Page 1

Page 2

Page 3

USER’S MANUAL

060 / 200 / 500 / 600 / 600H

Page 4

2

Content

Safety Notice …………………………………………………..3

Digital Scope Meters………………………..…………………5

CHAPTER 1: Getting Start…………………………………... 6

General Check………………………………………....6

User’s Interface……………………………………...…6

Input Connections…………………………………

....

.11

Function Check……………………………………….12

To compensate probes…………………………

…..

...13

To display a signal automatically…………………....15

Using the Scope Meter……………………………

...

.15

CHAPTER 2: Operating Scope……………………………..18

Set Vertical System……………………………

…….

..18

Set Horizontal System…………………………

…….

.32

Set Trigger System………………………………

…..

.36

Save / Recall Waveforms and Setups……………...42

Utility Function……………………………

…………

...46

Signal Measurement……………………………

…..

..55

Cursor Measurement…………………………

….......

57

CHAPTER 3: Using examples…………………………

…...61

CHAPTER 4: Multimeter………………………………….....69

CHAPTER 5: Troubleshooting………………………

……

...80

CHAPTER 6: Specications……………

………………

…...81

CHAPTER 7: Appendix.....................................................84

Page 5

General Safety Notice

1. Safety Terms and Symbols

Terms in this manual:

These terms may appear in this manual:

WARNING: Warning statements identify conditions or practices that could result in

injury or loss of life.

CAUTION: Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product:

These terms may appear on the product:

DANGER: indicates an injury hazard may be immediately accessible.

WARNING: indicates an injury hazard may be not immediately accessible.

CAUTION: indicates that a potential damage to the instrument or other property

might occur.

Symbols on the Product:

These symbols may appear on the product:

2. General Safety Information

Carefully read the following safety information in order to avoid any personal injury

or damage on this product or any products connected with it. Review the following

safety precautions carefully before operate the device to avoid any personal injuries or

damages to the device and any products connected to it. To avoid potential hazards use

the device as specied by this user’s manual only.

■ To Avoid Fire or Personal Injury.

■ Use Proper Power adapter. Use only the power cord specied for this product

Page 6

and certied for the country of use.

■ Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

■ Connect and Disconnect Properly. Connect the probe output to the

measurement device before connecting the probe to the circuit under test. Disconnect

the probe input and the probe reference lead from the circuit under test before

disconnecting the probe from the measurement device.

■ Observe All Terminal Ratings. To avoid re or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings information

before making connections to the product.

■ Use Proper Probe. To avoid shock hazard, use a properly rated probe for your

measurement.

■ Avoid Circuit or Wire Exposure. Do not touch exposed connections and

components when power is on.

■ Do Not Operate With Suspected Failures. If suspected damage occurs with the

device, have it inspected by qualied service personnel before further operations.

■ Provide Proper Ventilation. Refer to the installation instructions for proper

ventilation of the device.

■ Do not operate in Wet/Damp Conditions.

■ Do not operate in an Explosive Atmosphere.

■ Keep Product Surfaces Clean and Dry.

Page 7

5

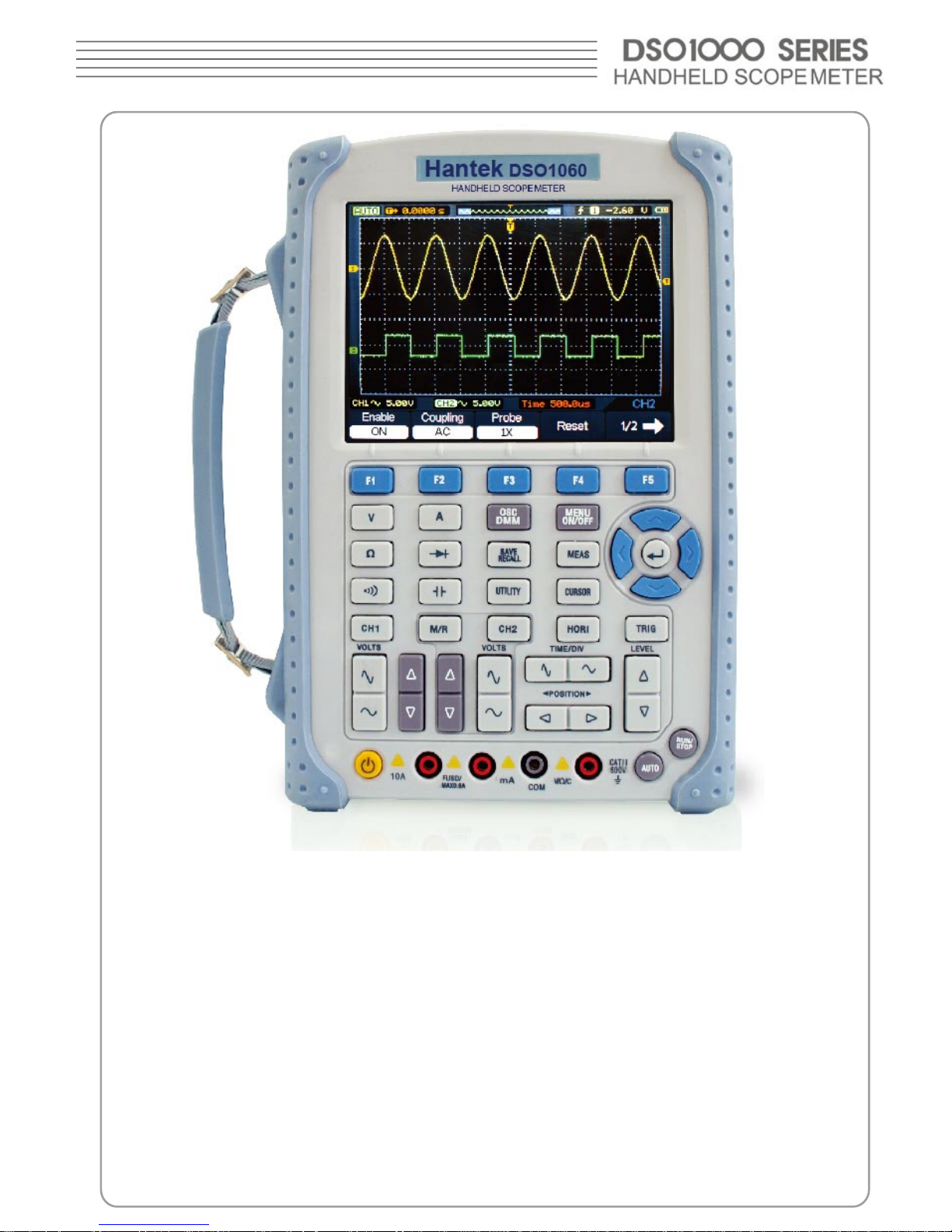

Digital Scope Meters

DSO1000 Series digital scope meters offer exceptional waveform viewing and

measurements in a compact, lightweight package. DSO1000 series is ideal for

production test, eld service, research, design, education and training involving

applications of analog circuit tests and troubleshooting.

Product features:

■ Dual Channel, Bandwidth:

60MHz (DSO1060)

200MHz (DSO1200)

500MHz (DSO1500)

600MHz (DSO1600)

600MHz (DSO1600H)

■ Maximum real-time sampling rate:

150MSa/s (DSO1060)

250MSa/s (DSO1200)

500MSa/s (DSO1500)

1GSa/s (DSO1600)

2GSa/s (DSO1600H)

■ Memory depth:

32K points (Single Channel), 16K points (Dual Channels)

■ Color TFT LCD, 320×240 pixels resolution.

■ USB storage and printing supports, rmware upgrade via USB interface.

■ Adjustable waveform intensity, more effective waveform viewing.

■ One-touch automatic setup, ease of use (AUTOSET).

■ 15 Waveforms, 15 setups, supports CSV and bitmap format.

■ 22 Automatic measurements.

■ Automatic cursor tracking measurements.

■ Waveform recorder, record and replay dynamic waveforms.

■ User selectable fast offset calibration.

■ Built-in FFT function, Frequency Counter.

■ Pass/Fail Function.

■ Addition, Subtraction, Multiplication and Division Mathematic Functions.

■ Advanced trigger types include: Edge, Pulse width.

■ Multiple Language User Interface.

■ Pop-up menu makes it easy to read and easy to use.

■ Built-in multi-language help system.

■ Easy-to-use le system supports Multi-Language characters le name

input.

■ Selectable 20 MHz bandwidth limit;

Page 8

6

CHAPTER 1: Getting Start

This chapter covers the following topics:

■ General Check

■ Functional Check

■ The User Interface

■ Input Connections

■ To compensate probes

■ To display a signal automatically

■ Using the Scope Meter

General Check

When you have got a new DSO1000 series scope meter, it is suggested that you

should perform a general inspection on the instrument according to the following steps:

■ Check the shipping container for damage:

Keep the damaged shipping container or cushioning material until the contents of the

shipment have been checked for completeness and the instrument has been checked

mechanically and electrically.

■ Check the accessories:

Accessories supplied with the instrument are listed in “Accessories” in this guide. If the

contents are incomplete or damaged,please notify our distributor at your local area or

the overseas sales dept.

■ Check the instrument:

In case there is any mechanical damage or defect, or the instrument does not operate

properly or fails performance tests, please notify our distributor at your local area or the

overseas sales dept.

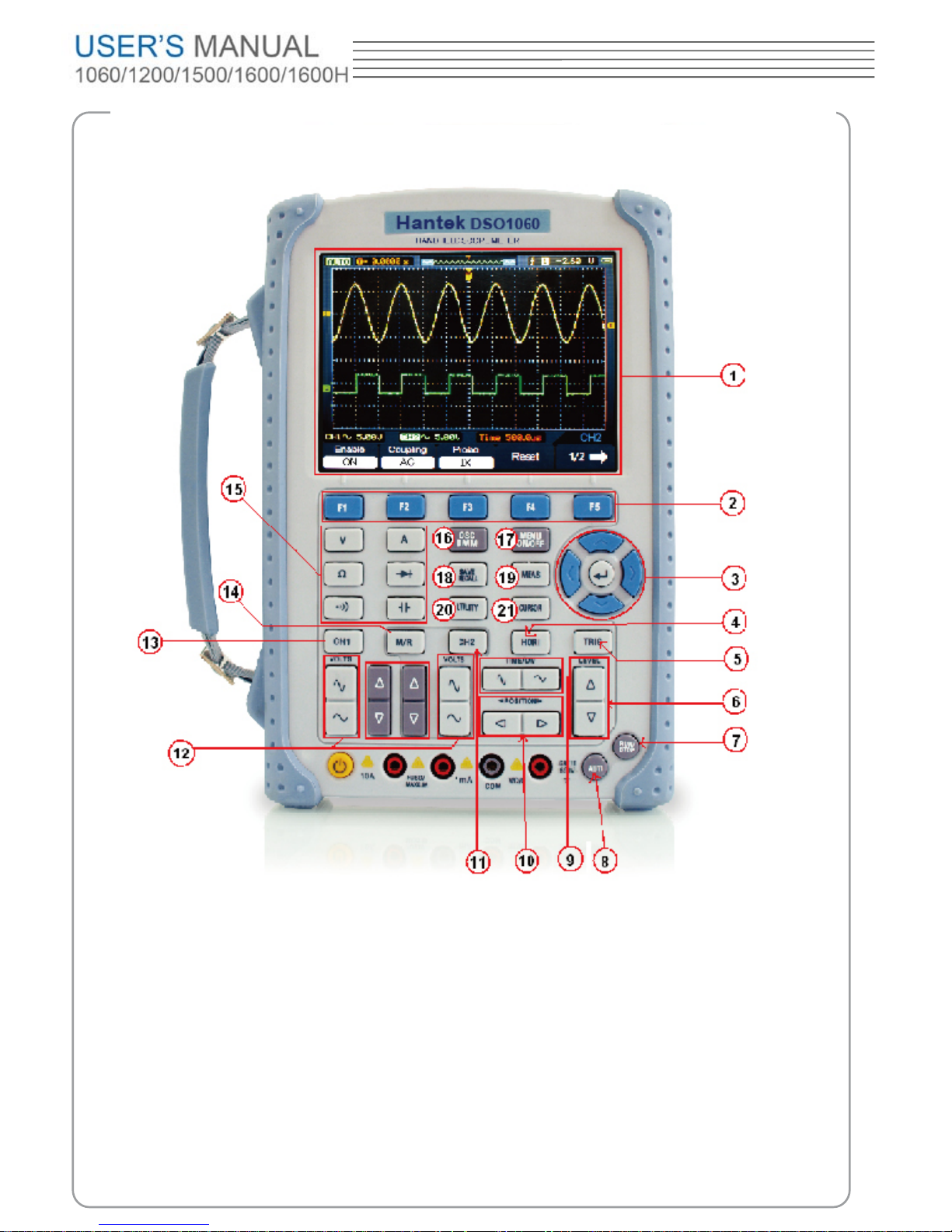

User’s Interface

The rst thing to do with a new scope meter is to know its front panel. This chapter

helps to be familiar with the layout of the keys and how to use them. Read this chapter

carefully before further operations.

Front Panel (Figure 1-1):

The buttons not only allow you to use some of the functions directly but also bring

up the manual keys on the screen, which enable the access to many measurement

features associated with advanced functions, mathematics, and reference or to run

control features.

Page 9

Figure 1-1

Scope Meter Front Panel

Page 10

Figure 1-2

Front Panel Description

Description

1. LCD Display

2. F1~F5: Sets or switch options for the menu

3. Arrow Keys

4. Hori: Shows Horizontal menu

5. TRIG: Shows Trigger menu

6. Level: Adjust the trigger level

Page 11

7. RUN/STOP: key for running or stopping the operation

8. AUTO: Be used for auto setting under the oscilloscope operation mode

9. TIME/DIV: Decrease or Increase the time base

10. POSITION: Adjust the horizontal trigger position

11. CH2: Shows the CH2 menu

12. VOLTS: Decrease or Increase the voltage/div

13. CH1: Shows the CH1 menu

14. M/R: Shows the Math or REF menu

15. DMM Buttons: The DMM control buttons

16. DMM/SCOPE: Switch DMM or Scope function

17. MENU ON/OFF: Turn on/off the menu

18. SAVE RECALL: Shows SAVE or RECALL menu

19. MEAS: Shows Measurement menu

20. UTILITY: Shows Utility menu

21. CURSOR: Shows Cursor menu

Display screen

Figure 1-3

Page 12

0

LCD Display screen

Description

1. Shows running status.

2. Shows delay time

3. Shows location of the current waveform in the memory.

4. Shows the trigger position in the memory.

5. Shows the trigger mode.

6. Shows the trigger source.

7. Shows the trigger level.

8. Shows the power.

9. The center of current waveform window.

10. CH1 waveform.

11. The trigger level symbol.

12. The grid

13. CH2 waveform.

14. Shows the time base.

15. Shows the menu title.

16. The menu

17. CH1/CH2

18. Shows the coupling.

19. Shows the voltage/div.

20. CH2 mark.

21. CH1 mark.

22. Shows the trigger position in current waveform window.

Page 13

Input Connections

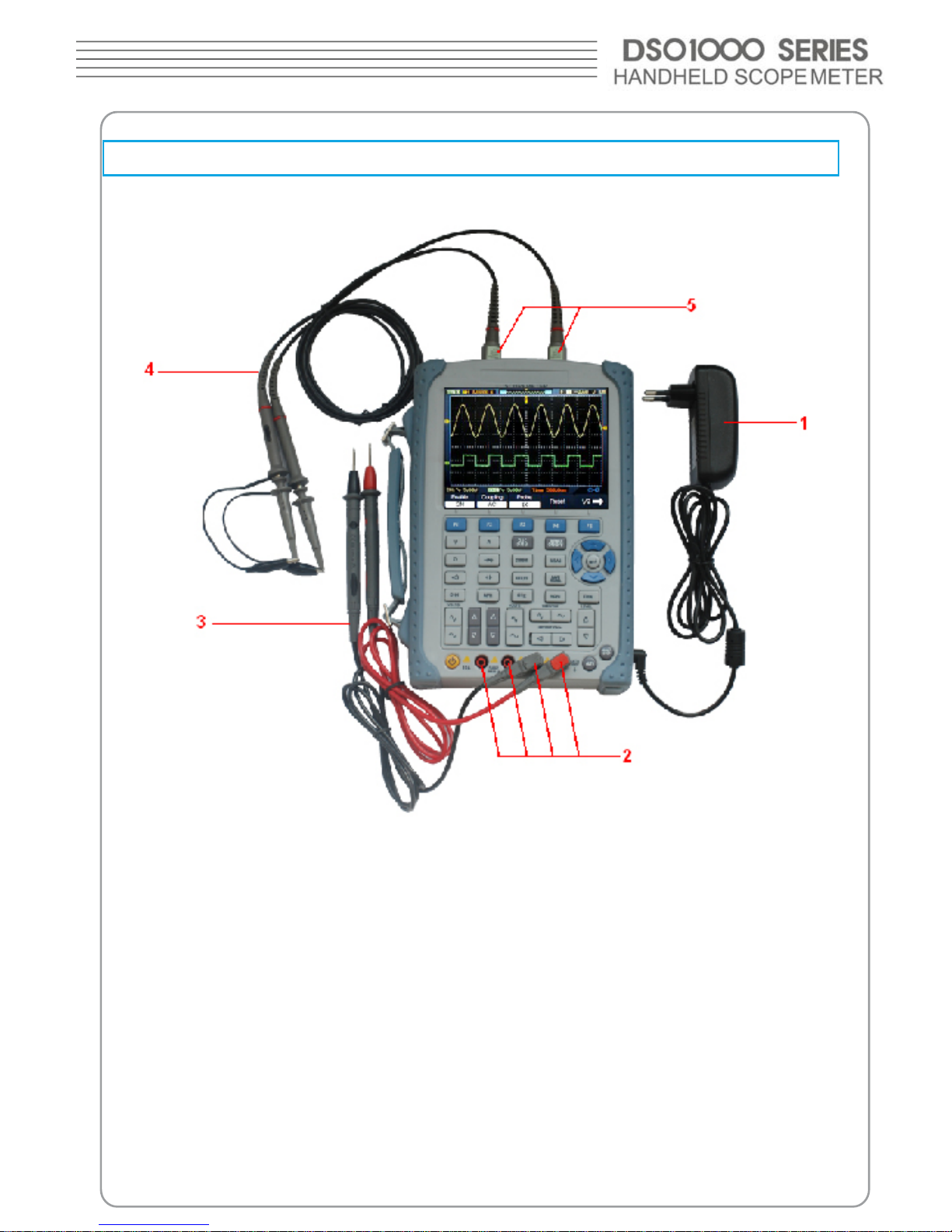

See the following Figure 1-4:

Figure 1-4

Input Connections

Description:

1. The power adapter is supplied for AC power supply and battery recharging.

2. Multi-meter input jacks, including four circular banana jacks .The four circular jacks

are used for voltage,resistance,mA range current and A range current inputs.

3. Multi-meter test lead.

4. Scope Meter probes.

5. Scope Meter input channels.

Page 14

2

Function Check

Perform this quick functional check to verify that your scope meter is operating correctly.

1. Turn on the instrument.

Use the power adapter designed for your scope meter only. Use a power source that

delivers 100 to 240 VACRMS, 50Hz. Turn on the scope meter.

2. Input a signal to a channel

Set the attenuation switch on the probe to 10X and connect the probe to Channel 1 on

the scope meter.

To do this:

■ Align the slot in the probe connector with the key on the CH 1 BNC connector.

■ Push to connect, and twist to the right to lock the probe in place.

■ Attach the probe tip and ground lead to the PROBE COMP connector.

Set the probe attenuation of the scope meter to 10X.To do this, push CH1→Probe→10X.

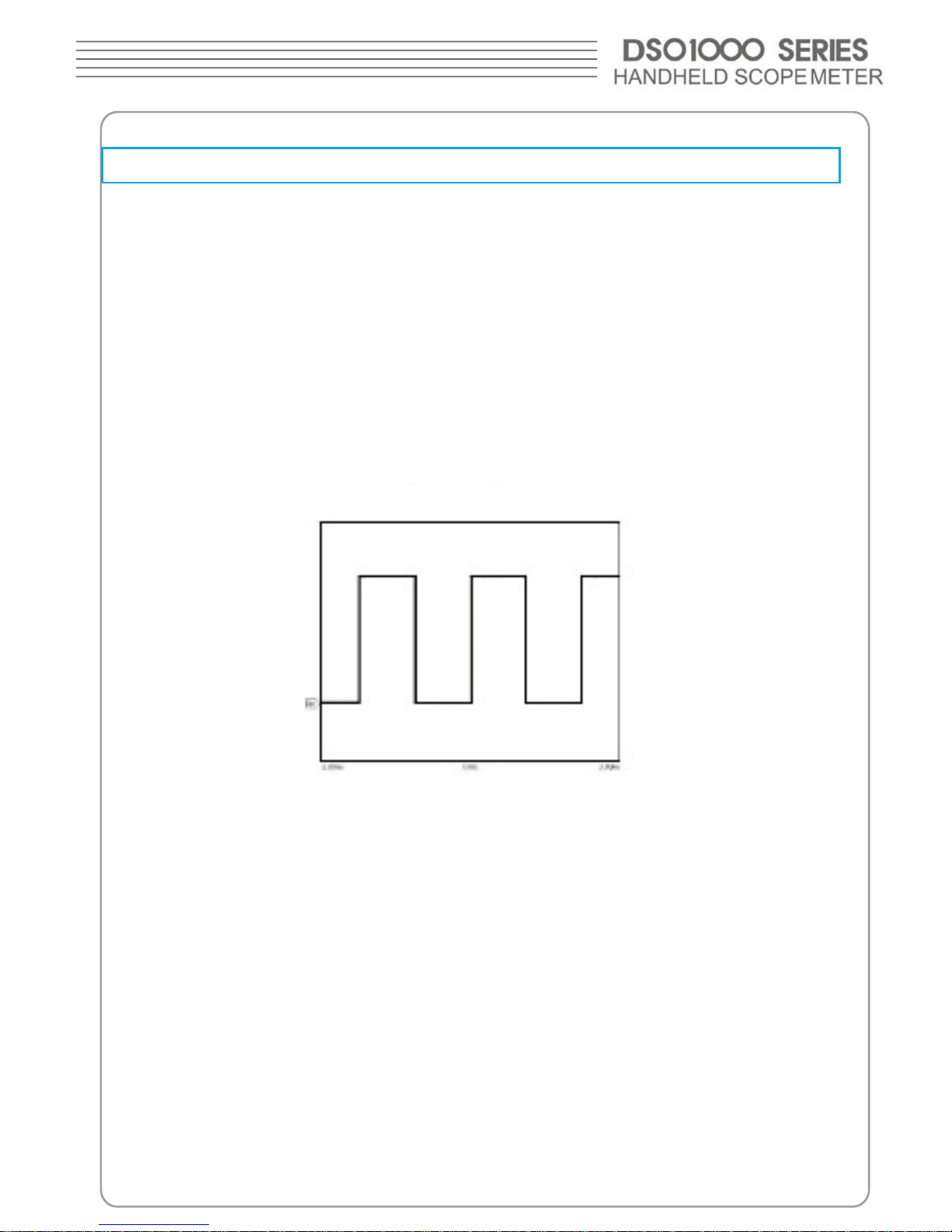

Figure 1-5

Set the probe

Push the AUTO button. Within a few seconds, a square wave will display

(approximately 1 kHz 2 V peak- to- peak).

Turn off Channel 1 and turn on Channel 2, repeat steps 2 and 3.

Page 15

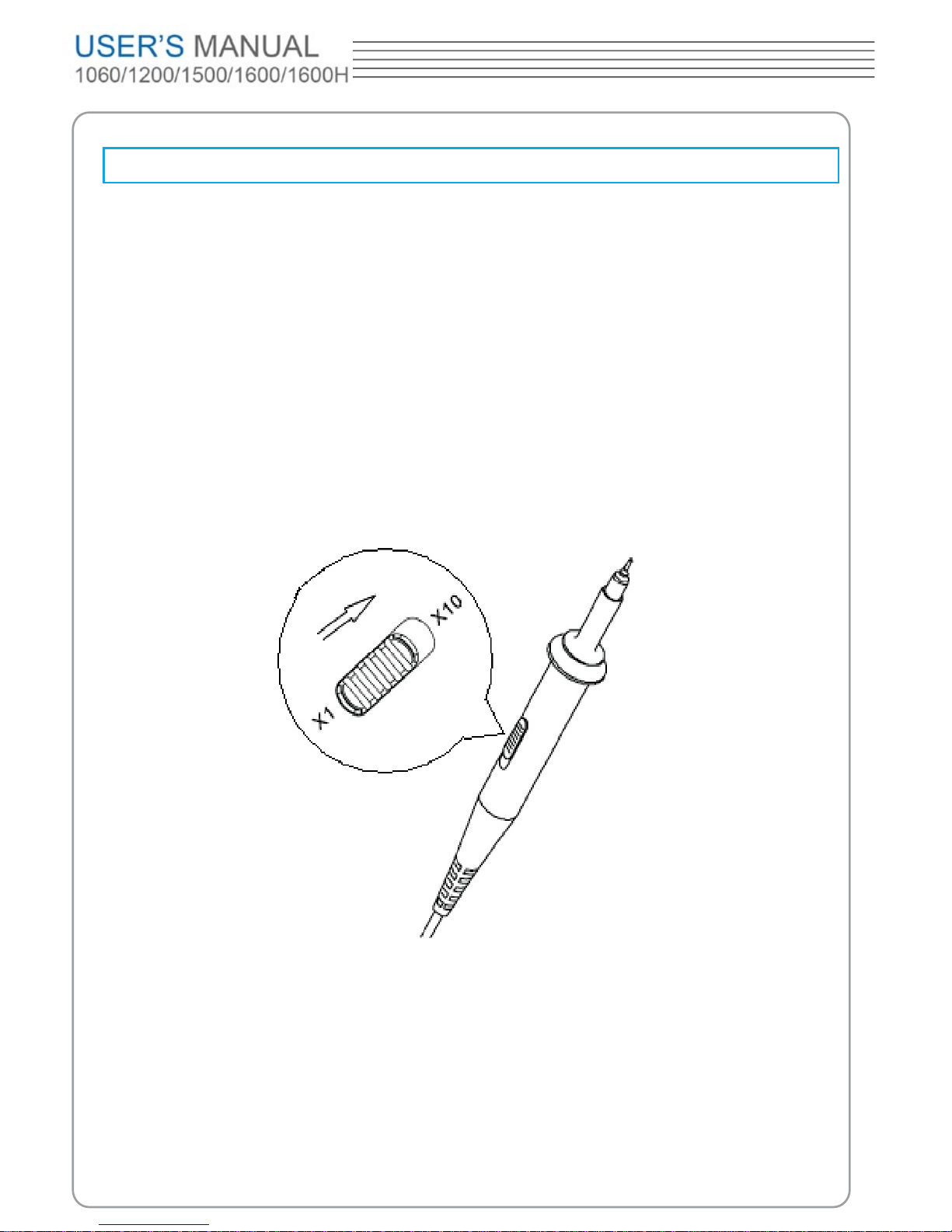

To compensate probes

Perform this adjustment to match the characteristics of the probe and the channel input.

This should be performed whenever attaching a probe to any input channel the rst time.

1. From CH1 menu, set the Probe attenuation to 10X (press CH1→Probe→10X).

Set the switch to 10X on the probe and connect it to CH1 of the scope meter.

When using the probe hook-tip, insert the tip onto the probe rmly to ensure proper

connection.

Attach the probe tip to the Probe compensator connector and the reference lead to the

ground pin, Select CH1, and then press AUTO.

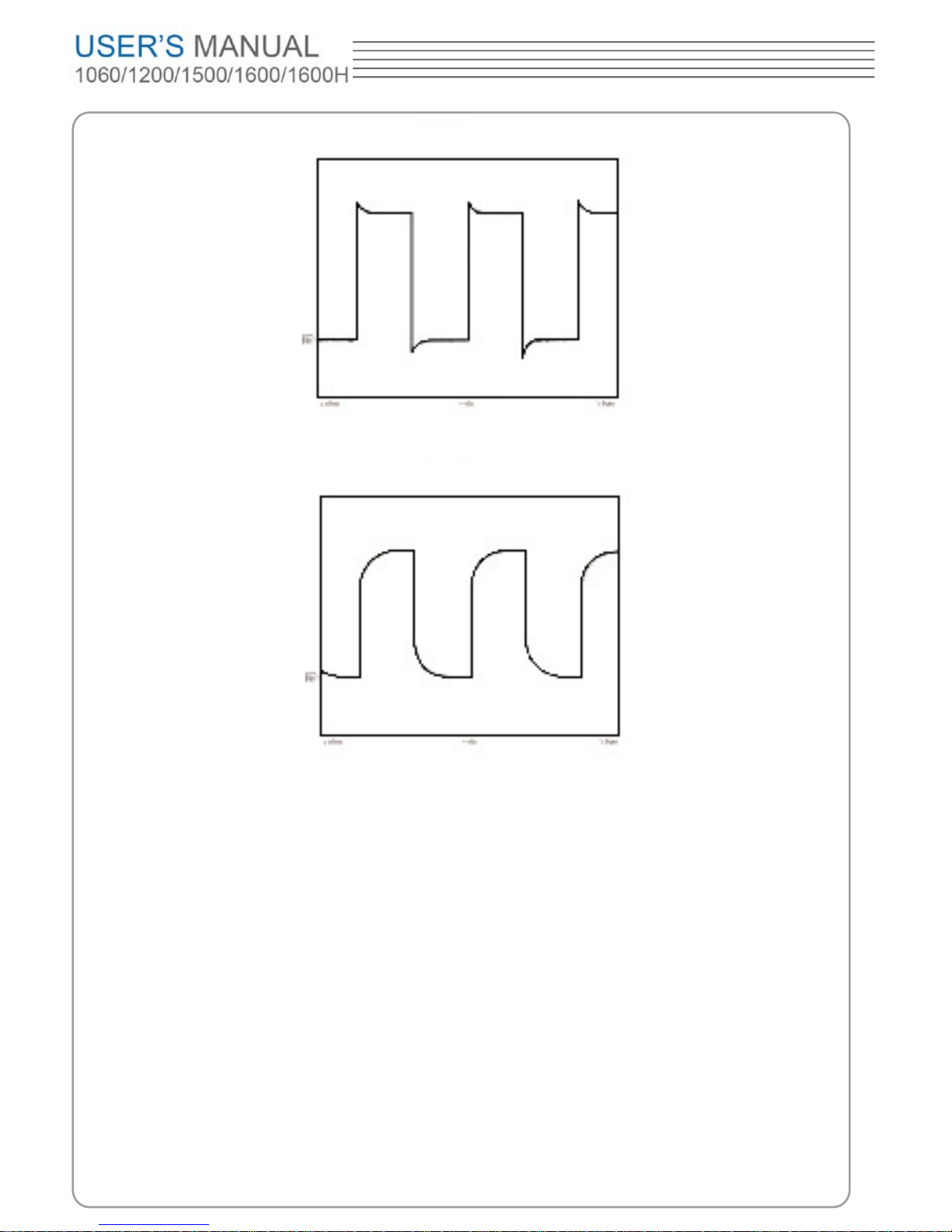

2. Check the shape of the displayed waveform.

Correctly Compensated

Page 16

Over compensated

Under Compensated

3. If necessary, use a non-metallic tool to adjust the trimmer capacitor of the probe for

the attest square wave being displayed on the scope meter.

4. Repeat if necessary.

WARNNING: To avoid electric shock while using the probe, be sure the perfection of

the insulated cable, and do not touch the metallic portions of the probe head while it is

connected with a voltage source.

Page 17

5

To display a signal automatically

The scope meter has an Auto feature that automatically sets up the scope meter to best

display the input signal. Using Auto requires signals with a frequency greater than or

equal to 50 Hz and a duty cycle greater than 1%.

Press the AUTO button, the scope meter turns on and scales all channels that have

signals applied, and it selects a time base range based on the trigger source. The trigger

source selected is the lowest numbered input that has a signal applied. The scope meter

has two-channels input . Connect a signal to the channel 1 input.

1.Connect a signal to the scope meter.

2.Press AUTO.

The scope meter may change the current setting to display the signal. It will

automatically adjust the vertical and horizontal scaling, the trigger coupling, type,

position, slope, level, and mode settings.

Using the Scope Meter

This part provides a step-by-step introduction to the scope functions. The introduction

does not cover all of the capabilities of the scope functions but gives basic examples to

show how to use the menus and perform basic operations.

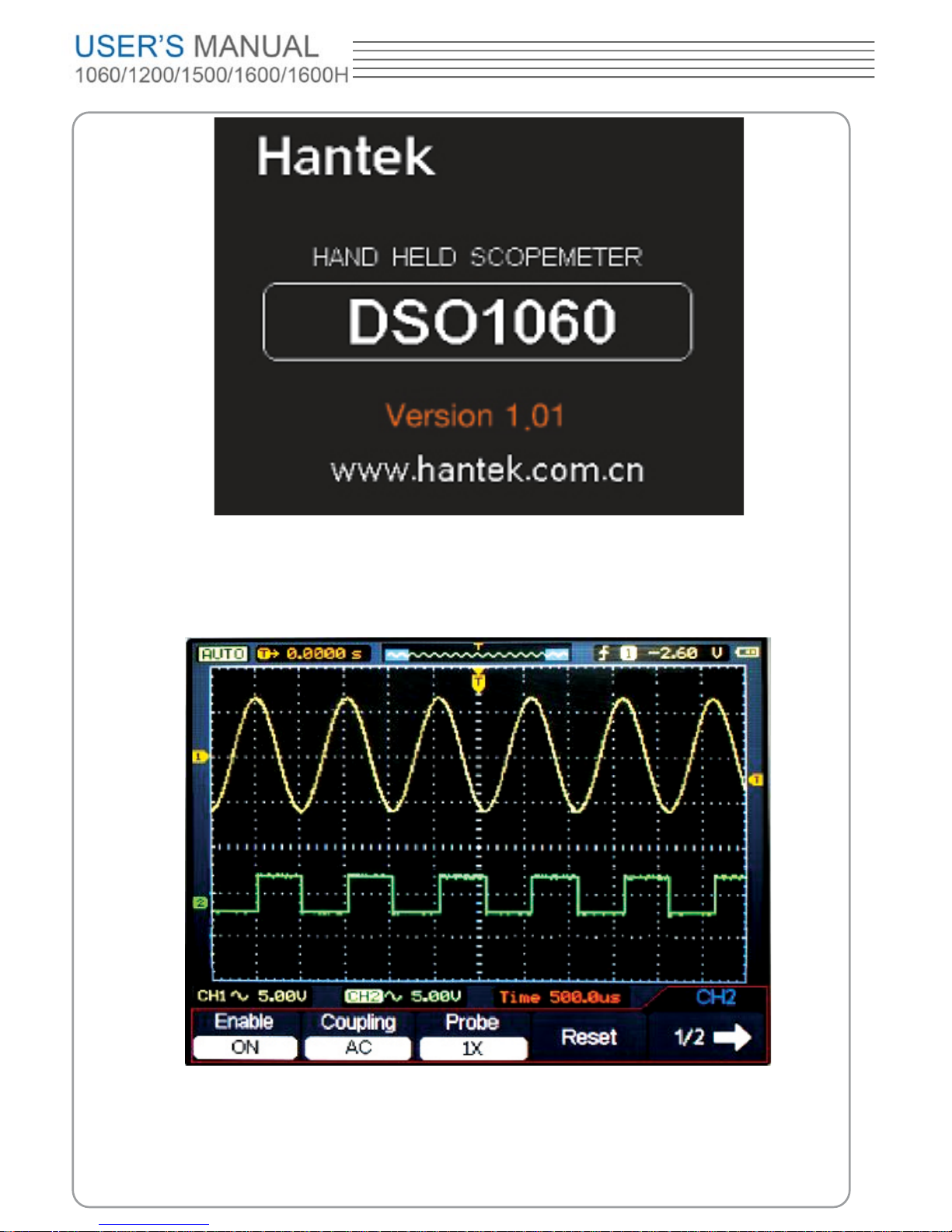

Turn on the scope meter

Connect scope meter to AC power via a power adapter. (The scope meter can still work

with built-in Li-ion battery even without AC power supply.)

Turn the scope meter on by pressing down the power on/off key.

The instrument then performs Self-checking after power on. The welcome picture will

display on the screen when the system nishes Self-checking.

The scope meter is powered up in its last setup conguration.

Page 18

6

Figure 1-6 The Login window

Menu Operation

The following example shows how to use the tools menus to select a function, as shown

in the following gure.

Figure 1-7 The Menu

Page 19

1. Press the MENU ON/OFF key to display the Function Menu on the bottom of the

screen and the corresponding optional settings on the bottom. Press MENU ON/OFF

again to hide the Function Menu.

2. Choose one key from F1 to F5 and press it to change function setting.

Set up the vertical system

1. Change the vertical setup and notice that each change affects the

status bar differently.

■ Change the vertical sensitivity with or button and notice the change in the

status bar.

2. Move the signal vertically.

■ The / button moves the signal vertically. Also notice that the channel symbol on

the left side of the display moves in conjunction with the button.

To set up the horizontal system

1. Change the time base.

■ The or button changes the time base in a 1-2-5 step sequence, and displays

thevalue in the status bar.

2. Move signal horizontally.

■ The or button moves displayed signal horizontally on waveform window. It sets

the trigger point position.

Set up the trigger system

1. Change the trigger Level

■ The or button changes the trigger level. The trigger level value is displayed

at the top-right of the screen and a line is displayed showing the location of the trigger

level.

2. Change the trigger setup and notice these changes in the status bar.

■ Press TRIG button in the key panel.

Choose one key from F1 to F5 and press it to change function setting.

Page 20

CHAPTER 2: Operating Scope

The end user should know how to determine the system setup from the status bar of a

Scope Meter. This chapter will detail the scope meter function of the test tool.

■ Set Vertical System

■ Set Horizontal System

■ Set Trigger System

■ Save and Recall waveforms and setups

■ Utility Function

■ Measure Signal

■ Cursor Measure

Set Vertical System

Each channel of Scope meter has its own independent operation menu and it will pop up

after pressing CH1 or CH2 button. The settings of all items in the menu are shown in the

table below.

To make vertical CH1 and CH2 settings, do the following:

1. Press the CH1 or CH2 button and then the function menu appears at the bottom of

the screen.

2. Select and press key from F1 to F5 keys to make different settings.

Now, you can nd the menu that looks like the following gure 2-1.

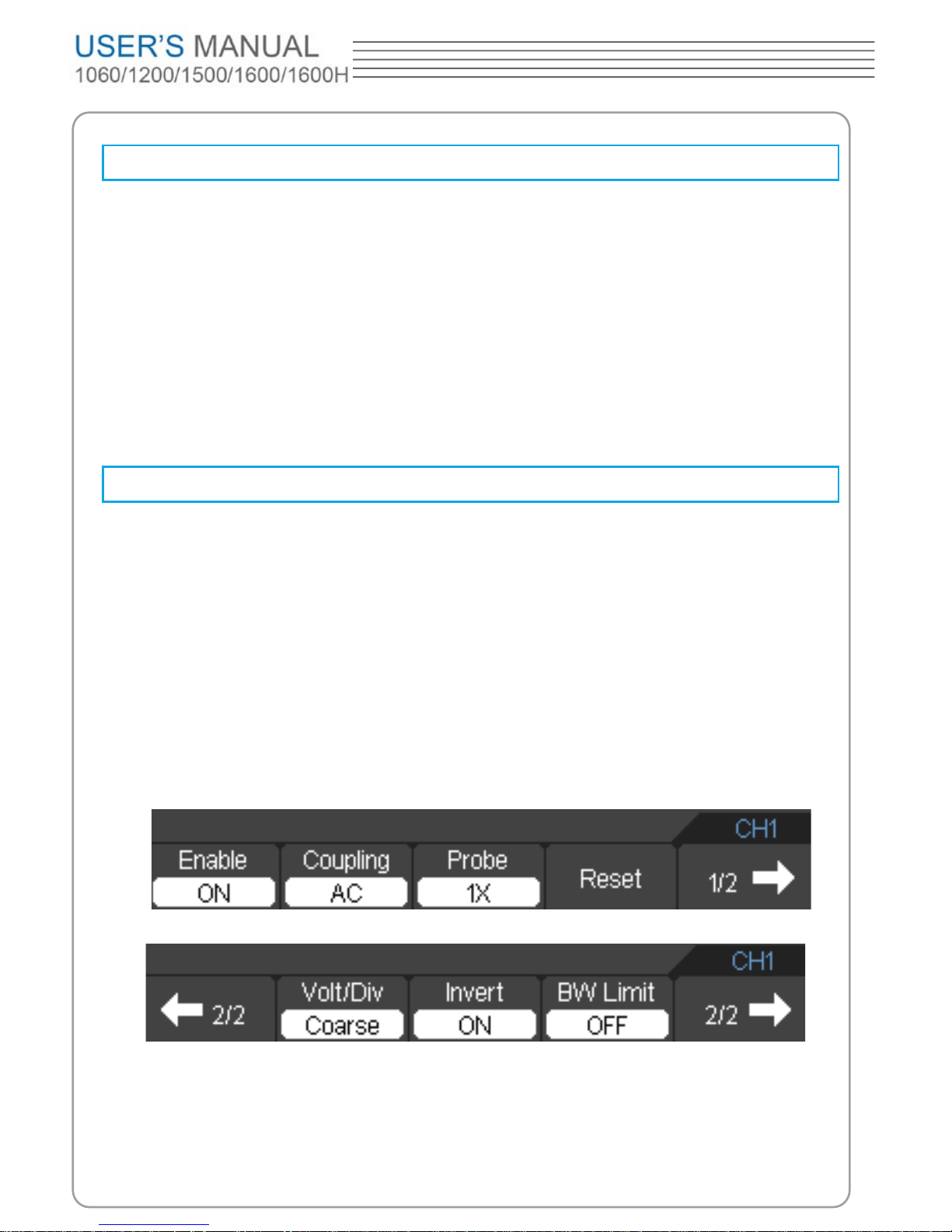

The CH1 menu (Page 1/2)

The CH1 menu (Page 2/2)

Figure 2-1

The CH1 Menu

The following table describes the channel menu:

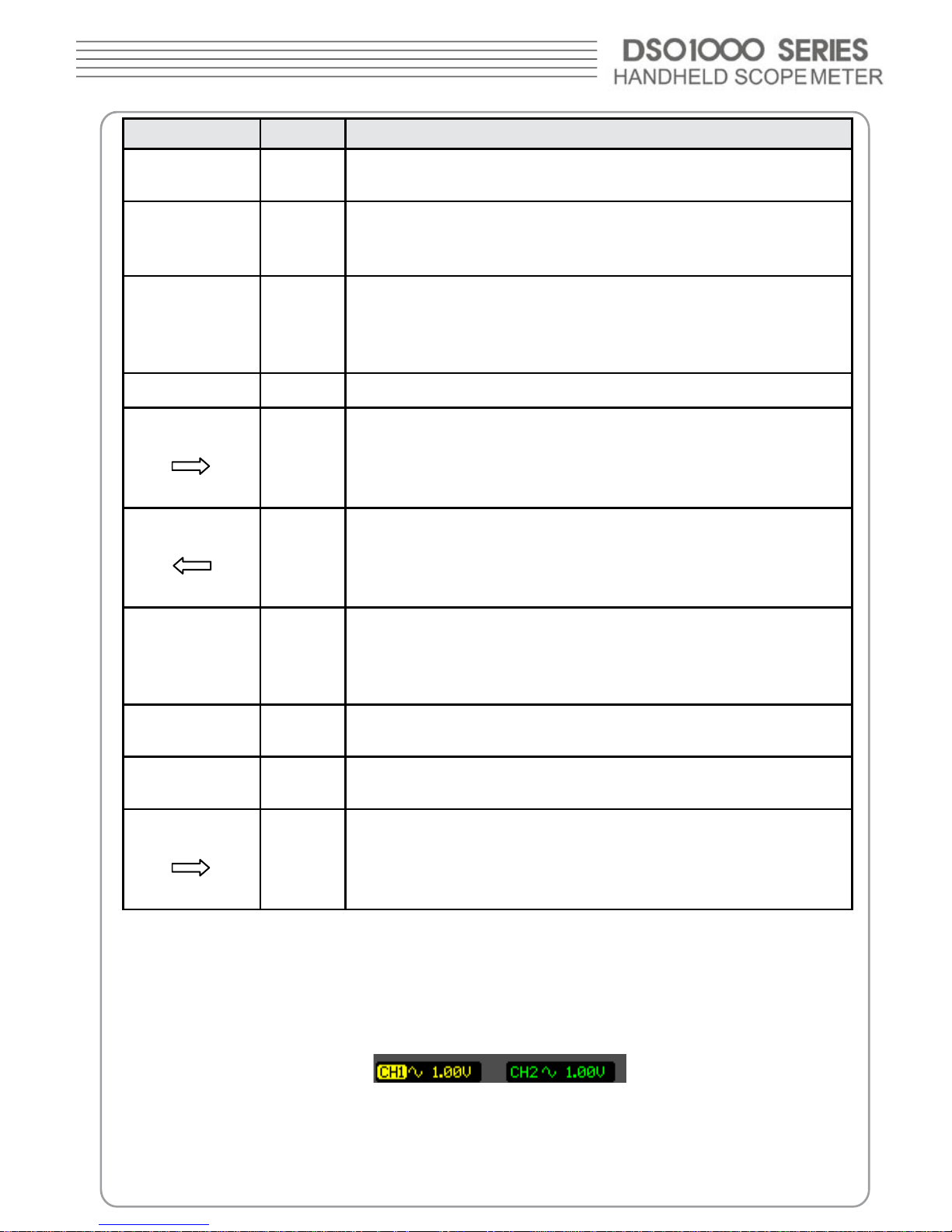

Page 21

Menu Setting Description

Enable

ON

OFF

Turn on Channel

Turn off Channel

Coupling

AC

DC

GND

The dc component in the input signal is blocked

The ac and dc components of the input signal are allowed

Disconnect the input signal

Probe

1X

10X

100X

1000X

Select one according to the probe attenuation factor to

ensure correct vertical scale reading

Reset

Set the vertical display position back to middle window

1/2

Go to the next menu page

2/2

Back to the previous menu page

Volt/Div

Coarse

Fine

Set Voltage range coarsely

Set Voltage range nely

Invert

ON

OFF

Turn on the invert function

Turn off the invert function

BW Limit

ON

OFF

Turn on the BW Limit

Turn off the BW Limit

2/2

Back to the previous menu page

1. Change Volt/DIV

It is the default setting of Volts/Div in a 1-2-5-step sequence from 10mV/div, 20mV/div,

50mV/div, to 1V/div,5 V/div or 10V/div.

The Volt/DIV will be displayed in the status bar on the bottom of the screen

Figure 2-2 Channel Volt/Div

Press CH1→Volt/Div→Coarse/Fine to Set Volt range.

Page 22

20

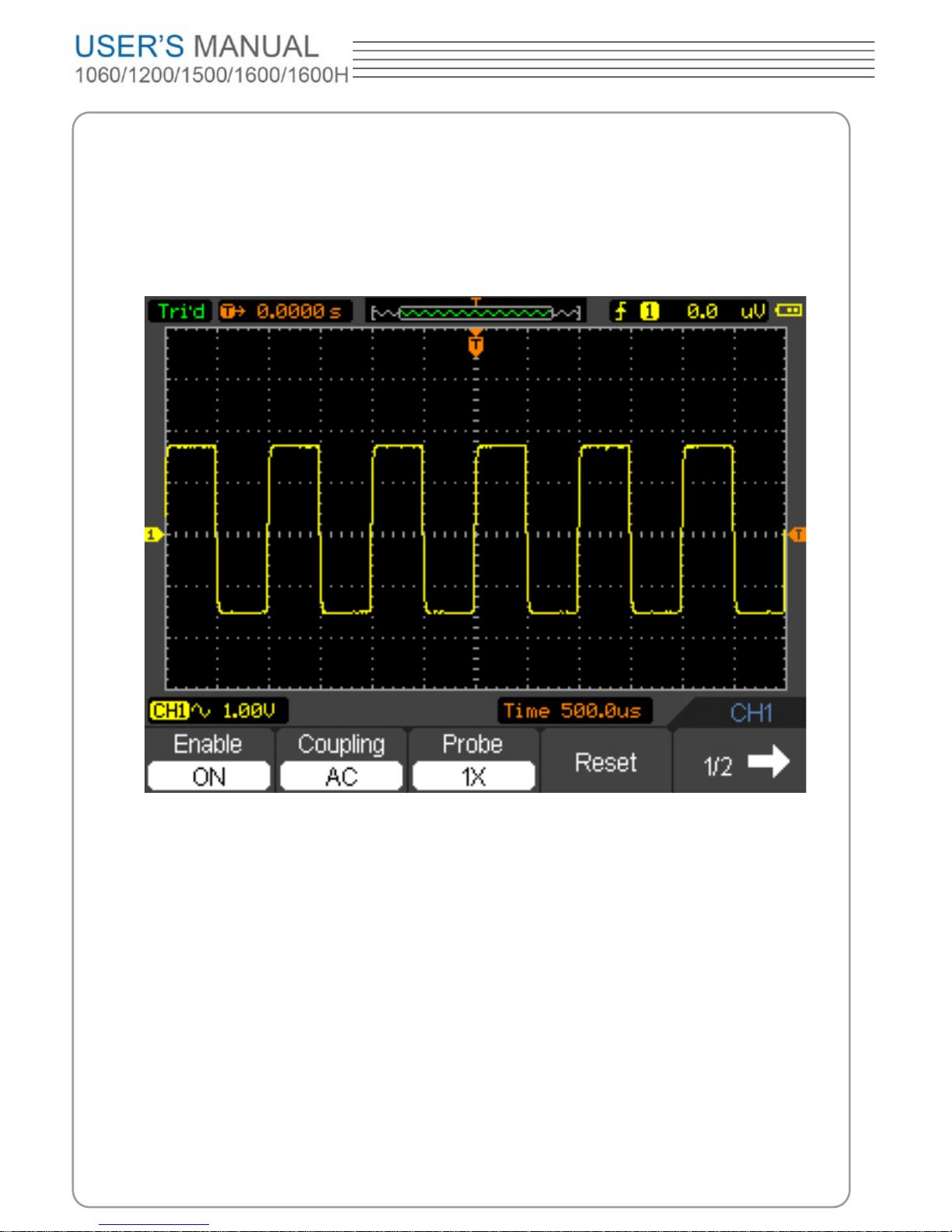

2. Set Channel Coupling

With CH1 taken for example, input a sine wave signal containing a dc offset.

Press CH1→Coupling→AC to set “AC” coupling. It will pass AC component but block the

DC component of the input signal.

The waveform is displayed as Figure 2-3

Figure 2-3 Waveform Display

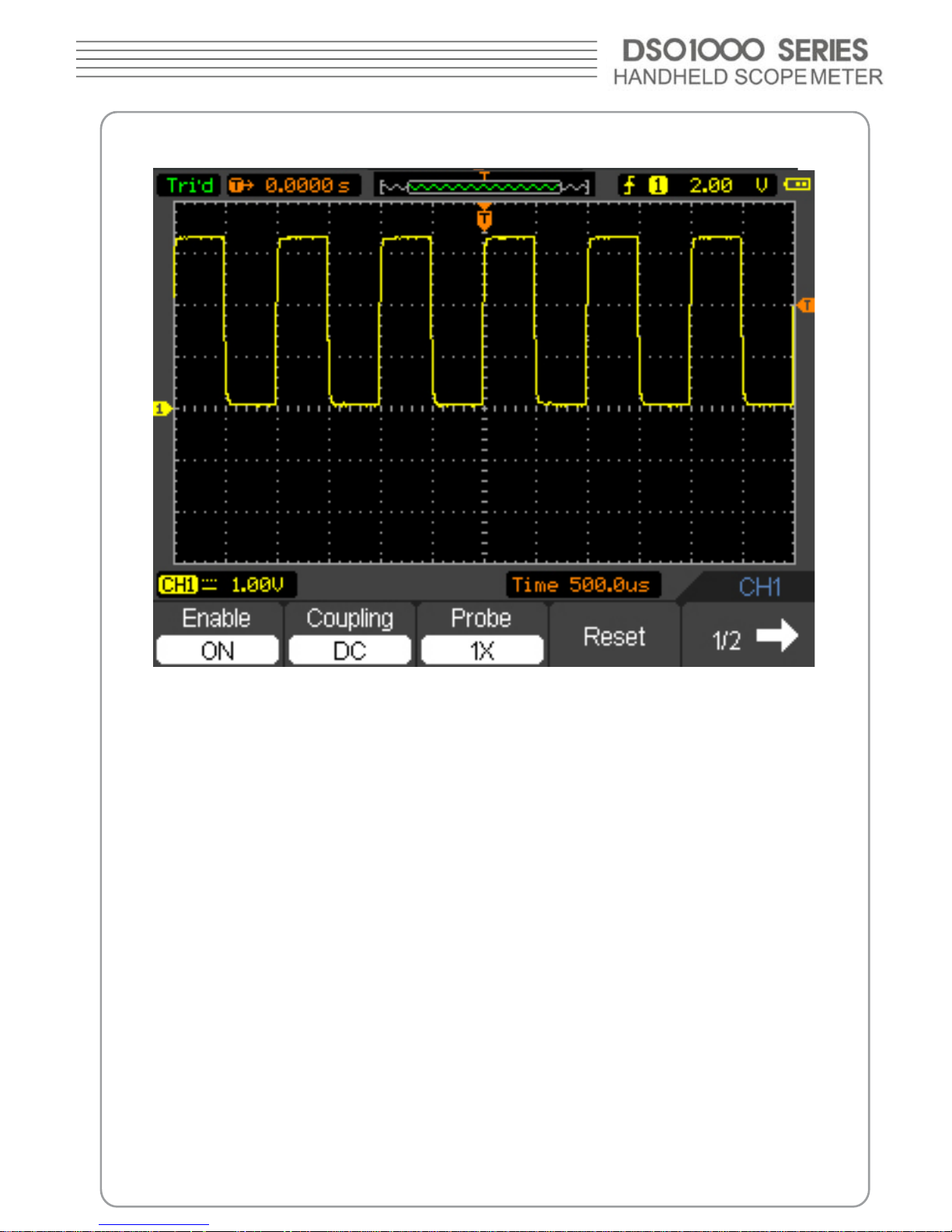

Press CH1→Coupling→DC, to set “DC” coupling. It will pass both AC and DC

components of the input signal.

The waveform is displayed as Figure 2-4:

Page 23

2

Figure 2-4 Waveform Display

Press CH1→Coupling→GND, to set “GND” coupling, it disconnects the input signal.

The screen displays as Figure 2-5:

Page 24

22

Figure 2-5 Waveform Display

3. Set Probe Attenuation

The scope meter allows adjusting the probe attenuation scale factor correspondingly

in the channel operation menu in order to comply with the probe attenuation scale.

The attenuation factor changes the vertical scaling of the scope meter so that the

measurement results reect the actual voltage levels at the probe tip.

To change (or check) the probe attenuation setting, press the CH1 or CH2 button

(according to which channel in using). Toggle the Probe soft button to match the

attenuation factor of the probe.

This setting remains in effect until changes again.

Figure 2-6 Probe Setting

4. Invert a waveform

The displayed waveform reverses 180 degrees relatively to the ground potential.

Press CH1 or CH2 → F5 → F3, to turn on/off the Invert

Page 25

2

Figure 2-7 Turn Invert off

Figure 2-8 Turn Invert on

5. Set Band-Width Limit

Page 26

2

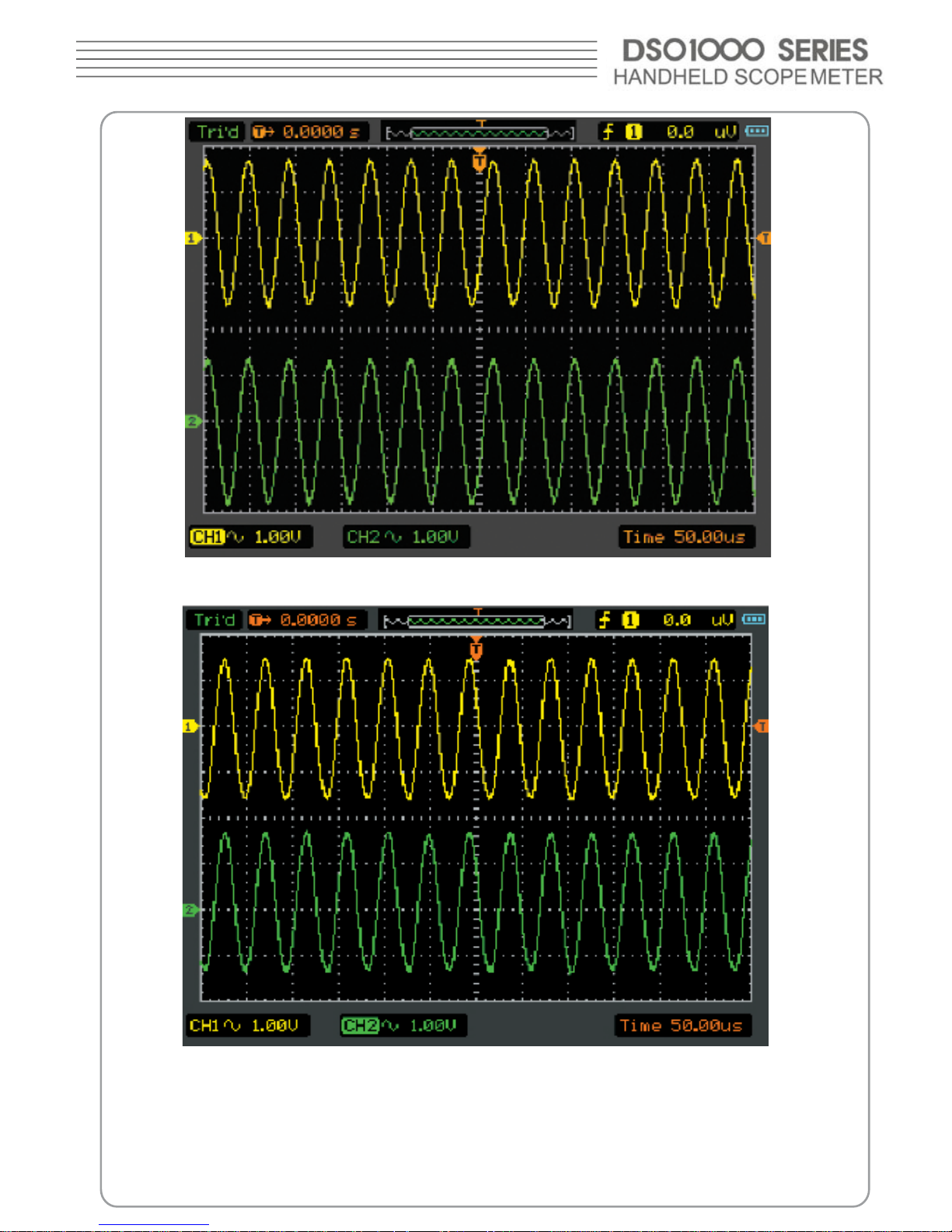

With CH1 taken for example, input a signal containing high frequency component.

Press CH1→F5→F4→OFF, to set up bandwidth limit to “OFF” status. The scope meter

is set to full bandwidth and passing the high frequency component in the signal.

The waveform is displayed as Figure 2-9:

Figure 2-9 Turn BW limit Off

Press CH1→F5→F4→ON, to set up bandwidth limit to “ON” status. It will reject the

frequency component higher than 20MHz.

The waveform is displayed as Figure 2-10:

Page 27

25

Figure 2-10 Turn BW limit On

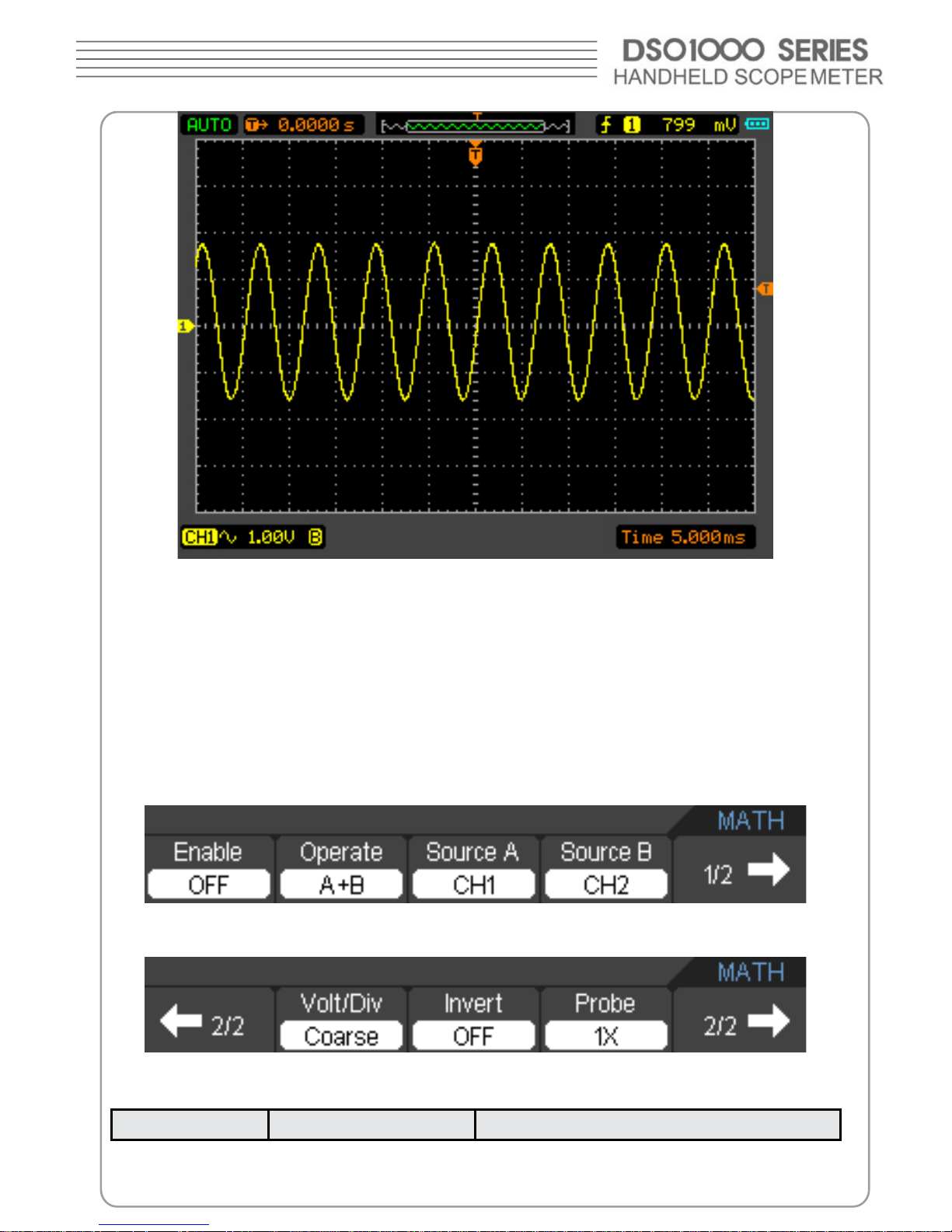

6. Math Setting

The mathematic functions include “add”, “subtract”, “multiply”, “division”, and “FFT” for

Channel 1 and Channel 2. The mathematic result can be measured by the grid and the

cursor.

The mathematic window is displayed as gure 2-11

The Math menu (Page 1/2)

Figure 2-11 The Math menu

The Math menu (Page 2/2)

Figure 2-12 The Math menu

The Math menu setting table

Menu Setting Description

Page 28

26

Enable

ON

OFF

Turn on math

Turn off math

Operate

A + B

A - B

A X B

A / B

FFT

Add source A and source B

Subtract source B from source A

Multiply source B by source A

Divide source A by source B

Fast Fourier Transform

Source A

CH1

CH2

Dene CH1 or CH2 as source A

Source B

CH1

CH2

Dene CH1 or CH2 as source A

1/2

Go to the next menu page

2/2

Back to the previous menu page

Volt/Div

Coarse

Fine

Set Voltage range coarsely

Set Voltage range nely

Invert

ON

OFF

Invert the MATH waveform

Waveform display normal

Probe

1x

10x

100x

1000x

Select one according the probe

attenuation factor to ensure a correct

vertical scale reading

2/2

Back to the previous menu page

Add, Subtraction, Multiplication,Division and FFT

In the Math function, use the addition, subtraction, multiplication,division and FFT to

operate and analyze the waveform.

The multiplication function window is displayed in gure 2-13

7. FFT

The FFT (Fast Fourier Transform) process converts a time-domain signal into its

frequency components mathematically.

FFT waveforms are useful in the following applications:

■ Measure harmonic content and distortion in systems

■ Characterize noise in DC power supplies

■ Analyze harmonics in power lines

Page 29

2

■ Analyze vibration

Figure 2-13 The multiplication

The FFT menu (Page 1/2)

The FFT menu (Page 2/2)

Figure 2-14 The FFT menu

The FFT menu table

Menu Setting Description

Enable

ON

OFF

Turn on FFT

Turn off FFT

Operate FFT Fast Fourier Transform

Page 30

2

Source

CH1

CH2

Dene CH1 or CH2 as FFT source

Window

Rectangle

Hanning

Hamming

Blackman

Select window for FFT

1/2

Go to the next menu page

2/2

Back to the previous menu page

Scale

Vrms

dBVrms

Set “Vrms” as vertical unit

Set “dBVrms” as vertical unit

Display

Full

Split

Display waveform in full screen

Display waveform in split screen

2/2

Back to the previous menu page

Note:

1. Signals that have a DC component or offset can cause incorrect FFT waveform

component magnitude values. To minimize the DC component, choose AC Coupling on

the source signal.

2. To reduce random noise and aliases components in repetitive or single-shot events,

set the oscilloscope acquisition mode to average.

3. To display FFT waveforms with a large dynamic range, use the “dBVrms” scale. The

“dBVrms” scale displays component magnitudes using a log scale.

FFT Window

The scope meter provides four FFT windows. Each window is a trade-off between

frequency resolution and amplitude accuracy. It depends on the desired measurement

and the source signals characteristics to determine the window to use.

Use the following guidelines to select the best window.

The FFT Window table

Window Features Best for measuring

Rectangle

Best frequency resolution and

worst magnitude resolution.This

is essentially the same as no

window.

Transients or bursts, the signal

levels before and after the

event are nearly equal.Equalamplitude sine waves with xed

frequencies. Broadband random

noise with a relatively slow

varying spectrum.

Page 31

2

Hanning

Hamming

Better frequency, poorer

magnitude accuracy than

Rectangular. Hamming has

slightly better frequency

resolution than Hanning.

Sine, periodic, and narrow-band

random noise. Transients or

bursts where the signal levels

before and after the events are

signicantly different.

Blackman

Best magnitude, worst frequency

resolution.

Single frequency waveforms, to

Find higher order harmonics.

8. REF

Reference Waveforms are saved waveforms to be selected for display. The reference

function will be available after saving the selected waveform to non-volatile memory.

Press M/R button to display the Reference waveform menu.

Select menu Enable->ON to enter reference function window. The reference function

window is displayed in gure 2-15.

Figure 2-15 The reference function window

Internal

Press M/R → REF → Internal and go to the following menu.

REF menu when using internal memory

Page 32

0

Figure 2-16 The Internal menu

REF menu table when using internal memory

Menu Setting Description

Enable

ON

OFF

Turn on REF

Turn off REF

Source

CH1

CH2

MATH

Select channel1 as REF channel

Select channel2 as REF channel

Select MATH as REF channel

Location

Internal

External

Select memory location in scope

Select memory location out scope

Save

Save REF waveform

Load

Go to import/export menu

REF menu table when using external memory

Menu Setting Description

Enable

ON

OFF

Turn on REF

Turn off REF

Source

CH1

CH2

Select channel1 as REF channel

Select channel2 as REF channel

Location

Internal

External

Select memory location in scope

Select memory location out scope

1/2

Go to the next menu page

External

Press M/R→REF→External and go to the following menu.

The External REF menu (Page 1/2)

Figure 2-17 The External menu

The External REF menu (Page 2/2)

Page 33

Figure 2-18 The External menu

The External menu table

Menu Setting Description

New File

To create ale

Delete File

To delete chosen le

Load

To load chosen le

Go to the Storage menu page

Display a Reference Waveform

Figure 2-19 Reference display

1. Press M/R button to show the reference waveform menu.

2. Press F2 to select the reference channel: CH1, CH2 or MATH.

3. Press F4 to save REF.

4. Press F5 to load an internal REF le.

5. Press F1 button to turn on REF.

Page 34

2

NOTE:

The Reference function is not available in X-Y mode.

Set Horizontal System

The horizontal system changes the horizontal scale and position of waveforms. The

horizontal center of the screen is the time reference for waveforms. Changing the

horizontal scale causes the waveform to expand or contract with respect to the screen

center.

Horizontal position changes the displayed waveform position, relative to the trigger point.

Press HORI button to show the horizontal system menu. The settings of this menu are

listed in the following table.

The Horizontal Menu

Figure 2-20 The Horizontal menu

The Horizontal Menu Table

Menu Setting Description

Time base

Y – T

X – Y

Roll

Show the relative relation between vertical

voltage and horizontal time.

Show CH1 value at X axis; CH2 value at Y axis.

In Roll Mode, the waveform display updates

from right to left.

Reset

Pressing this button clears trigger offset and

moves the trigger point to the horizontal center

of the screen.

ALT Mag

ON

OFF

Turn on ALT Mag

Turn on ALT Mag

Holdoff

ON

OFF

Turn on the Holdoff time

Turn off the Holdoff time

1. TIME/DIV

Use this button to select the horizontal time/div (scale factor) for the main.

Page 35

Figure 2-21 The TIME/DIV button

2. POSITION

Press this button to adjust the horizontal position of all channel waveforms. The

resolution of this control varies with the time base.

Figure 2-22 The POSITION button

Figure 2-23 The horizontal/Time base marks

Marks Indicator

1. The current waveform window’s position in the memory.

2. The trigger position in the memory.

3. The trigger’s horizontal offset according to the center of the window.

4. The horizontal time base (main time base).

5. The trigger position in the current waveform windows.

ALT Mag

The ALT Mag is a magnied portion of the waveform window. Use ALT Mag to locate

and horizontally expand part of the main waveform window for a more detailed (higher

Page 36

horizontal resolution) analysis of signal. The ALT Mag time base setting cannot be set

slower than the main time base setting.

Figure 2-24 ALT Mag Mode

Description:

1. Wave to be horizontally expanded.

2,3.The base of ALT Mag.

4.The main time base.

The following describes the ALT Mag display.

The screen is divides into two parts. The upper half displays the main waveform

window and the lower half displays an expanded portion of the main waveform window.

This expanded portion of the main window is called the ALT Mag window.Two blocks

shadow the upper half. The un-shadowed portion is expanded in the lower half. The

key control the size and position of the ALT Mag. The symbol at

the right bottom of the screen means the main time base and the symbol on the center

Page 37

5

bottom means the ALT Mag time.

X-Y Format

This format is useful for studying phase relationships between two signals. Channel 1 in

the horizontal axis (X) and channel 2 in the vertical axis (Y)

Figure 2-25 X-Y display format

The following modes or functions will not work in X-Y format.

■ Automatic Measurements

■ Cursor Measurements

■ REF and MATH Operations

■ Horizontal Position

■ Trigger Controls

Page 38

6

Set Trigger System

The trigger determines when the scope meter starts to acquire data and display a

waveform. When a trigger is set up properly, it can convert unstable displays or blank

screens into meaningful waveforms.

When the scope meter starts to acquire a waveform, it collects enough data so that it

can draw the waveform to the left of the trigger point. The scope meter continues to

acquire data while waiting for the trigger condition to occur. After it detects a trigger, the

scope meter continues to acquire enough data so that it can draw the waveform to the

right of the trigger point.

Trigger Modes

The scope meter provides seven trigger modes: Edge, Pulse and Alternative.

Edge: An edge trigger occurs when the trigger input passes through a specied

voltage level in the specied slope direction.

Pulse: Use this trigger type to catch pulses with certain pulse width.

Alternative: Trigger on non-synchronized signals.

Edge Trigger Setting

An edge trigger determines whether the oscilloscope nds the trigger point on the rising

or the falling edge of a signal. Select Edge trigger Mode to trigger on rising edge, falling

edge or rising & falling edge.

Press TRIG → F1 → Edge button to show the edge trigger menu as the following

table.

The Edge trigger menu

Figure 2-26 The Edge trigger menu

The Edge Trigger Table

Menu Setting Description

Source

CH1

CH2

Dene CH1 or CH2 as trigger signal

Slope

Rising

Falling

Trigger on rising edge or falling edge

Page 39

Sweep

Auto

Normal

Single

Acquire waveform even no trigger occurred

Acquire waveform when trigger occurred

When trigger occurs, acquire one waveform then stop

HF

Reject

ON

OFF

Reject high frequency signals

Pulse Trigger Setting

Pulse trigger occurs according to the width of pulse. The abnormal signals can be

detected through setting up the pulse width condition.

Press TRIG → F1 → Pulse button to show the pulse trigger menu as the following table.

The Pulse Trigger Menu (Page 1/2)

Figure 2-27 The Pulse Trigger Menu

The Pulse Trigger Menu (Page 2/2)

Figure 2-28 The Pulse Menu

The Pulse Trigger Table (Page 1/2)

Menu Setting Description

Source

CH1

CH2

Dene CH1 or CH2 as trigger signal

When

+more

+Less

+Equal

-more

-Less

-Equal

+Pulse width more than

+Pulse width less than

+Pulse width equal to

-Pulse width more than

-Pulse width less than

-Pulse width equal toTo select pulse condition.

Setting Value Set required pulse width.

1/2

Go to the next menu page

Page 40

The Pulse Trigger Table (Page 2/2)

Menu Setting Description

2/2

Back to the previous menu page

Sweep

Auto

Normal

Single

Acquire waveform even no trigger occurred.

Acquire waveform when trigger occurred.

When trigger occurs, acquire one waveform and then stop.

HF

Reject

ON

OFF

Reject high frequency signals.

50%

Set the trigger level to the center of the signal.

2/2

Back to the previous menu page

Note: The Pulse width adjust range is10ns ~ 10s. When the condition is met, it will

trigger and acquire the waveform.

ALT (Alternative) Trigger Setting

When alternative trigger is on, the trigger sources come from two vertical channels. This

mode can be used to observe two non-related signals. You can choose two different

trigger modes for the two vertical channels. The options are as follows: Edge, Pulse,

Slope and video. The info of the trigger level of the two channels will be displayed on the

upper-right of the screen.

See the ALT screen in gure 2-29.

Press TRIG → F1 → ALT button to show the ALT trigger menu as the following table.

The ALT Trigger menu (Type Edge)(Page 1/2)

Figure 2-30 The ALT trigger menu

The Alternative menu table (Type Edge)( Page 1/2)

Menu Setting Description

Channel

CH1

CH2

Set trigger for CH1.

Set trigger for CH2.

Type

Edge

Pulse

Set Edge/Pulse Trigger as the trigger

type.

Slope

Rising

Falling

Trigger on rising edge.

Trigger on falling edge.

Page 41

1/2

Go to the next menu page

The ALT Trigger menu (Type edge)(Page 2/2)

Figure 2-29 ALT Mode Screen

Description:

1. The Slope type of CH1 Trigger.

2. The horizontal trigger position of CH1 Trigger.

3. The trigger level value of CH1.

4. The trigger position of CH2.

5. The trigger level value of CH2.

6. The time base value of CH1.

7. The trigger level of CH1.

8. The trigger level value of CH1.

9. The horizontal trigger position of CH2.

10. The time base value of CH2.

11. The trigger level of CH2.

12. The trigger position value of CH2.

Page 42

0

13. The volt value of CH1.

14. The volt value of CH2.

The ALT Trigger menu (Type edge)(Page 2/2)

Figure 2-31 The ALT Trigger menu

The Alternative menu table (Type edge)(Page 2/2)

Menu Setting Description

2/2

Back to the previous menu page

HF Reject

ON

OFF

Reject high frequency signals or not

50% Set the trigger level to the center of the signal.

2/2

Back to the previous menu page.

The ALT Trigger menu (Type Pulse)(Page 1/2)

Figure 2-32 The ALT Tirgger menu

The Alternative menu table (Trigger Type: Pulse Page 1/2)

Menu Setting Description

Channel

CH1

CH2

Set trigger mode for Channel 1.

Set trigger mode for Channel 2.

Type EdgePulse Set Edge/Pulse Trigger as the trigger type.

When

+more

+Less

+Equal

-more

-Less

-Equal

+Pulse width more than

+Pulse width less than

+Pulse width equal to

-Pulse width more than

-Pulse width less than

-Pulse width equal toTo select pulse condition.

Page 43

1/2

Go to the next menu page

The ALT Trigger menu (Type Pulse)(Page 2/2)

Figure 2-33 The ALT Trigger menu

The Alternative menu table (Trigger Type: Pulse Page 2/2)

Menu Setting Description

2/2

Back to the previou menu page

Setting Value Set the width of the pulse.

HF Reject ON

OFF

Reject high frequency signals or not

50% Set the trigger level to the center of the signal

2/2

Back to the previous menu page

Term interpretation

■ Auto:

This sweep mode allows the scope meter to acquire waveforms even when it does

not detect a trigger condition. If no trigger condition occurs while the scope meter is

waiting for a specic period (as determined by the time-base setting), it will force itself

to trigger.

When forcing invalid triggers, the scope meter cannot synchronize the waveform,

and the waveform seems to roll across the display. If valid triggers occur, the display

becomes stable on the screen. Any factor results in the un-stability of waveforms can

be detected by Auto Trigger, such as the output of Power supply.

NOTE: When horizontal control is set more than 50 ms/div, Auto mode allows the

oscilloscope to capture without trigger signal.

■ Normal:

The Normal mode allows the scope meter to acquire a waveform only when it is

triggered. If no trigger occurs, the scope meter keeps waiting, and the previous

waveform, if any, will remain on the display.

■ Single:

Page 44

2

In Single mode, after pressing the RUN/STOP key, the scope meter waits for trigger.

While the trigger occurs, the scope meter acquires one waveform then stop.

Save / Recall Waveforms and Setups

Press the Save/Recall button, the interface menu for settings shows as follows.

The Save/Recall Menu Table

Menu Setting Description

Type

Wave

Setup

Bitmap

CSV

Factory

Store or recall waveform.

Store or recall instrument setups.

Create or delete bit map les.

Create or delete CSV les.

Recall factory setups.

Internal Go to menu for internal memory operation

External Go to menu for external memory operation

Wave

The Wave menu

Figure 2-34 The Wave menu

The Wave menu table

Menu Setting Description

Internal Go to menu for internal memoryoperation

External Go to menu for external memoryoperation

Setup

The Setup menu

Figure 2-35 The Setup menu

The Setup menu table

Menu Setting Description

Page 45

Internal Go to menu for internal memoryoperation

External Go to menu for external memoryoperation

Bitmap

The Bitmap menu

Figure 2-36 The Bitmap menu

The Bitmap menu table

Menu Setting Description

External Go to menu for external memoryoperation

CSV

The CSV menu

Figure 2-37 The CSV menu

The CSV menu table

Menu Setting Description

External Go to menu for external memoryoperation

Factory

The Factory menu

Figure 2-38 The Factory menu

The Factory menu table

Page 46

Menu Setting Description

Load Recall factory setups or les.

Internal Memory

Press SAVE/RECALL →Internal to go to the following menu.

Menu Setting Description

Internal

IN_01 (N)

.

IN_15 (N)

Set up the location of les in internal memory.

Load

Recall waveform les and setup les from the

internal memory location.

Save

Save waveform les and setup les to the

internal memory location.

External Memory

Press SAVE/RECALL → External to go to the following menu.

Menu Setting Description

New File

To create new le

Delete File

Delete le

Load

Recall waveform and setup from USB storage

device.

File system as following:

Page 47

5

Figure 2-39 File System

Factory

The scope meter has default settings and can be recalled at anytime by

Memory location

Specify the memory location to save/recall the waveforms and setups.

Load

Recall saved waveforms, setups and default settings.

Save

Save waveforms and setups.

NOTE:

1. Select save stores not only the waveforms, but also the current scope meter.

2. The oscilloscope can store 15 settings permanently and can restore at anytime.

Page 48

6

Utility Function

Press the Utility button to show the menu of the settings in the Utility system.

The Utility menu (Page 1/4)

Figure 2-40 The Utility menu

The Utility menu (Page 2/4)

Figure 2-41 The Utility menu

The Utility menu (Page 3/4)

Figure 2-42 The Utility menu

The Utility menu (Page4/4)

Figure 2-43 The Utility menu

The Utility menu table (Page 1/4)

Menu Setting Description

Sound

ON

OFF

Turn beeper sound on/off

F/C

ON

OFF

Turn on Frequency Counter

Turn off Frequency Counter

Display Show Display menu page

DMM

ON

OFF

Turn on the multimeter

Turn off the multimeter

Page 49

1/4

Go to the next menu page

The Utility menu table (Page 2/4)

Menu Setting Description

2/4

Back to the previous menu page

Pass/Fail Go to Pass/Fail menu page

Record Go to Record menu page

Acquire Go to the Acquire menu page

2/4

Go to the next menu page

The Utility menu table (Page 3/4)

Menu Setting Description

3/4

Back to the previous menu page

Shut

Down

Innite

5MIN

30MIN

Set the shut down time

Language

Select languages.

(More languages may be added in later rmware

versions.)

Calibrate

Calibrate the scope meter

3/4

Go to the next menu page

The Utility menu table (Page 4/4)

Menu Setting Description

4/4

Back to the previous menu page

Congure

No Save

Save

Not save the system conguration

Save the system conguration

Update

Update the system

System Info

Show the information of the system

Page 50

4/4

Go to the rst previou menu page

Calibrate

The calibration adjusts the internal circuitry to get the best accuracy. Use these functions

to calibrate the vertical and horizontal systems.

For maximum accuracy at any time, run this calibration if the ambient temperature

changes by 5°C or more.

Before running this procedure, do these steps:

1. Disconnect any probes or cables from all channel inputs, otherwise failure or damage

to the scope meter may be occurred.

2. Push the Utility button and select Calibrate.

The calibration screen is shown as in Figure 2-44.

Figure 2-44 The Calibration Screen

NOTE:

The scope meter must have been working or warm-up at least 30-minutes before

running calibration to get best accuracy.

The scope meter will calibrate parameter of vertical system (CH1, CH2).

Page 51

Pass/Fail

The Pass/Fail function monitors changes of signals and output pass or fail signals by

comparing the input signal is within the pre-dened mask.

Press Utility→Pass/Fail to go to the following menu.

The Pass/Fail menu (Page 1/2)

Figure 2-45 The Pass/Fail menu

The Pass/Fail menu (Page 2/2)

Figure 2-46 The Pass/Fail menu

The Pass/Fail menu table (Page 1/2)

Menu Setting Description

Enable ON

OFF

Turn on Pass/Fail test

Turn off Pass/Fail test

Source CH1

CH2

Select Pass/Fail test on CH1

Select Pass/Fail test on CH2

Output Fail

Pass

Fail+Beep

Pass +Beep

Output when Fail condition detected

Output when Pass condition detected

Output and Beep when Fail condition detected

Output and Beep when Pass condition detected

Operate Stop

Start

Pass/Fail test stopped, press to run

Pass/Fail test running, press to stop

1/2

Go to the next menu page

The Pass/Fail menu table (Page 2/2)

Menu Setting Description

2/2

Back to the previous menu page

Page 52

50

Stop

output

ON

OFF

Stop test when output occur.

Continue test when output occur.

Mask Go to Mask menu

2/2

Back to the previous menu page

Mask setting

Press Utility→Pass/Fail→Mask Setting to go to the following menu.

The Mask menu (Page 1/2)

Figure 2-47 The Mask menu

The Mask menu (Page 2/2)

Figure 2-48 The Mask menu

The Mask setting menu table (Page 1/2)

Menu Setting Description

Vertical

Set vertical clearance to the waveform(0.04div-4.00div)

Horizontal

Set horizontal clearance to the waveform (0.04div-4.00div)

Create

Create a test mask according to the above clearance

Location

Internal

External

Store created test mask into internal/External memory

1/2

Go to the next menu page

The Mask setting menu table (Page 2/2) When the save as internal memory

Menu Setting Description

2/2

Back to the previous menu page

Save

Store created test mask into internal memory.

Page 53

5

Load

Recall mask setting le from internal memory.

Back to the previous menu page

The Mask setting menu (Page 2/2) When the save as external memory

Menu Setting Description

Save Go to save menu (same as REF save menu).

Load Recall mask setting le from external memory.

Waveform Recorder

Waveform recorder records input waveforms from CH1 and CH2, with a maximum

record length of 1000 frames.

Press Utility→Record Setting to go to the following

Waveform recorder: Record the waveforms with specied interval.

The Recorder menu (Page 1/2)

Figure 2-49 The Recorder menu

The Recorder menu (Page 2/2)

Figure 2-50 The Recorder menu

The Record menu table (Page 1/2)

Menu Setting Description

Mode

Record

Play back

Storage

OFF

Select record mode.

Select play back mode.

Select storage mode.

Turn off all recorder function.

Source

CH1

CH2

Select record source channel.

End Frame <1-1000> Set number of record frames.

Page 54

52

Operate

Start

Stop

Record stopped, press to Start recording

Press to stop recording

1/2

Go to the next menu page

The Record menu table (Page 2/2)

Menu Setting Description

2/2

Back to the previous menu page

Interval <1.00ms-1000s> Set time interval between record frames

Back to the Utility menu page

Play back: Play back the recorded waveforms.

The Play back menu (Page 1/2)

Figure 2-51 The Play back menu

The Play back menu (Page 2/2)

Figure 2-52 The Play back menu

The Record menu table (Page 1/2)

Menu Setting Description

Operate Start

Stop

Play stopped, press to Start playback

Press to stop playing

Repeat ON

OFF

Set repeat play mode or not

Interval <1.00ms-20s> Set interval time to play back

1/2

Go to the next menu page

The Record menu table (Page 2/2)

Page 55

5

Menu Setting Description

2/2

Back to the previous menu page

Start Frame <1-1000> Set start frame

Cur Frame <1-1000> Select current frame to be played

End Frame <1-1000> Set End frame

2/2

Back to the previous menu page

Storage: Store recorded waveforms to non-volatile memory according to the setup

frames.

The storage menu (Page 1/2)

Figure 2-53 The Storage menu

The storage menu (Page 2/2)

Figure 2-54 The Storage menu

The storage menu (Page 1/2)

Menu Setting Description

Start

Frame

<1-1000> Set rst frame to be saved

End Frame <1-1000> Set end frame to be saved

Location

Internal

External

Set up Store location

1/2

Go to the next menu page

The Storage menu when the save to Internal memory (Page 2/2)

Menu Setting Description

Save Save recorded waveform to internal memory location.

Load Recall recorded waveform from internal memory location.

Page 56

5

Back to the Utility menu page

The Storage menu when the save as external memory (Page 2/2)

Menu Setting Description

Create File Create a new le

Delete File Delete a selected le

Load Recall recorded waveform from external memory location

Language:

DSO1000 series scope meters have multi-language user menu, choose as your desire.

Press Utility→Language to select the language.

Page 57

55

Signal Measurement

Press the MEAS button to display the menu of the automatic measurements settings.

The measure menu (Page 1/5)

Figure 2-55 The Measure menu

The measure menu (Page 2/5)

Figure 2-56 The Measure menu

The measure menu (Page 3/5)

Figure 2-57 The Measure menu

The measure menu (Page 4/5)

Figure 2-58 The Measure menu

The measure menu (Page 5/5)

Figure 2-59 The Measue menu

The scope meter provides 22 auto measurements: Vpp, Vmax, Vmin, Vtop,

Vmid,Vbase,Vamp, Vavg, Vrms,Vcrms, Overshoot, Preshoot, Freq, Period, Rise Time,

Fall Time, +Width, -Width, +Duty, -Duty , (12 voltage

and 10 timing measurements).

Page 58

56

The Measure menu table

Menu Setting Description

Source

CH1

CH2

Select CH1 or CH2 as source

channel for measurement.

Type

Voltage

Time

Select to measure voltage

parameter.

Meas All

ON

OFF

Turn on all measurement result.

Turn off all measurement result.

Clear

Clear measurement result on screen.

1/2

Go to the next menu page

The Voltage Measurement menu table

Menu

Description

Pk to Pk

Peak-to-peak = Max - Min

Measured over the entire waveform

Maximum

Voltage of the absolute maximum level

Measured over the entire waveform

Minimum

Voltage of the absolute minimum level

Measured over the entire waveform

Top

Voltage of the statistical maximum level

Measured over the entire waveform

Base

Voltage of the statistical minimum level

Measured over the entire waveform

Amplitude

Amp = Base - Top

Measured over the entire waveform

RMS

The Root Mean Square voltage over the entire waveform

Preshoot

Positive Overshoot = (Max - Top)/Amp x 100 %

Measured over the entire waveform

Overshoot

Negative Overshoot = (Base - Min)/Amp x 100 %

-Measured over the entire waveform

Middle

Voltage of the 50% level from base to top

Average

Average voltage of a waveform

CRMS

The Root Mean Square voltage over the rst cycle in the waveform

Page 59

5

The Time Measurement menu table

Menu Description

Frequency

Reciprocal of the period of the rst cycle in the waveform

Period Time to take for the rst signal cycle to complete in the waveform

Rising The time taken from lower threshold to upper threshold

Falling The time taken from upper threshold to lower threshold

+Width Measured of the rst positive pulse in the waveform

-Width Measured of the rst Negative pulse in the waveform

+Duty

Positive Duty Cycle = (Positive Pulse Width)/Period x 100%

Measured of the rst cycle in waveform

-Duty

Negative Duty Cycle = (Negative Pulse Width)/Period x 100%

Measured of the rst cycle in waveform

Delay 1->2

The delay of rising time between channel 1 and channel 2

Delay 1->2

The delay of falling time between channel 1 and channel 2

NOTE: The results of the automatic measurements will be displayed on the bottom of

the screen. Maximum 3 results could be displayed at the same time. When there is no

room, the next new measurement result will make the previous results moving left out of

screen.

Cursor Measurement

The screen displays two parallel cursors. Move the cursors to make custom voltage

or time measurements of the signal. The values are displayed on the boxes below the

menu. Before using cursors, make sure to set the Signal Source as the channel for

measuring.

Press CURSOR to shows the cursor menu as the following:

The Cursor menu

Figure 2-60 The Cursor menu

The Cursors menu table

Menu Setting Description

Mode

ON

OFF

Turn on/off the cursor measure

Page 60

5

Type

X

Y

Shown as vertical line to measure the horizontal

parameters.

Shown as horizontal line to measure the vertical

parameters.

Source

CH1

CH2

MATH

Select the measurement signal source.

Cursor A

Select Cursor A or not

Cursor B

Select Cursor B or not

The scope meter measures the Y or X coordinate values of the cursors, and the

increments between the two cursors.

To do cursor measurements, please do as the following steps:

1. Turn on the cursor measurement:

Cursor→Mode→Manual / Track / Auto.

2. Select channel Source for measurements by pressing soft button as:

Cursor→Source→CH1 / CH2 / MATH.

3. Select the cursors type by pressing soft button as Cursor→Type→ X or Y.

4. Press F4 or F5 to select the Cursor A or Cursor B.

5. Move the cursors to adjust the increment between the cursors.

The values will be automatically displayed on the right upper corner of screen when the

cursor function menu is hidden or displaying other menus.

Comments of Cursor Measurements

1. Auto Cursor Mode

The Auto Cursor Mode displays the cursors for the current measuring automatically. See

gure 2-61.

2. Manual Cursor Mode

In this mode, the scope meter measures the Y or X coordinate increments between the

two cursors. See gure 2-62.

1) Select menu Mode->Manual.

2) Select menu Type->X/Y to get the vertical or horizontal of Cursor A or Cursor B.

3) Select menu Source->CH1/CH2/MATH to Get the Cursor Source.

4 )Select Cursor A or Cursor B to adjust the increments between Cursor A and Cursor B.

5) Get the values between Cursor A and Cursor B.

delt x is the time between Cursor A and Cursor B.

1/delt x is the frequency between Cursor A and Cursor B.

3. Track Cursor Mode

In Track Cursor Mode, the Cursor A and Cursor B move together with the selected

waveform. See gure 2-63.

Page 61

5

Figure 2-61 The Automatic Cursor Mode

Page 62

60

Figure 2-62 The Manual Cursor Mode

Do as the following steps:

1. Select menu Mode->Manual.

2. Select menu Type->X/Y to get the vertical or horizontal of Cursor A or Cursor B.

3. Select menu Source->CH1/CH2/MATH to Get the Cursor Source.

4. Select Cursor A or Cursor B to adjust the increments between Cursor A and Cursor B.

5. Get the values between Cursor A and Cursor B.

delt x is the time between Cursor A and Cursor B.

1/delt x is the frequency between Cursor A and Cursor B.

3. Track Cursor Mode

In Track Cursor Mode, the Cursor A and Cursor B move together with the selected

waveform. See gure 2-63.

Figure 2-63 Track Cursor Mode

Please do the following steps:

1. Select menu Mode->Track.

2. Select Source for measurements. Select options as followings.

Cursor A->CH1/CH2. Cursor B->CH1/CH2.

3. Select Cursor A or Cursor B. Move the Select Cursors to adjust the increments

between the Cursors.

4. Get the values between Cursor A and Cursor B.

delt x is the time between Cursor A and Cursor B.1/delt x is the frequency between

Cursor A and Cursor B.delt y is the voltage between the Cursor A and Cursor B.

Page 63

6

Chapter 3 Using examples

Example 1: Simple Measurement

To acquire and display a signal, please do the steps as followings:

1. Connect signal to CH1 by using probe.

2. Press the key AUTO on key panel.

The Scope Meter set the vertical, horizontal, and triggers controls at the best status

automatically. Also, you can adjust the controls to meet your measurements to optimize

the waveform display.

To measure the frequency and Vpp, you can do these steps as followings:

1. Press the key MEAS , Select Source -> CH1 and select Type ->Voltage, then press

the key F5 and then press the key F2 to make a Pk to Pk test. The Vpp value will display

on the bottom of the waveform interface.

2. Press the key MEAS, select Source ->CH1and select type->Time, then Press the

key F5 and then press the key F2 to make a Frequency test. The Frequency value will

display on the bottom of the waveform interface.

3. Click the item Clear in the Measure menu, To clear the measurements on the

waveform interface.

See the measurements in the gure 3-1.

Figure 3-1 The Vpp and Freq measurement Window

Page 64

62

Example 2: The Application of the X-Y Operation

X-Y Plot acts to analyze correlation of data of two channels. Lissajous diagram

is displayed in the screen when you use X-Y Plot,which enables to compare

frequencies,amplitudes and phases of counterpart waveform against the reference

waveform. This makes it possible to compare and analyze frequency , amplitude and

phase between the input and output.

Do these steps as followings:

1. Set the probe attenuation to “x10”.Set the switch to”x10” on the probes.

2. Connect the CH1 probe to the input of the circuit, and connect the CH2 probe to the

output of the circuit.

3. Click the key AUTO on the panel.

4. Adjust the vertical scale and offset to display approximately the same amplitude

signals on each channel.

5. Select Time Base->X-Y format in Horizontal menu. The Scope Meter will display a

Lissajous pattern representing the input and the output characteristics of the circuit.

6. Adjust the scale and offset of the horizontal and vertical to a desirable waveform

display. The following picture shows a typical example.

7. Apply the Ellipse Method to observe the phase difference between the two channels.

See Signal in X-Y Format in gure 3-2.

Figure 3-2 Signal in X-Y Format

Instruction of the Ellipse Method

Page 65

6

Sinθ = A/B or C/D, where θ = phase shift (in degrees) between the two signals.

From the formula above:

θ = ±arcsine (A/B) or ±arcsine (C/D)

θ must be in the range of (0~π/2) or (3π/2~2π) if the main axis of the ellipse is between

I and III quadrant, . If the main axis is at II and IV quadrant, θ must be in the range of

(π/2~π) or (π~3π/2).

Page 66

6

Example 3: The FFT Cursor Measurements

FFT measurement includes: Amplitude measurement (Vrms or dBVrms) and the

Frequency measurement (Hz).

Do these steps as followings:

1. Press the key CURSOR to show Cursor menu.

2.Select Mode->Manual to enter the Manual Cursor Mode window.

3. Select Type->X/Y, select the Cursor Type to X or Y.

3. Select Source->MATH(FFT operation) in the Manual Cursor Mode window.

4. Drag the Cursor to the point of interest.

See the FFT Measurement (Cursor Type Y) in gure 3-3.

Figure 3-3 FFT Measurement (Cursor Type Y)

See the FFT Measurement (Cursor Type X) in gure 3-4.

Page 67

65

Figure 3-4 FFT Measurement (Cursor Type X)

Example 4: The Pass/Fail Test

The Pass/Fail Test is one of the enhanced special functions of the Scope Meter. By this

function, the Scope Meter could compare the input signal with the established waveform

mask. If the waveform “touches” the mask, a “Fail” signal occurs. Otherwise the test

passes. When needed, a programmable output can be used for external automatic

control applications. The output is built in as a standard feature and is optically isolated.

Do the steps as followings:

1. Press the key Utility to enter the Utility menu.

2. Press the key F5 in the panel to enter the page 2/4.

3. Select the Pass/Fail in the Utility menu to enter the Pass/Fail menu.

4. Select Enable to ON to turn on Pass/Fail, Select Source CH2 (the input source),

select Stop Output to OFF or ON in Page 2/2 of Pass/Fail menu.

5. Create the Pass/Fail Mask: Change the Vertical or Horizontal value by click the up or

down key in the panel to set the div of the vertical or horizontal values. Select Create or

Save or Load button if you need.

6. Select Operate to Start in Pass/Fail menu to start the Pass/Fail function.

See the Pass/Fail window in gure 3-5.

Page 68

66

Figure 3-5 The Pass/Fail Window

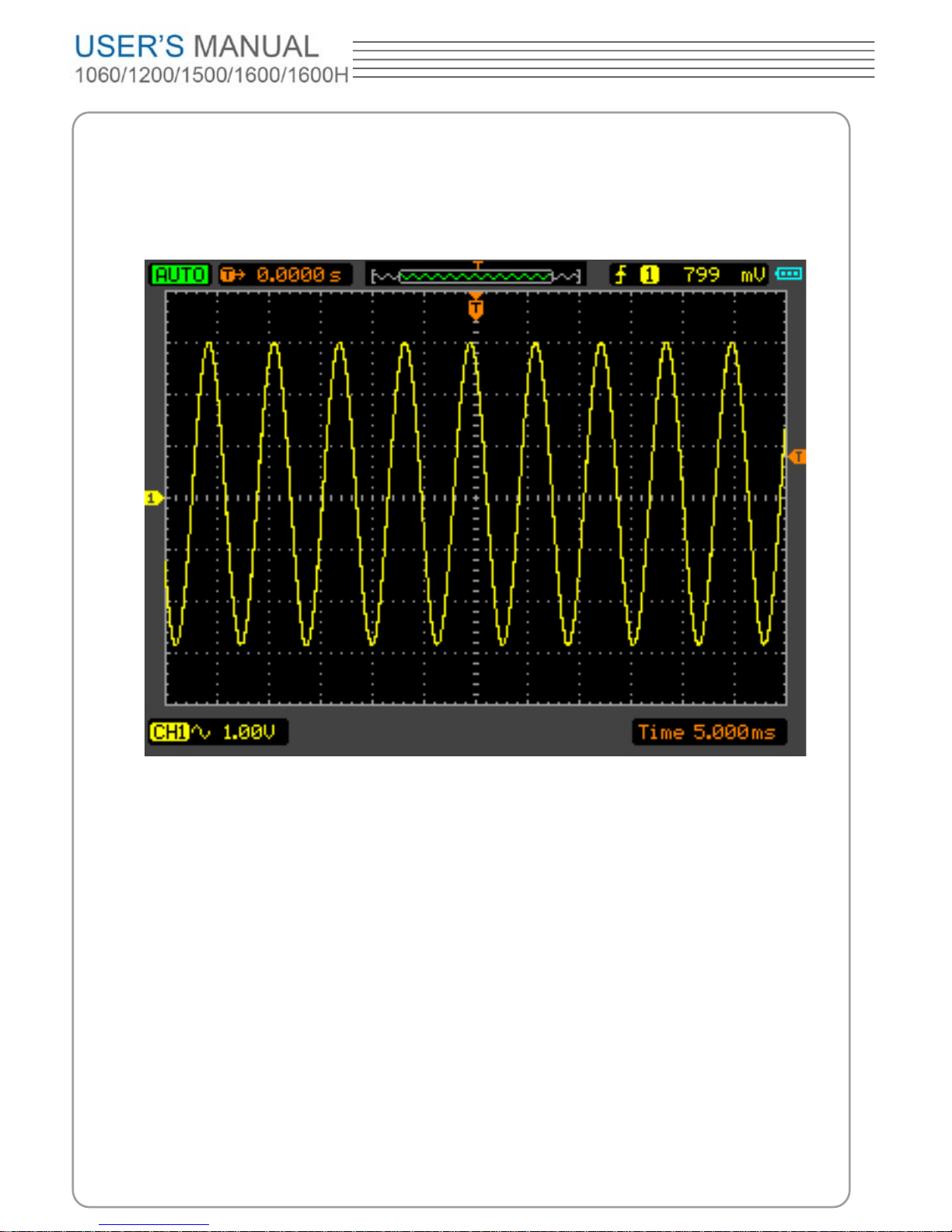

Example 5: Reduce the noise on a signal

See the signal with random noise in gure 3-6.

To reduce random noise, do the following steps:

1. Set the Probe and the channel attenuations to “x10”.

2. Connect the signal to the Scope Meter to display a stable wave.

3. Reduce the noise Select the Acquire Mode in Acquire menu.

If there is noise within the signal and the waveform looks too wide, in this case, choose

average acquisition. In this mode the waveform will be thin and easy to observe and

measure.

Use the Average following the steps:

1. Select Acquire in the Utility menu to enter the Acquire menu.

2. Select Mode to Average, then Press F2 to change the Averages

form 2 to 128 to switch the number of averages that best eliminates the noise from the

displayed waveform.

3. Select Mode to Normal to cancel this function.

See signal after reducing random noise in gure 3-7.

Page 69

6

Figure 3-6 Signal with random noise

Figure 3-7 Signal after reducing random noise

Page 70

6

Example 6: Capture a Single signal

To capture a single event, it needs to gather some pre-test knowledge of the signal in

order to set up the trigger level and slope correctly. For example, if the event is derived

from TTL logic, a trigger level of 2 Volts should work on a rising edge.

Do these steps as followings:

1. Set the probe and the channel attenuations to 1:10.

2. Press the key TRIG to show the Trigger menu.

3. Select Mode->Edge. Set Source to CH1 and Slope to Rising. Set Sweep to Single.

4. Adjust the Volts/Div and the time base in a proper range for the signal.

5. Drag the trigger level sign on the waveform display screen.

6. When the trigger conditions are met, data appears on the display representing the

data points that the Scope Meter obtained with one acquisition.

Page 71

6

CHAPTER 4: Multimeter

About this chapter

This chapter provides an introduction to the multimeter functions of Protek1000 Series.

The introduction gives guides to show how to use the menus and perform basic

measurements.

Connecting the Meter

Use the 4-mm safety banana jack inputs for the Meter functions: 10A , mA, COM,V/Ω/C.

Multimeter Operation Window

Figure 4-1 Multimeter operation window

Description

1) Battery electric quantity indictor.

2) Measurement mode indictors:

DC: Direct electric measurement

AC: Alternating electric measurement

Page 72

0

3)The symbol of Mutimeter current mode

4) Manual/Auto range indictors, among which the MANUAL refers to measuring range

in manual operation mode and Auto means the measuring range in automatic

operation mode.

5) The reading value of measurement.

6) The bar graph indictor.

7) DC or AC Measurement mode control.

8) Absolute /relative magnitude measuring control: The sign “||” expresses the absolute

magnitude measuring control and “ ” represents the relative magnitude measuring

control.

9) Manually or automatically measuring range control.

Operating the Multimeter

If you are in the scope mode window, press DMM/OSC key, the scope meter will switch

to the multimeter mode window.Then the screen will display the measure mode window

that was in use the last time before you quit multimeter measure. When you switch to the

multimeter measurement the rst time, the default measure mode is DC voltage mode.

Measuring Resistance Values

To measure a resistance, do the following:

1) Press the R key and then resistance measurement window appears on the screen.

2) Insert the black lead into the COM banana jack input and the red lead into the V/Ω/C

banana jack input.

3) Connect the red and black test leads to the resistor. The resistor value value is shown

on the screen in Ohm.

Then, the screen will look like the following gure 4-2.

Making a Diode Measurement

To make a measurement on the diode, do the following:

1) Press the diode key and a diode symbol appears at the top of the screen. .

2) Insert the black lead into the COM banana jack input and the red lead into the V/Ω/C

banana jack input.

3) Connect the red and black leads to the diode and the voltage value of the diode is

displayed on the screen in voltage value.

Then, the screen will look like the following gure 4-3.

Page 73

Figure 4-2 Resistance Measurement

Figure 4-3 Diode Measurement

Page 74

2

To perform an On-off test, do the following:

1) Press the On-off key and then On-off indictor appears on the top of the screen.

2) Insert the black lead into the COM banana jack input and the red lead into the V/Ω/C

banana jack input.

3) Connect the red and black leads to the test point. If the resistance value of the tested

point is less than 30 Ω, you will hear beep sound from the test tool.

Then, the screen will look like the following gure 4-4.

Figure 4-4: On-off Measurement

Making a Capacitance Measurement

To measure a capacitance, do the following:

1) Press the C key and a capacitor symbol appears on the top of the screen.

2) Insert the black lead into the COM banana jack input and the red lead into the V/Ω/C

banana jack input.

3) Connect the red and black leads to the capacitor and the capacitance value is displayed

on the screen in μF or nF.

Then, the screen will look like the following gure 4-5

Making On-off Test

gure 4-4

Page 75

Figure 4-5 Capacitance Measurement

Making a DC Voltage Measurement

To measure a DC voltage, do the following:

1. Press the V key and DC appears at the top of the screen.

2. Insert the black lead into the COM banana jack input and the red lead into the V/Ω/C

banana jack input.

3. Connect the red and black leads to the measured point and the measured point voltage value is displayed on the screen.

Making an AC Voltage Measurement

To measure the AC voltage, do the following:

1) Press the V key and DC appears at the screen.

2) Press the F1 key and AC appears at the screen.

3) Insert the black lead into the COM banana jack input and the red lead into the V/Ω/C

banana jack input.

4) Connect the red and black leads to the measured points and the AC voltage value of

measured points will be displayed on the screen.

Page 76

Then, the screen will look like the following gure 4-6.

Figure 4-6: AC voltage Measurement

Making a DC Current Measurement

To measure a DC current which is less than 600 mA , do the following:

1) Press the A key and then DC appears at the screen. The unit on the main reading

screen is mA. Press F2 to switch the measurement between mA and 10A. 600mA is

acquiescently.

2) Insert the black lead into the COM banana jack input and the red lead into the mA

banana jack input.

3) Connect the red and black leads to the measured points and the DC current value of

measured points will be displayed on the screen.

Then, the screen will look like the following gure 4-7.

To measure a DC current which is larger than 600 mA, do the following:

To measure a DC current which is larger than 600 mA, do the following:

1) Press the A key and then DC appears on the screen. The unit on the main reading

screen is mA.

2) Press F2 key to switch to 10A measurement, the unit on the main reading screen is A.

3) Insert the black lead into the COM banana jack input and the red lead into the 10A

Page 77

5

banana jack input.

4) Connect the red and black leads to the measured point and the DC current value of

the measured point will be displayed on the screen.

5) Press F2 to return to 600 mA measurement.

Then, the screen will look like the following gure 4-8.

Figure 4-7 DC current Measurement for 600 mA

Making an AC Current Measurement

To measure an AC current which is less than 600 mA, do the following:

1) Press the A key and then DC appears on the screen. The unit on the main reading

screen is mA,and mA will display on the bottom of the screen, press F2 to switch the

measurement between mA and 10A. 600mA is acquiescently.

2) Press the F1 key once and AC will display on the bottom of the screen.

3) Insert the black lead into the COM banana jack input and the red lead into the mA

banana jack input.

4) Connect the red and black leads to the measured points and the AC current values of

measured points will be displayed on the screen.

Then, the screen will look like the following gure 4-10.

To measure an AC current which is larger than 600 mA, do the following:

1) Press the A key and then DC appears on the screen. The unit on the main reading

screen is mA.

2) Press F2 key to switch to10A measurement, the unit on the main reading screen is A.

Page 78

6

Figure 4-8 DC Current Measurement for 10A

Page 79

Figure 4-9 AC Current Measurement for 600 mA

3) Press the F1 key once and AC will display on the bottom of the screen.

4) Insert the black lead into the COM banana jack input and the red lead into the 10A

banana jack input.

5) Connect the red and black leads to the measured point and the AC current value of

the measured point will be displayed on the screen.

6) Press F2 to return to 600 mA measurement.

Then, the screen will look like the following gure 4-10.

Figure 4-10 AC Current Measurement for 10A

Taking a Relative Measurement

A currently measured result relative to the dened reference value is displayed in a relative measurement.

The following example shows how to take a relative measurement. At rst, it is required

to acquire a reference value.

1) Press the R key.

2) Insert the black lead into the COM banana jack input and the red lead into the V/Ω/C

banana jack input.

3) Connect the red and black test leads to the resistor. The resistor value is shown on

the screen in Ohm.

4) When the reading leveling off, press F1 key and then ||/ ,is displayed on the top of

Page 80

the screen.

The saved reference value is displayed beside.

Then, the screen will look like the following gure 4-11.

Figure 4-11 Relative Measurement

Selecting Automatic/Manual Range Adjustment

The default range mode of the instrument is automatic range. Suppose you are using the

DC voltage mode, to switch to the manual range, perform the following steps:

1) Press F3 key to enter the manual range mode and then Manual is displayed on the

top of the screen.

2) Under the manual range mode, the measuring range is increased by a stage when

pressing F4 key each time, and when reaching the highest stage, it jumps to the lowest

stage by pressing F4 key once again.

3) Press F3 key to switch back to the automatic range mode and then Auto is displayed

on the top of the screen.

Attention: capacitance measurement without manual range mode.

Page 81

Figure 4-12 The Manual Mode window

Page 82

0

Chapter 5: Troubleshooting

1.The scope meter cannot start.

1) Check the power cable connection.

2) Ensure the power switch is turned on.

3) After the above inspection, restart the scope meter.

4) If the problem still remains, please contact us for help.

2. The measurement result is 10 times higher or lower than the value expected.

Check if the probe attenuation is the same as the channel attenuation.

3. The waveform is displayed on the screen but is not stable under the scope

meter mode.

1) Check the Trigger Source and notice if it is set to the channel in use.

2) Check the Trigger Type.

4. When select the average sampling in the sampling mode or select a long display time in the display mode under the scope meter, the display speed is slow.

It is normal in the above case.

5. After the Acquisition is set to “Averages” or Display Persistence is set ON, the

waveform refreshes slowly.

It is normal in these settings.

Page 83

Chapter 6: Specications

Vertical

Channels 2

Bandwidth

DSO1060: 60MHz

DSO1200: 200MHz

DSO1500: 500MHz

DSO1600: 600MHz

DSO1600H: 600MHz

Rise Time

DSO1060: 5.8ns

DSO1200: 1.7ns

DSO1500: 0.7ns

DSO1600: 0.58ns

DSO1600H: 0.58ns

Input Impedance Resistance: 1M;Capacitance: 15pF

Input Sensitivity

DSO1060: 10mv/div to 5v/div

DSO1200: 10mv/div to 5v/div

DSO1500: 2mv/div to 10v/div

DSO1600: 2mv/div to 10v/div

DSO1600H: 2mv/div to 10v/div

Input Coupling AC,DC with Ground Level Indicator

Vertical Resolution 8bits

Memory Depth 32k at single channel; 16k at dual channel

Maximum Input 400V(DC+AC Peak)

Horizontal

Sampling

DSO1060: 150MSa/s

DSO1200: 250MSa/s

DSO1500: 500MSa/s

DSO1600: 1GSa/s

DSO1600H: 2GSa/s

Equivalent Sampling 50GSa/s

Time Base Precision ±50ppm

Page 84

2

Time Base Range

DSO1060: 5ns/div ~ 1000s/div

DSO1200: 2ns/div ~ 1000s/div

DSO1500: 1ns/div ~ 1000s/div

DSO1600: 1ns/div ~ 1000s/div

DSO1600H: 1ns/div ~ 1000s/div

Trigger

Source CH1,CH2

Mode

DSO1060:

Edge, Pulse Width, Alternative

DSO1200,DSO1500,DSO1600,DSO1600H

: Edge, Pulse Width, Alternative, Vedio.

X-Y Mode

X-Axis Input Channel 1

Y-Axis Input Channel 2

Phrase Shift Max.3 degree

Cursors and Measurement

Voltage Vpp,Vamp,Vmax,Vmin,Vtop,Vmid,Vbase

,Vavg

Vrms,Vcrms,Preshoot,Overshoot

Time Frequency,Rise time,Fall Time,Postive

Width,Negative Width,Duty Cycle

Delay Delay 1->2↑, Delay 1-2↓

Cursor Manual,Track,Auto Measure Modes

Math Addition, Subtraction, Multiplication, Divi-

sion, FFT

Storage 15 Waveforms and setups

Meter Mode

Maximum Resolution 6000 Counts

DMM Testing Modes Voltage,Current,Resistance,Capacitance,Diode &

Continuity

Maximum Input Voltage AC : 600V DC :600V

Maximum Input Current AC : 10A DC : 10A

Input Impedance 10M

Page 85

METER SPECIFICATION

Range Accuracy Resolution

DC Voltage 60.00mV ±1%±1digit 10uV

600.0mV

100uV

6.000V 1mV

10mV

60.00V

100mV

600.0V

1V

800V

AC Voltage 60.00mV ±1%±3digit 10uV

600.0mV 100uV

6.000V 1mV

60.00V 10mV

600.0V 100mV

DC Current 60.00mA ±1.5%±1digit 10uA

600.0mA ±1.5%±1digit 100uA

6.000A ±2%±3digit 1mA

10.00A 10mA

AC Current 60.00mA ±1.5%±3digit 10uA

600.0mA ±2%±1digit 100uA

6.000A ±3%±3digit 1mA

10.00A 10mA

Resistance 600.0 ±1%±3digit 0.1Ω

6.000K ±1%±1digit 1Ω

60.00K 10Ω

600.0K 1KΩ

6.000M 10KΩ

60.00M ±1.5%±3digit 1Ω

Page 86

Capacitance 40.00nF ±3%±1digit 10pF

400.0nF ±1%±1digit 100pF

4.000uF 1nF

40.00uF 10nF

400.0uF 100nF