Page 1

Instruction Manual

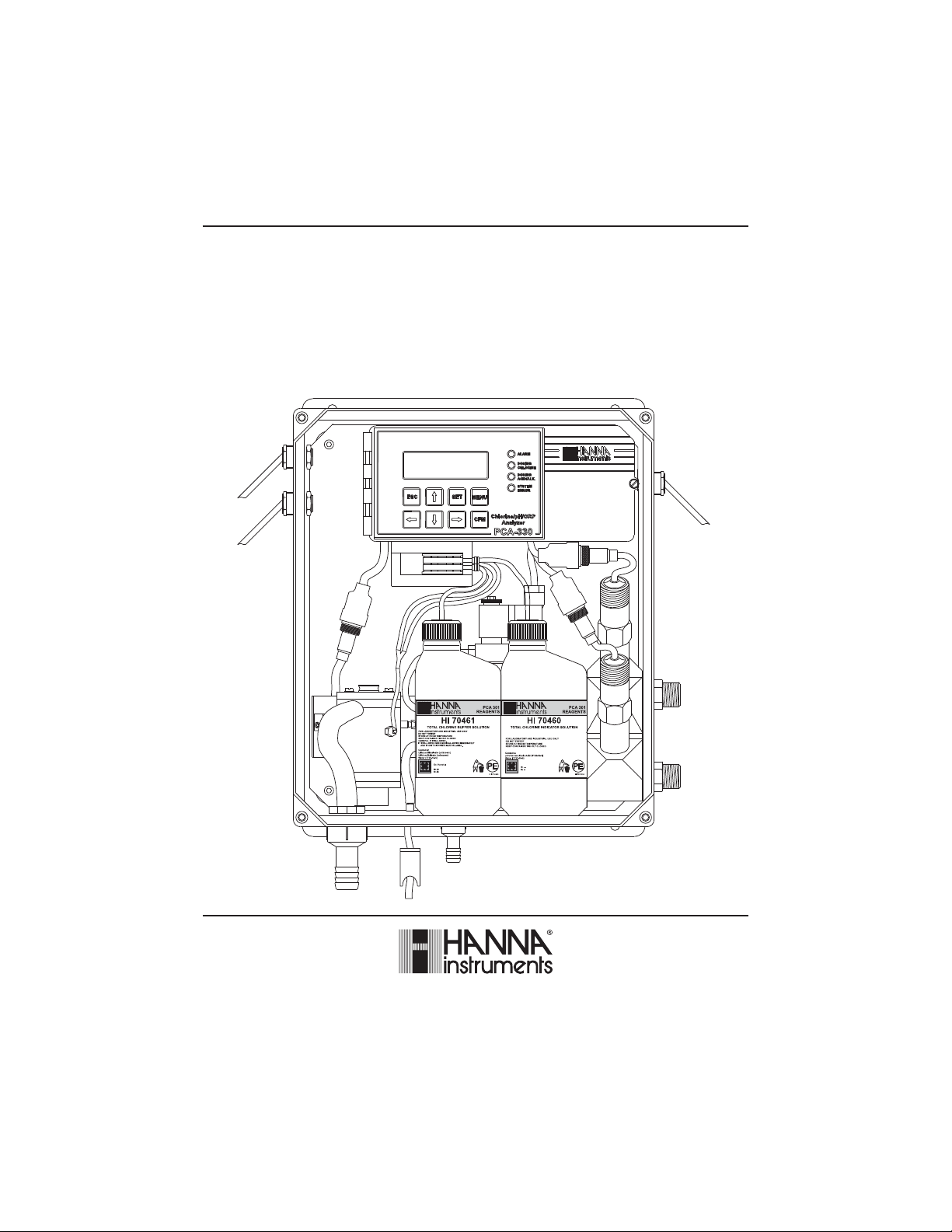

PCA 310, PCA 320, PCA 330

Chlorine, pH, Temperature, ORP

Analyzers

www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna Product.

This instruction manual has been written for the following:

PCA 330 – Chlorine, pH, temperature, ORP analyzer.

PCA 320 – Chlorine, pH, temperature analyzer.

PCA 310 – Chlorine analyzer.

The analyzers have features such as: automatic chlorine measurement, pH, temperature

and ORP measurement, chlorine and pH dosing regulator, selectable sampling

periods, alarm system, data link through GSM network, user friendly interface,

serial communication through RS485, recorder output, 4-20mA dosing output,

Nema 4X enclosure.

The ordering code for chlorine analyzers is:

PCA 3a0-b

a = 1 - Chlorine analyzer

2 - Chlorine, pH and Temperature analyzer

3 - Chlorine, pH, Temperature and ORP analyzer

b = 1 - 115Vac 50-60Hz

2 - 220Vac 50-60Hz

Note: If the instrument is set for free chlorine analysis, the software will report at

startup Free chlorine and if it is set for total chlorine, the software will report at

startup Total chlorine.

Please read this instruction manual carefully before using the instrument. It will provide

you the necessary information for the correct use of the instrument, as well as a

more precise idea of its versatility.

Hanna Instruments reserves the right to modify the design, construction and appearance

of its products without advance notice.

2

Page 3

TABLE OF CONTENTS

PRELIMINARY EXAMINATION........................................6

GENERAL DESCRIPTION..............................................7

MECHANICAL DIMENSIONS........................................9

FUNCTIONAL DESCRIPTION........................................10

DISPLAY, LEDS AND KEYBOARD...................................11

SPECIFICATIONS.......................................................14

OPERATING DESCRIPTION.........................................16

Chlorine measurement ......................................16

Method of analysis ........................................17

pH and temperature measurement ...................17

ORP measurement ........................................17

INITIAL PREPARATION AND INSTALLATION...................18

Installation Personnel......................................18

Location of the Instrument...............................18

Hydraulic Connections....................................18

Installing the Input Filter...................................20

Installing the pH and ORP probes .....................20

Installing the Pump Tubes.................................21

Electrical Connections.....................................22

STARTUP.....................................................................26

USER INTERFACE .......................................................27

Panels organization ........................................ 27

Main panels ............................................... 27

Measure panels ............................................. 28

Messages .................................................... 29

Menu mode ................................................ 29

Password procedure ..................................... 29

Navigating through menu .............................. 30

Modify a parameter ........................................ 30

PROGRAMMING THE ANALYZER .............................. 32

SETTING RESTORE.................... .............................. 32

GENERAL SETTINGS ...............................................33

3

Page 4

Changing the password ................................. 33

Setting the language ..................................... 33

Analyzer serial number and software version ...... 33

Time and date ............................................. 33

WORKING MODE ................................................... 34

Automatic mode .......................................... 34

Standby mode ............................................. 34

Manual mode ............................................. 34

Read on demand ........................................... 35

Direct read ................................................. 35

System error relay..............................................35

CHLORINE SETTINGS .............................................. 36

Reagent changing .......................................... 36

Measure settings .......................................... 37

Measure info ................................................ 37

Analog output ............................................. 37

Chlorine dosing .......................................... 38

Alarms ........................................................ 39

CALIBRATE THE MEASURING CELL ............................. 40

Calibration date and factor ............................ 40

Calibration procedure ..................................... 40

pH SETTINGS (PCA 320, PCA 330) ............................. 41

Measure info............................................... 41

Analog output ............................................. 42

pH dosing .................................................. 42

Alarms ....................................................... 44

pH CALIBRATION (PCA 320, PCA 330) ....................... 44

One point calibration ................................... 45

Two-points calibration ..................................... 46

Process pH calibration .................................... 46

Set default calibration ..................................... 47

TEMPERATURE SETTINGS (PCA 320, PCA 330) ............ 48

Units ......................................................... 48

Measure info .............................................. 48

4

Page 5

Analog output............................................. 48

Alarms ....................................................... 49

ORP SETTINGS (PCA 330) ..........................................50

Measure info .............................................. 50

Analog output ............................................ 50

Alarms ....................................................... 51

ANALOG OUTPUT .................................................. 52

Select the analog output type .......................... 52

Dosing through 4-20 mA output ...................... 52

CALIBRATE THE ANALOG OUTPUT .............................53

Output middle range ........................................54

SYSTEM LOG ..........................................................55

Set log ....................................................... 55

Clear system log .......................................... 55

View log ..................................................... 55

SERIAL COMMUNICATION ........................................ 57

Standard mode ............................................ 57

GSM ..................................................................... 58

GSM mode ................................................ 58

Setting the GSM feature ................................. 58

GSM connection .......................................... 59

Setting SMS feature ......................................... 60

Modem connection.......................................... 64

MAINTENANCE ...................................................... 65

Electrode conditioning and maintenance ........... 66

Changing peristaltic pump tubing .................... 68

Tubing replacement.......................................... 69

Cleaning measurement cell .............................. 69

Cell Cleaning Procedure ................................ 70

ERRORS, ALARMS AND WARNINGS ............................ 71

ACCESORIES ........................................................... 74

5

Page 6

PRELIMINARY EXAMINATION

Remove the analyzer from the packing material and examine

it carefully to make sure that no damage has occurred during

shipping. If there is any noticeable damage, notify your dealer

immediately.

Each analyzer is supplied complete with:

• 2 reagent bottles (1 indicator and 1 buffer solution)

• 2 reagent bottle caps

• 1 DPD compound powder

• tubing

Note: Save all packing materials until you are sure that the instru-

ment functions correctly. Any damaged or defective items must

be returned in their original packing materials together with

the supplied accessories.

WARNING: The PCA 310 - PCA 330 series of Chlorine, pH and ORP

Analyzers are not designed for use with samples that are inflammable or explosive in nature. If any sample solution other

than water is used with these products, test the sample/product compatibility to assure user safety and proper product performance.

Safety Precautions: Please take the time to read the safety precautions

carefully wherever they appear in this manual. They are provided to prevent personal injury and damage to the instrument. This safety information applies to the operators and service personnel and the following two captions are used:

CAUTION

Warning

Note: Because of the inherent dangers in handling chemical samples,

: :

: identifies conditions or practices that could result in dam-

: :

age to the instrument or persons;

::

: identifies conditions or practices that could result in personal

::

injury or loss of life.

standards and reagents, HANNA Instruments strongly recommends the users of this product to review the

Data Sheets and become familiar with safe handling procedures and proper usage prior to handling any chemicals.

Material Safety

6

Page 7

GENERAL DESCRIPTION

The Hanna PCA 310, PCA 320 and PCA 330 series of chlorine, pH, ORP and temperature analyzers are microprocessor

controlled, process analyzers which continuously monitor a

sample stream for chlorine content, pH, ORP and temperature

values.

The PCA 310-330 monitor the free chlorine or total chlorine

in the 0 to 5 mg/L range depending on the factory settings

and used reagents.

In the DPD Colorimetric method, N, N-Diethyl-p-phenylenediamine indicator and a buffer are mixed with the sample.

The resulting chemical reaction causes a magenta color to

form. The color intensity is proportional to the concentration

of chlorine. The color intensity is measured photometrically

(with a light beam and a photodetector) and converted to

chlorine concentration, in mg/L, which is displayed on the

front panel.

Indicator and buffer reagent bottles are placed directly into

the instrument case. With a sampling period of 5 minutes,

reagents need to be replenished about once a month. The

reagent bottles are easily visible through the transparent window allowing the operator to check the reagent levels.

PCA 320 and PCA 330 analyzers HI 1005 probe to continuously measure the pH of the sample stream in the range of 0

to 14 pH. The sample temperature is measured in the 5 to

75°C range. pH and temperature are displayed on the front

panel. pH value is corrected with temperature.

PCA 330 analyzer use HI 2008 platinum ORP electrode to

continuously measure the sample ORP value.

The pH/temperature combined sensor and the ORP sensor

are placed inside the case, directly in the sample stream.

The case of PCA 310-330 analyzers meet NEMA 4X, 12 and

7

Page 8

13 standards. Molded fiberglass polyester has outstanding

chemical and temperature resistance.

The case provides wall mounting capability and door gasket

assures a watertight and dust-tight seal.

The electrical and hydraulic connections are made through

the side of the enclosure.

The front cover is secured with two lockable latches.

Four chlorine level setpoints can be adjusted by the operator:

a proportional dosing setpoint, two alarm setpoints and a

minimum level for dosing.

The proportional dosing factor (1/delta) is user selectable with

a delta between 0.1 and 5 mg/L (ppm). Chlorine dosing system controls a SPST relay.

Each chlorine alarm can be enabled or disabled.

Three pH level setpoints can be adjusted by the operator: a

dosing setpoint and two alarm setpoints. The pH control mode

is user selectable: on/off or proportional dosing.

The proportional dosing factor (1/delta) is user selectable with

a delta between 0.1 and 2 pH . The on/off dosing hysteresis is

user selectable between 0.05 and 2.00 pH. pH dosing system

controls a SPST relay.

Each pH alarm can be enabled or disabled.

For temperature and ORP, two alarm levels can be set by the

user.

Each temperature or ORP alarm can be enabled or disabled.

Alarm condition controls a SPDT relay.

A system error feature provides relay activation to signals need

for operator intervention.

System error condition controls a SPST relay.

Two current outputs of 4-20 or 0-20 mA are available to drive

external devices such as chart recorders.

The analyzer can drive two dosing pumps through the 4-20

mA outputs for chloride and for acid/alkali dosing.

The analog output is fully programmable and could be propor-

tional with chlorine concentration, pH, ORP or temperature

value. The limits of the analog output is selectable for each

parameter.

8

Page 9

The analyzer can store up to 3500 readings (at least 7 days at

254

3

04.8

338.3

3

89.1

374.8

254

393.7

367.1

209.8

83.1

13.32"

10"

12"

15.32"

3.27"

8.26"

14.76"

15.5"

10"

14.45"

FRONT VIEW

SIDE VIEW

REAR VIEW

3 minutes sampling interval), that are available for consulting

or downloading.

The PCA 310-330 analyzers can be monitored or controlled

through RS485 or GSM network connection.

Errors, alarms and warnings are sent through SMS (using GSM

module HI 504900).

The analyzer state can be interrogated by a simple call using

GSM phone.

Time is displayed on the main panel and a time related warning system for “Old calibration” “Reagent expired” and “SIM

expired” is available.

The language for user interface can be easily changed without restarting the analyzer.

MECHANICAL DIMENSIONS

FRONT VIEW

SIDE VIEW

Case dimensions in mm & inches

REAR VIEW

9

Page 10

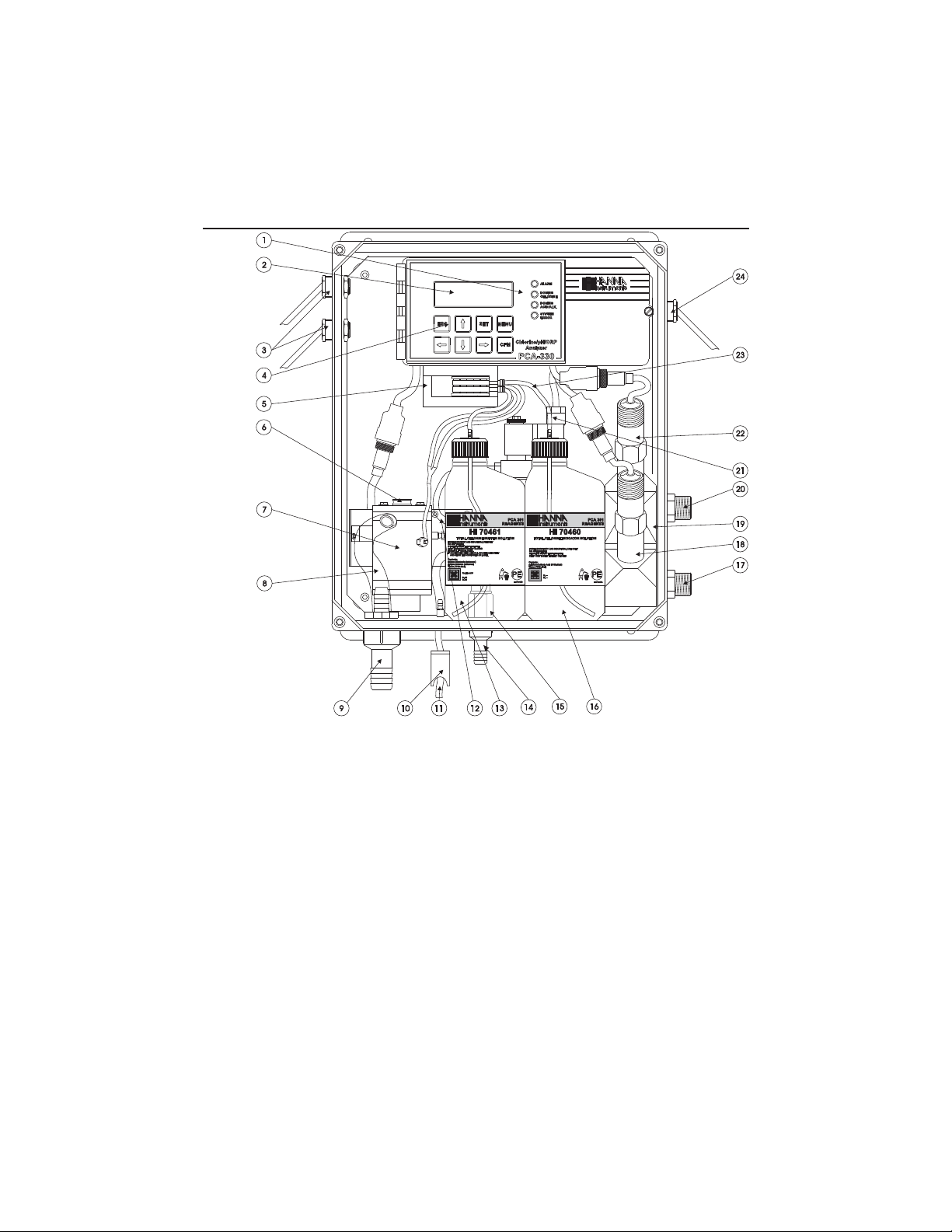

FUNCTIONAL DESCRIPTION

10

1. Alarms, dosing, system error LED’s

2. Character Display

3. Cable glands

4. Keypad

5. Peristaltic Pump

6. Access Point to Cell

7. Measuring Cell

8. Drain Tube

9. Output Port

10. Drain Port Valve

11. Drain Port of Measuring Cell

12. Sample Tubing

13. Buffer Bottle

14. Pressure Regulator Output Port

15. Incoming Pressure Regulator

16. Indicator Bottle

17. Sample Inlet Port

18. pH Electrode (not included)

19. Electrodes Holder

20. Sample Output Port

21. Electrovalve

22. ORP Electrode (not included)

23. Reagent Tubing

24. Line Input

Page 11

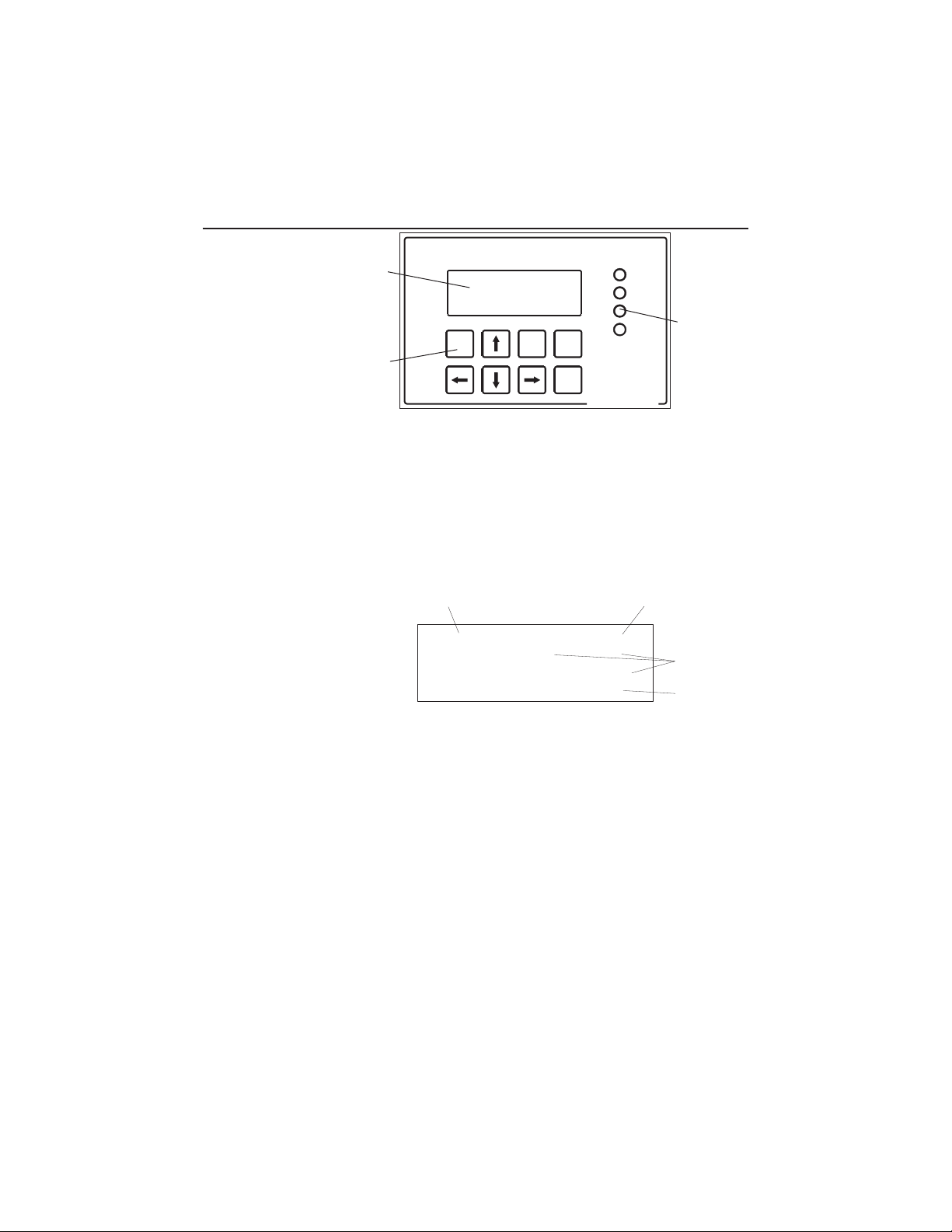

DISPLAY, LEDS AND KEYBOARD

DISPLAY

DISPLAY

KEYPAD

ESC

SET

MENU

CFM

ALARM

DOSING

CHLORINE

DOSING

ACID/ALK.

SYSTEM

ERROR

Chlorine/pH/ORP

Analyzer

PCA-330

The display contains 4 lines with 20 characters on one line.

The information and error messages are clearly displayed in

plain language, without error codes.

The display has back light for better visibility.

The analyzer is in main panels mode when displays a panel

that contains the measured values. Several main panels could

be selected by pressing the up and down arrow keys. The PCA

310 do not have the main mode for the display.

2

3

MANUAL 16:35

1.35 mg/L 2 mV

6.98 pH

pH Out of Range >

1 - measured values

2 - controller status

3 - current time and date

4 - message line

The display is in chlorine, pH, ORP or temperature measuring

panels mode when displays one of those values and secondary information related to it. Several panels with different secondary information could be selected by pressing the up or

down arrow keys.

When the display is in one of the above modes, the measuring units, the current time and the alarm or error status are also

displayed. PCA 310 is always in chlorine measuring panels.

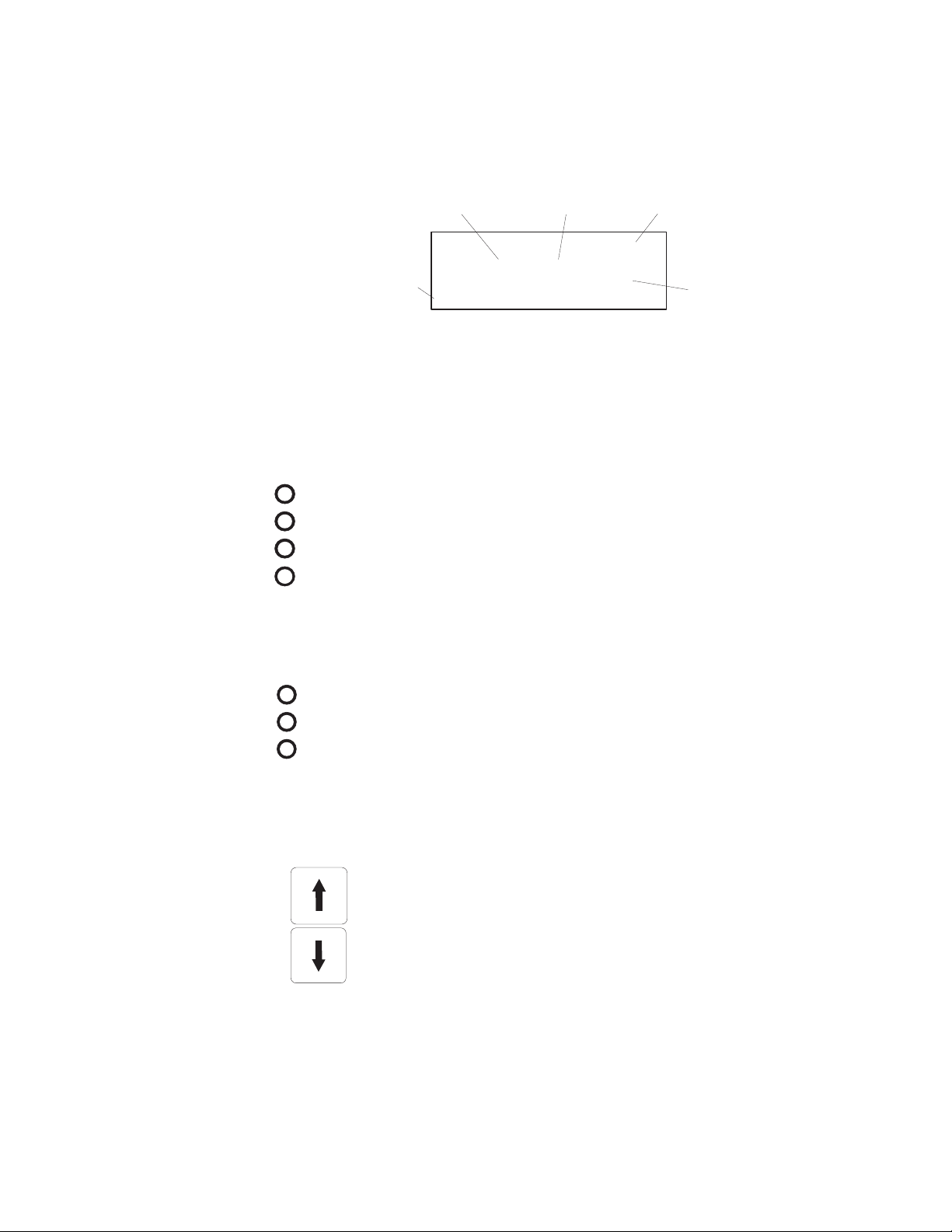

LEDS

1

4

11

Page 12

LEDs

KEYPAD

ALARM

DOSING

CHLORINE

DOSING

ACID/ALK.

SYSTEM

ERROR

ALARM

DOSING

CHLORINE

SYSTEM

ERROR

12

3

16:35

1.35 mg/L Alarm

<Cl Calibration Old>

5

Min:0.00 Max5.00

1 - measured value (chlorine, pH, ORP or temperature)

2 - measurement units (mg/L, pH, mV, °C or °F)

3 - current time in format HH:MM

4 - warnings, alarms and errors, displayed one at a time

5 - secondary information.

Three or four LEDs are present on the front panel:

ALARM LED (red) , signals the presence of at least one alarm

and the closing of the Alarm relay. When the alarm is

present, the LED blinks. When the analyzer is in

MANUAL mode, the LED is on but not blinking.

DOSING CHLORINE LED (green), signals the closing of the

chlorine dosing relay. When dosing stops, the LED is

turned off.

DOSING ACID/ALK. LED (green), signals the closing of the

acid/alkali dosing relay. When dosing stops, the LED

is turned off (PCA 320 and PCA 330 only).

SYSTEM ERROR LED (red), signals the presence of an error

and the closing of the System error relay. When the

error is present, the LED blinks. When in STANDBY

mode, the led is on but not blinking.

For PCA 310 the system error LED is moved in the dosing

ACID/ALK. LED position.

The keypad has 8 keys with the following signification:

4

12

UP and DOWN ARROWS

• select the main display appearance,

• select the menu,

• select an item from a list

• edit values.

Page 13

LEFT and RIGHT ARROWS

• select an error message,

• select an item to edit or

• select the current digit for editing.

MENU

CFM

SET

ESC

MENU enter in menu mode.

CFM confirm the selected menu and edited values.

SET starts editing the selected item.

ESC

• return to the previous menu,

• exit from operation without saving.

13

Page 14

SPECIFICATIONS

egnaRL/gm00.5ot00.0

noituloseRL/gm10.0

)sledomllA(GNISODDNATNEMERUSAEMENIROLHC

ycaruccAretaergsirevehcihwL/

noitaivedCMElacipyTL/gm50.0±

noitarbilaCtniop1

levelelbatcetedmuminiML/gm50.0

etargnilpmaSsetuni

egasoDtuptuoAm02-4royalerlanoitroporP

atleDL/gm5ot1.0elbatceles

EMHp

egnaRHp00.41ot00.0

noituloseRHp10.0

ycaruccAHp50.0±

noitaivedCMElacipyTHp2.0±

noitarbilaCnoitarbilacenilni

etargnisoDsdnoces021ot3

egasoDtuptuoAm02-4royaler,lanoitroporproffO/nO

m09ot3

gm50.0±ro%8±

)033ACPdna023ACP(GNISODDNATNEMERUSA

rostniop2;1

atleDHp2ot1.0elbatceles

s

iseretsyHHp2ot50.0elbatceles

egnaRVm0002ot0

noituloseRVm1

ycaruccAVm1±

pyTVm01±

14

)033ACP(TNEMERUSAEMPRO

noitaivedCMElaci

Page 15

egnaR)F°761ot14(C°0.57ot0.5

noituloseRC°1.0

ycaruccAC°5.0±

)033ACPdna023ACP(TNEMERUSAEMERUTAREPMET

CMElacipyTC°5.0±

et

arduaBspb0069;0084;0042;0021

yalpsiDsretcarahc02xsenil4DCLretcarahc

segaugnaLhcnerF,hsinapS,nailatI,hsilgn

goLsdrocergol0053

mralaMSGSMSgninraw,SMSofni,SMSmrala,srebmun2

yalermralAV032A5TDPS

syalergnisoDV032A5TSPS

noitaived

tuptuoredroceRAm02-0,Am02-4

noitacinummoclaireSdetarapescinavlag,584SR

y

alerrorremetsySV032A5TSPS

erusserptelnielpmaSrab4ot70.0

etarwolfelpmaSnim/Lm003ot001

erutarepmetelpmaSCº04ot

)sledomllA(SREHTO

E

5

telnielpmaSgnittifTPNelam)"2/1(mm21

teltuoelpmaSgnittifTPNelam)"2/1(mm21

noitcennocniarDbrab)"8/3(mm01

ebo

rppmet/HpssecorP5001IH

eborpPROssecorP8002IH

stnemeriuqerrewoPAV02

esaCX4-AMEN

15

Page 16

OPERATING DESCRIPTION

CHLORINE MEASUREMENT

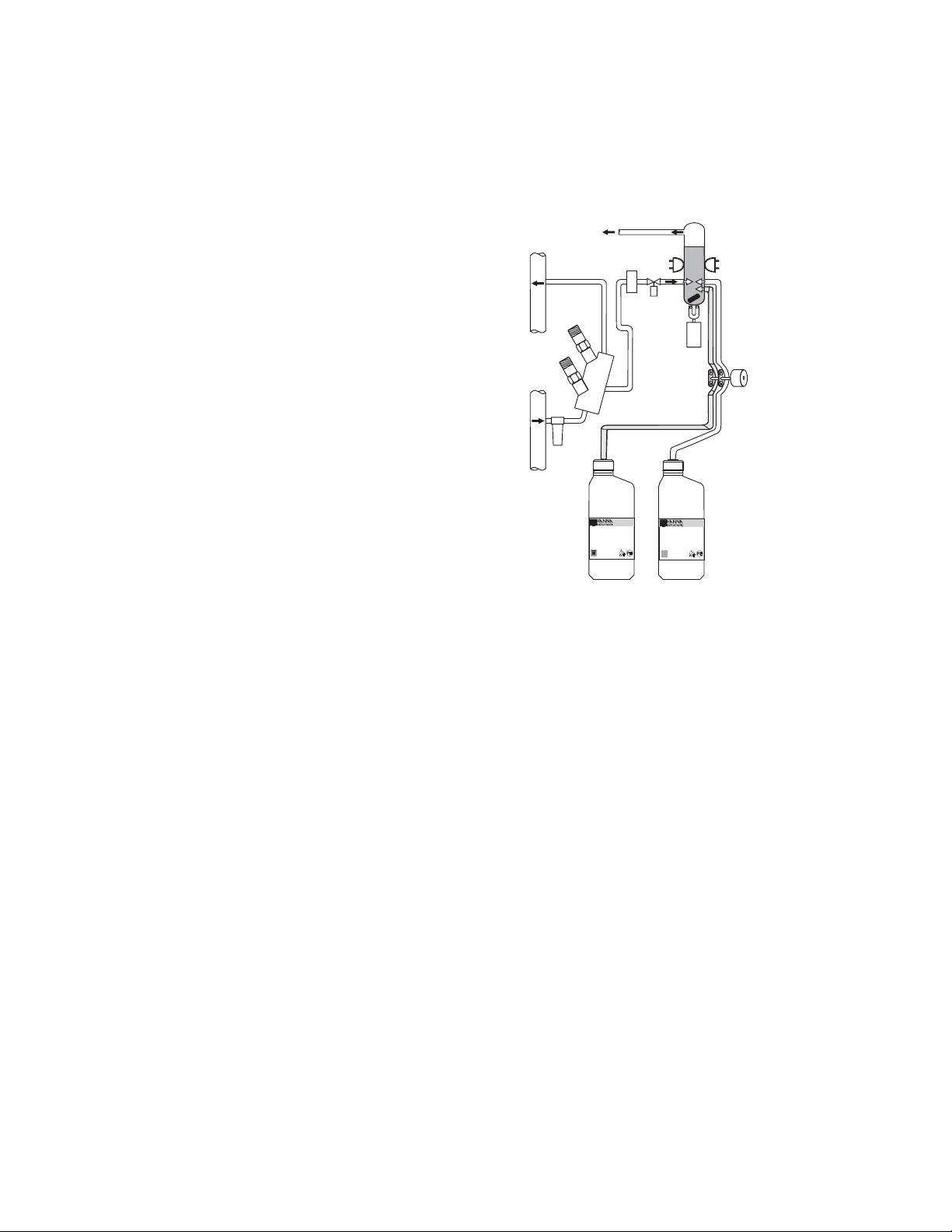

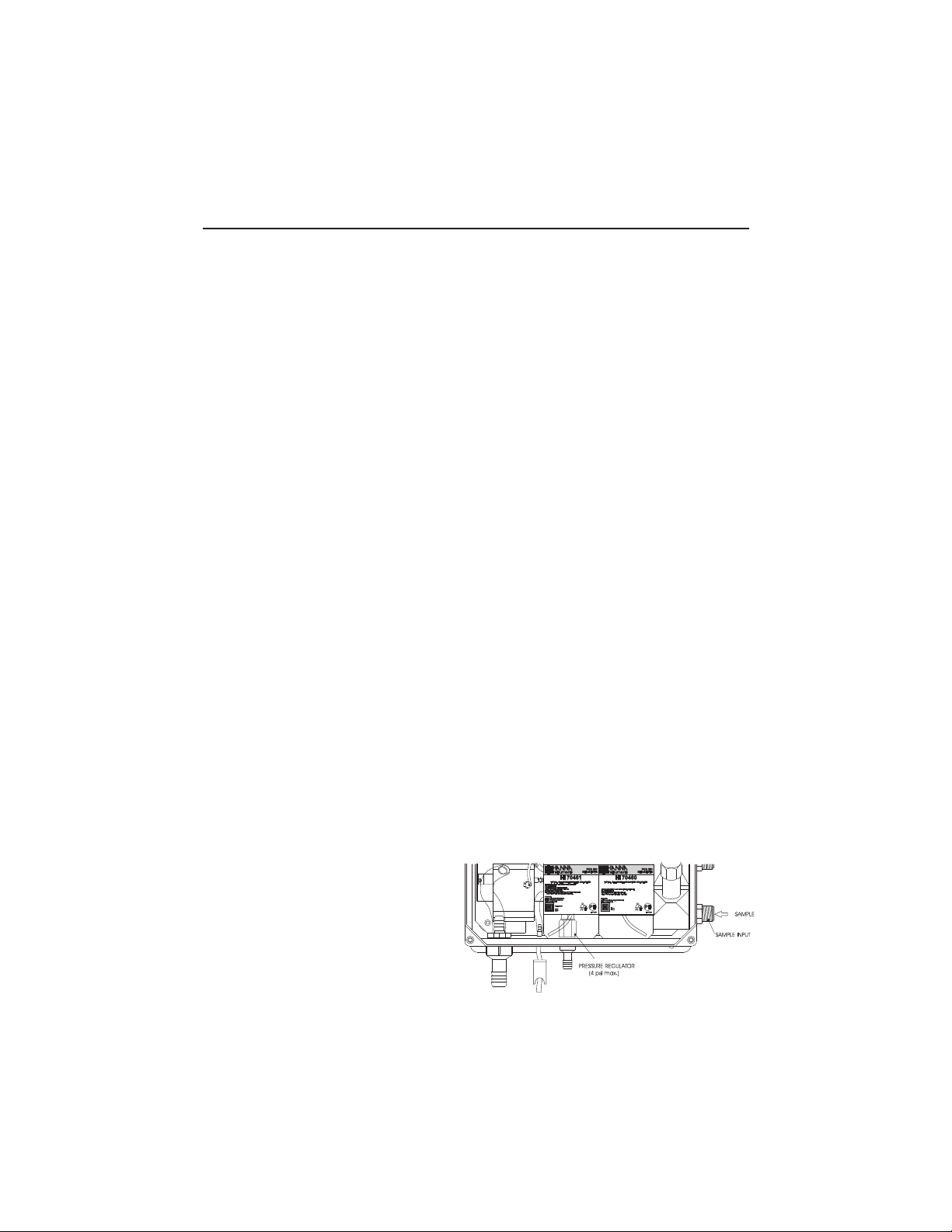

Referring to the drawing on page 10 and the Fluidic Diagram

on page 17, the Sample Line is connected to the instrument at

the Sample Port (#17); an internal Regulator (#15) reduces

the inlet pressure from a maximum of 4 bar (57.2 psi) down to

1 bar (14.3 psi); from the Regulator a nylon tube is connected

to the input of the Electrovalve (#21). The output of the valve

goes to the Drain Port (#11) and then to the Measuring Cell

(#7). An optional Filter can be installed to the sample port if

the stream is excessively turbid.

The sample coming from the line normally flows through the

Measuring Cell (#7). It goes out from the Measuring Cell

through the Drain Tube (#8) and the Output Port (#9).

The Measuring Cell is accessible from the port placed on the

top (#6) for speedy cleaning and maintenance.

During the 100 seconds preceding the sampling, the analyzer solenoid input valve is open to allow sample flow to flush

the colorimeter cell. Every 3 to 90 minutes (user selectable),

the electrovalve closes stopping the sample flow and leaving

the sample cell full of fresh sample. Cell volume is controlled

by an overflow gateway.

As the sample inlet electrovalve closes, a series of measurements (with LED on and off) of the unreacted sample is taken

to determine an average blank level prior to reagent addition.

The measurement of sample blank signal permits compensation for any turbidity or natural color, and provides the zero

reference point for the measurement.

The two channel Peristaltic Pump (#5) starts rotating causing

a precise quantity of buffer and indicator (#13 and #16) to

enter the colorimeter sample cell. Here a magnetically coupled

stirrer mixes the reagents with the sample.

After a delay for the color development, a series of measurements (with LED on and off) are taken (sample level) to determine an average chlorine concentration measurement. The

reacted sample signal is then measured and displayed.

This sequence is repeated every 3 to 90 minutes (user-selectable).

16

Page 17

METHOD OF ANALYSIS

Free available

chlorine oxidizes

the DPD indicator

reagent at a pH

between 5.5 and

6.0 to form a magenta-colored

compound. The

intensity of the resulting color is

proportional to

the concentration

of chlorine in the

sample. The purpose of the buffer

solution is to

maintain the

proper pH.

To measure total

residual chlorine

(free available

chlorine plus combined chlorine) the PCA adds potassium iodide. The chloramines in the sample cause iodide ions to become iodine which

then act with free chlorine to oxidize the DPD indicator. After

the chemical reaction is complete, the optical signal at 555

nm is compared to the signal measured through the sample

(before the reagents were added). From these measurements

chlorine concentration is calculated.

pH AND TEMPERATURE MEASUREMENT

The HI 1005 pH/temperature probe provides at the out port

a potential proportional with the pH. The temperature is measured with PT100 platinum sensor.

For increased accuracy the pH is corrected with temperature

and with the calibration coefficients. Up to 2 buffers can be

used for calibration.

The temperature can be displayed in °C or °F.

The probe can withstand pressure up to 6 bar (87 psi).

ORP MEASUREMENT

The HI 2008 probe provides at the out port a potential propor-

tional with the ORP value. The value is directly displayed in mV.

The probe can withstand pressure up to 6 bar (87 psi).

SAMPLE

OUTLET

SAMPLE

INLET

ORPprobe

PHprobe

FIL

TRAP

(OPTIONAL)

T

O DRAIN

PROBE

HOLDER

TER

HI 70461

TOTALCHLORINEBUFFER SOLUTION

FORLABORATORYANDINDUSTRIAL USEONLY

DONOTFREEZE

STOREATROOMTEMPERATURE

KEEPCONTAINERTIGHTLYCLOSED

HARMFULIFSWALLOWED.

IFSWALLOWEDSEEKMEDICAL ADVICEIMMEDIATELY

ANDSHOWTHISCONTAINER ORLABEL.

Contents:

LithiumBimaleate(unknown)

LithiumMaleate(unknown)

Water(7732-18-5)

Xn:Harmful

R:22

S:46

PRESSURE

OR

REGULAT

REAGENT

BOTTLES

PCA301

REAGENTS

ETICPCA30B

SOLENOID

SAMPLE

VVE

AL

SAMPLEOUTLET

DETECT

TOTALCHLORINEINDICATOR SOLUTION

FORLABORATORYANDINDUSTRIAL USEONLY

DONOTFREEZE

STOREATROOMTEMPERATURE

KEEPCONTAINERTIGHTLYCLOSED

Contents:

p-ToluenesulfonicAcid(6192-52-5)

Water(7732-18-5)

R:-S:--

OR

STIR

BAR

MAGNET

HI 70460

MOT

DC

PUMP

ROLLERS

PCA301

REAGENTS

LED

OR

OR

MOT

&REDUCER

ETICPCA30A

17

Page 18

INITIAL PREPARATION AND INSTALLATION

INSTALLATION PERSONNEL

Installation of the PCA 310-330 Chlorine, pH, ORP and

temperature analyzers should be undertaken by persons with

technical knowledge of the dangers associated with chemical

exposure and electrical shock.

Hanna Instruments assumes that persons performing the installation tasks are aware of the appropriate safety procedures.

CAUTION:Review the Material Safety Data Sheets (MSDS) before han-

dling the supplied chemical reagents.

LOCATION OF THE INSTRUMENT

Analyzer Location

Locate the analyzer as close as is reasonably possible to the

point where the sample is withdrawn from the product stream

(referred to as the sampling point).

The instrument should be mounted indoors, out of direct sunlight. Instrument operating temperature is 5 to 40°C (41 to 104°F).

Sampling Point Location

Locate the sampling point to obtain a truly representative sample

from the product stream. For example, be sure the sampling

point is well downstream from a Chlorine and acid / alkali

feed. This assures that adequate mixing and reaction of the

Chlorine and acid / alkali before a sample is extracted.

HYDRAULIC CONNECTIONS

Note: Hydraulic connections should be installed only by qualified

personnel to assure conformity to applicable plumbing codes.

Sample Line Installation

Direct routing of sample lines is recommended.

If the large process pipes are horizontal, taps should be in-

serted vertically in the middle of the pipe to avoid pulling

sediment from

the bottom or

air bubbles

from the top

of the pipe

into the sample line.

18

Page 19

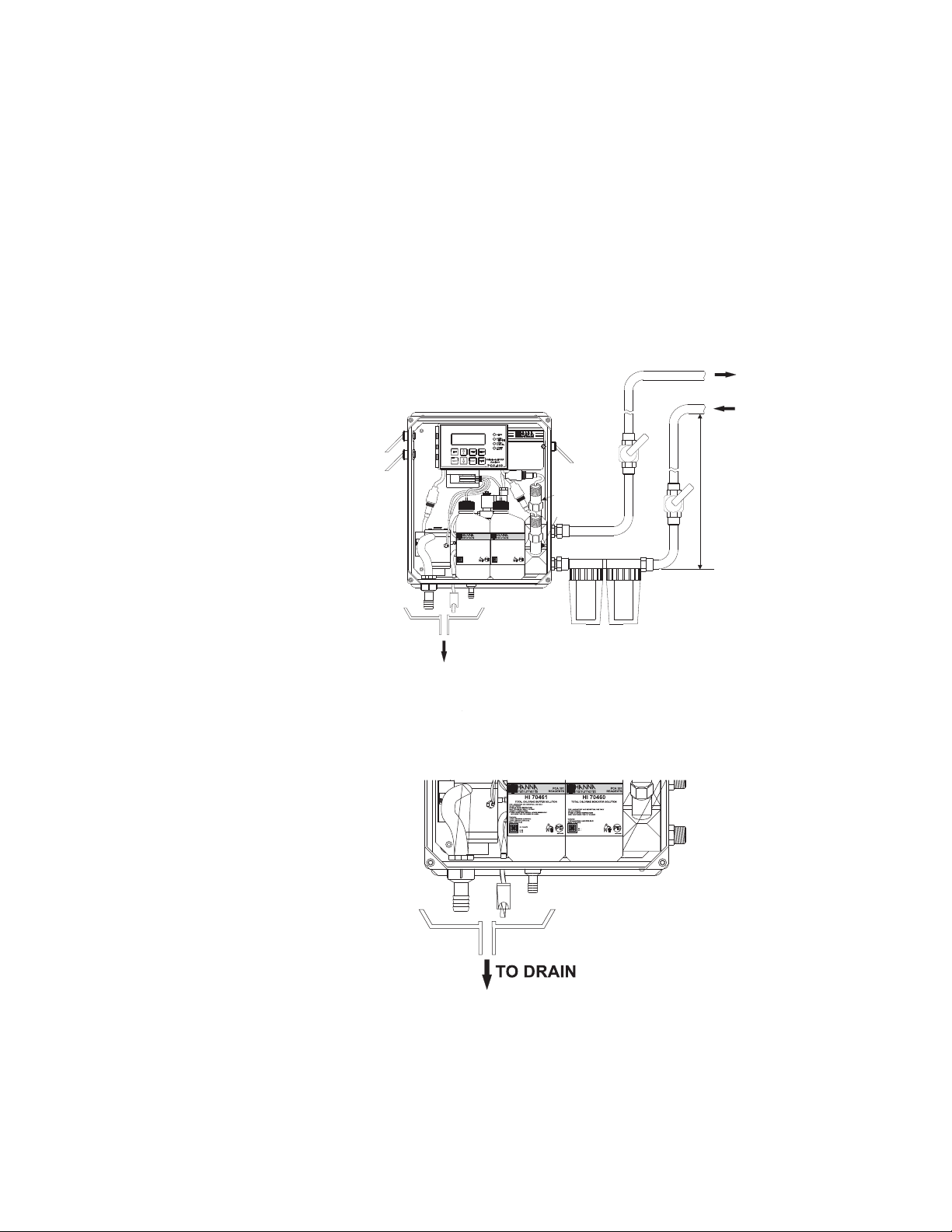

A 1/2 BSP sample input fitting allows direct connection to the

optional input filter.

Sample line pressure should be between 0.07 and 4 bar (1

and 57.2 psi) with an ideal pressure of 0.7 bar (10 psi).

It is recommended to assure that the water inlet come at 1 m

above the instrument sample input pitting. For maintenance

issues is also recommended to install valves on both sampling pipes.

WATER OUTLET

WATER INLET

Drain Line Installation

The drain hose fitting is a 20 mm (3/4”) hose barb on the

bottom of the instrument enclosure. An air gap between the end

of the drain hose and the drain is recommended to prevent any

back flow into the instrument in the event of drain blockage.

PCA301

REAGENTS

HI70461

TOTALCHLORINEBUFFERSOLUTION

FORLABORATORYANDINDUSTRIALUSE ONLY

DONOTFREEZE

STOREATROOMTEMPERATURE

KEEPCONTAINERTIGHTLYCLOSED

HARMFULIFSWALLOWED.

IFSWALLOWEDSEEKMEDICALADVICE IMMEDIATELY

ANDSHOWTHISCONTAINEROR LABEL.

Contents:

LithiumBimaleate(unknown)

LithiumMaleate(unknown)

Water(7732-18-5)

Xn:Harmful

R:22

S:46

ETICPCA30B

TO DRAIN

HI70460

TOTALCHLORINEINDICATORSOLUTION

FORLABORATORYANDINDUSTRIALUSE ONLY

DONOTFREEZE

STOREATROOMTEMPERATURE

KEEPCONTAINERTIGHTLYCLOSED

Contents:

p-ToluenesulfonicAcid(6192-52-5)

Water(7732-18-5)

R:-S:--

ORP probe

MIN.

1m

PH probe

PCA301

REAGENTS

ETICPCA30A

FILTER

19

Page 20

Return Line Installation

The return hose fitting is a 12 mm (1/2”) hose barb on the

bottom of the regulator output port and should always be

connected even when pressure is below 1 bar.

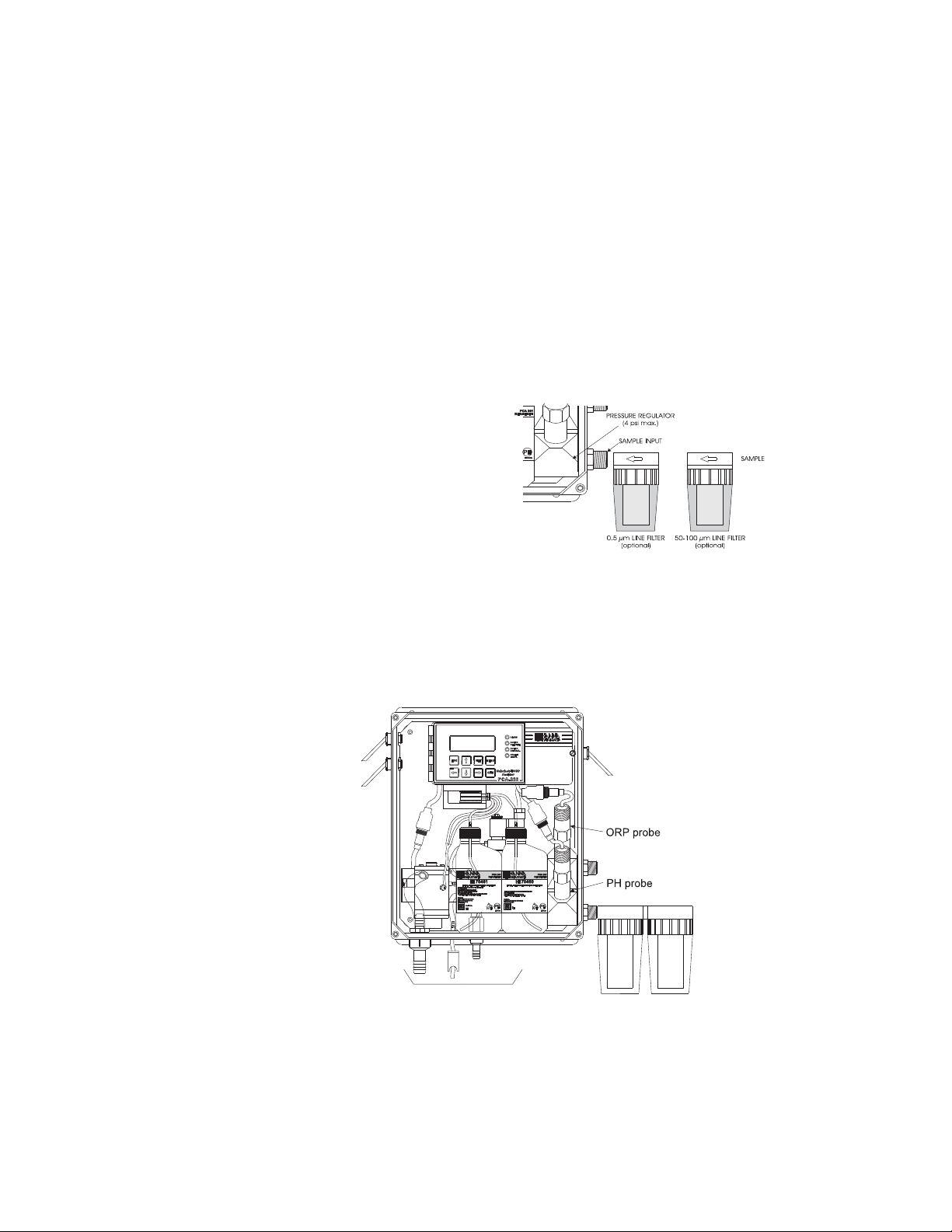

INSTALLING THE INPUT FILTER

In order to ensure maximum accuracy of measurements, it is

recommended to have always clear sample, with suspended

particles smaller than 0.5 μm. This can be achieved by installing two filters before the sample input.

The type of filters depends on the quality of

the water: the first filter

should have 50-100

μm pore size, whereas

in any case the second

filter, the one closer to

the analyzer, has to be

0.5 μm.

For correct installing procedure and maintenance, see the

instructions of filters.

INSTALLING THE pH AND ORP PROBES

To mount the pH and ORP probes, first tunr off the analyzer.

Unscrew the closing caps from the electrode holder and remove

20

Page 21

the protective cap from electrodes and electrodes connectors.

From Buffer Bottle

From Indicator Bottle

To "Y" Connector

and Measuring Cell

To "Y" Connector

and

Measuring Cell

Screw the pH probe (

HI 2008HI 2008

(

HI 2008) in the higher position and assure that no leakage occurs.

HI 2008HI 2008

Only after the probe is in final position connect the probe to the

dedicated connector. Lock the connector with the built in nut.

Warning

::

: Never connect or disconnect the probes when the analyzer is

::

powered on.

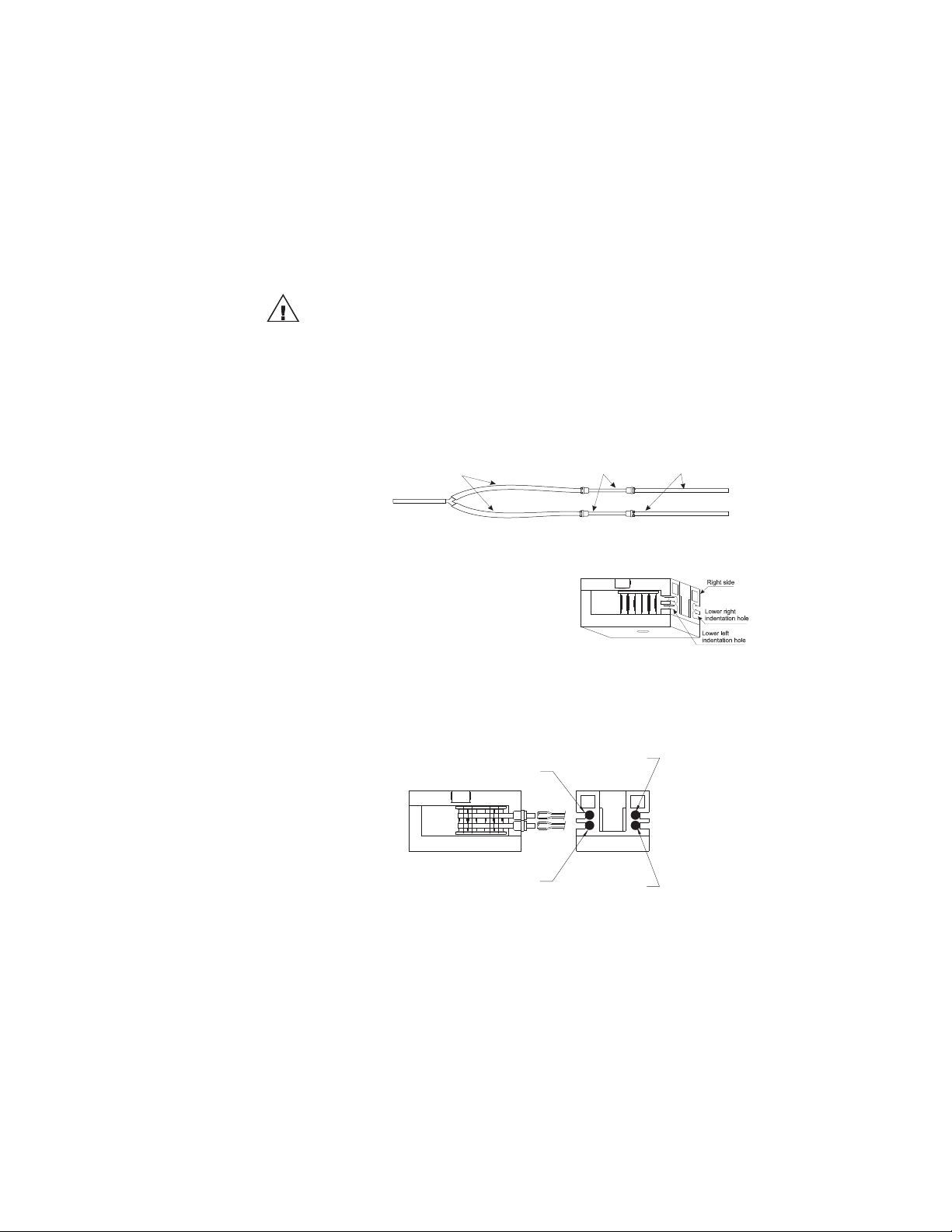

INSTALLING THE PUMP TUBES

Locate the analyzer reagent tubes in the accessory kit. Each

tube is composed of three sections. The sections are joined

together by plastic connectors with plastic collars at the ends

of the center section.

Locate the peristaltic pump.

Feed one tube from the shorter

end section behind the pump

rollers from the right side of the

pump. Seat the plastic collar at

the right end of the center section

of tubing into the lower right indentation hole of the pump face.

Grasp the other plastic collar and pull, stretching the center

section, and place the grommet in the lower left indentation

hole.

HI 1005HI 1005

HI 1005) in the lower position and the ORP probe

HI 1005HI 1005

HI 70479

From Indicator Bottle

HI 70474 or HI 70475

To "Y" Connector

and Measuring Cell

HI 70473

Repeat this process with the second pump tube, placing it in

the upper indentation holes.

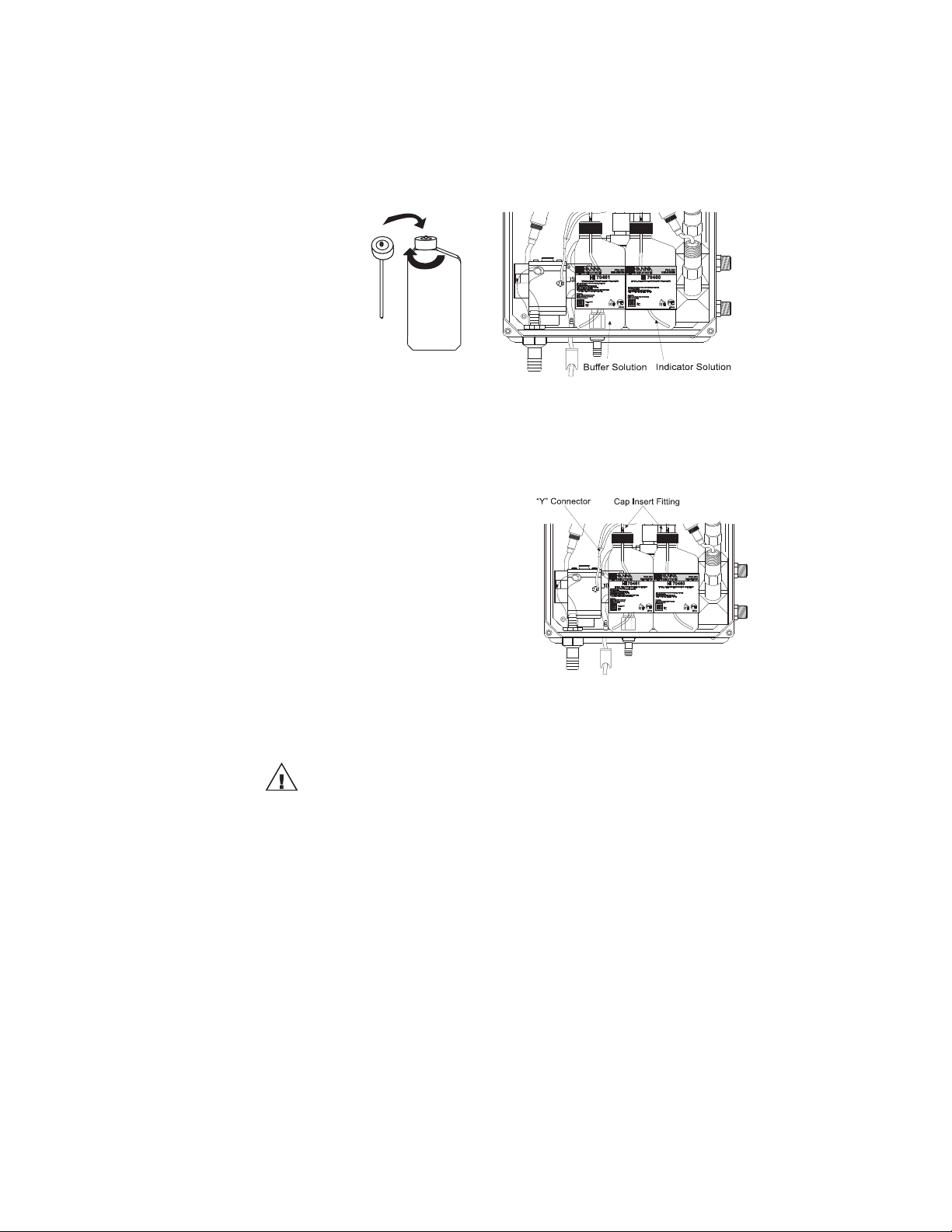

Separate reagent caps are provided in the accessory kit. Put

the supplied caps onto each reagent bottle prior to installing

From Buffer Bottle

To "Y" Connector

and Measuring Cell

21

Page 22

them. Place the indicator bottle (HI 70450 for free chlorine

and HI 70460 for total chlorine) on the right and the buffer

bottle (HI 70451 for free chlorine and HI 70461 for total chlorine) on the left.

Note: Add the content of 5 HI70452 sachets, DPD Compound, to

the Indicator Solution prior

to installing it.

Connect the longer tube

ends on the left side of the

pump to the reagent bottle

cap insert fitting.

Connect the short ends in

the right side of the pump

to the measuring cell reagent input port through

the “Y” connector.

ELECTRICAL CONNECTIONS

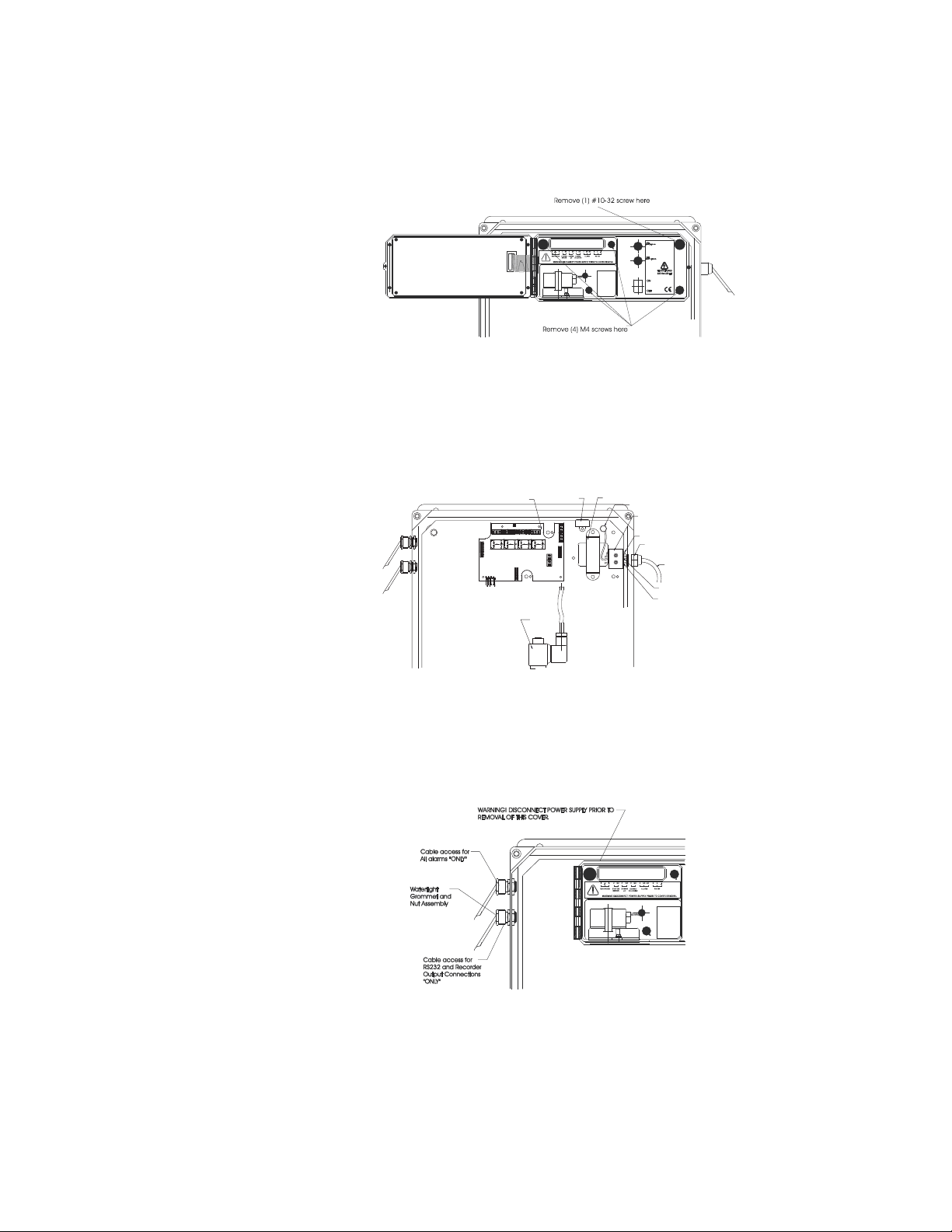

A power cable (3 mt.) is provided with your analyzer. However, if access to the terminal block is required, see below.

Warning Electrical connections should be installed only by qualified

personnel to assure conformity to applicable electrical codes.

Unplug the meter before any electrical connection.

Power Connection

Power connections are made at a terminal block located in the

center of the electrical compartment to the right of the fuses.

Hard wiring with 13 mm (½”) conduit is recommended and

usually required by most municipal electrical codes.

Warning Before connecting the instrument to the line:

1) Check the label near the fuses for proper voltage.

2) Be sure the power cord is not connected to the line.

22

Page 23

3) Open front panel.

CSR2

PPCA320P-3

+

5

V

2

1

2

3

1

M

O

R

3

P

1

3

2

M

O

R

3

P

1

2

RELICAMRELICAM

RELICAM

R

ED

P

IN

K

G

R

EY

B

LU

E

G

R

E

E

N

B

RO

W

N

YE

L

LO

W

RELICAM

Electrovalve

Earth

Watertight

Neutral

Terminal

block

Ground screw

Transformer

Line Filter

Main Power PCB

24

VAC

1

4) Remove the cover screws (Allen head).

5) Do not remove peristaltic pump or motor.

6) Unplug all alarms and recorder jacks.

Feed the power cord through the watertight grommet and

tighten the grommet nut. See the picture below for proper wire

connections.

Main Power PCB

V

5

+

N

N

K

EY

W

E

W

R

IN

E

P

G

R

E

ED

LO

RO

L

R

G

B

LU

B

YE

Line Filter

PPCA320P-3

CSR2

P

3

R

O

M

P

3

R

O

RELICAM

M

Grommet and

Nut Assembly

Main Power

Cord

Phase

24 VAC

Recorder Output and Relay Access

Hard wiring for alarms and relays recorder outputs and serial

communication can be accomplished through four watertight

connectors on the left side of the enclosure, by passing wires through

the rubber grommet and tightening the nut as described earlier.

Refer to the drawings for proper wire connections.

23

Page 24

DOSING

CHLORINE

C

NO

Alarm Relay

ALARM

C

NO

NC

SYSTEM

ERROR

C

NC

A system alarm feature provides relay activation

to signal that the measuring value exceed the

alarm setpoints. The alarm relay is closed (Common connect to Normal Close) if the value is

lower than alarm low setpoint or higher than

alarm high setpoint.

The ALARM LED blinks when alarm is active.

Note: The Alarm relay is power-fail safe and is closed when the

analyzer is not powered.

System Error Relay

A system error feature provides relay activation to

signal the need for operator intervention through

an external device, such as a buzzer, a light or any

other electrical equipment. When errors appears,

the relay is closed (Common connect to Normal

Close).

The SYSERR LED blinks when a system error occurred.

If the situation persists for more than a few samples, the op-

erator should notify maintenance personnel for investigation

of the problem.

Note: When the meter is in alarm mode or in system error mode, the

user could directly view the alarm or error description on the

display.

If GSM transmitter is installed and GSM mode is selected, the

alarms and errors are sent as SMS message.

The System error relay is power-fail safe and is closed when

the analyzer is not powered.

Chlorine Dosing Relay

The chlorine dosing relay is activated (Common

connected to Normal Open) when chlorine concentration is under the dosing setpoint. The chlorine dosing use a proportional algorithm that depends on both, setpoint and delta.

The DOSING CHLORINE LED is turned on when

the dosing relay is closed.

Note: The chlorine dosing is stopped when the concentration is over

Alarm high setpoint or when a System error related to chlorine

measurement occurs.

SYSTEM

ERROR

DOSING

CHLORINE

24

Page 25

Acid/alkali Dosing Relay

DOSING

pH

C

NO

RS 485

B

A

I

I

Acid/alk dosing relay is activated (Common connected

to Normal Open) depending on the setpoint and

selected delta. If the analyzer is set to dose acid, the

relay is active when the pH value is over the setpoint.

If alkaline is dosed, the relay is activated when the

pH value is under the setpoint.

The DOSING ACID/ALK. LED is turned on when the dosing

relay is closed.

Note: The acid/alk dosing is stopped when system error related to

pH occurs.

Recorder Outputs

The recommended recorder hookup uses a twisted

pair shielded cable. The shield should be connected

to the terminal at the instrument end and left open

at the recorder end.

To operate with this hookup, the following conditions

are required at the recorder end:

• The input to the recorder must be isolated from the chassis

ground (earth) of the recorder;

• If the recorder has more than one input, they must be

differential inputs.

Two types of outputs are available: 0-20 mA or 4-20 mA for

each output. The recorder outputs could be assigned to Cl,

pH, Temperature or ORP.

Proportional dosing pump

Two proportional dosing pumps could be connected to the 4-20

mA outputs. The pump could be used to dose chlorine and

acid/alk as selected by the user. When the output is 4 mA, the

pump must be stopped and when the output is 20 mA, the

pump must provide the maximum output.

RS485

The analyzer has RS485 serial communication

with selectable baud rate between 1200 and

9600 Bps. The GSM module HI 504900 is also

connected using the RS485 port.

Note: The RS485 could use also the ground wire to

prevent common mode voltages.

DOSING

pH

RS 485

25

Page 26

STARTUP

To power up the analyzer open the electronic

box door and turn on the main switch.

When the analyzer is powered up, the display

backlight is turned on and the initialization take

place. In this phase, the integrity of the stored

data is checked and the information regarding

the language is loaded.

The display will show HANNA INSTRUMENTS, the name of

the instrument and the software version.

or

Note: If the instrument is set for free chlorine analysis, the software

will report at startup Free Chlorine and if it is set for total

chlorine, the software will report at startup Total Chlorine.

After initialization, the analyzer will show the main panel (or

chlorine measuring panel for PCA 310). The measured value

are displayed. The chlorine concentration will be updated only

after a full measuring cycle. The first reading is 0.00 mg/L and

the dosing relay is not active.

After the first chlorine concentration is measured and displayed,

the chlorine dosing relay is activated if necessary.

Note: If the SMS feature is selected and correctly configured, the

analyzer will send a SMS at each power up sequence.

26

Page 27

USER INTERFACE

PANELS ORGANIZATION

The PCA 310 – 330 analyzers provide a friendly interface that

display all important parameters of the analyzer. The appearance

of the display could be selected by the user.

The panels are organized

in circular loops. PCA

330 has a main loop

where panels with all

measurements are displayed, chlorine measurement loop, pH measurement loop, temperature measurement loop

and ORP measurement

loop where only information related to the parameter is displayed.

PCA 320 has the same structure but without the ORP measurement panels.

PCA 310 has only the chlorine measurement panels.

Pressing “UP” and “DOWN” keys will move inside loop in a

circular way (after last panel, the first panel is displayed). Pressing “CFM” to move from main panels to measurement panels.

Pressing “ESC” to move from measurement panels to main

panels.

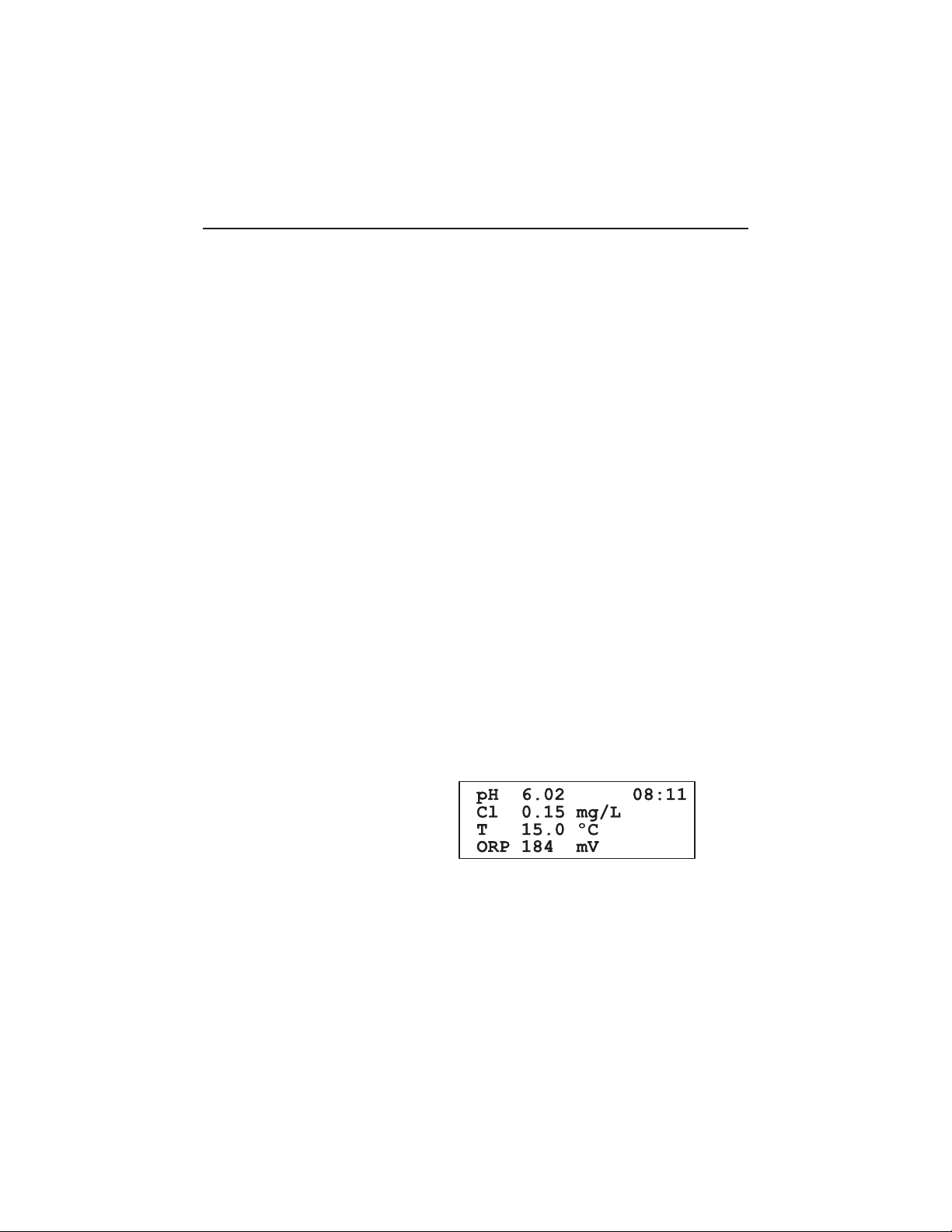

MAIN PANELS

At startup the display

shows one of the

main panels. This

panel contains the

chlorine, pH, ORP

and temperature values and the related measuring units. The

panel contains also the current time and the alarm / error

status.

Other panels are available by pressing “UP” or “DOWN”

keys. On each of this panels one measurement is displayed

on the left side and the others on the right side.

UP

DOWN

UP/DOWN

Main panels

CFM

CFM

Cl panels

ESC ESC ESC ESC

pH panels

CFM

Temp. panels

CFM

ORP panels

27

Page 28

Example: When pH is displayed on the left side and the chlorine, ORP

MEASURE PANELS

One row with messages is also displayed.

When the display

show one of this panels, pressing “CFM”,

will enter in the panels related to the parameter displayed in

the left side.

and temperature on the right side, pressing “CFM” will go in

one of the pH measure panels.

For each parameter, several measure panels are available.

One panel contains large digits for better visibility.

The measure panels contains:

12

5

< Low ORP >

Min:4.18 Max:7.00

6.29 pH Error

STANDBY 16:35

08:10

3

4

1.35 mg/L Alarm

<Cl Calibration Old>

7

Min:0.00 Max5.00

1 = the measured value (chlorine, pH, ORP or temperature)

2 = the measurement units (mg/L, pH, mV, °C or °F)

3 = the current time in format HH:MM

4 = error or alarm indicator

5 = information about the operating mode.

6 = warnings, alarms and errors, displayed one at a time

7 = the last row displays less important information:

• Maximum and minimum value

• Sampling time

• Reagent doses left

• Alarm High and Alarm Low

• Regulator Setpoint and Delta or Hysteresis

• Analog output maximum and minimum

• Cl measuring phase

6

28

Page 29

The display go in large

digits panel if no key

is pressed for about 4

minutes. If key is

pressed, the display

returns in the panel

where it was before.

Pressing “ESC” when in one of those panels will return in

main panels mode.

MESSAGES

When warnings, alarms or errors appears, the message line is

displayed. The meanings of each message is explained in

chapter ERRORS, ALARMS AND WARNINGS.

If many messages are present, the “<“and “>” signs are

displayed on the left and/or the right side.

Pressing “LEFT” or “RIGHT” arrow keys the messages are

scrolled. If is no message in the left or right side, the corresponding sign “<“ or “>” disappears.

When at least one alarm is active, the “Alarm” appears in the

right side of the display. The ALARM LED will start to blink.

When errors or both, errors and alarms are active, “Error”

appears in the right side of the display. The SYSTEM ERROR

LED will blink.

The “MANUAL” or “STANDBY” information is displayed on the

first line of the LCD.

MENU MODE

By pressing “MENU” key, the analyzer will enter in menu mode.

In this mode, the analyzer settings can be consulted or modified.

The settings are organized in menus and grouped by functions.

The menu is password protected.

PASSWORD PROCEDURE

When the “MENU” key is pressed, the analyzer ask for the

password.

If the password is set

to “0000” (default

value) the analyzer will

not ask for password.

16:49

mg/L

Enter password:0000

29

Page 30

If correct password is entered and confirmed, the analyzer will

go in menu mode.

If wrong password is entered, the analyzer displays “Password

incorrect. Settings are not allowed!”, and the user could only

view the analyzer parameters.

NAVIGATING THROUGH MENU

The menu is organized as a list of options. Each line of this

list:

- could contain a

sub-menu;

- could display an

analyzer parameter or

- could start a function.

To select a menu line, press “UP” or “DOWN” arrows.

The selected line is signaled by a black square in the left side

of the display.

If the menu continues outside the viewing area, a double up or

down arrow is displayed on the first or last line of the display.

As a general rule, the “CFM” key will descend into menu and

“ESC” key will return to a higher level.

Pressing “CFM” will make the following actions:

• descend into the sub-menu for sub-menu line.

• no action for parameter line.

• start the function for function line.

Pressing ESC will make the following actions

• Return in measure mode when in the main menu

• Return in the previous menu when in submenu

• Return from function before the normal ending

when function is executing

• Exit from edit mode without saving.

MODIFY A PARAMETER

To modify a parameter, press “SET” key when a line that

displays a parameter is selected.

The cursor will go to the first digit or letter of the parameter.

Note: If wrong password is entered, editing is not allowed.

The editing sequence depend upon the parameter type.

General Menu

Chlorine Menu

pH Menu

ORP Menu

Temperature Menu

30

Page 31

For list type parameter

Set Time: 10:31

Set Date:2004/01/01

In this case the cursor will blink and first letter alternates with a

black square. To modify the value press “UP” or “DOWN”

arrow key until the correct value appears.

Setpoint :2.50 mg/L

Delta :0.1 mg/L

Low Point:0.02 mg/L

Low Point:Inactive

Press “CFM” to save the value or press “ESC” to end the

editing without saving the value.

For single numeric values

In this case the cursor will blink by alternating the first digit

and a black square.

Press “RIGHT” or “LEFT” arrow key to focus on the digit that

has to be edited.

To edit the current digit press “UP” or “DOWN” arrow keys.

Press “CFM” to save the value or press “ESC” to end the

editing without saving the value.

For many numeric values on a row

In this case the cursor will go to the first digit of the first parameter.

The cursor will blink but no black square will be displayed.

Select the parameter to be edited by pressing “RIGHT” or “LEFT”

arrows.

To edit the parameter press “SET” key again and the black

square alternating with the first character appears, signaling

that the parameter could be edited.

Depend on the parameter type, the edit procedure is as described for list type or single numeric value.

Press “CFM” to save the value or press “ESC” to end the

editing without saving the value. The cursor will prompt the

edited parameter.

31

Page 32

Pressing “RIGHT” or “LEFT” arrow keys, another parameter

can be set.

Pressing “ESC” key will return to menu.

Note: If the edited value is outside the allowed range, a warning

panel appears when “CFM” is pressed. This panel contains

the parameter limits. Pressing again “CFM” or “ESC” will

return to the edit mode.

PROGRAMMING THE ANALYZER

To set the parameters press “MENU” while in the measure

mode. The main Menu is displayed.

General Menu

Chlorine Menu

pH Menu

ORP Menu

Temperature Menu

Select the appropriate entry as described in next pages.

SETTING RESTORE

The settings are stored in a nonvolatile EEPROM memory. If a

power failure appears the settings are restored after power on.

When power is first time applied to PCA 310-330 analyzers,

the settings are set to factory default values.

At startup the EEPROM content is analyzed and, if some settings are corrupted, a restore procedure is started. The instrument displays the following screen:

32

Press “CFM” to restore the settings that are out of range. In

this case, the corrupted settings are set to default. In this case

all settings should be checked in to see the values.

Press “SET” to restore to default of all settings.

In extreme situation when the LCD is blank at startup, is pos-

sible to reset the instrument by keeping the keys “UP” + “SET”

+ “MENU” pressed while the instrument is powered on.

Page 33

GENERAL SETTINGS

The analyzer settings,

common for all measurements, are grouped

in “General Menu”.

System Log

Analog Output

SMS Settings

Serial & GSM Comm.

Time and Date

System Functions

CHANGING THE PASSWORD

The password is a numeric value with 4 digits.

To change the password, enter in “General Menu” - “System

Functions” and edit the “Change Pass” line. Press “CFM” to

save.

After new value is confirmed, the displayed password is set to

0000 for protection against unauthorized reading.

SETTING THE LANGUAGE

The PCA 310-330 analyzers has 4 languages stored inside.

The user could easily change the language without restarting

the analyzer.

To select a new language, enter in “General Menu” - “Language

Change” and select the new language. After pressing “CFM”

key, the new language is loaded.

ANALYZER SERIAL NUMBER AND SOFTWARE VERSION

The unique serial number can be viewed by selecting the “General Menu” - “System Functions” - “Serial Nr.”.

Serial number is not editable.

The software version is displayed each time the analyzer is

turned on and lasts during the initialization phase.

TIME AND DATE

The PCA 310-330 analyzers have a built in real time clock.

When the analyzer is in normal mode, the current time is

displayed on the right side of the display in HH:MM format.

To set the time and

date, select the “General Menu” - “Time

and Date”. Set the time

and the date as described in the User interface chapter.

Language Change

Set Time: 10:31

Set Date:2004/01/01

33

Page 34

WORKING MODE

AUTOMATIC MODE

STANDBY MODE

Note: When the analyzer exit from STANDBY, the relays and corre-

MANUAL MODE

Three working modes

could be selected for

the analyzer. The selection is available in

“General Menu” “System Functions” “Manual Commands”

- “Work Mode”.

The work mode could

be set as AUTOMATIC,

STANDBY or MANUAL.

In this mode the analyzer performs the measurements continuously accordingly with the settings.

When in standby, the sampling electrovalve is closed, the measurements are stopped and the peristaltic pump is activated

for 2 seconds each 100 minutes to preserve the elasticity of

the tubes.

The display will show “STANDBY” on the first line when in the

measurement mode. The chlorine, pH, ORP, and temperature displayed values will be all time the last measured ones.

The SYSTEM ERROR LED is always on (no blinking).

sponding LED’s are activated only after a new value is read.

For testing, maintenances and setup purposes, the analyzer

has the possibility to use direct manual commands.

In this operating mode, by setting the “Alarm Relay”, “Dose

Cl Rel.”, “Dose pH Rel.”, “Sys. Err. Rel”, “Stirrer”, “Valve”,

“Cell Led” and “Reagent Pump” as “ON” or “OFF” will turn

on or off the corresponding device.

The display will show “MANUAL” on the first line when in the

measurement panels. The displayed values will be the last

measured ones and the measuring sequence is stopped.

When in manual mode the ALARM LED is always on (no blinking).

Work Mode:AUTOMATIC

Read On Demand

Alarm Relay :ON

Dose Cl Rel :ON

Dose pH Rel :ON

Sys.Err. Rel:OFF

Stirrer :OFF

Valve :OFF

Cell Led :OFF

Reagent Pump:OFF

34

Page 35

Note: The read on demand function is active only when the analyzer

DIRECT READ

SYSTEM ERROR RELAY

READ ON DEMAND

When this function is selected, (“General Menu” - “System

Functions” - “Manual commands” - “Read On Demand”) a

new chlorine measuring cycle is immediately started.

This command is useful when calibrate or whenever an immediate result is needed.

is in automatic mode.

For rapid diagnostics of the measuring cell, the converter readings for dark (cell LED off) and blank (cell LED on) could be

consulted.

To display the dark reading activate the “General Menu” “System Functions” - “Dark Read” function. After confirmation the dark value is displayed.

Manual Commands

Dark Read

Blank Read

Change Pass: 0000

To display the blank reading activate the “General Menu” “System Functions” - “Blank Read” function. After confirmation the blank value is displayed.

If the cell work correctly, the values must be between -20000

and 20000 with a minimum difference blank – dark of 20000

converter points.

The PCA 320-330 controller has a single system error relay

for all measured parameters.

To allow chlorine errors to activate the relay, set “Chlorine

Menu” - “Alarm&Err Chlorine” - “Err.Relay” to Active.

For pH errors set the item “pH Menu” - “Alarms&Err pH” “Err. Relay” to Active.

For ORP errors set the item “ORP Menu” - “Alarms&Err ORP”

- “Err. Relay” to Active.

For temperature errors set the item “Temperature Menu” -

“Alarms&Err Temp.” - “Err. Relay” to Active.

35

Page 36

CHLORINE SETTINGS

The settings related to

chlorine measurement

are grouped in “Chlorine Menu”. The following options are

available:

REAGENT CHANGING

One set of reagents is enough for at least 16000 samples.

The remaining doses of

reagent are displayed

on one chlorine measuring panel.

When the reagent is

changed, several actions

must be performed:

Prepare the reagent and install the new bottles as described in

initial preparation and installation chapter.

Prime the reagent pump if needed or simply reset the reagent

counter.

The used reagent doses and the remaining reagent doses could

be viewed on the first two lines when enter in “Chlorine Menu”

- “Reagent change”.

If “Chlorine Menu” - “Reagent change” - “Reset Reag.

Counter” function is selected and confirmed, the used doses

become 0 and the remaining doses become 16000. This command does not perform a priming of the reagent pump.

If “Chlorine Menu” “Reagent change” “Prime Reag. Circuit”

function is selected and

confirmed, the dosing

pump is turned on for 180 seconds. The remaining time is

displayed on the right-down corner of the display.

The process could be terminated by pressing “ESC” at any

moment.

Priming in progress

...

168s

36

Page 37

MEASURE SETTINGS

MEASURE INFO

ANALOG OUTPUT

Select “Chlorine Menu” - “Measure Settings” and set the

“Period” between 3 and 90 minutes.

Period (sampling rate) is the elapsed time between two consecutive chlorine measurements. The sampling rate is also

important when the analyzer is used for chlorine dosing. For

larger pools, the period must be longer, and for smaller pools,

the period must be shorter.

The sampling rate can be quickly consulted on one chlorine

measuring panel.

The analyzer calculates the maximum and minimum concentration value since the first measurement.

The maximum and minimum can be quickly consulted on

chlorine measuring panel.

To see information about these values, select “Chlorine Menu”

- “Measure Info”. The time stamp when maximum and minimum appears are also displayed in this menu.

To reset the maximum

or minimum values,

select the functions

“Chlorine Menu” “Measure Info” “Clear Max. Value” or

“Chlorine Menu” “Measure Info” “Clear Min. Value”.

The maximum or minimum value will be set to the current

read value.

The type of analog output can be set as described in “Analog

output” chapter. The analog output span for chlorine could

be set in “Chlorine Menu” - “Analog Output Cl”.

“Min. Rec” will set the recorder lower limit and “Max. Rec”

will set the recorder

higher limit. The Max.

Rec. value must be

greater than Min.

Rec. value.

Max.Value:0.25 mg/L

Date:04/01/16 22:45

Min.Value:0.00 mg/L

Date:04/01/03 00:16

Clear Max. Value

Clear Min. Value

Max. Rec:5.00 mg/L

Min. Rec:0.00 mg/L

37

Page 38

Example: if the 0.0 to 20.0 mA recorder output has been selected, the

CHLORINE DOSING

Note: If the measured concentration is lower than setpoint minus delta,

Example: For setpoint 3.00 mg/L, delta=0.5, sample rate 5 minutes and

The output will be proportional with chlorine if the read value

is between those limits.

operator can select 0.0 mA to correspond to a concentration

of 3.00 mg/L (Min. Rec. setting) and 20.0 mA to correspond

to a concentration of 4.50 mg/L (Max. Rec. setting).

The full scale span of the recorder would then be 1.5 mg/L,

yielding a magnified view of the 3.00 to 4.50 mg/L concentration

range on the recorder.

The analog output limits can be quickly consulted in one of

the chlorine measuring panels.

The PCA 310-330

analyzers contain a

simple proportional

dosing algorithm.

Cl

mg/L

delta

Relay off

Setpoint

Proportional dosing

Proportional dosing

establishes and maintains

Relay on

a controlled and consistent concentration level.

The analyzer has a relay for chlorine dosing and also the 4-20 mA

outputs could be configured as dosing outputs.

The equation for determining the time for relay on is:

dosing time = (set value - measured value)*Period/Delta

The analog output will have the value:

analog output [mA] = 4 + 16 * dosing time/Period [mA]

the dosing will be continuous until the next measurement is

taken (one period).

measured value 2.80 mg/L, the proportional dosing will be active

for the initial 2 minutes and will stop for the remaining 3 minutes.

In fact: Time = (3-2.8)*5/0.5 = 2 minutes

Analog output = 4 + 16*2/5 = 10.4 mA

To modify the dosing

setpoint, enter the

“Chlorine Menu” “Dosing control Cl”

and edit the “Setpoint”

line. The value must

Setpoint :2.50 mg/L

Delta :0.1 mg/L

Low Point:0.01 mg/L

Low Point:Inactive

Max. ON :060 min

be between 0.10 and

4.90 mg/L.

time

38

Page 39

To modify the Delta, edit the “Delta” line. The available values

are 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1, 1.5, 2, 3, 4, 5.

Note: The speed of the analyzer could be modified by changing the

sampling rate. A new decision regarding the chlorine regulator is taken only after a new measurement.

The Setpoint and Delta could be quickly consulted on one

chlorine measuring panel.

LOW READING PROTECTION

To prevent excessive chlorine dosing if the detector is not working properly or the reagent bottle is empty, a “Detector Error”

is generated if the measured chlorine value is under the low

point value. This error is generated only if the low point feature is set active.

The chlorine dosing is stopped and the SYSTEM ERROR LED

starts blinking.

To enable this feature, edit “Chlorine Menu” - “Dosing control Cl” - “Low Point” value and set the “Low Point” status as

“Active”. The allowed value is 0.00 to 1.00 mg/L.

OVERDOSING PROTECTION

To prevent overdosing a “Detector Error” is generated if the

dosing command is on for the Max. ON time and the read

value is changing less than 0.05 mg/L.

The chlorine dosing is stopped and the SYSTEM ERROR LED

starts blinking. The dosing could be resumed only by restarting

the controller.

To modify this protection, edit “Chlorine Menu” - “Dosing

control Cl” - “Max. ON” value. The allowed range is between 30 and 720 minutes.

ALARMS

Two alarm setpoints are available for chlorine: Alarm high

and Alarm low.

The ALARM LED and alarm relay are activated when the chlorine concentration is higher than Alarm high or lower than

Alarm low.

To modify the alarm setpoints, enter the “Chlorine Menu” “Alarms Chlorine” and edit “Alarm Hi” or “Alarm Lo” value.

39

Page 40

The alarms could be separately activated or inactivated.

To modify the alarms status, enter the “Chlorine Menu” - “Alarms

Chlorine” menu and edit “Alarm Hi” or “Alarm Lo” status.

When the status is set to “Inactive”, the alarm is ignored.

Note: The Alarm high must be greater than Alarm low value. The

analyzer display a warning if the settings are incorrect.

The Alarm high setpoint and Alarm low setpoint could be quickly

consulted on one chlorine measuring panel. When an alarm is

disabled, the —.— is displayed instead of alarm value.

CALIBRATE THE MEASURING CELL

The PCA 310-330 analyzers have the possibility to calibrate

the measuring cell.

When a new calibration is performed, calibration factor is

recalculated and all measurements are multiplied with it.

CALIBRATION DATE AND FACTOR

The last calibration date

can be found in the

“Chlorine menu” “Cal. Measuring Cell”

- “Cal. Date”. Calibration date is in the

YY / MM / DD format.

A warning “Cl Calibration Old” is displayed if one month

elapsed from the last calibration.

The calibrated date is updated after a new calibration is done.

The calibration factor is displayed in “Chlorine menu” - “Cal.

Measuring Cell” - “Factor”.

The default calibration factor is 1.000. Each measurement

result is multiplied with calibration factor.

The calibration factor could be reset to 1.000 by activating

the “Chlorine menu” - “Cal. Measuring Cell” - “Reset Cal.

Factor” function.

CALIBRATION PROCEDURE

To calibrate the measuring cell, follow the steps:

• Withdraw a sample of the measured liquid directly from the

drain port of the measuring cell (#11) by opening its valve

(#10) - see figure on page 10.

Note: Withdraw the sample just before the electrovalve stops the liq-

uid flow to the measuring cell.

Cal.Value:0.14 mg/L

Factor :0.954

Cal. Date:04/01/20

Reset Cal. Factor

Calibration Blank

40

Page 41

• With a calibrated meter take a measure of the sample. This

is the calibration value.

• Wait for the PCA to display the new reading.

• Go in “Chlorine menu” - “Cal. Measuring Cell” and edit

“Cal. Value” field.

• Enter the calibration value and save with “CFM”.

• The calibration coefficient and the calibration date will be

updated.

• Press repeatedly “ESC” to exit from menu mode. The displayed

chlorine concentration will be equal with the calibration value.

Note: It is not recommended to calibrate the analyzer at values below

2 mg/L in order to maintain enough accuracy in the whole

range. Calibration below 2 mg/L does not guarantee declared

accuracy outside an interval of ±50% from the calibration value.

pH SETTINGS (PCA 320, PCA 330)

Settings related to pH

measurement are

grouped in “pH

Menu”. The following options are

available:

MEASURE INFO

The analyzer calculates the maximum and minimum pH value

since the first measurement.

The maximum and minimum can be quickly consulted on one

pH measuring panel.

For more detailed information select “pH Menu” - “Measure

Info” The “Max. Value” and “Min. Value”. The time stamp

when maximum and minimum occurs are also displayed in

this menu.

To reset the maximum

or minimum values,

select the functions

“pH Menu” - “Measure Info” - “Clear

Max. Value” or “pH

Menu” - “Measure

Info” - “Clear Min.

Value”.

The maximum or minimum value is set to the current read value.

Max.Value:14.00 pH

Date:03/01/01 14:39

Min.Value:00.00 pH

Date:04/01/01 00:03

Clear Max. Value

Clear Min. Value

41

Page 42

ANALOG OUTPUT

pH DOSING

PROPORTIONAL DOSING

The type of analog output could be set as described in “Analog output” chapter. The analog output span for pH could be

set in “pH Menu” - “Analog Output pH”.

“Min. Rec” will set the recorder low limit and “Max. Rec” will

set the recorder high limit. The Max. Rec. value must be greater

than Min. Rec. value.

The output will be proportional with pH value if the read value

is between those limits.

The analog output limits could be quickly consulted in one of

the pH measuring panel.

The PCA 320 and PCA 330 can use ON/OFF or proportional dosing algorithm to stabilize the pH .

The analyzer has a relay for acid or alkali dosing and also the

4-20 mA output could be configured as a dosing output.

To select the type of pH

dosing edit the “pH

Menu” - “Dosing

Control pH” - “pH

Control” line. The

available options are

Proportional and

pH Control:On/Off

Dosing Type:Acid

Period :003 sec

Setpoint :07.00 pH

Delta :0.1

Hysteresis:1.00 pH

Max. ON :060 min

ON/OFF.

The acid or alkali dosing is set in the “pH Menu” - “Dosing

Control pH” - “Dosing Type”. When “Acid” is selected, the

analyzer will dose when the pH value is higher than the setpoint and when “Alk” is selected, the analyzer will dose when

the pH value is lower than the setpoint.

The proportional dosing

algorithm turns on the

dosing relay proportion-

pH

Proportional dosing

delta

Relay off

Setpoint

ally with the difference

between the setpoint

and measured value.

Relay on

time

The equation for determining the time for relay on is:

dosing time = (set value - measured value)*Period/Delta

42

Page 43

The analog output will have the value:

analog output [mA] = 4 + 16 * dosing time/Period [mA]

Note: If the measured pH is lower (or higher for acid dosing) than

setpoint minus (plus) delta, the dosing will be continuous until

the pH period elapsed.

To modify the dosing setpoint, enter the “pH Menu” - “Dosing Control pH” edit the “Setpoint” line. The value must be

between 2.00 and 12.00 pH.

To modify the Delta, edit the “Delta” line. The available values

are 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1, 1.5, 2.

To modify the dosing time edit the “Period” line. The allowed

values are between 3 and 120 seconds.

Note: The period is related only to the dosing process. The pH mea-

surement take place with a higher rate.

Note: The speed of the analyzer could be modified by changing the

regulator period. A new decision regarding the pH dosing is

taken only after one period elapsed.

The Setpoint and Delta could be quickly consulted on one pH

measuring panel.

ON/OFF DOSING

If this mode is selected the Period and Delta has no effect. The

algorithm will use only Setpoint and Hysteresis.

For alkaline dosing, the

relay will stay on until the

pH increases to the setpoint plus hysteresis value,

then the relay stays off until

the pH decreases to a

value equal to setpoint.

For acid dosing, the relay will stay on until the pH decreases

to the setpoint minus hysteresis value, then the relay stays off

until the pH increases to a value equal to setpoint.

To set the hysteresis edit the “pH Menu” - “Dosing Control

pH” - “Hysteresis” line. The hysteresis value must be between

0.05 and 2.00 pH.

OVERDOSING PROTECTION

To prevent overdosing a “Detector Error” is generated if the

dosing command is on for the Max. ON time and the read

value is changing less than 0.1 pH.

The acid/alkali dosing is stopped and the SYSTEM ERROR

LED starts blinking. The dosing could be resumed only by

restarting the controller.

pH

Hysteresis

Setpoint

Relay on

Relay off

Relay off

Relay on

Relay on

time

43

Page 44

To modify this protection, edit “pH Menu” - “Dosing control

pH” - “Max. ON” value. The allowed range is between 30 and

720 minutes.

ALARMS

Two alarm setpoints are available for pH: Alarm high and

Alarm low.

The ALARM LED and relay are activated when the pH value is

higher than Alarm high or lower than Alarm low.

To modify the alarms setpoints, enter the “Alarms pH” menu

and edit “Alarm Hi” value or “Alarm Lo” value.

The alarms can be separately activated or inactivated.

To modify the alarms status, enter the “pH Menu” - “Alarms

pH” menu and edit “Alarm Hi” status or “Alarm Lo” status.

When the status is set to “Inactive”, the alarm is ignored.

Note: The Alarm high value must be greater than Alarm low value.

The analyzer display a warning if the settings are incorrect.

The Alarm high Setpoint and Alarm low setpoint could be quickly

consulted on one pH measuring panel. When an alarm is disabled, the —.— is displayed instead of alarm value.

pH CALIBRATION (PCA 320, PCA 330)

It is recommended to perform pH calibration when the probe

is replaced and after any cleaning action.

The analyzer can perform 2 points calibration, 1 point calibration or process pH calibration.

To perform any pH calibration enter in “pH Menu” - “Cal. pH

Probe”.

Initial Preparation

44

Set Default pH Cal.

Process pH Cal.

Buffer pH Cal.

Cal. Date :01/01/01

In this menu the last calibration date is displayed on the “Cal.

Date” line. If the probe calibration is older than 1 month, a

warning is displayed.

Pour small quantities of pH 7.01 (HI 7007) and pH 4.01

(HI 7004) or 10.01 (HI 7010) solutions into individual

beakers. If possible, use plastic beakers to minimize any EMC

interference. Also NIST buffers of 6.86 or 9.18 could be used.

Page 45

For accurate calibration use two different beakers for each buffer

solution, the first one for rinsing the probe and the second one

for calibration. By doing this, contamination between buffers is

minimized.

Unscrew the probe from its position. Take care to stop the

sample flow before removing the probe. If necessary, disconnect the probe from analyzer to prevent the damage of the

probe cable.

ONE POINT CALIBRATION

Immerse the pH probe into the buffer solution

(e.g. pH 7.01) until the metal ring is immersed,

then stir gently.

Select the “pH Menu” - “Cal. pH Probe” - “Buffer

pH Cal.”.

• The analyzer will prompt to select the first buffer. Select the

buffer (e.g. pH 7.01) using “UP” or ”DOWN” arrow keys

and confirm.

• The analyzer checks

for readings stability. During this period, the “Wait for

stabilize” message

is displayed.

Note: If the read value, calculated with the default offset and slope, is

different from the expected value with more than 1.15 pH (i.e. offset

> 68mV), the “Wrong calib. values” message is displayed.

The message “Wrong calib. values” appears also if the pH

probe is defective or not connected. The problem could be

identified if the buffer set value is compared with the actual

read value (first and second line of the display).

If the probe is inserted in the appropriate buffer, the measuring cycle is restarted automatically and message “Wait for

stabilize” is displayed again.

• If the temperature reading is wrong, the value is set to 25 °C

and a blinking “*” is displayed near it, indicating that is not

the real temperature value. The calibration procedure is not

interrupted.

• When the reading become stable, the analyzer displays

“Stable... press CFM”.

Probe

pH 7.01

Buffer 1 pH: 7.01

Measured pH: 7.02

Temp. [ºC]: 25.1

Wait for stabilize

45

Page 46

• The analyzer prompts for the second buffer selection, and

displays the message “Select buffer pH... or press SET for

one point cal.”.

Pressing “SET” key will end the one point calibration procedure.

TWO-POINTS CALIBRATION

• To perform a two-points pH calibration follow the steps de-

scribed at one-point calibration until the analyzer displays the

message: “Select buffer pH... or press SET for one point cal.”.

• Immerse the pH electrode into the second buffer

solution (e.g. pH 4.01) until the metal ring is

immersed, then stir gently.

• Press “UP” or “DOWN” arrow keys to select

the second buffer from the list to continue the

calibration and confirm with “CFM”.

Note: The difference between the first and second buffer must be

more than 1 pH in order to assure the calibration accuracy.

Calibration using 7.01 and 6.86 pH or 10.01 and 9.18 pH is

not allowed.

• The analyzer checks for readings stability. During this period, the “Wait for stabilize” message is displayed.

• When the reading becomes stable, the instrument checks if

the calculated slope is between 47.3 and 68 mV/pH. If the

value is not within this range, the message “Wrong calib.

values” is displayed. In this case it is necessary to perform a

cleaning procedure (see “Electrode conditioning and maintenance” section) or to replace the probe.

• If the value is accepted, the analyzer displays “Stable... press

CFM”.

Pressing CFM, the two point calibration is completed.

PROCESS pH CALIBRATION

The PCA 320 and PCA 330 has the possibility to calibrate the

pH probe without using buffers and without dismount the

probe. For doing this calibration, a reference pH-meter must

be used. To complete the process calibration, follow the steps:

Probe

pH 4.01

46

• Pour a quantity of sample in a beaker. Use the sample of the

measured liquid directly from the drain port of the measuring cell (#11) by opening it’s valve (#10) to do this as

described in the Calibration Procedure chapter.

• Place the pH probe of the reference meter in the beaker and

stir gently.

Page 47

• Wait for readings to stabilize.

• Enter in “pH Menu”- “Cal. pH Probe” - “Process pH Cal.”

and enter in the

“Cal. Value” field

the reading from the

reference pH meter.

• Press “CFM” key

when the analyzer

prompt for “Overwrite pH cal. ?”.

•The analyzer checks for readings stability (see One-point

calibration) and when the value is stable the message

“Stable... press CFM” is displayed.

• Pressing “CFM” key will complete the process pH calibration.

Note: The calibration could be terminated at any time by pressing

“ESC”. In this case the new calibration is not saved and the