Happy HCS Instruction Book

HCS

COMPACT ELECTRONIC EMBROIDERY MACHINE

INSTRUCTION BOOK

CSK101-2

INDEX

0-0

IMPORTANT SAFETY INSTRUCTIONS.. 1-1

WARNING MARKS, LABELS, MEANINGS AND LOCATION ..

1-2

SETTING UP THE MACHINE

Remove the machine from box .............................2-1

Accessories...........................................................2-2

Assemble machine kit ...........................................2-3

Machine installation ..............................................2-4

Grounding instruction............................................2-6

Disposal of a battery .............................................2-6

MAIN PARTS ............................................ 3-1

HOW TO READ

THESE

INSTRUCTIONS .............

3-3

MESSAGE ................................................ 3-4

LET'S TURN ON THE MACHINE

How to turn on the machine ..................................3-5

If the display is not clear .......................................3-5

Calendar and clock setting....................................3-6

FUNCTION OF THE CONTROL BOX ...... 3-7

CONTROL MENU .............................................

3-9

INSERTING A NEEDLE............................ 4-1

SELECT NEEDLES AND THREADS....... 4-2

BACKING MATERIALS............................. 4-3

BOBBIN WINDING

Winding the bobbin ...............................................4-4

Removing the bobbin ............................................4-5

Inserting the bobbin ..............................................4-5

Adjusting bobbin thread tension............................4-5

Inserting the bobbin case......................................4-5

THREADING THE MACHINE

How to thread upper thread ..................................4-6

MACHINE SETTINGS............................... 5-1

PREPARATION OF PATTERN DATA

Connecting to a PC by Serial or USB connection.5-4

Reading embroidery pattern data from the PC .....5-4

Read embroidery pattern data from memory media

Select embroidery pattern from memory...............5-7

Erase embroidery pattern from memory ...............5-8

Erase all designs...................................................5-9

Export memorized pattern from memory ............ 5-9b

How to select monogram letters .........................5-10

SETTING AUTOMATIC COLOR CHANGE ...

5-5

5-15

SEWING WITH TUBULAR FRAMES

Installing and removing the frame base ................6-1

How to hoop..........................................................6-2

Putting the hoop in the machine ...........................6-3

Starting to sew ......................................................6-4

CAP FRAME (OPTION)

Changing the needle plate ....................................7-2

Installing and removing the cap drive frame .........7-3

Normal cap frame..................................................7-5

Wide cap frame.....................................................7-8

Starting to sew ......................................................7-B

ADJUSTING THE THREAD TENSIONS .. 8-1

ADJUSTING THE LASER POINTER (OPTION)...

8-2

SEWING

What to do if the thread breaks while sewing ...........

Stopping and resuming sewing .............................9-1

Loss of power while embroidering ........................9-2

Moving the hoop while embroidering then

returning to the correct location (Position) .......... 9-3

Moving to the beginning position of pattern

(Origin) ................................................................9-3

Going back to the start of design data (Top).........9-4

Placing the design in the center of the selected

embroidery frame (Center)..................................9-4

Rotating and mirroring designs (Convert) .............9-5

Starting from a midpoint of a design (F.Posi)............

9-1

9-6

OTHER SETTINGS

Create network......................................................9-8

LOG-IN • LOG-OUT • TURN-OFF ............ 9-B

SPECIFICATIONS • MAINTENANCE

Specifications ......................................................10-1

Oiling...................................................................10-1

Cleaning of the rotary hook

Cleaning the thread cutting knife ............................

10-2

ERRORS AND WHAT TO DO ................ 10-3

INITIALIZING OF MACHINE SETTINGS

Initializing of machine system ................. 11-1

Initializing of machine speed ................... 11-1

CHANGE OF THREAD BREAK DETECTION ....

11-3

HELPFUL HINTS .................................... 12-1

EMBROIDERY TERMS .......................... 12-2

BUILT-IN FONT LIST.............................. 12-3

-CS -2

0_0 I916

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the following.

1-1

Read all instructions before using this appliance.

DANGER - To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this appliance

from the electric outlet immediately after using and before cleaning.

WARNING

1. Do not allow to be used as a toy. Close attention is necessary when this appliance is used

by or near children.

2. Use this appliance only for its intended use as described in this manual. Use only attachments recommended by the manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it

has been dropped or damaged, or dropped into water. Return the appliance to the nearest

authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air openings blocked. Keep ventilation openings of the

sewing machine and foot controller free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10.Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11.Always use the proper needle plate. The wrong plate can cause the needle to break.

12.Do not use bent needles.

13.Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14.Switch the sewing machine off (“0”) when making any adjustments in the needle area, such

as threading needle, changing needle, threading bobbin, or changing presser foot, etc.

15.Always unplug sewing machine from the electrical outlet when removing covers, lubricating,

or when making any other user servicing adjustments mentioned in the instruction manual.

- To reduce the risk of burns, fire, electric shock, or injury to persons:

SA VE THESE INSTRUCTIONS

-CS -3

1_1 F201

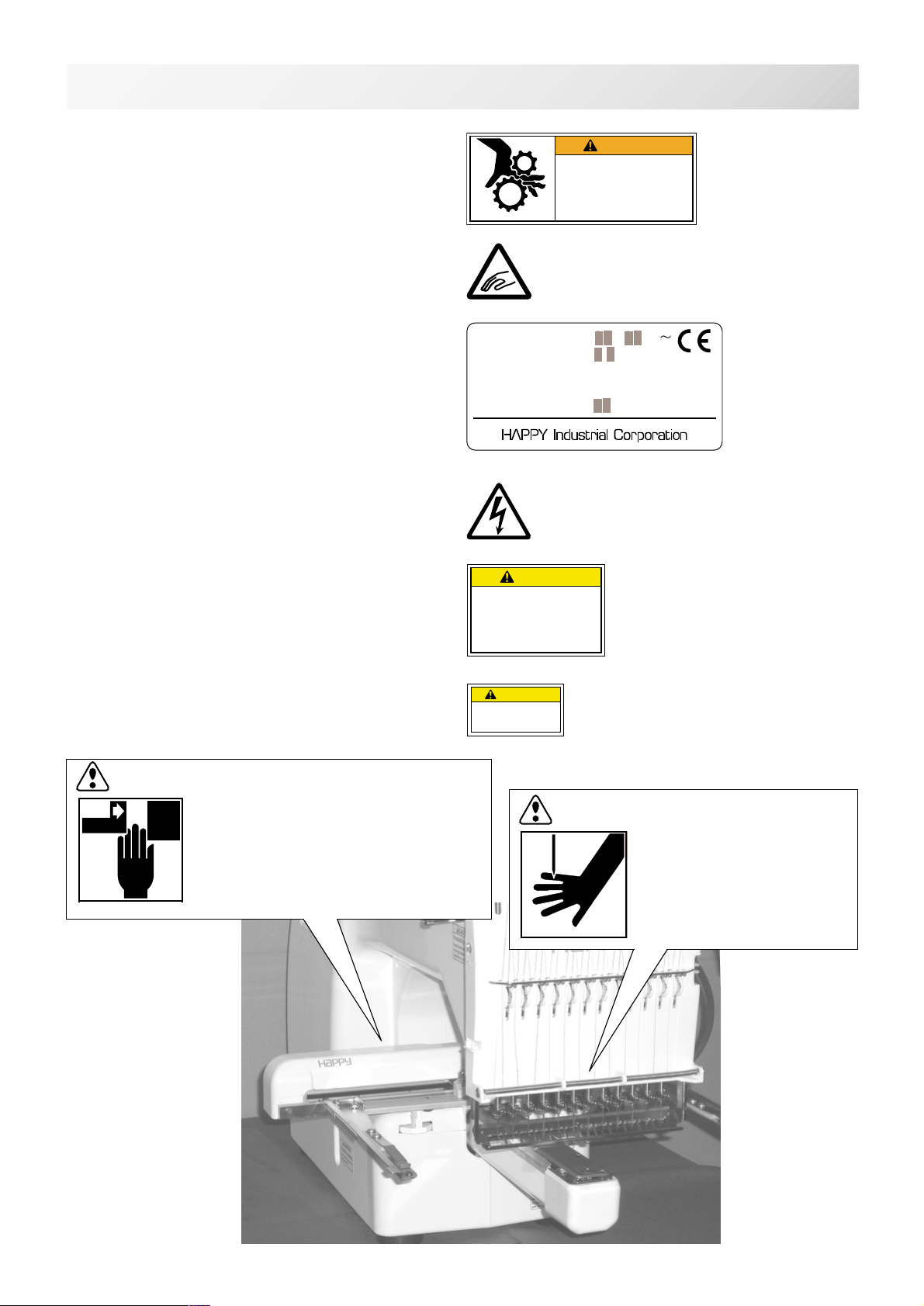

WARNING LABELS & THEIR LOCATIONS

1-2

Trapping hazard

Shut the cover when starting the machine.

Do not put hands in while the machine is running.

Trapping, Puncture, Cut hazard wherever this

label is found

Power Supply Voltage sticker

Risk of electrical shock and fire if the power

recommendations on this label are ignored!

Make sure that the power supply meets the exact

specifications as provided by the manufacturer.

Shock hazard on all electrical components

Injury risk on moving head(s)

Keep hands away from the moving heads while the

machine is running.

WARNING

Fear of serious injury.

Shut the cover when starting the

machine. Do not put hands in

while the machine is running.

VOLTAGE

AMPERE

PHASE SINGLE

FREQUENCY

POWER CONSUMPTION

CAUTION

Possibility of injury.

Keep hands away from the

moving heads while the

machine is running.

200-230V

1.1A

50/60Hz

220W

ES-HMF-5117-0

ES-HMF-5113-0

****

Laser beam (Class 1)

Do not stare into the beam.

CAUTION: Injury risk on frame and carriage

Keep hands away from the drive

frame while the machine is

running.

Catch a finger in the X-carriage.

CAUTION

Laser beam (Class1)

Do not stareinto the beam.

WARNING: Injury risk warning

for all needles

Keep fingers away from

the needles while

the machine is running.

-CS -6

1_2 K101

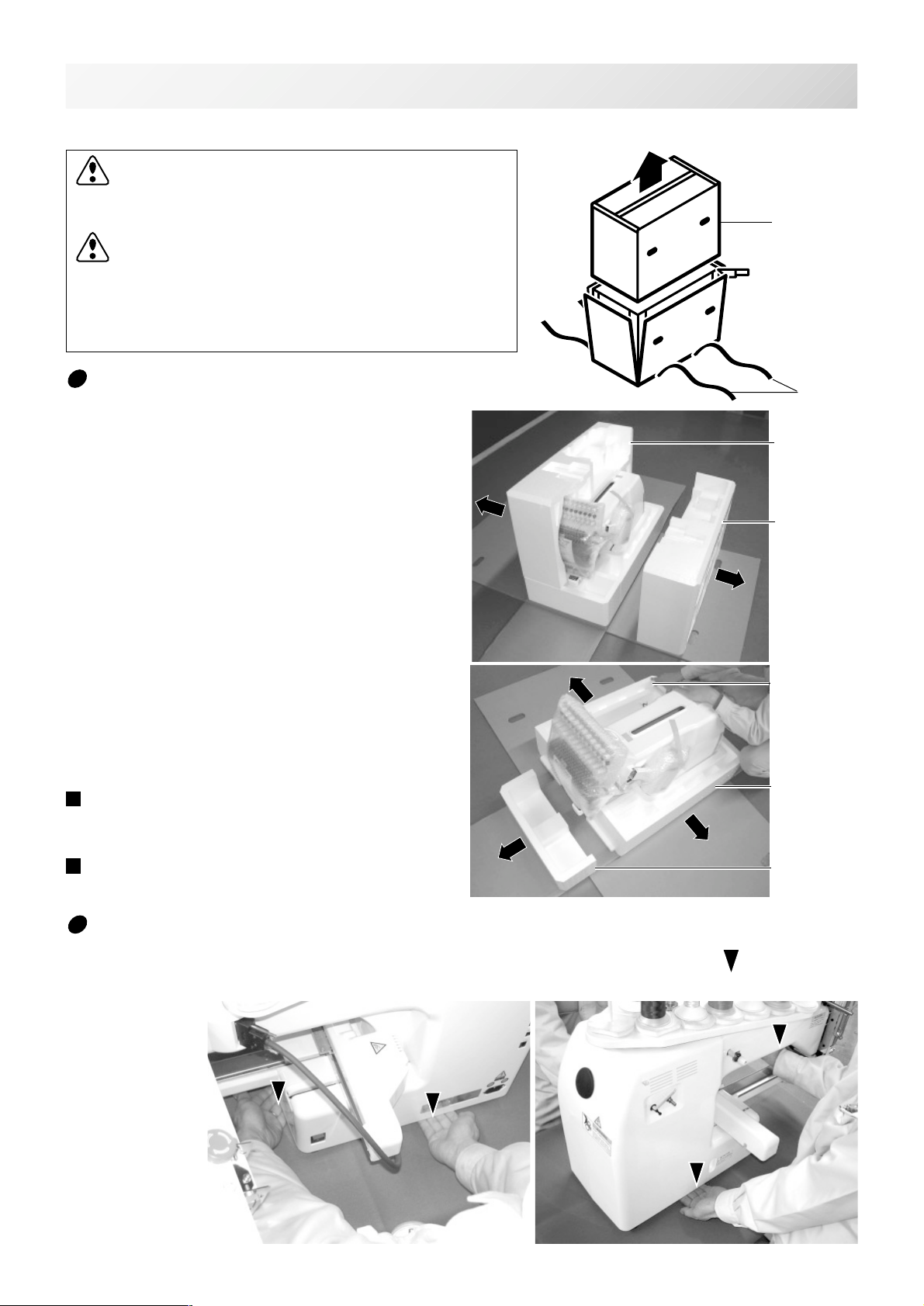

SETTING UP THE MACHINE

We recommend unpacking should be done where it has enough room.

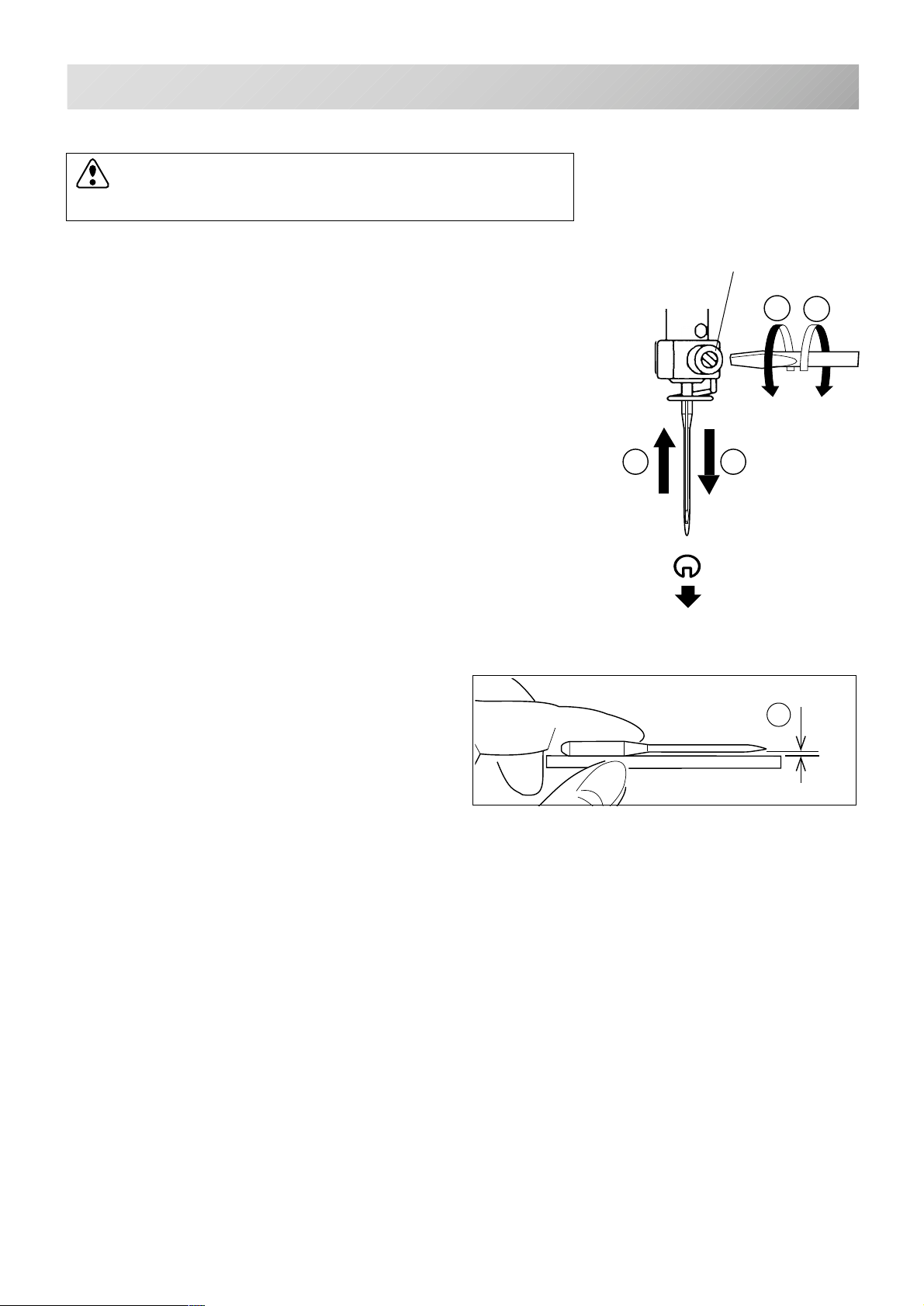

CAUTION: To prevent accidents.

The machine is quite heavy for one person to carry.

Please use two persons when unpacking or carrying.

CAUTION: To avoid problems.

Make sure to hold bottom of the machine body when

removing from the box.

Do not hold any other place. (bed, moving head,

control box etc.).

2-1

Box (upper)

Remove the machine from box

1. Remove 2 straps from the carton.

2. Lift the box (upper) to remove.

3. Take out the accessories.

Refer to the next page.

4. Take out the styrene foam (right) and (left).

5. Take out the styrene foam (lower front),

(lower right), and (lower left).

Be careful not fall down the machine, tilt the

machine slightly when taking out the styrene

form (lower right) and (lower left).

6. Carry the machine to installation location.

Please keep those packing materials in

case of necessary for repair or other reasons.

Packing procedure is the reverse from

unpacking procedure.

Straps

Styrene

foam (left)

Styrene

foam (lright)

Styrene foam

(lower left)

Styrene foam

(lower right)

Styrene foam

(lower front)

How to carry machine

The unpacked machine should be carried by 2 person with the hand position at mark shown

in photos.

The person holding

the machine from

left side need to

hold the machine

arm by right hand.

Right side

Left side

-BD -5

2_1 K101

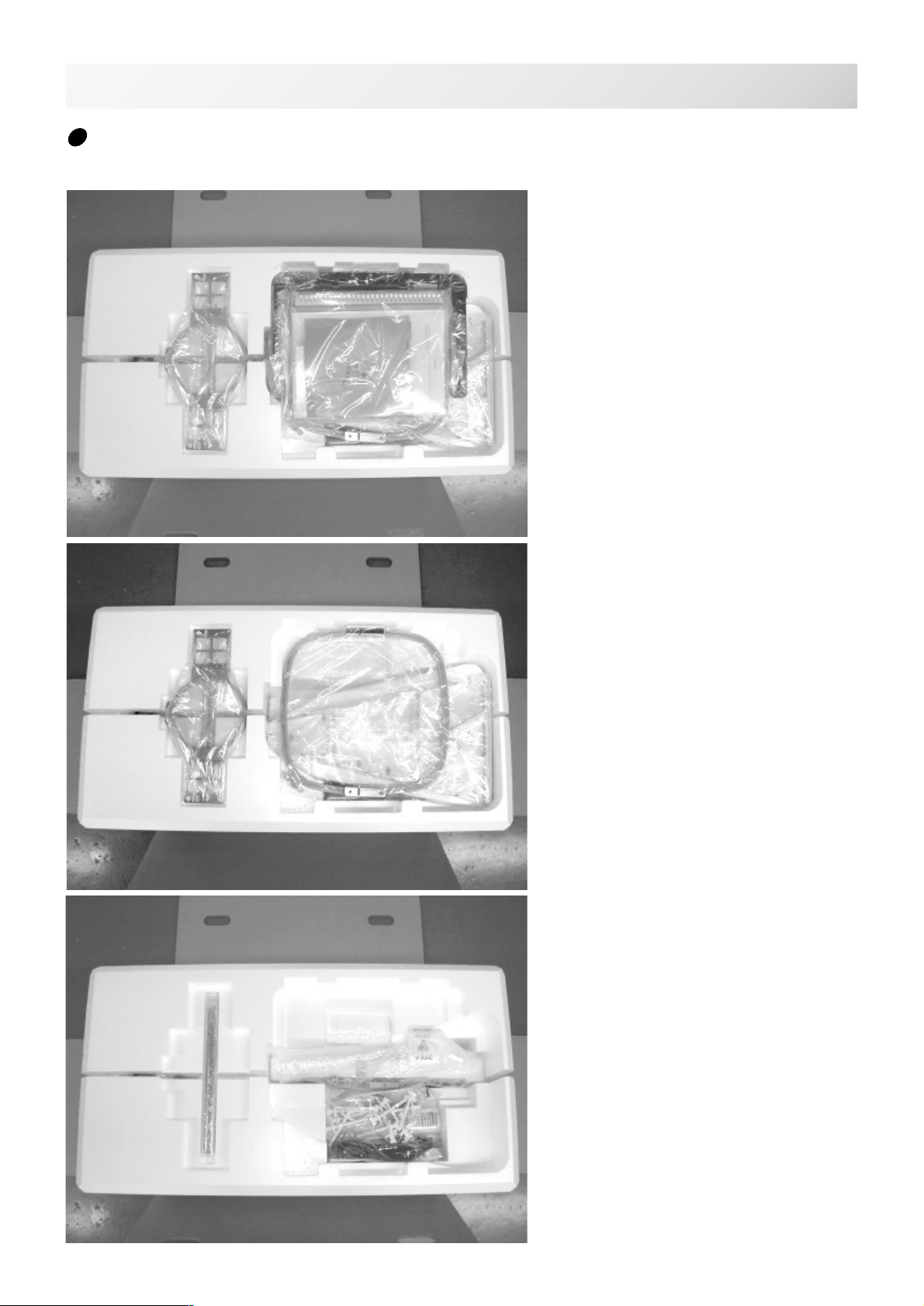

SETTING UP THE MACHINE

Placement of Accessories

Confirm all the accessories are contained when unpacking.

Frame base

CD-ROM

CD-ROM (HAPPY Link Software)

Instruction manual

Embroidery sample

2-1b

(Instruction manual, Parts list)

Embroidery frame (Round)

Embroidery frame (Square)

Thread stand

Thread guide bracket

Carriage

Thread stand felt (13 pcs)

USB cable

Power line cord ass'y

Tool set

Needle (10 pieces)

Fuse (6A)

Oiler

Sewing machine oil

Thread guide pillar (2 pcs)

Thread stand pin (13 pcs)

Wave washer (13 pcs)

-BD -6

2_1b K101

SETTING UP THE MACHINE

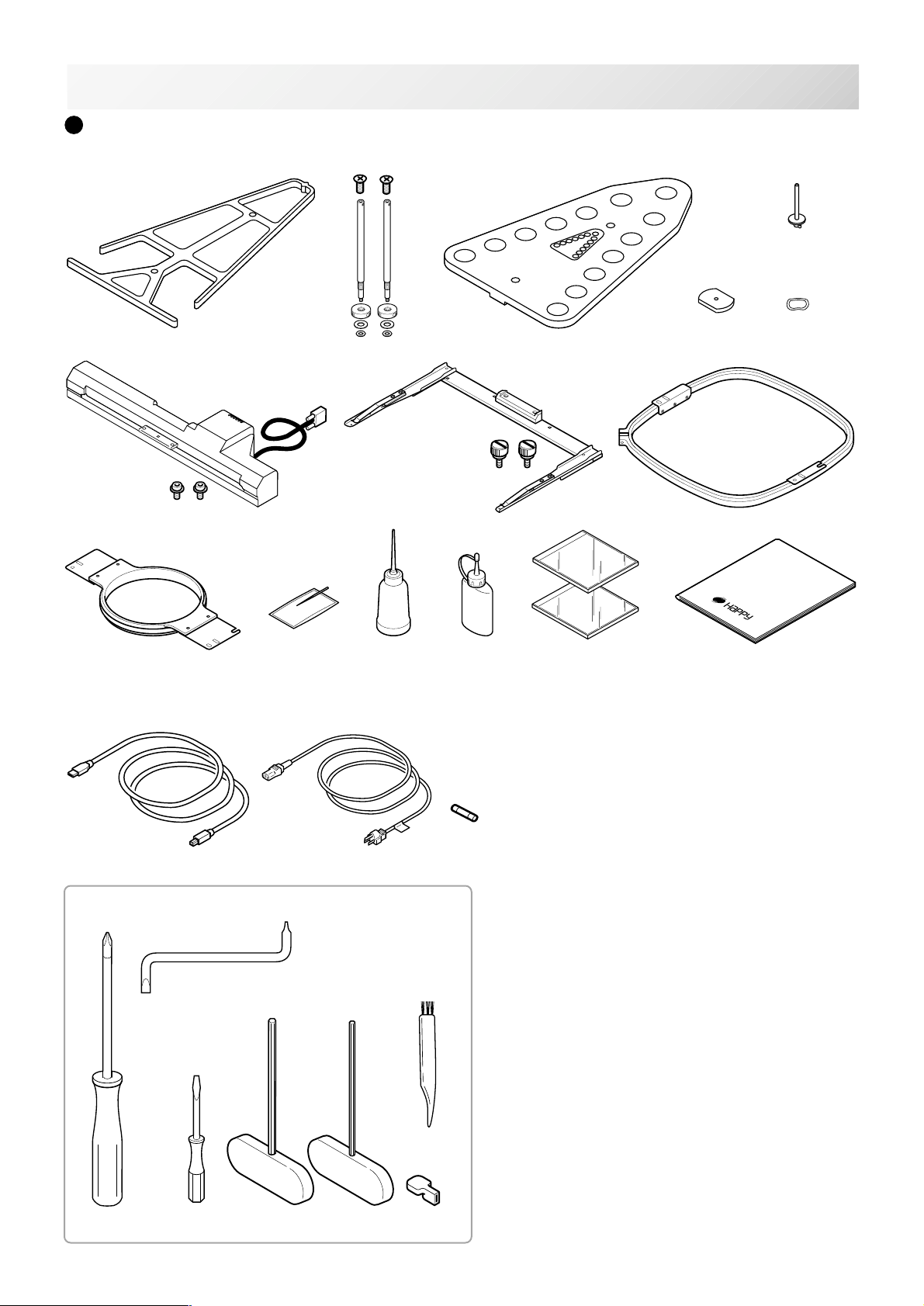

Accessories

Please confirm you have received the following.

2-2

5

Tools

21

1

78

10 11

17 18 19

20

22

23

12 13

24

2

463

9

14

15 16

1. Thread guide bracket

2. Thread guide pillar (2 pcs)

3. Thread stand

4. Thread stand felt (13 pcs)

5. Thread stand pin (13 pcs)

6. Wave washer (13 pcs)

7. Carriage

8. Frame base

9. Embroidery frame (square) PTA-32320-360

25

26

10. Embroidery frame (Round)

11. Needle (DB X K5) (10 pcs)

12. Oiler

13. Sewing machine oil

14. CD-ROM (Happy Link)

15. CD-ROM (Instruction manual, Parts list)

16. Instruction book (How to open the CD-ROM)

17. USB cable

18. Power line cord ass'y (A shape will be changed

depending on a destination)

19. Fuse (6A)

20. Off set screw driver HCB53050

21. #2 (+) Screw driver HCB53011

22. 2 mm (-) Screw driver HCB53020

23. 3 mm hexagonal driver HCB53130

24. 2.5 mm hexagonal driver HCB53120

25. Brush HCB53070

26. Manual lever

PTA-15-360

-CS -7

2_2 K101

SETTING UP THE MACHINE

2-3

Assemble machine unit

1. Insert the thread stand pin with wave washer on the

thread stand by turning clockwise, Then insert thread

stand felt.

2. Put the thread stand on to the machine and insert the

thread guide pillar.

(set nut knob nut into the thread guide pillar and 2

washers)

Turn the thread guide pillar clockwise with a 3 mm

hexagonal driver until tight.

Turn the knob nut clockwise with a 3 mm hexagonal

driver until tight.

3. Install the thread guide bracket with supplied screws

(pan head screw M6 x 10 2 pcs).

4. Loosen the screw with a offset driver and remove the

red shipping collars that are equipped on the both side

of the guide bar. (

essary when packing.)

5. Put the carriage and carriage arm together with screw

(M4 X 8 2 pcs).

2 pins in the upper carriage arm will fit into holes on

the lower carriage.

6. Raise slowly the control box to the front then fix it with

2 supplied screws (M4 2 pcs).

7. Connect the cable of carriage to the machine with

fixed screw.

8. Install the arm for tubular embroidery. Please refer to

(page 6-1) "Installing and removing the frame base".

Or, Install the cap frame for the cap embroidery.

Please refer to (page 7-1) "Installing and removing the

cap drive frame".

Keep the shipping collars. It is nec-

1

2

3

2

When taking the machine apart in case of packing,

the process is opposite of assembling the machine.

Please do exactly the opposite way of assembling.

When packing the machine up for transportation,

be sure to select the sixth needle and fix it with

shipping collars on the both side of the guide bar.

4

5

6

7

-CS -8

2_3 I201

SETTING UP THE MACHINE

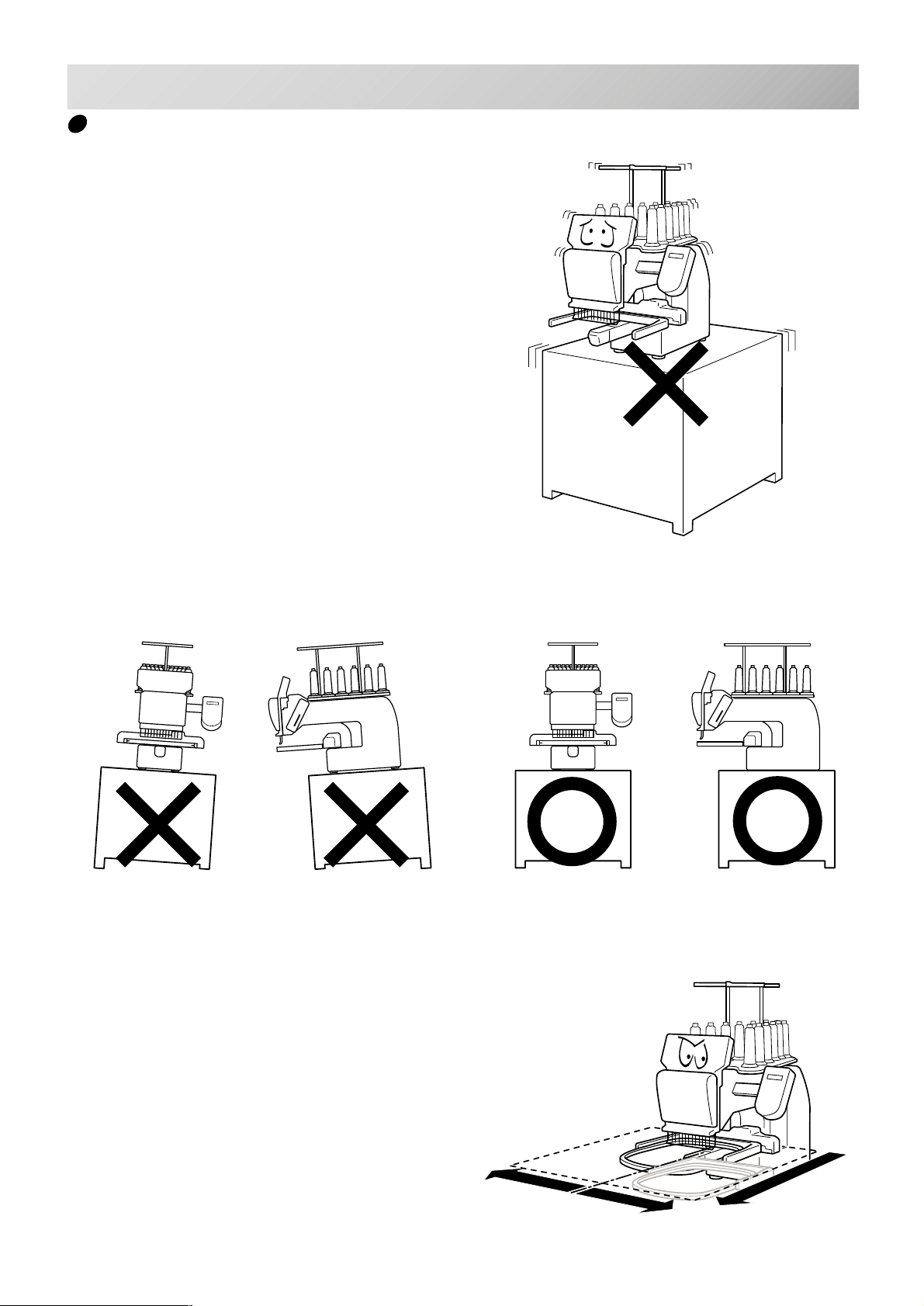

Machine installation

1. Please use a stout table to set the machine

on.

Please check for any shaking or excessive vibrating of the machine table when the machine is

running.

If you have a problem, Please use a stronger

table for the machine.

2-4

2. Please sit the machine level on the table.

3. Please be sure you have this much room

around your machine for it to move.

It is possible for the embroidery frame to hit you

and cause injury.

350 mm

350 mm

720 mm

-CS -7

2_4 D607

SETTING UP THE MACHINE

4. Please be sure you have this much room around

your cap drive for it to move.

Please machine on the table positioning like right side

drawing.

5. Please do not sit the machine near any

kind of other electric equipment

(Examples: Microwave or electric tool).

Has possible to wrong movement of the

machine.

2-5

0 ~ 10 mm

6. Please keep away from dusty and high moisture environments.

Has case of rusting or damaging.

7. Please do not sit the machine in direct

sunshine or windy locations.

Has case of rusting or damaging.

-CS -82_5 D607

SETTING UP THE MACHINE

2-6

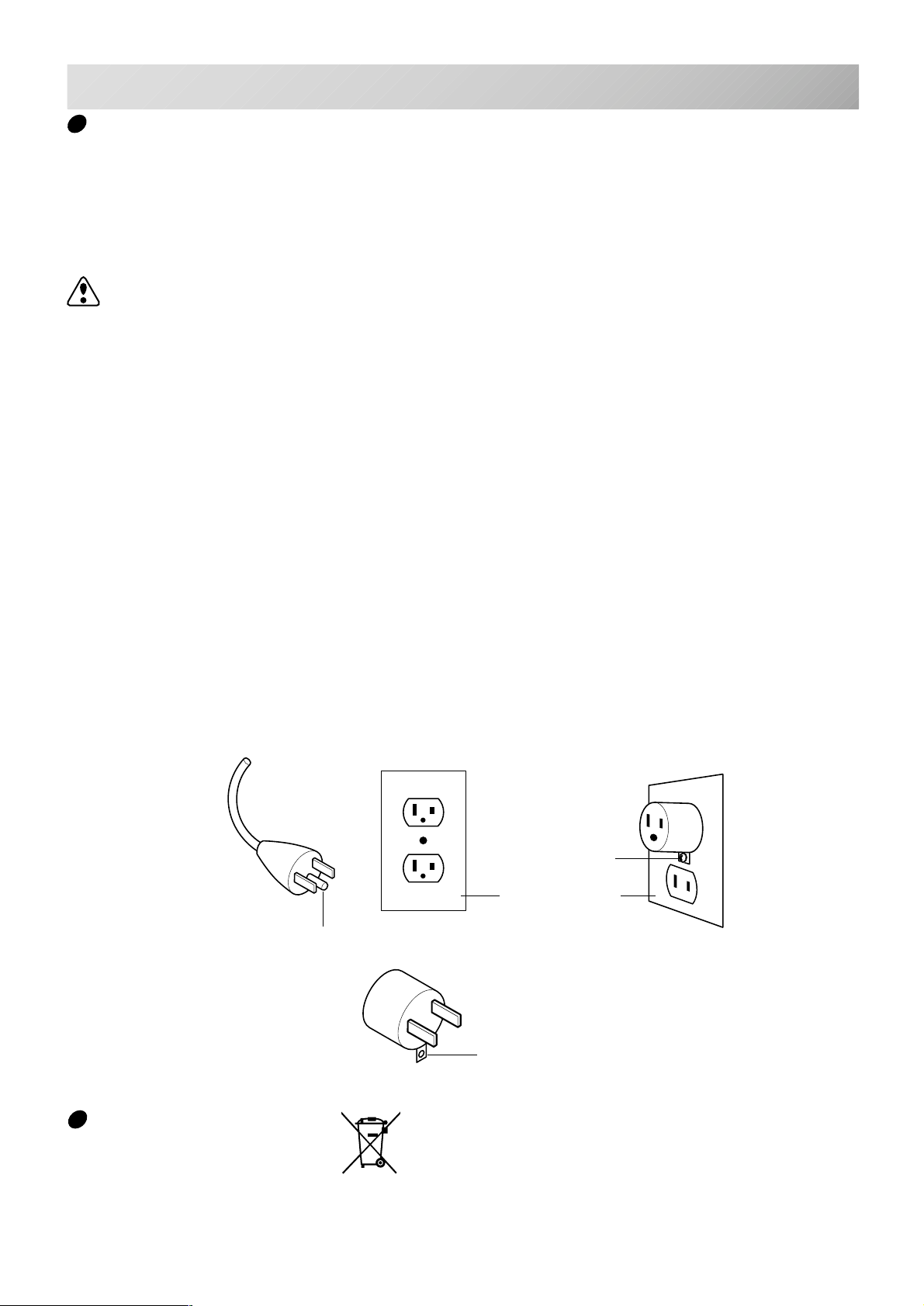

Grounding instruction (for type of 120V)

This product must be grounded. In the event of malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce the risk of electric shock. This product is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a

risk of electric shock. The conductor with insulation having an outer surface that is green with or

without yellow stripes is the equipment-grounding conductor. If repair or replacement of the cord

or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman if the grounding instructions are not completely

understood, or if in doubt as to whether the product is properly grounded.

Do not modify the plug provided with the product – if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

This product is for use on a nominal 120 V circuit, and has a grounding plug that looks like the

plug illustrated in sketch A in Figure. A temporary adaptor, which looks like the adaptor illustrated in sketches B and C, may be used to connect this plug to a 2-pole receptacle as shown in

sketch B if a properly grounded outlet is not available. The temporary adaptor should be used

only until a properly grounded outlet can be installed by a qualified electrician. The green colored rigid ear, lug, and the like, extending from the adaptor must be connected to a permanent

ground such as a properly grounded outlet box cover. Whenever the adaptor is used, it must be

held in place by the metal screw.

Grounding methods

Metal screw

Cover of grounded

outlet box

Grounding pin

A

Adapter

B

Grounding means

C

Disposal of a battery

A battery is had built-in to this embroidery machine.

When you dispose of a battery, according to each country or a method determined in each area,

please dispose appropriately.

-CS -11

2_6 I916

MAIN PARTS

14

13

12

11

3-1

10

9

8

7

6

5

4

15

16

17

18

19

20

21

22

23

24

25

26

3

2

1

1. Hook cover

2. Bobbin case

3. Hook

4. Needle plate

5. Thread check spring

6. Take-up lever cover

7. Take-up lever

8. Lower rectifier

9. Thread tension

10. Detecting roller

11. Minor thread tension

12. Thread guide support

13. Thread guide

14. Upper rectifier

15. Thread stand pin

16. Thread stand felt

17. Thread stand

18. Needle bar selection knob

19. Control box

20. Serial port

27

21. USB port (based on the USB)

22. LAN Port

23. Frame base

24. Carriage

25. Fuse (6A)

26. Terminal box

27. Power switch

-CS -12

3_1 I331

MAIN PARTS

3-2

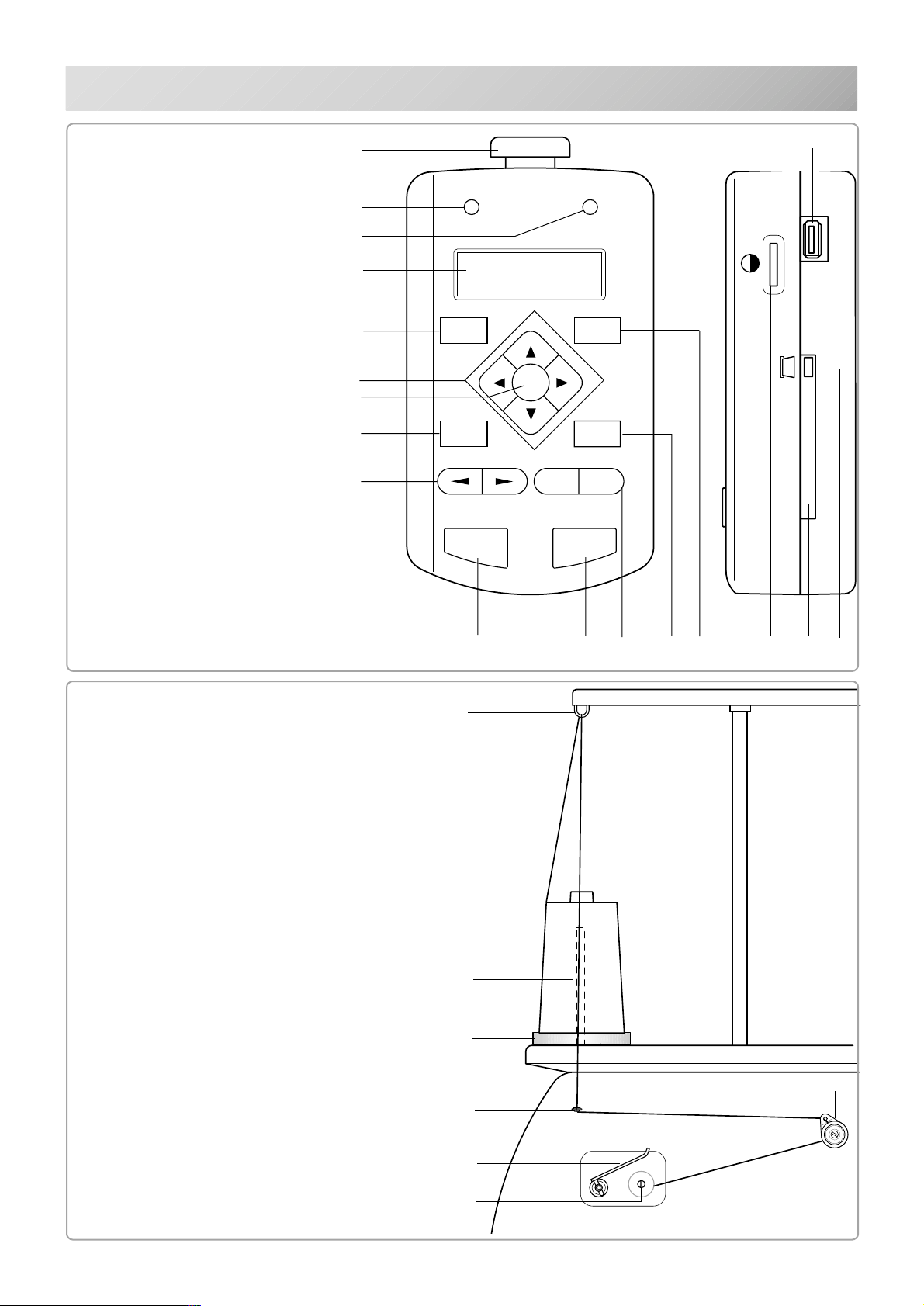

CONTROL BOX

31. Emergency stop button

32. Drive lamp

33. Thread break lamp

34. Display (L.C.D.)

35. Menu button

36. Forward button

37. Arrow button (Up, Down,

Left, Right)

38. Enter button

39. Pressure foot button

40. Thread cut button

41. Needle change button

42. Speed control button

43. Start button

44. Stop button

45. Contrast control dial

46. Memory card eject button

47. Memory card slot

48. USB memory port

31

32

33

34

35

37

38

39

41

ERROR

MENU

ENT.

P.FOOT

-

START STOP

48

T.BREAKDRIVE

FORW ARD

T.CUT

+

BOBBIN WINDING

49. Upper Thread guide

50. Thread stand pin

51. Thread stand felt

52. Thread guide

53. Thread tension

54. Spindle

55. Lever

43 44

49

50

51

42

40

36

45

47

46

53

52

55

54

-CS -133_2 H701

P.FOOT T.CUT

MENU

FORWARD

ENT.

P.FOOT T.CUT

MENU

FORWARD

ENT.

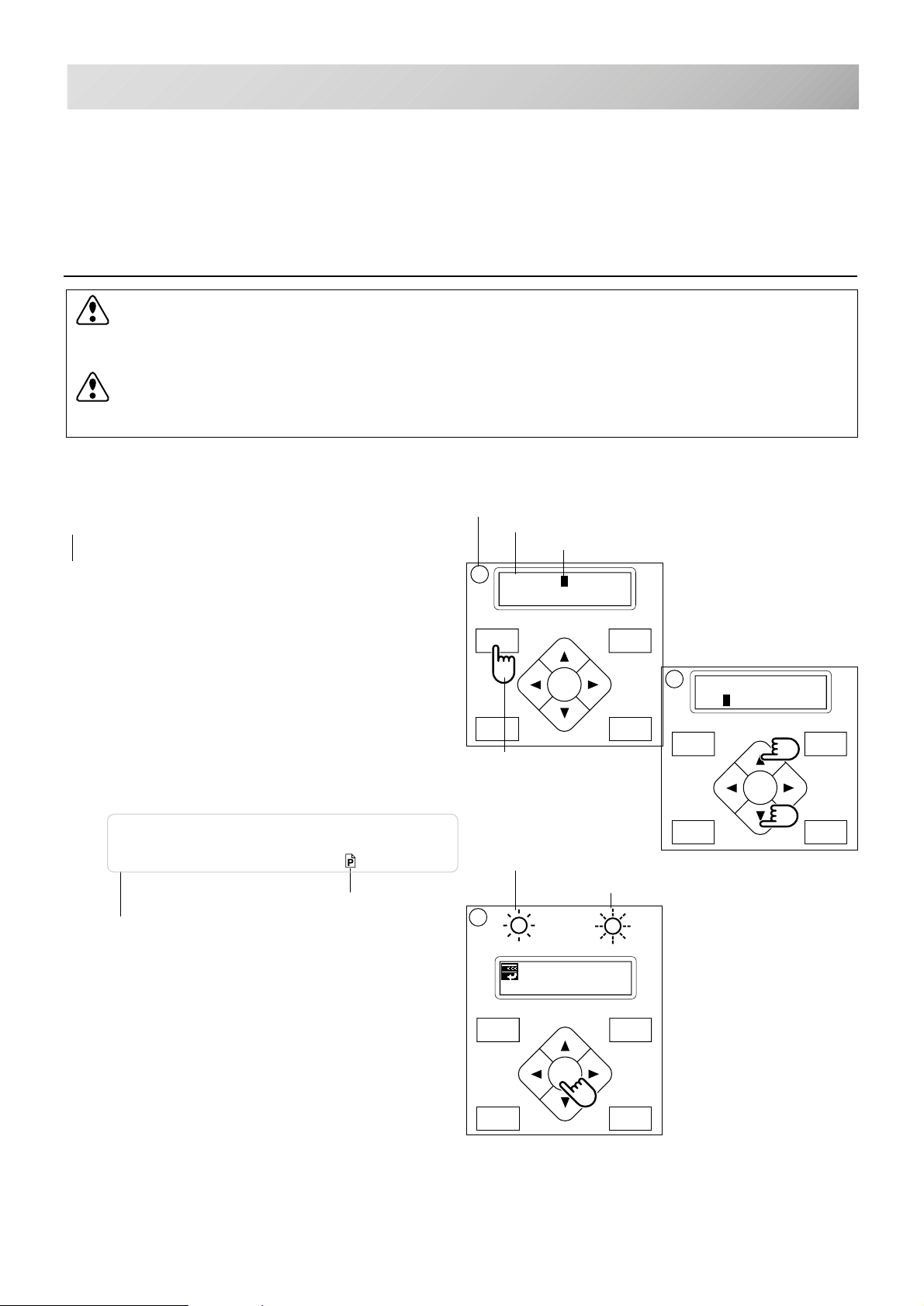

HOW TO READ THESE INSTRUCTIONS

FORWARD

P.FOOT T.CUT

MENU

ENT.

G

3-3

This manual consists of the following instruction.

We will display the items on the left with graphics on the right to clearly show the steps necessary to perform any function.

Graphics at the far right will show the display after performing the requested steps.

CAUTION: To prevent accidents.

This will appear for items related to your safety.

CAUTION: To avoid problems.

This will appear for items related to potential problems.

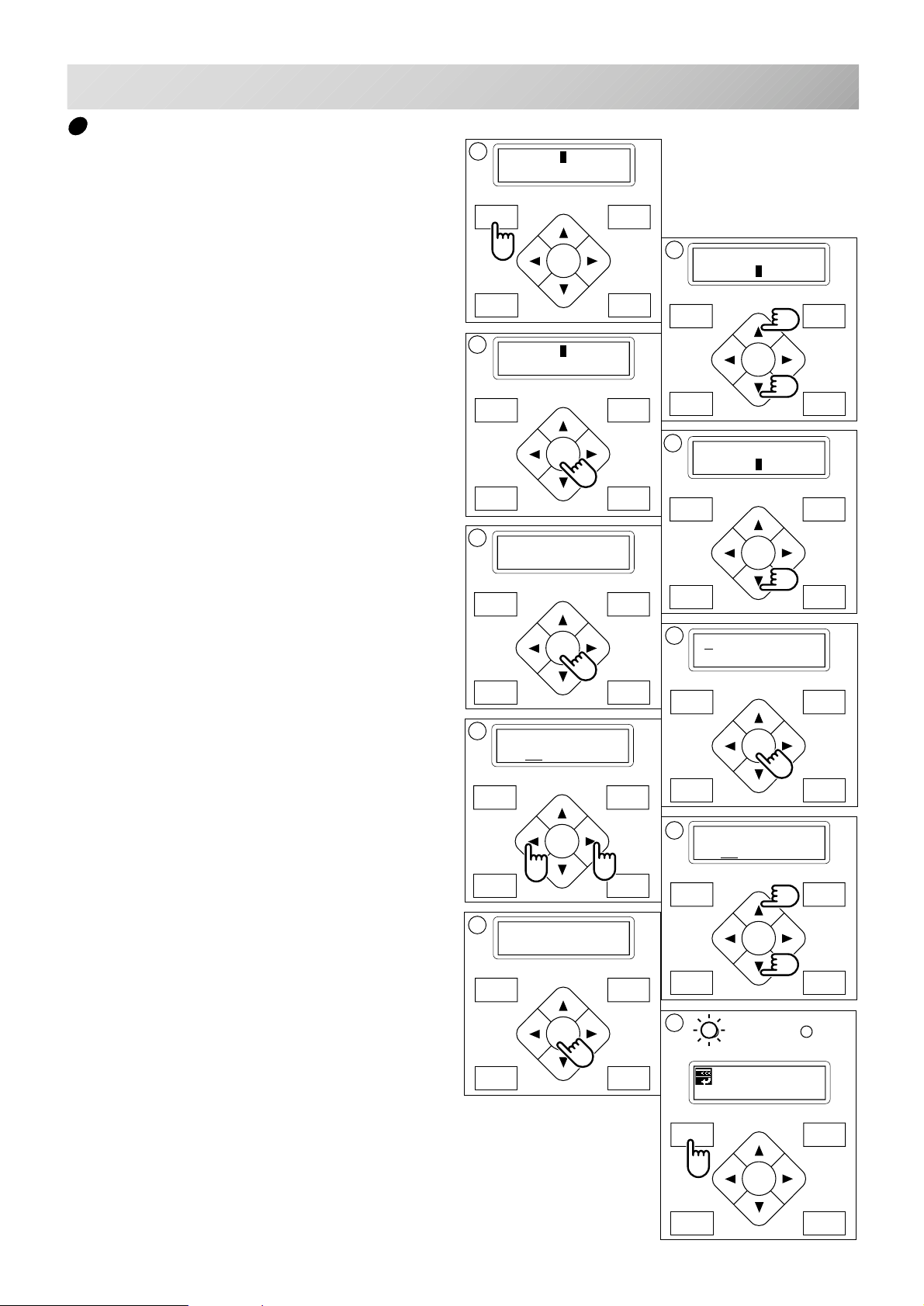

Order of operation

Order of operation

Indicate menu item

Cursor : Presently selected item

1. When the machine is stopped, Press

“MENU” button until display shows [MENU].

2. Select the design name you wish to sew, by

use of the up and down arrow buttons.

3. When you press the "ENTER" button, the

machine will return to drive mode.

If you wish to cancel of your selection, Press the

down arrow button then press ENT.

(Drive lamp will change to green) 3-4

This indicates an

This indicates supplementary

explanation on operation or action

of the machine against operation.

additional explanation on an

operation.

Sample page No.

for more detail.

1

[MENU] Pattern

Needle

Showing the button

to be pressed

"G" indicating the lamp is

glowing Green to show the

machine is ready to sew.

"R" indicating the lamp is

glowing Red to show an error

has occurred.

3

ID:10 Nd: 4

BIRD

This lamp will blink to

show a thread break.

2

[SELECT](ID:10)

14 FANTASIA

-CS -12

3_3 D607

FORWARD

MENU

P.FOOT

T.CUT

ENT.

START STOP

+

-

MESSAGE

If the machine shows an message when turn

on the power, or when you stop the machine by

pressing the “STOP” button.

Please proceed as shown in the following table.

CAUTION: To prevent accidents.

The embroidery frame may move. Please

remove your hand for your safety.

Message

Enter button

Pressure foot button

Needle selection button

3-4

>>Stop Switch

Start button

dnE>>

BA

EGASSEM NOITANALPXE NOITAREPO EGAP

yalpsidehtnoretteldetangiseD

!!noituaC

?roloC>>

dneecarT>>

.detacirbuleboteudsi

ehtdnakoohyratorehtnaelC

.efinkgnittucdaerht

ezingocerotevomlliwemarF

sevomemarF

hctiwSpotS>>

.ngised

.ngised

potSegnahC>>

.noitcnuf"tniop

kaerBdaerhT>>

.ecartngised

tooferusserP>>

.noitisopemarflautcaeht

deppotssienihcamehT

sawnottubpotsehtesuaceb

ehtgnirediorbmeelihwdesserp

deppotssienihcamehT

ehtdehsinifsahtiesuaceb

uoyesuaceb,deppotsenihcaM

egnahcroloctapotS"desu

uoyesuaceb,deppotsenihcaM

.oNroloctxentcelestondid

esuaceb,deppotsenihcaM

.nekorbdaerhtnibbobroreppu

deppotssienihcamehT

ehthtiwdehsinifsahtiesuaceb

.nwodsitooferusserPputfilotnottub"TOOF.P"sserP

.BroAyb

.nottub”RETNE“

.nottub"RETNE"

"ehtsserpuoynehWRETNE"

.noitisop

.yrediorbmeemuser

.emarf

.yrediorbme

.notub"TRATS"

detacidninoitacolehtetacirbuL

niegapdetacidniehtotrefeR

ehtsserpnehtlaunamsiht

ehtninoitcurtsnihtiwnaelC

ehtsserpnehtegapecnerefer

suoiverpehtotnruterdnaevom

otnottub"TRATS"ehtsserP

,ngisedtxenwesothsiwuoyfI

yrediorbmeecalperesaelP

"TRATS"ehtsserpuoynehW

tceleslliwenihcameht,nottub

emuserdnaroloctxeneht

.yllacitamotuagnirediorbme

eldeentxentcelesesaelP

"noitceleseldeeN"ybrebmun

."TRATS"ehtsserpnehtnottub

rodaerhtreppudaerhtesaelP

sserpnehtdaerhtnibbobkcehc

emuserotnottub"TRATS"

sserpnehT.tooferusserpeht

1-01

2-01

5-3

lliwemarfyrediorbmeeht,nottub

.KOfinottub"TRATS"ehtsserP4-6

6-7

-CS -13

3_4 E201

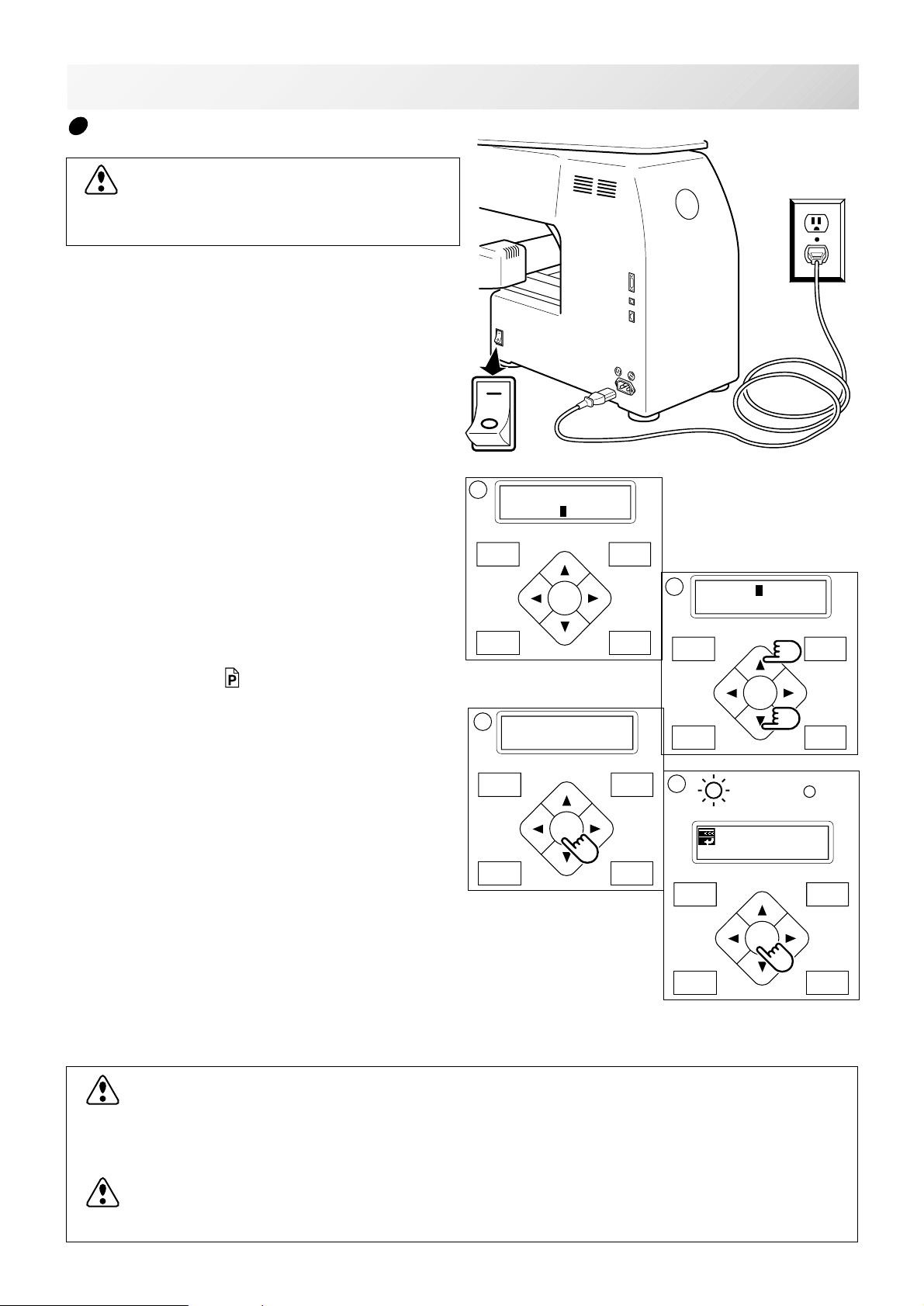

LET'S TURN ON THE MACHINE

FORWARD

P.FOOT T.CUT

MENU

ENT.

How to turn on the machine

CAUTION: To prevent accidents.

The embroidery frame and carriage will move.

Please remove your hand for your safety.

1. Please connect power line cord to inlet on

right side of the machine.

3-5

2. Connect the power line plug to the electric

outlet.

3. Turn on the power switch.

Push the power switch firmly so it will remain on.

4. Press the “Up” or “Down” Arrow button until

the cursor points to "Tubular".

Please select "Other", only when you use special

shape frames. 3-5b

5. Press the "ENT.” button.

6. Press the "ENT.” button.

The embroidery frame will return to the previous

position automatically.

ON

OFF

3

[Frame] Tubular

Other

MENU

FORWARD

ENT.

P.FOOT T.CUT

5

Caution !!

Frame Moves

4

[Frame] Tubular

Other

MENU

FORWARD

ENT.

P.FOOT T.CUT

6

G

ID:10 Nd: 4

BIRD

To disconnect, switch the power switch to the

off position, then remove plug from outlet.

DANGER: To reduce the risk of electric shock.

Never leave the machine unattended when plugged in.

Always unplug this machine from the electric outlet immediately after using and before maintenance.

WARNING: To reduce the risk of burns, fire, electric shock, or injury to persons.

Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

MENU

FORWARD

ENT.

P.FOOT T.CUT

-CS -16

3_5 K101

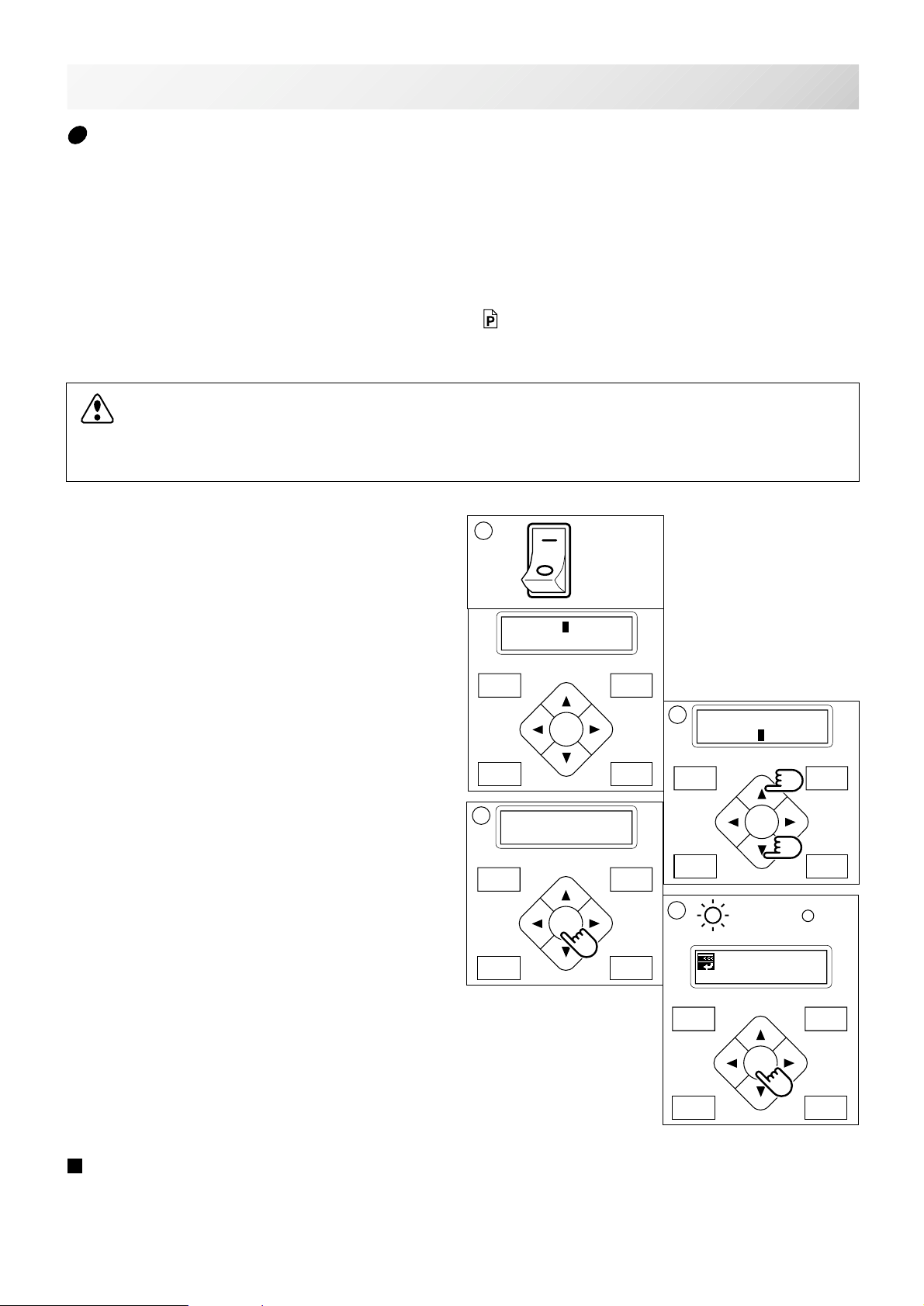

LET'S TURN ON THE MACHINE

FORWARD

P.FOOT T.CUT

MENU

ENT.

3

FORWARD

P.FOOT T.CUT

MENU

ENT.

1

FORWARD

P.FOOT T.CUT

MENU

ENT.

3-5b

Non registered

In case Non Registered Frame is selected, carriage does not have movement for creating the

coordinates of frame position at the time of turning machine on.

Please select Non Registered Frame, when you need use special frame which can hit pressure

foot or other machine parts by movement of carriage for creating the coordinates of frame position.

The following functions is canceled by selecting Non Registered Frame;

* Restore the position at the time of power failure

9-2

* Autostop function when movement exceeds the carriage limit.

Except using special shape frame, please do not select Non Registered Frame.

In case you have operation mistake, needle and/or pressure foot may hit frame and machine

and/or frame can be damaged.

1. Turn on the power switch.

ON

OFF

[Frame] Tubular

Other

2. Press the “Up” or “Down” Arrow button until

2

the cursor points to "Other" (Non registered).

[Frame] Tubular

Other

MENU

3. Press the "ENT.” button.

4. Press the "ENT.” button.

Caution !!

Frame no limit

P.FOOT T.CUT

4

BIRD

ENT.

G

ID:10 Nd: 4

When you need to change from Non Registered frame to other type of frame, please powor

machine off and start again.

Without re-starting machine, machine will move incorrectly.

FORWARD

-CS -17

3_5b K101

LET'S TURN ON THE MACHINE

If the display is not clear

Please adjust the contrast of the LCD display by

turning the small dial on the right side of the

control box.

3-5c

Contrast

control dial

-CS -18

3_5c H701

P.FOOT T.CUT

MENU

FORWARD

ENT.

P.FOOT T.CUT

MENU

FORWARD

ENT.

P.FOOT T.CUT

MENU

FORWARD

ENT.

P.FOOT T.CUT

MENU

FORWARD

ENT.

LET'S TURN ON THE MACHINE

Calendar and clock setting

If you set up the calendar and clock, the machine will advise when oiling and other maintenance is scheduled to occur.

1

3-6

[MENU] Pattern

Needle

1. Press the "MENU" button until the display

shows [MENU] while the machine is

stopped.

2. Select "Other" by pressing the up and down

"Arrow" buttons.

3. Press the "ENT.” button.

4. Select "Clock" by pressing the down "Arrow" button.

5. Press the "ENT.” button.

The display will show the month, date, year, day

and time.

6. Press the "ENT.” button.

A cursor ( _ ) will appear at the bottom of the

month. You can then set the number.

3

[OTHER] Setup

Clock

5

1.23.2003.THU

10:09:56

MENU

ENT.

FORWARD

2

[MENU] Letter

Other

MENU

FORWARD

ENT.

P.FOOT T.CUT

4

[OTHER] Setup

Clock

MENU

FORWARD

ENT.

P.FOOT T.CUT

6

1.23.2003.THU

10:09:56

7. Move the cursor to the next item you wish

to change by using the “right” and “left”

Arrow buttons.

8. Change the numbers by using the “up” and

“down” Arrow buttons.

9. Press the "ENT.” button.

If you wish to change other item of calendar and

clock, Please continue 7. and 8.

10.Finally, Press "MENU" button until the

green lamp is showing on the control box.

If a green lamp is showing, you are in “Drive”

mode.

P.FOOT T.CUT

7

1.23.2003.THU

10:09:56

9

1.23.2003.THU

10:10:56

MENU

FORWARD

ENT.

P.FOOT T.CUT

8

1.23.2003.THU

10:10:56

MENU

FORWARD

ENT.

P.FOOT T.CUT

10

G

ID:10 Nd: 4

BIRD

MENU

FORWARD

ENT.

P.FOOT T.CUT

-CS -15

3_6 D424

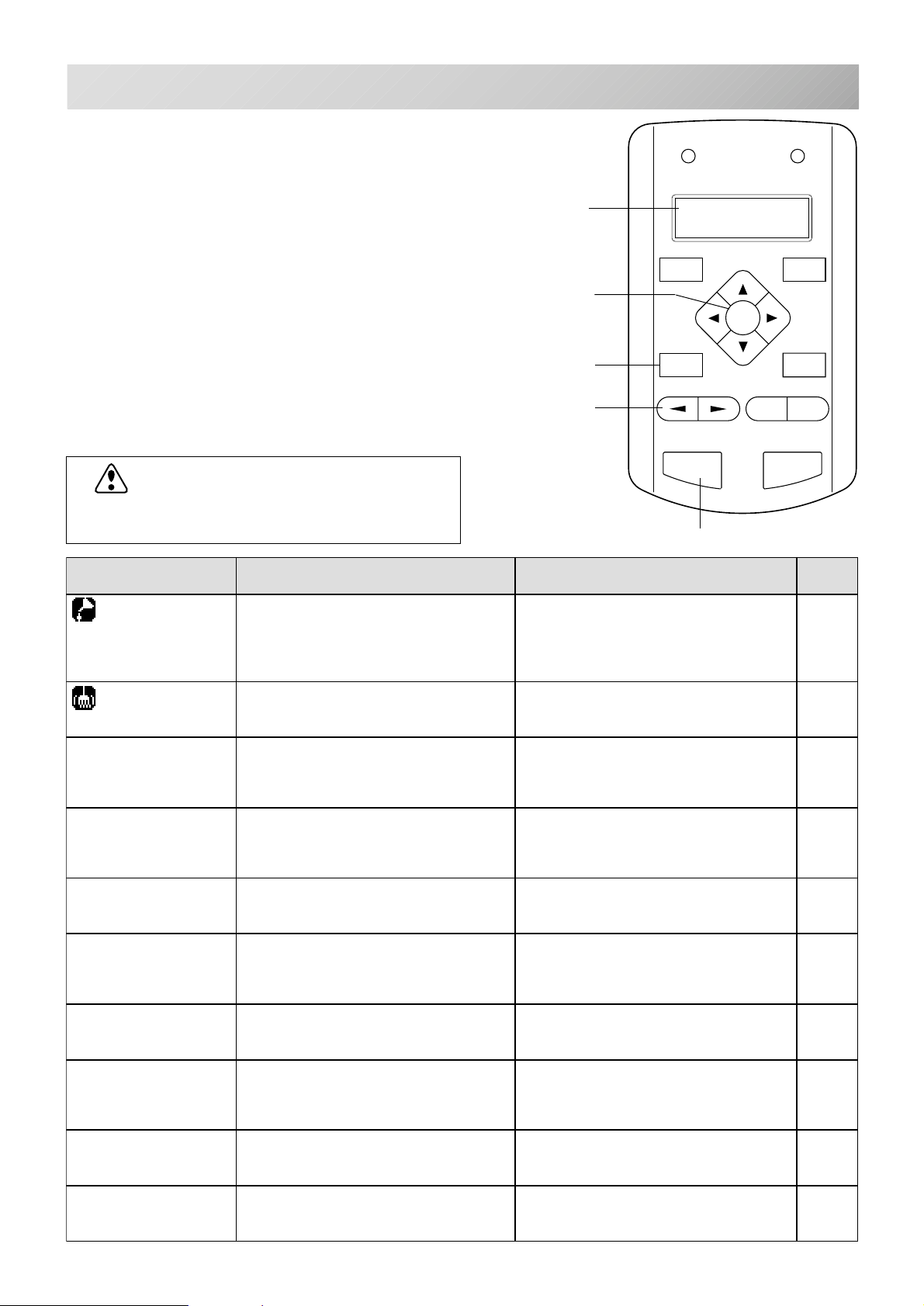

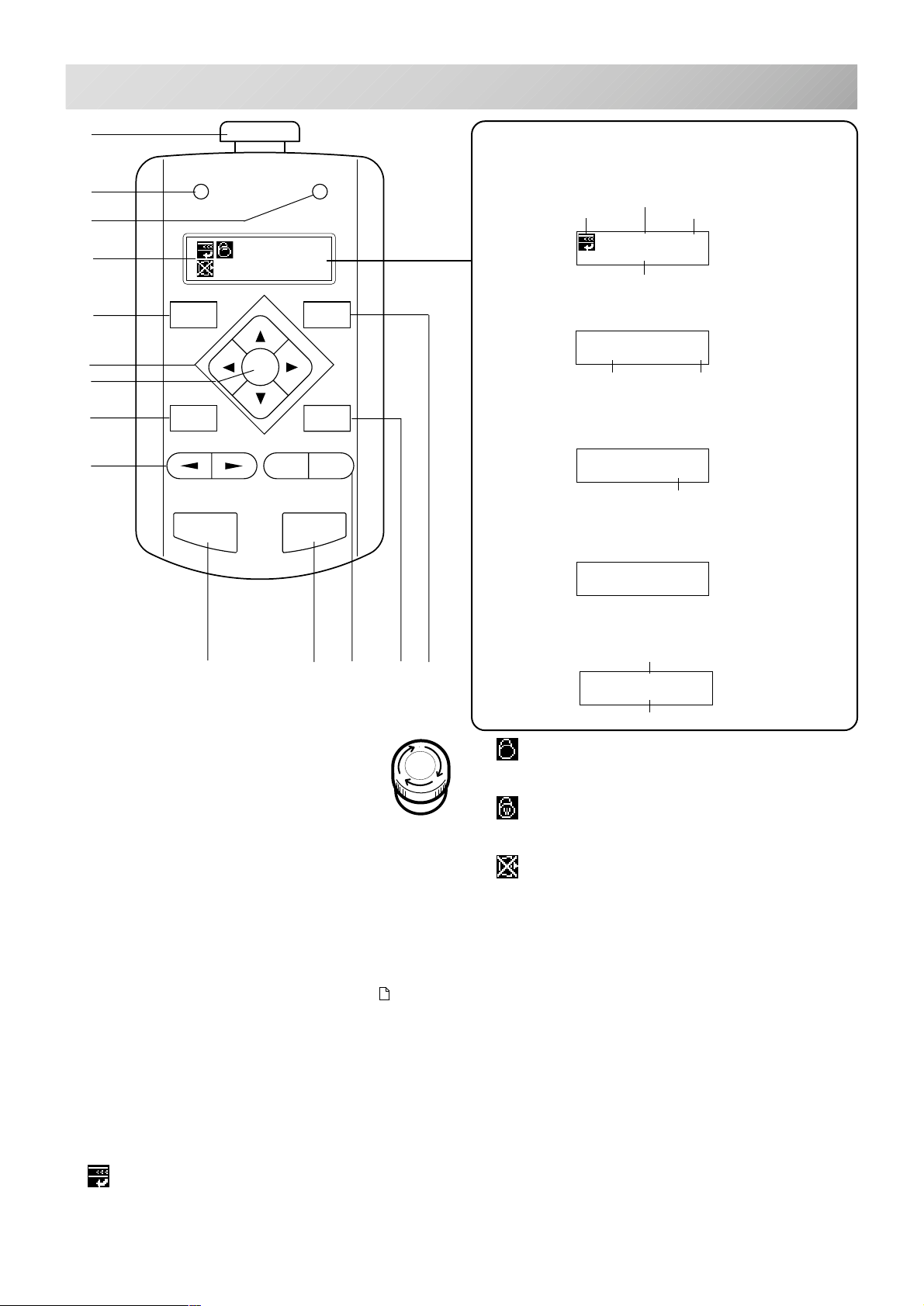

FUNCTION OF THE CONTROL BOX

3-7

B

C

D

E

F

G

H

A

I

ERROR

MENU

ENT.

P.FOOT

-

START STOP

T.BREAKDRIVE

FORW ARD

T.CUT

+

Display example

When beginning an embroidery

Selected memory registration number

Top

ID:10 Nd:12

FLOWER

Selected pattern name

While embroidering

ID:10 Nd:12

123456 1000

Number of stitches

sewn up to now Speed

Machine stopped during embroidering

ID:10 Nd:12

123456

Number of stitches sewn up to now

Display if the machine has no design

in memory

Nd:12

HAPPY

Present needle number

Speed

JK

L

A. Emergency stop button

When you press this button, the power is

switched off and the machine stops.

The Emergency button will be locked,

whenever it is pushed.

To unlock, turn the emergency button to the right

(Arrow direction) then release and the button will

unlock.

Please use this button only for emergency.

B. Drive lamp

Green .................... You can start embroidery.

Red ........................You have a machine error.

an error number will be shown

on the LCD screen. 10-3

C. Thread break lamp

Blinking red lamp... Indicates the upper thread has

broken or the Bobbin thread

has run out.

D. Display

Shows the embroidery design name, the number of

the current needle and other machine generated

messages.

Top

This icon when displayed indicates that the machine is ready to start sewing from the top of the

design.

M

Display when manually moving the

hoop

Moving distance of X

N

X:-234.5

Y: 123.8

Moving distance of Y

Normal cap frame

Shows cap drive frame is set and normal cap

frame is available.

Wide cap frame

Shows cap drive frame is set and wide cap frame

is available.

Do Not Remove the memory media

Please do not remove memory media when this

icon is displayed.

If you remove the memory media when this Icon

is displayed, it is possible to corrupt the design

data in the machine memory and on the memory

media.

E. Menu button

Displays the function menu for the machine settings and the design set-up.

F. Arrow button (Up, Down, Left, Right)

The frame moves toward direction of the arrow

mark on the pressed button.

G. Enter button

If you depress this button while also pressing an

arrow button, the frame will move more quickly.

H. Pressure foot button

You can raise or lower the presser foot .

Showing distance

on X and Y from

origin point

-CS -18

3_7 H701

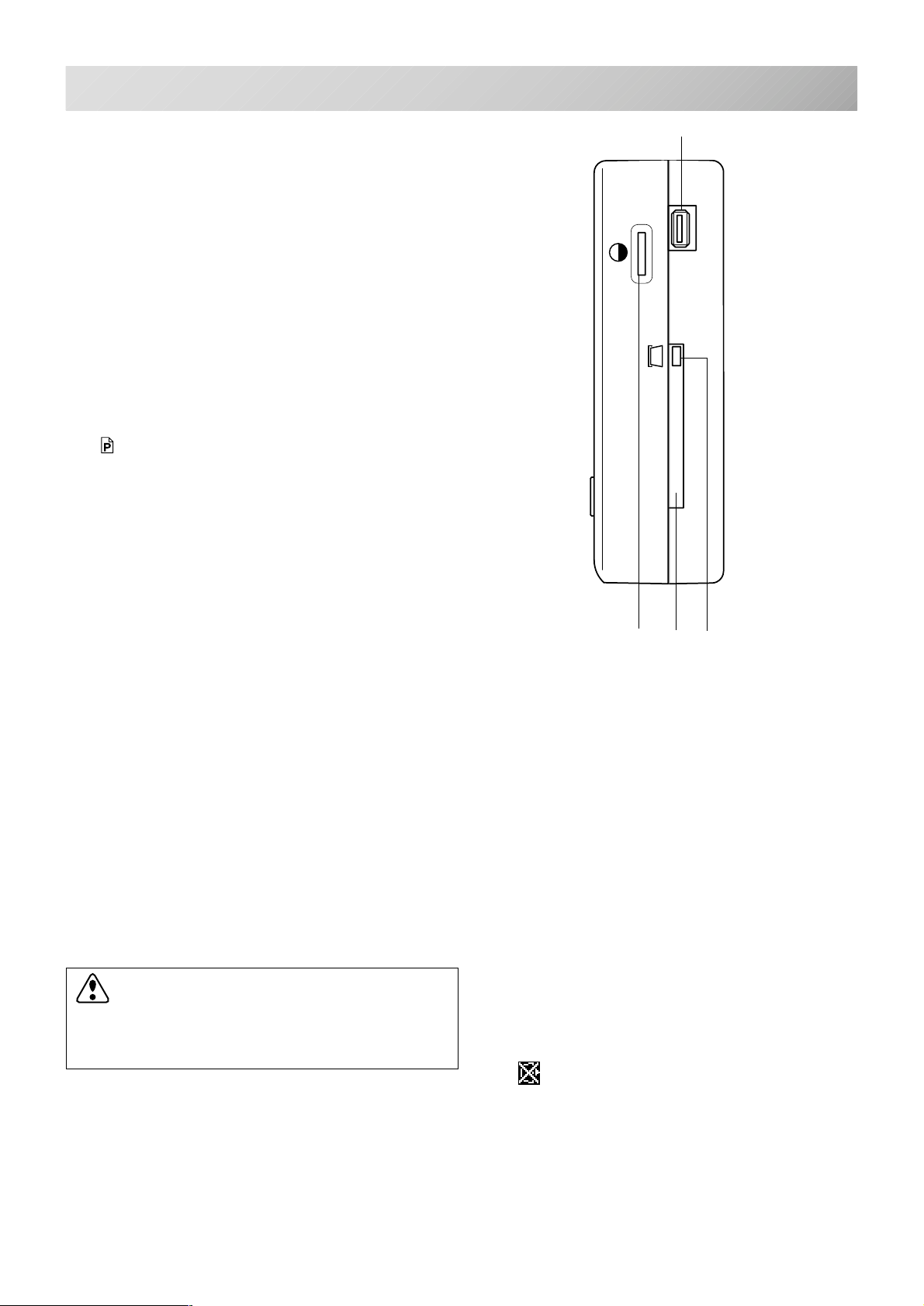

FUNCTION OF CONTROL BOX

3-8

I. Needle change button

Move the sewing head in the direction of the

arrows.

J. Start button

Machine starts working.

If you press this button while the machine is

running, the machine will switch to “inching”.

(Super slow speed)

The Machine will return to the previous speed

when you remove your finger from this button.

If you use the inching function for an extended

length of time it is possible to influence the

stitch quality.

If you press start button when the take up lever

cover is open, an error message will be shown.

You cannot start embroidery when take up lever

cover is open.

10-4

K. Stop button

The machine stops when pressed.

When the Stop button is pressed while the Drive

Lamp is blinking (green color), the followings will

come due to how the Stop button is pressed.

Press one time ........... The frame move back one

stitch.

Keep pressing .............

Keep pushing longer ...

Keep pressing still longer...

The frame will move

backwards continuously.

Function of button is

locked. The frame goes

back by 1 stitch at a time

continuously. Push the

stop button again to stop it.

Function of button is

locked. The frame goes

back by 10 stitches at a

time continuously. Push

the stop button again to

stop it.

L. Speed control button

Press the + button to increase the machine sewing

speed and the - button to lower the machine

speed. The sewing speed is shown on the display.

M. Thread trim button

The Machine will cut the upper and lower thread

when this button is pressed.

CAUTION: To prevent accidents.

If you press the thread trim button, the needle

will penetrate the fabric. Please keep your

hands clear for your safety.

R

OPQ

Keep pressing longer ..

Keep pressing still longer...

Function of button is

locked. The frame will

move forward by 1 stitch

continuously. Push the

“STOP” button to stop it.

When you stop it, push

stop button.

Function of button is

locked. The frame will

move forward by 10

stitches continuously.

Push the “STOP” button

to stop it.

When you stop it, push

stop button.

O. Contrast control dial

Adjust the contrast of the display by turning the

contrast control dial.

P. Memory card eject button

Press this button to take out the memory card.

Please do not remove the memory card when the

icon is displayed on the LCD display.

N. Forward button

Press one time ........... The frame moves forward

one stitch.

Keep pressing............ The frame will move

forward continuously.

Q. Memory card insertion slot

PCMCIA card socket for installing the memory

cards.

R. USB memory port

USB memory socket.

-CS -19

3_8 H701

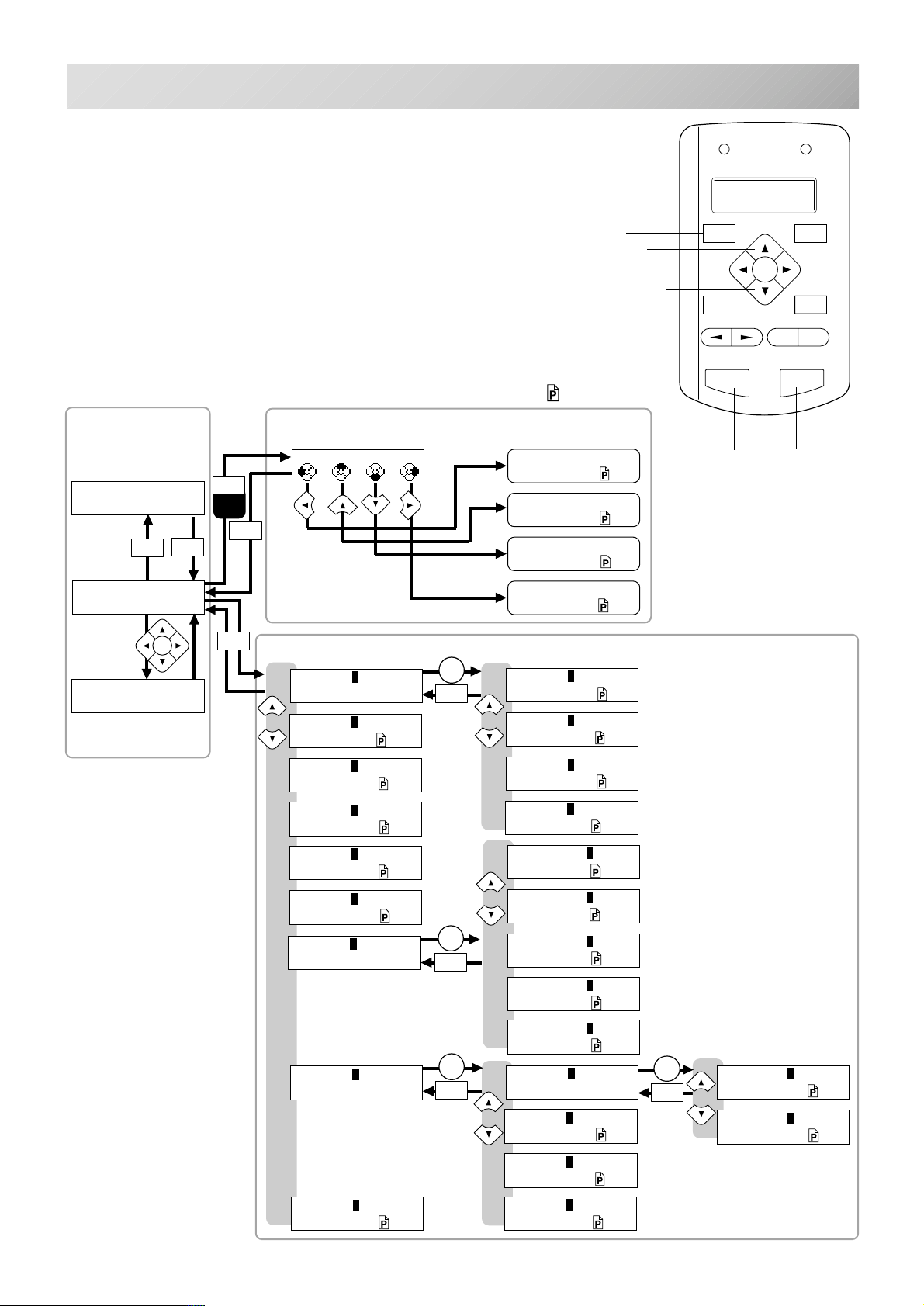

CONTROL MENU

FORWARD

MENU

P.FOOT

T.CUT

ENT.

START STOP

+

-

MENU

This page shows the relationships for all machine functions. (Drive mode and Function menu)

You can start embroidery and manually move the frame

only in Drive mode.

If you keep pressing a "MENU" button longer than 1

second, the direct frame movement menu will come up.

Use the "MENU" button to switch between Drive mode

and Menu mode. If you press the "MENU" button from

Drive mode, you will be switched to Menu mode. Then

you can select any function by the up and down arrow

keys. Pressing the “ENT” key enters your choice.

If you press the "MENU" button from any point in the

Menu mode, you will change to Drive mode.

3-9

Menu button

Up arrow button

Enter button

Down arrow button

Explanation page

DRIVE

START

ID:10 Nd:12

123456 1000

STOP

START

STOP

ID:10 Nd:12

123451

ENT.

Frame move

X:-234.5

Y: 123.8

MENU

Keep

pressing

MENU

MENU

DIRECT FRAME MOVEMENT MENU

Org Top Cnt Pos

Original point return

Top 9-4

Frame center 9-4

Position return

9-3

9-3

MENU

[MENU] Pattern

Pattern data

[MENU] Needle

Auto.needle change

5-15

[MENU] Read

Memory media

5-6

[MENU] Convert

Convert 9-5

[MENU] F•Posi

Frame position

9-6

[MENU] Create

Create 5-1

[MENU] Letter

Emb. letter

[MENU] Other

Other

ENT.

MENU

ENT.

MENU

ENT.

MENU

[PAT.] Select

Select 5-7

[PAT.] Erase

Erase 5-8

[PAT.] All clr

All clear 5-9

[PAT.] Write

Export 5-9b

[LETTER] Char

Character 5-10

[LETTER] Area

Area 5-11

[LETTER] Size

Size 5-12

[LETTER] Style

Style 5-12

[LETTER] Mode

Mode 5-13

[OTHER] Setup

Setup

ENT.

Start button

Stop button

[SETUP] System

System initialize

11-1

[MENU] Log

Log-in•Log-out

9-B

[OTHER] Clock

Clock 3-6

[OTHER] Detect

T.break detection

11-3

[OTHER] Net

Network 9-8

[SETUP] Speed

Speed setting 11-1

-CS -203_9 H701

INSERTING A NEEDLE

Select a needle of the right type. See the following “SELECT THREADS”.

CAUTION: To prevent accidents.

Turn off the power before removing the needle.

4-1

1. Loosen the needle clamp screw slightly with the screwdriver.

2. Remove the needle.

3. Insert a new needle into the needle clamp with push it up

as far as it will go keeping the slotted side of the needle in

front.

4. Tighten the needle clamp screw with the screwdriver.

A. Do not use a bent or blunt needle.

Place the needle on a flat surface and check

for straightness.

Needle clamp screw

1

4

3

2

Front

A

-CS -19

4_1 D424

T

S

SELECT NEEDLES AND THREADS

About needle

Please select needles by type of material .

Normally, We supply a DB X K5 needle as in the machine accessory kit.

4-2

EPYTNOITACILPPA

5KXBDyrediorbmelamronroF81~9

32K-BDtinkroF21~9

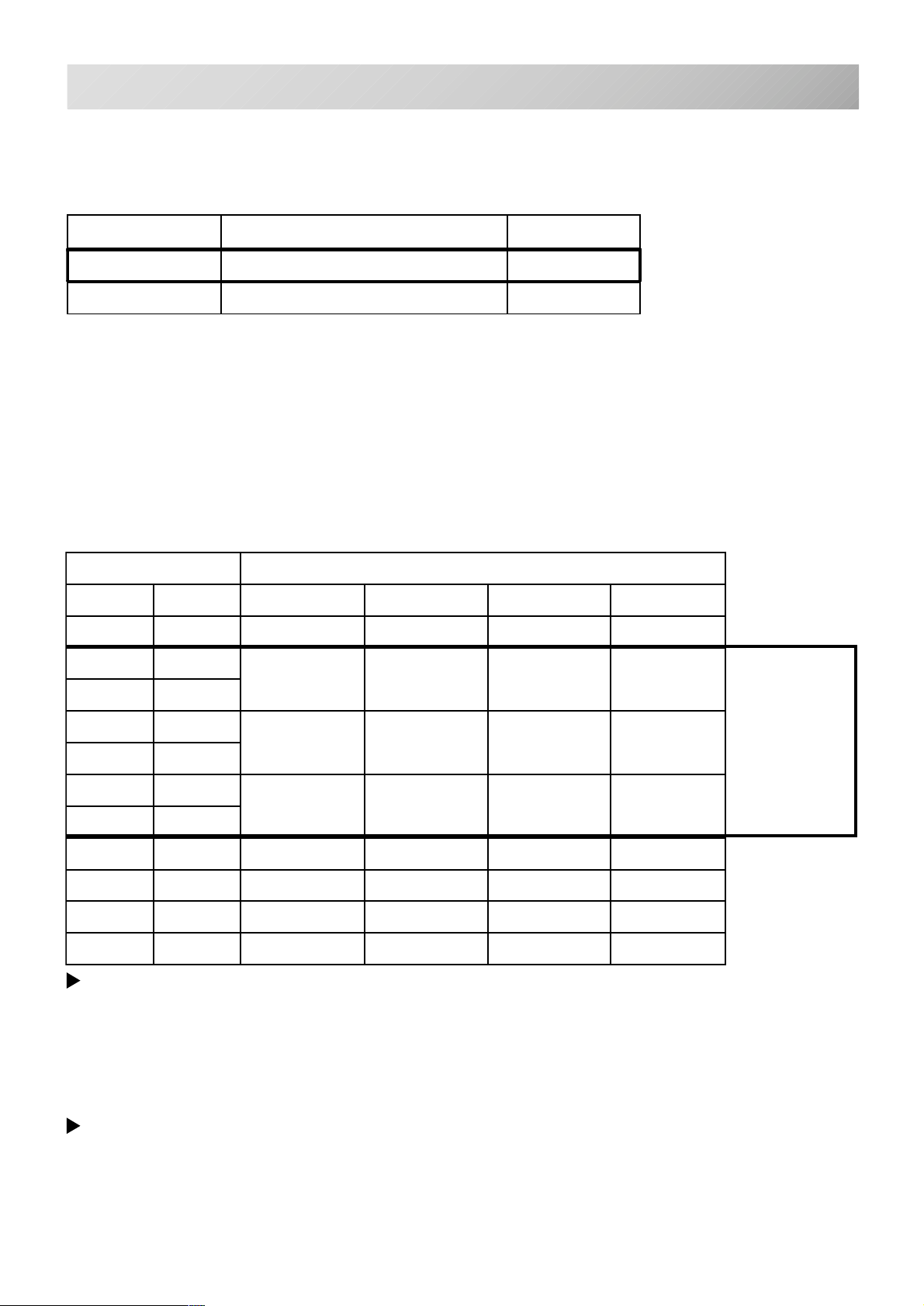

Relation of needle and upper thread

Please select type of needle and upper thread by flowing list.

eziSdaerhtreppudnaeldeenfonoitaleR

nagrOnamreG#nottoCkliSretseyloPnoyaR

8#06#031~001061~041002~05107~05

956

08~07021~001051~031001~07

0107

eziSeldeeN

1157

06~05001~08031~001031~001

2108

3158

04~6307~06001~08051~031

4109

5159

6100163~0306~0508~06061~051

71501

8101103~4205~0406~05032~081

Normal embroidery field

Normal use embroidery needle and upper thread.

Upper thread : Rayon 120 d/2 (120 denier)

Polyester 120 d/2 (120 denier)

Needle : #11 ( DB X K5 )

If the relationship of needle size and thread type is incorrect, it is possible to have any of the

following problems.

• Thread break

• Skip stitch (Upper thread does not catch bobbin thread)

• Other stitch quality problem

-CS -20

4_2 D607

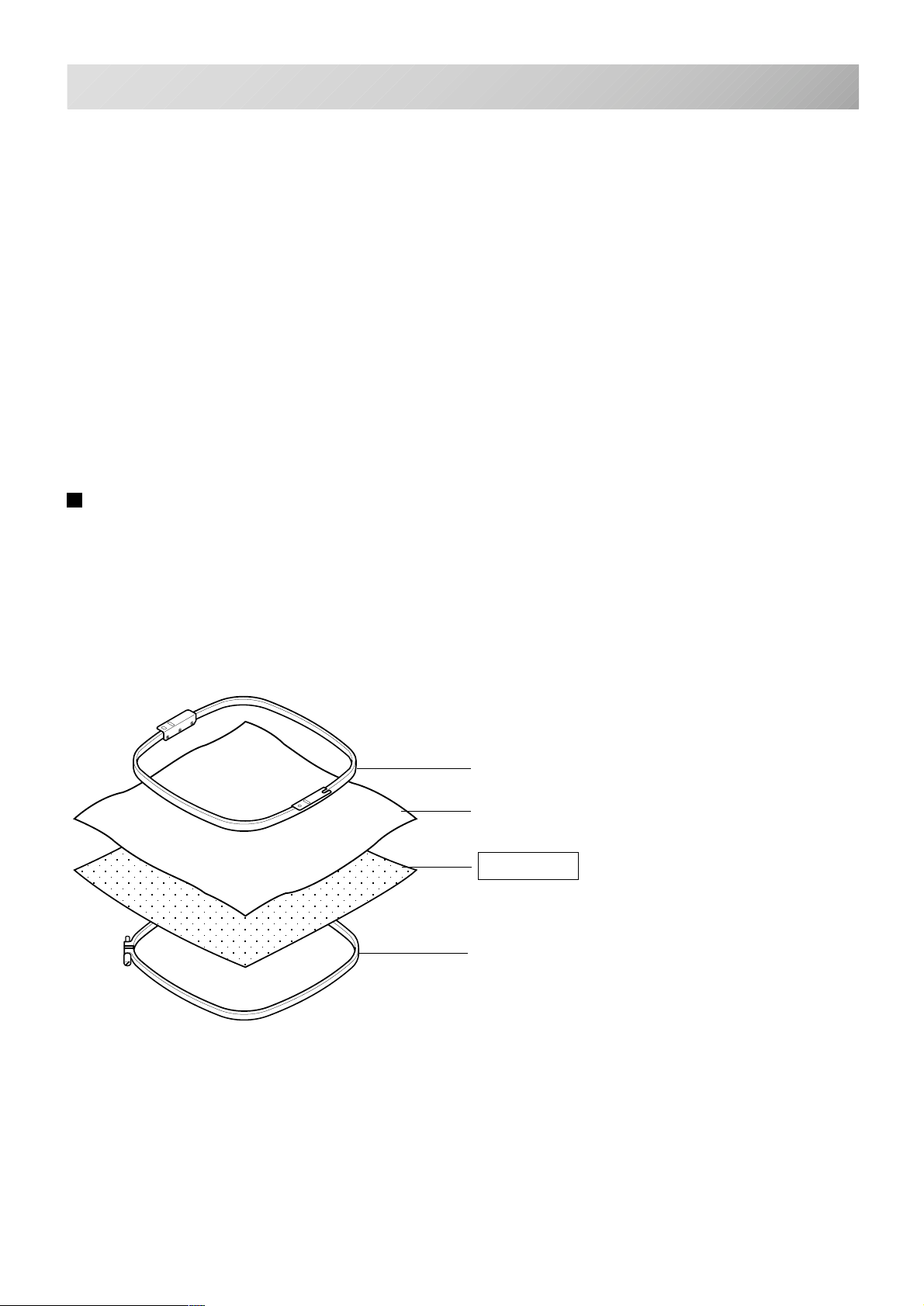

BACKING MATERIALS

4-3

Backing

Generally, Backing is used for hooped embroidery fabric. Knit fabrics particularly require the use

of embroidery backings.

Embroidery backings will allow the hoop to move the fabric more accurately, creating a more

beautiful embroidery.

Select backing type

Choose the thickness and number of sheets by the type of material and embroidery condition.

Generally, you should consider the following items.

•Embroidery stitch quality

•Contraction or compression of fabric caused by sewing, etc.

•Stiffness of fabric

In case, if you sew lace and leather, you may not need backing sheet.

Example of using a backing

Embroidery frame (Inner frame)

Fabric

Backing sheet

Outer frame

-CS -21

4_3 D607

BOBBIN WINDING

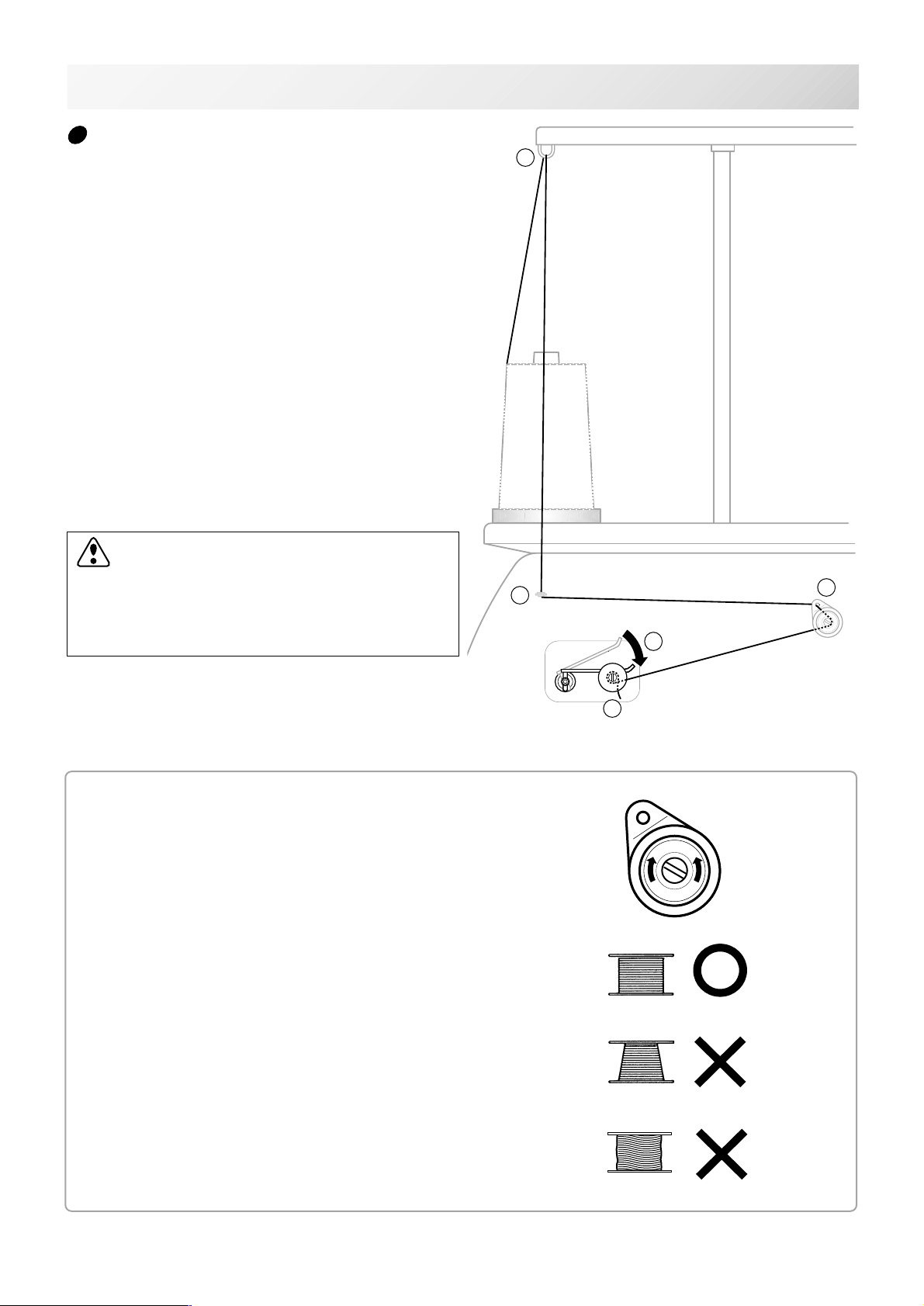

Winding the bobbin

Thread the bobbin winder as shown below:

1. Upper Thread guide

2. Thread guide

3. Thread tension – Be sure to thread through the

small eye before going between the disks.

4. Bobbin (Place the bobbin on the bobbin winder

spindle.)

5. Press the limit lever as indicated by the arrow

to start the winder. The lever stops the winder

automatically after the winding is complete.

4-4

1

CAUTION: To prevent accidents.

When lever is pressed down, the bobbin

winder spindle and the bobbin start turning.

Keep fingers and body away until the bobbin

winder stops turning.

Tension

When adjusting bobbin winder tension:

• Ensure thread winds evenly on bobbin as

shown.

Confirm that the bobbin is wound properly..

2

5

4

Increase Decrease

3

• Keep the tension constant while winding.

Tighten thread tension if thread winds too loosely.

-CS -24

4_4 K101

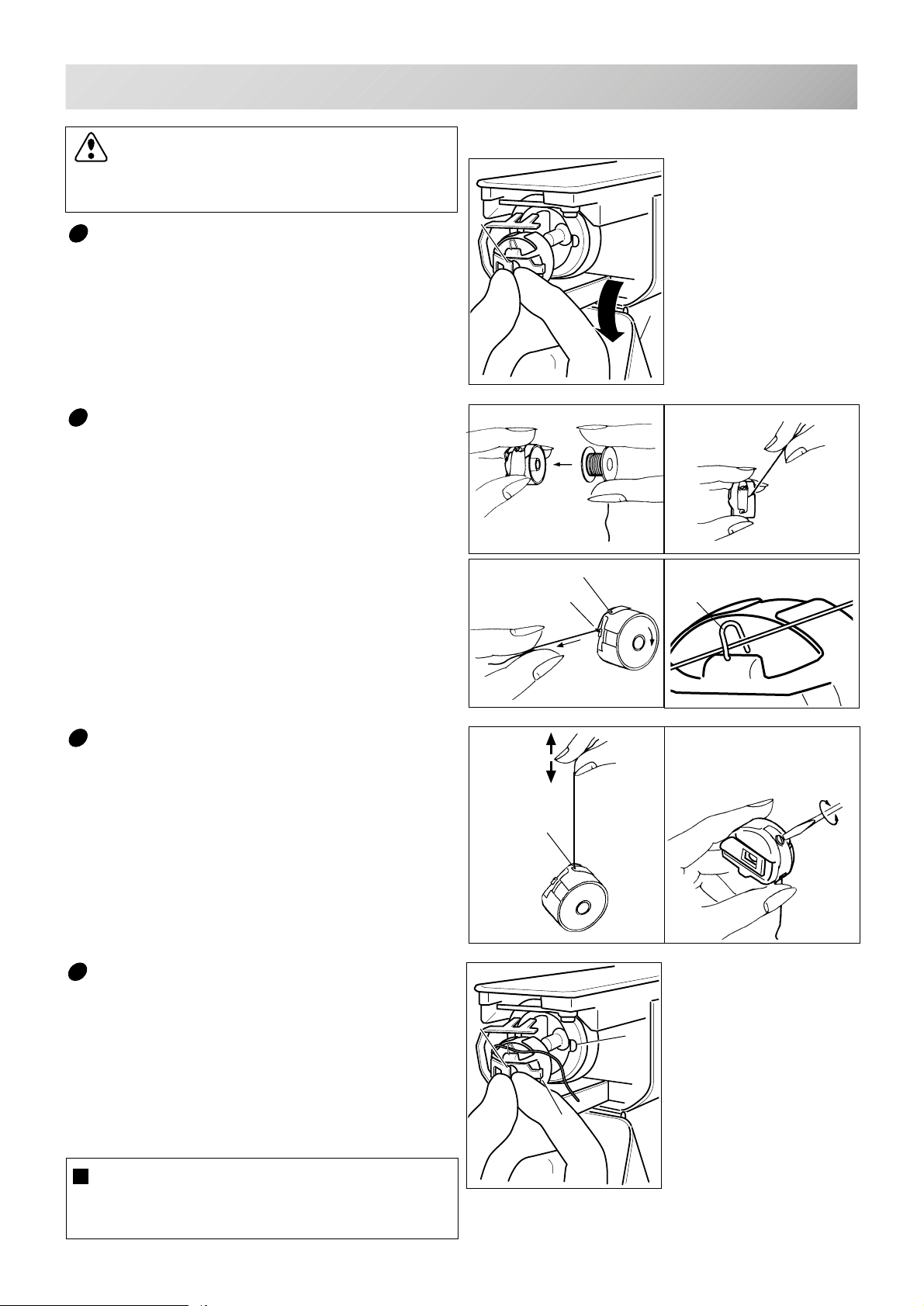

BOBBIN WINDING

CAUTION: To prevent accidents.

Please watch out for the point of the rotary

hook when you replace the bobbin.

4-5

Removing the bobbin

1. Open hook cover (A) to front.

2. Grasp bobbin case latch (B) and withdraw

bobbin case from hook taking care not to

damage the thread keeper.

Inserting the bobbin

1. Hold the bobbin case in left hand. Hold the

bobbin in your right hand with thread on top

leading from left to right.

2. Insert bobbin in case and draw thread up

into slot in case.

3. Draw thread under tension spring (A) and

wind into guide coil (B). The bobbin should

turn clockwise in the case when the thread

is pulled.

B

B

A

A

B

Adjusting bobbin thread tension

1. Hold bobbin thread and jerk upward approx.

an inch. Thread should unspool further

approx. the same amount.

2. The screw on the tension spring is for adjusting bobbin tension. This adjustment is

very delicate. Please turn the screw only a

small amount. Only 1/8 of a turn maximum.

Inserting the bobbin case

1. After threading bobbin in case, open bobbin

case latch (A), grasping it in fingers as

shown.

Slip bobbin and case on stud of rotary hook

body, and press in securely. Release bobbin case latch. Press the bobbin case in to

be sure it is fully seated.

2. Close hook cover.

The attached bobbin case is available only

for this machine. Thread may be caught in

thread guide coil if other types are used.

A

Increase

A

Decrease

C

B

-CD -28

4_5 FA21

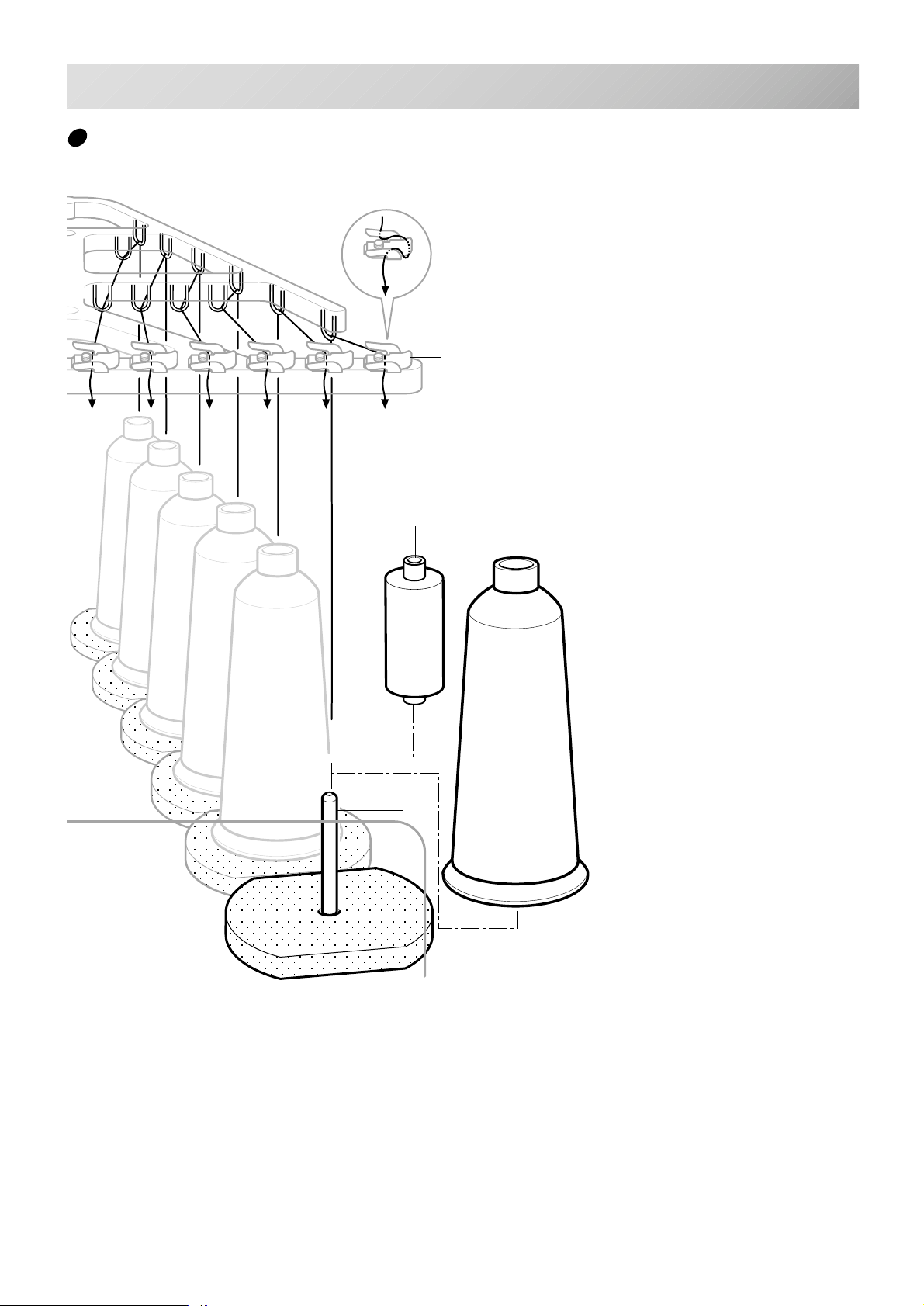

THREADING THE MACHINE

How to thread upper thread

Pass upper threads in order according to the figure:

2

3

Small cone

4-6

1

1. Thread stand

Set thread cone on the stand.

Small cones can also be used as shown.

2. Thread guide

Thread through the thread guide above each

thread cone.

3. Upper rectifier

Continued next page

-CS -24

4_6 AF27

Loading...

Loading...