Page 1

MIG 200 AMP WELDERMIG 200 AMP WELDER

®

MIG 200 AMP WELDER

MIG 200 AMP WELDERMIG 200 AMP WELDER

03664

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright© 2003 by Harbor F reight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

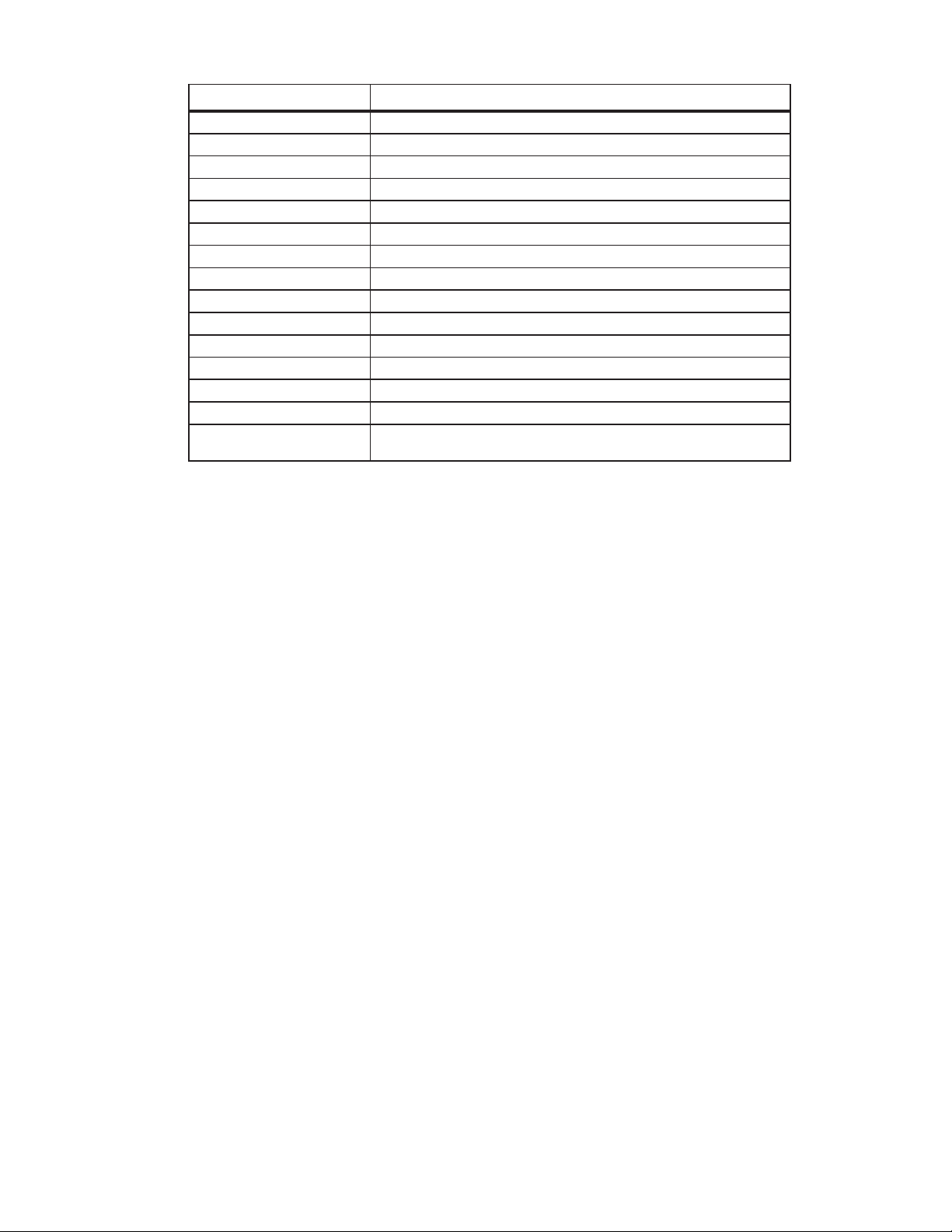

METINOITPIRCSED

tnerruCgnidleWCAspma002~03

yticapaCgnidleWrekcihtdnalatemeguag42gnidlewroF

elcyCytuD spma002ta%52;spma051ta%04;spma021ta%001

noitpmusnoCrewoPzH06taspma21,CAV022

egatloVnepOA002taV82;A051taV52;A021taV32

lortnoCtaeHelbairav,spma002~03

elbaCdnuorGpmalcgnidnuorgytudyvaehhtiwteef8

elbaCrewoPhcroTteef8

droCrewoP devorppa.L.U,GWA21,detalusnielbuod,eroc-3

thgiLhtiwdaolrevOlamrehT nwodloocretfatratserdnanwodtuhscitamotuA

eziSeriW"530.0ot"030.0

eziSloopSeriWretemaidloops"4/3-11

snoisnemiDllarevOsehcni)H(4/3-52x)W(2/1-01x)L(4/3-72

thgieW.sbl97

seirosseccA

Specifications

,hcrotGIM,pmalcdnuorg,eldnahgnillup,tikleehW

eriw"230.fo.bl1sedulcnI

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front co ver. Keep the man ual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should alwa ys be f ollowed to reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

3. Keep children away . Children must ne ver be allow ed in the work area. Do not let them

handle machines, tools, or extension cords.

4. Store idle equipment. When not in use , tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

5. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to e xceed the tool capacity .

6. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

7. Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving

parts. Protective, electrically non-conductive clothes and non-skid footwear are

recommended when working. Wear restrictive hair cov ering to contain long hair.

REV 06/05

Page 2SKU 03664 For technical questions, please call 1-800-444-3353.

Page 3

8. Use the right tool for the job. Do not attempt to force a small tool or attachment to do

the work of a larger industrial tool. There are certain applications for which this tool was

designed. Do not modify this tool and do not use this tool for a purpose for which it was

not intended.

9. Use eye and ear protection. Always wear ANSI approved, arc shaded, impact safety

full face shield (not included) when arc welding. Wear an ANSI approved dust mask or

respirator when working around metal, chemical dusts, fumes and mists.

10. Maintain tools with care. Keep tools sharp and clean for better and saf er performance.

Follow instructions for lubricating and changing accessories. Inspect tool cords

periodically and, if damaged, have them repaired by an authorized technician. The

handles must be kept clean, dry, and free from oil and grease at all times.

11. Disconnect power. Unplug tool when not in use.

12. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches are

removed from the tool or machine work surface before plugging it in.

13. Av oid unintentional starting. Be sure the switch is in the Off position when not in use

and before plugging in. Do not carry any tool with y our finger on the trigger , whether it is

plugged in or not.

14. Stay alert. Watch what y ou are doing, use common sense. Do not operate any tool when

you are tired.

15. Check for damaged parts. Before using any tool, an y part that appears damaged should

be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment and binding of moving parts; any brok en parts or mounting

fixtures; and any other condition that ma y affect proper operation. Any part that is damaged

should be properly repaired or replaced by a qualified technician. Do not use the tool if

any switch does not turn On and Off properly.

16. Guard against electric shock. Prevent body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerator enclosures.

17. Replacement parts and accessories. When servicing, use only identical replacement

parts. Use of any other parts will void the warranty. Only use accessories intended for

use with this tool. Approved accessories are available from Harbor Freight Tools.

18. Do not operate tool if under the influence of alcohol or drugs. Read warning labels

on prescriptions to determine if your judgment or reflexes are impaired while taking drugs.

If there is any doubt, do not operate the tool.

19. Maintenance. For your saf ety, service and maintenance should be performed regularly

by a qualified technician.

20. Use proper size and type extension cord. If an extension cord is required, it must be of

the proper size and type to supply the correct current to the tool without heating up.

Otherwise, the extension cord could melt and catch fire, or cause electrical damage to

the tool. This tool requires use of an 220 VAC extension cord of 20 amps minimum

capability (up to 30 feet), with wire size r ated at 10 AWG. Longer e xtension cords require

larger size wire. If you are using the tool outdoors, use an extension cord rated for outdoor

use (signified by “WA” on the jacket).

Page 3SKU 03664 For technical questions, please call 1-800-444-3353.

Page 4

21. Pacemaker safety warning. People with pacemakers should consult with their

physician(s) before using this product; operation of equipment in close proximity to a

heart pacemaker could cause interference or failure of the pacemak er.

22. Use tools with both hands when required. Many tools such as chain saws, drills,

routers, and welders, etc., require the use of both hands when operating. This helps

maintain tool stability and keeps hands away from the working area of the tool.

Note: Performance of this tool may vary depending on variations in local line voltage. Extension cord usage may also affect tool performance.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, b ut m ust be supplied b y the operator.

Arc Welding Safety Warnings and Precautions

Warning: This product, when used for welding and similar applications, produces chemicals known to the State of California to cause cancer and birth defects (or other reproductive harm). California Health & Safety Code 25249.5, et seq.

1. Avoid electrical shock. Do not permit electrically live par ts, cables, or electrodes to

contact skin, clothing, or gloves. Protective clothing should be free of holes, dry, and

ANSI approved.

This unit draws enough current to cause serious injury or death. Before turning the welder

on, check the electrode holder to be sure that there are no protruding screw heads, and

that all insulation is secure. Do not weld unless you are insulated from ground and the

work piece.

2. Avoid breathing fumes or gases. They can cause serious health problems. Use an

active ventilation system directly above the welding area. Keep your head out of the

fumes.

Inhalation Hazard

Welding Pr oduces T O XIC FUMES and GASSES.

Exposure to welding gasses can increase the risk of developing

certain cancers, such as cancer of the larynx and lung cancer . Also,

some diseases that may be linked to exposure to welding gasses or

fumes are:

• Early onset of Parkinson’s Disease • Heart Disease

• Damage to the reproductive organs • Ulcers

• Inflammation of the small intestine or stomach • Kidney damage

• Respiratory diseases such as emphysema, bronchitis or pneumonia

Safety precautions, such as using natural or forced air ventilation and

wearing an ANSI approved respirator , are ESSENTIAL to reduce the risk

of developing the above illnesses.

REV 06/04

Page 4SKU 03664 For technical questions, please call 1-800-444-3353.

Page 5

3. Av oid e ye and body damage. Arc rays and infrared radiation can injure ey es and burn

skin. Wear ANSI appro ved arc shaded, impact safety full f ace shield and body protection.

Do not allow viewing by visitors without proper eye and body protection.

4. Know proper arc welding practices. Read and understand the manufacturer’s

instructions, and well as your employer’s safety practices for arc welding.

5. Connect only to a code approved power source. Connect only to a grounding power

source conforming to the National Electrical Code and Local Codes.

6. Avoid fire and explosion. Remove flammable and explosive material from at least 35

feet from the welding arc to pre vent welding sparks or molten metal from starting a fire.

Keep a type ABC fire e xtinguisher within easy reach. Thoroughly clean the object being

welded of any paint, grease, or other foreign material.

7. Av oid being burned. Alwa ys wear ANSI approved welding gear: leather gloves , leather

apron, and shoes.

Unpacking

When unpacking, check to make sure the following parts are included.

MIG 200 Amp W elder

Wire Spool (1) not shown

220 V AC Power Cord

Torch Cable and Handle (2)

Ground Cable and Clamp (3)

If any parts are missing or broken, please call Harbor Freight Tools at the number on the

cover of this manual as soon as possible.

Assembly

1. Insert the Torch Cable (connection end) into the cable strain relief on the end of the

unit. Refer to the photos on the next page.

2. Loosen and unlock the Wire Tension Control.

Page 5SKU 03664 For technical questions, please call 1-800-444-3353.

Page 6

Wire T ension

Control and Lock

Bracket “A”

Current Collector (with

Wire Routing Housing)

Feed Control

Wheel

Cable Strain Relief

Square

Connector “C”

Gas T ube

Wire Routing

Housing

Outlet “B”

Receptacle “D”

3. Attach the Current Collector (with Wire Routing Housing) to Bracket “A” and tighten.

Refer to photos above.

4. Press the white Gas Tube onto the black outlet “B”.

5. Plug the white tube Square Connector “C” into the matching receptacle “D”.

6. Wind (or place) the welding wire onto the Wire Spool (not shown), and mount the Wire

Spool onto the Wire Feed Axis Mechanism. See photo on next page.

7. Guide the welding wire into the Wire Routing Housing until it passes the Feed Control

Wheel, and into the Torch Cable.

8. Connect a 220 VAC plug (not supplied) to the line cord. This step must be done by a

licensed electrician.

9. Plug the line cord into a 220 VAC electrical outlet.

10. Flip the Power Switch on the front of the unit to the ON (I) position. The blower will

start.

Page 6SKU 03664 For technical questions, please call 1-800-444-3353.

Page 7

Warning: The Torch Handle is now active. Do not touch anything grounded while performing the next step.

11. While holding the Torch Handle away from any grounding points, press and hold the

Trigger Switch to begin feeding the welding wire through the Torch Cable until it

reaches the Torch Head.

Turn the Wire Feed Speed Control clockwise to increase the wire feed. If the wire is

not feeding properly, It may also be necessary to increase the tension of the Wire

Tension Control knob by turning it clockwise.

12. Release the Trigger Switch and flip the Power Switch to the OFF (0) position.

13. Close all unit compartment doors. The unit is now ready for welding.

Wire Routing

Housing

Wire Feed Axis

Mechanism

Argon/CO2 Gas

Hose Connector

Controls and Indicators

Wire Spool

Welding Current

Adjustment Knob:

30~200 Amps

Operation

Nozzle

Trigger Switch

Torch Handle

Wire Feed Speed Control

Overheating Indicator - Red

Trigger Switch On Indicator Green

Ground Clamp

Po wer Switch

REV 03/05

Page 7SKU 03664 For technical questions, please call 1-800-444-3353.

Page 8

Welding

Warning: Before ar c welding, read and under stand all safety precautions and warnings

listed on pages 2 through 5.

1. Connect and secure the Argon/CO2 gas hose to the rear of the MIG Welder.

2. Securely clamp the Ground Cable Clamp as close as possible to the metal object to

be welded, or to the metal work bench where the object is mounted and electrically

connected.

3. Set the Welding Current Adjustment Knob ( 30~200 Amps) to the desired current

setting for the type of metal being welded.Thinner metals use lower current. Heavier

metals use higher current.

4. Verify that the Power Switch is in the OFF (0) position, then plug the MIG Welder plug

into a dedicated, 220 VAC, 20 amp line with delayed action type circuit breaker or

fuses. If an extension cord is used, it must have the following wire size: up to 30 feet,

use 10 AWG size wire; 30 to 50 feet, use 8 AWG wire; Over 50 feet, use 6 AWG wire.

5. While holding the Torch Handle with electrode wire clearly out of the way of any

grounded objects, turn the Power Switch to the ON (I) position.

6. Momentar ily press the Torch Trigger Switch to test the wire feed speed.

Adjust the speed by turning the Wire Feed Speed Control knob.

7. Orient yourself on the area to be welded, then place the Arc Shaded Face Shield over

your eyes.

Warning: Never look at the ignited arc without ANSI approved, arc shaded, eye protection in a full face shield. P ermanent eye damage or blindness can occur . Skin burns can

occur. Never breath arc fumes.

8. Press (and hold) the Torch Trigger Switch and stroke the area to be welded with the

electrode wire to ignite the arc.

Never tap the electrode wire into the welding surface to ignite the arc. This damages

its external coating on the electrode which prevents oxygen in the air from coming into

contact with the molten metal, causing it to oxidize.

9. Once the arc is ignited, tilt the electrode wire forward at an angle of about 35°. Refer

to the illustration below.

The wire feeds automatically at a speed dependent on the Min. or Max. current

setting. The wire speed can also be adjusted using the Wire Feed Speed Control.

Page 8SKU 03664 For technical questions, please call 1-800-444-3353.

Page 9

Note: If too much current is dra wn from the MIG Welder, the Thermal Overload protector will

activate, the red Overheating indicator will light, and the Arc Welder will turn off until it cools

down. If this happens, turn the Power Switch to the OFF (0) position and wait about 3 ~ 5

minutes.

10. When the weld is complete, lift the Torch Handle electrode wire clearly away from any

grounded object, lift your Face Shield, and turn the Power Switch to the OFF (0)

position.

11. Unplug the Power Cord from the electrical outlet.

Maintenance

Warning: Before performing an y maintenance on the MIG Welder , unplug the P ower Cord

from the electrical outlet.

1. Periodically using compressed air, open the top and side panels and blow out all dust

from the interior.

2. Store the unit in a clean and dry location.

3. Periodically clean out the Torch Head.

Replacing the Wire Reel

When the wire on the Feed Reel is used up, you will need to replace it as described on

page 6, step 6 through step 13.

Parts List

traPnoitpircseDtraPnoitpircseDtraPnoitpircseD

1esaC71loopSeriW23lenaP

2revoCgnidloF81ekarB

3revoCtneV91naF

4revoClioC02lenaPtnorF43leehWlortnoCdeeF

5revoCremrofsnarT12yalpsiDDEL53rotcelloCtnerruC

6bonKgnitsujdAtnerruC22hctiwSrewoP63sleehW

7remrofsnarTniaM32lortnoCdeepSeriW73eldnahthgiR

8draoBtiucriC42bonKdeepSeriW83eldnahtfeL

9draoBedoiD52tekcarBeldnaH93reggirT

01retratS62eldnaH04ebuTelzzoN

11elttorhT72droCeniLtupnI14piT

21pmalCdnuorG82feileRniartSelbaC24elzzoN

31elbaCdnuorG

41lanimreTdnuorG44droC

51reniateR03rotoMcirtcelE

61lenaPkcaB13lenaP

92

yssAesoH&hcroT

)44-73strapsniatnoC(

33

34piT

54

kcoL

eriWgnidleW

REV 06/05

/lortnoCnoisneTeriW

"230.foloopS.bL1

Page 9SKU 03664 For technical questions, please call 1-800-444-3353.

Page 10

Part 45 - W elding Wire - not shown.

NOTE: Some parts are listed and shown for illustration purposes only and are not availab le individually as replacement parts.

This diagram and the parts list that preceded it show the major components of this unit and are not comprehensive.

Assembly Diagram

REV 06/05

Page 10SKU 03664 For technical questions, please call 1-800-444-3353.

Page 11

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE T OOL ONLY . NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES

ANY REPRESENT ATION OR W ARRANTY OF ANY KIND T O THE BUYER THAT HE OR SHE IS QUALIFIED

TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY

P AR TS OF THE PR ODUCT . IN F ACT, THE MANUF A CTURER AND/OR DISTRIBUTOR EXPRESSLY ST A TES

THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO , OR ARISING OUT OF HIS OR HER INST ALLATION OF REPLACEMENT PARTS THERET O.

Schematic Diagram

REV 06/05

Page 11SKU 03664 For technical questions, please call 1-800-444-3353.

Loading...

Loading...