Page 1

Instruction Manual

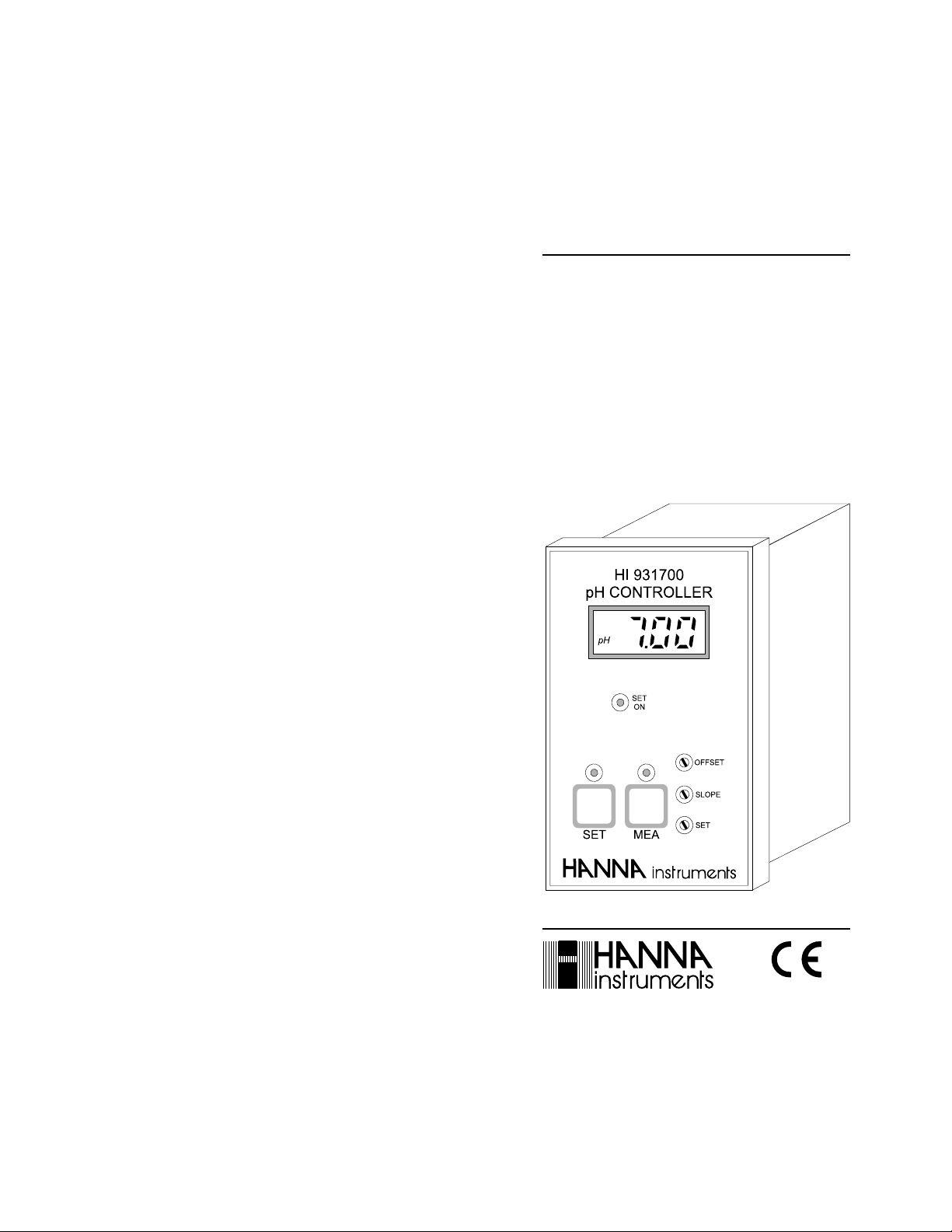

HI931700

HI932700

Panel - Mounted

pH - ORP Indicators

Controllers

http://www.hannainst.com

These Instruments are in

Compliance with the CE Directives

Page 2

Dear Customer,

Thank you for chosing a Hanna Instruments

Product.

Please read this instruction manual carefully

before using the instrument.

This manual will provide you with all the necessary information for the correct use of the

instrument, as well as a precise idea of its

versatility in a wide range of applications.

These instruments are in compliance with

directives EN 50081-1 and 50082-1.

TABLE OF CONTENTS

Preliminary Examination ............................ 3

General Description ................................... 3

Functional Description HI 931700 .............. 5

Functional Description HI 932700 .............. 6

Mechanical Dimensions ............................. 8

Specifications HI 931700 ........................... 9

Specifications HI 932700 ........................... 9

Initial Preparation ..................................... 10

Operational Guide .................................... 12

Calibration ................................................ 13

Taking Redox Measurements................... 16

Electrode Conditioning and Maintenance. 19

Temperature-Resistance Correlation for

HANNA pH Sensitive Glass ..................... 24

Suggested Installations ............................ 26

Accessories .............................................. 28

Warranty................................................... 34

CE Declaration of Conformity .................. 35

ISO 9000 Certified

Company since 1992

2

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it carefully to make sure

that no damage has occurred during shipping.

If there is any noticeable damage, notify your

Dealer.

Note: Save all packing materials until you

are sure that the instrument functions

correctly. All defective items must be

returned in the original packing materials

together with the supplied accessories.

GENERAL DESCRIPTION

HI 931700 and HI 932700 respectively are pH

and ORP panel-mounted indicators and controllers designed for simplicity of use in a wide

range of industrial applications.

The models are panel mount designed with

membrane keypads on the front panel and a

12x30 mm LCD display. Connections to the

electrodes, power supply, contacts and recorders are made via the plug-in terminal

blocks on the rear panel.

The instruments are equipped with a BNC

socket and accept input direct from pH or ORP

electrode.

Other features include: recorder output 0 to

20mA or 4 to 20 mA as indicated; LED indicators which identify whether the controller is in

operation mode or selection mode.

3

Page 3

FUNCTIONAL DESCRIPTION HI 931700

FRONT PANEL

HI 931700

pH CONTROLLER

pH

SET

ON

OFFSET

SLOPE

REAR PANEL HI 931700

SET MEA

SET

Keypad

SET To display and to set the working

point of pH dosage

MEASURE To set HI 931700 to the measure-

ment mode

Trimmers

OFFSET For Offset Calibration

SLOPE For Slope Calibration

SET To adjust the Set Point

Leds

SET ON To show that acidic or alkaline

dosage is in progress

4

1. Power Supply

15-24 VDC: 115 or 220 VAC:

P1 !Not Connected Earth

P2 ! Negative Neutral

P3 ! Positive Live

2. Acid/Base Dosage Selection (see page 10);

3. Connections for dosing pump to dose either

acid or base products. These contacts act

only as a switch for the power to the drive;

4. Recorder output(M1 ! + mA output,

M2 ! - mA output);

5. BNC for pH electrode;

6. Connection for Potential Matching Pin;

7. Connection for Electrode Reference.

Note: Be sure your main line is protected by

a fuse.

5

Page 4

FUNCTIONAL DESCRIPTION HI 932700

FRONT PANEL

HI 932700

ORP CONTROLLER

mV

SET

ON

SLOPE

REAR PANEL HI 932700

SET MEA

SET

Keypad

SET To display and to set the working

point of ORP dosage

MEASURE To set HI 932700 to the measure-

ment mode

Trimmers

SLOPE For Slope Calibration

SET To adjust the Set Point

Leds

SET ON To show that oxidant or reduc-

tant dosage is in progress

6

1. Power Supply

15-24 VDC: 115 or 220 VAC:

P1 ! Not Connected Earth

P2 ! Negative Neutral

P3 ! Positive Live

2. Oxidant/Reductant dosage selection (see

page 10);

3. Connections for dosing pump to dose either oxidant or reductant products. These

contacts act only as a switch for the power

to the drive;

4. Recorder output(M1 ! + mA output,

M2 ! - mA output);

5. BNC for ORP electrode;

6. Connection for Potential Matching Pin;

7. Connection for Electrode Reference.

Note: Be sure your main line is protected by

a fuse.

7

Page 5

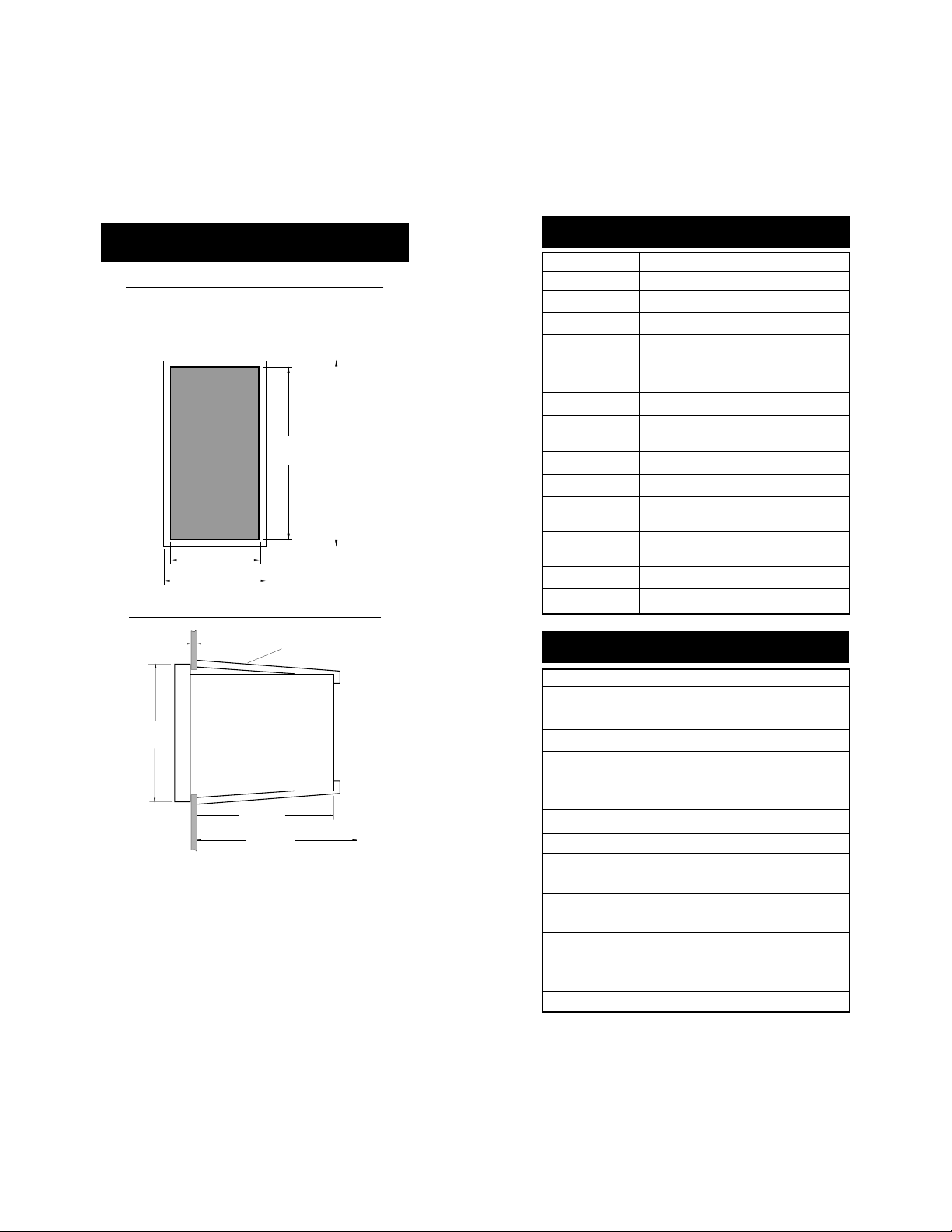

MECHANICAL DIMENSIONS

Front view of the panel-mounted unit.

Dimensions show the cutout size for the installation and also the outside dimensions of the

panel.

42mm

1.65"

49mm

1.93"

73mm

2.87"

79mm

3.11"

Side view of the panel-mounted unit.

79mm

3.11"

0.25/4mm

0.01/0.160"

76mm

3"

95mm MIN

3.74"

ADJUSTABLE

LOCATION

BRACKET

Adjustable location brackets (supplied with

the meter) allow the controller to slide into the

cutout and will hold the unit securely in place.

95 mm (3.74") is the minimum amount of

space required to install the controller with the

cables connected.

8

SPECIFICATIONS HI 931700

HI 931700

Range 0.00 to 14.00 pH

Resolution 0.01 pH

Accuracy ±0.02 pH

Typical EMC

Deviation

±0.02 pH

Installation Cat. II

Input 1012 Ohm

Calibration Offset: ±2 pH through Offset trimmer

Slope: 80 to 110% through slope trimmer

Readout 4-digit LCD plus graphic symbols

Recorder Output 0 to 20mA or 4 to 20mA (not isolated)

Set Point Relay Isolated, 2A, max 240 V,

resistive load, 1.000.000 strokes

Power Supply 115±10% or 230±10% VAC, 50/60 Hz

or 15-24VDC (according to the model)

Environment -10 to 50°C (14 to 122°F)

Weight 130 g (4.58 oz)

SPECIFICATIONS HI 932700

HI 932700

Range -1000 to +1000 mV

Resolution 1 mV

Accuracy ±5 mV

Typical EMC

Deviation

Installation Cat. II

Input 1012 Ohm

Calibration Slope: 90 to 110% through slope trimmer

Readout 4-digit LCD plus graphic symbols

Recorder Output 0 to 20 mA or 4 to 20 mA (not isolated)

Set Point Relay Isolated, 2 A, max 240 V,

resistive load, 1.000.000 strokes

Power Supply 115±10% or 230±10% VAC, 50/60 Hz

or 15-24VDC (according to the model)

Environment -10 to 50°C (14 to 122°F)

Weight 130 g (4.58 oz)

±2 mV

9

Page 6

INITIAL PREPARATION

• Connect a 3-wire (115 or

230VAC versions) or 2-wire

(15-24VDC version) power

Neutral

P1

Earth

P2

P3

Live

cable to the terminal strip

paying attention to the correct live, earth and neutral

(115 or 230VAC version)

or positive and negative

(15-24VDC version) terminal connections.

• Connect the pH or ORP

electrode to the BNC connector marked "INPUT

ELECTRODE".

• To benefit from the differential input, connect the proper electrode wire (if available) or a cable with a potential matching pin (grounding bar) to the relevant

terminal (# 6 at pages 5 and 7).

Note: When it is not possible to immerse

the Potential Matching Pin together with

the electrode in the solution, disable the

differential input by connecting the connection for Potential Matching Pin with

the connection for Electrode Reference

with a jumper wire.

• Recorder Terminals: these

contacts are the output terminals for connection to a

recorder. The output is from

M1

M2

0 to 20 mA or 4 to 20 mA

as indicated and is proportional to the measured pH

or ORP value.

Note: Calibrate the external recorder to be in

accordance with the display reading

(consult recorder manufacturer instruction manual).

• HI 931700 and HI 932700 are single set

point dosing controllers for dosing respectively acid or alkaline / reducing or oxidizing products.

HI 931700:

dose acid (e.g. in

hexavalent chromium re-

If you plan to

S1

S2

duction), make an open circuit between terminals

marked "S1" and "S2" on

the rear panel (description

on page 3).

If you plan to dose base

S1

S2

(e.g. in cyanide oxidation),

short terminals "S1" and

"S2".

HI 932700:

dose oxidants (e.g. in cya-

If you plan to

S1

S2

nide oxidation), make a

short circuit between terminals marked "S1" and "S2"

on the rear panel (description at page 5).

If you plan to dose reductants (e.g. in hexavalent

S1

S2

chromium reduction), make

an open circuit across terminals "S1" and "S2".

• Set Contacts: these contacts (maximum 2A, 220 V)

are used for connection to

dosing pumps. Use HI

931700 for dosage of acidic

C1

C2

or alkaline reagents, and

HI 932700 for dosage of

oxidizing or reducing reagents. Both units act as a

switch for power to the control element (e.g. pump).

Note: all external cables connected to the

rear panel should end with cable lugs.

10

11

Page 7

OPERATIONAL GUIDE

CALIBRATION

The setting of the various parameters are

made via the front panel keys and trimmers.

When each key is pressed the LED is lighted

indicating to the user that the function is in

operation.

Make sure that the meters and electrodes are

calibrated before operating the instruments

(see page 13).

To set the working point of pH or ORP dosage,

press the "SET" key. The display will show the

set value for the dosage.

SET MEA

SLOPE

SET

pH

Use a small screwdriver to adjust the "SET"

trimmer until the desired set value is displayed.

SET MEA

SLOPE

SET

pH

After setting the pH or ORP

value immerse the electrode in

the test solution and press the

SET MEA

SLOPE

SET

"MEASURE" key. The actual

pH or ORP value of the test

solution is displayed.

When the chemicals are dosed,

the "SET ON" LED will be lit.

12

SET MEA

SET

ON

OFFSET

SLOPE

SET

Make sure the meter is in the measurement

mode (MEASURE LED light is on) before

starting the calibration procedure.

HI 931700:

Note the temperature of the buffer

solution using a thermometer.

Immerse the electrode and the Potential Matching Pin in pH 7.01 buffer

solution (HI 7007).

Note: When it is not possible to immerse

the Potential Matching Pin together with the

electrode in the solution, disable the differential input by connecting the connection for

Potential Matching Pin with the connection

for Electrode Reference with a jumper wire.

SET MEA

SET

ON

OFFSET

SLOPE

SET

pH

Shake briefly and

wait one minute before adjusting the

Offset trimmer to

display pH 7.01 on the LCD if the temperature

of the buffer solution is at 25°C.

If the buffer solution temperature is not 25°C,

refer to Table 1 for the appropriate buffer

value to adjust at the noted temperature.

Rinse the electrode and the Potential Matching Pin thoroughly

in water and immerse them in

4.01pH (HI7004) or 10.01pH

(HI7010) buffer solution.

Shake briefly and

wait one minute before adjusting the

slope trimmer to

SET MEA

SET

ON

OFFSET

SLOPE

SET

pH

display pH 4.01 (or

10.01) on the LCD if the temperature of the

buffer solution is at 25°C, if not refer to Table 1

for appropriate buffer value at the corresponding temperature.

13

Page 8

Temperature

°C

Buffer

pH 4.01

°F

pH 6.86

Buffer

Buffer

pH 7.01

Buffer

pH 9.18

Buffer

pH 10.01

0 32 4.01 6.98 7.13 9.46 10.32

5 41 4.00 6.95 7.10 9.39 10.24

10 50 4.00 6.92 7.07 9.33 10.18

15 59 4.00 6.90 7.04 9.27 10.12

20 68 4.00 6.88 7.03 9.22 10.06

25 77 4.01 6.86 7.01 9.18 10.01

30 86 4.02 6.85 7.00 9.14 9.96

35 95 4.03 6.84 6.99 9.10 9.92

40 104 4.04 6.84 6.98 9.07 9.88

45 113 4.05 6.83 6.98 9.04 9.85

50 122 4.06 6.83 6.98 9.01 9.82

55 131 4.07 6.84 6.98 8.99 9.79

60 140 4.09 6.84 6.98 8.97 9.77

65 149 4.11 6.85 6.99 8.95 9.76

70 158 4.12 6.85 6.99 8.93 9.75

75 167 4.14 6.86 7.00 8.91 9.74

80 176 4.16 6.86 7.01 8.89 9.73

85 185 4.17 6.87 7.02 8.87 9.74

90 194 4.19 6.88 7.03 8.85 9.75

95 203 4.20 6.89 7.04 8.83 9.76

Table 1

Note: For better accuracy, calibrate the meter

using a calibration solution at the same

temperature of the liquid to be measured.

If calibration is performed at a different

temperature, the error is approx.

0.0035pH for each 1°C difference multiplied by the difference between the pH

of the measured liquid and pH7;

e.g. meter calibrated at 25°C/measured

liquid: pH 4 / liquid temperature: 35°C;

the error is approx.:

0.0035x(35-25)x(7-4) = 0.10 pH

The error is added or subtracted to the

reading according to table 2.

HI 932700:

Immerse the electrode and the

Potential Matching Pin in HI 7020

ORP solution.

Note: When it is not possible to

immerse the Potential Matching Pin together

with the electrode in the solution, disable

the differential input by connecting the connection for Potential Matching Pin with the

connection for Electrode Reference with a

jumper wire.

Adjust the slope trimmer until an ORP value

from 200 mV and 275 mV is displayed.

SET

ON

SET MEA

OFFSET

SLOPE

SET

mV

The calibration is now complete and the instrument is ready for use.

.

Temp.above 25°CTemp. below 25°C

pH above 7 Subtract Add

pH below 7 Add Subtract

Table 2

14

15

Page 9

TAKING REDOX MEASUREMENTS

To make correct redox measurements the

following conditions must prevail:

Redox measurements allow the quantification of the oxidizing or reducing power of a

solution, and are commonly expressed in

mV.

Oxidation may be defined as the process

during which a molecule (or an ion) loses

electrons and reduction as the process by

which electrons are gained.

Oxidation is always coupled together with

reduction so that as one element gets oxidized, the other automatically is reduced,

therefore the term oxidation-reduction is frequently used.

Redox potentials are measured by an electrode capable of absorbing or releasing electrons without causing a chemical reaction

with the elements with which it comes into

contact.

The electrodes most usually available for

this purpose have gold or platinum surfaces;

gold possesses a higher resistance than platinum in conditions of strong oxidation, while

platinum is preferred for the measurements

of oxidizing solutions containing halides and

for more general uses.

When a platinum electrode is immersed in

an oxidizing solution a monomolecular layer

of oxygen is developed on its surface. This

layer does not prevent the electrode from

functioning, but it increases the response

time. The opposite effect is obtained when

the platinum surface absorbs hydrogen in

the presence of reducing mediums. This phenomenon is rough on the electrode.

16

- The surface of the electrode must be

cleaned and smooth.

- The surface of the electrode must undergo a preventive treatment depending whether the solution to be measured has oxidizing or reductive characteristics.

Because the Pt/PtO system depends on the

pH, the pretreatment of the electrode may

be determined by the pH and the redox

potential of the solution to be measured.

As a general rule, if the ORP mV reading

corresponding to the pH solution value is

higher than the value in the Table below, an

oxidizing pre-treatment is necessary; otherwise a reducing pre-treatment is necessary:

pH m V pH mV pH mV pH mV pH m V

0 990 1 920 2 860 3 800 4 740

5 680 6 640 7 580 8 520 9 460

10 400 11 340 12 280 13 220 14 160

Reducing pre-treatment: immerse the electrode for a few minutes in HI 7091.

Oxidizing pre-treatment: immerse the electrode for a few minutes in HI 7092.

If pre-treatment is not performed, the electrode will take a significantly longer time to

respond.

When working with electrodes of the refilling type, the electrolyte used for filling must

be constantly kept at an adequate level (no

less than 2½ centimeters from the filling

hole) and topped up if necessary with HI 7071

refilling solution.

17

Page 10

In the event that measurements are performed with solutions containing sulfides or

proteins, the cleaning of the diaphragm of

the reference electrode must be performed

(see page 21, "Cleaning Procedure").

ELECTRODE CONDITIONING

AND MAINTENANCE

In order to have a correct functioning of the

ORP electrode, immerse it into HI 7020 and

measure the response; the obtained value

should be within 200 and 275 mV.

After this functional test, it is suggested to

wash the electrode thoroughly with water

and proceed to the oxidizing or reducing

pre-treatment before taking measurements.

When not in use, the electrode tip should be

kept moist and far from any type of mechanical stress which might cause damage.

For this reason , the use of the protective

cap supplied with the electrode is advised.

Reference

Filling Hole

Fill Hole

Screw

Sensitive

Wire

Reference

Wire

Reference

Junction

Glass

Bulb

Reference

Wire

Reference

Junction

Platinum or

Gold tip

Plastic Body

pH Electrode

Reference

Plastic Body

ORP Electrode

Reference

Filling Hole

Reference

Wire

Sensitive

Wire

Reference

Junction

Glass

Bulb

Glass Body

pH Electrode

Wire

Reference

Junction

Platinum or

Gold tip

Glass Body

ORP Electrode

18

PREPARATION

Remove the protective cap.

DO NOT BE ALARMED IF ANY SALT DE-

POSITS ARE PRESENT.

This is normal with electrodes and they will

disappear when rinsed with water.

During transport tiny bubbles of air may have

formed inside the glass bulb. The electrode

19

Page 11

cannot function properly under these conditions. These bubbles can be removed by

"shaking down" the electrode as you would

do with a glass thermometer.

If the bulb and/or junction are dry, soak the

electrode in HI70300 Storage Solution for at

least one hour.

For refillable electrodes:

If the fill solution (electrolyte) is more than

1 cm (½") below the fill hole, add HI7082

3,5M KCl Electrolyte Solution for double

junction or HI7071 3,5M KCl+AgCl Electro-

lyte Solution for single junction electrodes.

For a faster response unscrew the fill hole

screw during measurements.

Follow the Preparation Procedure above before taking measurements.

Note: NEVER STORE THE ELECTRODE

IN DISTILLED WATER OR DRY.

PERIODIC MAINTENANCE

Inspect the electrode and the cable. The

cable used for the connection to the meter

must be intact and there must be no points

of broken insulation on the cable or cracks

on the electrode stem or bulb.

Connectors must be perfectly clean and dry.

If any scratches or cracks are present, replace the electrode. Rinse off any salt deposits with water.

For AmpHel® electrodes:

If the electrode does not respond to pH

changes, the battery is run down and the

electrode should be replaced.

MEASUREMENT

Rinse the electrode tip with distilled water.

Immerse the tip (4 cm / 1½") in the sample

and stir gently for approx. 30 seconds.

For a faster response and to avoid cross

contamination of the samples, rinse the electrode tip with a few drops of the solution to

be tested, before taking measurements.

STORAGE

To minimize clogging and assure a quick

response time, the glass bulb and the junction should be kept moist and not allowed to

dry out.

Replace the solution in the protective cap

with a few drops of HI 70300 Storage Solu-

tion or, in its absence, Filling Solution

(HI7071 for single junction or HI7082 for

double junction electrodes).

AmpHel® is a registered Trademark of "Hanna Instruments"

20

For refillable electrodes:

Refill the electrode with fresh electrolyte

(HI7071 for single junction or HI7082 for

double junction electrodes). Allow the electrode to stand upright for 1 hour.

Follow the Storage Procedure above.

CLEANING PROCEDURE

General

Soak in Hanna HI7061 Gen-

eral Cleaning Solution for approximately 1 hour.

Removal of films, dirt or deposits on the

membrane/junction:

Protein

Soak in Hanna HI7073 Protein

Cleaning Solution for 15 minutes.

Inorganic

Soak in Hanna HI7074 Inor-

ganic Cleaning Solution for 15

minutes.

Oil/grease

Rinse with Hanna HI7077 Oil

and Fat Cleaning Solution.

21

Page 12

IMPORTANT: After performing any of the

cleaning procedures rinse the electrode thoroughly with distilled water, drain and refill

the reference chamber with fresh electrolyte, (not necessary for GEL filled electrodes)

and soak the electrode in HI 70300 Storage

Solution for at least 1 hour before taking

measurements.

TROUBLESHOOTING

Evaluate your electrode performance based

on the following.

• Noise (Readings fluctuate up and down)

could be due to:

- Clogged/Dirty Junction: Refer to the

Cleaning Procedure above.

- Loss of shielding due to low electro-

lyte level (in refillable electrodes only):

refill with HI7071 for single junction or

HI7082 for double junction electrodes.

• Dry Membrane/Junction: Soak in Stor-

age Solution HI70300 for at least 1 hour.

ter and then follow the Cleaning Procedure above.

• For ORP Electrodes: polish the metal

tip with a light abrasive paper (paying

attention not to scratch the surface) and

wash throughly with water.

• Drifting: Soak the electrode tip in warm

Hanna Solution HI7082 for one hour and

rinse tip with distilled water. Refill with

fresh HI7071 for single junction electrodes

and HI7082 for double junction electrodes.

• Low Slope: Refer to the cleaning proce-

dure above.

• No Slope: Check the electrode for cracks

in glass stem or bulb (replace the electrode if cracks are found).

• Slow Response/Excessive Drift: Soak

the tip in Hanna Solution HI7061 for 30

minutes, rinse thoroughly in distilled wa-

22

23

Page 13

TEMPERATURE-RESISTANCE

20

0 +10+20+30+40+50+60+70 +80+90

C

CORRELATION FOR HANNA

pH SENSITIVE GLASS

The resistance of glass electrodes partially

depends on the temperature. The lower the

temperature, the higher the resistance. It

takes longer time for the reading to stabilize

if the resistance is higher. In addition, the

response time will suffer to a greater degree

at temperatures below 10°C.

Ω

9

2x10

-10

9

1x10

-10

8

-10

2x10

8

1x10

-10

7

2x10

-10

-10

7

1x10

-10

-20-

Since the resistance of the pH electrode is

in the range of 200 Mohm, the current across

the membrane is in the pico Ampere range.

Large currents can disturb the calibration of

the electrode for many hours.

Typical Electrode Life

Ambient Temperature 1- 3 years

90 °C Less than 4 months

120°C Less than 1 month

High concentrations of sodium ions interfere

with readings in alkaline solutions; the pH at

which the interference starts to be significant depends upon the composition of the

glass. This interference is the alkaline error

and causes the pH readings to be underestimated. Hanna's glass formulations have the

indicated characteristics.

Alkaline Error

Sodium Ion Correction for the Glass

at 20-25°C

Concentration pH Error

°

0.1 Mol L-1 Na

+

13.00

13.50

14.00

1.0 Mol L-1 Na

+

12.50

13.00

13.50

14.00

0.10

0.14

0.20

0.10

0.18

0.29

0.40

For these reasons high humidity environ-

ments, short circuits and static discharges are detrimental for a stable pH

reading.

The pH electrode's life also depends on the

temperature. If constantly used at high temperatures, the electrode life is drastically

reduced.

24

25

Page 14

SUGGESTED INSTALLATIONS

SHORT DISTANCE, INDOOR INSTALLATION

Due to the high impedance of the pH and

ORP electrode's glass membrane (usually

more than 100 MΩ), a very high grade of

insulation is required.

A dry environment is needed in order to

obtain a level of insulation not lower than

12

10

Ω.

MAXIMUM 10 METERS

DRY ENVIRONMENT

LESS THAN 80%

RELATIVE HUMIDITY

pH METER

WITH CONVENTIONAL ELECTRODES

MEASUREMENTS CAN BE

TAKEN FROM DISTANCES UP TO

10 METERS (33 FEET)

This type of connection is very delicate and

requires constant attention to maintain proper

operating conditions.

The conventional electrodes should be used

in indoor applications only, and should not

use a cable longer than 10m (33').

MAXIMUM 50 METERS

WET ENVIRONMENT

RELATIVE HUMIDITY UP TO 100%

pH METER

WITH AN AmpHel ELECTRODE

TAKEN FROM DISTANCES UP TO

®

MEASUREMENTS CAN BE

50 METERS (165 FEET)

AmpHel® electrodes have a micro-amplifier

in the electrode cap to boost the signal,

drastically reducing susceptibility to noise

and drift.

With all of the components sealed in the

electrode body, moisture up to 100% RH

will not effect the signal.

MEDIUM DISTANCE,

INDOOR/OUTDOOR INSTALLATION

Since the introduction of AmpHel® these distances are no longer a problem. You are

now able to connect your meter directly to

an AmpHel® electrode, saving the cost of a

transmitter or costly coaxial cable.

The standard cable length of the AmpHel

electrode is 5 m (16.5'). Additional lengths

of regular cable up to 50 m (165'), can be

installed without special connectors.

AmpHel® is a registered Trademark of "Hanna Instruments"

26

®

AmpHel® is a registered Trademark of "Hanna Instruments"

27

Page 15

M13 x 1.5

DIA

16

mm

7

mm

25

mm

M13 x 1.5

DIA

16

mm

7

mm

25

mm

ACCESSORIES

pH CALIBRATION SOLUTIONS

HI7004M pH 4.01 Buffer Solution, 230 mL

HI7004L pH 4.01 Buffer Solution, 460 mL

HI7006M pH 6.86 Buffer Solution, 230 mL

HI7006L pH 6.86 Buffer Solution, 460 mL

HI7007M pH 7.01 Buffer Solution, 230 mL

HI7007L pH 7.01 Buffer Solution, 460 mL

HI7009M pH 9.18 Buffer Solution, 230 mL

HI7009L pH 9.18 Buffer Solution, 460 mL

HI7010M pH 10.01 Buffer Solution, 230 mL

HI7010L pH 10.01 Buffer Solution, 460 mL

ORP SOLUTIONS

HI 7020M 200-275mV Buffer Solution, 230 mL

HI 7020L 200-275mV Buffer Solution, 460 mL

HI 7091M Pre-Treatment Reducing Solution,

230 mL

HI 7091L Pre-Treatment Reducing Solution,

460 mL

HI 7092M Pre-treatment Oxidizing Solution,

230 mL

HI 7092L Pre-Treatment Oxidizing Solution,

460 mL

ELECTRODE STORAGE SOLUTIONS

HI70300MStorage Solution, 230 mL

HI70300L Storage Solution, 460 mL

ELECTRODE CLEANING SOLUTIONS

HI7061M General Cleaning Sol., 230 mL

HI7061L General Cleaning Sol., 460 mL

HI7073M Protein Cleaning Sol., 230 mL

HI7073L Protein Cleaning Sol., 460 mL

HI7074M Inorganic Cleaning Sol., 230 mL

HI7074L Inorganic Cleaning Sol., 460 mL

HI7077M Oil & Fat Cleaning Sol., 230 mL

HI7077L Oil & Fat Cleaning Sol.,460 mL

REFILLING ELECTROLYTE SOLUTIONS

HI7071 3.5M KCl+ AgCl Electrolyte,

4x50 mL, for single junction electrodes

HI7072 1M KNO3 Electrolyte, 4x50 mL

HI7082 3.5M KCl Electrolyte, 4x50 mL,

for double junction electrodes

28

pH ELECTRODES

HI 1090T Screw cap PG13.5 connector,

double junction, glass-body

PG13.5 THREAD

φ 12mm φ 9.5mm

110mm30mm

HI 1110S Screw connector, single junction,

glass-body

HI 1130B/3 BNC connector, 3 m (9.9') cable,

single junction, glass-body

3/4 x 16 UNF

DIA 20.5mm

38.5mm

HI 1110S HI 1130B/3

DIA 9.5mm

DIA 12mm

110mm

HI 1110T Screw cap PG13.5 connector,

double junction, glass-body

PG13.5 THREAD

φ 12mm φ 9.5mm

110mm30mm

HI 1114S Screw connector, double junc-

tion plastic-body

HI 1134B/3 BNC connector, 3 m (9.9') cable,

double junction plastic-body

3/4 x 16 UNF

DIA 20.5mm

38.5mm

HI 1114S HI 1134B/3

DIA 12mm

110mm

HI 1115S Screw connector, single junction,

glass-body

HI 1135B/3 BNC connector, 3 m (9.9') cable,

single junction, glass-body

DIA 16.5mm

5mm

M13 x 1.5

DIA

16

mm

25

7

mm

mm

HI 1115S HI 1135B/3

DIA 7.6mm

25mm

29

DIA 12mm

150mm

Page 16

M13 x 1.5

DIA

16

mm

7

mm

25

mm

HI 1210T Screw cap PG13.5 connector,

double junction, plastic-body

PG13.5 THREAD

φ 12mm

HI 2910B/5 BNC connector, 5 m (16.5') cable,

double junction, plastic-body,

built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

DIA 12mm

110mm30mm

HI 1910B BNC connector, 1 m (3.3') cable,

double junction, plastic-body,

built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

38.5mm

DIA 12mm

110mm

HI 1911B BNC connector, 1 m (3.3') cable,

double junction, plastic-body,

built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

38.5mm

DIA 12mm

110mm

HI 1912B BNC connector, 1 m (3.3') cable,

double junction, plastic-body,

built-in amplifier

HI 1912B/5 BNC connector, 5 m (16.5') cable,

double junction, plastic-body,

built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

DIA 9.5mm

DIA 12mm

38.5mm

110mm

ORP ELECTRODES

HI 2930B/5 BNC connector, 5 m (16.5') cable,

Pt, Ultem®-body, built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

38.5mm

DIA 12mm

110mm

HI 3110S Screw-type connector, Pt, glass-

body

HI 3130B/3 BNC connector, 3 m (9.9') cable,

Pt, glass-body

3/4 x 16 UNF

DIA 20.5mm

HI 3110S HI 3130B/3

38.5mm

DIA 12mm

110mm

HI 3110T Screw cap PG13.5 connector,

Pt, glass-body

PG13.5 THREAD

φ 12mm φ 1mm

38.5mm

110mm

HI 2114B/5 BNC connector, 5 m (16.5') cable,

double junction, plastic-body

3/4 x 16 UNF

DIA 20.5mm

38.5mm

30

DIA 12mm

110mm

110mm30mm

HI 3115S Screw-type connector, side-arm,

Pt, glass-body

HI 3135B/3 BNC connector, 3 m (9.9') cable,

side-arm, Pt, glass-body

DIA 16.5mm

5mm

M13 x 1.5

DIA

16

mm

25

7

mm

mm

HI 3115S HI 3135B/3

Ultem® is a registered Trademark of "General Electrics Company"

DIA 7.6mm

25mm

31

DIA 12mm

150mm

Page 17

HI 3210T Screw cap PG13.5 connector,

M13 x 1.5

DIA

16

mm

7

mm

25

mm

Pt, plastic-body

PG13.5 THREAD

φ 12mm

110mm30mm

HI 3410S Screw connector, Pt, plastic-body

HI 3430B/3 BNC connector, 3 m (9.9') cable,

Pt, plastic-body

3/4 x 16 UNF

DIA 20.5mm

38.5mm

HI 3410S HI 3430B/3

DIA 12mm

110mm

HI 3932B/5 BNC connector, 5 m (16.5') cable,

Pt, Ultem®-body, built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

38.5mm

DIA 12mm

110mm

HI 4110S Screw-type connector, Au, glass-

body

HI 4130B/3 BNC connector, 3 m (9.9') cable,

Au, glass-body

DIA

16

mm

3/4 x 16 UNF

DIA 20.5mm

M13 x 1.5

25

7

mm

mm

HI 4110S HI 4130B/3

38.5mm

DIA 12mm

110mm

HI 4932B/5 BNC connector, 5 m (16.5') cable,

Au, Ultem®-body, built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

38.5mm

DIA 12mm

110mm

EXTENSION CABLES FOR SCREW-TYPE

ELECTRODES ONLY (SCREW TO BNC

CONNECTOR)

HI 7855 SERIES CABLE CONNECTORS

CONNECTOR AND 3.0 mm (0.12") CABLE WITH BNC

CONNECT TO

SCREW TYPE

ELECTRODES

CONNECT TO THE

BNC SOCKET

OF THE METER

HI7855/1 Extension cable 1m (3.3') long

HI7855/3 Extension cable 3m (9.9') long

HI7855/5 Extension cable 5m (16.5') long

HI7855/10 Extension cable 10m (33') long

HI7855/15 Extension cable 15m (49.5') long

OTHER ACCESSORIES

BL PUMPS Dosing Pumps with Flow Rate

from 1.5 to 20 LPH

ChecktempC Pocket-size thermometer with

penetration probe and 0.1°C

resolution (range -50.0 to

150.0°C)

HI6050 Submersible Electrode Holders

& HI 6051

HI 6054 Electrode Holders for In-Line

& HI 6057 Applications

HI731326 Calibration Screwdriver (20 pcs)

HI 7871 Level Controllers

& HI 7873

HI8427 pH and ORP Electrode

Simulator with 1 m (3.3') Coaxial

Cable ending in Female BNC

Connectors (HI 7858/1)

HI931001 pH and ORP Electrode

Simulator with LCD Display and

1 m (3.3') Coaxial Cable ending

in Female BNC Connectors

(HI 7858/1)

MANMINPRR2 Instruction Manual

Ultem® is a registered Trademark of "General Electrics Company"

32

33

Page 18

WARRANTY

All Hanna Instruments meters are warranted

for two years against defects in

workmanship and materials when used for

their intended purpose and maintained

according to instructions.

The probes and the electrodes are

warranted for a period of six months.

Damages due to accident, misuse, tampering

or lack of prescribed maintenance are not

covered. This warranty is limited to repair or

replacement free of charge.

If service is required, contact the dealer

from whom you purchased the instrument. If

under warranty, report the model number,

date of purchase, serial number and the

nature of the failure. If the repair is not

covered by the warranty, you will be notified

of the charge for repair or replacement. When

shipping any instrument, make sure it is

properly packaged for complete protection.

CE DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

We

Hanna Instruments Srl

V.le delle industrie 12

35010 Ronchi di Villafranca (PD)

ITALY

herewith certify that the panel mounted pH / ORP controllers

have been tested and found to be in compliance with the following regulations:

IEC 801-2 Electrostatic Discharge

IEC 801-3 RF Radiated

IEC 801-4 Fast Transient

EN 55022 Radiated, Class B

Date of Issue: 16-04-1996

HI 931700 HI 932700

D.Volpato - Engineering Manager

On behalf of

Hanna Instruments S.r.l.

To validate your warranty, fill out and return

the enclosed warranty card within 14 days

from the date of purchase.

All rights are reserved. Reproduction in whole

or in part is prohibited without the written

consent of the copyright owner.

Hanna Instruments reserves the right to

modify the design, construction and

appearance of its products without

advance notice.

34

Recommendations for Users

Before using these products, make sure that they are entirely suitable for the environment

in which they are used.

Operation of these instruments in residential area could cause unacceptable interferences

to radio and TV equipments, requiring the operator to take all necessary steps to correct

interferences.

The trimmers are sensitive to electrostatic discharges. It is recommended to use anti-static

screwdriver.

Any variation introduced by the user to the supplied equipment may degrade the instruments'

EMC performance.

To avoid electrical shock, do not use these instruments when voltages at the measurement

surface exceed 24VAC or 60VDC.

To avoid damages or burns, do not perform any measurement in microwave ovens.

35

Page 19

PRINTED IN

PORTUGAL

MANMINPRR2

02/99

http://www.hannainst.com

Loading...

Loading...