Page 1

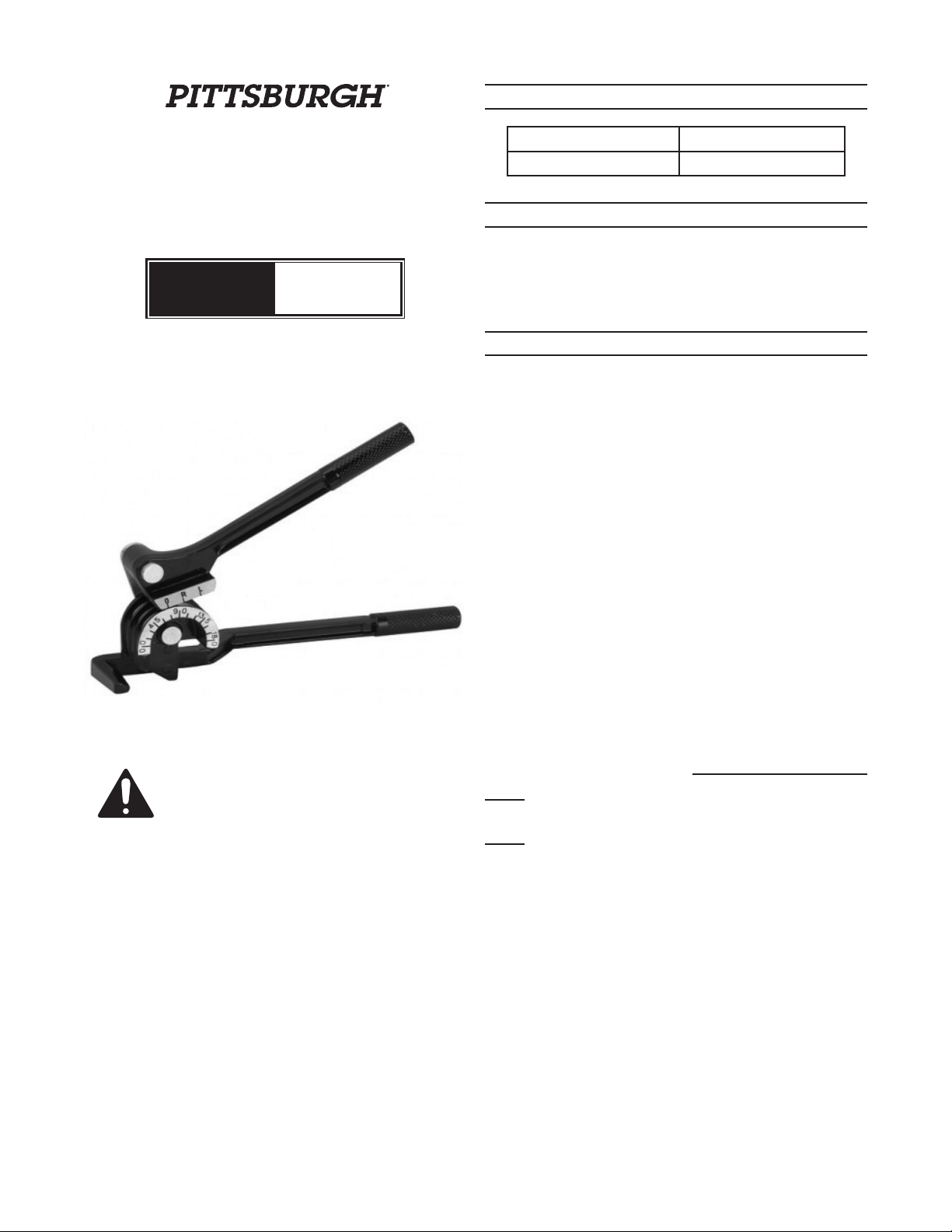

TUBING

BENDER

Model

3755

SPECIFICATIONS

Die Range 1/4”, 5/16”, 3/8”

Max. Bending Angle 180°

UNPACKING

When unpacking, make sure that the item

is intact and undamaged. If any parts are missing

or broken, please call Harbor Freight Tools at

1‑800‑444‑3353 as soon as possible.

INSTRUCTIONS AND

PRECAUTIONS

Visit our website at: http://www.harborfreight.com

SAVE THESE

INSTRUCTIONS.

READ ALL

PRECAUTIONS AND

IMPORTANT SAFETY INFORMATION

To prevent serious injury and/or property damage:

1. Wear ANSI‑approved safety goggles and heavy‑

duty work gloves during assembly.

2. Use for 1/4” to 3/8” tubing only. Do not attempt to

bend tubing greater than 3/8”.

3. Use for aluminum, copper and steel tubing only.

4. Inspect lines carefully after forming; discard

damaged or malformed lines.

5. This product is not a toy. Do not allow children to

play with or near this item.

6. Use as intended only.

7. Inspect before every use; do not use if parts are

loose or damaged.

8. Maintain product labels and nameplates. These

carry important safety information. If unreadable

or missing, contact Harbor Freight Tools for a

replacement.

Record Serial Number Here:

Note: If product has no serial number, record month

and year of purchase instead.

Note: Some parts are listed and shown for illustration

purposes only, and are not available individually

as replacement parts.

INSTRUCTIONS.

Copyright© 2010 by Harbor Freight Tools®. All rights

reserved. No portion of this document or any artwork

contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight

Tools. Diagrams within this document may not be drawn

proportionally. Due to continuing improvements, actual

product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

For technical questions or replacement parts,

please call 1‑800‑444‑3353.

Please Note:

No replacements parts are available for this item.

Page 2

OPERATION

Read the ENTIRE IMPORTANT SAFETY

INFORMATION section at the beginning

of this document including all text under

subheadings therein before set up or use

of this product.

1. Before inserting tubing into Bender, estimate the

location of the bend area and mark the location

with a pencil. This mark will indicate the location

of the bend.

2. Once the tube is marked, swing the Bending

Handle up above the Bender Die. See Figure 1

on reverse side of this Instruction Sheet.

3. Place the tube in the appropriate sized die

groove (1/4”, 5/16” or 3/8”), making sure the end

rests under the Tube Holder. The Tube Holder

will help restrict movement of the tube during the

initial bending. See Figure 1 on reverse side.

4. NOTE: Make sure the reference mark is facing

towards the Main Gauge on the Bender Die.

5. Carefully lower the Bending Handle until the Roll

Die rests gently on the tube. Make sure tube is

kept straight and aligned with the Main Handle.

6. WARNING! Premature bending can occur if the

tubing is not kept straight and aligned with Main

Handle.

7. Align the “0” mark on the Roll Die with the “0”

mark on the Main Gauge.

8. SLOWLY push down the Bending Handle until

the “0” on the Roll Die aligns with the desired

degree marking on the Main Gauge.

9. WARNING! Do not bend all the way to the

reference mark when bending softer tubing

material such as copper or aluminum.

10. Once the designated bend is complete, swing the

Bending Handle up and away from the tube.

11. Slide the bent tube out of the die groove.

12. NOTE: All tubing will display “springback” after

a bend is complete. The degree of springback

depends on the designated angle and the tubing

material. For most bends, 1° to 3° of springback

is to be expected.

Figure 1

Bender

Die

Roll Die

Main Gauge

Bending Handle

Main Handle

Tube Holder

Page 2 For technical questions, please call 1‑800‑444‑3353. SKU 3755

Loading...

Loading...