Page 1

HAND OPERATED

WATER PUMP

01318

SET UP AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 1999 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual Revised 10k

Page 2

SPECIFICATIONS

Handle 7”

Inlet Pipe Diameter 1-1/4” NPT

Maximum Lift 25 Feet

Maximum Volume 12 oz. Per Stroke

Assembled Dim. 17” H x 8” W

Spout to Handle 12-1/2”

Construction Cast Iron Body, Base, and Handle

Aluminum Internal Parts

This product can be set up to pump water but

never use this product to pump drinking (potable)

water.

WARNING!

Wear ANSI-approved safety goggles during 1.

assembly.

Use for pumping water only. 2.

WARNING:3. This product contains or, when

used, produces a chemical known to the State

of California to cause cancer and birth defects

or other reproductive harm. (California Health

& Safety Code § 25249.5, et seq.)

(5). The large bolt hole on the Cover (5) should

sit opposite the spout on the Cylinder (9). The

two recessed Screw Bolts (4) should straddle

each side of the spout on the Cylinder (9).

Tighten the recessed Screw Bolts (4) with a

small at screwdriver. With a crescent wrench,

tighten the large Bolt (6) on the Cover (5)

opposite the spout.

Attach the 7. Handle (2) to the Piston Assembly

(8) using a Bolt (3) and Nut (1). Make sure

the hole on the Handle (2) that attaches to the

Cover (5) rests between the bolt housing on the

Cover (5). If necessary, rotate the screw eyelet

on the Piston Assembly (8) to nd the best

t. Tighten the Nut (1). Next, run the Bolt (7)

through the bolt housing on the Cover (5) and

the Handle (2) and tighten the Nut (1).

Attach 1-1/4” NPT threaded water source 8.

pipe to the threaded inlet on the bottom of the

pump.

Secure the pump by screwing the base to a 9.

stable surface.

ASSEMBLY

Place the 1. Base (13) on a flat, sm ooth

surface.

Set the 2. Valve Assembly (12) in the circle

groove of the Base (13). It will only t with the

metal plate up.

Put the 3. Cylinder (9) on the Valve Assembly

(12). Line up the Cylinder (9) so that the bolt

holders on each side of sit over the two drilled

openings on the Base (13). The spout on the

Cylinder (9) should rest over the at side of

the Base (13).

Slip a 4. Bolt (10) and a Washer (11) into the

bolt holder on the Cylinder (9). Put a Nut (14)

under the Base (13) and screw it onto the Bolt

(10). Hand tighten. Repeat the procedure

on the other side. Then, wrench tighten both

Bolts (10).

Set the 5. Piston Assembly (8) with the screw

eyelet up, down into the Cylinder (9).

OPERATION

This pump needs to be primed before every 1.

use. Keep a pitcher (not included) of water near

the pump for this purpose. Pump the handle

up and down while pouring about a quart of

water into the top of the pump to prime it and

start the water ow.

Note: DO NOT STOP PUMPING THE HANDLE

UNTIL FINISHED! Stopping, even momentarily,

will cause the pump to lose its prime and no

longer work until primed again.

Rell the pitcher. Then, continue pumping as 2.

needed.

Note: Do not pump drinking water from this

pump.

Put the 6. Cover (5) onto the Cylinder (9) so the

screw eyelet on the Piston Assembly (8) ts

through the opening in the center of the Cover

REV 02d; 09b

SKU 01318 For technical questions, please call 1-800-444-3353. Page 2

Page 3

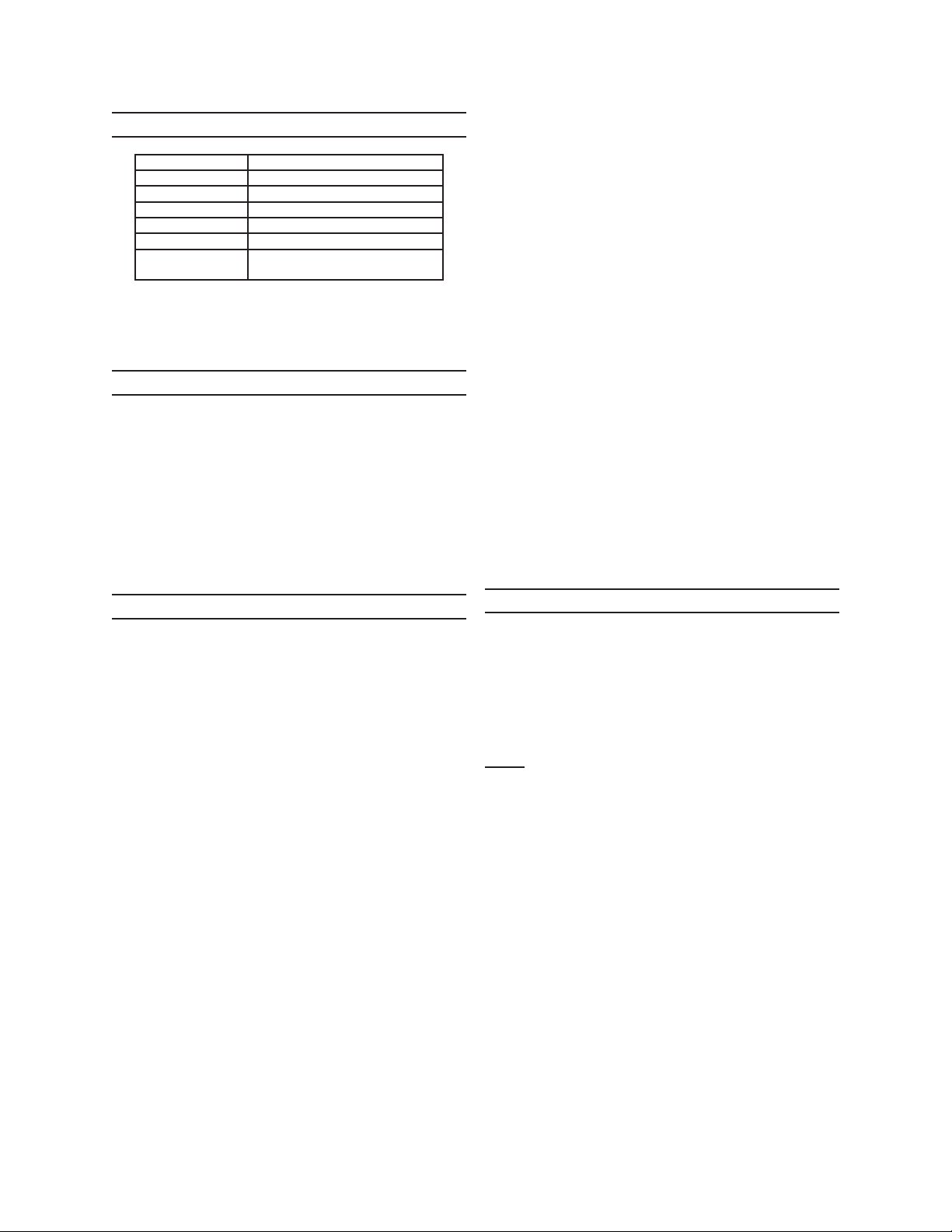

Part Description Qty

1 Nut M8 2

2 Handle 1

3 Bolt M8 x 30 1

4 Bolt M6 x 10 2

5 Cover 1

6 Bolt M8 x 40 1

7 Bolt M8 x 40 1

8 Piston Assembly 1

9 Cylinder 1

10 Bolt M10 x 40 2

11 Washer M10 2

12 Valve Assembly 1

13 Base 1

14 Nut M10 2

PARTS LIST AND DIAGRAM

1

2

3

4

5

6

7

10

11

12

13

14

8

9

SKU 01318 For technical questions, please call 1-800-444-3353. Page 3

Page 4

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN

THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY

REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT.

IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS

REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION

OF REPLACEMENT PARTS THERETO.

SKU 01318 For technical questions, please call 1-800-444-3353. Page 4

Loading...

Loading...