Page 1

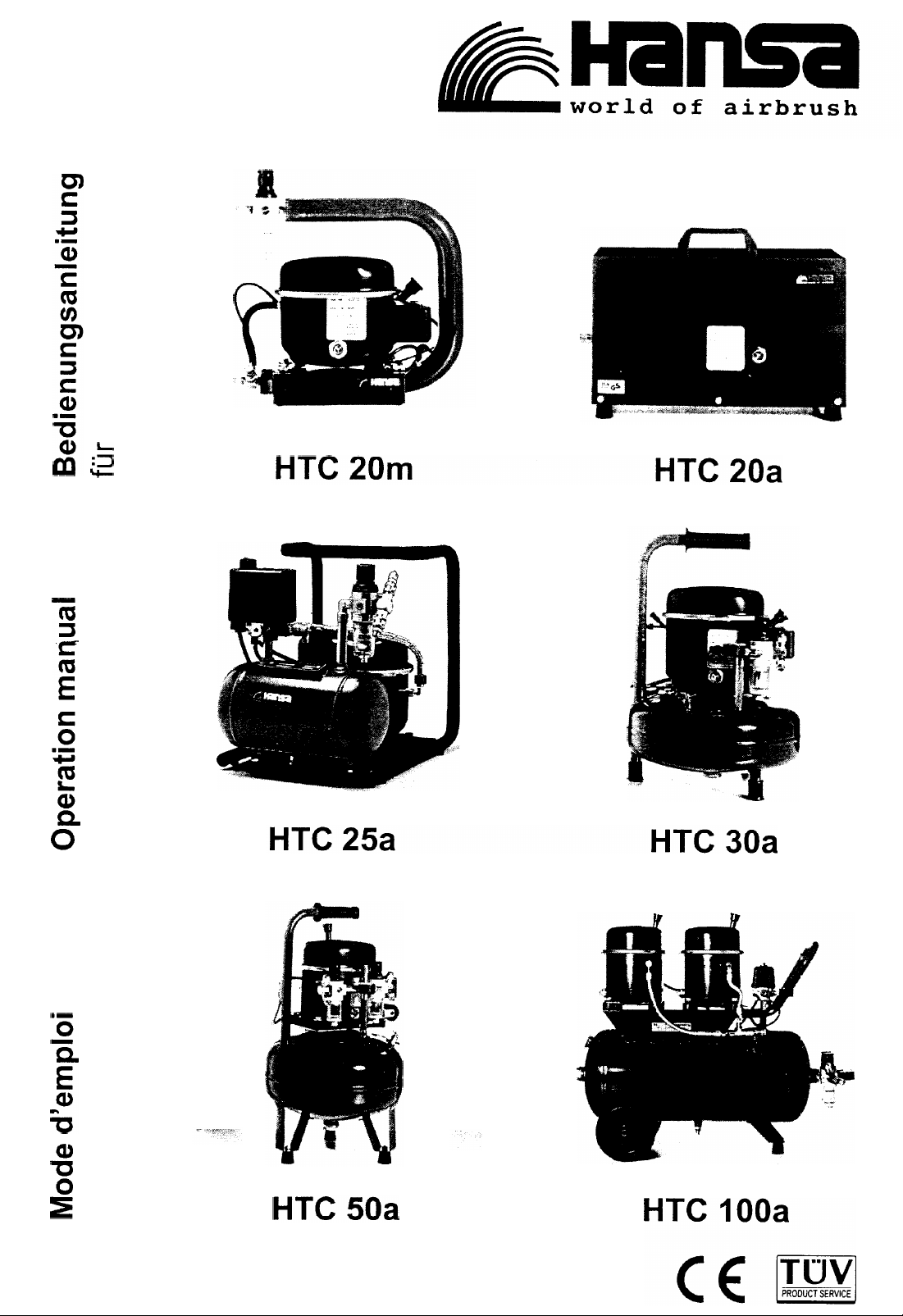

Kompressoren

Bedienungsanleitung

fijr

manual

Operation

for compressors

d’emploi

Mode

pour compresseurs

Page 2

Operation Manual

Page 3

-

Table

of~Contents -

ENGLISH

Introduction . . . . . . . . . . . . . . . . , . . . . , . . . . . .

Preface

Useasintended

Notes of warning and paragraph formats

Compressor nameplate

Guarantee

Supplier’s address.

Important Notes

General safety instructions

Environmental protection

Transportation

Before You Begin

Unpackdevice

Check package for completeness

Installation

.................................................

..........................................

.......................

................

...............................................

........................................

,

........

..................................

...................................

............................................

..........l

............................................

...............................................

.........................

.................,...

.............................

..................

.1-.

-...m

. . . . 3

3

3

4

4

5

5

7

7

8

8

9

9

9

9

Fillupoil

Drainoil

Initial Operation

Setting the operating pressure

Motor protection switch

Switching the compressor off

Maintenance

Weekly

Monthly ................................................

Quarterly or six-monthly

Failure List

Technical Data ,

Technical compressor data

HTC20m

HTC20a

...............................................

.................................................

............

..............................

...................................

...............................

..........,.

................................................

...................................

....

............

,

n

....................

,

.......................

...................

,

...........................l.....

.................................

..............................................

...............................................

10

12

13

14

15

15

17

I7

17

20

21

23

23

25

27

HTC25a

HTC30a

HTC50a

HTClOOa

...............................................

...............................................

...............................................

..............................................

29

31

33

35

Page 4

INTRODUCTION

Preface

Operation Manual - ENGLISH

This operation manual applies to compressor models HTC

HTC

tains valuable information on how to safely, properly and economically operate your compressor.

In your own interest, please observe the following points:

0

l

20a,

Use as intended

This compressor has been designed for the operation of com-

mercially available airbrushes.

20m,

HTC

Read this operation manual prior to initial opera-

tion and any maintenance work.

Observing the notes and instructions contained in

this manual is the only way that guarantees use as

intended.

Always keep the operation manual in the immediate

proximity of the compressor.

25a,

HTC

30a,

HTC

50a,

and HTC

IOOa.

It con-

Please observe the following notes:

The intended use includes the taking of all preventive

maintenance action described in this manual as well as

the proper disposal of all operating materials at the end

of their serviceable life.

Every application other than the use described in this

manual shall be considered not as intended. All conse-

quences shall be borne by the operator.

It is not allowed to change the compressor’s design or

construction.

Page 5

Introduction

Notes of warning and paragraph formats

In this manual, you will repeatedly come across certain notes of

warning and paragraph formats standing for the following types

of information:

Caution:

Note:

Note:

1.

0

This symbol makes you aware of any danger to

human

and/or

machine. Observe these safety

notes in your own interest.

This symbol marks helpful tips and other useful information.

This symbol appears every time the text mentions

operating or other materials for which legal processing and disposal rules exist to protect the environment.

Paragraphs preceded by a number mark instructions to

be worked through in the numbered sequence.

Paragraphs preceded by a dot refer to general lists.

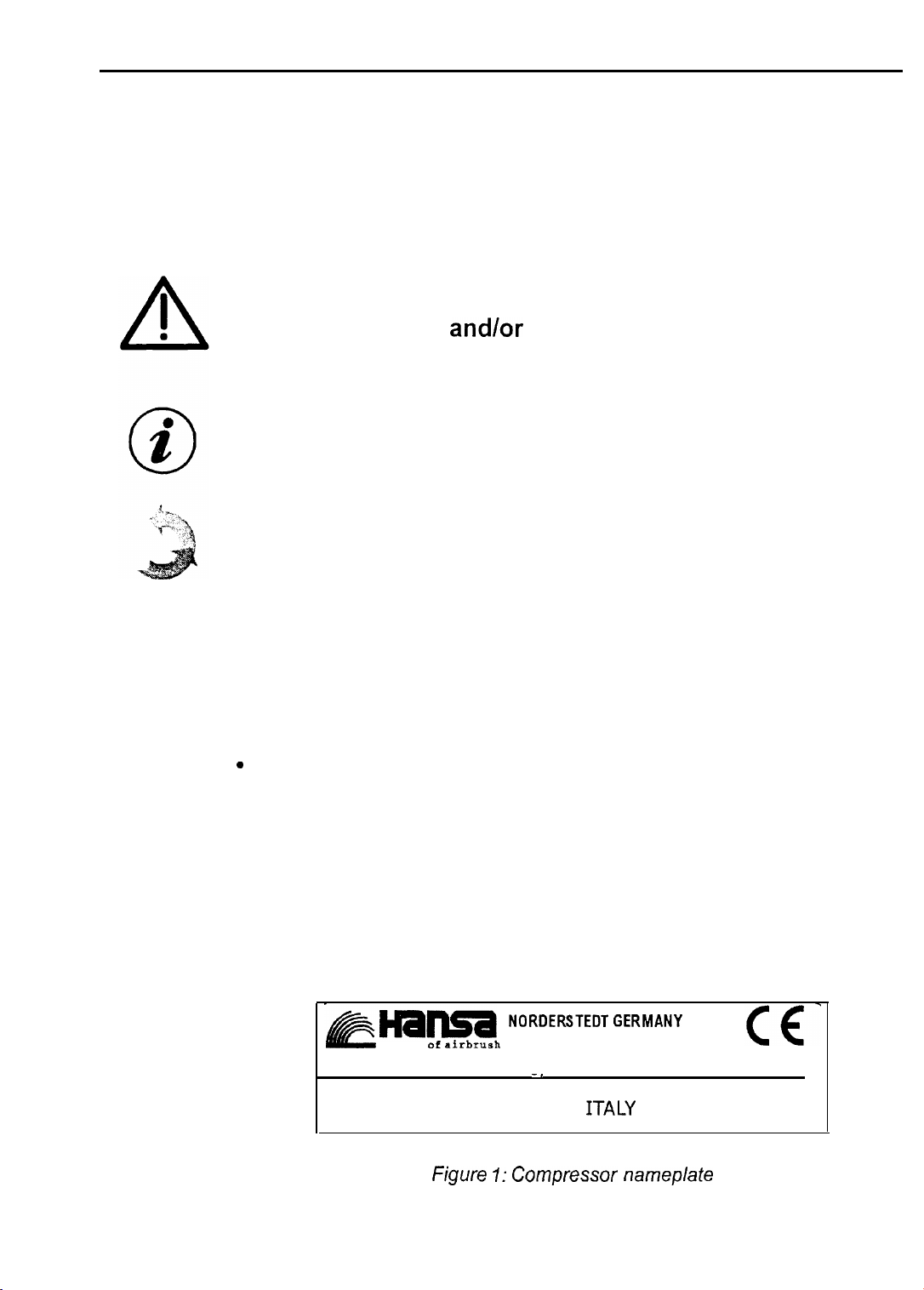

Compressor nameplate

The nameplate attached to the compressor displays information

about the compressor type, serial number, pressure rating,

model year and manufacturer.

world

MOD.HTC 20M

Manufactured by

WERTHER INT.CADE (R.E)

NORDERSTEDT GERMANY

of

airbrush

S/N 428492 L. 1

-’

ITALY

Figure I: Compressor nameplate

YEAR M/l997

BAR 6

Page 6

Guarantee

Operation Manual - ENGLISH

Hansa-Technik

mance of the device.

The guarantee period is 12 months, starting on the day of purchase.

The guarantee shall only be performed if the receipt is sent in

with the device to Hansa-Technik GmbH. We will remove all defects or damages caused by material or production failures.

The guarantee shall be performed by repair or replacement of

defective parts according to our best choice.

Damages to wearing parts as well as damages caused by improper use or maintenance action shall be excluded from the

guarantee.

Supplier’s address

GmbH

guarantees perfect quality and perfor-

.

Hansa-Technik

Oststr. 67

D-22844 Norderstedt - Germany

Telephone

Telefax

E-mail:

Internet:

+49-40-526

hansa@on-line.de

http://www.hansa-airbrush.de

GmbH

+49-40-

526 58-O

58-l 10

Page 7

Operation Manual

IMPORTANT NOTES

General safety instructions

The compressor must only be installed in dry rooms and protected against dampness and dust.

The spraying of combustible fluids constitutes a fire hazard and/

or a risk of explosion. Only use in well-aired rooms.

Install the compressor such that it can take in enough air at any

time. It may overheat otherwise.

Safety and protective devices on or in the compressor must not

be modified or disabled.

-d~ENGLISH

Immediately disconnect the device if you detect any unusual

sounds or smells during operation. Contact a specialised workshop if necessary. The compressor must only be restarted when

it has been put back into proper working order.

Repairs must only be made by qualified and trained persons.

Switch off and unpressurise the compressor prior to any mainte-

nance work.

The device has been designed for an operating voltage of

50Hz.

stalled and secured wall outlet.

The wall outlet to which the device is connected must be easily

accessible so that you can quickly disconnect the compressor

from the mains if and when required.

It is mandatory that power be supplied via a properly in-

23OW

Page 8

Important Notes

Environmental protection

Disposal of compressor oil must comply with your local authorities’ regulations.

At the end of its serviceable life, the compressor too is to be disposed in compliance with legal regulations.

Transportation

Drain all the oil from the compressor if you wish to transport it

(forwarder, P.O., etc.) any time after initial installation and setup.

You otherwise run the risk of oil escaping or getting into the

pression

Catch the oil to be drained off in a suitable container.

Hansa-Technik

by the transportation or dispatch of oil-filled compressors.

chamber thus damaging the device.

GmbH

shall not be liable for damages caused

co-

Page 9

Operation Manual - ENGLISH

BEFORE YOU BEGIN

Unpack device

After unpacking, check the compressor for any transport damages.

0

2

0

Check package for completeness

Note:

Note:

Check whether the delivery package was complete. Apart from

the compressor, the package should contain the following parts:

Keep the packing material so that you can reuse it

for any later transportation.

Dispose of the packing material in compliance with

the applicable regulations if you no longer need it.

I

bottle of oil (2 bottles for model HTC

1 screw-on filler tip for the oil bottle (2 filler tips for mod-

el HTC

plug-type connectors;

1 air filter (two filters for model HTC 1

IOOa);

IOOa);

OOa),

and

installation

of the appropriate size.

The room temperature should be no higher than 35”

with fresh air.

1 plastic tube for draining the condensation water off

the fluid container (applies to models HTC 30a and

HTC

Install the compressor on an even surface in a well-aired room

Provide extra ventilation if the room is not sufficiently supplied

50a

only).

C.

Page 10

Before

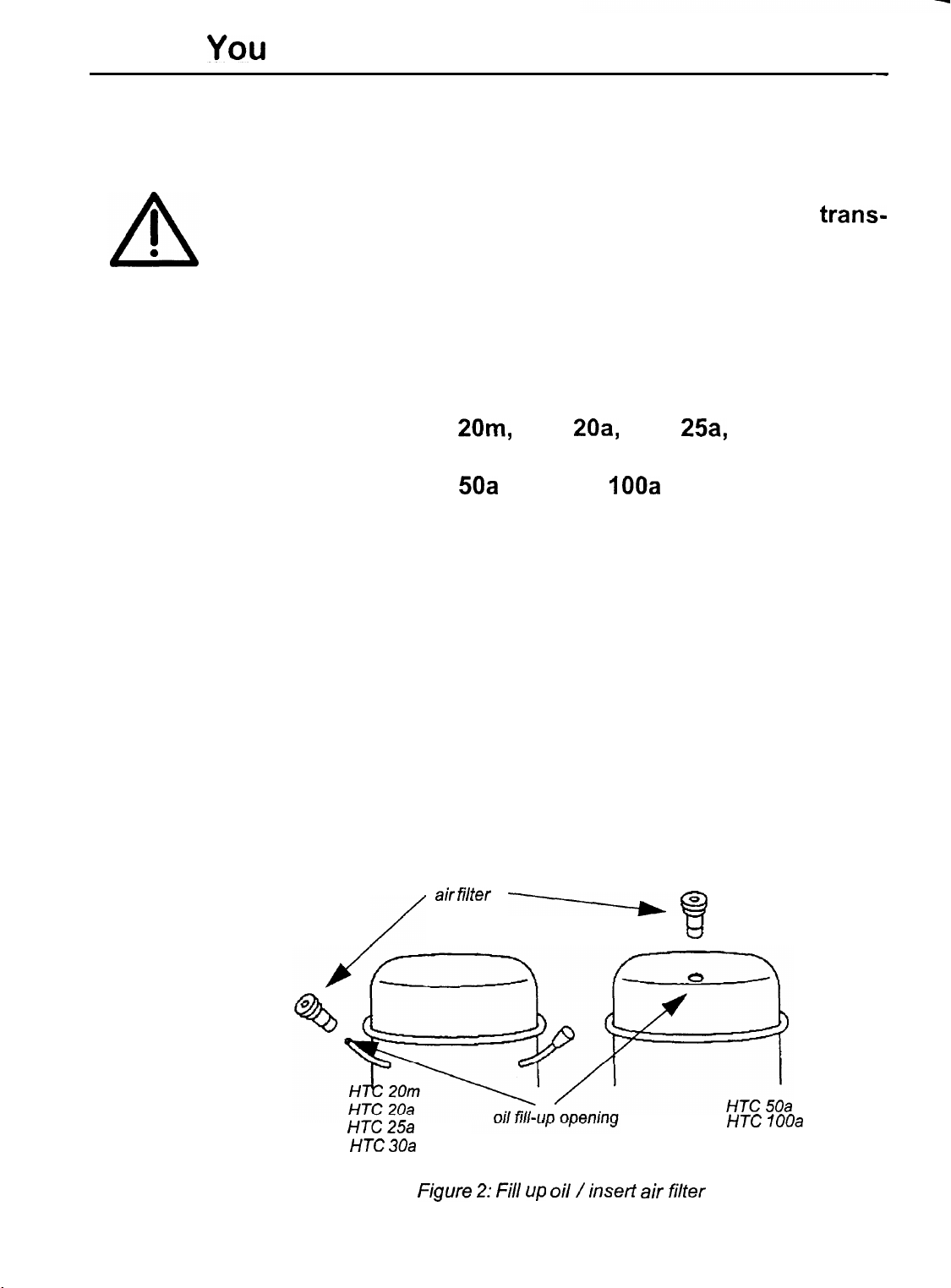

Fill up oil

You

Begin-

-

Caution:

I.

2.

3.

There is no oil in the compressor during

trans-

portation. This avoids oil getting into the com-

pression chambers which would damage the de-

vice. You therefore have to fill up oil before you

put the compressor into operation for the first

time. The device might otherwise be damaged.

Models HTC

20m,

HTC

20a,

HTC

25a,

and HTC 30a

Remove the cap from the intake fitting.

Models HTC

50a

and HTC

IOOa

Remove the cap from the opening in the lid of the motor.

Screw the filler tip (part of delivery package) on the

open oil bottle and cut off the end.

Connect the compressor to the appropriate power

source.

4.

5.

Turn the ON/OFF switch to I (ON) to switch on the com-

pressor.

Attach the oil bottle to the intake fitting or the opening in

the lid of the motor resp. (depending on your model).

air filter

/

HTC 25a

HTC 30a

Figure 2: Fill up oil / insert air filter

-----be

k?

HTC 100a

The motor will now suck in the oil.

Page 11

Operation Manual - ENGLISH

6.

7.

8.

Caution:

Note:

Switch off the motor when about

in.

Check the oil level via the oil-level gauge.

Repeat the above steps if the oil level is not correct yet.

Make sure that the oil level does not exceed the

maximum reading. Drain any excessive oil if it

does; see ,,Drain oil“ on page 12.

It is mandatory to use the compressor oil supplied by

ranty claims.

Keep any remaining oil for later replenishment.

Hansa

exclusively to maintain your war-

2/3

of the oil have run

9.

The compressor is now ready to operate. Make sure that it stays

in its horizontal position because non-compliance may cause oil

to get into the compression chamber which might cause damage.

When filling up is complete, insert the air filter (part of

delivery package) into the intake fitting or the opening

in the lid of the motor (depending on the model you

use), see figure

,,Fill

up oil / insert air filter” on page IO.

Page 12

Before You Begin

Drain oil

Drain oil every time you wish to transport the compressor or if

you filled up too much oil by mistake.

Caution:

1.

2.

3.

It is mandatory to drain off the oil prior to any

transportation or dispatch of the compressor

because non-compliance may cause oil to escape or to get into the compression chamber

which might damage the device.

Unscrew the oil-level gauge.

Let the oil run off into a suitable container.

Screw the oil-level gauge back in and check for safe

and proper seat.

Page 13

INITIAL OPERATION

Operation Manual - ENGLISH

Caution:

1.

Caution:

2.

The motor starts building up the operating pressure which takes

about 40 to 240 seconds, depending on the model you use.

HTC

20a,

Check whether there is enough oil in the

pressor

time.

Verify that there is enough oil in the compressor.

Proceed as described in section

page 10 if there is no or not enough oil in the

compressor.

Set the ON/OFF switch to I (ON).

HTC

before you start the machine for the first

,,Fill

up oil” on

25a,

HTC

30a,

HTC

50a,

HTC

IOOa

com-

These compressors are equipped with an automatic pressure

monitoring feature which will automatically switch off the motor

when it has built up the maximum pressure.

The motor restarts automatically when the pressure drops to

four (or six) bar after air bleeds from the pressure vessel.

HTC 20m

This model activates a safety valve when the pressure has built

up to its maximum of six bar. Any overpressure escapes through

this safety valve producing a soft hissing sound.

Page 14

Initial Operation

Switch off compressors of this type to avoid

their overheating during no-operation intervals.

All compressors are equipped with a safety

valve which must neither be removed nor modified in any way. Have a qualified workshop repair or exchange the safety valve.

I

0

A

Caution:

Setting the operating pressure

Use the pressure controller to set the required operating pressure. Monitor the pressure reading via the pressure gauge.

1.

2.

Pull up the rotary switch.

To increase the pressure

Turn the control button clockwise.

To reduce the pressure

Turn the control button anti-clockwise.

3.

Push the rotary switch back in (down) when you have

set the correct operating pressure.

Figure 3: Setting the operating pressure

Page 15

Motor protection switch

All of the compressors are equipped with a motor protection

switch that avoids damage to the motor by automatically switching it off in instances of overload or overheating.

Proceed as follows if the motor shuts down during normal operation:

Operation Manual - ENGLISH

1.

2.

Set the ON/OFF switch to 0 (OFF) and allow the machine to cool off for about 30 minutes.

Restart the compressor after about 30 minutes.

Switching the compressor off

Switch off the compressor at longer idle periods.

Also switch off the machine when it seems to be

not operating, i.e. when the motor is not running. This situation occurs when the motor has

built-up maximum pressure thus activating the

automatic monitoring device. In this case, the

motor is in stand-by mode which means that it

will restart immediately when the pressure falls

below a specified value.

A

I

0

Caution:

Set the ON/OFF switch to 0 (OFF) to switch off the motor.

Page 16

MAINTENANCE

To extend the life of your compressor, we recommend that you

take the preventive maintenance action below at the suggested

intervals.

Operation Manual - ENGLISH

Weekly

l

2

0

Caution:

Check the oil level

Note:

Check the oil level via the oil-level gauge once every week

(compressor off) and fill up oil if necessary, see

page 10.

Switch on the compressor and remove the air filter from the air

Disconnect the machine

all maintenance work.

Fill up oil while the motor is running.

from the mains prior to

,,Fill

up oil“ on

Monthly

intake fitting or the opening in the lid of the motor (depending on

the model you use). Fill up the required amount of oil. Check the

oil level again via the oil-level gauge. Then insert the air filter in

the relevant opening again.

Visual inspection

Visually inspect the machine once every month taking particu-

larly care to find any loose connectors or screws and verifying

the general condition of the pressure hoses.

Page 17

Page 18

Operation

Draining water from the water trap

Jl/lan.uq! -

ENGLISH

a

2

0

Note:

Drain the condensation water from the water trap once every

month (or more frequently if required).

Turn the rotary button clockwise, push it in and hold it until all

water has been drained off. Turn the rotary button anti-clockwise when there is no more water coming. Make sure that the

tank is under pressure.

Use the appropriate means, e.g. a piece of cloth, to

catch any condensation water escaping.

Figure 5: Drainage of water from the water trap

Page 19

Mainte.nance

_.

Quarterly or six-monthly

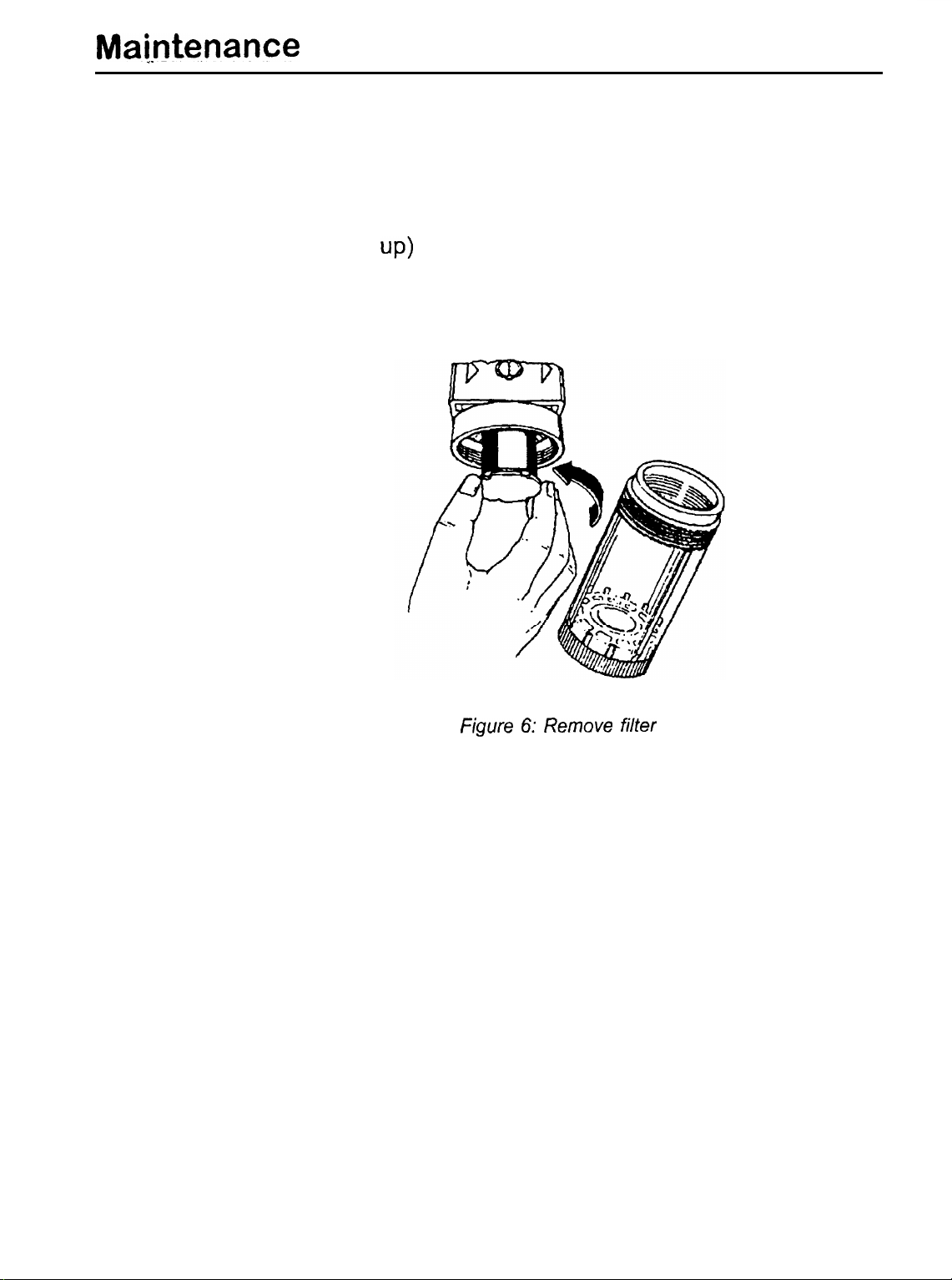

Replace the filter

Replace the filter’every 3 to 6 months (depending on how much

it has clogged

up)

Figure 6: Remove filter

Page 20

FAILURE LIST

Operation Manual - ENGLISH

Caution:

Problem

The motor of the

pressor does not start

com-

Immediately switch off the power supply to the

device if any failures occur.

Have only trained and qualified persons do any

repairs.

Table I: Failure List

Possible Cause

No power

Wire failure or lose

trical

connections

Too much oil

Too much tank pressure,

pressure control switch tank

turned motor off

elec-

Corrective Action

Check fuse and plug

Specialist’s workshop

Drain oil

Let some air out of the

The compressor is

king but builds up no

pressure

The compressor is

king but does not build up

the maximum pressure

The compressor

ches off during operation

wor-

wor-

swit-

Cap not removed from

the intake tube

Air filter clogged up

System leaks

System leaks Check hoses and con-

Wrong pressure control

switch settings

Check valve defect or

blocked

Motor overheated, motor

protection switch actua-

ted

Remove cap

Replace air filter

Check hoses and con-

nectors for leaks

nectars

Check settings, contact

specialist if required

Replace check valve

Switch off compressor,

allow motor to cool off

for leaks

Page 21

Failure List

Table I: Failure List

Problem

The compressor is

ning without any work

being done

The compressor does Pressure control switch

not start when the

sure falls below the

mum or does not stop at

max. pressure

The compressor

heats

run-

pres-

mini-

over-

Possible Cause

System leaks

defect

Oil level not ok

Wrong type of oil

Air filter clogged up

Corrective Action

Check hoses and con-

nectars for leaks

Have specialist replace

the pressure control

switch

Check oil level and fill up

if necessary

Drain oil and replace by

Hansa

sors

Replace air filter

oil for compres-

Note:

Room temperature too

high or not enough air

Compressor overload Check whether the com-

Provide enough fresh air

pressor matches the de-

mands

The above list of possible failures and problems

does not claim to be comprehensive.

Page 22

Operation Manual - ENGLISH

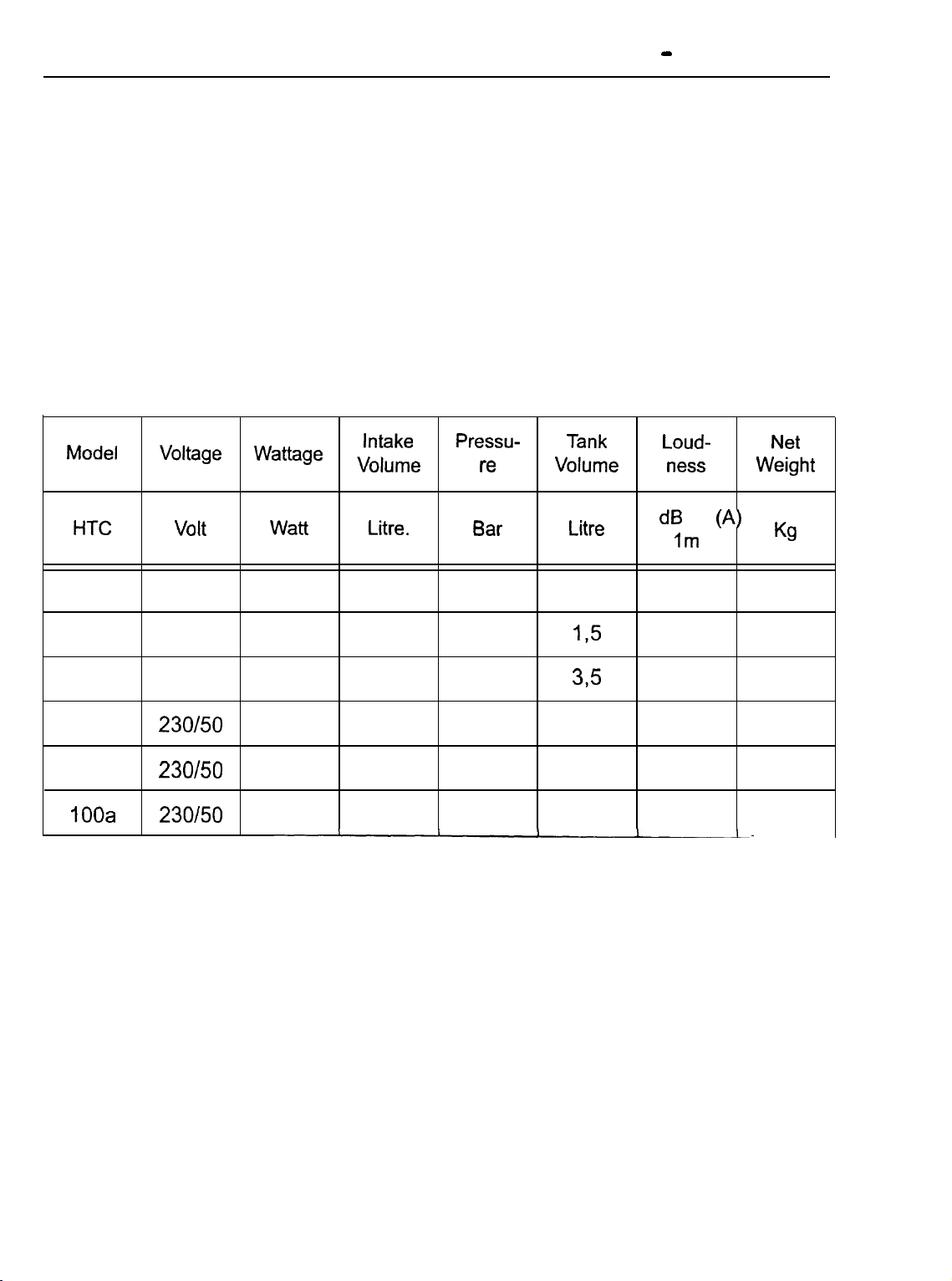

TECHNICAL DATA

Technical compressor data

The table below lists the ratings of the different compressor

types.

Table 2: Technical Data

Model

HTC

20m

20a

25a

30a

50a

IOOa

Voltage

Volt

230150

230150

230150

230/50

230/50

230/50

Wattage

Watt

135

135

135

200

340

680

Intake

Volume

Litre.

20

20

20

30

50

100

Pressu-

t-e

Bar

6

6

6

8

8

8

Tank

Volume

Litre

1

1,5

395

9

15

24

Loud-

ness

dB

Im

38

38

38

40

43

43

tA)

Weight

Net

Kg

12

14

16

18

24

39

Page 23

Technical Data

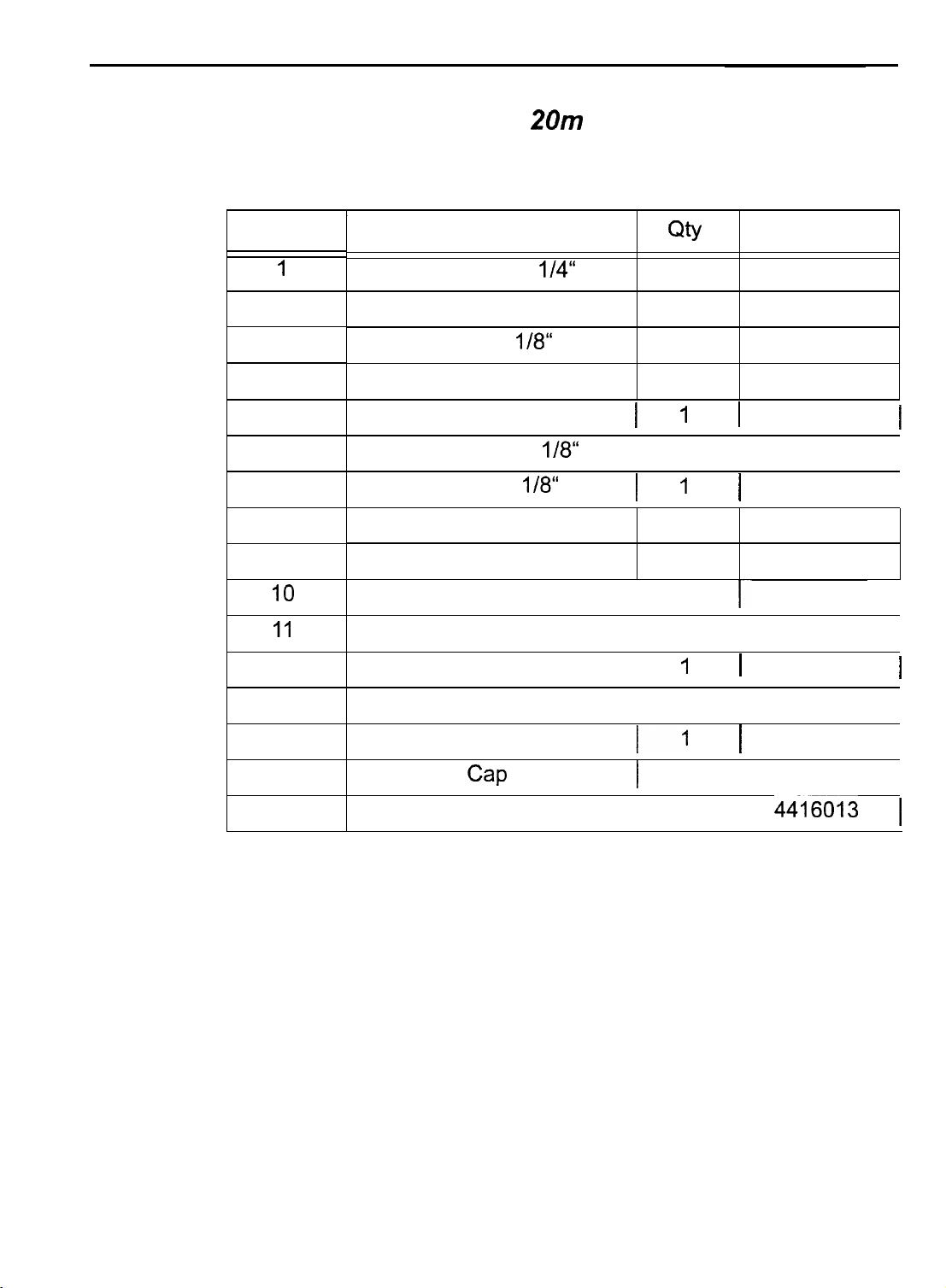

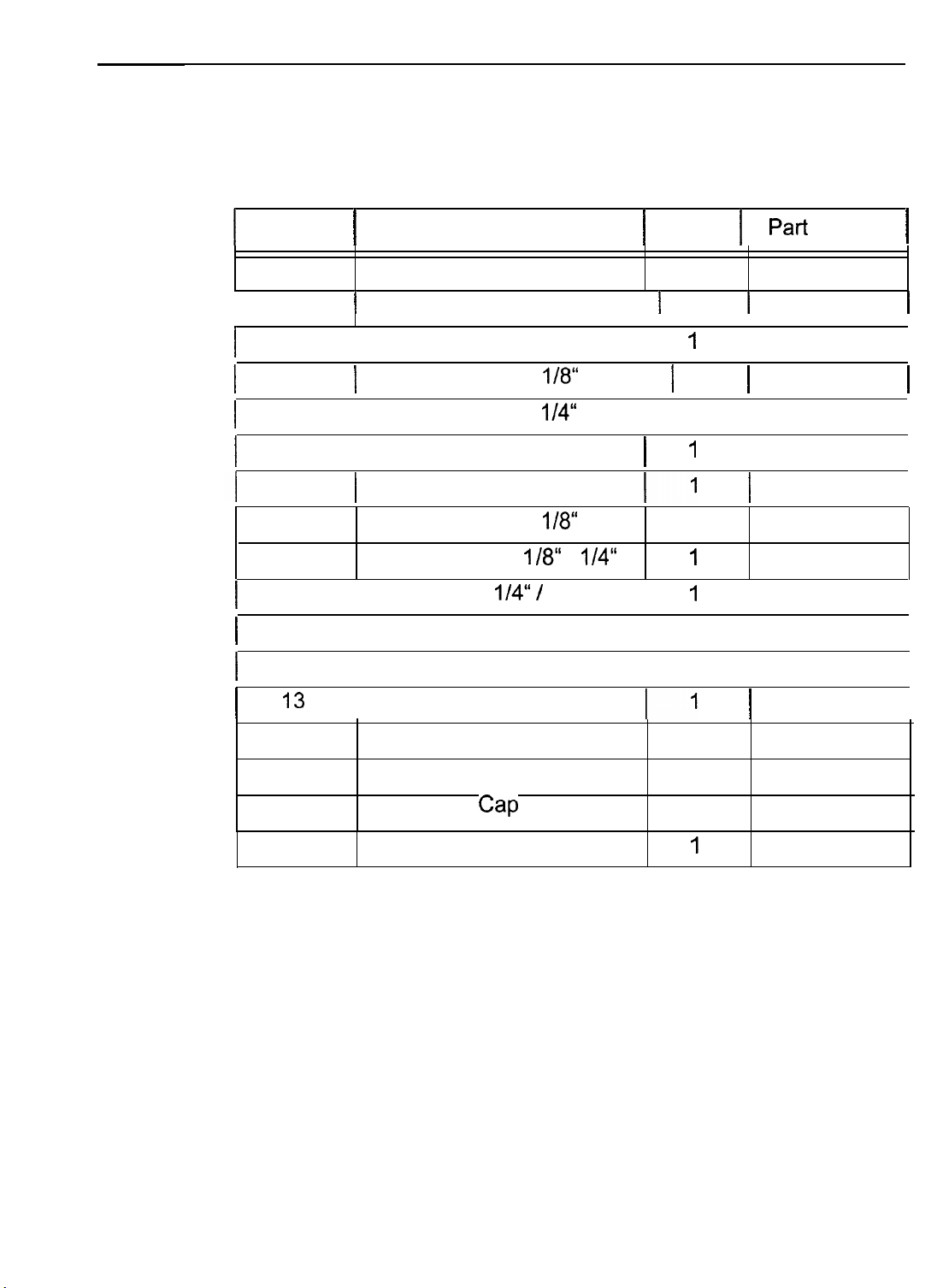

Spare parts list for HTC

Number

1

2

3

4

5

6

7

8

9

10

11

12

I

Double nipple

Pressure controller and filter

Pressure gauge

Pressure hose

Name

Rilsan hose

Clip

Drain plug

Safety valve

ON/OFF switch

Screw for clip

Motor lid clip

Air filter

20m

l/8“

l/8“

l/4“

10 bar

l/8“

Qty

1

1

1

1

I

1

1

I

1

I

1

1

1

I

1

I

I

1

Part No.

4416014

4416073

4416074

4416009

1

4416007

4416006

I

4416015

I

4416008

4416010

4416077

1~

4416012

I

1

4416072

1

I

I

I

I

1

13

14

15

16

Motor

Oil-level gauge

Cap

Motor lid seal

1

I

1

I

1

I

4416001

I

4416071

I

4416016

I

44-16013 1

I

I

I

I

Page 24

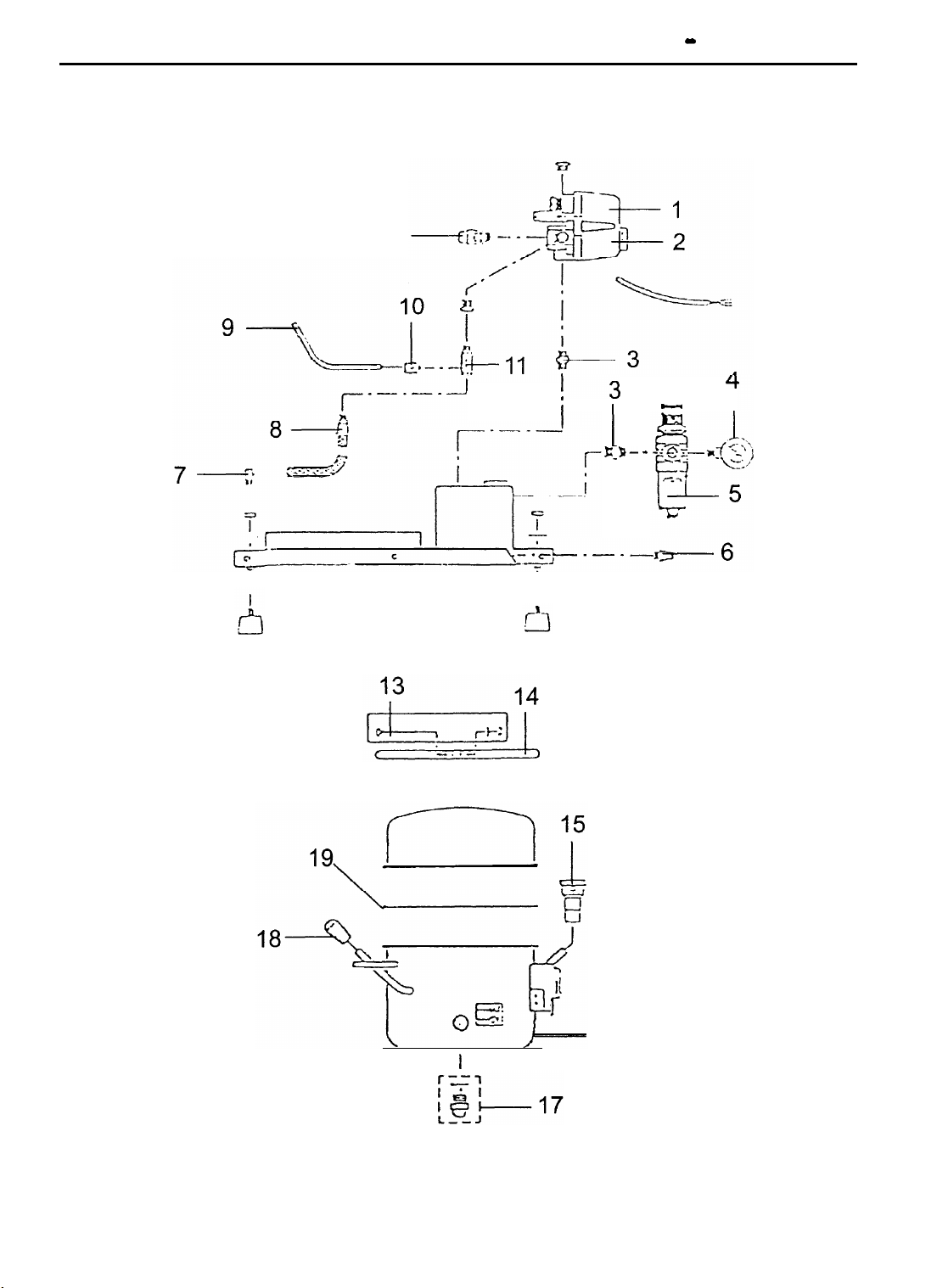

HTC 20 m

Operation Manual - ENGLISH

3

I--

4

fl

5

8

Page 25

Technical Data

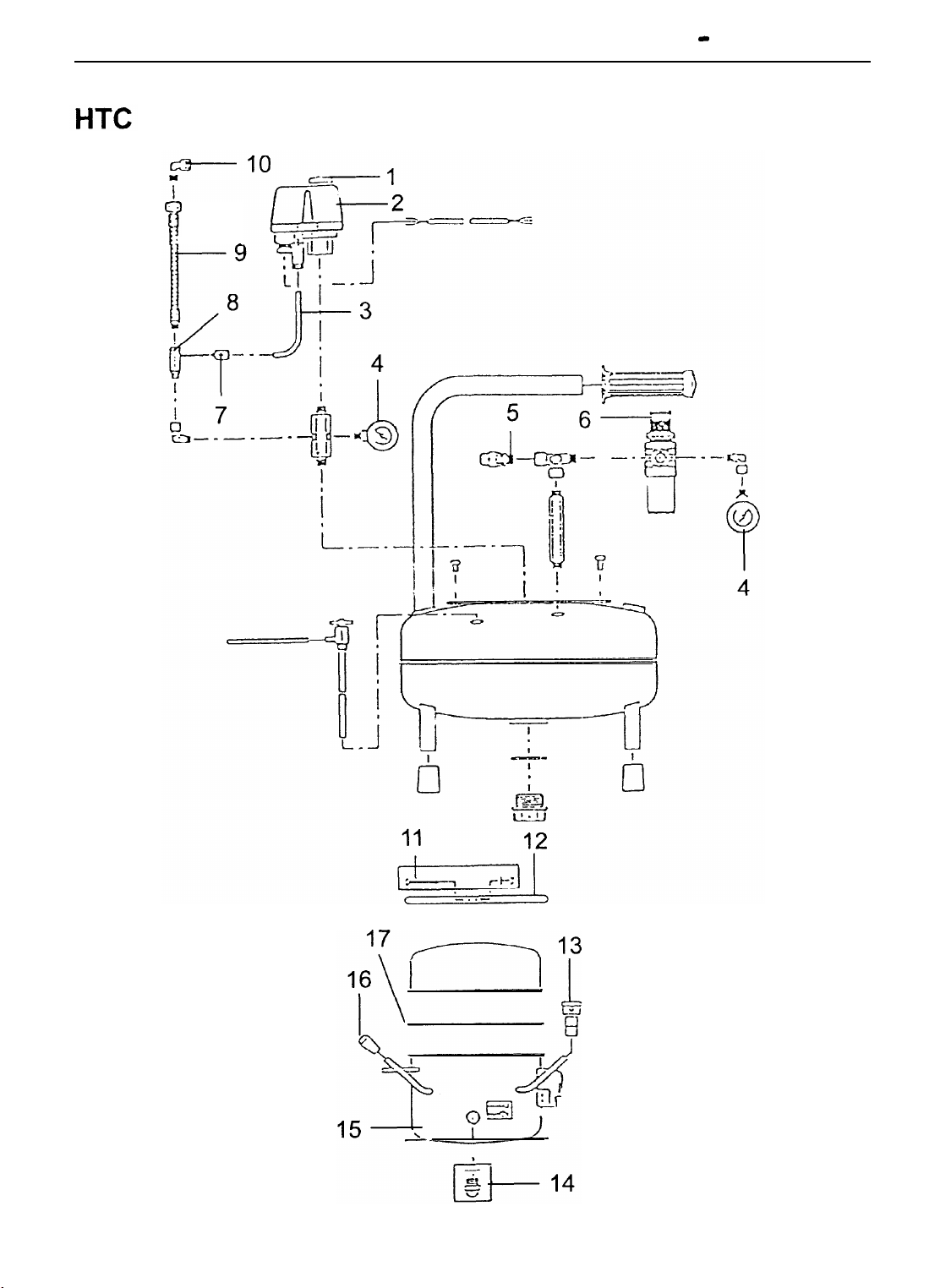

Spare parts list for HTC

Number

I

I

1

2

3

4

5

6

7

8

9

10

Pressure control switch

I

Double nipple

Pressure gauge

Pressure controller and filter

I

Pressure hose

Hose connector M5

Name

ON/OFF switch

Drain plug

Clip

Rilsan hose

20a

l/8“

l/8“

l/4“

10 bar

l/8“

I

I

Qty

1

2

1

1

1

1

1

1

1

Part No.

4416018

I

4416014

4416074

4416073

4416015

4416007

I

4416006

4416019

4416040

I

I

11

12

13

14

15

16

17

18

19

Check valve

Safety valve 114"

Screw for clip

Motor lid clip

Air filter

Motor

Oil-level gauge

Cap

Motor lid seal

118“

1

1

1

1

1

1

1

1

1

4416017

4416079

4416077

4416012

4416072

4416001

4416071

4416016

4416013

Page 26

HTC 20a

Operation Manual - ENGLISH

I2

I3

.

I

I

I

E-E,- -

4

-

I

I

I6

Page 27

Technical Data

Spare parts list for HTC 25a

Number

I

Name

1

2

Pressure control switch

I

Pressure

Pressure controller and filter

ON/OFF switch

Bracket 118“ 118“

gauge

l/8“

10 bar

Drain plug

Bracket

Pressure hose 235 mmm

Rilsan hose

l/4”

l/8“

6.3

QtY

1

I

I

1

1

1

1

1

1

Part No.

4416018

I

1

4416036

4416074

4416073

4416015

4416035

4416038

4416019

I

I

1

I

17

18

19

Oil-level

Motor lid seal

gauge

Cap

1

1

1

4416071

4416016

4416013

Page 28

Operation Manual - ENGLISH

HTC

25a

.-.-r

e-10

.

..-.-. -

7

.

$

I5

Page 29

Technical Data

Spare parts list for HTC 30a

1

Number

1

Name

1

Qty

1 Part

No.

1

1

I

I

2

3

I

4

5

I

6

I

7

8

9

IO

I

II

I

12

I

13

I

14

1

Pressure control switch 1 1

I

1

Pressure gauge

I

Pressure controller and filter

I

I

I

I

I

I

ON/OFF switch

Rilsan hose

Safety vavle

Hose connector M5

Check valve

Pressure hose I

Bracket

Screw for clip

Motor lid clip

Oil-level gauge

l/4“ /

Air filter

l/8”

10 bar 1 2

l/4”

l/8“

/8”

l/4“

6.3

1

4416041

I

I

1

I

I

I

1

I

I

I

1

I

1

I

1

4416039

I

1

4416074

4416079

I

4416073

I

4416040

I

4416017

4416038

4416035

I

4416077

I

4416012

I

4416072

I

4416071

1

I

1

I

I

I

I

I

I

I

15

16

17

Motor

Cap

Motor lid seal

1

1

I

4416030

4416016

4416013

Page 30

30a

c

‘I

I:

Operation Manual - ENGLISH

-

Page 31

Technical Data

Spare parts list for HTC 50a

Number

I

2

I

3

4

5

6

7

9

10

11

12

13

Name

ON/OFF switch

Pressure control switch

I

Pressure

Pressure controller and filter

Pressure hose

gauge

Safety valve

Extension

Check valve

Hose connector

Rilsan hose

Motor lid clip

1/8” IObar

114“

I /4“

118“

Air filter

Plug

l/8“

M5

QtY

I

I

3

2

1

1

1

1

1

1

I

I

Part No.

4416041

I

44 I 6074

4416073

4416079

4416059

4416038

4416017

I

4416040

4416039

4416057

4416072

4416082

I

,

I

14

15

16

17

Oil-level

Motor lid seal

Screw for clip

gauge

Motor

1

I

1

1

4416071

4416050

4416056

4416077

Page 32

HTC 50a

Operation Manual - ENGLISH

~7~kq---,:

16

i

l$--==

! u

I

II

i-l

----------\

..-.-

c

&I2

f

t.

11

13

r-+--‘-l

\

Page 33

Technical Data

Spare parts list for HTC 700a

Number

I

I

1

2

3

4

5

6

7

8

9

IO

11

12

13

Name

Pressure control switch

ON/OFF switch

Safety valve

Pressure gauge

Check valve

I

Pressure hose

Pressure hose

Pressure controller and filter

I

Rilsan hose

Drain plug

Extension

Screw for clip

Motor lid clip

118“

1 Obar

318”

l/8“ l/8“

l/8” 118“

l/4“

l/4“

I

I

Qty

I

1

3

1

1

1

I

I

1

2

1

2

Part No.

4416018

4416079

4416074

4416063

4416019

I

4416062

4416061

4416060

4416059

4416073

4416077

I

4416057

I

I

14

15

16

17

18

Air filter

Plug

Oil-level gauge

Motor

Motor lid seal

2

2

2

2

2

44 16072

4416082

4416071

4416050

4416056

Page 34

TC

Operation Manual - ENGLISH

IOOa

8

12

18,

---------->

;t-rq-c+5

c

-

-is

e-5

r”‘l

13

14

Page 35

Index - ENGLISH

C

compressor

switch off 15

switch on 13

compressor nameplate 4

contents of delivery package 9

E

environmental protection 8

F

failures 21

first start of operation 9

G

guarantee 5

I

initial operation 13

M

machine

check delivery package 9

install 9

unpack 9’

maintenance 17

check oil level 17

drain water from water trap 19

0

oil

drain off 12

fill up 10

operating pressure

set 14

P

preface 3

S

safety instructions 7

spare parts

HTC 20m 24

HTC 20a 26

HTC 25a 28

HTC 30a 30

HTC 50a 32

HTC

supplier’s address 5

IOOa

34

T

technical data 23

transportation 8

lJ

use as intended 3

replace filter 20

visual inspection 17

motor protection switch 15

N

notes of warning and paragraph

formats 4

Loading...

Loading...