Page 1

TRANSMISSION JACKTRANSMISSION JACK

®

TRANSMISSION JACK

TRANSMISSION JACKTRANSMISSION JACK

ONE TON ONE TON

ONE TON

ONE TON ONE TON

37481

ASSEMBLY and OPERATING

INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Copyright © 1997 by Harbor F reight Tools®. All rights reserved. No portion of

this manual or any artwork contained herein may be reproduced in any shape

or form without the express written consent of Harbor F reight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

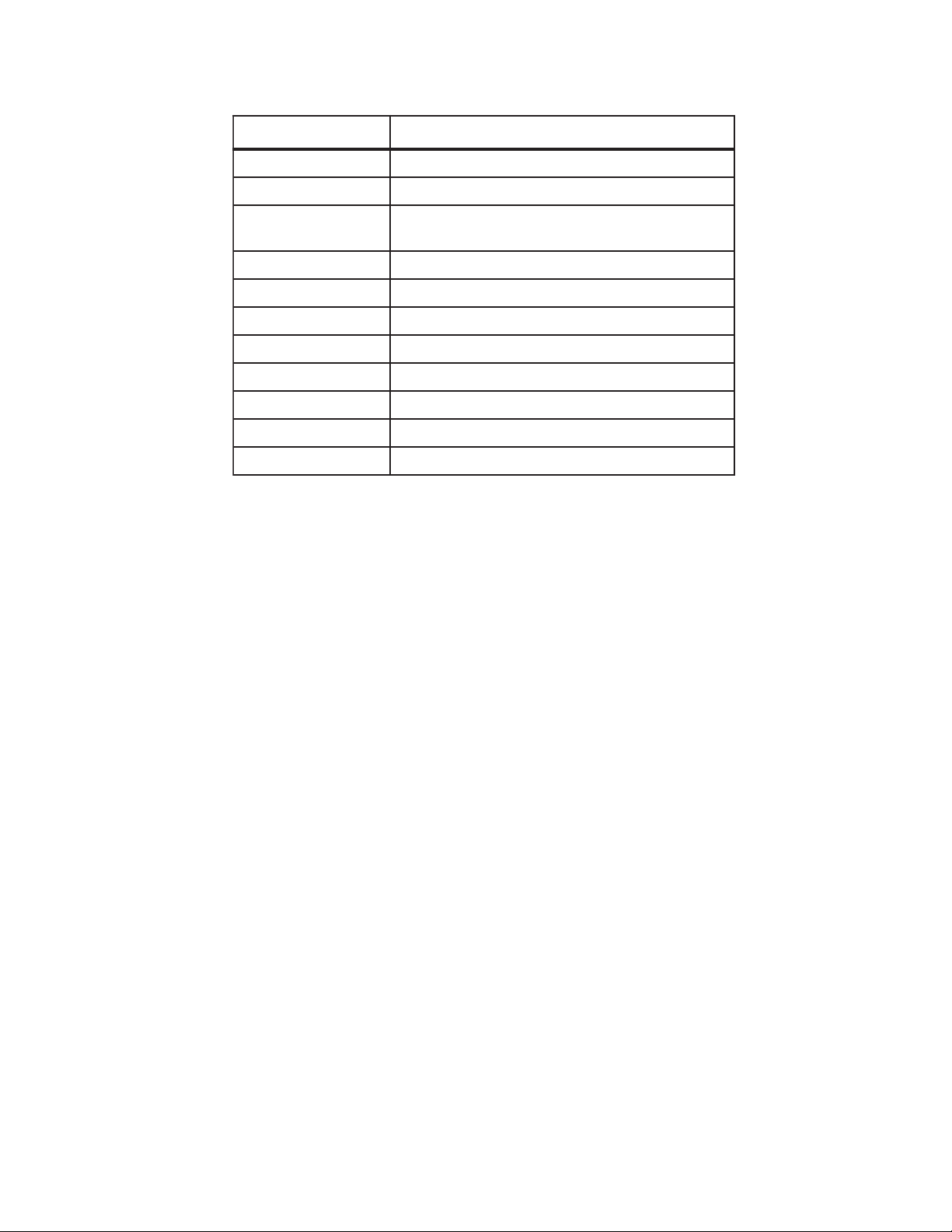

Specifications

METINOITPIRCSED

yticapaCnotenO

noitcurtsnoCleetsllA

egnaRtfiL

tliTelddaSdrawkcab°42,drawrof°41

tnemevoMelddaS)syawedis(laretalsehcni61/3-1

eziSelddaSsehcni8/1-41x4/3-7

MARsehcni5:htgneL,sehcni20.1:retemaiD

niahCytefaS08edarG

rotsaCsehcni2/1-3:retemaiD

snoisnemiDllarevOsehcni)H(2/1-31x)W(2/1-91x)L(52

thgieW.sbl491

sehcni4/1-8:muminiM

sehcni2/1-03:mumixaM

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front co v er. Keep the man ual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to reduce

the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Do not use jack until properly trained. The transmission jack is intended for use by

properly trained and experienced personnel only. If you are not familiar with the proper

and safe operation of a transmission jack, do not use until trained.

2. Keep work area clean. Cluttered areas invite injuries.

3. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

4. Secure vehicle. The vehicle must be properly supported and blocked before starting

repairs.

5. Do not overload. Use the proper size and capacity transmission jack to handle the

anticipated load or damage may occur to the jack and create a safety hazard.

Page 2SKU 37481

Page 3

6. Avoid moving parts on the jack. Keep fingers, hands, and arms awa y from moving

parts of the jack at all times.

7. Secure load. Secure the load with a safety chain before lowering or moving.

8. Use jack on hard surfaces onl y . The jack is designed for use only on hard, level

surfaces capable of sustaining the load. Using the jack on a soft surface can result in

jack instability and possible loss of load.

9. Keep children awa y. Children must never be allo w ed in the work area. Do not let

them handle machines, tools, or extension cords.

10. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

11. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool

capacity.

12. Use the right tool for the job. The use of this jack is limited to the removal,

installation, and transportation (in the lowered position), of transmissions and

differentials.

13. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically nonconductive clothes and nonskid footwear are

recommended when working. Wear restrictive hair co v ering to contain long hair.

14. Use eye and ear protection. Always wear ANSI approved impact safety goggles.

Wear a full face shield if you are producing metal filings or wood chips. Wear an ANSI

approved dust mask or respirator when working around metal, wood, and chemical

dusts and mists.

15. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

16. Maintain tools with care. K eep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect tool

cords periodically and, if damaged, have them repaired by an authorized technician.

The handles must be kept clean, dry, and free from oil and grease at all times.

17. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches

are removed from the tool or machine work surface before plugging it in.

18. Stay alert. Watch what you are doing, use common sense. Do not oper ate any tool

when you are tired.

19. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; an y broken parts

or mounting fixtures; and an y other condition that ma y aff ect proper operation. Any part

that is damaged should be properly repaired or replaced by a qualified technician. Do

not use the tool if any switch does not turn On and Off properly.

Page 3SKU 37481

Page 4

20. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor Freight

Tools.

21. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels on prescriptions to determine if your judgment or reflexes are impaired while

taking drugs. If there is any doubt, do not operate the tool.

22. Comply with safety warnings. F ailure to comply with all of these warnings may

cause loss of load, damage or failure of the jack, or personal injury and property

damage.

Unpacking

When unpacking, check to make sure the following parts are included. If an y parts are

missing or broken, please call Harbor F reight Tools at the number on the cover of this

manual. If an y part of the machine is missing or broken, please call Harbor Freight Tools at

the number on the front cover as soon as possible.

WARNING:

ALWAYS EVALUATE YOUR TASK BEFORE USING THIS JACK. This jack is

designed to support a transmission or a differential as individual components.

Assemblies such as a differential with axle, or a transmission with bell housing, can be

bulky and difficult to balance on the jack’s platform or cradle.

LIFTING OR SUPPORTING SUCH ASSEMBLIES, EVEN WITHIN THE WEIGHT LIMIT,

CAN CREATE AN OFF-BALANCE SITUATION, CAUSING THE JACK TO TIP OVER

AND LEAD TO SERIOUS PERSONAL INJURY OR PROPERTY DAMAGE.

The load should be evenly distributed on the jack, and should not extend beyond the

area of the castor wheelbase. Always use safety straps or chains to secure the load.

If you are working and the load becomes off-balance and/or the jack begins to tip o ver,

DO NOT ATTEMPT TO CATCH OR LIFT WHEN FALLING. SERIOUS PERSONAL

INJURY CAN BE SUFFERED! In this event, clear the area as quickly and safely as

possible in order to avoid injury from the falling load, including getting hit with flying

fragments.

IF IN DOUBT ABOUT THE SAFETY OF YOUR PROJECT, WE ADVISE YOU TO HAVE

THE WORK DONE BY A PROFESSIONAL FAMILIAR WITH APPLICABLE SAFE

PRACTICES.

Assembly

Before installing the angle brackets (#30), claws (#27), and chain (#26) to the base panel

(#24), refer to parts breakdown illustration on the last page. Verify all necessary parts for

assembly are in the parts bag.

1. Place the Transmission Jack on a clear area on the floor.

Page 4SKU 37481

REV 09/02

Page 5

2. Place the angle br ackets (#30) on each side of the base panel (#24) as shown below.

3. Insert the bolts (#30A) up through the bottom of the base panel (#24), and then the

washers and nuts onto the bolts as they protrude through the angle brackets (#30).

Adjust to desired width then tighten nuts thoroughly.

Claw (#27 - Typical of 4)

Nut (#48 - Typical of 4)

Chain (#26)

bolted to claw

Bolt (#49 Typical of 4)

Base Panel (#24)

Angle Bracket (#30)

Bolt, washer , nut (#30A)

Ke y , W asher, Nut (#28)

Angle Bracket (#30)

Angle Screw (#25)

4. Mount each claw (#27) on the inside of the angle brackets (#30) using bolts (#48), nuts

(#49), and washers, as shown in the illustrations. Nuts and washers should be on the

inside. Adjust distance to desired cradle width for the transmission, then tighten.

5. Insert the key ( #28 - where chain is temporarily attached) into the upper claw (#27)

hole from the outside.

6. Place the washer and nut on the other end of the key (inside claw) and tighten.

7. Bolt the chain (#26) to the outside of the diagonally opposite claw (top hole).

8. Remo ve the plastic cap on the Air Valve (#9) before operating the jac k. Failure to do so

may cause improper jack operation.

Operation

1. Turn the Pressure Valve Knob (#6) counterclockwise to open, lowering tranmission

saddle. Tur n Pressure Valve Knob clockwise to close.

2. With the vehicle properly secured and raised to the correct height to remove the

transmission, move the jack into position under the transmission.

3. Raise the saddle by moving the Pump Handle (#11) up and down until the claws (#27)

are just below the front and rear of the transmission.

Page 5SKU 37481

REV 09/02

Page 6

T ra vel Screw

(#29 opposite side)

Angle Screw (#25)

Pump Handle (#11)

Air Valv e (#9)

Pressure V alv e Knob (#6)

4. Adjust the saddle Travel Screw (#29) and the slant Angle Screw (#25) to align with the

shape of the transmission. Adjust the cla ws (#27) if necessary.

5. Continue moving the saddle up until the transmission is resting on the saddle.

6. Carefully move the jack to free the transmission from its location.

7. Slowly turn the Pressure Valve Knob (#6) counterclockwise to open, lowering the

transmission.

8. Pull the Chain tightly over the transmission and hook the nearest link onto the chain

Ke y (#28) to secure.

9. The transmission can now be safely moved.

10. Reverse this procedure when mounting a transmission.

Page 6SKU 37481

REV 09/02

Page 7

Maintenance

The hydraulic cylinder assembly contains hydraulic fluid that must be kept approximately

80% full at all times for proper operation. To check the lev el and refill, follow these steps.

Note: The hydraulic cylinder has a capacity of 8.4 ounces of hydraulic fluid.

Adding Hydraulic Fluid

1. Turn the Pressure Valve Knob (#6) counterclockwise to allow saddle to lower

completely.

2. Remove the Air Valve (#9) by unscrewing. (Keep screw in a safe place)

3. Visually inspect the inside of the air valve opening. The hydraulic fluid must be 80% of

the capacity of the hydraulic cylinder.

4. Fill with clean hydraulic fluid only.

5. Replace Air Valve.

Bleeding Air from the Hydraulic System

1. Place jack in a clear floor area.

2. Turn the Pressure Valve Knob (#6) counterclockwise to allow saddle to lower

completely and release pressure.

3. Unscrew Air Valve (#9) 1/2 turn counterclockwise.

4. Hold the saddle down while moving the Pump Handle (#11) up and down several

times.

5. Tighten the Air Valve.

Seal Replacement

0-rings and seals can be purchased if you need to have y our jac k serviced. Take the jack to

a qualified mechanic along with the 0-rings and seals. The Transmission Jack cannot be

user serviced.

Page 7SKU 37481

REV 09/02 REV 02/04

Page 8

#metInoitpircseDytQ

32ylbmessAesaBCF1

42lenaPesaB1

52ylbmessAwercSelgnA1

62niahC1

72walC4

82stuNdnasrehsaW/wyeK1

92niPdnatuN/wyssAwercS1

03elgnA2

13niPgnixiFrednilyC1

23niPdnaBmrA1

33ylbmessAretsaC1

B33gniraeBtsurhT1

C33)ylno(retsaC1

53)nwohston(eldnaHgarD1

A53PCylbmessAnotsiP1

A-B53teSgnikcaPnotsiP1

D53teStuNxeHCF1

KR53)tikriaper(teSgnikcaP1

73tloBgnixiFdoR1

64niPdnaBnotsiP1

A64niPtilpS1

74tuNpotSliO1

84tuN5

94tloB5

05doRgnitfiL1

15doRgnoL1

25llaBleetS1

35gnisuoHevlaV1

45gnirpS1

55tloB1

65rehsaWgnikcaP1

75tloB1

Parts List

#metInoitpircseDytQ

1ydoBrednilCretsaM1

2evlaVssarB1

3regnulP1

A3gnir-O1

4notsiPpmuP1

A4gnir-OpmuP1

5tekcarBpmuP1

A5niPtilpS1

6bonKevlaVerusserP1

A6niP1

7tloBknaTliO1

A7rehsaWgnikcaPesaeleR1

8knaTliO1

9evlaVriA1

A9gnir-O1

01ylbmessAdnaBpmuP1

11eldnaHpmuP1

21)epip(rednilyC1

31notsiPCF1

41doR1

A41niP1

C41niP1

D41gniRgnirpS1

51gnikcaPrednilyC1

61tuNxeHCF1

A61gnir-O1

71elzzoNreppoC1

81gnir-OevlaVerusserP1

B81epiPgnixiFdoR1

B91emarF1

02gniRpukcaBxeHCF1

12)S(gnikcaPrebbuR1

22)L(gnikcaPrebbuR1

B22tekcarBlatnoziroH1

Page 8SKU 37481

REV 09/02

Page 9

Parts Illustration

Page 9SKU 37481

REV 09/02

Loading...

Loading...