Page 1

Instruction Manual

HI 98360

Autoranging & Logging

Portable Waterproof

Microprocessor

EC/TDS/NaCl/°C Meter

www.hannainst.com

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments product.

Please read this instruction manual carefully before using the instrument.

This manual will provide you with the necessary information for correct

use of the instrument, as well as a precise idea of its versatility.

If you need additional technical information, do not hesitate to e-mail

us at tech@hannainst.com or turn to the back cover for our

worldwide contact list.

This instrument is in compliance with directives.

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

HI 98360 is guaranteed for two years against defects in workmanship

and materials when used for its intended purpose and maintained

according to instructions. Electrodes and probes are guaranteed for six

months. This warranty is limited to repair or replacement free of charge.

Damage due to accidents, misuse, tampering or lack of prescribed

maintenance is not covered.

If service is required, contact the dealer from whom you purchased the

instruments. If under warranty, report the model number, date of

purchase, serial number and the nature of the problem. If the repair

is not covered by the warranty, you will be notified of the charges

incurred. If the instrument is to be returned to Hanna Instruments,

first obtain a Returned Goods Authorization number from the Technical Service department and then send it with shipping costs prepaid.

When shipping any instrument, make sure it is properly packed for

complete protection.

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

WARRANTY ............................................................................................. 2

PRELIMINARY EXAMINATION ...................................................................... 3

GENERAL DESCRIPTION ............................................................................ 3

FUNCTIONAL DESCRIPTION ........................................................................ 4

SPECIFICATIONS ....................................................................................... 5

CONNECTIONS ......................................................................................... 5

SETUP .................................................................................................... 7

TAKING MEASUREMENTS .......................................................................... 9

AUTORANGING ...................................................................................... 10

AUTO ENDPOINT MODE .......................................................................... 10

TEMPERATURE COMPENSATION ............................................................... 11

EC/TDS CALIBRATION ............................................................................. 12

NaCl CALIBRATION ................................................................................. 13

TEMPERATURE CALIBRATION (for technical personnel only) .......................... 13

TEMPERATURE ADJUSTMENT .................................................................. 14

LOGGING FUNCTION ............................................................................... 15

DATA TRANSFER TO PC ........................................................................... 1 8

BATTERY REPLACEMENT ......................................................................... 19

PROBE MAINTENANCE ............................................................................ 19

CONDUCTIVITY VS. TEMPERATURE CHART ................................................ 2 0

ACCESSORIES ........................................................................................ 21

2

Page 3

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

PRELIMINARY EXAMINATION

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it

carefully to make sure that no damage has occurred during shipping.

If there is any damage, notify your dealer or the nearest Hanna

Customer Service Center.

Each instrument is supplied with:

• HI 76309/1.5 Conductivity/TDS probe with 1.5 m cable

• 1.5V, AA size Alkaline Batteries (4 pcs)

• Instruction Manual

• Rugged Carrying Case

Note: Save all packing material until you are sure that the instrument

functions correctly. All defective items must be returned in the

original packing with the supplied accessories.

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

HI 98360 is a waterproof portable logging microprocessor-based Conductivity/TDS/NaCl/Temperature meter.

The autoranging feature of the EC and TDS ranges automatically sets

the meter to the scale with the highest possible resolution.

The Auto Endpoint feature automatically freezes the display when a

stable reading is reached.

The measurements are automatically (ATC) or manually (MTC) compensated for temperature. The temperature coefficient value is user

selectable. It is possible to disable the temperature compensation and

measure the uncompensated conductivity.

The Battery Error Prevention System (BEPS) turns the meter off when

the batteries level is too low to ensure reliable readings.

The meter can store data in memory at the user’s request for later

retrieval.

HI 98360 also allows data transfer to computer through the RS232

port.

3

Page 4

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

1) Power adapter socket.

2) RS232 serial communication connector.

3) DIN electrode connector.

4) Liquid Crystal Display (LCD).

5) ON/OFF key, to turn the meter on and off.

6) ALT key, to enable alternate key function.

7) RANGE FIXED key, to select measurement range or (with ALT) to

freeze the current range on the LCD.

8) CAL AutoEnd key, to enter calibration mode or (with ALT) to

enter Auto Endpoint mode.

9) CFM key, to move down or (with ALT) confirm values.

10) ATC TC key, to select temperature compensation mode or (with

ALT) to view the temperature coefficient value.

11) FNC key, to move up or (with ALT) enter setup mode.

12) LOG RCL key, to store or (with ALT) recall measurements.

4

Page 5

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

RA EGN

NOITULOSER

YCARUCCA

Fº86/Cº02@

noitarbilaCCE

99.92ot00.0

9.992ot0.03

9992ot003

cnu

l/g0.004otpudetasnepmo

µ

10.0

1.0

µ

µ

mc/S

1

mpp10.0

mpp1.0

mpp1

l/g1.0

Cº1.0

± gnidaerfo%5.0

± gnid

± gnidaerfo%5.0

± Cº4.0

µ

3141,0.48

µ

mc/S

µ

mc/S

µ

mc/S

mc/Sm99.92ot00.3

mc/Sm0.002ot0.03

)*(

detasnepmocnumc/Sm0.005otpu

ytivitcudnoc

mpp99.41ot00.0

mpp9.941ot0.51

mpp9941ot051

l/g99.41ot05.1

l/g0.001ot0.51

)*(

SDT

)rotcaf08.0htiw(

lCaN%0.004ot0.0

Cº0.021ot9.9–

mc/S

mc/S

mc/Sm10.0

mc/Sm1.0

l/g10.0

lCaN%1.0

aerfo%5.0

:elbaliavasreffub6htiwtniop1

mc/S

mc/Sm8.111,0.08,88.21,00.5

(*)

Uncompensated conductivity (or TDS) is the conductivity (or TDS) value without

temperature compensation.

5

Page 6

SPECIFICATIONS (SPECIFICATIONS (

SPECIFICATIONS (

SPECIFICATIONS (SPECIFICATIONS (

cont.cont.

cont.

cont.cont.

))

)

))

A5.1x4

htiwtniop1 7307IH reffub

.9–

Erof(

)lanoitpo(

morfcitamotuArolaunaM

Cº0.021ot9

erusaemotdelbasidebnac(

)ytivitcudnocdetasnepmocnu

Cº/%00.6ot00.0

;)ylnoSDTdnaC

Cº/%09.1sieulavtluafed

08.0ot04.0

)05.0sieulavtluafed(

setunim5retfA

)delbasidebnac(

esufosruoh002.xorppa-

retpadaCDV21ro

)Fº221–23(Cº05–0

%001HRxam

noitarbilaClCaN

erutarepmeT

noitasnepmoc

tneiciffeocerutarepmeT

erutarepmetecnerefeRCº52roCº02

rotcafSDT

eborP)d

ffo-otuA

ylppusrewoP

snoisnemiD)”4.2x1.3x7.7(mm06x08x691

thgieW)zo81(g005

tnemnorivnE

ytnarraWsraey2

edulcni(eborpCE5.1/90367IH

)dedulcni(seirettabenilaklaA

CONNECTIONSCONNECTIONS

CONNECTIONS

CONNECTIONSCONNECTIONS

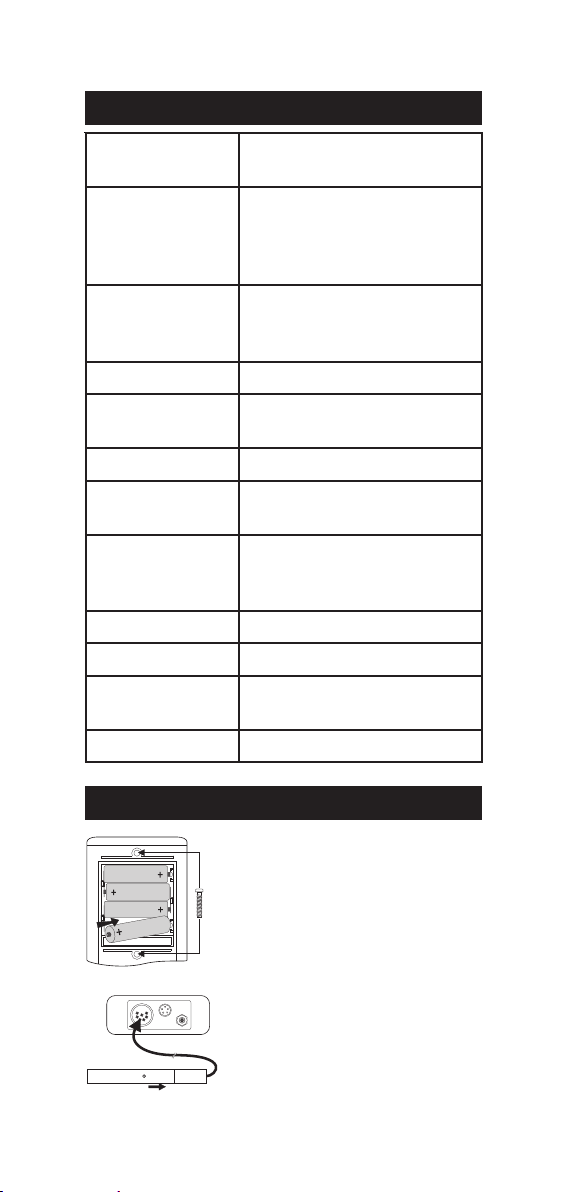

Remove the back cover, unwrap the batteries

and install them while paying attention to

the polarity. Replace the back cover.

Alternatively, connect the voltage adapter

to the power adapter socket.

Connect the EC/TDS probe to the 7-pin

connector located on the top of the instrument.

Tighten the threaded ring.

Make sure the probe sleeve is properly

inserted, as shown in the nearby figure.

6

Page 7

SETUPSETUP

SETUP

SETUPSETUP

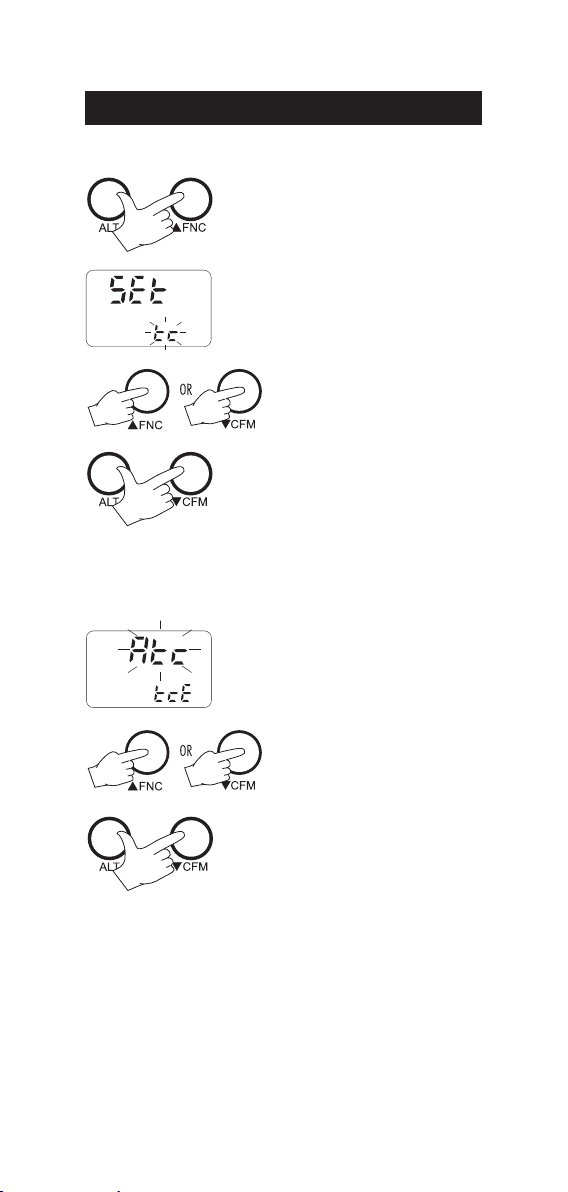

Setup is used to view or change the instrument parameters.

To enter setup press ALT+FNC when the

meter is in measurement mode.

"Set" is displayed on the upper LCD. The

lower LCD displays the blinking code of the

current setup item.

Select the desired setup item using

the or key.

Press ALT+CFM to confirm.

Note: If ALT+FNC are pressed before item confirmation, the meter

will escape and return to measurement mode.

Once the desired setup item has been

selected, its current value blinks (if it is a

changeable parameter).

To change the value use the or

key.

Press ALT+CFM to confirm.

Note: Press ALT+FNC before confirmation to escape without changing

the previously set value.

The following table lists the setup items, their valid range of values

and the factory settings (default):

7

Page 8

Item Description Valid values Default

tc Temp. compensation coeff. 0.00 to 6.00 %/°C 1.90

tcE Temp. compensation mode Atc, Mtc, notc Atc

rEF Reference Temperature 20 or 25°C 25°C

tdS TDS factor 0.40 to 0.80 0.50

CEL Cell constant (K) 0.500 to 1.700 1.000

Aof Auto-Off enable On, OFF On

YEA Year 1999 to 2098 1999

dAT Date dd:mm 01:01

hou Hour hh:mm 00:00

uEr Firmware release

Chr Battery level test

Notes:

• Once enabled, the Auto Off time is fixed at 5 minutes.

• When the battery level test is selected (Chr), LCD will display

the remaining percentage of battery charge. 100% means

fully charged battery and 0% corresponds to the minimum

battery level that allows the meter to operate.

The battery charge level calculation is based on a typical

alkaline battery discharge curve.

If the meter is connected to an external power adapter and

"Chr" is selected, the LCD will display "LINE".

• At startup, the main LCD shows briefly the reference temperature, while the secondary LCD shows "rEF".

8

Page 9

TAKING MEASUREMENTSTAKING MEASUREMENTS

TAKING MEASUREMENTS

TAKING MEASUREMENTSTAKING MEASUREMENTS

Press the ON/OFF key to turn the meter on.

At startup the display will show the reference

temperature value with "rEF" indication for a few

seconds.

Immerse the probe into the solution to be tested.

The sleeve holes must be completely submerged.

Tap the probe repeatedly to remove any air bubbles

that may be trapped inside the sleeve.

If needed, press the RANGE key repeatedly

until the desired range (EC, TDS, NaCl) is

selected on the LCD.

Allow for the reading to stabilize. The upper

LCD displays the measure in the selected range

while the temperature is displayed on the lower

LCD.

Notes:

• If the meter displays "----", the reading is out of range.

• If the reading is not stable, the stability indicator " " blinks.

• Make sure the meter is calibrated before taking measurements.

• If measurements are taken successively in different samples, to

have accurate readings it is recommended to rinse the probe

thoroughly with deionized water before immersion in the samples.

• To maximize battery life, the meter is automatically switched off

after 5 minutes of non-use. To reactivate the instrument press the

ON/OFF key. This feature can be disabled by entering the setup

mode and selecting the "AoF" item (see SETUP section for details).

• TDS reading is obtained multiplying the EC reading by the TDS

factor, which has a default value of 0.50. It is possible to change

the TDS factor in the 0.40 to 0.80 range by entering the setup

mode and selecting the "tdS" item (see SETUP section). Always set

the reference temperature to 25°C when measuring TDS.

• When the use of an alternate function (RCL, FNC, CFM, FIXED,

TC and AutoEnd) is requested, press and hold the ALT key first

and then the second key.

9

Page 10

AUTORANGINGAUTORANGING

AUTORANGING

AUTORANGINGAUTORANGING

The EC and TDS scales are autoranging. The meter automatically sets

the scale with the highest possible resolution.

By pressing ALT+FIXED, the autoranging

feature is disabled and the current range

is frozen on the LCD. "F1" symbol blinks

on the LCD.

To restore the autoranging option press ALT+FIXED again.

Note: Autoranging is automatically restored if the RANGE key is pressed,

if the setup or calibration modes are entered and if the meter is

turned off and back on again.

AUTO ENDPOINT MODAUTO ENDPOINT MOD

AUTO ENDPOINT MODE

AUTO ENDPOINT MODAUTO ENDPOINT MOD

The Auto Endpoint feature allows the user to freeze the display, when

a stable reading is reached (EC/TDS/NaCl and temperature range).

To enter the Auto Endpoint mode, press

ALT+AutoEnd keys.

The LCD will show the current reading

together with a blinking "H" tag.

When measurement becomes stable, the "H"

symbol stops blinking and the measured

value is frozen on the display.

To exit this mode and return to normal operations, press again ALT

+AutoEnd.

Note: While in Auto Endpoint mode, current measurement (both

stable and unstable) can be stored in the meter memory by

pressing the LOG key.

Note: While in Auto Endpoint mode, calibration mode can not be

entered and it is not allowed to change the temperature

compensation and the range options.

10

Page 11

TEMPERATURE COMPENSATIONTEMPERATURE COMPENSATION

TEMPERATURE COMPENSATION

TEMPERATURE COMPENSATIONTEMPERATURE COMPENSATION

Three options of compensating temperature are available:

Automatic (Atc): The probe has a built-in temperature sensor; the

value of the temperature is used to automatically compensate the EC/

TDS reading. This is the default option.

Manual (Mtc): The temperature value, shown on the lower LCD, can

be manually set by the user with the up and down arrow keys. The

"°C" symbol blinks when this option is active.

No Compensation (notc): The temperature reading shown on the

lower LCD is not taken into account. The reading displayed on the

upper LCD is the actual EC or TDS value. The "%TC" symbol blinks

when this option is active.

To select the desired option press the ATC key until the

option is briefly displayed on the LCD.

If temperature compensation is active, measurements are compensated using a default temperature coefficient of 1.90 %/°C.

It is possible to select a different temperature coefficient (TC) in the

0.00 to 6.00 %/°C range by entering the setup mode and selecting

the "tc" item (see SETUP section for details).

The current temperature coefficient can be

quickly viewed pressing ALT+TC. The value

is briefly displayed on the lower LCD.

Note: If the temperature reading is out of –9.9 - 120.0 °C interval,

and ATC or MTC option is selected, the temperature limit range

value will be displayed together with the "°C" tag blinking.

Temperature compensation is performed by means of the following

formula:

Compensated conductivity = Measured conductivity/[1+α(T-T

where T is the measured temperature and T

is the reference

ref

)/100]

ref

temperature (20 or 25°C).

Note that if a solution has a temperature coefficient α with T

=25°C,

ref

when changing the reference temperature to 20°C, the temperature

coefficient must be manually adjusted by the user according to the

following formula: β=α/(1-α/20)

For example, β=2.10%/°C when α=1.90%/°C.

Note that: α=β/(1+β/20)

Always set reference temperature to 25°C when measuring TDS.

11

Page 12

EC/TDS CALIBRATIONEC/TDS CALIBRATION

EC/TDS CALIBRATION

EC/TDS CALIBRATIONEC/TDS CALIBRATION

EC calibration is a single point procedure. Selectable calibration points

are: 0.0, 84.0 µS/cm, 1413 µS/cm, 5.00 mS/cm, 12.88 mS/cm,

80.0 mS/cm,111.8 mS/cm.

To enter EC calibration select the EC range and press

the CAL key.

Note: TDS reading is automatically derived from the EC reading

and no specific calibration for TDS is needed. Pressing CAL

while TDS range is selected has no effect.

Rinse the probe with some of the calibration solution or deionized

water. Immerse the probe into the solution. The sleeve holes must be

completely submerged. Tap the probe repeatedly to remove any air

bubbles that may be trapped inside the sleeve.

For zero calibration, just leave the dry probe in air.

The indications "STD" and "CAL" are displayed. The upper LCD shows the uncalibrated

EC reading. The lower LCD shows the buffer

value. The stability indicator " " blinks.

Select the desired value with the and

keys, if necessary.

When the " " symbol stops blinking, the

reading is stable. The "CFM" indication starts

blinking on the LCD asking for confirmation.

Press ALT+CFM to confirm the calibration.

If everything is satisfactory, the meter displays the "Stor Good" message and returns

to measurement mode.

Notes:

• If the uncalibrated reading is too far from the expected value or

the temperature value is out of 0 – 60°C range, calibration is not

recognized. The "CFM" indication does not appear; the " " and

"STD" symbols blink to signal wrong or contaminated calibration

solution. If the temperature value is out of 0 – 60°C range,

the "°C" tag will also be displayed blinking on the LCD.

• For best results choose a calibration value close to the sample to test.

• In order to minimize the EMC interferences, use plastic beakers.

• The meter uses 1.90%/°C compensation factor during calibration.

If the setup item "tc" has been set to a different value, when

exiting the calibration mode the value displayed on the upper LCD

could be different from the nominal buffer value.

• It is possible to set the cell constant value directly without following

the calibration procedure. To set the cell constant enter the setup

mode and select "CEL" (see SETUP for details).

12

Page 13

NN

aa

CC

ll

CALIBRATION CALIBRATION

N

a

C

l

CALIBRATION

NN

aa

CC

ll

CALIBRATION CALIBRATION

Calibration is 1-point at 100.0% NaCl. Use the HI7037 calibration

solution (sea water solution) as a 100% NaCl standard solution.

• To enter NaCl calibration select the NaCl range and press CAL.

• Rinse the probe with some of the calibration solution or deionized

water. Immerse the probe into HI 7037 solution. The sleeve holes

must be completely submerged. Tap the probe repeatedly to remove any air bubbles that may be trapped inside the sleeve.

• The indications "STD" and "CAL" are displayed. The upper LCD

shows the uncalibrated NaCl reading in percentage. The lower LCD

shows "100".

• When the " " symbol stops blinking, the reading is stable. The

"CFM" indication starts blinking on the LCD asking for confirmation.

• Press ALT+CFM to confirm the calibration.

• If everything is satisfactory, the meter displays

the "Stor Good" message and returns to measurement mode.

Note: If the uncalibrated reading is too far from the expected value,

the calibration is not recognized. The "CFM" indication does not

appear; the " " and "STD" symbols blink to signal wrong or

contaminated calibration solution.

TEMPERATURE CALIBRATIONTEMPERATURE CALIBRATION

TEMPERATURE CALIBRATION

TEMPERATURE CALIBRATIONTEMPERATURE CALIBRATION

((

for technical personnel only)for technical personnel only)

(

for technical personnel only)

((

for technical personnel only)for technical personnel only)

The calibration is a 2-point procedure at 0.0 and 50.0°C.

• Immerse the probe in a 0°C temperature bath.

• To enter temperature calibration mode, press and hold LOG+CAL,

then turn the meter on.

• The lower LCD displays "0.0°C"; "STD" and "CAL" tags appear.

• When the reading is stable, "CFM" symbol starts to blink.

• Press ALT+CFM to confirm. The lower LCD displays 50.0°C.

• Immerse the probe in a 50°C temperature bath.

• When the reading is stable, "CFM" symbol starts to blink.

• Press ALT+CFM to confirm and return to normal operation.

13

Page 14

TEMPERATURE ADJUSTMENTEMPERATURE ADJUSTMEN

TEMPERATURE ADJUSTMENT

TEMPERATURE ADJUSTMENTEMPERATURE ADJUSTMEN

The temperature reading can be manually fine-tuned by following

this procedure:

To enter the temperature calibration mode,

press and hold LOG+CAL, then turn the

meter on.

Press CAL to enter the temperature adjustment mode. The upper and lower LCD will

display the current temperature reading.

Adjust the temperature reading on

the upper LCD using the arrow

keys. The maximum adjustment is

±1°C around current reading.

Press ALT+CFM to confirm. The meter

returns to measurement mode and displays the new temperature.

Note: Press LOG+CAL to escape without any changes.

14

Page 15

LOGGING FUNCTIONLOGGING FUNCTION

LOGGING FUNCTION

LOGGING FUNCTIONLOGGING FUNCTION

To store the current reading in memory press the LOG key while in

measurement mode. The LCD will display "Stor" along with the "LOG"

indication and the sample number for a few seconds.

By pressing the LOG key a complete set of information is memorized:

date, time, EC/TDS/NaCl and temperature readings.

Up to 250 samples can be stored into memory.

When the memory is full and the LOG key is

pressed, the sample will not be stored and the

LCD will display "FULL". In this case it is necessary

to delete some data from memory to proceed.

TO VIEW LOGGED DATATO VIEW LOGGED DATA

TO VIEW LOGGED DATA

TO VIEW LOGGED DATATO VIEW LOGGED DATA

To retrieve the memorized information press ALT+RCL.

The meter displays the date (upper LCD) and the number (lower LCD)

of the last logged sample. The "ZERO" indication will be displayed if

no samples are stored in memory.

• Select the desired sample number with the

arrow keys. Pressing the key while the

last sample is displayed causes the meter to

go to the first sample.

• Press RANGE to view remaining data of the

selected sample. After the date information,

the remaining data will be displayed in the

following order:

15

Page 16

– Year

– Time

– EC, TDS, NaCL reading;

"----" means reading out of range or

no probe was connected.

– Temperature reading;

"----" means reading out of range.

• It is always possible to skip to another sample using the up and

down arrow keys. For example, if the reading of a sample is

displayed, pressing the up arrow key will cause the meter to

display the reading of the next sample.

• It is possible to return to normal operational mode at any time by

pressing ALT+RCL.

TO DELETE LOGGED DATATO DELETE LOGGED DATA

TO DELETE LOGGED DATA

TO DELETE LOGGED DATATO DELETE LOGGED DATA

It is possible to delete a single sample or all the memory at one time.

To delete a single sample:

• Enter the viewing logged data mode and select the desired

sample number.

• Press ALT+AutoEnd. The "CFM" indication

starts blinking asking for confirmation.

• Press the ALT+CFM to confirm deletion.

Note: Press ALT+AutoEnd to escape without data deletion.

When viewing through the logged data, the "NULL" message will be

displayed when selecting a deleted sample.

16

Page 17

To delete all logged data:

• Enter the viewing logged data mode.

• Press ALT+TC. The "CFM" indication will

start blinking asking for confirmation.

• Press ALT and CFM to confirm deletion.

Note: Press ALT+TC to escape without data deletion.

Note: If no samples are stored in memory and a deletion is

attempted, the meter will show the message "Zero" and then

returns to normal operational mode.

17

Page 18

DATA TRANSFER TO PCDATA TRANSFER TO PC

DATA TRANSFER TO PC

DATA TRANSFER TO PCDATA TRANSFER TO PC

Connect the meter

is located on the top of the meter). Use HI 920011 (5 to 9-pin)

connection cable.

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

Isolated 8-bit data transmission

Baud Rate: 2400

Start bit: 1

Stop bit: 1

Parity bit: none

SENDING COMMANDS FROM PCSENDING COMMANDS FROM PC

SENDING COMMANDS FROM PC

SENDING COMMANDS FROM PCSENDING COMMANDS FROM PC

It is possible to remotely control the instrument with any terminal

programs. Connect the meter to the PC through the HI 920011

cable, start the terminal program and set the communication options

as follows: 8, N, 1, no flow control.

To send a command to the meter, follow the next scheme:

The computer sends the command expressed as a 3-character sequence

and a CR character.

Note: All the terminal programs that support the ANSI escape

sequence, represent the CR character with the string '^M'.

The available commands are the following:

MOD - to request the firmware code of the meter.

RPA - to request the setup parameters setting.

LTB - to request the number of logged samples.

LOD - to request the logged data.

Note: The meter will send <CAN> if a corrupted or unknown

command is received.

to a PC through the RS232C output (the connector

<

command>

The meter answers with the following order:

status byte

date (ddmmyy)

time (hhmm)

measurement (binary)

temperature reading (binary)

At the end of the logged data the checksum (2 complement)

is sent.

<CR>

18

Page 19

BATTERY REPLACEMENTBATTERY REPLACEMENT

BATTERY REPLACEMENT

BATTERY REPLACEMENTBATTERY REPLACEMENT

When the batteries are inserted and no power adapter is connected,

the meter can recognize the following battery charge levels:

• Low battery - the battery symbol is displayed on the LCD.

Backlight is automatically disabled and it is not possible to

enable it until new batteries are inserted or an external power

adapter is used. When the battery symbol appears, batteries

have typically 10% of their life left and the meter is still

measuring properly.

• Very weak battery - The meter shuts off to avoid erroneous

operations.

Note: If the meter is not powered for several minutes (e.g. in dead

battery condition), the current date and time are lost.

Battery replacement must only take place in a non-hazardous area

using 1.5V alkaline AA type batteries.

In order to replace run down batteries, simply

remove the two screws on the rear cover of the

instrument and replace the four 1.5V AA

batteries with new ones, paying attention to

the correct polarity.

New batteries allow approx. 200 hours of continuous use (with 2700

mA/h batteries).

A 12VDC power adapter can also be used. It is recommended to use the

Hanna voltage adapters that use the proper polarity configuration.

However, other adapters can be used. In

this case, check the polarity of your adapter

before connecting it to the meter.

PROBE MAINTENANCEPROBE MAINTENANCE

PROBE MAINTENANCE

PROBE MAINTENANCEPROBE MAINTENANCE

Rinse the probe with clean water after measurements. If a more

thorough cleaning is required, remove the probe sleeve and clean the

probe with a cloth or a nonabrasive detergent.

Make sure to reinsert the sleeve onto the probe properly and in the

right direction.

After cleaning the probe, recalibrate the instrument.

19

Page 20

CONDUCTIVITY VS. TEMPERATURECONDUCTIVITY VS. TEMPERATURE

CONDUCTIVITY VS. TEMPERATURE

CONDUCTIVITY VS. TEMPERATURECONDUCTIVITY VS. TEMPERATURE

CHARTCHART

CHART

CHARTCHART

The conductivity of an aqueous solution is the measure of its ability to

carry an electrical current by means of ionic motion.

The conductivity invariably increases with increasing temperature.

It is affected by the type and number of ions in the solution and by

the viscosity of the solution itself. Both parameters are temperature

dependent. The dependency of conductivity on temperature is expressed as a relative change per degree Celsius at a particular

temperature, commonly as percent per °C.

The following table lists the temperature dependence of HANNA EC

calibration buffers.

0307IH

1307IH

3307IH

4307IH

CºFº

02305176774600384004560672

51402286985600535001470813

0105033902017600695002385163

51950840174118600456005293604

60270137110700276004495514

618.0

716.260590199111700586003695424

814.460911152213700896002897334

912.6603411152147003170020019244

02860761187

128.9601911503187000470004017164

226.1705121233197002570095011174

324.3709321953118005670097015084

422.5704621683

527708821314148000080081110005

628.8703131044168003180083116905

726.0807331764178000380075110915

824.280263149419800

922.4807831125109003680079113835

036802141845129002880081219745

138.7807341575149000090093215755

0308IH

1308IH

(μ )mc/S

(μ )mc/S

2167004270012013254

128003870089012094

3308IH

(μ )mc/S

(μ )mc/S

9480077116825

5307IH

4308IH

5308IH

(μ )mc/S

7IH

930

9308IH

(μ )mc/S

20

Page 21

ACCESSORIESACCESSORIES

ACCESSORIES

ACCESSORIESACCESSORIES

CONDUCTIVITY CALIBRATION SOLUTIONSCONDUCTIVITY CALIBRATION SOLUTIONS

CONDUCTIVITY CALIBRATION SOLUTIONS

CONDUCTIVITY CALIBRATION SOLUTIONSCONDUCTIVITY CALIBRATION SOLUTIONS

HI 70030P 12880 µS/cm solution, 20 mL sachet (25 pcs.)

HI 7030L 12880 µS/cm solution, 500 mL bottle

HI 7030M 12880 µS/cm solution, 230 mL bottle

HI 70031P 1413 µS/cm solution, 20 mL sachet (25 pcs.)

HI 7031L 1413 µS/cm solution, 500 mL bottle

HI 7031M 1413 µS/cm solution, 230 mL bottle

HI 70033P 84 µS/cm solution, 20 mL sachet (25 pcs.)

HI 7033L 84 µS/cm solution, 500 mL bottle

HI 7033M 84 µS/cm solution, 230 mL bottle

HI 7034L 80000 µS/cm solution, 500 mL bottle

HI 7034M 80000 µS/cm solution, 230 mL bottle

HI 7035L 111800 µS/cm solution, 500 mL bottle

HI 7035M 111800 µS/cm solution, 230 mL bottle

HI 70039P 5000 µS/cm solution, 20 mL sachet (25 pcs.)

HI 7039L 5000 µS/cm solution, 500 mL bottle

HI 7039M 5000 µS/cm solution, 230 mL bottle

HI 7037L 100% NaCl sea water standard solution, 500 mL

bottle

PROBE CLEANING SOLUTIONSPROBE CLEANING SOLUTIONS

PROBE CLEANING SOLUTIONS

PROBE CLEANING SOLUTIONSPROBE CLEANING SOLUTIONS

HI 7061M General Cleaning Solution, 230 mL bottle

HI 7061L General Cleaning Solution, 500 bottle

21

Page 22

OTHER ACCESSORIESOTHER ACCESSORIES

OTHER ACCESSORIES

OTHER ACCESSORIESOTHER ACCESSORIES

HI 76309/1.5 stainless steel 4-ring conductivity/TDS probe with

temperature sensor and 1.5 m cable.

HI 710005 12VDC voltage adapter (US plug)

HI 710006 12VDC voltage adapter (European plug)

HI 710012 12VDC voltage adapter (UK plug)

HI 710013 12VDC voltage adapter (S. Africa plug)

HI 710014 12VDC voltage adapter (Australian plug)

HI 740027 1.5V AA batteries (4 pcs)

HI 740036 100 mL plastic beaker (6 pcs)

HI 740034 Cap for 100 mL beakers (6 pcs)

HI 76405 Electrode holder

22

Page 23

RECOMMENDATIONS FOR USERS

Before using this product, make sure that it is entirely suitable for the

environment in which it is used.

Operation of this instrument in residential areas could cause

unacceptable interferences to radio and TV equipment, requiring

the operator to follow all necessary steps to correct interferences.

The metal bands of the probe are sensitive to electrostatic discharges. Avoid

touching these metal bands at all times.

To maintain the EMC performance of this equipment the recommended

cables must be used.

Any variation introduced by the user to the supplied equipment may

degrade the instrument's EMC performance.

To avoid electrical shock, do not use this instrument when voltages at

the measurement surface exceed 24 VAC or 60 VDC.

To avoid damage or burns, do not perform any measurement in

microwave ovens.

Hanna Instruments reserves the right to modify the design,

construction and appearance of its products without advance notice.

23

Page 24

SALES AND TECHNICAL SERVICE CONTACTS

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (21) 4584.2941 • Fax (21) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. 66.2619.0708 • Fax 66.2619.0061

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and a complete list of Sales and

Technical offices, please see www.hannainst.com

MAN98360

02/05

.

Loading...

Loading...