Hansgrohe Interaktiv Showerpanel Installation Instructions / Warranty

Interaktiv

Showerpanel

Installation Instructions / Warranty

Interaktiv Showerpanel I

Interaktiv Showerpanel II

Showerpanel I Showerpanel II

handshower & bodyjets handshower, bodyjets, tub spout

Metro 06572000 06573000

Solaris 06549XX0 06550XX0

Stratos 06564XX0 06565XX0

Interaktiv S 06893000 06894000

Proaktiv* 06964000 06971000

Product Specification

Flow rate of handshower 2.5 gpm

Flow rate of each bodyjet 1.0 gpm

Maximum flow rate of thermostatic mixing valve 8 gpm @ 45 psi

10 gpm @ 65 psi

Recommended incoming hot water temperature 120

o

– 140o F**

Recommended incoming water pressure 45 – 72 psi

Anodized aluminum body

Listed by Underwriters Laboratories

Backflow protection provided by check valve in handshower outlet.

The high temperature limit stop on the thermostatic mixing valve cartridge can be re-set to

comply with local plumbing codes -- see page 13.

*Proaktiv showerpanels are sold without trim. Proaktiv showerpanel trim kits are sold separately.

**Please know and follow all applicable local plumbing codes when setting the temperature on the water heater. In

Massachusetts, the water heater may be set no higher than 112oF.

2

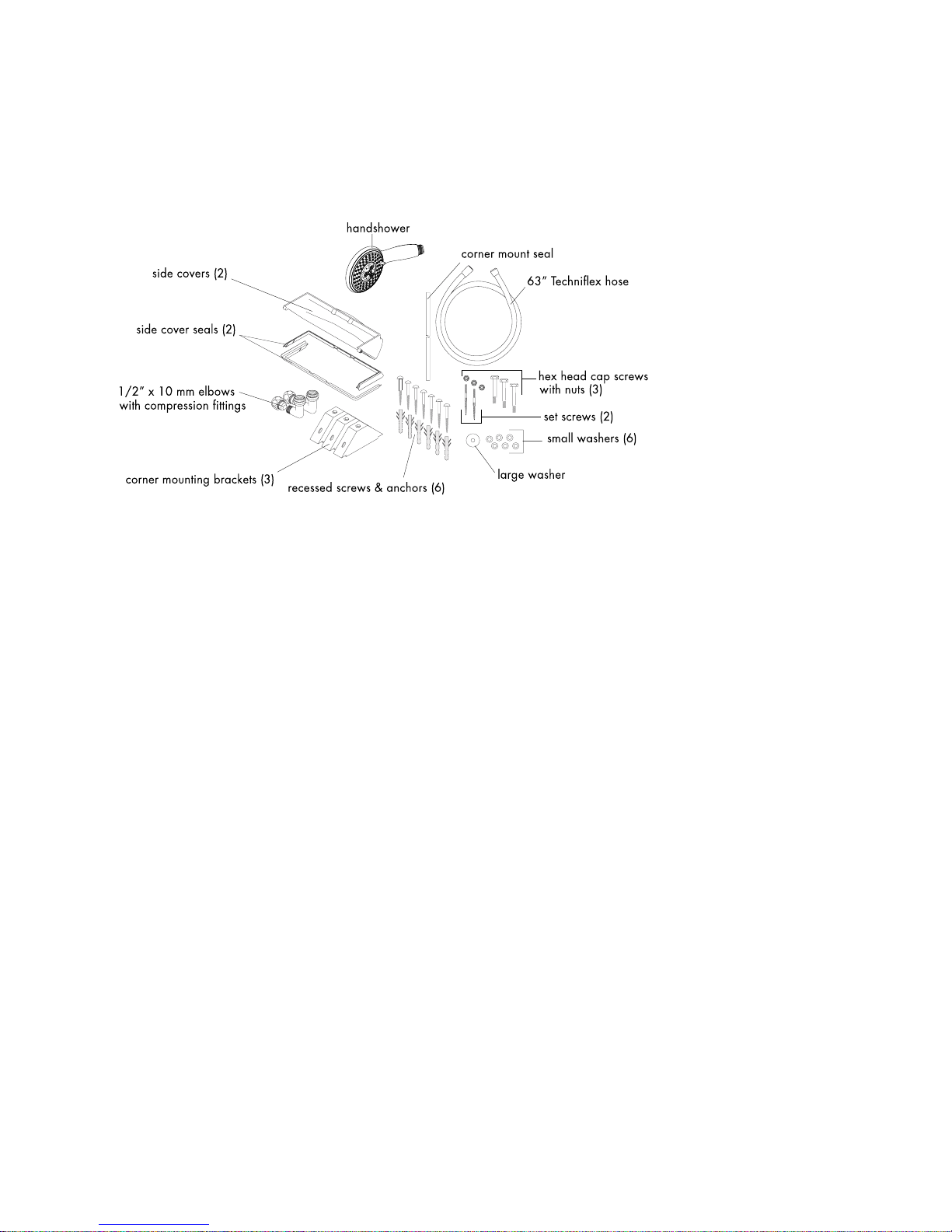

Check Package Contents

Save time and aggravation. Before beginning installation, check the contents of this

package. Make sure that all parts are present and in good condition. If any part is missing

or damaged, please contact Hansgrohe Customer Service before proceeding.

Tools Required

The following tools are suggested for installing the Interaktiv Showerpanel:

Tape measure

Level

Grease pencil or other marking device

Drill with 6 mm bit suitable for wall surface

10 mm nut driver

10, 11 and 19 mm wrenches

3 mm Allen wrench

Philips screwdriver

Waterproof sealant

Mallet (to install anchors)

Teflon

thread tape

Note: the handshower

and Techniflex hose are

not included with the

Proaktiv showerpanel.

They are included with

the trim kit (sold separately).

3

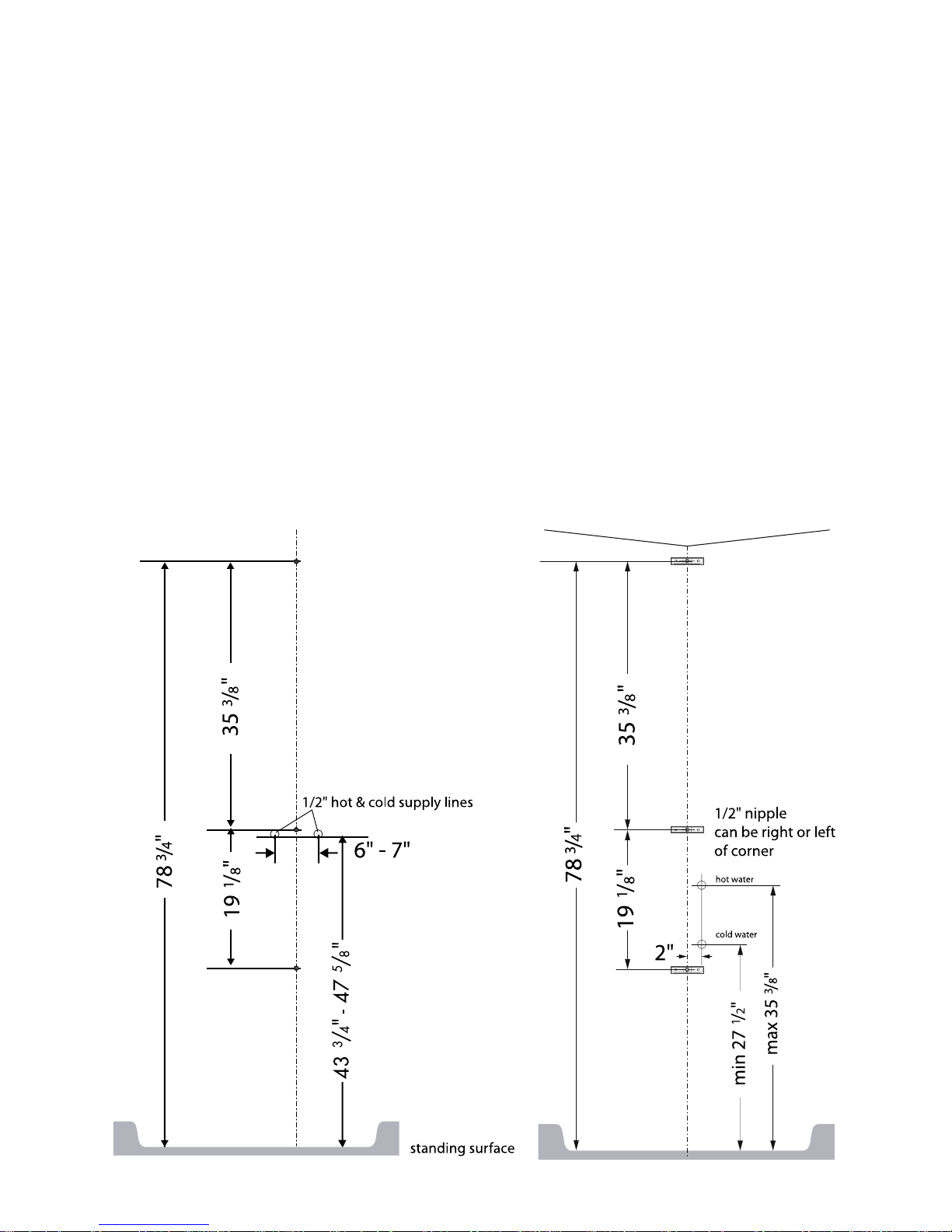

Roughing-in

This unit can be installed on a flat wall or in a 90o corner. Instructions for installation on a

flat wall begin on page 5. Go to page 8 if the panel is to be installed in a corner.

Ensure that you have a minimum 83” ceiling height from the standing

surface.

Stub out 1/2" NPT male nipples for the hot and cold water supplies at the locations shown

on the appropriate rough-in diagram. The nipples should extend 5/8" outside the surface

of the finished wall.

Install the wall surface and make the wall watertight before installing the panel

. The panel

hangs on the finished wall. Seal the wall around the nipples with waterproof sealant.

4

Installation on a Flat Wall Installation in 90o Corner

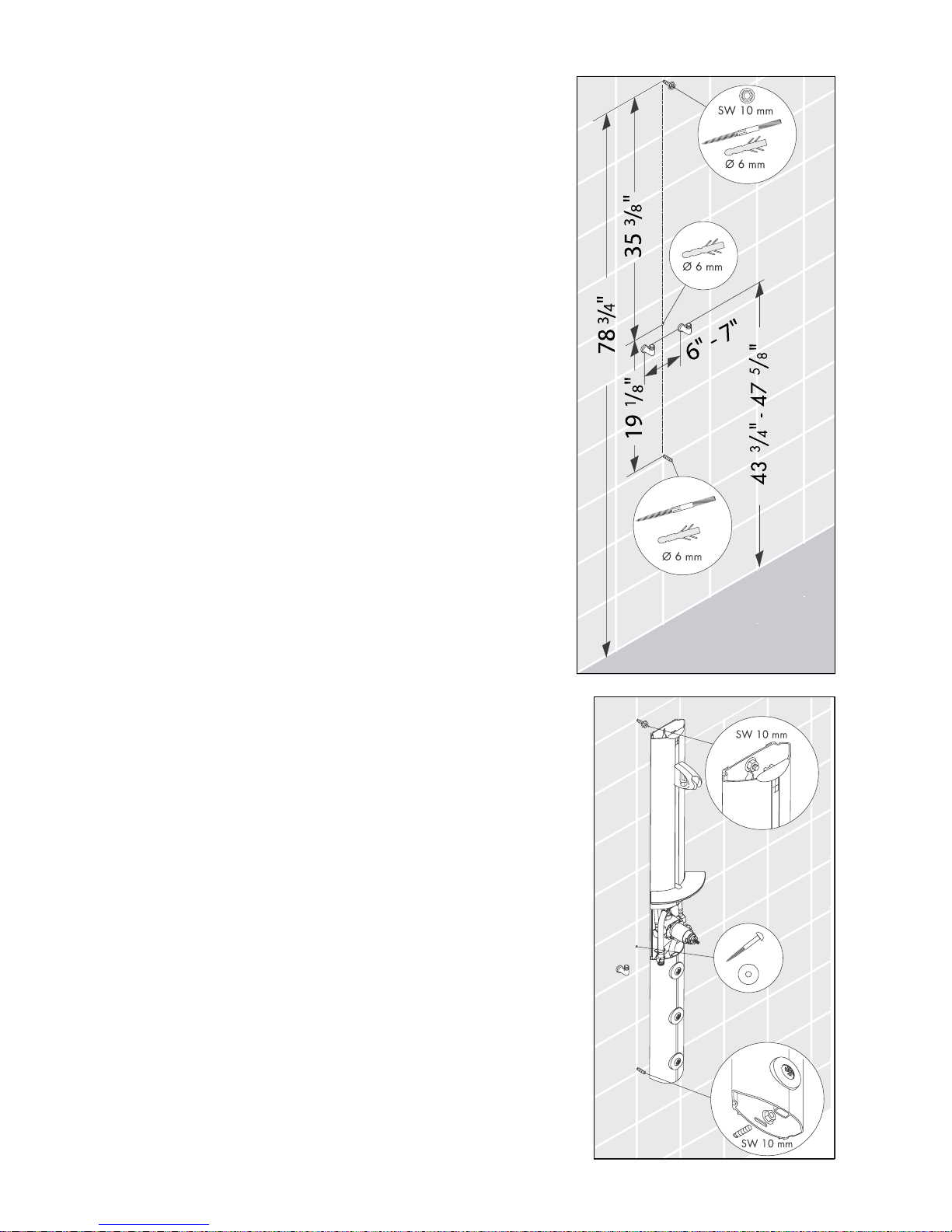

Installation -- Flat Wall

Wrap the threads on the supply nipples with Teflon thread

tape.

Install the enclosed elbows so that the outlets face

upwards.

Measure up the wall 78 ¾”, making sure that the line is

plumb. Mark the position for the top screw hole.

From the position of the top screw hole, measure down

35 3/8”. Mark the position for the center screw hole.

From the center screw hole, measure down 19 1/8”.

Mark the position for the bottom screw hole.

Use a 6 mm drill bit suitable for the wall surface. Drill the

three screw holes.

Install the anchors. Seal the wall around the anchors with

waterproof sealant.

Install the set screws in the top and bottom holes.

Use a 10 mm nut driver to attach a nut to the top set

screw.

Slide the panel over the top and bottom set screws.

Tighten the nut on the top set screw.

Install and tighten the nut on the bottom set screw.

Install one recessed head screw and the large washer on

the center hole. Tighten the screw.

5

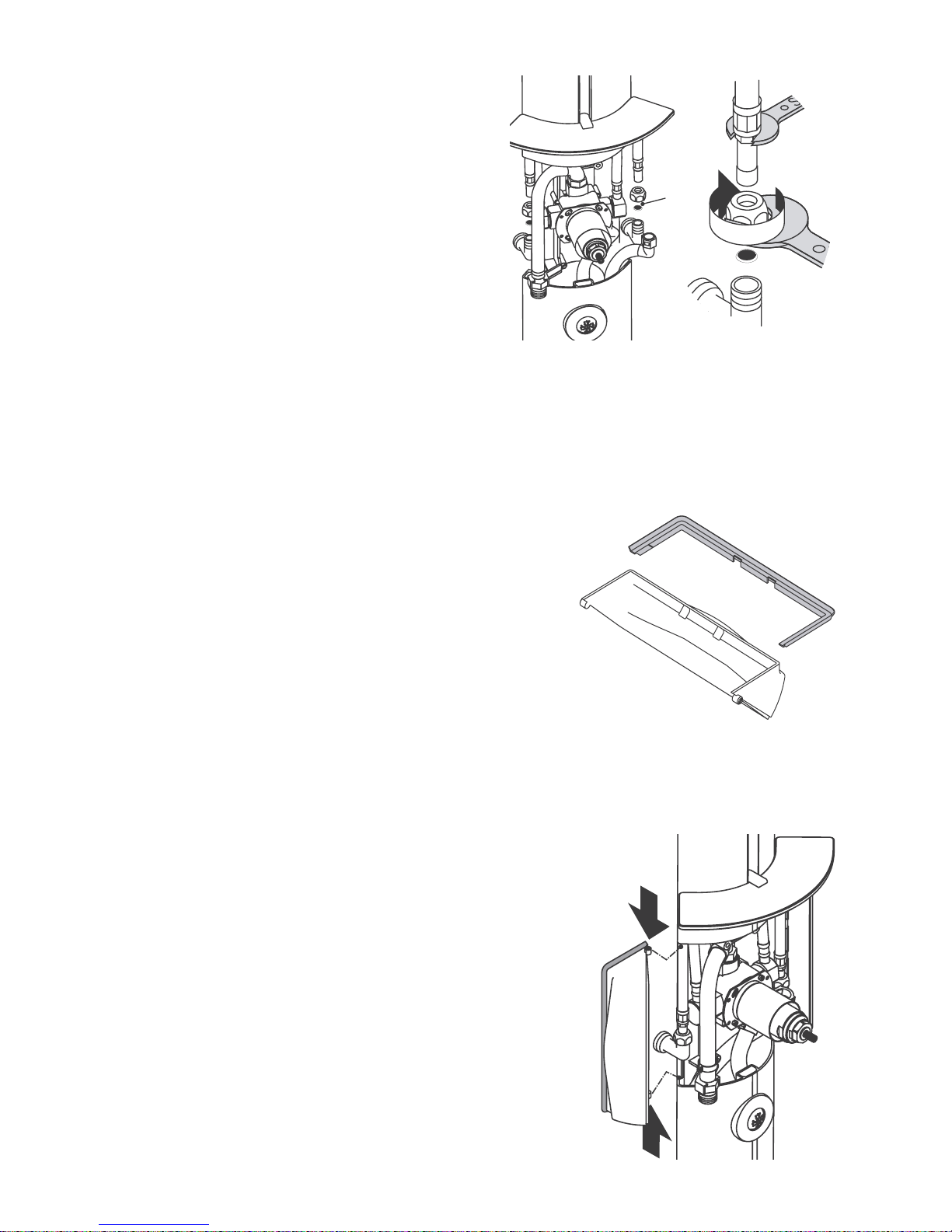

Use the compression nuts and ferrules to connect

the supply hoses on the panel to the supply

elbows. Use two wrenches, as shown, to prevent

the supply hoses from twisting.

Attach the seals to the side covers.

Install the side covers. The pins on the covers must go into

the grooves on the sides of the panel.

6

Loading...

Loading...