Page 1

Handheld LCR Meter

User’s Manual

V1.0.1

Page 2

Content

Content ................................................................................................................................ ...... I

Safety ........................................................................................................................................ 1

Safety Guidelines ...................................................................................................................... 1

Safety Symbols ......................................................................................................................... 1

Introduction ............................................................................................................................... 3

Chapter 1 Overview of front panel ............................................................................................ 4

1.1 Front panel .................................................................................................................. 4

1.2 User’s Interface ........................................................................................................... 6

Measurement Interface .............................................................................................. 6

System settings interface ........................................................................................... 7

1.3 Test port ....................................................................................................................... 7

Chapter 2 Operation instruction................................................................................................ 8

2.1 Startup and shutdown ................................................................................................. 8

2.2 Test parameter ............................................................................................................. 8

2.2.1 Test frequency ................................................................................................... 8

2.2.2 Test level ........................................................................................................... 8

2.2.3 Test range .......................................................................................................... 9

2.2.4 Test speed ......................................................................................................... 9

2.2.5 Main parameters ............................................................................................... 9

2.2.6 Secondary parameters ...................................................................................... 9

2.2.7 Set nominal value of tolerance mode ............................................................... 9

2.2.8 Equivalent mode ............................................................................................. 10

2.3 Relative mode ............................................................................................................ 10

2.4 Reading hold mode (HOLD) ...................................................................................... 1 1

2.5 Data recording function ............................................................................................. 1 1

2.6 Correction function .................................................................................................... 1 1

2.7 Firmware Update ....................................................................................................... 12

Chapter 3 Quick application guide ......................................................................................... 14

3.1 Resistance measurement.......................................................................................... 15

3.2 Capacitance measurement ....................................................................................... 16

3.3 Inductance measurement .......................................................................................... 16

3.4 Impedance measurement ......................................................................................... 17

Chapter 4 Telecommunication ................................................................................................ 18

4.1 Connect the instrument to PC ................................................................................... 18

4.2 Command Reference ................................................................................................ 20

4.2.1 Public command .............................................................................................. 20

4.2.2 Subsystem commands .................................................................................... 20

Chapter 5 Specification................................................................ ................................ ........... 23

I

Page 3

5.1 General Specification ................................................................................................ 23

5.2 Accuracy .................................................................................................................... 23

Chapter 6 Maintenance .......................................................................................................... 28

6.1 Service ....................................................................................................................... 28

6.2 Clean ......................................................................................................................... 28

Accessories ............................................................................................................................. 29

II

Page 4

Safety

Review the following safety precautions carefully before operate the device to avoid any

personal injuries or damages to the device and any products connected to it. To avoid potential

hazards use the device as specified by this user’s guide only.

Only professionally authorized personnel can perform maintenance.

Do not run the product when the outer cover or panel is open.

Do not operate with suspected failures. If suspected damage occurs with the device, have

it inspected by qualified service personnel before further operations.

Do not operate in wet/damp conditions.

Do not use in explosive environments

Keep product surfaces clean and dry.

Security warning: One should abide by the relevant terms in the manual regarding safety or

injury to human body or damages to the product, as well as operation or environment which

may result in test failure.

Safety Guidelines

To make sure safe use of equipment, follow these guidelines:

The instrument is suitable for indoor use and an altitude of less than 2,000 meters. In case of

short-term outdoor use, prevent it from direct sunlight, water, electromagnetic radiation, dust,

etc.

Before the use, please read and understand the warning and safety information mentioned in

this manual.

Use the instrument according to the function specified in the manual.

If the component needs measurement, make sure the circuit is turned off and all capacitors in

the circuit are discharged before the measurement.

Before the measurement, components such as capacitors shall be discharged.

The lithium battery of 18650 or Type C-USB is used to provide power for the instrument. It

can be charged with Type C-USB port.

Safety Symbols

Warning: Remind the user to follow the operating procedures in the manual.

1

Page 5

Environment

Please do not operate the instrument in the place that is dusty, vibrative, under direct sunlight

or where there is corrosive air.

The normal working temperature is 0℃~40℃, relative humidity ≤75%, so the instrument

should be used under above condition to guarantee the accuracy.

Please store the instrument in the place where temperature is between 5℃ and 40℃,

humidity is less than 85%RH. If the instrument will not be put in use for a time, please have it

properly packed with its original box or a similar box for storing.

The instrument, especially the test cable should be far from strong electro-magnetic field, to

avoid the jamming on measurement.

Use of Test Fixture

Please use the accessory test fixture or cable together with your device. The test fixture made by

user or from other company may cause the incorrect measurement result. The test fixture, cable

and the pin of DUT should be kept clean, thus to guarantee the good connection between DUT

and fixture.

Warm-up

To guarantee the accurate measurement, the warm-up time is no less than 15min.

Please not turn on or off instrument frequently, in order to avoid the inner data fluster.

General Check

When you have got a new LCR, it is suggested that you should perform a general inspection on

the instrument according to the following steps:

Check the shipping container for damage:

Inspect the shipping container for damage after unpacking it. It is not recommended to power on

the instrument in the case of a damaged container.

Check the accessories:

Accessories supplied with the instrument are listed in “Accessories” in this manual. If the contents

are incomplete or damaged, please notify our distributor at your local area or the sales

department.

Check the instrument:

In case there is any mechanical damage or defect, or the instrument does not operate properly,

please notify our distributor at your local area or the sales department.

2

Page 6

Introduction

This handheld LCR meter is used to measure inductance, capacitance, resistance and other

components of the parameters, small size, using 7.4V lithium battery power supply, can be

applied to desktop applications, more mobile measurement and handheld measurement

occasions to provide great convenience.

It provides a resolution of four thousands digits for main parameters and a resolution of 0.0001 for

secondary parameter. The highest measurement frequency is 100kHz, and can measure the level

of 0.6Vrms, 0.3Vrms. Its automatic range can display the results in the fast, medium, or slow

mode. It can automatically select the appropriate measurement parameters according to the

characteristics of the component. The measurement accuracy can reach 0.25%. It combines the

convenience of a handheld instrument and good performance of a table-type one.

The operation is simple and intuitive, and the test frequency, parameters and speed can be

selected immediately. It also has a recording mode to assist in reading data. Open circuit and

short circuit correction function to improve the accuracy of measurement. Practical configuration

menu can set buzzer, automatic shutdown, language and other operations.

The instrument is equipped with remote communication function and can be connected to PC via

Type C-USB cable for remote control and data acquisition.

3

Page 7

Chapter 1 Overview of front panel

1.1 Front panel

Description of the front panel is shown in the figure (Note: In this manual, long press means

holding the key for more than 2 seconds).

1. Display: 2.8 inch TFT LCD screen, which display all functions of the instrument.

2. R-X shortcut key: Select the main parameter as R and the secondary parameter as X directly.

3. C-D shortcut key: Select the main parameter as C and the secondary parameter as D directly.

4. L-Q shortcut key: Select the main parameter as L and the secondary parameter as Q directly.

5. Data holding recording key: Turn on or off the data holding function.

6. Frequency key: Switch to fixed frequency quickly.

7. Range key: Switch to the required range quickly. You can select Auto, 10Ω, 100Ω, 1kΩ, 10kΩ

and 100kΩ in turn. Auto is the automatic range, LCR will automatically select the appropriate

hardware range according to the current tested component, and the other ranges are the fixed

gear position.

8. Level shortcut key: Switch to the fixed level (300mV, 600mV RMS) quickly.

9. Measuring speed key: Switch to the required measurement speed (Fast, Medium and Slow).

4

Page 8

10. Main parameter key: Switch to the main parameters quickly. You can select Auto, R, L, C, Z

in turn. Auto is the function of automatic parameters. LCR selects the appropriate combination of

main parameters and secondary parameters according to the properties of the current tested

component.

11. Secondary parameter key: Switch to the secondary parameters quickly. If the main

parameter select as Auto, this key will not work.

12. Equivalent mode key: Switch equivalent between SER and PAL quickly. User should select

the equivalent mode according to test need.

13. Set key: Press the key to enter the setting interface to set the system language, automatic

shutdown, display brightness, boot state and buzzer. Click again the key in the setting interface to

view the device system information. Click again it to return to the test interface.

14. Arrow keys: left and right arrow keys to control the movement of the cursor; up and down

arrow keys to select the parameter.

15. Power key: Press it to turn on or off the instrument.

16. Data holding recording key: Press to turn on or off the data holding function. Press the key

successively can switch functions of MAX, MIN and AVG in turn, and return to normal test

interface after completing one cycle. If you change the main or secondary parameter, it will exit

this function. The function is disabled in automatic parameters.

17. Relative and correction multifunctional key: Short press to turn on or off the relative

function, short press again to exit the relative value (REL) function. Long press to turn on the

correction function.

18. Comparator switch and tolerance limits shortcut multifunctional key: Long press to

turn on or off the comparator. Short press to quickly switch deviation tolerance limit.

19. 3-terminal test jack

20. 5-terminal test notch

Note: Please see the label on the adapter for its input parameters; use the supplied

adapter, or purchase the specified power adapter from our company. The use of other

adapters may cause unnecessary damage.

Reminder: After connect the external power supply, the internal battery power supply

circuit will be automatically cut off and charge the battery,

the LCR

has an independent

charging management controller, even when the instrument is turned off, the charging

control still works normally.

5

Page 9

1.2 User’s Interface

Measurement Interface

1. Main parameter display

2. Secondary parameter display

3. ’HOLD’ indicates the data holding state.

4. USB connection state, displayed when it is connected to the PC and hidden at any

other time;

When connected the instrument to the computer in the initial, the USB icon is white, which

means that the USB is connected. At this time, the key is still available and unlocked. After

receiving the first effective command, the USB icon becomes green, which means that the

computer is communicated with the instrument successfully. The front panel button is unlocked

after USB is pulled out or *GTL command is used. Then the USB icon turns white again and the

button is available.

5. Measurement parameter settings

6. Battery power icon: The remaining power is indicated. Please timely charge the instrument

when the power is insufficient.

6

Page 10

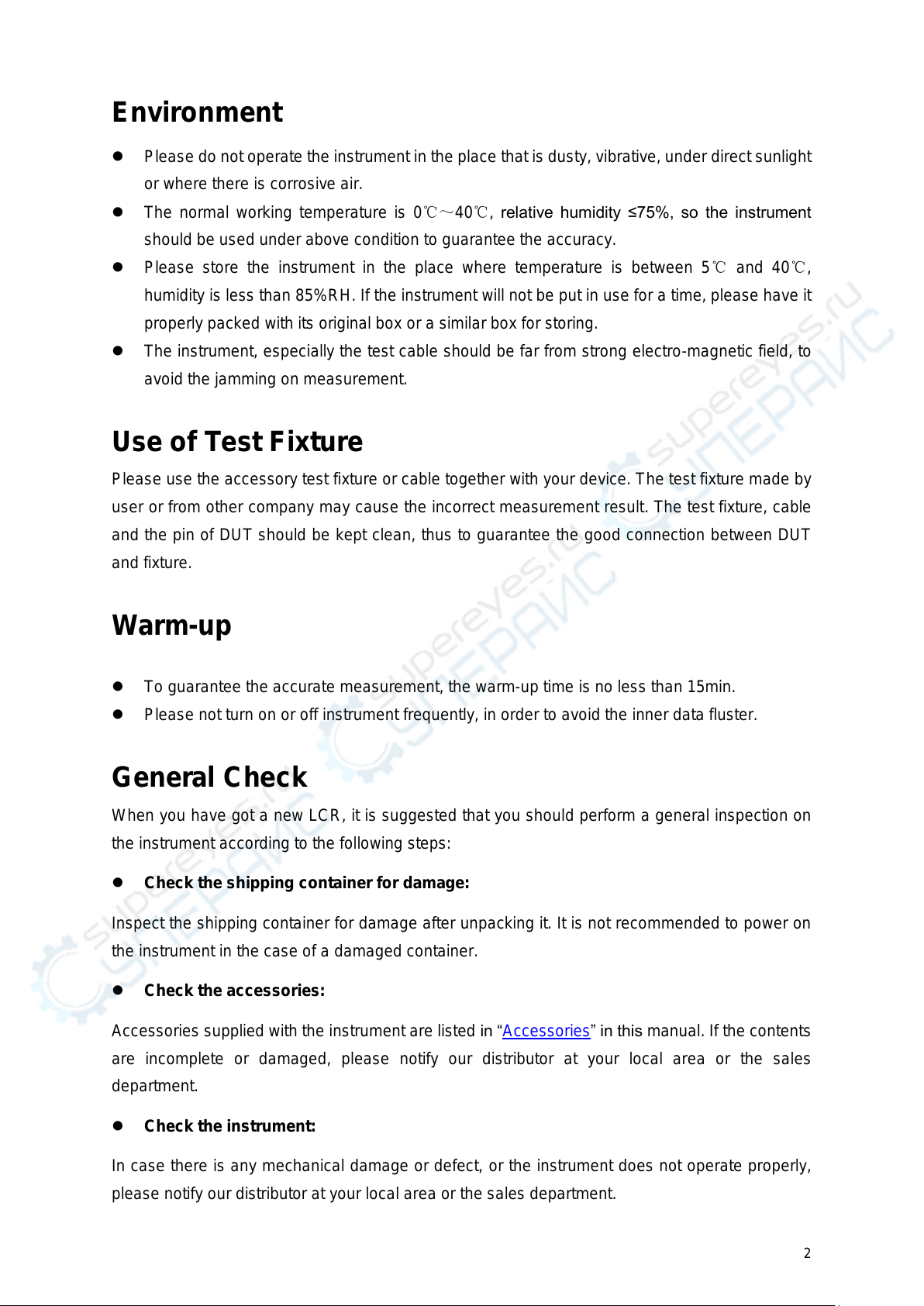

System settings interface

Complete

five terminal

test hole

Access three

terminal test

hole

HI

LO

GUARD

On the system settings interface users can set the language, auto power off, brightness, power

setting and buzzer. And view the model and version of the instrument.

Press [SET] key to enter the system setting interface, press the arrow key to select the setting

option and highlight, and press the arrow key for specific setting. Then press the [SET] button

again to view the model and version of the instrument. Press [SET] key again to exit the system

setting interface.

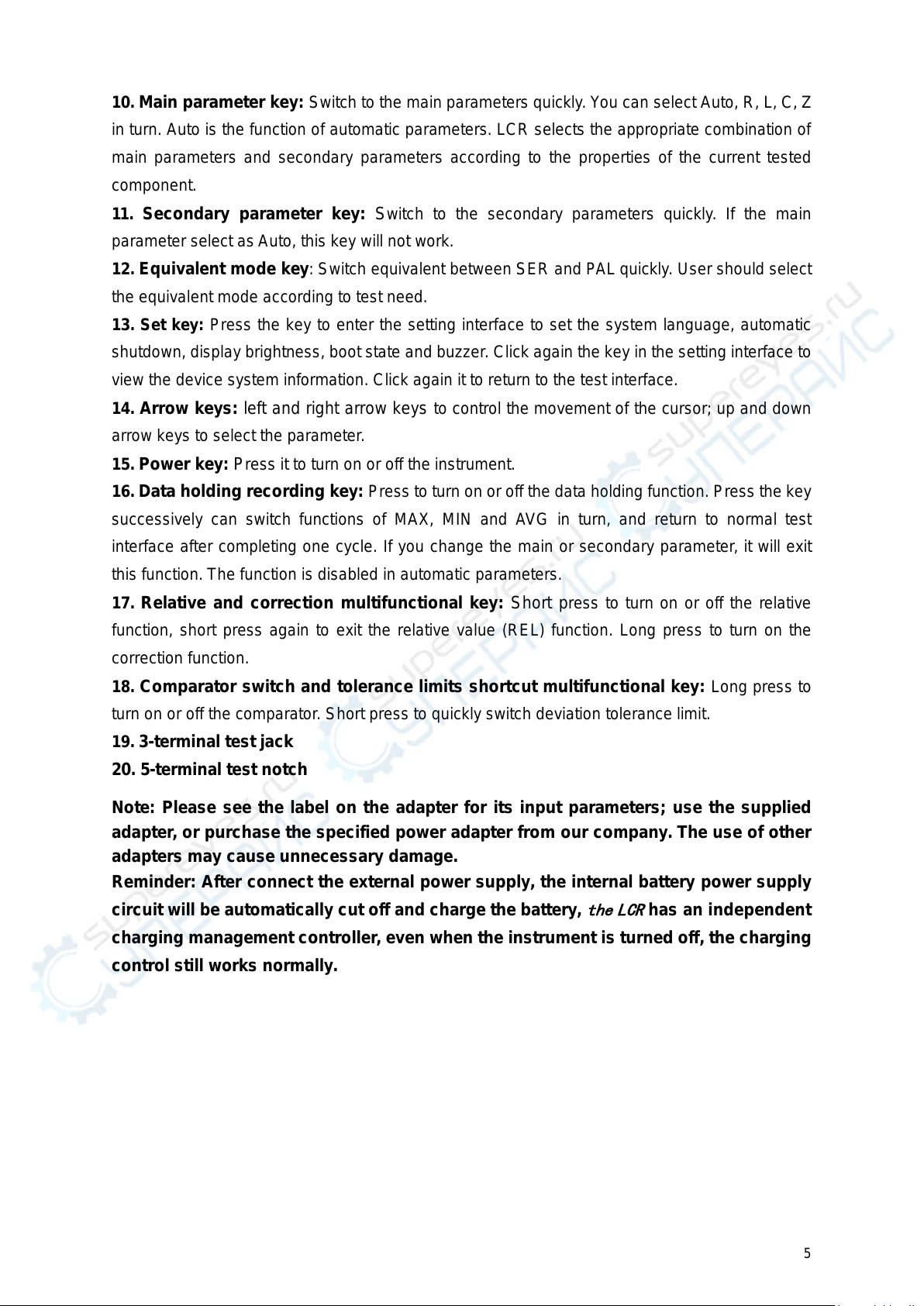

1.3 Test port

The serial LCR uses the 3-terminal and 5-terminal test ports at the same time, which is to

combine convenience and high accuracy for the test. See the figure for the test terminal.

The three-terminal test port of the instrument uses the standard rubber jack, therefore the

inexpensive rubber plug- alligator clip can be used as the test line. It is very convenient to apply

the extended test, but the drawback is low testing accuracy.

To improve the accuracy of the test line when using the extension line, the LCR is also equipped

with the five-terminal test notch for dedicated test fixture. It renders possible the complete

four-terminal measurement of the extension line to ensure the high testing accuracy.

7

Page 11

Chapter 2 Operation instruction

2.1 Startup and shutdown

Press the power key to start the instrument and the measurement interface is shown (default).

Press the power key again to shutdown it.

2.2 Test parameter

2.2.1 Test frequency

Handheld LCR applies AC test signal to the DUT for measurement. Frequency is one of the main

parameters of the AC source. Due to the presence of the non-ideal and distributed parameters of

component, and the impact of the distributed parameters between the test terminals, the same

component may have different results with different test frequencies. So, please select

appropriate frequency to test.

There are two ways to change the test frequency:

Method 1: Press [FREQ] key to switch different frequencies.

Method 2: Press the right and left arrow keys to move the cursor to the FREQ zone as shown in

below figure, and press the up and down arrow keys to switch frequencies.

2.2.2 Test level

Handheld LCR applies AC test signal to the DUT for measurement. Both the frequency and signal

level can be changed.

There are two ways to change the test level:

Method 1: Press [LEVEL] key to switch between different test signals level.

Method 2: Press the right and left arrow keys to move the cursor to the LEVEL zone, and press

8

Page 12

the up and down arrow keys to switch levels.

2.2.3 Test range

There are two ways to change the test range:

Method 1: Press [RANGE] key to switch between different test ranges.

Method 2: Turn on the instrument and the measurement display is shown, press the left and right

arrow keys to move the cursor to the RANGE zone, and the up and down arrow keys to switch the

range (AUTO, 100Ω, 1kΩ, 10kΩ, 100kΩ).

2.2.4 Test speed

There are two ways to change the test speed:

Method 1: Turn on the instrument and the measurement display is shown, press [SPEED] to

switch to the next measurement speed (fast, medium, slow). Above the status bar the

corresponding measurement speed is displayed. Fast (4 times /s), Medium (2 times /s), Slow (1

time /s).

Method 2: Turn on the instrument and the measurement display is shown, press the left and right

arrow keys to move the cursor to the SPEED zone, and the up and down arrow keys to switch the

test speed.

2.2.5 Main parameters

Parameter and symbol

R: resistance C: capacitance L: inductance Z: impedance

Select the type of measurement parameter, then select the main parameter.

Press [AUTO/R/L/C/Z] key to switch the main parameters(R, L, C, Z and AUTO) in sequence.

When AUTO is selected for the main parameter, the main parameter font is shown in red.

2.2.6 Secondary parameters

Parameter and symbol

X: reactance D: dissipation factor Q: quality factor θ: phase angle

ESR: equivalent series resistance

If necessary, press [X/D/Q/θ/ESR] key to select the secondary parameter.

If the main parameter select as Auto, this key will not work.

2.2.7 Set nominal value of tolerance mode

The method of setting the nominal value is as follows:

9

Page 13

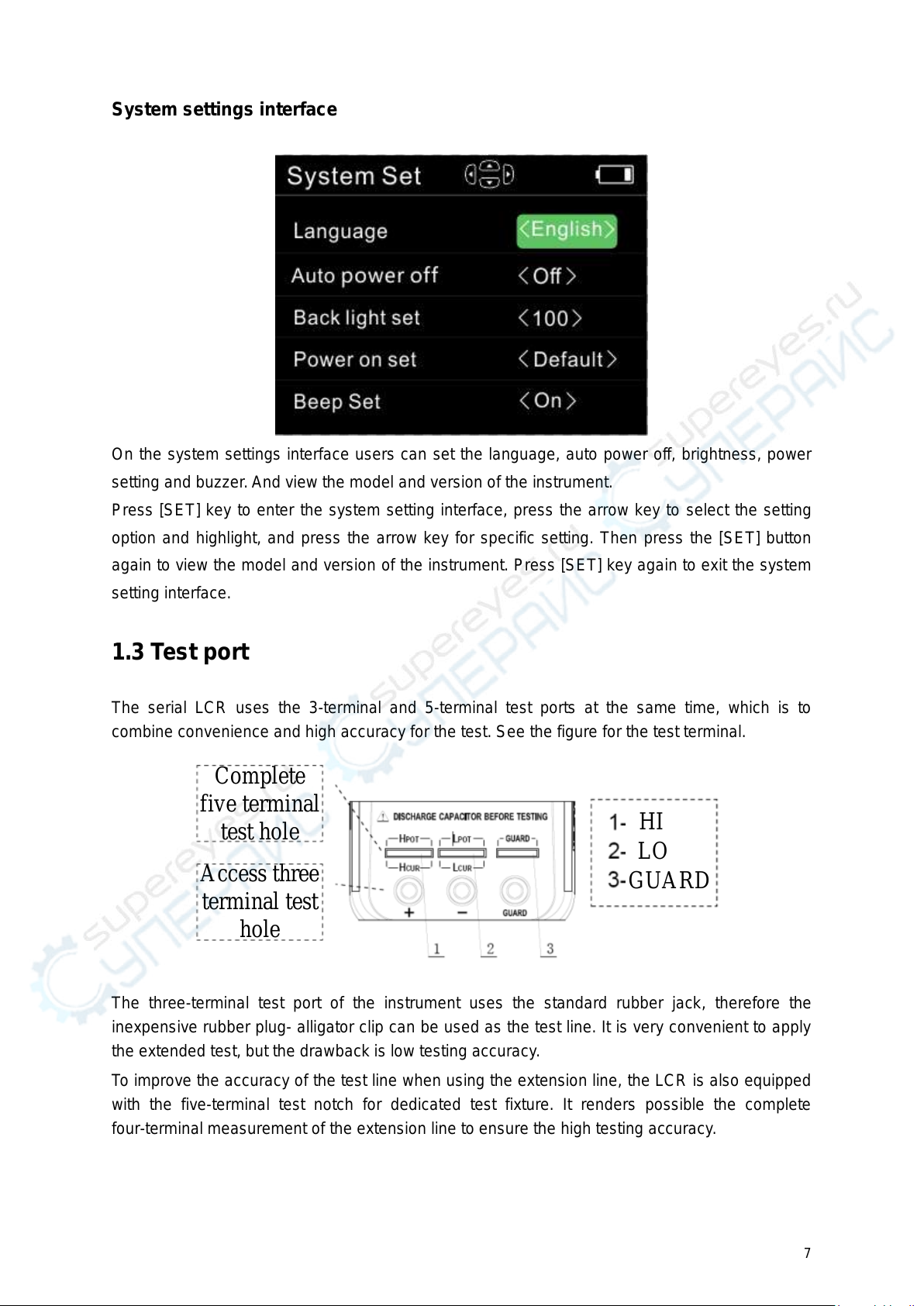

1. Turn on the instrument and the measurement display is shown, the component with required

nominal should be placed on the test clip of the instrument.

2. Long press [COMPARE] to turn on the comparator, and the nominal value is the value of the

measured element.

The nominal value and tolerance will be displayed in the status bar as shown in the below figure.

The deviation value between current test value and standard value will display on the secondary

parameter position.

Short press this key to select the required tolerance value successively (1%, 5%, 10% and 20%

optional). The color bar at the top of the screen will be used to judge GOOD/NG.

Long press this button or change the primary and secondary parameters to exit this function.

Note: This function cannot work if the main parameter select as Auto.

2.2.8 Equivalent mode

Due to the non-ideal and distributed parameters of component, the actual components tend to be

equivalent with the combination of ideal elements. Generally LCR tester uses two simple

equivalent models--series and parallel. Selecting the proper equivalent model will lead to better

measurement results. In general, low-impedance elements (such as that below 100Ω) should use

the series equivalent model; a high impedance element (such as that above 10kΩ) should use the

parallel equivalent model; the equivalent model affects less the measurement result of the one in

between the two above models.

Press [SER/P AL] key to switch equivalent mode (SER, PAL).

2.3 Relative mode

Press [REL] to turn on the relative function and the current value is used as reference. The

reference value and relative value will be shown respectively on the secondary and main display.

Press the key again to exit the function.

10

Page 14

2.4 Reading hold mode (HOLD)

The data hold function is used to freeze the displayed data. The measurement is still in progress,

but the data on the LCD is not updated as the measurements proceed.

Turn on reading hold:

Press the [HOLD] key, and "LOLD" will be shown on the LCD to indicate that the data hold

function is activated. And measurement results for the main and secondary parameters are those

displayed before pressing the HOLD key.

Turn off reading hold:

In hold mode, press again the [HOLD] key, and "HOLD" disappears from the LCD, the instrument

returns to normal measurement mode.

2.5 Data recording function

If the measurement data of the DUT see poor stability and fluctuate within a certain range, use the

data recording mode to acquire the readings. In the data recording mode, the maximum, minimum

and average can be dynamically obtained within a certain range.

Turn on the recording function:

Press [RECORD] key to turn on the data recording function, and the recorded value is shown on

the secondary display, then press the key to select the display of the maximum, minimum, or

average in successively.

This function records the maximum value, minimum value of the main parameter and the average

value of the last ten tests.

Note: After changing the type of the measurement parameter, it will

automatically exit from the data recording function. This function cannot work

if the main parameter select as Auto.

2.6 Correction function

The correction function includes the open and short circuit. By correcting it can effectively reduce

the error of distributed parameters caused by the test line. The short circuit correction can reduce

the impact of the contact resistance and lead resistance on the measurement of low impedance

element. The open circuit correction can reduce the impact of the distributed capacitance and

resistance between the two ends of the test line on the measurement of high impedance element.

The method of correction is shown as follows:

1. Before entering the correction function, please ensure that the test terminals are open- or

short-circuited. Long press [REL] key to enter the correction interface, then the instrument

automatically identify whether it is open or short circuit.

2. Short press [REL] key for open (OPEN) or short (SHORT) circuit correction. If the correction is

1 1

Page 15

successful, the secondary display shows "SUCESS"; or it shows "FAILED".

Note: Do not change the state of the test terminals during the correction.

3. Once finished the correction ends, press [REL] key to return to the measurement display.

2.7 Firmware Update

1. Download the tool "DfuSe Demo v3.0.5" and install it. Download upgrade firmware (***. Dfu).

2. In the shutdown state, keep pressing R-X key and insert the USB cable into the Type C port of

the device to connect the device to the computer.

You can see the device is identified in device manager of the PC:

3. Open DfuSe Demo software, click "Choose" button to select the Upgrade firmware (***. Dfu),

and click "Upgrade" to Upgrade it. After finished it, click "Leave DFU mode" to exit the

programming mode.

12

Page 16

If the device is not identified, please repeat step 2.

4. Close the “DfuSe Demo” software.

13

Page 17

Chapter 3 Quick application guide

Warning:

Do not measure the charged capacitor, or it may cause damage to the

instrument.

In case of measurement of on-board devices, make sure the power is turned

off. The active circuit cannot be measured directly.

When used in the dusty environment, the instrument is easy to gather dirt,

so it should be cleaned periodically to protect the test port to prevent the

dust from entering the instrument. The accumulation of dust will be

conductive and affect the use of the instrument.

Do not place the instrument directly in the environments with explosives,

direct sunlight and excessive heat.

Reminder: To achieve the proper measurement accuracy, refer to the

"correction function" section for open and short circuit correction before the

measurement. The test fixture can be rubber plug - alligator clip (see figure), or

the component can be directly inserted into the test notch. The rubber plug -

alligator clips are mainly used in the following examples.

14

Page 18

3.1 Resistance measurement

See the below figure for the connection test.

1. Press the power key to start the instrument.

2. Press the [AUTO/R/C/L/Z] key until Rs/Rp is displayed on the interface which means to select

resistance measurement.

3. Insert the resistor into the test notch, or choose the appropriate test accessories (rubber plug -

alligator clip) and connect it with the measured resistance.

4. Press the [FREQ] key to select the desired test frequency, press [LEVEL] to select the desired

level.

5. Read the measurement results from the screen.

Note: the AC signal is used by the instrument to measure the resistance, so the test result

reflects the AC resistance characteristics of the instrument instead of its DC resistance.

15

Page 19

3.2 Capacitance measurement

Warning: Make sure that the capacitor has been fully discharged before

measuring.

See the below figure for the connection test.

1. Press the power key to start the instrument.

2. Press the [AUTO/R/C/L/Z] key until Cs/Cp is displayed on the interface which means to select

capacitance measurement.

3. Insert the capacitor into the test notch, or choose the appropriate test accessories (rubber plug

- alligator clip) and connect it with the measured capacitor.

4. Press the [FREQ] key to select the desired test frequency, press [LEVEL] key to select the

desired level.

5. Read the measurement results from the screen.

Note: The capacitor or capacitive device must be fully discharged before

the test; the capacitor with large capacity may need longer time to discharge. If

the capacitive device not fully discharged is connected, it can damage the

components inside the instrument.

3.3 Inductance measurement

See below figure for the connection test.

16

Page 20

1. Press the power key to start the instrument.

2. Press the [AUTO/R/C/L/Z] key until Ls/Lp is displayed on the interface which means to select

inductance measurement.

3. Insert the inductor into the test notch, or choose the appropriate test accessories (rubber plug -

alligator clip, Kelvin test fixture, etc.) and connect it with the measured inductor.

4. Press the [FREQ] key to select the desired test frequency, press [LEVEL] to select the desired

level.

5. Read the measurement results from the screen.

3.4 Impedance measurement

1. Press the power key to start the instrument.

2. Press the [AUTO/R/C/L/Z] key until Z is displayed on the interface which means to select

impedance measurement.

3. Insert the impeder into the test notch, or choose the appropriate test accessories (rubber plug -

alligator clip, Kelvin test fixture, etc.) and connect it with the measured impeder.

4. Press the [FREQ] key to select the desired test frequency, press [LEVEL] to select the desired

level.

5. Read the measurement results from the screen.

17

Page 21

Chapter 4 Telecommunication

The instrument can be connected to PC through the Type C-USB interface. After installing the

driver on the PC, handheld LCR can be controlled from or the test results acquired by the PC

through the virtual serial port.

4.1 Connect the instrument to PC

Please refer to following steps to connect to PC:

1. Locate the USB driver software in the CD.

2. Use the Type C-USB cable to connect the instrument to the USB port of the PC, shown in

below Figure, press the power key to start the instrument.

3. After the installation is completed, check the serial number in Windows’ Device Manager.

Remote Control State:

When the LCR receives the remote operation state instruction from the host, the instrument

automatically enters into the remote control state. USB icon is displayed in green to show the

entry into the remote control state. To exit the remote control state, please send the “*GTL”

command.

Command Protocol:

Handheld LCR uses SCPI command set to transfer control command and return query

information and data with string. The terminator specified by the protocal shows the end of a

command line or information enquiry line.

Using SCPI command set enables the interaction control of PC over the instrument by

programming. The command format meets the standard which is easy to understand and use.

18

Page 22

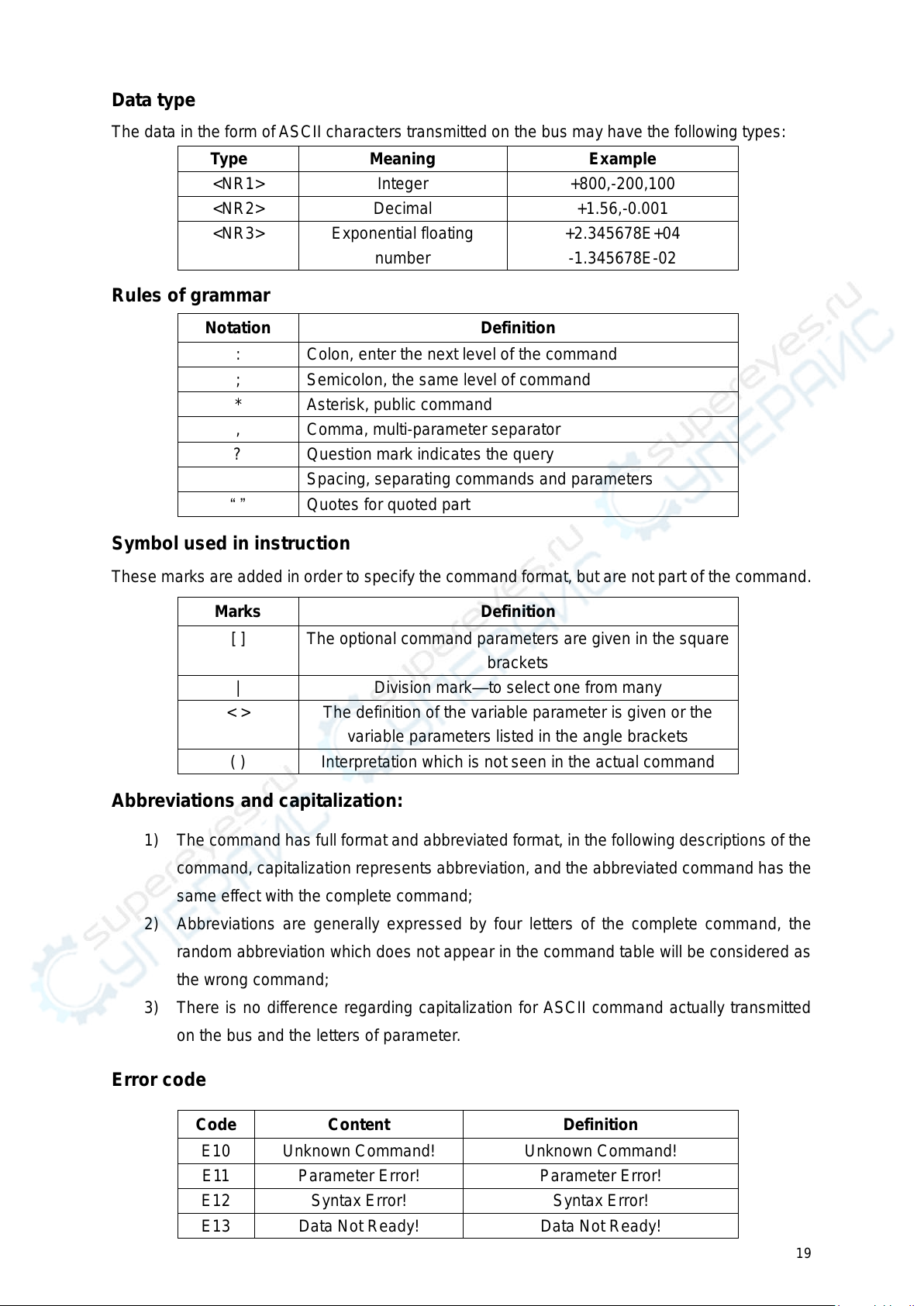

Data type

Type

Meaning

Example

<NR1>

Integer

+800,-200,100

<NR2>

Decimal

+1.56,-0.001

<NR3>

Exponential floating

number

+2.345678E+04

-1.345678E-02

Notation

Definition

:

Colon, enter the next level of the command

;

Semicolon, the same level of command

*

Asterisk, public command

,

Comma, multi-parameter separator

?

Question mark indicates the query

Spacing, separating commands and parameters

“ ”

Quotes for quoted part

Marks

Definition

[ ]

The optional command parameters are given in the square

brackets

|

Division mark—to select one from many

< >

The definition of the variable parameter is given or the

variable parameters listed in the angle brackets

( )

Interpretation which is not seen in the actual command

Code

Content

Definition

E10

Unknown Command!

Unknown Command!

E11

Parameter Error!

Parameter Error!

E12

Syntax Error!

Syntax Error!

E13

Data Not Ready!

Data Not Ready!

The data in the form of ASCII characters transmitted on the bus may have the following types:

Rules of grammar

Symbol used in instruction

These marks are added in order to specify the command format, but are not part of the command.

Abbreviations and capitalization:

1) The command has full format and abbreviated format, in the following descriptions of the

command, capitalization represents abbreviation, and the abbreviated command has the

same effect with the complete command;

2) Abbreviations are generally expressed by four letters of the complete command, the

random abbreviation which does not appear in the command table will be considered as

the wrong command;

3) There is no difference regarding capitalization for ASCII command actually transmitted

on the bus and the letters of parameter.

Error code

19

Page 23

Terminator

You can choose anyone of the following characters to end.

<CR> (Enter 0x0D)

<LF> (Line break 0x0A)

<CR> <LF>

4.2 Command Reference

4.2.1 Public command

Public command applied universally to various kinds of instrument defined by the public

command IEEE488, the public command starts with *. For example, *IDN?,*GTL,*LLO. This

machine supports only a few Public commands.

(1) *IDN?

Description: inquiry instrument information and version information

Return: < instrument hardware name >, < software version >, < serial number >,

< hardware version >

(2) *GTL

Description: used to unlock keyboard and resume keyboard operation

Return: None

4.2.2 Subsystem commands

FREQuency Subsystem

(1) FREQuency <value>

Description: set the measurement frequency

Parameter: 100, 120, 400, 1000, 4000, 10000, 40000, 50000, 75000, 100000 or

100Hz,120Hz, 400Hz, 1kHz, 4kHz, 10kHz ,40kHz, 50kHz, 75kHz, 100kHz (Please refer to the

model of LCR.)

Return: None

(2) FREQuency ?

Description: query current test frequency

Parameter: None

Return: <100|120|400|1000|4000|10000|40000|50000|75000|100000>(Please refer to the

FUNCtion Subsystem

(1) FUNCtion:impa <R|L|C|Z|Auto>

Description: Select the main parameter type

Parameter: <R|L|C|Z|Auto>

20

Page 24

Return: None

(2) FUNCtion:impa ?

Description: Query the main parameter type

Parameter: None

Return: <l-auto|c-auto|z-auto|r|l|c>

(3) FUNCtion:impb <X|Q|D|THETA|ESR>

Description: Select a secondary parameter type

Parameter: <X|Q|D|THETA|ESR>

Return: None

(4) FUNCtion:impb ?

Description: Query a secondary parameter type

Parameter: None

Return: <rec|q-auto|d-auto|theta-auto|x|q|d|theta|esr>

(5) FUNCtion:RANGe <AUTO|10|100|1000|10000|100000>

Or FUNCtion:RANGe <AUTO|10ohm|100ohm|1kohm|10kohm|100kohm>

Description: Select the range

Parameter: <AUTO|10|100|1000|10000|100000>

Or <AUTO|10ohm|100ohm|1kohm|10kohm|100kohm>

Return: None

(6) FUNCtion: RANGe ?

Description: Query the range

Parameter: None

Return: <auto|10|100|1000|10000|100000>

(7) FUNCtion:LEVel <300|600>

Or FUNCtion: LEVel <300mv|600mv>

Description: Select the level

Parameter: <300|600> or <300mv|600mv>

Return: None

(8) FUNCtion: LEVel ?

Description: Query the level

Parameter: None

Return: <300|600>

(9) FUNCtion:EQUivalent <SER|PAL>

Or FUNCtion:EQUivalent <SERIES| PARALLEL>

Description: Select the equivalent mode

Parameter: <SER|PAL> or <SERIES| PARALLEL>

Return: None

(10) FUNCtion: EQUivalent ?

Description: Query the equivalent mode

Parameter: None

Return: <ser|pal>

21

Page 25

FETCh Subsystem

FETCh ?

Description: Query data

Parameter: None

Return: <NR3,NR3,NR1> Main parameters, secondary parameters, gear number

22

Page 26

Chapter 5 Specification

Model

Hantek1832C

Hantek1833C

Measurement parameters

Main parameter: L/C/R/Z Secondary parameter:

X/D/Q/θ/ESR

Equivalent mode

Series, parallel

Mode of range

Manual, automatic

Measurement speed

Fast(4 times/s), medium(2 times/s), slow(1 times/s)

Configuration of the test terminal

3-terminal, 5-terminal

Correction function

Short circuit, Open circuit

Communication interface

Type C(virtual serial port)

Test signal frequency

100Hz, 120Hz, 400Hz,

1kHz, 4KHz, 10kHz,

40kHz

100Hz, 120Hz, 400Hz,

1kHz, 4KHz, 10kHz,

40kHz, 50KHz, 75KHz,

100kHz

Test signal level

0.6Vrms

0.3Vrms, 0.6Vrms

Output impedance

100Ω

Highest accuracy (see accuracy

index for details)

Resistance: 0.25%

Capacitance: 0.4%

Measurement range

L: 0-2000H C: 0-20mF R: 0-20MΩ

The general and measurement precision specification of LCR are described below.

5.1 General Specification

5.2 Accurac y

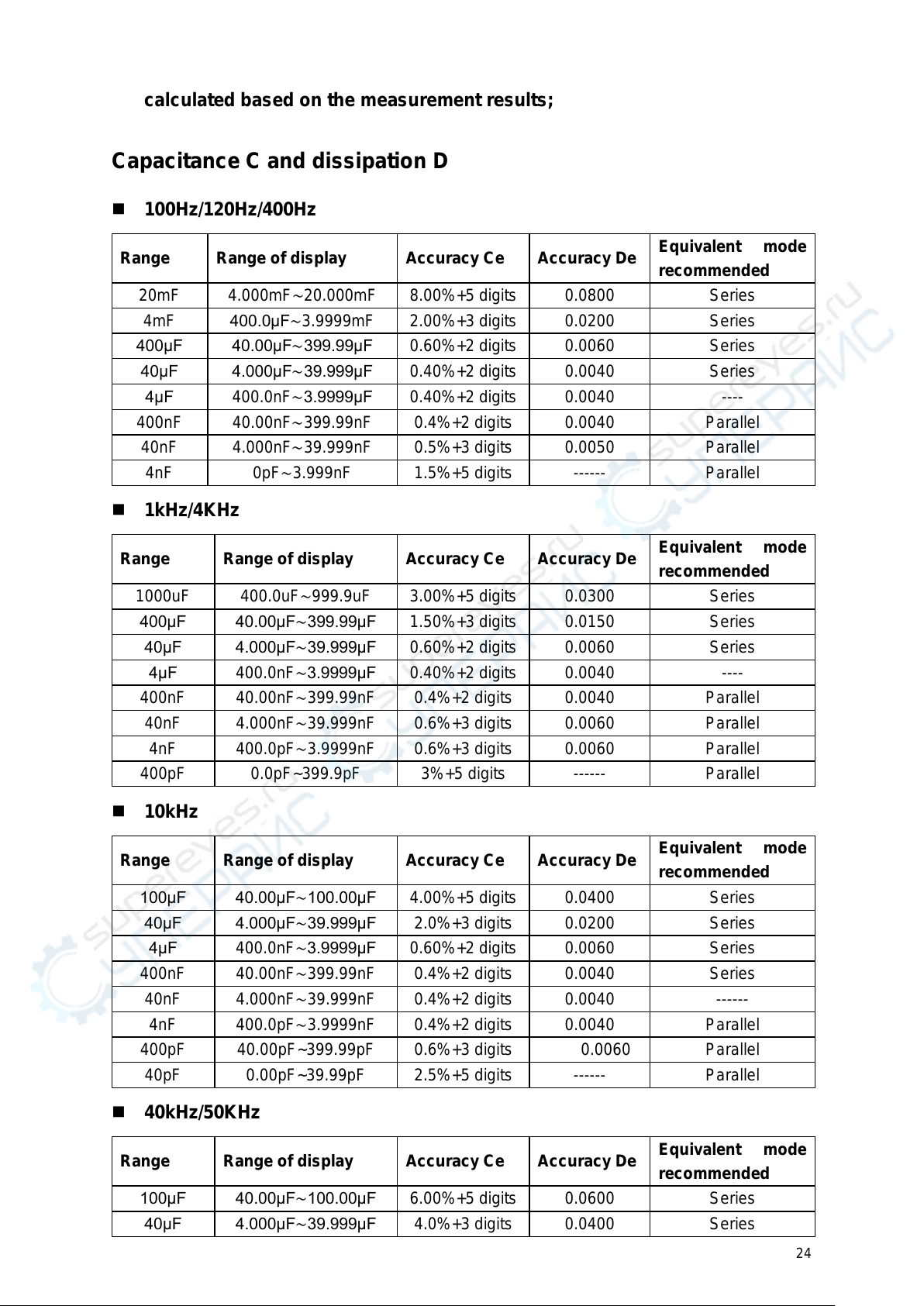

Notes:

Environment temperature: 20℃ ± 2℃, humidity: ≤75% R.H;

Preheat the instrument for at least 30 minutes before the test;

Test at the test notch on the end face of the instrument;

It is better to conduct open and short circuit correction before the test;

Measure with the recommended equivalent mode;

The percentage in terms of error indicates:

± (% of the reading + last digit)

If the actual measurement of the instrument and the display exceeds the

scope specified in the table, the accuracy of the excessive part will not be

given;

The meaning of the subscript

S- series equivalent; p- parallel equivalent; e- accuracy

Some parameters cannot be given in the data table, and it can only be

23

Page 27

calculated based on the measurement results;

Range

Range of display

Accuracy Ce

Accuracy De

Equivalent mode

recommended

20mF

4.000mF∼20.000mF

8.00%+5 digits

0.0800

Series

4mF

400.0μF∼3.9999mF

2.00%+3 digits

0.0200

Series

400μF

40.00μF∼399.99μF

0.60%+2 digits

0.0060

Series

40μF

4.000μF∼39.999μF

0.40%+2 digits

0.0040

Series

4μF

400.0nF∼3.9999μF

0.40%+2 digits

0.0040

----

400nF

40.00nF∼399.99nF

0.4%+2 digits

0.0040

Parallel

40nF

4.000nF∼39.999nF

0.5%+3 digits

0.0050

Parallel

4nF

0pF∼3.999nF

1.5%+5 digits

------

Parallel

Range

Range of display

Accuracy Ce

Accuracy De

Equivalent mode

recommended

1000uF

400.0uF∼999.9uF

3.00%+5 digits

0.0300

Series

400μF

40.00μF∼399.99μF

1.50%+3 digits

0.0150

Series

40μF

4.000μF∼39.999μF

0.60%+2 digits

0.0060

Series

4μF

400.0nF∼3.9999μF

0.40%+2 digits

0.0040

----

400nF

40.00nF∼399.99nF

0.4%+2 digits

0.0040

Parallel

40nF

4.000nF∼39.999nF

0.6%+3 digits

0.0060

Parallel

4nF

400.0pF∼3.9999nF

0.6%+3 digits

0.0060

Parallel

400pF

0.0pF~399.9pF

3%+5 digits

------

Parallel

Range

Range of display

Accuracy Ce

Accuracy De

Equivalent mode

recommended

100μF

40.00μF∼100.00μF

4.00%+5 digits

0.0400

Series

40μF

4.000μF∼39.999μF

2.0%+3 digits

0.0200

Series

4μF

400.0nF∼3.9999μF

0.60%+2 digits

0.0060

Series

400nF

40.00nF∼399.99nF

0.4%+2 digits

0.0040

Series

40nF

4.000nF∼39.999nF

0.4%+2 digits

0.0040

------

4nF

400.0pF∼3.9999nF

0.4%+2 digits

0.0040

Parallel

400pF

40.00pF~399.99pF

0.6%+3 digits

0.0060

Parallel

40pF

0.00pF~39.99pF

2.5%+5 digits

------

Parallel

Range

Range of display

Accuracy Ce

Accuracy De

Equivalent mode

recommended

100μF

40.00μF∼100.00μF

6.00%+5 digits

0.0600

Series

40μF

4.000μF∼39.999μF

4.0%+3 digits

0.0400

Series

Capacitance C and dissipation D

100Hz/120Hz/400Hz

1kHz/4KHz

10kHz

40kHz/50KHz

24

Page 28

4μF

400.0nF∼3.9999μF

1.0%+2 digits

0.0100

Series

400nF

40.00nF∼399.99nF

0.6%+2 digits

0.0060

Series

40nF

4.000nF∼39.999nF

0.6%+2 digits

0.0060

------

4nF

400.0pF∼3.9999nF

0.6%+2 digits

0.0060

Parallel

400pF

40.00pF~399.99pF

1%+3 digits

0.0100

Parallel

40pF

0.000pF~39.999pF

3%+5 digits

------

Parallel

75KHz/100kHz

Range

Range of display

Accuracy Le

Accuracy

De*

Equivalent mode

recommended

1H

400.0mH∼999.9mH

1.50%+3 digits

0.0150

Parallel

400mH

40.00mH∼399.99mH

0.4%+2 digits

0.0040

Parallel

40mH

4.000mH∼39.999mH

0.4%+2 digits

0.0040

------

4mH

400.0uH∼3.9999mH

0.4%+2 digits

0.0040

Series

400uH

40.00uH~399.99uH

0.8%+3 digits

0.0080

Series

40uH

0.0uH~39.9uH

3.0%+5 digits

------

Series

Range

Range of display

Accuracy Ce

Accuracy De

Equivalent mode

recommended

10μF

4.000μF∼10.000μF

8.0%+20 digits

0.0800

Series

4μF

400.0nF∼3.9999μF

5.0%+10 digits

0.050

Series

400nF

40.00nF∼399.99nF

1.5%+5 digits

0.0150

Series

40nF

4.000nF∼39.999nF

1%+2 digits

0.0100

Series

4nF

400.0pF∼3.999nF

1%+2 digits

0.0100

------

400pF

40.00pF~399.99pF

1.5%+2 digits

0.0150

Parallel

40pF

4.000pF~39.999pF

2%+5 digits

0.0200

Parallel

4pF

0.000pF~3.999pF

5%+10 digits

------

Parallel

Range

Range of display

Accuracy Le

Accuracy

De*

Equivalent mode

recommended

1000H

400.0H∼999.9H

2.00%+3 digits

0.0200

Parallel

400H

40.000H∼399.99H

0.60%+2 digits

0.0060

Parallel

40H

4.000H∼39.999H

0.40%+2 digits

0.0040

Parallel

4H

400.0mH∼3.9999H

0.40%+2 digits

0.0040

----

400mH

40.00mH∼399.99mH

0.4%+2 digits

0.0040

Series

40mH

4.000mH∼39.999mH

0.6%+3 digits

0.0060

Series

4mH

0uH∼3.999mH

3.0%+5 digits

------

Series

Range

Range of display

Accuracy Le

Accuracy

De*

Equivalent mode

recommended

Inductance L and quality factor

100Hz/120Hz/400Hz

1kHz/4KHz

10kHz/40KHz

25

Page 29

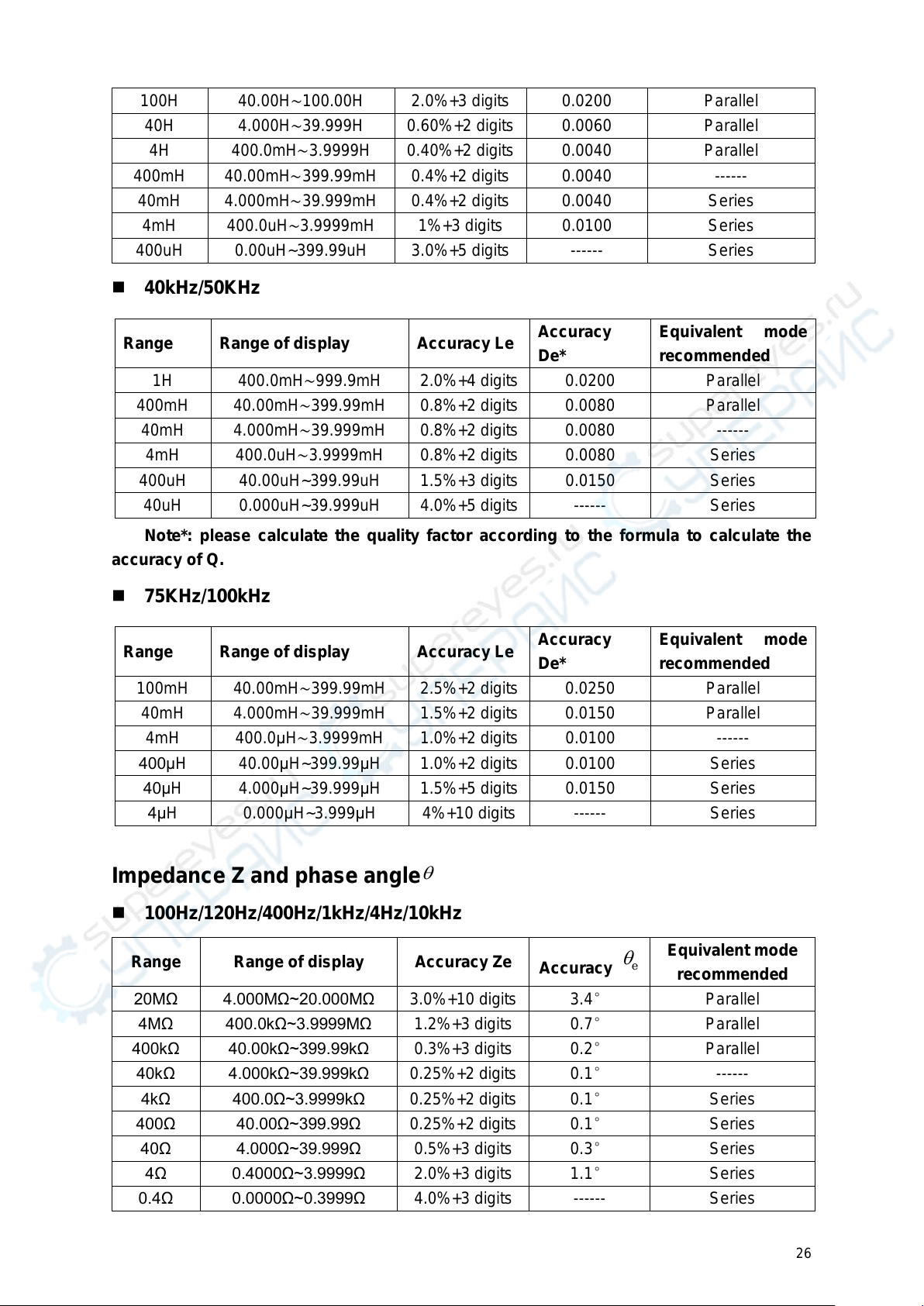

40kHz/50KHz

Range

Range of display

Accuracy Ze

Accuracy

e

Equivalent mode

recommended

20MΩ

4.000MΩ~20.000MΩ

3.0%+10 digits

3.4°

Parallel

4MΩ

400.0kΩ~3.9999MΩ

1.2%+3 digits

0.7°

Parallel

400kΩ

40.00kΩ~399.99kΩ

0.3%+3 digits

0.2°

Parallel

40kΩ

4.000kΩ~39.999kΩ

0.25%+2 digits

0.1°

------

4kΩ

400.0Ω~3.9999kΩ

0.25%+2 digits

0.1°

Series

400Ω

40.00Ω~399.99Ω

0.25%+2 digits

0.1°

Series

40Ω

4.000Ω~39.999Ω

0.5%+3 digits

0.3°

Series

4Ω

0.4000Ω~3.9999Ω

2.0%+3 digits

1.1°

Series

0.4Ω

0.0000Ω~0.3999Ω

4.0%+3 digits

------

Series

100H

40.00H∼100.00H

2.0%+3 digits

0.0200

Parallel

40H

4.000H∼39.999H

0.60%+2 digits

0.0060

Parallel

4H

400.0mH∼3.9999H

0.40%+2 digits

0.0040

Parallel

400mH

40.00mH∼399.99mH

0.4%+2 digits

0.0040

------

40mH

4.000mH∼39.999mH

0.4%+2 digits

0.0040

Series

4mH

400.0uH∼3.9999mH

1%+3 digits

0.0100

Series

400uH

0.00uH~399.99uH

3.0%+5 digits

------

Series

Range

Range of display

Accuracy Le

Accuracy

De*

Equivalent mode

recommended

1H

400.0mH∼999.9mH

2.0%+4 digits

0.0200

Parallel

400mH

40.00mH∼399.99mH

0.8%+2 digits

0.0080

Parallel

40mH

4.000mH∼39.999mH

0.8%+2 digits

0.0080

------

4mH

400.0uH∼3.9999mH

0.8%+2 digits

0.0080

Series

400uH

40.00uH~399.99uH

1.5%+3 digits

0.0150

Series

40uH

0.000uH~39.999uH

4.0%+5 digits

------

Series

Range

Range of display

Accuracy Le

Accuracy

De*

Equivalent mode

recommended

100mH

40.00mH∼399.99mH

2.5%+2 digits

0.0250

Parallel

40mH

4.000mH∼39.999mH

1.5%+2 digits

0.0150

Parallel

4mH

400.0μH∼3.9999mH

1.0%+2 digits

0.0100

------

400μH

40.00μH~399.99μH

1.0%+2 digits

0.0100

Series

40μH

4.000μH~39.999μH

1.5%+5 digits

0.0150

Series

4μH

0.000μH~3.999μH

4%+10 digits

------

Series

Note*: please calculate the quality factor according to the formula to calculate the

accuracy of Q.

75KHz/100kHz

Impedance Z and phase angle

100Hz/120Hz/400Hz/1kHz/4Hz/10kHz

26

Page 30

40kHz/50KHz

Range

Range of display

Accuracy Ze

Accuracy

e

Equivalent mode

recommended

20MΩ

4.000MΩ~20.000MΩ

7.0%+41 digits

4.0°

Parallel

4MΩ

400.0kΩ~3.9999MΩ

2.5%+3 digits

1.4°

Parallel

400kΩ

40.00kΩ~399.99kΩ

1.0%+4 digits

0.6°

Parallel

40kΩ

4.000kΩ~39.999kΩ

1.0%+4 digits

0.6°

------

4kΩ

400.0Ω~3.9999kΩ

0.5%+3 digits

0.3°

Series

400Ω

40.00Ω~399.99Ω

0.5%+3 digits

0.3°

Series

40Ω

4.000Ω~39.999Ω

0.7%+4 digits

0.4°

Series

4Ω

0.4000Ω~3.9999Ω

2.0%+6 digits

1.1°

Series

0.4Ω

0.0000Ω~0.3999Ω

5.0%+10 digits

------

Series

Range

Range of display

Accuracy Ze

Accuracy

e

Equivalent mode

recommended

20MΩ

4.000MΩ~20.000MΩ

9.0%+20 digits

5.2°

Parallel

4MΩ

400.0kΩ~3.9999MΩ

4.0%+10 digits

2.3°

Parallel

400kΩ

40.00kΩ~399.99kΩ

1.5%+4 digits

0.9°

Parallel

40kΩ

4.000kΩ~39.999kΩ

1.0%+2 digits

0.6°

Parallel

4kΩ

400.0Ω~3.9999kΩ

0.7%+2 digits

0.4°

------

400Ω

40.00Ω~399.99Ω

0.7%+2 digits

0.4°

Series

40Ω

4.000Ω~39.999Ω

1.0%+5 digits

0.6°

Series

4Ω

0.4000Ω~3.9999Ω

3.0%+10 digits

1.7°

Series

0.4Ω

0.0000Ω~0.3999Ω

7%+20 digits

------

Series

75KHz/100kHz

27

Page 31

Chapter 6 Maintenance

Warning:

Do not repair the instrument arbitrarily; it should be maintained and

repaired by professional personnel.

Keep the instrument away from liquid; do not leave articles especially

conductive objects in the instrument.

6.1 Service

If the equipment fails and cannot be switched on, you should first check the battery and external

power supply, power jack, etc.; check whether the key is invalid;

If the test result is abnormal, first check if the test accessories have problems, and if there is

damage of the spring in the test notch; at the same time review the specification to confirm if the

operation is correct;

Do not arbitrarily replace the components and specific parts, please contact the relevant dealer or

service company for problems which cannot be confirmed.

6.2 Clean

Before cleaning, user should remove the battery and external power supply and shut down the

instrument.

Prevent water or other liquids to enter the instrument through the test slot, keys, or other joints. If it

happens by accident, you should immediately stop using it and remove the power supply and

battery.

Please clean with a soft cloth and diluted neutral detergent, and carefully wipe the dirty parts to

prevent scratches on the surface.

After cleaning, the instrument should be completely dry before used.

28

Page 32

Accessories

Standard accessories list:

Handheld LCR (lithium battery installed)

CD

A type C-USB communication cable

An AC power adapter

A pair of red / black rubber plugs –alligator clip test line

A short-circuit bar

Please check according to the accessories list after the box is opened, if any component is

missing, please immediately contact the company or the related dealer.

29

Loading...

Loading...