Page 1

Instruction Manual

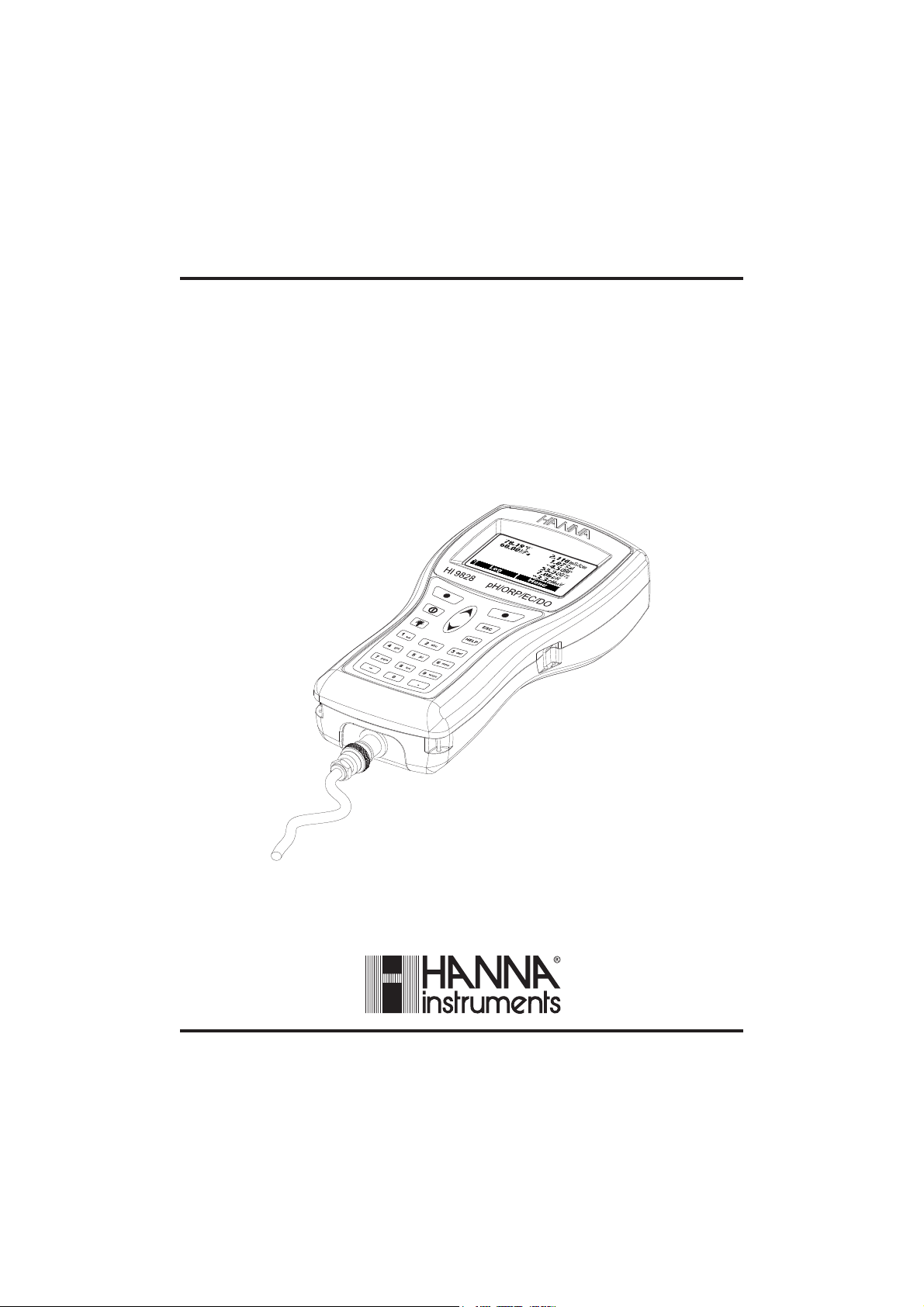

HI 9828

Multiparameter

www.hannainst.com

1

Page 2

2

Page 3

Dear CustomerDear Customer

Dear Customer,

Dear CustomerDear Customer

Thank you for choosing a Hanna Instruments product.

Please read this instruction manual carefully before using the instrument. It will

provide you with the necessary information for correct use of the instrument, as

well as a precise idea of its versatility.

If you need additional technical information, do not hesitate to e-mail us at

tech@hannainst.comtech@hannainst.com

tech@hannainst.com or see the back cover for our worldwide contact list.

tech@hannainst.comtech@hannainst.com

This instrument is in compliance with the

directives.

Hanna Instruments reserves the right to modify the design,

construction and appearance of its products without advance notice.

3

Page 4

TABLE OF CONTENTS

CHAPTER 1- INTRODUCTION

1.1 Preliminary examination .............................................................................. 7

1.2 Model identification .................................................................................... 7

1.3 General description .................................................................................... 8

1.4 Power supply.............................................................................................. 9

1.4.1 Batteries installation .............................................................................. 9

1.4.2 Recharging batteries ............................................................................. 9

1.5 Probe description & installation .................................................................. 10

1.5.1 Sensors description ............................................................................. 10

1.5.2 Sensors specifications ......................................................................... 11

1.5.3 D.O. sensor activation ........................................................................ 12

1.5.4 Installation ......................................................................................... 12

1.6 Specifications ........................................................................................... 13

1.7 Display & keyboard description .................................................................. 17

1.8 Help function ........................................................................................... 18

CHAPTER 2 - MEASUREMENT MODE

2.1 Procedure ................................................................................................ 19

CHAPTER 3 - SYSTEM SETUP

3.1 Measurement setup .................................................................................. 20

3.2 System setup ............................................................................................ 22

3.3 Table of measurement & setup items .......................................................... 26

CHAPTER 4 - CALIBRATION MODE

4.1 Quick calibration ..................................................................................... 28

4.2 pH calibration .......................................................................................... 30

4.2.1 Preparation ........................................................................................ 30

4.2.2 Procedure .......................................................................................... 30

4.2.3 Error list ............................................................................................ 32

4

Page 5

4.3 Dissolved oxygen calibration ..................................................................... 33

4.3.1 Procedure .......................................................................................... 33

4.4 Conductivity calibration ............................................................................ 34

4.4.1 Procedure .......................................................................................... 35

4.5 Atmospheric pressure ................................................................................ 37

4.5.1 Procedure ............................................................................................. 37

4.6 ORP calibration ....................................................................................... 37

4.6.1 Procedure .......................................................................................... 37

4.7 Temperature calibration ........................................................................... 38

4.7.1 Procedure .......................................................................................... 38

CHAPTER 5 - LOGGING MODE

5.1 Logging ................................................................................................... 39

5.1.1 Logging options ................................................................................. 39

5.2 Log data setup ......................................................................................... 40

5.2.1 Lots ................................................................................................... 41

5.2.2 Delete all lots ..................................................................................... 42

5.2.3 Remarks ............................................................................................ 42

5.2.4 Delete all remarks .............................................................................. 43

5.2.5 Tags .................................................................................................. 43

CHAPTER 6 - GLP

6.1 Probe information..................................................................................... 45

6.2 pH .......................................................................................................... 46

6.3 Dissolved oxygen...................................................................................... 46

6.4 Conductivity............................................................................................. 47

6.5 Atmospheric pressure ................................................................................ 47

6.6 ORP........................................................................................................ 48

6.7 Temperature............................................................................................. 48

CHAPTER 7 - PC CONNECTION

7.1 Software installation ................................................................................. 49

7.2 PC connection ......................................................................................... 49

CHAPTER 8 - ERROR MESSAGES................................................................ 51

5

Page 6

APPENDIX

A - PROBE MAINTENANCE ............................................................................ 53

B - ACCESSORIES.......................................................................................... 55

C - WARRANTY.............................................................................................. 57

USER NOTES ............................................................................................ 58

6

Page 7

Chapter 1 - INTRODUCTION

1.1 PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it carefully to

make sure that no damage has occurred during shipping. If there is any noticeable damage, notify your Dealer or the nearest Hanna Customer Service Center

immediately.

HI9828HI9828

HI9828 is supplied complete with:

HI9828HI9828

- Multisensor probe (pH/ORP, Conductivity, D.O.)

HI9828-25HI9828-25

-

HI9828-25 quick calibration standard solution, 500 mL

HI9828-25HI9828-25

- Calibration beaker

- Probe maintenance kit

- 4 rechargeable C size, Ni-MH batteries

- Power adaptor and cable

- Cigarette lighter cable

- 5 i-Button

HI7698281HI7698281

-

HI7698281 USB interface cable

HI7698281HI7698281

HI92000HI92000

-

HI92000 Windows® compatible software

HI92000HI92000

- Instruction manual

- Rugged carrying case

©

with holder

NONO

TETE

NO

TE Save all packing materials until you are sure that the instrument func-

NONO

TETE

tions correctly. Any damaged or defective items must be returned in

their original packing materials together with the supplied accessories.

1.2 MODEL IDENTIFICATION

Based on probe cable length, 3 different models are available according to the

following scheme:

Windows® is a registered Trademark of “Microsoft Co.”

7

Page 8

1.3 GENERAL DESCRIPTION

HI 9828HI 9828

HI 9828 is a multiparameter system that benefits from years of experience of

HI 9828HI 9828

Hanna Instruments as a manufacturer of analytical instruments. Waterproof,

resistant and easy to use, it is the ideal solution for field measurements of lakes,

rivers and sea. Thanks to the microprocessor based multisensor probe, it is possible to measure all the parameters necessary to evaluate the water quality, as

dissolved oxygen saturation percentage, conductivity, seawater specific gravity

and other parameters that ensure life in water as pH and temperature. It is also

possible to use the same probe with different meters without the need to recalibrate

the system.

Up to 12 parameters can be enabled and seen on the large graphic display with

backlight. All readings can be memorized and associated to a precise sampling

area thanks to the i-Button

©

system and the remarks that the operator can insert

before or during measurements. The same data can be plotted on the meter and

also downloaded to a PC by means of USB connector and

HI92000HI92000

HI92000 Windows

HI92000HI92000

compatible application for successive elaborations.

The setting menu can be protected by password to avoid not authorized modifications and the help function is always available to explain the selected function,

operation or message.

®

The main features of

HI9828HI9828

HI9828 series include:

HI9828HI9828

• Measurement of dissolved oxygen, pH, ORP, conductivity and related param-

eters, temperature, atmospheric pressure and seawater specific gravity

• Field replaceable sensor modules for DO, EC and pH/ORP

• 5 interface languages: English, Spanish, French, Portuguese, Italian

• Graphical display with backlight

• GLP features

• i-Button

©

system to remark the sampling area

• Up to 60,000 samples stored in 100 different lots

• Four C size Ni-MH rechargeable batteries

• Batteries recharged from mains power supply and from cigarette lighter

• Password protection

8

Page 9

1.4 POWER SUPPLY

HI9828HI9828

HI9828 runs with 4 rechargeable C size, Ni-MH batteries.

HI9828HI9828

On the display the battery symbol visualizes the remaining battery charge. When

this symbol starts blinking, it is necessary to recharge or replace them with new

ones. When the batteries are completely rundown the meter automatically shuts

off to avoid wrong readings.

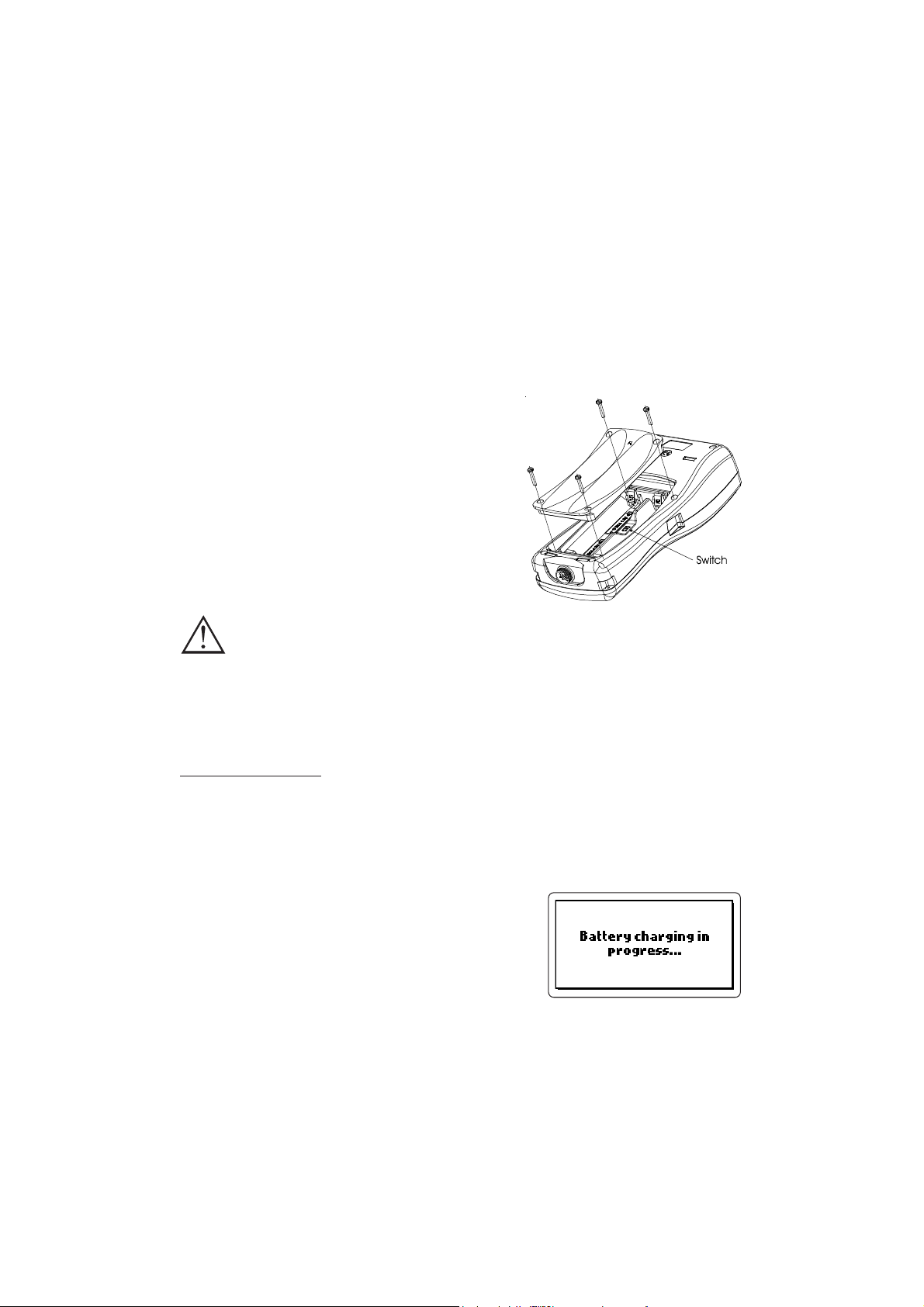

1.4.1 Batteries installation

Battery replacement must only take place in a

nonhazardous area.

Remove the 4 screws on the rear cover of the

instrument and insert the batteries while paying

attention to the correct polarity.

Move the switch down toward the probe connector if using rechargeable batteries. Move the

switch up for alkaline batteries.

Alkaline batteries can explode or leak when attempting to

recharge them with the switch set to down position.

1.4.2 Recharging batteries

HI9828HI9828

HI9828 is supplied with two cables for recharging batteries:

HI9828HI9828

HI710046HI710046

HI710046.

HI710046HI710046

HI710045HI710045

HI710045 and

HI710045HI710045

Mains power supply

In order to recharge batteries from the mains power supply, use

combined with the 12 Vdc adapter.

• With the meter OFF, disconnect the probe.

• Connect

HI710045HI710045

HI710045 to the meter and to the power adapter; connect the

HI710045HI710045

adapter to the mains power supply.

• The message “Battery charging in progress” ap-

pears and then the battery symbol.

• A complete batteries recharging will last about

14 hours.

HI710045HI710045

HI710045

HI710045HI710045

9

Page 10

Cigarette lighter supply

To recharge

HI9828HI9828

HI9828 from a vehicle cigarette lighter supply, use

HI9828HI9828

HI710046HI710046

HI710046.

HI710046HI710046

• Simply connect the cable to the meter and to the car’s cigarette lighter.

• The message “Battery charging in progress” appears on the display, followed

by the battery symbol.

• A complete batteries recharging will last about 14 hours.

NONO

TETE

NO

TE Batteries can also be recharged with the meter ON; if the auto-off

NONO

TETE

feature is enabled, the meter turns off automatically after the set time.

1.5 PROBE DESCRIPTION & INSTALLATION

HI9828HI9828

HI9828 is supplied with the multisensor probe for dissolved oxygen, tempera-

HI9828HI9828

ture, conductivity, pH and redox measurements.

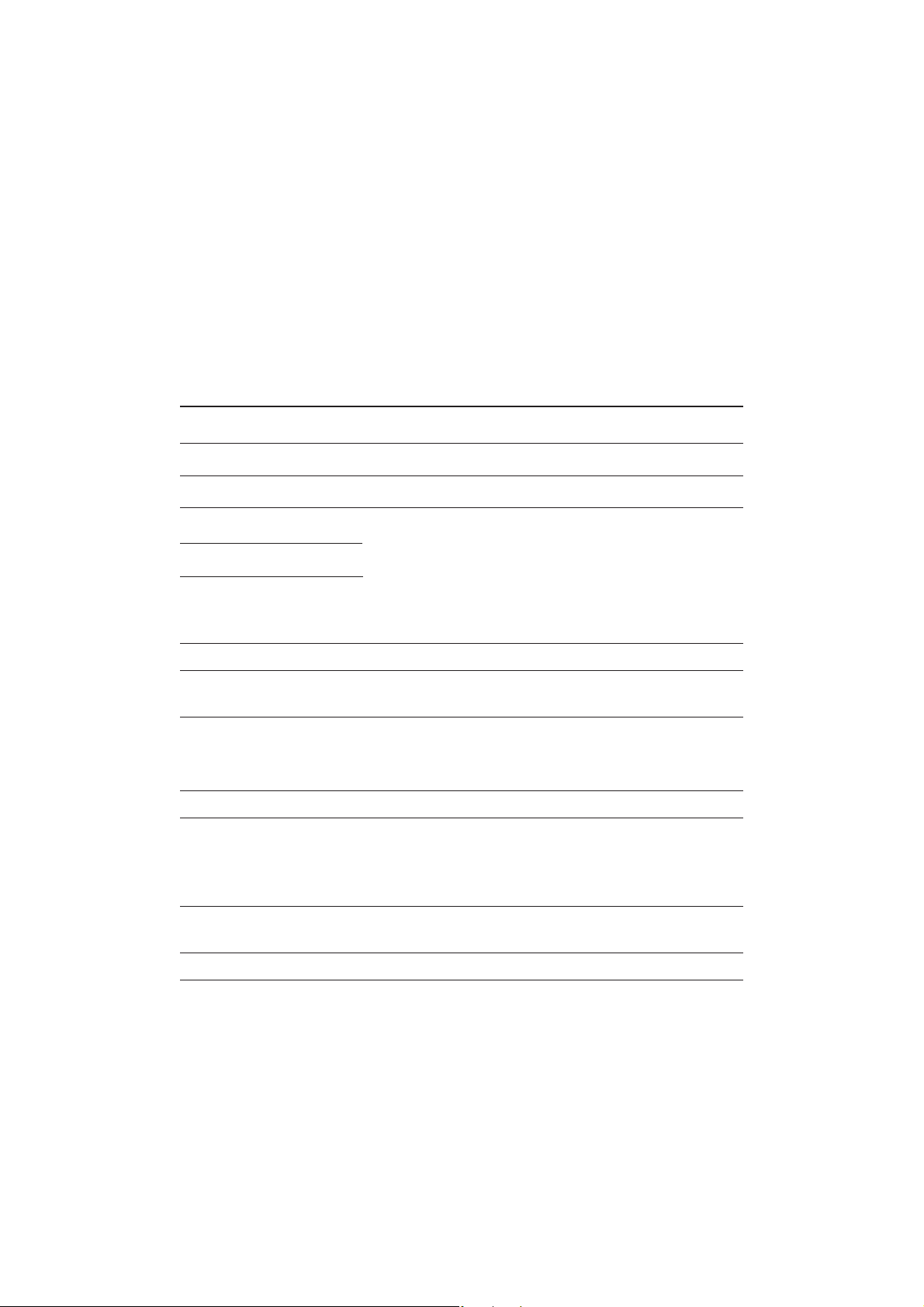

1.5.1 Sensors description

The galvanic D.O. sensor allows to have stable readings in

a few seconds. The thin permeable membrane isolates the

sensor elements from the testing solution, but allows oxygen

to enter. Oxygen that passes through the membrane causes

a current flow, from which the oxygen concentration is determined. Before installing the probe, it is necessary to activate the D.O. sensor; see paragraph 1.5.3 for details.

The conductivity sensor uses the 4-ring technology that allows stable and linear readings without any interference in

the whole range.

The pH/ORP sensor features a glass membrane for pH readings and a Pt sensor for redox measurements.

To avoid clogging problems and ensure a fast response, the

pH bulb must be kept moist at any time. Store the electrode

with few drops of

HI70300HI70300

HI70300 storage solution in the protec-

HI70300HI70300

tive cap.

The EC sensor also works as matching pin

and must be always mounted to have correct pH readings.

For correct redox measurements, the surface of the electrode must be clean and smooth, and a pretreatment procedure should be performed to ensure quick responses.

10

Page 11

Since the Pt/PtO system depends on the pH, the pretreatment of the electrode

may be determined by the pH and the redox potential values of the solution to be

measured.

As a general rule, if the ORP (mV) reading corresponding to the solution pH

value is higher than the values in the table below, an oxidizing pretreatment is

necessary; otherwise perform a reducing pretreatment.

pHpH

mVmV

pHpH

mVmV

pHpH

mVmV

pHpH

mVmV

pH pH

pH

pHpH

mV

mVmV

pH

pHpH

mV

mVmV

pH

pHpH

mV

mVmV

pH

pHpH

mV

mVmV

pH

pH pH

mV mV

mV

mV mV

pHpH

pH

pHpH

mVmV

mV

mVmV

0 990 1 920 2 860 3 800 4 740 5 680

6 640 7 580 8 520 9 460 10 400 11 340

12 280 13 220 14 160

For reducing pretreatment: immerse the electrode for a few minutes in HI 7091L.

For oxidizing pretreatment: immerse the electrode for a few minutes in HI 7092L.

1.5.2 Specifications of sensors

HI769828-0 HI769828-1 HI769828-2 HI769828-3

Sensor Type pH pH/ORP DO EC

Measure Type pH; mV (pH) pH; mV (pH); mV DO% sat; DO conc. EC; TDS;

resistivity; salinity

Measure Range 0.00 to 14.00 0.00 to 14.00 0.0 to 500.0 % 0.000-200.000 mS/cm

±600.0 mV (pH) ±600.0 mV (pH) 0.00 to 50.00 mg/L 0-400000 mg/L

Color Code Red Red White Blue

Materials Tip: glass (pH) Tip: glass (pH); Pt (ORP) Cat/An: Ag/Zn Stainless steel

Junction: cloth Junction: cloth Membrane: PTFE AISI 316

Body: PEI Body: PEI Body: PVC Body: PVC

Electrolyte: gel Electrolyte: gel

Reference: double Reference: double

Maintenance HI 70300 HI 70300 HI 7042S -

Solution (storage) (storage) (refilling)

Dimensions 100 x 14 Ø mm 100 x 14 Ø mm 101 x 16.5 Ø mm 111 x 14 Ø mm

±2000.0 mV 0 to 1.0000 MΩ/cm

0.00 to 70.00 PSU

11

Page 12

1.5.3 D.O. sensor activation

The D.O. probe is shipped dry. To hydrate the probe and prepare it for use proceed as follows:

• Remove the black & red plastic cap. This cap is used for shipping purposes only

and can be thrown away.

• Insert the supplied O-ring in the membrane.

• Rinse the supplied membrane with electrolyte while shaking it gently. Refill with

clean electrolyte. Gently tap the membrane over a surface to ensure that no air

bubbles remain trapped. To avoid damaging the membrane, do not touch it

with your fingers.

• With the sensor facing down screw the cap clockwise to the end of the threads.

Some electrolyte will overflow.

1.5.4 Installation

The multisensor probe can support 3 different electrodes, DO, EC, pH/ORP. To

make easier the installation, the 3 sensors have 3 proper color codes.

For correct sensor installation, proceed as follow:

• Grease the O-ring gaskets.

• Insert the sensor while paying attention to the correct alignment with the corre-

sponding colored connector; fix the sensor by screwing the locking nut with

the supplied tool.

• When all sensors are mounted, screw the protection sleeve for taking mea-

surements or the transparent beaker for calibration.

• With the meter off, connect the probe to the DIN socket on

the bottom of the meter by aligning the pins and pushing

in the plug. Tighten the nut to ensure a good connection.

12

Page 13

1.6 SPECIFICATIONS

TEMPERATURE

RR

angeange

R

ange -5.00 to 55.00 °C;

RR

angeange

23.00 to 131.00 °F; 268.15 to 328.15 K

RR

esolutionesolution

R

esolution 0.01 °C; 0.01 °F; 0.01 K

RR

esolutionesolution

AccuracyAccuracy

Accuracy ± 0.15 °C; ± 0.27 °F; ±0.15 K

AccuracyAccuracy

CalibrationCalibration

Calibration Automatic at 1 custom point

CalibrationCalibration

pHpH

pH

pHpH

RR

angeange

R

ange 0.00 to 14.00 pH; ± 600.0 mV

RR

angeange

RR

esolutionesolution

R

esolution 0.01 pH; 0.1 mV

RR

esolutionesolution

AccuracyAccuracy

Accuracy ± 0.02 pH; ± 0.5 mV

AccuracyAccuracy

CalibrationCalibration

Calibration Automatic 1, 2 or 3 points with 5 memorized

CalibrationCalibration

standard buffers (pH 4.01, 6.86, 7.01, 9.18, 10.01)

or 1 custom buffer

ORP

RR

angeange

R

ange ± 2000.0 mV

RR

angeange

RR

esolutionesolution

R

esolution 0.1 mV

RR

esolutionesolution

AccuracyAccuracy

Accuracy ± 1.0 mV

AccuracyAccuracy

CalibrationCalibration

Calibration Automatic at 1 custom point

CalibrationCalibration

DISSOLVED OXYGEN

RR

angeange

R

ange 0.0 to 500.0 %

RR

angeange

0.00 to 50.00 mg/L

RR

esolutionesolution

R

esolution 0.1 %

RR

esolutionesolution

0.01 mg/L

AccuracyAccuracy

Accuracy 0.0 to 300.0 %: ± 1.5 % of reading

AccuracyAccuracy

or ± 1.0% whichever is greater;

300.0 to 500.0 %: ± 3% of reading

0.00 to 30.00 mg/L: ± 1.5 % of reading

or 0.10 mg/L whichever is greater;

30.00 mg/L to 50.00 mg/L: ± 3% of reading

CalibrationCalibration

Calibration Automatic 1 or 2 points at 0, 100 % or 1 custom point

CalibrationCalibration

13

Page 14

CONDUCTIVITY

RR

angeange

R

ange 0.000 to 200.000 mS/cm

RR

angeange

(actual EC up to 400 mS/cm)

RR

esolutionesolution

R

esolution

RR

esolutionesolution

Manual 1 µS/cm; 0.001 mS/cm; 0.01 mS/cm; 0.1 mS/cm; 1 mS/cm

Automatic 1 µS/cm from 0 to 9999 µS/cm

0.01 mS/cm from 10.00 to 99.99 mS/cm

0.1 mS/cm from 100.0 to 400.0 mS/cm

Automatic mS/cm 0.001 mS/cm from 0.000 to 9.999 mS/cm

0.01 mS/cm from 10.00 to 99.99 mS/cm

0.1 mS/cm from 100.0 to 400.0 mS/cm

AccuracyAccuracy

Accuracy ±1 % of reading or ±1 µS/cm whichever is greater

AccuracyAccuracy

CalibrationCalibration

Calibration Automatic at 1 point with 6 memorized standards

CalibrationCalibration

(84 µS/cm, 1413 µS/cm, 5.00 mS/cm, 12.88 mS/cm,

80.0 mS/cm, 111.8 mS/cm) or custom point

RESISTIVITY

RR

angeange

R

ange 0 to 999999 Ω·cm;

RR

angeange

(depending on measurement setup) 0 to 1000.0 kΩ·cm;

0 to 1.0000 MΩ·cm

RR

esolutionesolution

R

esolution Depending on resistivity reading

RR

esolutionesolution

CalibrationCalibration

Calibration Based on conductivity or salinity calibration

CalibrationCalibration

TDS

RR

angeange

R

ange 0 to 400000 mg/L or ppm;

RR

angeange

(the maximum value depends on the TDS factor)

RR

esolutionesolution

R

esolution

RR

esolutionesolution

Manual 1 mg/L (ppm); 0.001 g/L (ppt);

0.01 g/L (ppt); 0.1 g/L (ppt); 1 g/L (ppt)

Automatic 1 mg/L (ppm) from 0 to 9999 mg/L (ppm)

0.01 g/L (ppt) from 10.00 to 99.99 g/L (ppt)

0.1 g/L (ppt) from 100.0 to 400.0 g/L (ppt)

Automatic g/L (ppt) 0.001 g/L (ppt) from 0.000 to 9.999 g/L (ppt)

0.01 g/L (ppt) from 10.00 to 99.99 g/L (ppt)

0.1 g/L (ppt) from 100.0 to 400.0 g/L (ppt)

AccuracyAccuracy

Accuracy ±1 % of reading or ±1 mg/L (ppm) whichever is greater

AccuracyAccuracy

CalibrationCalibration

Calibration Based on conductivity or salinity calibration

CalibrationCalibration

14

Page 15

SALINITY

RR

angeange

R

ange 0.00 to 70.00 PSU (extended Practical Salinity Scale)

RR

angeange

RR

esolutionesolution

R

esolution 0.01 PSU

RR

esolutionesolution

AccuracyAccuracy

Accuracy ±2% of reading or ±0.01 PSU whichever is greater

AccuracyAccuracy

CalibrationCalibration

Calibration 1 custom point

CalibrationCalibration

SEAWATER SPECIFIC GRAVITY

RR

angeange

R

ange 0.0 to 50.0 σt, σ0, σ

RR

angeange

RR

esolutionesolution

R

esolution 0.1 σt, σ0, σ

RR

esolutionesolution

AccuracyAccuracy

Accuracy ± 1σt, σ0, σ

AccuracyAccuracy

CalibrationCalibration

Calibration Based on conductivity or salinity calibration

CalibrationCalibration

15

15

15

ATMOSPHERIC PRESSURE

RR

angeange

R

ange 450 to 850 mmHg;

RR

angeange

17.72 to 33.46 inHg;

600.0 to 1133.2 mbar;

8.702 to 16.436 psi;

0.5921 to 1.1184 atm;

60.00 to 113.32 kPa

RR

esolutionesolution

R

esolution 0.1 mmHg; 0.01 inHg; 0.1 mbar

RR

esolutionesolution

0.001 psi; 0.0001 atm; 0.01 kPa

AccuracyAccuracy

Accuracy ± 3 mmHg within ± 15 °C

AccuracyAccuracy

from the temperature during calibration

CalibrationCalibration

Calibration Automatic at 1 custom point

CalibrationCalibration

15

Page 16

GENERAL CHARACTERISTICS

TT

emperature Compensationemperature Compensation

T

emperature Compensation automatic from -5 to 55 °C (23 to 131 °F)

TT

emperature Compensationemperature Compensation

LL

ogging Memoryogging Memory

L

ogging Memory Up to 60,000 samples with 13 measurements each*

LL

ogging Memoryogging Memory

LL

ogging Intervalogging Interval

L

ogging Interval From 1 second to 3 hours

LL

ogging Intervalogging Interval

PC InterfacePC Interface

PC Interface USB (with HI 92000 software)

PC InterfacePC Interface

WW

aterproof Paterproof P

W

aterproof P

WW

aterproof Paterproof P

EnvironmentEnvironment

Environment 0 to 50 °C (32 to 122 °F); RH 100 %

EnvironmentEnvironment

PP

ower Supplyower Supply

P

ower Supply 4 x 1.5 V alkaline C cells (approximately 150

PP

ower Supplyower Supply

rotectionrotection

rotection Meter IP67, Probe IP68

rotectionrotection

hours of continuous use, without backlight) or

4 x 1.2 V rechargeable C cells (approximately 70 hours

of continuous use, without backlight)

DimensionsDimensions

Dimensions

DimensionsDimensions

Meter 221 x 115 x 55 mm (8.7 x 4.5 x 2.2”)

Probe L = 270 (10.6”), dia = 46 mm (1.8”)

WW

eighteight

W

eight

WW

eighteight

Meter 750 g (26.5 oz.)

Probe 750 g (26.5 oz.)

* Without remarks. When using remarks the maximum number of samples decreases but in practical cases

it will never be less than 50,000.

16

Page 17

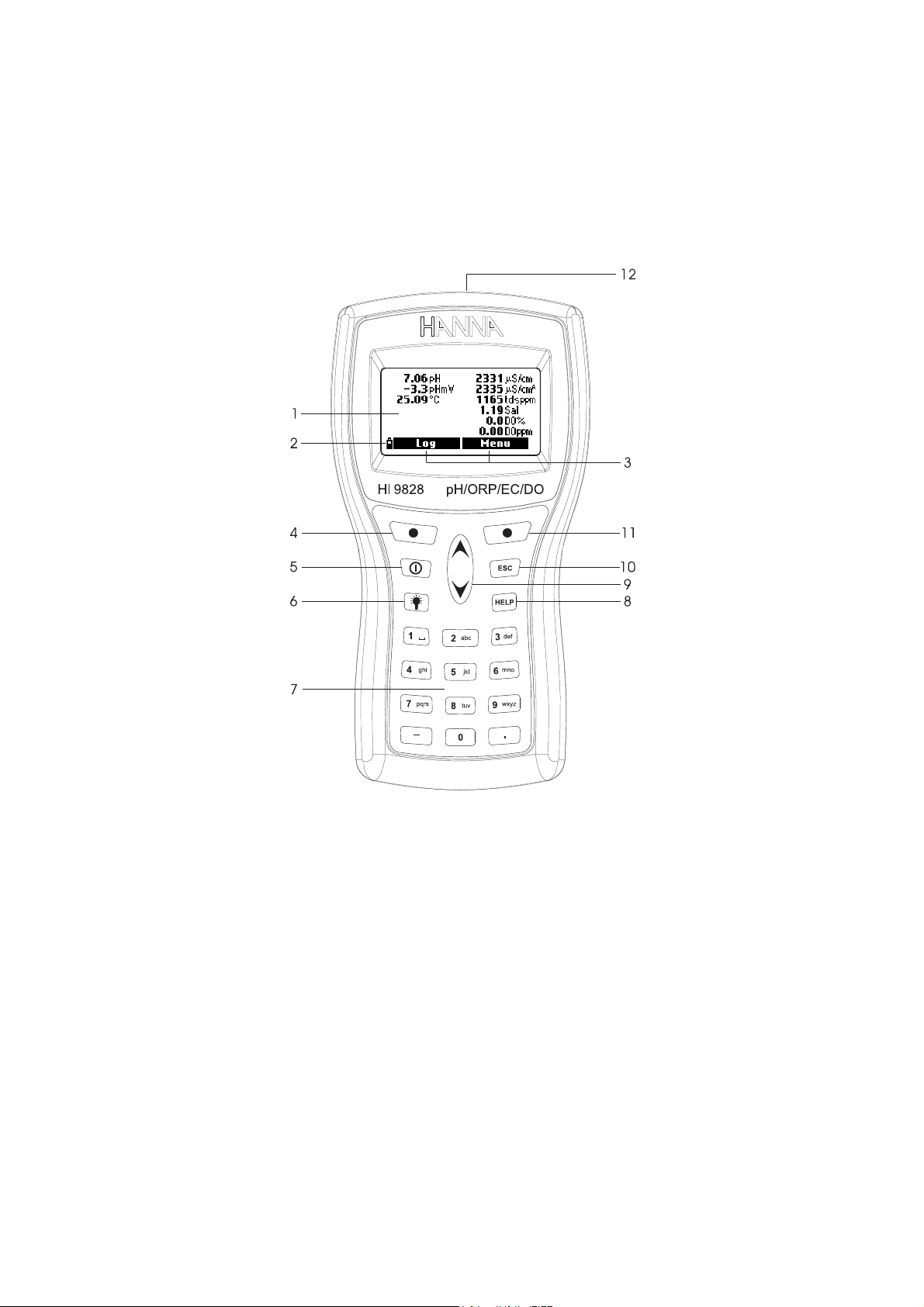

1.7 DISPLAY & KEYBOARD DESCRIPTION

1. Display

2. Battery level indicator

3. Softkey functions

4. Left softkey: function defined on display

5. On/Off key: to turn on and off the meter

6. Backlight: to activate the backlight

7. Alphanumeric keyboard: to insert alphanumeric codes

8. HELP key: to have information about the shown screen

9. Arrow keys: to scroll between options

10. ESC key: to go back to the previous screen

11. Right softkey: function defined on display

12. Tag reader

17

Page 18

1.8 HELP FUNCTION

HI9828HI9828

HI9828 is provided with the HELP function, useful to have short information

HI9828HI9828

regarding the displayed screen. Simply press the HELP key and an information

window will appear.

For longer messages press the arrow keys to scroll.

To escape from the help window press again the HELP key or ESC.

18

Page 19

Chapter 2 - MEASUREMENT MODE

HI9828HI9828

HI9828 can read at the same time different parameters from the same probe.

HI9828HI9828

As described in the previous section, up to 3 sensors can be mounted on the

probe.

2.1 PROCEDURE

• Connect the probe to the meter and carefully fix the protection sleeve to the

probe.

• Immerse the probe into the sample while paying attention to avoid stones.

• Turn the meter on by pressing the On/Off key. The display will show “HANNA

HI9828”, the firmware version and then enters the measurement mode.

• The meter displays the readings for all the enabled parameters. See Chapter 3

for details.

• Press LOG to store the readings or MENU to enter in the main menu. See

Chapter 5 for details.

NONO

TETE

NO

TE If the meter does not find the probe, the message “Probe disconnected!”

NONO

TETE

appears. In this case only “Menu” softkey is available and only the functions that not require any reading are active.

It is possible to enable up to 12 measurements at the same time. Based

on the number of enabled parameters, the display graphical resolution

changes: the lower the number of parameters, the bigger the size of

the digits.

A small “A” letter added to µS/cm or mS/cm units, refers to actual conductivity value, i.e. the conductivity reading with no temperature compensation.

When a measurement is out of range, the nearest full scale value will

slowly and continuously blink.

By pressing the lamp key, the backlight turns on and off. After one minute

with no key pressed, the backlight turns off automatically.

19

Page 20

Chapter 3 - SETUP MODE

A few parameters have to be set before taking any measurements. In the main

menu two setup items are available: “Measurement” and “System”.

The measurement setup allows to set the displayed readings and their units,

while the system setup is used to set the system parameters, as the interface

language, date and time, LCD contrast, acoustical signals, etc.

3.1 MEASUREMENT SETUP

• Switch the meter on by pressing On/Off.

After the initialization has been completed, the

meter enters the measurement mode. The active

softkeys are LOG and MENU.

• Press MENU, select “Measurement Setup” using the arrow keys, then press OK.

• The display shows the complete list of measurable parameters.

• To select a parameter, scroll with the arrow keys.

It is possible to enable or disable each parameter. A checked box or the measure

unit means that the parameter is enabled. Press the right softkey to enable or

disable the parameter.

For some parameters it is also possible to select the measure unit and the resolution by pressing the UNIT or RESOLUTION softkey.

NONO

TETE

NO

TE If the password is enabled, the meter will ask to insert it prior to change

NONO

TETE

the first parameter.

Temperature

The user can select the measure unit: K, °F or °C.

20

Page 21

pH, mV of pH Input, ORP, D.O. % Saturation, Salinity

These parameters can only be enabled or dis-

abled; the measure unit and the resolution are

fixed.

D.O. concentration

It is possible to select ppm or mg/L measure unit.

Conductivity and Actual Conductivity

It is possible to select among the following op-

tions: Auto (autoranging both µS/cm and mS/

cm ranges), 1 µS/cm, 0.001 mS/cm, 0.01 mS/

cm, 0.1 mS/cm, 1 mS/cm, Auto mS (autoranging for mS/cm ranges).

NONO

TETE

NO

TE The actual conductivity is the conductivity reading with no temperature

NONO

TETE

compensation.

Resistivity

It is possible to select Ω·cm, kΩ·cm or MΩ·cm.

TDS

It is possible to select among the following op-

tions: Auto (autoranging both ppm (mg/L) and

ppt (g/L) ranges), 1 ppm (mg/L), 0.001 ppt (g/

L), 0.01 ppt (g/L), 0.1 ppt (g/L), 1 ppt (g/l), Auto

ppt (g/L) (autoranging for ppt (g/L) ranges).

NONO

TETE

NO

TE

NONO

For setting ppm or mg/L, see paragraph 3.2 “System Setup”.

TETE

Seawater specific gravity

This value is a widely used parameter for seawater; it is similar to density mea-

surement and it is an expression of salt content in water.

It depends on water

pressure, temperature and salinity.

In the seawater specific gravity menu it is possible to select the reference tem-

perature: σ

, σ0 and σ15 (i.e. current temperature, t=0°C and t=15°C).

t

Atmospheric pressure

It is possible to select among the following mea-

sure units: atm, kPA, mmHg, inHg, mbar, psi.

21

Page 22

NONO

TETE

NO

TE A maximum of 12 measurements can

NONO

TETE

be displayed simultaneously. A warning

message appears if trying to enable

more than 12 measurements.

3.2 SYSTEM SETUP

• From measurement mode, press MENU, select “System Setup” using the arrow

keys and then press OK.

• To select a parameter, scroll with the arrow keys to highlight it and then press

MODIFY.

NONO

TETE

NO

TE If the password is enabled, the meter will ask to insert it prior to change

NONO

TETE

the first parameter.

Language

The display language can be selected among the

following available options: English, Spanish,

French, Portuguese and Italian. The language

selection can be modified by pressing the MODIFY

softkey.

ID

The meter can be labelled with an identification

code: press MODIFY and a text box will be displayed. Use the keyboard to insert the desired alphanumeric code and then press OK. A maximum of 25 characters can be used.

Date

Select the desired date format by pressing repeat-

edly FORMAT. The available formats are: DD/

MM/YYYY, YYYY-MM-DD and MM/DD/YYYY.

Use the keyboard to insert the date and then press

OK.

Time

Select the desired time format by pressing repeatedly FORMAT. The available

formats are: hh:mm:ss (24 hours) and hh:mm:ss (12 hours).

22

Page 23

Use the keyboard to insert the time and then press OK.

To choose AM or PM, press A or P on the keyboard after inserting the time.

Auto off

The meter shuts off automatically if no keys are

pressed for the set time. By pressing the MODIFY

softkey it is possible to select the desired option

for this feature: NO (disabled), 5, 10, 15, 20,

30 or 60 minutes.

Log interval

Set the logging time interval from 1 second to 3 hours.

Reference temperature

For conductivity readings, a reference tempera-

ture for the displayed value has to be set. The

available options are 20°C and 25°C. Press the

MODIFY softkey to select the desired option.

Temperature coefficient

The temperature coefficient can be set from

0.00%/°C (no temperature compensation) to

6.00%/°C. Press MODIFY and then use the

keyboard to insert the desired value. The left arrow softkey allows to shift the cursor. To confirm

the value press OK.

TDS factor

The conversion factor can be set from 0.00 to

1.00. Usually for strong ionic solutions the fac-

tor is 0.5 and for weak ionic solutions, as nutritive solutions, is 0.7.

To set this parameter, press MODIFY, insert the

value and then confirm by pressing OK.

23

Page 24

TDS unit

TDS readings can be displayed in ppm-ppt or mg/L-g/L unit. Press MODIFY to

select the desired option.

Average length

In order to obtain an average and more repre-

sentative measurement with unstable samples, set

a reading repetition number for the displayed

parameters.

To select the desired average length, press

MODIFY. The value can be set from 1 to 30.

Key beep

If enabled, the meter emits an acoustical signal

every time a key is pressed.

Error beep

If enabled, the meter emits an acoustical signal

every time a wrong key is pressed, or when some

particular errors occur.

Decimal separator

It is possible to select the type of decimal separa-

tor: dot or comma; press MODIFY to select the

desired symbol.

LCD contrast

For setting the LCD contrast, select the corre-

sponding setup item and press MODIFY. An horizontal bar will be displayed. Use the arrow keys

to modify the contrast and then press OK.

Password

To enable the password proceed as follows:

• Press MODIFY to select the password setup item.

• Insert the desired password in the text box and press OK.

NONO

TETE

NO

TE While typing, the characters are masked with “*” (star) symbol.

NONO

TETE

• The meter will ask to confirm. Type again the same password and then press

OK to confirm.

24

Page 25

• The meter returns to the “System Setup” menu and the checkbox near the

password entry is signed.

To disable the password proceed as follows:

• Press MODIFY to select the password setup item.

• Insert the password and then press DISABLE. “NO” will appear in the text box.

• Press OK to confirm.

Restore factory settings

It is possible to reset the “System Setup” and “Measurement Setup” parameters to

their default values.

• Select the “Restore factory settings” item and

press OK.

• The meter will ask to confirm: press YES to

confirm or NO to escape.

NONO

TETE

NO

TE To quit the system setup mode at any time, press ESC. For all setup

NONO

TETE

items, if the selection is not confirmed, the previous setting will be kept.

25

Page 26

3.3 TABLE OF MEASUREMENT AND SETUP ITEMS

Measurement SetupMeasurement Setup

Measurement Setup

Measurement SetupMeasurement Setup

Item Description Default value Valid Values

Temperature Temperature unit °C K; °C; °F;

pH pH measure 55;

mV of pH input mV of pH readings 55;

ORP Redox measure 55;

D.O. % saturation Dissolved oxygen measure 55;

D.O. concentration Dissolved oxygen measure ppm ppm; mg/L;

Conductivity Electrical conductivity Auto ; Auto; 1 µS; 0.001 mS;

measure 0.01 mS; 0.1 mS; 1 mS; Auto mS

Actual conductivity No temperature compensated Auto ; Auto; 1 µS; 0.001 mS;

conductivity measure 0.01 mS; 0.1 mS; 1 mS; Auto mS

Resistivity Resistivity measure MΩ·cm Ω·cm; kΩ·cm; Ω·cm

TDS Total dissolved solids Auto ; Auto; 1 ppm; 0.001 ppt;

measure 0.01 ppt; 0.1 ppt; 1 ppt; Auto ppt

Salinity Salinity measure 55;

Seawater specific gravitySpecific gravity measure σ

Atmospheric pressure Atm. pressure measure ; mmHg; inHg; mbar;

t

; σt; σ0; σ

psi; atm; kPa

15

System SetupSystem Setup

System Setup

System SetupSystem Setup

Item Description Default value Valid values

Language Interface language English English; Español; Français;

Português; Italiano

ID Meter identification code - Max 25 characters

Date Update calendar YYYY-MM-DD YYYY-MM-DD;

MM/DD/YYYY;

DD/MM/YYYY

Time Update clock hh:mm:ss (24 hours) hh:mm:ss (12 hours);

hh:mm:ss (24 hours)

Auto-off (min) Auto shut-off after a 5 min NO; 5; 10; 15;

period of non use 20; 30; 60 min

Log interval Period between 2 subsequent 00:00:01 00:00:01 to 03:00:00

automatic records

26

Page 27

Ref. temperature Reference temperature for 25°C 20°C; 25°C

conductivity measurements

Temp. coefficient Temperature coefficient for 1.90%/°C 0.00 to 6.00%/°C

conductivity measurements

TDS factor Conversion factor from 0.50 0.00 to 1.00

conductivity to TDS readings

TDS unit Measure unit for TDS ppm-ppt ppm-ppt; mg/L-g/L

Average length Number of readings for 01 1 to 30

average value calculation

Key beep Acoustic signal for key pressed 55 ;

Error beep Acoustic signal for wrong 55 ;

key pressed

Decimal separator Symbol used for decimal separator . . ; ,

of displayed numbers

LCD contrast Contrast for the LCD 8 0 to 15

Password Password insertion - Max 25 characters

27

Page 28

Chapter 4 - CALIBRATION MODE

HI9828HI9828

HI9828 allows to perform six different types of calibration, one for each param-

HI9828HI9828

eter and also a quick single-point calibration for some parameters.

The calibration data are stored in the non volatile probe memory, so that the

same probe can be used with different meters without needing recalibration.

• To perform a calibration, select “Calibration”

in the main menu with the arrow keys and then

press OK.

NONO

TETE

NO

TE If the password is enabled and the latest

NONO

TETE

function displayed was not a password

protected feature, the meter will ask to

insert the password.

• Select the calibration type with the arrow keys and then press OK.

The available options are:

Quick calibration (single point procedure to calibrate the D.O. saturation, pH

and conductivity ranges), pH, D.O., conductivity, atmospheric pressure, ORP and

temperature.

4.1 QUICK CALIBRATION

The quick calibration feature allows a fast and easy calibration of the multiparameter probe on the field, using only one solution (

• Fill the calibration beaker with the

• Screw the calibration beaker on the probe body. Some solution will overflow.

• Wait a few minutes to stabilize.

• In “Calibration” menu, select the “Quick calibration” option and press OK.

• A 3-item (pH, Conductivity and Dissolved Oxygen) screen appears, “pH” starts blinking and

the “Not ready” message is shown on the lower

part of the window.

28

HI9828-25HI9828-25

HI9828-25 calibration solution.

HI9828-25HI9828-25

HI9828-25HI9828-25

HI9828-25).

HI9828-25HI9828-25

Page 29

• When the measure is stable, “Ready” is shown.

Press CONFIRM to store the value.

• The messages “Storing data on probe, please

wait...” and “Updating GLP data, please wait

...” appear.

NONO

TETE

NO

TE If pH calibration is not required, the meter allows to skip to the EC quick

NONO

TETE

calibration, by pressing the SKIP soft key.

If the pH sensor is missing the message “pH sensor not installed! Skip to

conductivity calibration” appears.

• After the pH calibration is completed, the

“Conductivity” option will blink.

• When the measure is stable, “Ready” appears.

Press CONFIRM to store the value.

• The messages “Storing data on probe, please

wait...” and “Updating GLP data, please wait ...” appear.

NONO

TETE

NO

TE If EC calibration is not required, skip to the DO quick calibration, by

NONO

TETE

pressing the SKIP soft key.

• The message “Empty the beaker. Shake the

probe and put it in the beaker again” appears.

• Unscrew the calibration beaker and remove

the solution.

• To dry the probe shake it as you would do with a clinical thermometer. Pay

attention that no drops are present on the DO sensor.

NONO

TETE

NO

TE To avoid sensor damages, do not use paper to dry the probe.

NONO

TETE

• Screw back the calibration beaker on the probe body.

• Wait for reading to stabilize and then press OK to close the displayed message.

• When the measurement is stable, the message “Ready” appears. Press CONFIRM to store the value.

• The messages “Storing data on probe, please wait...” and “Updating GLP data,

please wait...” appear.

• The 3-calibration-item screen appears again

and the check box corresponding to the calibrated parameters will be marked.

• Press OK to return to the calibration menu.

NONO

TETE

NO

TE To quit any quick calibration procedure,

NONO

TETE

press ESC at any time.

29

Page 30

4.2 pH CALIBRATION

Calibrate the meter often, especially if high accuracy is required.

Selecting pH calibration the display shows two options: “Calibrate pH” and “Clear old calibration”.

If “Calibrate pH” is selected, it is possible to perform a new calibration at 1, 2 or 3 points with

standard buffers (pH 4.01, 6.86 or 7.01, 9.18 or

10.01) or a single calibration with custom buffer.

If “Clear old calibration” is selected, all calibration data will be deleted and the

default data restored.

NONO

TESTES

NO

TES Old calibration data have to deleted every time the pH electrode is

NONO

TESTES

replaced and after a cleaning procedure.

When a 3-point calibration is performed, all the old data are overwritten, while with a 1 or 2-point calibration procedure the meter will use

the previous data stored with the last 3-point calibration for the missing

points.

4.2.1 Preparation

Pour small quantities of selected buffer solutions into clean beakers. If possible,

use plastic beaker to minimize EMC interferences. To minimize cross contamination, use two beakers for each buffer solution: the first one for rinsing the electrode and the second one for calibration.

4.2.2 Procedure

The current measured value is shown on the primary display and the buffer value is displayed in

the secondary one.

Press the BUFFER softkey to change the buffer

value or insert a custom buffer.

1, 2 or 3-point calibration

• Immerse the probe into the selected buffer and

stir gently. The current pH value, the buffer

value and “Not ready” are displayed.

• When the reading is stable and close to the

selected buffer value, the display shows

“Ready”.

30

Page 31

• Press CONFIRM to accept the value or BUFFER to select another buffer using

the arrow keys.

• After the first calibration point is confirmed, immerse the probe in the second

buffer solution and stir gently.

• When the reading is stable and close to the selected buffer, the display shows

the message “Ready”.

• Press CONFIRM to accept the value or BUFFER to change the buffer.

• After the second calibration point is confirmed, proceed by immersing the probe

in the third buffer solution, stirring gently and waiting for stable reading.

• When the calibration is completed, the display shows the following messages:

“Storing data on probe, please wait...”, “Updating GLP data, please wait ...”

and “Calibration completed”.

• Press OK to return to the calibration menu.

• To return to the main menu, press ESC repeatedly.

NONO

TETE

NO

TE The user can terminate the pH calibration mode at any time, by press-

NONO

TETE

ing the ESC key.

Custom buffer calibration

HI 9828 allows a single point procedure to cali-

brate with a custom buffer value.

• Select this option by pressing BUFFER and then

CUSTOM keys while the meter is waiting for

stable reading.

• The display shows a window with a text box for inserting the desired custom

value. The valid range for custom buffer is 0.00 to 14.00 pH.

31

Page 32

4.2.3 Error list

If the meter does not accept a pH calibration point, a short message is displayed

to indicate the possible error source. See for example the following screens:

These are the available messages:

• “Input out of scale”: the pH value is out of scale.

• “Wrong buffer”: this message means that the difference between the pH reading and the selected buffer is too big. Check if the proper calibration buffer has

been selected.

• “Invalid temperature”: this message means that the buffer temperature is outside the allowed range.

• “Wrong & Contaminated buffer / Check electrode”: this message means that

the buffer is contaminated or the electrode is broken or very dirty.

• “Wrong & Check electrode / Clean electrode”: this message means that the

electrode is broken or very dirty.

• “Wrong & Clear old calibration”: this message indicates an erroneous slope

condition. This message appears if the slope between current and previous

calibration points exceeds the slope window (80% to 110%). Press the CLEAR

sofkey to clear the old data and continue the calibration procedure, or press

ESC to quit the pH calibration mode.

32

Page 33

4.3 DISSOLVED OXYGEN CALIBRATION

If D.O.% saturation range is calibrated, D.O. concentration range will also be

calibrated, and vice-versa.

The D.O.% saturation value is referred to the D.O. concentration in air (100%).

For this reason it is recommended to calibrate the probe near the area where the

measurements will be taken.

Also note that the D.O. concentration values are based on D.O.% saturation,

temperature, salinity and atmospheric pressure. It is recommended to use a standard solution or a reference D.O. meter to compare readings during calibration.

The calibration of D.O.% saturation range can be performed at 1 or 2 standard

points (0% and 100%), or at a single custom point (50 to 500%).

The calibration of D.O. concentration range can be performed at a single custom point (4 to 50 mg/L).

4.3.1 Procedure

Choose the D.O. calibration mode in the main

calibration menu, then select the calibration type

using the arrow keys and confirm by pressing OK.

D.O. % saturation

This calibration starts by default with 100 %.

• Fill the calibration beaker with approximately 4

mm (5/32”) of distilled water and screw it on

the probe.

• The message NOT READY is displayed until a

stable reading is reached.

• To change the standard calibration point, press

the CAL. POINT softkey and select the desired

standard point.

• To insert a different calibration value, press CAL.

POINT and then CUSTOM. Insert the desired

value using the keyboard.

• When the reading is stable, READY and CONFIRM appear. Press CONFIRM to

store the calibration point.

• After the first calibration point is confirmed, put the probe in a zero oxygen

standard solution and wait for stable reading.

33

Page 34

• Press CONFIRM to store the calibration point.

• The following messages will appear: “Storing data on probe, please wait...”,

“Updating GLP data, please wait ...” and “Calibration completed”.

• Press OK to return to the calibration menu.

• To return to the main menu, press ESC repeatedly.

NONO

TETE

NO

TE The user can perform a single point calibration with standard values.

NONO

TETE

To abort the calibration press ESC after the first point is accepted.

If the D.O. input is not within the acceptable range, the message “IN-

VALID INPUT” is displayed.

D.O. concentration

A solution with known D.O. concentration is

needed to calibrate the D.O. concentration

range.

• From D.O. calibration menu, select DO concentration and insert the known value and press

OK.

• When the reading is stable, press CONFIRM to accept the value.

• When the messages “Storing data on probe, please wait...”, “Updating GLP

data, please wait ...” and “Calibration completed” appear, the calibration is

completed. To return to the main calibration menu, press OK

• To return to the main menu, press ESC repeatedly.

4.4 CONDUCTIVITY CALIBRATION

For a correct conductivity calibration the probe sleeve must be always inserted.

The conductivity calibration menu includes 3 different type of calibration: Conductivity, Actual

conductivity and Salinity.

The “Conductivity” option allows a single point

calibration with a standard solution selectable

by the user. This calibration is temperature compensated.

The “Actual conductivity” option allows a single point calibration with a custom

conductivity solution of known actual value (not temperature compensated).

The “Salinity” option allows calibration with a standard salinity solution.

34

Page 35

The 3 options are related, so that one of this calibration procedure also calibrate

the two remaining ranges.

NONO

TETE

NO

TE For correct EC readings it is recommnded to calibrate using a standard

NONO

TETE

solution with a conductivity value close to the sample being measured.

4.4.1 Procedure

After choosing the conductivity calibration mode in the main calibration menu,

select the type of calibration with the arrow keys and then press OK.

Conductivity

• Select the “Conductivity” option and press OK to confirm.

• Fill a beaker with a standard conductivity solution (see “Accessories” section for

choosing the proper HANNA solution).

• Immerse the probe in the solution and wait for the stable reading. The probe

sleeve must be inserted.

• The primary display shows the actual reading and the secondary one the standard value.

• To change the standard value, press CAL. POINT. The available values of standard solutions are displayed: 0 µS/cm, 84 µS/cm, 1413 µS/cm, 5.00 mS/cm,

12.88 mS/cm, 80.0 mS/cm and 111.8 mS/cm.

• Press CUSTOM to insert a custom value (compensated conductivity value).

Choose “Resolution” to select the desired resolution.

• When the reading is stable, press CONFIRM to store the value.

• After confirmation, the following messages are displayed: “Storing data on

probe, please wait...”, “Updating GLP data, please wait...”, “Calibration complete”.

• Press OK to return to the main calibration menu.

• To return to the main menu, press ESC repeatedly.

35

Page 36

Actual Conductivity

• Select the “Actual conductivity” option and

press OK to confirm.

• Insert the custom value and set its resolution.

• Immerse the probe in the conductivity solution

and wait for stable reading. The probe sleeve

must be inserted.

• When the reading is stable, press CONFIRM to store the value.

• After confirmation, the following messages are displayed: “Storing data on

probe, please wait...”, “Updating GLP data, please wait...”, “Calibration complete”.

• Press OK to return to the main calibration menu.

• To return to the main menu, press ESC repeatedly.

Salinity

• Select the “Salinity” option and press OK.

• Insert the salinity value of the custom calibration solution.

• Immerse the probe in the solution and wait for

stable reading. The probe sleeve must be inserted.

• When the reading is stable, press CONFIRM to store the value.

• After confirmation, the following messages are displayed: “Storing data on

probe, please wait...”, “Updating GLP data, please wait...”, “Calibration complete”.

• Press OK to return to the main calibration menu.

• To return to the main menu, press ESC repeatedly.

NONO

TESTES

NO

TES These calibration procedures set the slope value. To calibrate the offset,

NONO

TESTES

repeat the procedure setting the calibration point at 0 µS/cm.

If the temperature input is not within the acceptable range (0 to 50°C),

the message “Invalid temperature” is displayed.

If the conductivity input is not within the

acceptable range, the message “Invalid input” is displayed.

36

Page 37

4.5 ATMOSPHERIC PRESSURE

For this calibration procedure a reference barometer is needed. A maximum

difference of 40 mbar between current reading and calibration point is allowed

during calibration.

4.5.1 Procedure

Choose the “Atmospheric pressure” calibration

mode in the calibration menu, then select the

calibration type using the arrow keys and confirm

the selection by pressing OK.

• To perform a pressure calibration at a custom

point, select the “Custom pressure” option.

• Select the measure unit with the UNIT key and

insert the pressure value with the keyboard.

• Press OK and wait for the measure stability.

• When the reading is stable, press CONFIRM to

store the value.

• After confirmation, the following messages are displayed: “Storing data on

probe, please wait...”, “Updating GLP data, please wait...”, “Calibration complete”.

• Press OK to return to the main calibration menu.

• To return to the main menu, press ESC repeatedly.

• To restore the factory calibration, select the corresponding option in the “Pressure calibration” menu and then press OK.

4.6 ORP CALIBRATION

It is possible to calibrate at one custom point or

restore the factory calibration.

4.6.1 Procedure

• Select the “Custom ORP” option and press OK.

• Fill a beaker with a ORP solution (see “Accessories” section for choosing the proper HANNA

solution).

• Using the keyboard, insert the solution value and

then press OK to confirm.

37

Page 38

• When the reading is stable, press CONFIRM to store the calibration point.

• After confirmation, the following messages are displayed: “Storing data on

probe, please wait...”, “Updating GLP data, please wait...”, “Calibration complete”.

• Press OK to return to the main calibration menu.

• To return to the main menu, press ESC repeatedly.

• To restore the factory calibration data, select the corresponding option in the

“ORP calibration” menu and then press OK.

4.7 TEMPERATURE CALIBRATION

The meter is factory calibrated for temperature readings. If necessary, temperature calibration may be performed as explained below.

4.7.1 Procedure

• Select “Temperature” in the main calibration menu and press OK to enter the

temperature calibration mode.

• Insert the probe in the thermoregulated bath.

• Select the measure unit (°C, °F or K) and insert

the bath temperature value (read by a reference thermometer).

• When the reading in stable, READY and CONFIRM appear on the display.

• Press CONFIRM to store the calibration point.

• After confirmation, the following messages are

displayed: “Storing data on probe, please

wait...”, “Updating GLP data, please wait...”,

“Calibration complete”.

• Press OK to return to the main calibration menu.

• To return to the main menu, press ESC repeatedly.

NONO

TETE

NO

TE The meter allows a maximum difference

NONO

TETE

of ±2°C between the current reading

and the set value. If this condition is

not satisfied, the display will show the

message “Max +/-2°C is allowed”.

38

Page 39

Chapter 5 - LOGGING MODE

HI9828HI9828

HI9828 can store up to 60,000 samples in 100 different lots. The value 60,000

HI9828HI9828

is reached if no remarks are used. When using remarks, the maximum number

of stored measurements decreases, but in practical cases it will never be less

than 50,000.

5.1 LOGGING

• From measurement mode press LOG to store the enabled readings. The default setting suggests the last used lot to store the sample. Each sample can be

associated to a tag by simply touching the tag with the tag reader.

• The meter asks the location for storing the readings. Press OK to accept the

proposed lot.

• The “SAMPLE LOGGED” message is shown, then the meter returns to the

measurement mode.

5.1.1 Logging options

• To insert additional information for the logged

value or to select the continuous logging mode,

press OPTIONS.

• The following softkeys will appear: “One

sample” and “Continuous”. Select the desired

option.

• To choose the reading storing location, select

an existing lot using the arrow keys and press

OK to confirm. To create a new lot press the

NEW LOT softkey and insert the desired code

in the displayed text box using the keyboard.

Press OK to confirm. If the name already ex-

39

Page 40

ists, a waring message advises the user: “The file already exists! Insert a different file name”. Press OK to insert a different file name.

• The “Add remark? Yes or No” window will then appear. If YES is pressed and a

remark list already exists, it is possible to select the desired note or press NEW

to insert a new remark in a text box appears.

• The “Tag reading” option allows to associate

the logged or to be logged samples to a tag.

The message “Touch the tag with the tag

reader” is displayed. Press SKIP if no tags are

available or to skip this option.

• If the tag is touched, the associated ID will be

displayed. If no ID is associated to the tag, the

serial number is shown.

• Press TAG ID to insert an id. code for the used tag and then press OK (or

simply press OK if not interested in a tag ID).

NONO

TESTES

NO

TES A logging list with relative remarks can be created before taking any

NONO

TESTES

measurements and logging. See below paragraph “Log data setup”.

To abort the logging procedure at any time, press the ESC softkey re-

peatedly.

In case of continuous logging, the data collection will start after the last

option is confirmed. In case of one sample logging, the data is stored

after LOG is pressed.

5.2 LOG DATA SETUP

To set lots, insert remarks, review logged or plotted data and to delete lots, from the main menu

select LOG DATA using the arrow keys. Press

OK to confirm the selection.

A list of available functions appears.

40

Page 41

5.2.1 Lots

This option allows to insert a new lot, to view

logged measurements, to plot data or to delete

lots.

• Scroll with the arrow keys to select the desired

lot and then press OK.

• To create a new lot press the NEW LOT softkey

and insert the identification name with the keyboard. Press OK to confirm.

NONO

TETE

NO

TE In the upper line of the window, the dis-

NONO

TETE

play shows the percentage of memory

still available for inserting new data, for

example “Data lots (free: 100%)”.

• After OK is pressed, the meter displays all the

data related to the selected lot: number of

samples, memory space used, time and date of

the first and the last reading.

• If OPTIONS is pressed, a 3-option menu appears:

VIEW to visualize the readings stored in the selected lot; PLOT to visualize the corresponding

graph; DELETE to delete the selected lot.

NONO

TETE

NO

TE The first line of the 3-option window indicates the lot name.

NONO

TETE

View

• Press VIEW and the sample details will be displayed.

Use the arrow keys to change the sample number

in the selected lot. The sample number is shown

on the down right corner of the display.

NONO

TETE

NO

TE Details are available only for the cur-

NONO

TETE

rently enabled parameters (see section

3.1 “Measurement setup”).

• Press INFO to see the sample number, time and

date, remarks and tag ID or serial number (if

available).

• Press DATA to return to the previous screen or

JUMP to select another sample in the same lot.

If JUMP is pressed a text box appears to insert

the desired sample number.

• Press ESC to return to the 3-option menu.

41

Page 42

Plot

• Press PLOT and the list of the available parameters for the selected lot will appear.

• Use the arrow keys to scroll and select the desired parameter. Press OK to view the graph.

• Use the arrow keys to move the cursor in the

graph and highlight a sample. The sample data

are displayed below the graph.

• Press ESC to return to the parameter list.

• Press ESC again to return to the 3-option menu.

NONO

TETE

NO

TE The number of lot samples that can be plotted is limited by the display

NONO

TETE

resolution. To view a complete graph download data to PC.

Delete

• Press DELETE and the meter will display the message “The selected lot will be erased! Continue?”. Press YES to delete or NO to return to

the previous screen.

• To return to the LOG DATA menu, press ESC repeatedly.

5.2.2 Delete all lots

• If the “Delete all data” option is selected, the display shows the message “All

stored log data will be erased! Continue?”. Press YES to delete or NO to return

to the previous screen.

5.2.3 Remarks

A remark can be associated to each sample.

• To add a remark, use the arrow keys to scroll

and highlight the REMARKS option. Press OK to

confirm the selection.

• The display shows the list of memorized remarks.

• Press NEW to insert a new remark. A text box

appears to insert the desired information.

• Press DELETE to cancel an existing remark.

NONO

TETE

NO

TE During logging each reading can be associated to a remark either se-

NONO

TETE

lected from a previously created remarks list or new. See paragraph

5.1.1 ”Logging options”.

42

Page 43

5.2.4 Delete all remarks

• To delete all the inserted remarks, use the arrow keys to select the entry and press OK. The

display will shows the message “All stored remarks will be erased! Continue?”. Press YES to

delete or NO to return to the previous screen.

5.2.5 Tags

Read tag

• Select READ TAG to view and modify the information associated to a tag, or to

insert a tag ID if the tag has never been memorized in the meter. The display

shows the message “Touch the tag with the tag reader”. Touch the tag with the

tag reader located on the top of the meter (#12 at page 18).

• When the tag is detected the meter displays the information regarding the tag

serial number and the tag ID (if available).

• Press the TAG ID softkey (available only if the tag has never been identify) to

insert the current tag ID.

• Press MODIFY to change the tag information or OK to close the window.

S/N Æ ID

This option allows to view the ID code associated to a tag serial number.

• Select S/NÆID and press OK.

• Insert the serial number using the keyboard and

then press OK.

• The tag information window will appear. Press

OK to return to the previous screen or MODIFY

to modify the tag ID.

• If the typed S/N is not stored in memory, the warning message “This tag S/N is

not stored in memory” advises the user.

43

Page 44

ID Æ S/N

This option allows to view the tag serial number related to an ID.

• Select IDÆS/N and press OK.

• Insert the identification code using the keyboard and then press OK.

• The tag information window will appear. Press

OK to return to the previous screen or MODIFY

to modify the tag ID.

NONO

TETE

NO

TE If the inserted ID is not present in the

NONO

TETE

memory, a warning message advises

the user.

Add tag manually

An ID code can be associated to a tag even if the tag is not physically available.

• Select the proper option and press OK.

• Insert the tag serial number using the keyboard and then press OK.

• Insert an ID code for the added tag and then press OK.

• The meter will now display all information just entered.

Clear tag memory

The tag memory can be completely cleared.

• Select the “Clear tag memory” option and press OK.

• The display will show the message “All tag identifiers will be erased. Continue?”.

• Press YES to confirm tag erasing or NO to return to the previous screen.

• To return to measurement mode, press ESC repeatedly.

44

Page 45

Chapter 6 - GLP

GLP (Good Laboratory Practice) is a set of functions that allows to store or recall

data regarding the probe calibration. This feature also allows to associate a

reading to “certified data” (standard solutions, reference meters, etc.) put in the

meter through the calibration procedure.

To visualize GLP data, from measurement mode

press the MENU softkey and scroll using the down

arrow key to highlight the “GLP data” option.

Press OK: the complete list of available parameters appears. Select the desired option using the

arrow keys and press OK to view the relative information.

NONO

TETE

NO

TE When there are no available calibration

NONO

TETE

data for the selected parameter, the display shows the message “No GLP data

available for this measurement”. Press

OK to return to the previous screen.

6.1 PROBE INFORMATION

• To view the probe information, select the “Probe

information” option and press OK.

• The following information appear: model, firmware version, ID and serial number.

• Press OK to return to the previous screen or

MODIFY ID to change the identification code.

• When MODIFY ID is pressed, a text box appears to insert the code. Press OK to confirm

or ESC to escape without saving the changes.

• The messages “Storing data on probe, please

wait...” and “Data successfully stored on probe”

appear.

• Press OK to return to the “Probe information”

screen.

NONO

TESTES

NO

TES If no probe is connected a warning mes-

NONO

TESTES

sage appears.

45

Page 46

6.2 pH

• From the GLP data main menu, select the pH option and press OK.

• All the information about the last pH calibration appears: offset, acidic slope, basic slope,

used buffers, time and date of procedure.

• Use the arrow keys to scroll the last 5 calibration data sets stored.

• Press ESC to return to the GLP data main menu.

NONO

TETE

NO

TE The C label near the buffer value indicates a custom point, while the H

NONO

TETE

means HANNA standard value.

If a quick calibration was performed, the buffer values are replaced with

“Quick calibration”.

If the calibration was cleared, the values for offset and slope are the

default values and the message ”Old calibrations cleared” appears.

If no pH calibration has been performed, a warning message advise

the user. Press OK to return to the previous screen.

6.3 DISSOLVED OXYGEN

• From GLP data main menu select the Dissolved

Oxygen option and press OK.

• All the information about the last D.O. calibration appears: calibrated points, % saturation or concentration, time and date.

• Use the arrow keys to scroll the last 5 memorized calibrations.

• GLP calibration data for D.O. include 3 options: 2-point percentage D.O. calibration, single point percentage D.O. calibration and concentration D.O. calibration.

NONO

TETE

NO

TE The C label near the calibration point indicates a custom point, while

NONO

TETE

the H means HANNA standard value.

When the D.O. percentage saturation is calibrated, also the D.O. con-

centration range is calibrated, and vice-versa.

If no D.O. calibration has been performed, a warning message advise

the user. Press OK to return to the previous screen.

46

Page 47

6.4 CONDUCTIVITY

• From GLP data main menu select the “Conductivity” option and press OK. This menu allows

to view data for conductivity, actual conductivity and salinity calibrations.

• All the information about the last conductivity calibration appears: calibrated

point, cell constant value, calibration type (conductivity, actual conductivity or

salinity), time and date.

• Use the arrow keys to scroll the last 5 memorized calibrations.

• For conductivity calibration GLP data the following screens are available: conductivity, actual conductivity, salinity.

NONO

TETE

NO

TE The C letter near the conductivity calibration indicates a custom point,

NONO

TETE

while the H means HANNA standard value.

If no conductivity calibration has been performed, a warning message

advise the user. Press OK to return to the previous screen.

If the selected calibration is a factory calibration, the meter shows the

message “Factory calibration”.

6.5 ATMOSPHERIC PRESSURE

• From GLP data menu select the “Atmospheric pressure” option and press OK.

• All the information about the last atmospheric pressure calibration appears:

custom calibration point, time and date.

• In case of restoring factory calibration data, the

display will show the warning message “Factory calibr. restored”.

• Use the arrow keys to scroll the last 5 memorized calibrations.

NONO

TETE

NO

TE If no atmospheric pressure calibration has been performed, a warning

NONO

TETE

message advise the user. Press OK to return to the previous screen.

If the selected calibration is a factory calibration, the meter shows the

message “Factory calibration”.

47

Page 48

6.6 ORP

• From GLP data main menu select the “ORP” option and press OK.

• All the information about the last ORP calibration appears: calibrated point,

time and date

• In case of restoring factory calibration data, the

display will show the warning message “Factory

calibr. restored”.

• Use the arrow keys to scroll the last 5 memorized calibrations.

NONO

TETE

NO

TE If no ORP calibration has been performed, a warning message advise

NONO

TETE

the user. Press OK to return to the previous screen.

If the selected calibration is a factory calibration, the meter shows the

message “Factory calibration”.

6.7 TEMPERATURE

• From GLP data main menu select the “Temperature” option and press OK.

• All the information about the last temperature

calibration appears: calibrated point, time and

date.

• Use the arrow keys to scroll the last 5 memorized calibrations.

NONO

TETE

NO

TE If no temperature calibration has been performed, a warning message

NONO

TETE

advise the user. Press OK to return to the previous screen.

If the selected calibration is a factory calibration, the meter shows the

message “Factory calibration”.

48

Page 49

Chapter 7 - PC CONNECTION MODE

The logged data can be transferred to PC using the

HI92000HI92000

HI92000 Windows® com-

HI92000HI92000

patible application software.

HI92000HI92000

HI92000 allows to use the powerful capabilities of most spread sheet programs

HI92000HI92000

(e.g. Excel

©

, Lotus 1-2-3©). Simply open the file downloaded by

HI92000HI92000

HI92000 from

HI92000HI92000

the selected spread sheet program and you can do any elaboration available

with the software (e.g. graphics, statistic analysis).

HI92000HI92000

HI92000 offers a variety of

HI92000HI92000

features and is provided with an on-line-help to support the user throughout any

situation.

7.1 SOFTWARE INSTALLATION

• Insert the installation CD into the PC.

• The software menu window should start automatically (if it does not, go to the

main CD folder and double-click “histart.exe”). Click “Install software” and

follow the instructions.

7.2 PC CONNECTION

• With the meter OFF, disconnect the probe.

• Connect the

HI 7698281HI 7698281

HI 7698281 USB adapter to the

HI 7698281HI 7698281

meter and to the USB port on PC.

• Turn the meter ON and the message “PC con-

nection” appears.

• Run the

HI92000HI92000

HI92000 application software, select the number of the used COM

HI92000HI92000

port within the “Settings” window and then press CONNECT.

HI92000HI92000

•

HI92000 downloads the logged data. The PC monitor shows the GLP data

HI92000HI92000

and the logged lot (see figure on next page). To download and view all samples

of a certain lot, select the desired lot and press the “Acquire lot” option.

• During download, the meter displays a visual

representation of the transferred data percentage.

NONO

TETE

NO

TE To verify the PC COM port number used for connecting the meter, with

NONO

TETE

the cable connected, press START in the Windows

®

task bar. In the main

menu select “Settings” and then “Control panel”, “System”, “Hardware”,

“Device Manager” and “Ports”. This last menu shows the number of the

used COM port near the USB serial port.

49

Page 50

50

Page 51

Chapter 8 - ERROR MESSAGES

HI9828HI9828

HI9828 displays a series of messages if probe or meter errors are generated.

HI9828HI9828

Here below are described the error messages with their meaning and indication

to solve the problem. For quick information the help menu is always available on

the meter by pressing the “Help” button.

• “Continuous logging - Flash memory is full”.

This message means that the memory is full and

no reading can be logged. Press OK and delete one or more lots.

• “Flash memory error!”. This message indicates

an error in the meter internal memory. Press OK,

download the data and delete all lots. If the problem persists, contact the HANNA service center.

•”Probe communication error!”. This message

means that there is a communication problem

between probe and meter. Check if the cable is