Page 1

INSTRUCTION MANUAL

HI 95747HI 95747

HI 95747

HI 95747HI 95747

Copper Low Range ISM

Dear Customer,

Thank you for choosing a Hanna product. This manual will provide you

with the necessary information for the correct use of the instrument. Please

read it carefully before using the meter. If you need additional technical

information, do not hesitate to e-mail us at tech@hannainst.com.

This instrument is in compliance with

directives.

Preliminary examination:

Please examine this product carefully. Make sure that the instrument is

not damaged. If any damage occured during shipment, please notify

your Dealer.

Each HI 95747 Ion Selective Meter is supplied complete with:

• Two Sample Cuvets and Caps

• 9V Battery

• Instruction Manual

Note: save all packing material until you are sure that the instrument

works correctly. Any defective item must be returned in its original

packing.

For more details about spare parts and

accessories see “Accessories”

Technical specifications:

Range 0.000 to 1.500 mg/L

Resolution 0.001 mg/L for

0.01 mg/L for

Precision ±0.015 mg/L @ 0.750 mg/L

Typical EMC Dev. ±0.001 mg/L

Light Source Tungsten lamp with narrow band interfer-

ence filter @ 560 nm

Light Detector Silicon Photocell

Method Adaptation of the USEPA approved

bicinchoninate method.

Environment 0 to 50°C (32 to 122°F);

max 95% RH non-condensing

Battery Type 1 x 9 volt

Auto-Shut off After 10' of non-use in measurement mode;

after 1 hour of non-use in calibration mode.

Dimensions 180 x 83 x 46 mm (7.1 x 3.3 x 1.8”)

Weight 290 g (10 oz.).

measurement

calibration

and

validation

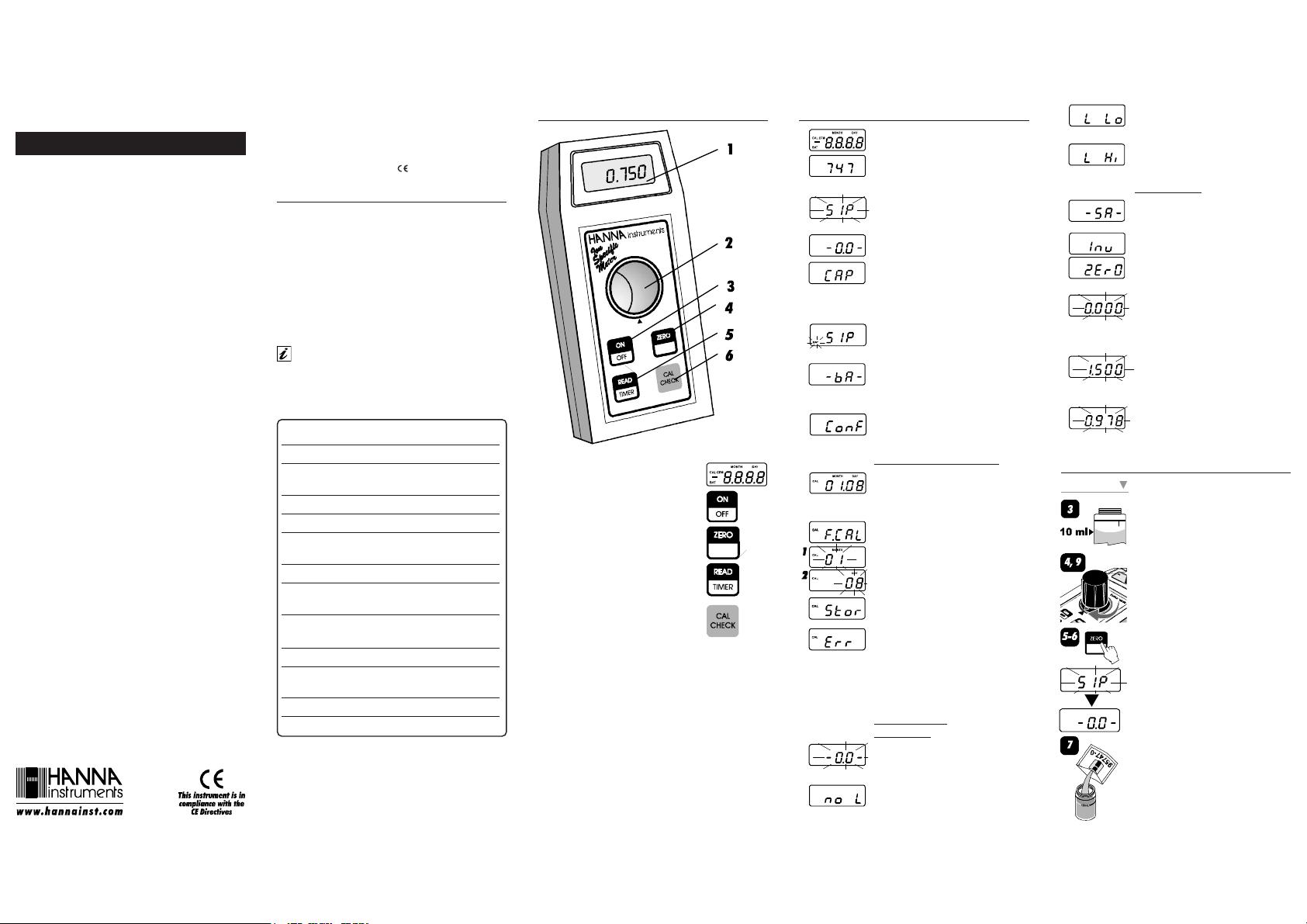

Functional description:

1. Liquid Crystal Display.

2. Cuvet Holder with transparent protective

cup and alignment indicator.

3. ON/OFF key: to turn the meter on and

off.

4. ZERO key: press to zero the meter prior to

measurement.

5. READ/TIMER key: press for making a

measurement, or hold the key for 3

seconds to start a pre-programmed

countdown prior to measurement.

6. CAL CHECK key allows direct validation

with the exclusive Hanna CAL CHECK™

NIST traceable standards.

Guide to display codes:

This prompt appears for 1 second each time the

instrument is turned on.

The parameter code “747” indicates that the

meter is in a ready state and zeroing can be

performed.

Sampling In Progress. Flashing “SIP” prompt

appears each time the meter is performing a

measurement.

“-0.0-”, the meter is in a zeroed state and

measurement can be performed.

“CAP”, Light over range: the cuvet is not inserted

correctly and an excess ambient light is reaching

the detector. If the cover is properly installed,

then contact your dealer or the nearest Hanna

Customer Service Center.

The blinking “BAT” indicates that the battery

voltage is getting low and the battery needs to

be replaced.

“-bA-”, the battery is dead and must be replaced. Once this indication is displayed, the

meter will lock up. Change the battery and

restart.

“Conf”, the meter has lost its configuration. Contact

your dealer or the nearest Hanna Customer Service

Center.

CALIBRATION MODE MESSAGES

The date of the last calibration appears on the

LCD each time the

calibration is performed for the first time, “F.CAL”

appears.

“F.CAL” indicates that the factory calibration is

selected.

The flashing digits indicate that:

1. the month can be set

2. the day can be set

“Stor”, appears for 1 second at the end of the

calibration procedure, to indicate that the

calibration data has been stored.

“Error”, the concentration of the calibration solution

used is not correct. Repeat the calibration procedure

with the right standard solution, and verify it is

not expired.

If the calibration procedure fails again, contact

your dealer or the nearest Hanna Customer Service

Center.

ERROR MESSAGES

On zero reading

Blinking “-0.0-” indicates that the zeroing

procedure failed due to a low signal-to-noise

ratio. In this case press ZERO again.

“no L”, the instrument cannot adjust the light

level. Please check that the sample does not

contain any debris.

calibration mode

is entered. If

“L Lo”, there is not enough light to perform a

measurement. Please check the preparation of the

zero cuvet.

“L Hi”, there is too much light to perform a

measurement. Please check the preparation of the

zero cuvet.

On sample reading

“-SA-”, there is too much light for the sample

measurement. Please check if the right sample

cuvet is inserted.

“Inv”, the sample and the zero cuvet are inverted.

“ZErO”, a zero reading was not taken. Follow the

instruction in the measurement procedure for zeroing the meter.

Under range. A blinking “0.000” indicates that

the sample absorbs less light than the zero

reference. Check the procedure and make sure you

use the same cuvet for reference (zero) and

measurement.

A flashing value of the maximum concentration

indicates an over range condition. The concentration of the sample is beyond the programmed

range: dilute the sample and re-run the test.

A flashing value lower than the maximum concentration indicates a low signal-to-noise ratio

condition. In this case accuracy of the result is not

guaranteed. Repeat the measurement procedure.

Measurement procedure:

Measurement

1• Turn the meter on by pressing ON/OFF.

2• When the LCD displays “747”, it is ready.

3• Fill the cuvet with 10 mL of unreacted

sample, up to the mark, and replace the

cap.

4• Place the cuvet into the holder and ensure

that the notch on the cap is positioned

securely into the groove.

5• Press ZERO and “SIP” will blink on the

display.

6• After a few seconds the display will show

“-0.0-”. The meter is now zeroed and ready

for measurement.

7• Remove the cuvet and add the content of

one packet of HI 95747-0 Copper Low Range

reagent.

8• Replace the cap and shake gently for 15

seconds.

9• Replace the cuvet into the holder and ensure

that the notch on the cap is positioned

securely into the groove.

10•Hold READ/TIMER for three seconds. The

display will show the countdown prior to

measurement.

Alternatively, wait for 45 seconds and just

press READ/TIMER.

Page 2

In both cases “SIP” will blink during

measurement.

11•The instrument directly displays concentration

in mg/L of copper on the Liquid Crystal

Display.

INTERFERENCES

• Cyanide

• Silver

• For strongly buffered alkaline or acidic samples,

pH should be adjusted between 6 and 8 before

addition of reagent.

• To avoid interferences due to fingerprints, oil or

dirt it is very important that the cuvet is wiped

clean prior to insertion in the cuvet holder.

Replacement of scratched cuvets is strongly

recommended.

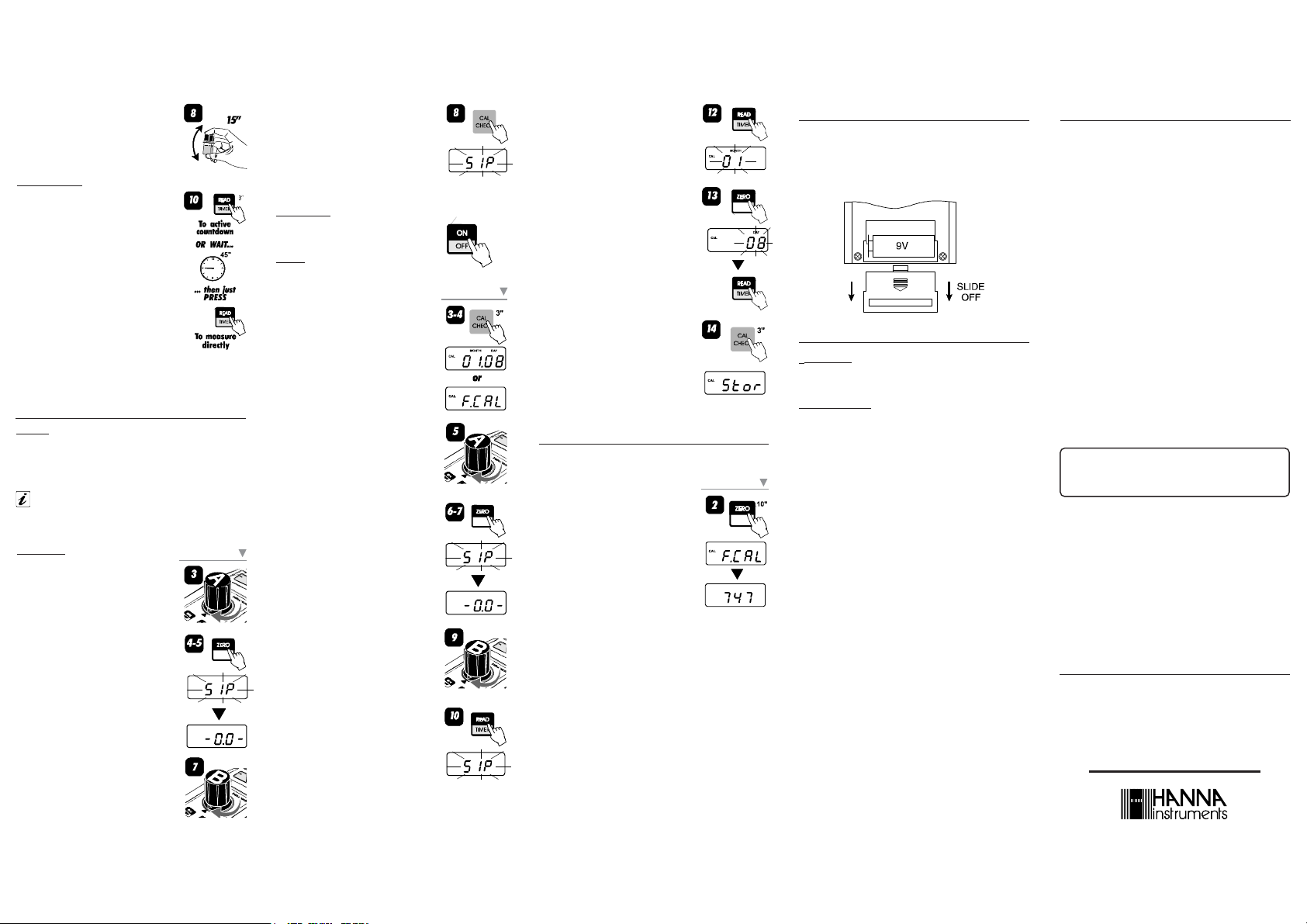

Validation and Calibration procedures

Warning: do not validate or calibrate the instrument with standard

solutions other than the Hanna CAL CHECK™ Standards, otherwise

erroneous results will be obtained.

For accurate validation and calibration results, please perform tests at

room temperature (18 to 25°C; 64.5 to 77.0°F).

Use the optional CAL CHECK™ cuvets (see

“Accessories”) to validate or calibrate

instruments.

VALIDATION

1• Turn the meter on by pressing ON/OFF.

2• When the LCD displays “747”, it is ready.

3• Place the CAL CHECK™ Standard Cuvet A

into the holder and ensure that the notch on

the cap is positioned securely into the groove.

4• Press ZERO and “SIP” will blink on the

display.

5• After a few seconds the display will show

“-0.0-”. The meter is now zeroed and ready

for validation.

6• Remove the cuvet.

7• Place the CAL CHECK™ Standard

HI 95747-11 Cuvet B into the holder and

ensure that the notch on the cap is positioned

securely into the groove.

8• Press CAL CHECK key and “SIP” will blink

during measurement.

9• Wait for a few seconds and the display will

show the validation standard value.

Validation

The reading should be within specifications as

reported on the CAL CHECK™ Standard

Certificate. If the value is found out of

specifications, please check that the cuvets are

free of fingerprints, oil or dirt and repeat

validation. If results are still found out of

specifications then recalibrate the instrument.

CALIBRATION

Note: It is possible to interrupt the calibration

procedure at any time by pressing ON/OFF.

Warning: do not validate or calibrate the instrument

with standard solutions other than the Hanna

CAL CHECK™ Standards, otherwise erroneous results

will be obtained.

For accurate validation and calibration results, please

perform tests at room temperature (18 to 25°C;

64.5 to 77.0°F).

1• Turn the meter on by pressing ON/OFF.

2• When the LCD displays “747”, it is ready.

3• Enter the calibration mode by holding CAL

CHECK key for three seconds.

4• The date of the last calibration appears (e.g.:

month “01”, day “08”). “F.CAL” means that

the factory calibration is selected.

Note: at this point it is possible to reset the

instrument to restore FACTORY CALIBRATION

5• Place the CAL CHECK™ Standard Cuvet A

into the holder and ensure that the notch on

the cap is positioned securely into the groove.

6• Press ZERO and “SIP” will blink on the

display.

7• After a few seconds the display will show

“-0.0-”. The meter is now zeroed and ready

for calibration.

8• Remove the cuvet.

9• Place the CAL CHECK™ Standard

HI 95747-11 Cuvet B into the holder and

ensure that the notch on the cap is positioned

securely into the groove.

10•Press READ/TIMER and “SIP” will blink on the

display.

11•The instrument will show for three seconds the

CAL CHECK™ standard value.

Then the date of last calibration (e.g.:

“01.08”) appears on the display, or “01.01”

if the factory calibration was selected. In both

cases the number of the month is blinking,

ready for date input.

Note: if display will show “ERR” the calibration

procedure failed. Verify that the right CAL

CHECK™ Standard Cuvet B is inserted, that

both A and B cuvets are free from fingerprints

or dirt and that they are inserted correctly.

Calibration

12•Keep READ/TIMER pressed to scroll to the

desired month number (01-12).

13•When the correct month has been set, press

ZERO to confirm. Now the display will show

the day number blinking.

Keep READ/TIMER pressed to scroll to the

desired day number (01-31).

Note: it is possible to change from

day

to

month

and vice versa by pressing ZERO.

14•When both the day and month have been

selected, hold CAL CHECK key for three seconds

to store date and calibration values. The

instrument will show for one second “Stor”, to

confirm that the new calibration data has

been accepted.

15•The instrument will return automatically to

the measurement mode by displaying the

parameter code (“747”) on the LCD.

Factory calibration reset

It is possible to restore factory calibration:

1• Enter the

2• Hold ZERO for 10 seconds. The display will

calibration mode

CHECK key for three seconds.

show for 2 seconds “F.CAL” and the parameter

code “747” appears. The factory calibration

is automatically restored and the instrument

is ready for measurement.

by holding CAL

Factory

Calibration

Reset

Battery replacement

Battery replacement must only take place in a non-hazardous environment.

Simply slide off the battery cover on the back of the meter.

Detach the battery from the terminals and attach a fresh 9V battery

while paying attention to the correct polarity. Insert the battery and

replace the cover.

Accessories:

REAGENT SETS

HI 95747-01 Reagents for 100 Copper LR tests

HI 95747-03 Reagents for 300 Copper LR tests

OTHER ACCESSORIES

HI 95747-11 CAL CHECK™ kit

Low Range (1 set)

HI 710009 Blue rubber boot

HI 710010 Orange rubber boot

HI 721310 9V battery (10 pcs)

HI 731318 Tissue for wiping cuvets (4 pcs)

HI 731331 Glass cuvets (4 pcs)

HI 731335 Caps for cuvets (4 pcs)

HI 93703-50 Cuvets cleaning solution (230 mL).

for Calibration & Validation of Copper

Warranty

HI 95747 is warranted for two years against defects in workmanship and

materials when used for its intended purpose and maintained according

to the instructions.

This warranty is limited to repair or replacement free of charge.

Damages due to accident, misuse, tampering or lack of prescribed

maintenance are not covered.

If service is required, contact your dealer. If under warranty, report the

model number, date of purchase, serial number and the nature of the

failure. If the repair is not covered by the warranty, you will be notified

of the charges incurred.

If the instrument is to be returned to Hanna Instruments, first obtain a

Returned Goods Authorization Number from the Customer Service Department

and then send it with shipment costs prepaid. When shipping any

instrument, make sure it is properly packaged for complete protection.

To validate your warranty, fill out and return the enclosed warranty card

within 14 days from the date of purchase.

Recommendations for Users

Before using these products, make sure that they are entirely suitable for your specific application and for

the environment in which they are used.

Operation of these instruments may cause unacceptable interferences to other electronic equipments, this

requiring the operator to take all necessary steps to correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the instrument’s EMC

performance.

To avoid damages or burns, do not put the instrument in microwave oven. For yours and the instrument

safety do not use or store the instrument in hazardous environments.

Hanna Instruments reserves the right to modify the

design, construction and appearance of its products

without advance notice.

For additional information, contact your

dealer or the nearest

Hanna Customer Service Center.

To find the Hanna Office in your area,

IST95747R1 12/03

www.hannainst.com

visit our web site

Loading...

Loading...