts listed in the

following

on page

Specifications

224184

Setup - Before Use:

Page 9

Operating Instructions

Y

INFORMATION

section at the beginning of this

FROM A

unplug the tool from its

before performing any procedure in this section.

firmly against the motor housing (5).

SAFETYOPERATIONMAINTENANCE SETUP

Page 10

SAFETY OPERATION MAINTENANCESETUP

Adjust the Straight Guide by turning

flat against the side of the material to be chamfered or

Standoffs can be mounted to the Straight Guide

Standoffs can be mounted to the Straight Guide

Adjust the Trimmer Guide by turning the Fine

Adjustment Screw (A) to the desired distance from

flat against the side of the material to be chamfered

Adjustment

Page 11

SAFETYOPERATIONMAINTENANCE SETUP

The cut size may be slightly different from that

The cut size may be slightly different from that

Workpiece and Work Area Set Up

working. Do not cut nails or screws.

Verify Lock Lever (26) is loose.

plug in the tool

from the torque of turning it on.

Allow bit to come to full speed, slowly engage

after use.

Clean, then

Page 12

SAFETY OPERATION MAINTENANCESETUP

FROM A

unplug the tool from its

before performing any procedure in this section.

FROM TOOL FAILURE:

inspect the general

AFTER USE,

wipe external surfaces

WARNING! If the supply cord of this

4.

wear.

4.

Allow tool to work at its own rate.

in

4.

Allow tool to work at its own rate.

Wear ANSI-approved safety goggles and

4.

in

Maintenance and Servicing

Page 13

Parts List and Diagram

AREFULL

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

Accessory Parts List and Diagram

A = 37/64″, B = 5/8″, C = 33/64″

If product has no serial number, record month and year of purchase instead.

If product has no serial number, record month and year of purchase instead.

Some parts are listed and shown for illustration purposes only,

Some parts are listed and shown for illustration purposes only,

SAFETYOPERATIONMAINTENANCE SETUP

Page 14

SAFETY OPERATION MAINTENANCESETUP

w/washer

(GB/1276-94)

Armature Assembly w/ items 9-12

(GB/1276-94)

w/ washer

w/ washer

w/ washer

(GB/1276-94)

w/ washer

Page 15

SAFETYOPERATIONMAINTENANCE SETUP

Assembly Diagram

Page 16

Limited 90 Day Warranty

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER

from causes not within the scope of our warranty, then you must bear the cost of returning the product.

Loading...

Loading...