Page 1

AIR HYDRAULIC RIVETER

®

167

ASSEMBLY AND OPERATING INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2005 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions, please call 1-800-444-3353.

Page 2

PRODUCT SPECIFICATIONS

yticapaCteviR

erusserPriAgnitarepOISP09

noitpmusnoCriAISP09@MFC4

eziStelnIriA

seziSeceipesoN

snoisnemiDllarevO3xL"9xH"11

thgieWteN3

3

/23,"1/8,"5/

1

/

4

3

/23,"1/8,"5/23,"3/61"

7

/

8

TPN81-"

sdnuoP

3

&,"

23

/

61

1

/8W"

snipdezis"

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures, parts list and assembly

diagram. Keep your invoice with this manual. Write the invoice number on the inside of the

front cover. Keep this manual and invoice in a safe and dry place for future reference.

UNPACKING

When unpacking, check to make sure that all the parts and accessories listed on

page 11 are included, and the product is intact and undamaged. If any parts are missing or

broken, please call Harbor Freight Tools at the number shown on the cover of this manual

as soon as possible.

SAFETY WARNINGS AND PRECAUTIONS

1. WARNING! Use eye and hearing protection. Always wear ANSI approved

safety impact goggles, hearing protection, and heavy-duty work gloves when

using this Riveter. Other people in the work area must also wear appropriate

ANSI approved safety equipment.

2. Keep work area clean. Cluttered areas invite accidents.

3. Stay within air pressure capacity. Never operate the Riveter above 90 PSI.

4. Observe work area conditions. Keep work area well lit. Do not use pneumatic

tools in the presence of flammable gases or liquids.

5. Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools, extension cords, or air hoses.

6. Store idle equipment. When not in use, tools must be stored in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

7. Use the right tool for the job. Do not attempt to force a small tool or attachment to

do the work of a larger industrial tool. There are certain applications for which this

tool was designed. It will do the job better and more safely at the rate for which it

SKU 167 For technical questions, please call 1-800-444-3353 PAGE 2

Page 3

was intended. Do not modify this tool, and do not use this tool for a purpose for

which it was not intended.

8. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically nonconductive clothes and nonskid footwear

are recommended when working. Wear restrictive hair covering to contain long

hair.

9. Do not overreach. Keep proper footing and balance at all times. Do not reach over

or across running tools or air hoses.

10. Disconnect air hose and release any built-up air pressure. Never service the

Riveter or disassemble with the air hose attached. Always release any built-up air

even after disconnecting hose. Disconnect the Riveter when not in use.

11. Remove adjusting wrenches. Check that adjusting wrenches are removed from

the tool and work surface before attaching to an air source.

12. Avoid unintentional starting. Be sure the Trigger (40) is in the OFF position when

not in use and before plugging in. Do not carry any tool with your finger on the

Trigger, whether it is attached to an air source or not. Do not point the tool towards

yourself or anyone.

13. Stay alert. Watch what you are doing. Use common sense. Do not operate any tool

when you are tired.

14. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts, any broken

parts, and any other condition that may affect proper operation. Any part that is

damaged should be properly repaired or replaced by a qualified technician. Do not

use the tool if the Trigger does not operate properly.

15. Replacement parts and accessories. This product is to be repaired and serviced

only by a qualified technician. When this product is serviced, only identical

replacement parts should be used. Use of any other parts will void the warranty.

Only use accessories intended for use with this tool. Approved accessories are

available from Harbor Freight Tools.

16. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels if taking prescription medicine to determine if your judgement or reflexes are

impaired while taking drugs. If there is any doubt, do not operate the tool.

17. Maintenance. The maintenance outlined in the “Maintenance” section should be

performed regularly. For your safety, this product should be serviced or repaired

regularly only by a qualified technician.

18. Compressed air only. Never use combustible gas as a power source.

19. Fire the Rivets into an appropriate work surface only. This Riveter is designed

for use on metal objects only, and is not suitable for soft surfaces.

SKU 167 For technical questions, please call 1-800-444-3353 PAGE 3

Page 4

20. Do not fire the Rivets too close to the edge of a workpiece. They may split the

workpiece and cause it to fly free, causing personal injury.

21. Transport the Riveter safely. Always disconnect the air supply when moving the

tool in the workplace. Carry the tool by the handle and avoid contact with the Trigger

(40).

22. Avoid working alone. If an accident happens, an assistant can bring help.

23. Always attach the Safety Cap (23) to the Riveter prior to using the tool. Make

sure the

slot

in the Safety Cap faces upward to avoid spilling used Rivet Pins.

24.

WARNING! Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities contain chemicals known (to the State of California)

to cause cancer, birth defects, or other reproductive harm.

Some examples of these chemicals are:

* Lead from lead-based paints,

* Crystalline silica from bricks, cement, and other masonry products,

* Arsenic and chromium from chemically treated lumber.

25.

(California Health & Safety Code § 25249.5,

WARNING! The warnings, cautions, and instructions discussed in this instruction

et seq.

)

manual cannot cover all possible conditions and situations that may occur. It must

be understood by the operator that common sense and caution are factors which

cannot be built into this product, but must be supplied by the operator.

ASSEMBLY INSTRUCTIONS

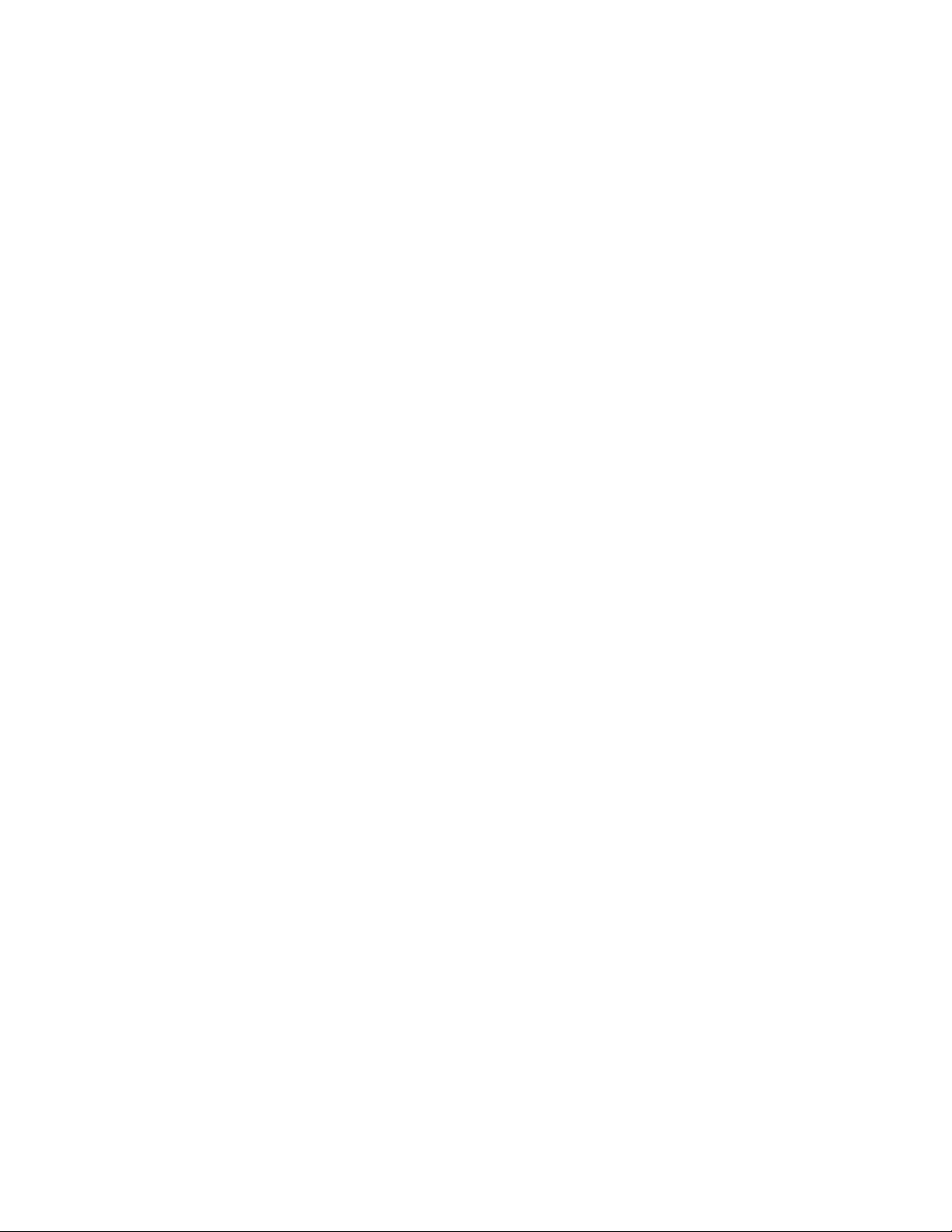

1. For best service, you should incorporate an oiler, regulator, and inline filter, as shown

in the diagram below. Hoses, couplers, oilers, regulators, and filters are all available

at Harbor Freight Tools. NOTE: If an automatic oiler is not used, put 3-5 drops of

pneumatic Tool Oil (not included) in the tool’s quick connector before each use.

(See Figure A.)

REGULATOR

FIGURE A

OILER

FILTER

SKU 167 For technical questions, please call 1-800-444-3353 PAGE 4

Page 5

2. Prior to use, the Riveter requires the attachment of the Quick Connector (53) to its

Air Cylinder (29). To do so, make sure the screen

Air Filter

is properly seated in the

Air Cylinder. Wrap approximately 3” of pipe thread seal tape (not included) around

the male threads of the Quick Connector. Then, firmly tighten the Quick Connector

into the Air Cylinder. (See Figure B.)

AIR CYLINDER

(29)

FIGURE B

QUICK CONNECTOR

(53)

To Prime The Riveter:

1. WARNING! Make sure the Riveter is disconnected from its air supply hose

prior to performing any maintenance, service, or changing accessories.

2. To prime the Riveter, use the Spanner (36) to unscrew and remove the Cylinder

Cap (33) from the bottom of the Riveter. (See Figure C, next page.)

3. Use a pair of pliers (not included) to remove the Piston Assembly (30 thru 33) from

the Air Cylinder (29). (See Figure C.)

4. Hold the Air Cylinder (29) upside down, and pour in hydraulic oil (not included).

The fill level should only reach the top of the Frame (15). (See Figure C.)

SKU 167 For technical questions, please call 1-800-444-3353 PAGE 5

Page 6

5. Insert the Piston Assembly (30 thru 33) back into the Air Cylinder (29).

(See Figure C.)

6. Use the Spanner (36) to firmly screw the Cylinder Cap (33) back onto the Air Cylinder

(29). (See Figure C.)

AIR CYLINDER

(29)

CYLINDER CAP

(33)

AIR PISTON LOCK NUT

(30-3)

SPANNER

(36)

PISTON ASSY.

(30 THRU 33)

AIR CYLINDER

(29)

FIGURE C

REV 09/05

SKU 167 For technical questions, please call 1-800-444-3353 PAGE 6

Page 7

Nosepieces:

OPERATING INSTRUCTIONS

1. The Riveter comes with

four

Nosepieces. The Nosepiece part numbers and sizes

are as follows: (1A = 3/16”), (1B = 5/32”), (1C = 1/8”), (1D = 3/32”). (See Figure D.)

2. Use the Spanner (36) when changing Nosepieces. (See Figure D.)

FRAME HEAD

(11)

SAFETY CAP

(23)

FRAME

CAP NUT

(22)

TRIGGER

(40)

NOSEPIECE

(1A, 1B, 1C, 1D)

FIGURE D

QUICK CONNECTOR

(53)

To Operate The Riveter:

1. Make sure the Safety Cap (23) is firmly secured to the Riveter by tightening the

Frame Cap Nut (22). Also, make sure the slot in the Safety Cap is turned upward to

avoid spilling used rivet pins. (See Figure D.)

2. Depending on the size of rivet’s pin (not included) used, attach the corresponding

Nosepiece size (3/16”, 5/32”, 1/8”, or 3/32”) with the Spanner (36).

(See Figure D.)

3. IMPORTANT: When drilling rivet holes in a workpiece, make sure to use the same

diameter drill bit as the outer diameter of rivet you will be using.

4. Attach an air hose to the Quick Connector (53) of the Riveter. (See Figure D.)

5. Turn on the air compressor, and set its regulator at 90 PSI.

Do not exceed 90 PSI.

SKU 167 For technical questions, please call 1-800-444-3353 PAGE 7

Page 8

6. Insert the small end of a rivet fully through the Nosepiece (1A, 1B, 1C, or 1D).

CAUTION! Make sure to NEVER to touch the Trigger (40) when you are inserting

rivets. (See Figure D.)

7. Insert the rivet through the predrilled hole in the workpiece.

8. Hold the Riveter firmly with both hands, and squeeze the Trigger (40) to activate the

Riveter. Repeat as necessary. Then, release pressure on the Trigger.

(See Figure D.)

9. When finished using the Riveter, turn off the air compressor. Squeeze the Trigger

again to release any compressed air in the Riveter. Disconnect the air hose from

the tool. Then, store the Riveter in a clean, dry, safe location out of reach of children.

(See Figure D.)

INSPECTION, MAINTENANCE, AND CLEANING

1. WARNING! Always wear ANSI approved safety impact goggles when

performing any inspection, maintenance, or cleaning procedures.

2. WARNING! Prior to performing any inspection, maintenance, or cleaning of

the Riveter, make sure to disconnect the air hose from the tool. Then, squeeze the

Trigger (40) again to release any compressed air in the Riveter.

3. To clean the exterior of the Riveter, wipe with a clean, damp cloth using a mild

detergent or mild solvent. Do not immerse the tool in liquids.

4. To clean and change the Jaws:

A. Unscrew and remove the Frame Head (11), using the Spanner (36).

(See Assy. Diagram.)

B. Use the Spanner (36) to unscrew and remove the Jaw Case (6). Use care as

there is a Spring (10) behind the Jaw Case (6) which may fly out.

(See Assy. Diagram.)

C. Remove the Jaws (7) from inside the Jaw Case (6).

(See Assy. Diagram.)

SKU 167 For technical questions, please call 1-800-444-3353 PAGE 8

Page 9

D. If you are going to clean the Jaws (7), use a steel brush and mild solvent. Then,

apply a light coat of machine oil to the Jaws. If you are going to replace the

Jaws, the entire assembly (6, 7, 8, 9, & 10) must be replaced at the same time,

due to the possibility of additional parts being damaged when the Jaws were

damaged. (See Assy. Diagram.)

E. Insert the Jaws (7) back into the Jaw Case (6).

(See Assy. Diagram.)

F. When reassembling the Jaw Case (6), make sure the wedge on the Jaw Pusher’s

(8) head lines up in between the Jaws, pushing them slightly apart.

(See Assy. Diagram.)

G. Check the distance from the head of the Jaw Case (6) to the mounting threads of

the Frame Head (11) using the gauge on the Spanner (35). With the gauge at a

slight incline, the back of the gauge should rest on the beginning of the Frame

Head threads, while the front of the gauge should rest on the front edge of the

Jaw Case (6). If it does not, tighten/loosen the Jaw Case until the distance is

corrected. (See Figure E.)

5. When storing, always store the Riveter in a clean, dry, safe location out of reach of

children.

6.

FIGURE E

WARNING! All maintenance, service, and repairs not mentioned in this manual

must only be performed by a qualified service technician.

SPANNER GAUGE (35)

JAW CASE

(6)

(THREADS)

FRAME HEAD (11)

SKU 167 For technical questions, please call 1-800-444-3353 PAGE 9

Page 10

TROUBLESHOOTING

melborPesuaCelbissoPnoituloSylekiL

.eceipesoNe

.gniR-OdegamaD

.swaJdegamadronroW.swaJecalpeR

riaetauqedani/nekorB

.snoitcennocesohrooP

.eceipesoNnethgiT

.swaJnaelC

detresniylreporptonnipteviR

.detresniyllufsiniPtahterusekaM

.reteviRemirP

.htgneltevirreporpesU

.rotalugerkcehC

aybdecivresrosserpmocevaH

nhcetdeifilauq

otedargpu/naici

.ytilibapactneiciffusforosserpmoc

.epatlaesdaerhtepipgnisutcennoceR

.gniR-OecalpeR

lootcitamuenphtiwetacirbuldnanaelC

.lio

lootcitamuenphtiwetacirbuldnanaelC

.lio

.gnippilsswaJ

.nepotonlliwswaJ

sooL

.swaJytriD

.reteviRotni

.trohsootsiekortS

woL

.lio

.ezisgnorwteviR

.erusserpriawoL

.noitcagnillupkaeW

.riagnikaeL

ytriD

.rosserpmoc

.evlaVriA

.telnienilriaytriD

PARTS LIST

traPnoitpircseDtraPnoitpircseDtraPnoitpircseD

A1(eceipesoN

B1(eceipesoN

C1(eceipesoN

D1(eceipesoN

6esaCwaJ42niPwercSgnitteS04reggirT

7waJ52)21(gniR-OpukcaB14rotcennoC

8rehsuPwaJ62gniRpukcaB24reve

9gniRrehsaWesaC72tuNkcoLemarF34niPreveL

01gnirpSrehsuPwaJ82noihsuCrebbuRA34)7p(gniR-OrehsuPevlaV

A01)2x72(

11daeHemarF1-03metSnotsiPriAA44gnirpSevlaV

21tuNkcoLesaC2-03tresnInotsiPri

31gniRpUkcaB3-03tuNkcoLnotsiPriAA54ralloCevlaV

41)21p(gniR-OpUkcaB4-03etalPnorIegraLB54)5p(gniR-OralloC

51em

arF5-03etalPnorIllamS64gnirpSevlaV

61notsiPliOA13gniRnotsiPriA15)11p(gniR-OpaCevlaV

71)A22p(gniR-OnotsiPliO23)26.2x

81gniRpUkcaB33paCrednilyC35rotcennoCkciuQ

91gnirpSnruteR53eguaGrennapS

3

/61)"02pilCgnignaH63rennapS

5

/23)"12paCemarF73niPreggirT

1

/8)"22tuNpaCemarF83rotcennoC

3

/23)"32paCytefaS93doRreggirT

gniR-OpaCemarF92rednilyCriA44rehsuPevlaV

A54evlaV

49.76(gniR-OrednilyC25paCevlaV

LreggirT

SKU 167 For technical questions, please call 1-800-444-3353 PAGE 10

Page 11

ASSEMBLY DIAGRAM

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL

AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY

PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK

AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS

THERETO.

1A

40

30-1

30-4

30-2

30-3

11

41

31A

30-5

32

33

6

10

39

44A

43A

45B

7

13

12

14

9

14

10A 2 0

8

15 16

38

24

17

18

23

22

1937

35

43A

23

36

44

26

25

29

24

1B 1C

1D

43

35

45

44

51

52

28

27

NOTE:

Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

SKU 167 For technical questions, please call 1-800-444-3353 PAGE 11

Loading...

Loading...