Page 1

Instruction Manual

HI 983318-0

HI 983318-1

Panel-Mounted

TDS Indicators &

Controllers

These Instruments are in

Manufacturers since 1978

WARRANTY

These meters are warranted for two years against defects in workmanship and materials when used for their intended purpose and

maintained according to instructions. The probe is warranted for a

period of six months. This warranty is limited to repair or replacement

free of charge.

Damages due to accident, misuse, tampering or lack of prescribed maintenance are not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of purchase, serial number and the nature of the failure. If the repair is not

covered by the warranty, you will be notified of the charges incurred. If

the instrument is to be returned to Hanna Instruments, first obtain a

Returned Goods Authorization Number from the Customer Service department and then send it with shipment costs prepaid. When shipping any

instrument, make sure it is properly packaged for complete protection.

To validate your warranty, fill out and return the enclosed warranty card

within 14 days from the date of purchase.

All rights are reserved. Reproduction in whole or in part is prohibited

without the written consent of the copyright owner, Hanna Instruments

Inc., Woonsocket, Rhode Island, 02895 , USA.

Compliance with the CE Directives

Dear Customer,

Thank you for choosing a Hanna product. This manual will

provide you with the necessary information for the correct

operation of the meter. Please read it carefully before using

the meter. If you need additional technical information, do

not hesitate to e-mail us at tech@hannainst.com.

These instruments are in compliance with the directives.

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and

examine it carefully. If any damage has occurred during

shipment, immediately notify your Dealer or the nearest

Hanna Customer Service Center.

The meter is supplied with:

• Instruction manual;

• Mounting brackets.

Note: Conserve all packing material until the instrument

has been observed to function correctly. Any defective

item must be returned in its original packing.

GENERAL DESCRIPTION

HI983318-0 and HI983318-1 are conductivity indicators

and controllers with a relay output designed for simplicity of

use in a wide range of applications.

The models are panel mounted with membrane keypads on

the front panel and an easy-to-read LCD display.

All the meters compensates for the temperature variation

automatically. The probe is easy to clean and requires little

maintenance.

Measurements are highly accurate and the meters can be

calibrated at one point.

Power supply, wiring and selection are made via the plugin terminal blocks on the rear panel.

LED indicators on the front panel identify whether the

controller is in set or measurement mode, and if alarm is

active.

SPECIFICATIONS

HI 983318

Range 0.00 to 10.00 ppt

Resolution 0.01 ppt

Accuracy (@ 20°C) ±2% f.s.

Setpoint Adjustable through multiturn trimmer

Alarm Condition LED ON and alarm contact closed

when TDS value is higher than setpoint

Alarm Output 2-contact relay, no fuse protected.

5A, 240 VAC, 30 VDC

Probe HI 7632-00 EC/TDS probe

Temp. Compensation Automatic from 5 to 50°C

(41 to 122°F) with ß=2%

TDS Conversion Factor 0.5

Calibration Manual, at one point through trimmer

Calibration Solution HI 7038 (6,44 ppt)

Power supply: External

HI983318-0 12 VDC

HI983318-1 115/230 VAC; 50/60Hz

Dimensions 79 x 49 x 95 mm (3.1 x 1.9 x 3.7”)

Weight:

HI983318-0 140 g (4.96 oz)

HI983318-1 250 g (8.85 oz)

CE DECLARATION

OF CONFORMITY

Recommendations for Users

Before using these products, make sure that they are entirely suitable for

the environment in which they are used. Operation of these instruments in

residential areas could cause unacceptable interferences to radio and TV

equipment. The metal band at the end of the probe is sensitive to electrostatic discharges. Avoid touching this metal band at all times. During operation, ESD wrist straps should be worn to avoid possible damage to the

probe by electrostatic discharges. Any variation introduced by the user to

the supplied equipment may degrade the instrument’s EMC performance.

To avoid electrical shock, do not use these instruments when voltage at the

measurement surface exceeds 24 VAC or 60 VDC. Use plastic beakers to

minimize any EMC interferences.

To avoid damage or burns, do not perform any measurement in microwave

ovens.

ISTR983318R4 12/01

Hanna Instruments reserves the right to modify the design, construction and appearance of its products without advance notice.

http://www.hannainst.com

Page 2

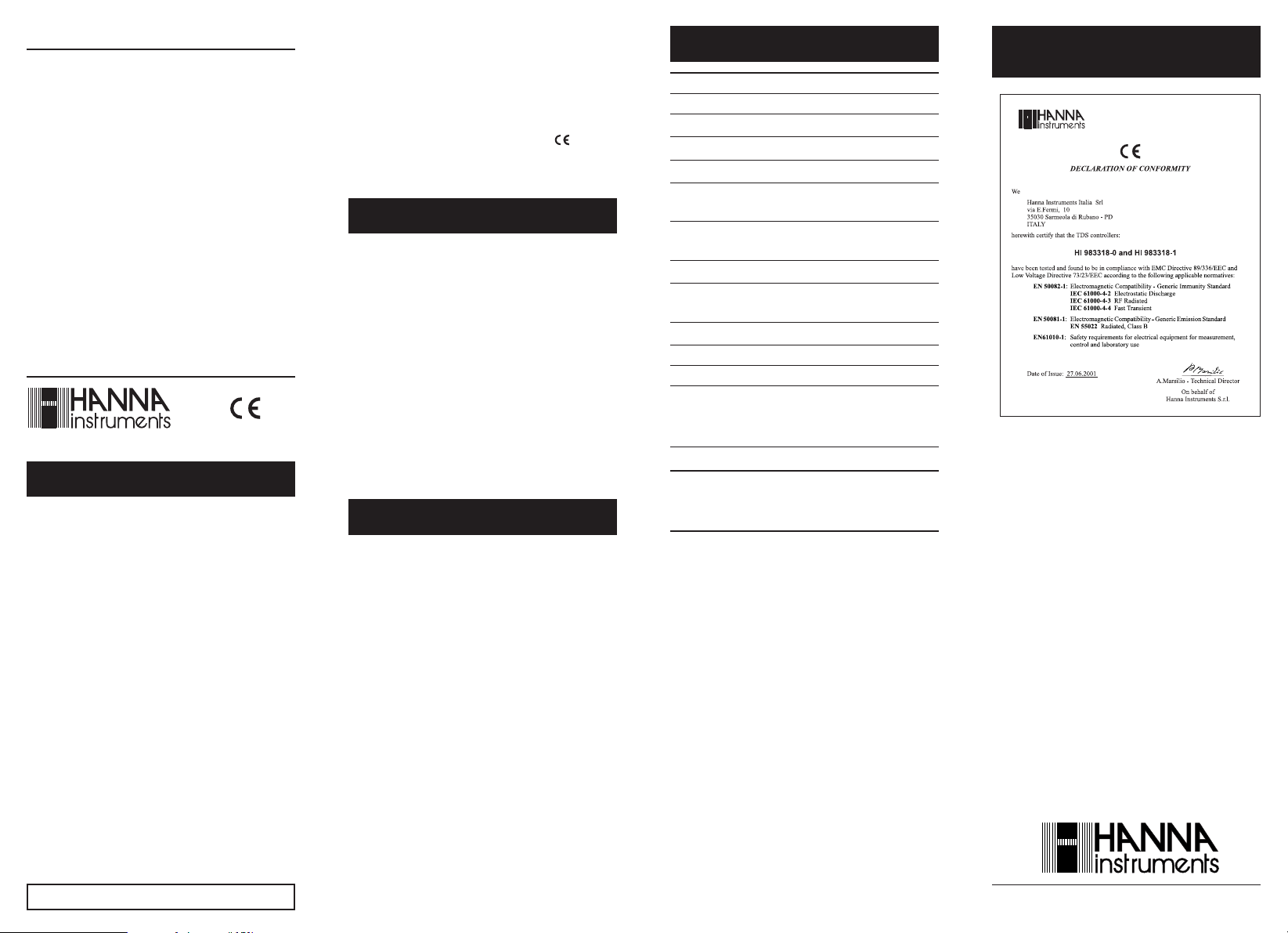

FUNCTIONAL DESCRIPTION

HI 983318

TDS CONTROLLER

FRONT PANEL

Keypad

SET To display

setpoint

MEAS To display mea-

surement

Trimmers

CAL For calibration

SET To adjust

setpoint

LEDs

SET ON when LCD displays the set value

MEAS ON when LCD displays the measured value

ALARM ON when alarm contact is activated

REAR PANEL

1. Power Supply:

HI 983318-0 HI 983318-1

12 VDC 115/230 VAC

L1: Positive 230 VAC

L2: Negative 115 VAC

L3: ------- Neutral

L4: ------- Protection Earth

Note: the power input is internally protected by a 400 mA fuse

2. Alarm Contact: A1, A2.

This contact acts as a switch for the power. The contact

has to be protected outside by the user.

HI 983318

TDS CONTROLLER

0.00 ...10.00 ppt

ALARM

SET MEAS

CAL

SET

ppt

3. Probe Connection: follow the above diagram and connect the

colored wires of probe cable as indicated. It is recommended

to connect the shield (P5) to avoid any interference.

OPERATIONAL GUIDE

POWER CONNECTION

HI 983318-0

Connect a 2-wire power cable to the terminal strip while

paying attention to the correct positive and negative polarities (12 VDC).

HI 983318-1

Connect a 3-wire power cable to the terminal strip while

paying attention to the correct earth, neutral and line

contacts (115/230 VAC).

Notes:

• All external cables connected to the rear panel should

end with wire lugs.

• It is recommended to cover the unused terminals with

insulating tape.

• At start up the meter needs a few seconds to stabilize.

Wait until a stable reading is displayed.

ALARM CONTACT

Use this contact (maximum 5A, 240VAC, 30 VDC) for

connection to an alarm or dosing system. The unit acts as a

switch to control an external device.

OPERATING THE METER

All operations are via the front panel keys and trimmers.

“SET” and “MEAS” LEDs light up to indicate which is the

operating function.

Make sure that the meter is calibrated and the Setpoint is

properly selected before performing any measurement.

Attach the probe to the meter. Install the probe in the

fittings or immerse it in the solution to be monitored, while

making sure that metal pins are completely submerged.

Press the “MEAS” key.

The he LCD will show the TDS value of the solution in ppt

unit. Any initial variation on readings may be due to

temperature compensation.

The “ALARM” LED will light up when the alarm contact is

closed, to indicate a TDS value higher than selected setpoint.

sample.

When the alarm contact is closed, the "ALARM" LED will be

lit.

CALIBRATION

Make sure the meter is in the measurement mode (the

MEAS” LED lights on).

Immerse the probe in HI7038 (6,44 ppt) calibration solution or another solution with a known g/L value.

Shake briefly and wait for reading to stabilize.

Using a small screwdriver adjust the calibration trimmer

until the meter displays “6.44” ppt or any other value

accordingly to the calibration solution. All future measure-

ments will be compensated for temperature with reference to

25ºC (77ºF).

SETPOINT

Press the “SET” key. The display will show the default or

previously adjusted value for the setpoint.

Using a small screwdriver, adjust the “SET” trimmer until

the required limit value is displayed.

PROBE MAINTENANCE

To improve probe performance and prolong its life, it is

recommended to clean it regularly.

• Immerse the tip of the probe in HI 7061 Cleaning

Solution for one hour.

• If a more thorough cleaning is required, brush the

metal pins with very fine sandpaper.

• After cleaning, rinse the probe with tap water and

recalibrate the meter.

• When not in use, clean the probe before storing it away.

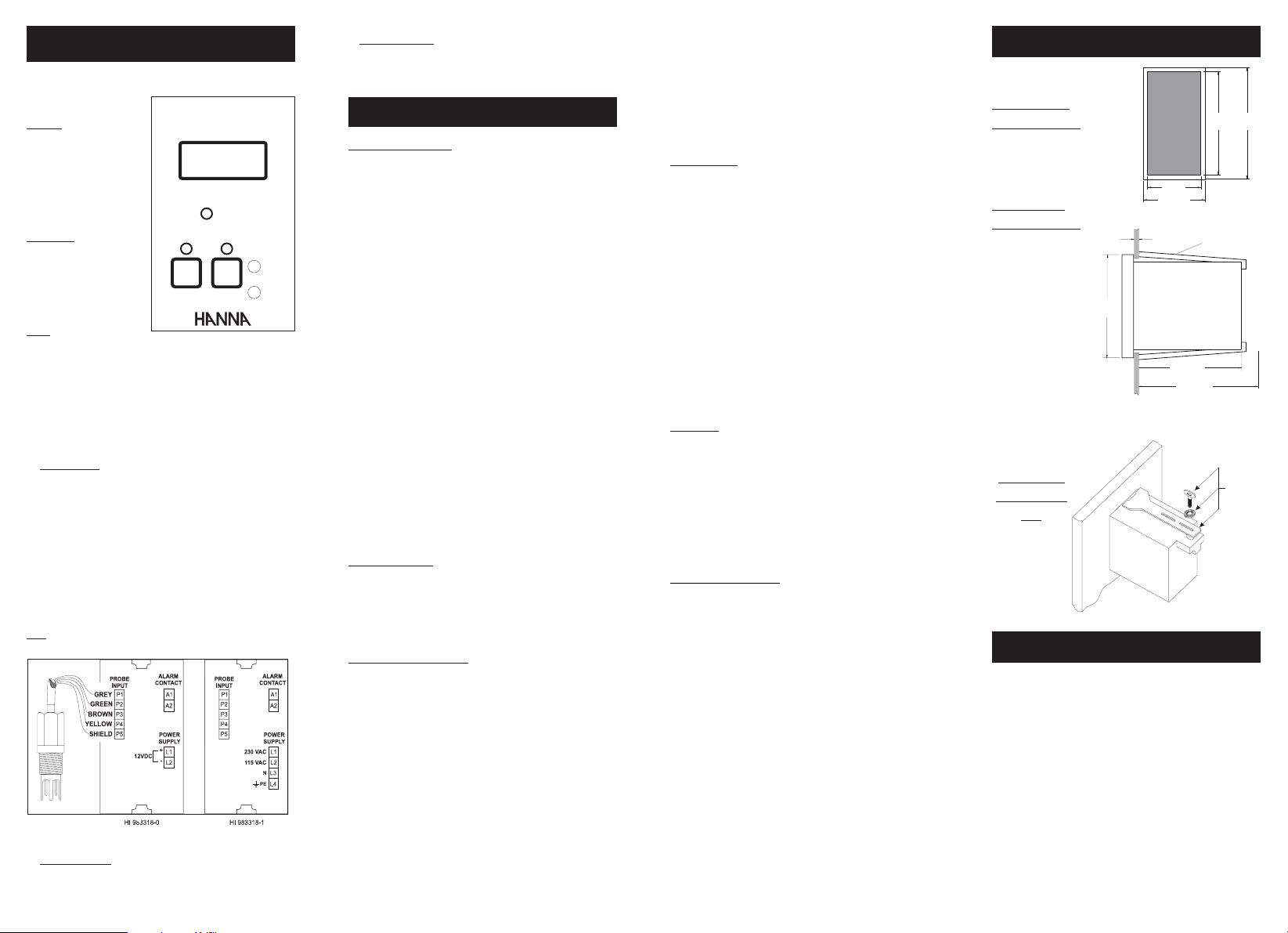

HI 983318 LAYOUT

Front view of the

panel-mounted unit

Side view of the

panel-mounted unit

Supplied adjustable location brackets allow

the controller to slide

into the cutout and will

hold the unit securely

in place. 95 mm

(3.74") is the minimum

amount of space required to install the

controller with the cables

connected.

Panel-mounted

unit assembling

view

79mm

3.11"

0.25/4mm

0.01/0.160"

42mm

1.65"

49mm

1.93"

76mm

3"

95mm MIN

3.74"

73mm

2.87"

ADJUSTABLE

LOCATION

BRACKET

79mm

HI 740146

ACCESSORIES

HI 7632-00 EC/TDS probe

HI 70038P 6,44 ppt Calibration solution, 20mL sachet (25 pcs)

HI 7061M Electrode cleaning solution, 230 mL bottle

HI 710005 12 VDC power adapter, US plug

HI 710006 12 VDC power adapter, European plug

HI 710012 12 VDC power adapter, Australian plug

HI 710013 12 VDC power adapter, Southern african plug

HI 710014 12 VDC power adapter, UK plug

HI 731326 Calibration Screwdriver (20 pcs)

HI 740146 Mounting brackets

3.11"

Loading...

Loading...