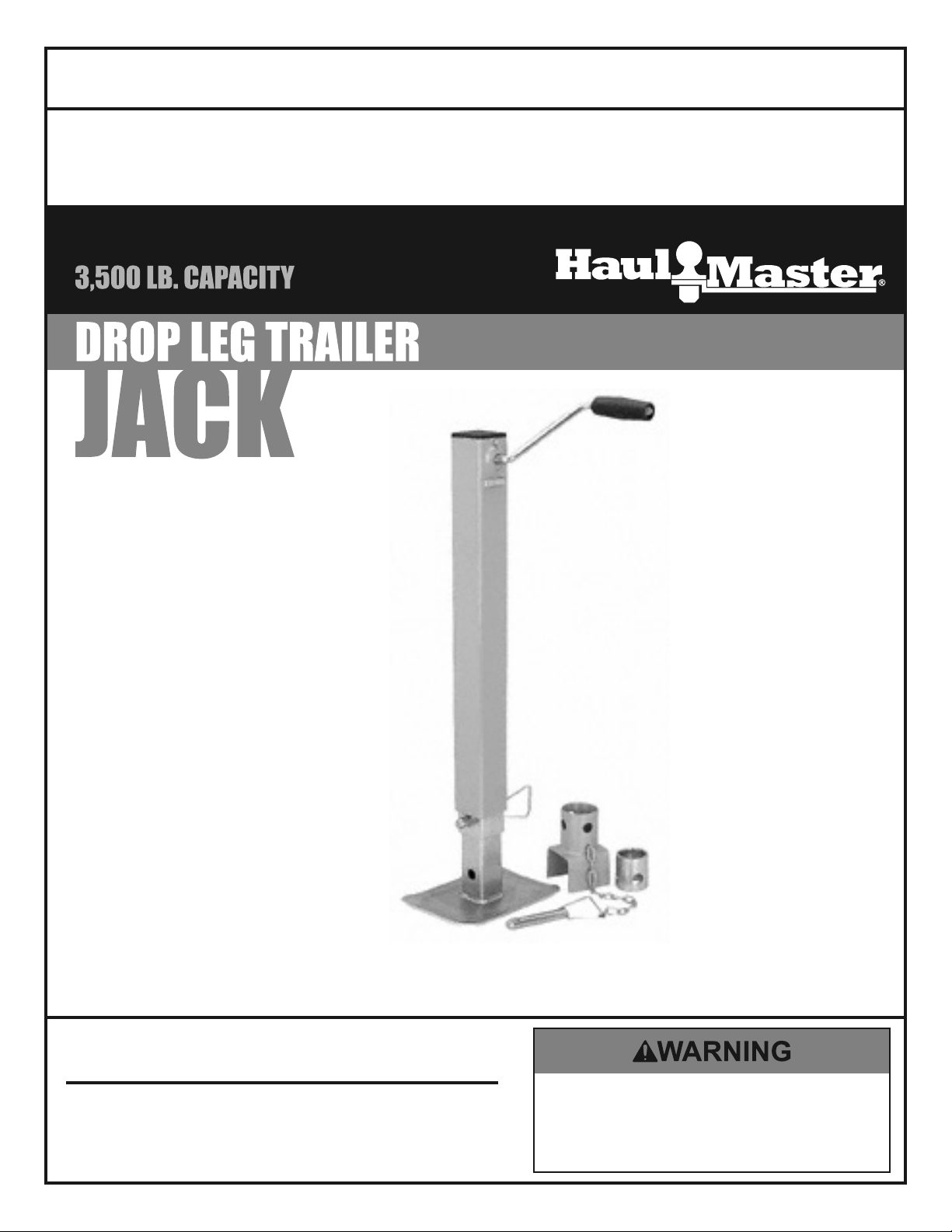

Harbor Freight Tools 03961 Product manual

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference.

ITEM 03961

REV 15b

Visit our website at: http://www.harborfreight.com

Email our technical support at: productsupport@harborfreight.com

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 2007 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling, and all

other information provided with this

product:

This is the safety alert symbol. It

is used to alert you to potential

personal injury hazards. Obey all

safety messages that follow this

symbol to avoid possible injury

or death.

DANGER indicates a

hazardous situation

which, if not avoided, will result in

death or serious injury.

WARNING indicates a

hazardous situation

which, if not avoided, could result in

death or serious injury.

CAUTION, used with the

safety alert symbol,

indicates a hazardous situation

which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to

address practices not

related to personal injury.

CAUTION, without the

safety alert symbol, is

used to address practices not

related to personal injury.

GENERAL SAFETY WARNINGS

AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY.

Cluttered, damp, or wet work areas invite

injuries.

3. STORE IDLE EQUIPMENT. When not in use,

tools and equipment should be stored in a

dry location to inhibit rust. Always lock up

tools and equipment, and keep out of reach of

children.

4. DO NOT USE THIS PRODUCT IF UNDER

THE INFLUENCE OF ALCOHOL OR DRUGS.

Head warning labels on prescriptions to

determine If your judgement or reflexes are

impaired while taking drugs. If there is any

doubt, do not attempt to use this product.

5. USE EYE AND HAND PROTECTION. Wear

ANSI approved safety impact eyeglasses

and heavy-duty work gloves when using

this product. ANSI approved safety impact

eyeglasses and heavy-duty work gloves are

available from Harbor Freight Tools.

6. DRESS SAFELY. Do not wear loose clothing

or jewelry, as they can become caught

in moving parts. Wear a protective hair

covering to prevent long hair from becoming

caught in moving parts. If wearing alongsleeve shirt, roll sleeves up above elbows.

7. DO NOT OVERREACH. Keep proper

footing and balance at all times to prevent

tripping, falling, back injury, etcetera.

8. INDUSTRIAL APPLICATIONS MUST

FOLLOW OSHA REQUIREMENT.

9. STAY ALERT. Watch what you are doing at

all times. Use common sense. Do not use

this product when you are tired or distracted

from the job at hand.

10. CHECK FOR DAMAGED PARTS. Before

using this product, carefully check that it will

operate properly and perform its intended

function. Check for damaged parts and

any other conditions that may affect the

operation of this product. Replace or repair

damaged or worn parts immediately.

2. KEEP CHILDREN AWAY FROM WORK AREA

Do not allow children to handle this product.

Page 2 For technical questions, please call 1-888-866-5797. Item 03961

11. REPLACEMENT PARTS AND

ACCESSORIES: When servicing, use

only identical replacement parts. Only

use accessories intended for use with this

product. Approved accessories are available

from Harbor Freight Tools.

12. MAINTAIN THIS PRODUCT WITH CARE.

Keep this product clean and dry for better

and safer performance.

13. MAINTENANCE: For your safety, service

and maintenance should be performed

regularly by a qualified technician.

14. USE THE RIGHT TOOL FOR THE JOB.

Do not attempt to force a small tool or

attachment to do the work of a larger

industrial tool. There are certain applications

for which this tool was designed. It will do

the job better and more safely at the rate for

which it was intended. Do not modify this

tool, and do not use this tool for a purpose

for which it was not intended.

15. The warnings, precautions, and instructions

discussed in this manual cannot cover all

possible conditions and situations that may

occur. The operator must understand that

common sense and caution are factors,

which cannot be built into this product, but

must be supplied by the operator.

Page 3For technical questions, please call 1-888-866-5797.Item 03961

SPECIFIC PRODUCT WARNINGS

AND PRECAUTIONS

1. THE JACK IS DESIGNED FOR USE.

WITH THE MODEL 47283 ROUND

JACK MOUNT (AVAILABLE FROM

Harbor Freight Tools).

THE ROUND JACK MOUNT ALLOWS THE

JACK TO BE SWIVELED AND SAFELY

LOCKED IN PLACE WHEN THE JACK IS

NOT BEING USED.

DO NOT ATTEMPT TO WELD THE JACK

IN A VERTICAL POSITION DIRECTLY

ONTO THE TRAILER TONGUE. (See

Figures A and B.)

2. WELDING IS REQUIRED TO SECURELY

AND PERMANENTLY ATTACH THE

JACK TO THE TRAILER TONGUE. ONLY

A QUALIFIED, CERTIFIED, WELDER

SHOULD DO THE WELDING. A poor

weld may cause the trailer to fall suddenly,

potentially causing serious personal and/or

property damage. (See Figure A.)

3. DO NOT EXCEED THE MAXIMUM LIFT

CAPACITY (3,500 POUNDS) FOR THE

JACK. Overloading the Jack could cause

personal injury and/or property damage. Be

aware of dynamic loading! A sudden drop

of the Jack (with load attached) may create

for a brief instant, an excess load, which

may result in damage to the product and/or

personal injury.

4. MAKE SURE TO READ AND

UNDERSTAND ALL INSTRUCTIONS AND

SAFETY PRECAUTIONS AS OUTLINED

IN THE MANUFACTURER’S MANUAL

FOR THE TRAILER YOU ARE LIFTING.

Make sure to attach the Jack at the trailer

manufacturer’s recommended lifting point.

(See Figure A.)

5. ALWAYS EXAMINE THE JACK FOR

STRUCTURAL CRACKS, BENDS,

DAMAGE, AND ANY OTHER CONDITION

THAT MAY AFFECT THE SAFE

OPERATION OF THE JACK.

Do not use the Jack even if minor damage

appears.

6. DO NOT USE THE JACK ON ANY SOFT

GROUND SURFACE. Make sure the Jack is

used on a dry, hard, ground surface capable

of supporting the weight of the Jack, the

trailer, contents being lifted, and any

additional tools and equipment. Do not use

on asphalt, which may soften in hot weather.

7. ROLL AWAY: Avoid situations that allow

the trailer to roll away on the Inner Tube (1)

of the Jack and trailer wheels. Always use

wheel chocks to prevent rolling. Never leave

the trailer unattended while on the Jack. The

possibility of roll away always exists.

8. MAINTAIN A SAFE WORKING

ENVIRONMENT. Keep the work area well

lit. Make sure there is adequate surrounding

workspace. Always keep the work area free

of obstructions, grease, oil, trash, and other

debris.

9. ALWAYS KEEP HANDS, FINGERS, ARMS,

AND FEET OUT FROM UNDER THE

TRAILER TONGUE WHEN· APPLYING OR

RELEASING A LOAD. Remain clear of the

trailer when raising or towering. People and

animals should be kept at a safe distance

when using the Jack.

10. USE EXTREME CAUTION WHEN

APPLYING OR RELEASING A LOAD.

Never allow the load to suddenly release.

Slowly and carefully apply and release the

load.

11. NEVER LIFT A TRAILER WITH ANYONE

ON IT. Do not allow others in the lift area

while operating the Jack.

Page 4 For technical questions, please call 1-888-866-5797. Item 03961

Loading...

Loading...