Page 1

1

HI5321

Conductivity/Resistivity/TDS/

Salinity/Temperature

Bench Meter

INSTRUCTION MANUAL

Page 2

2

Thank you for choosing a Hanna Instruments product.

Please read this instruction manual carefully before using the instrument.

This manual will provide you with the necessary information for correct

use of the instrument, as well as a precise idea of its versatility.

If you need additional technical information, do not hesitate to e‑mail

us at tech@hannainst.com or view our worldwide contact list at

www.hannainst.com.

Dear Customer,

All rights are reserved. Reproduction in whole or in part is prohibited without the written consent

of the copyright owner, Hanna Instruments Inc., Woonsocket, Rhode Island, 02895, USA.

Page 3

3

PRELIMINARY EXAMINATION ................................................................................................

GENERAL DESCRIPTION .......................................................................................................

FUNCTIONAL DESCRIPTION ..................................................................................................

SPECIFICATIONS .................................................................................................................

OPERATIONAL GUIDE ..........................................................................................................

DISPLAYING MODES ............................................................................................................

SYSTEM SETUP ...................................................................................................................

CONDUCTIVITY SETUP .........................................................................................................

RESISTIVITY SETUP .............................................................................................................

TDS SETUP .........................................................................................................................

SALINITY SETUP ..................................................................................................................

CONDUCTIVITY CALIBRATION ................................................................................................

CONDUCTIVITY MEASUREMENT ............................................................................................

USP EVALUATION ...............................................................................................................

RESISTIVITY MEASUREMENT ................................................................................................

TDS MEASUREMENT ............................................................................................................

SALINITY CALIBRATION ........................................................................................................

SALINITY MEASUREMENT ....................................................................................................

TEMPERATURE CALIBRATION ...............................................................................................

LOGGING ............................................................................................................................

PC INTERFACE .....................................................................................................................

EC PROBE USE AND MAINTENANCE ......................................................................................

TROUBLESHOOTING GUIDE ..................................................................................................

ACCESSORIES .....................................................................................................................

TABLE OF CONTENTS

4

5

8

11

21

37

41

44

48

50

52

6

10

14

35

39

43

48

49

51

56

58

55

57

Page 4

4

Remove the instrument from the packing material and examine it carefully to make sure that no

damage has occurred during shipping. If there is any damage, notify your dealer or the nearest

Hanna Service Center.

The meters are supplied complete with:

• HI76312 Four‑ring Conductivity Probe with built‑in temperature sensor and ID

• HI76404W Electrode Holder

• Conductivity Calibration Solutions Kit

• 12 Vdc Power Adapter

• Instruction Manual and Quick Reference Guide

• Certificate

HI5321‑01 is supplied with 12 Vdc/120 Vac adapter.

HI5321‑02 is supplied with 12 Vdc/230 Vac adapter.

Note: Save all packing material until you are sure that the instrument works properly. Any

defective item must be returned in the original packing with the supplied accessories.

PRELIMINARY EXAMINATION

Page 5

5

HI5321 is a professional bench meter with color graphic LCD, conductivity, resistivity, TDS, salinity

and temperature measurements.

The display may be viewed with: Basic information only, GLP information, Graph and Log History.

The main features of the instruments are:

• Single input channel;

• Capacitive touch keypad;

• Five measurement parameters: conductivity, resistivity, TDS, salinity and temperature;

• Dedicated Help key with contextual message;

• Application for water for injection the USP <645> standard;

• Conductivity probe automatic recognition;

• Standard or custom standard conductivity calibration in up to four points, probe offset calibration;

• Single fixed point salinity calibration (Percent Scale only);

• AutoHold feature to freeze first stable reading on the LCD;

• Two selectable alarm limits (for conductivity, resistivity, TDS, salinity);

• Three selectable logging modes: Automatic, Manual or AutoHold;

• Up to 100 logging lots for automatic or manual modes and up to 200 USP reports;

• Selectable sampling period for automatic logging: 1 second to 180 minutes;

• Continuous Lot logging directly on meter. Store up to 100.000 total data points;

• GLP feature;

• Online and offline graph;

• Large color backlight graphic LCD (240 x 320 pixels) with selectable color palette;

• PC interface via USB; download logged data to PC or use for Real time logging (HI92000 PC

application required);

• Profile feature: store up to ten different user setups.

GENERAL DESCRIPTION

Page 6

6

1

2

Conductivity

HI5321 DESCRIPTION

FRONT PANEL

REAR PANEL

1) Liquid Crystal Display (LCD)

2) Capacitive touch keypad

3) ON/OFF switch

4) Power adapter socket

5) Conductivity probe connector

6) USB connector

FUNCTIONAL DESCRIPTION

Page 7

7

KEYBOARD DESCRIPTION

VIRTUAL KEYS

The upper row keys are assigned to the virtual keys placed on the bottom of the LCD, which allow

you to perform the displayed function, depending on the current menu (e.g. and

in Measure mode).

LCD GENERAL DESCRIPTION

To enter/exit calibration mode;

To select the desired measurement mode: Conductivity, Resistivity, TDS, Salinity;

To enter Setup (System Setup, Conductivity Setup, Resistivity Setup, TDS Setup or

Salinity Setup) and to access Log Recall function;

To obtain general information about the selected option / operation.

FUNCTION KEYS

FUNCTIONAL DESCRIPTION

Page 8

8

Conductivity

Range

0.000 to 9.999 µS/cm

10.00 to 99.99 µS/cm

100.0 to 999.9 µS/cm

1.000 to 9.999 mS/cm

10.00 to 99.99 mS/cm

100.0 to 1000.0 mS/cm

Resolution

0.001 µS/cm

0.01 µS/cm

0.1 µS/cm

0.001 mS/cm

0.01 mS/cm

0.1 mS/cm

Accuracy ±1% of reading (±0.01 µS/cm)

Cell constant 0.0500 to 200.00 /cm

Cell type 4 cells

Calibration type/points

Auto standard recognition / User standard, Single Point / Multi Point

calibration

EC calibration solution

84.00 µS/cm, 1.413 mS/cm, 5.000 mS/cm, 12.88 mS/cm, 80.00 mS/cm,

111.8 mS/cm

Conductivity probe recognition Yes

Temperature compensation Disabled / Linear / Non linear (natural water)

Temperature coefficient 0.00 to 10.00 %/°C

Reference temperature 5.0 °C to 30.0 °C

Profiles Up to ten

USP <645> Application Yes

Resistivity

Range

1.0 to 99.9 Ω·cm

100 to 999 Ω·cm

1.00 to 9.99 KΩ·cm

10.0 to 99.9 KΩ·cm

100 to 999 KΩ·cm

1.00 to 9.99 MΩ·cm

10.0 to 100.0 MΩ·cm

Resolution

0.1 Ω·cm

1 Ω·cm

0.01 KΩ·cm

0.1 KΩ·cm

1 KΩ·cm

0.01 MΩ·cm

0.1 MΩ·cm

Accuracy ±1 % of reading (±1 Ω·cm)

Calibration Uses Conductivity

SPECIFICATIONS

Page 9

9

TDS

Range

0.000 to 9.999 ppm

10.00 to 99.99 ppm

100.0 to 999.9 ppm

1.000 to 9.999 ppt

10.00 to 99.99 ppt

100.0 to 400.0 ppt

actual TDS (with 1.00 factor)

Resolution

0.001 ppm

0.01 ppm

0.1 ppm

0.001 ppt

0.01 ppt

0.1 ppt

Accuracy ±1% of reading (±0.01 ppm)

Salinity

Range

Practical Scale

0.00 to 42.00 PSU

Natural Sea Water

0.00 to 80.00 ppt

Percent Scale

0.0 to 400.0 %

Resolution 0.01 for Practical Scale / Natural Sea Water 0.1 % for Percent Scale

Accuracy ±1% of reading

Calibration Percent Scale ‑ 1 point (with HI7037 standard)

Temperature

Range

‑20.0 to 120.0 °C

‑4.0 to 248.0 °F

253.2 to 393.2 K

Resolution 0.1 °C / 0.1 °F / 0.1 K

Accuracy ±0.2 °C / ±0.4 °F / ±0.2 K (without probe)

Calibration User calibration in 3 points (0, 50, 100 °C)

Input channel Conductivity / Resistivity / TDS / Salinity

PC interface Opto‑isolated USB

GLP

Probe cell constant / offset, reference teperature, compensation coefficient, calibration

points, calibration time stamp

Auto Hold Yes

Calibration reminder Yes

Logging

feature

Record Up to 100 lots, 50,000 records max / lot / maximum 100,000 data points

Interval 14 selectable between 1 second and 180 minutes

Type Automatic, Log on demand, AutoHold

EC Probe HI76312

Implemented standards USP stage 1, 2, 3

LCD Color Graphic LCD 240 x 320 pixels

SPECIFICATIONS

Page 10

10

POWER CONNECTION

Plug the 12 Vdc adapter into the power supply socket.

Note: This instrument use non volatile memory to retain the meter settings, even when

unplugged.

ELECTRODE AND PROBE CONNECTIONS

For conductivity, resistivity, TDS or salinity measurements connect a conductivity probe to the DIN

connector located on the rear panel of the instrument.

INSTRUMENT START UP

• Please ensure that the capacitive keypad is not covered by hand or other objects at the meter

power on.

• Turn the instrument on from the power button located on the rear panel of the instrument.

• Please wait until the instrument finishes the initialization process.

Note: It is normal for the loading process to take a few seconds. If the instrument doesn’t

display the next screen, restart the meter using the power switch. If the problem persists,

contact your dealer.

OPERATIONAL GUIDE

Keyboard 8 keys capacitive touch

Power Supply 12 Vdc adapter

Dimensions 160 x 231 x 94 mm (6.3 x 9.1 x 3.7”)

Weight 1.2 Kg (2.6 lbs)

Page 11

11

GLP (Conductivity and Salinity Percent scale only)

Detailed GLP data will be displayed on the custom LCD for the Conductivity and Salinity Percent

scale: Last Calibration date and time, Calibration Standards and general information regarding

the standards, the calibration temperature, temperature

compensation mode, date and time.

To access the GLP display option:

• Press while in Measure mode. The “Choose

Display Configuration” message will be displayed in

the Reminder messages area.

• Press . The instrument will display the

detailed GLP data.

For measurement mode’s the following display configurations are available: Basic, Graph and Log

History. A GLP display is available for Conductivity and Salinity Percent scale.

Basic

The main measured value and it’s units are displayed on the LCD, along with the temperature

value, temperature probe status and basic calibration

information (when available).

To choose the Basic display mode:

• Press while in Measure mode. The “Choose

Display Configuration” message will be displayed in

the Reminder messages area.

• Press . The instrument will display the basic

information for the selected measurement mode.

DISPLAYING MODES

Page 12

12

Graph

The on‑line graph with real time logging (Conductivity, Resistivity, TDS, Salinity vs. Seconds) will be

displayed when this option is selected.

If there is no active log, the previously logged data for the selected parameter will be shown.

To access the off‑line / on‑line graph:

• Press while in Measure mode. The “Choose

Display Configuration” message will be displayed in

the Reminder messages area.

• Press .

• Press to begin online graph.

To Zoom Graph

• Press then . and will appear in virtual keys.

• Use and to move along the X (Time) axis of the graph.

• Press to access the zoom menu for Y axis. Use or for zooming Y

(parameter) axis.

• Press to return to the main menu.

When the off-line graph is displayed:

• Use the arrow keys to move along the X (Time) and Y (parameter) axes of the graph.

• Press to access the zoom menu for X and Y axes.

Use , or / / / to switch between the active zooming

axes.

Press or to zoom the selected axis.

Note: While in zoom graph menu the key is not accessible.

• Press to return to the main menu.

DISPLAYING MODES

Page 13

13

Log History

The measurement, along with LOG History, will be visible

when this option is selected:

1) The last stored logged data (Not actively logging) or

2) The last data logged from an active logging lot or

3) An empty display ‑ NO LOTS saved, Not currently

logging

The log history list also contains the main measured

value, the temperature, as well as a record time stamp.

To access the Log History display option:

• Press while in Measure mode. The “Choose

Display Configuration” message will be displayed in

the Reminder messages area.

• Press . The instrument will display the log history regarding the selected Measure mode.

Notes: When an alarm condition is active, the logged records will have an exclamation mark “!”.

If logged in Auto Hold, logged records will have an “H”.

If another Measure mode is selected, the Log History will reset.

If the temperature unit is changed, all logged temperature values will be automatically

displayed in the new temperature unit.

“A” denotes automatic temperature compensation.

“M” denotes manual temperature compensation.

DISPLAYING MODES

Page 14

14

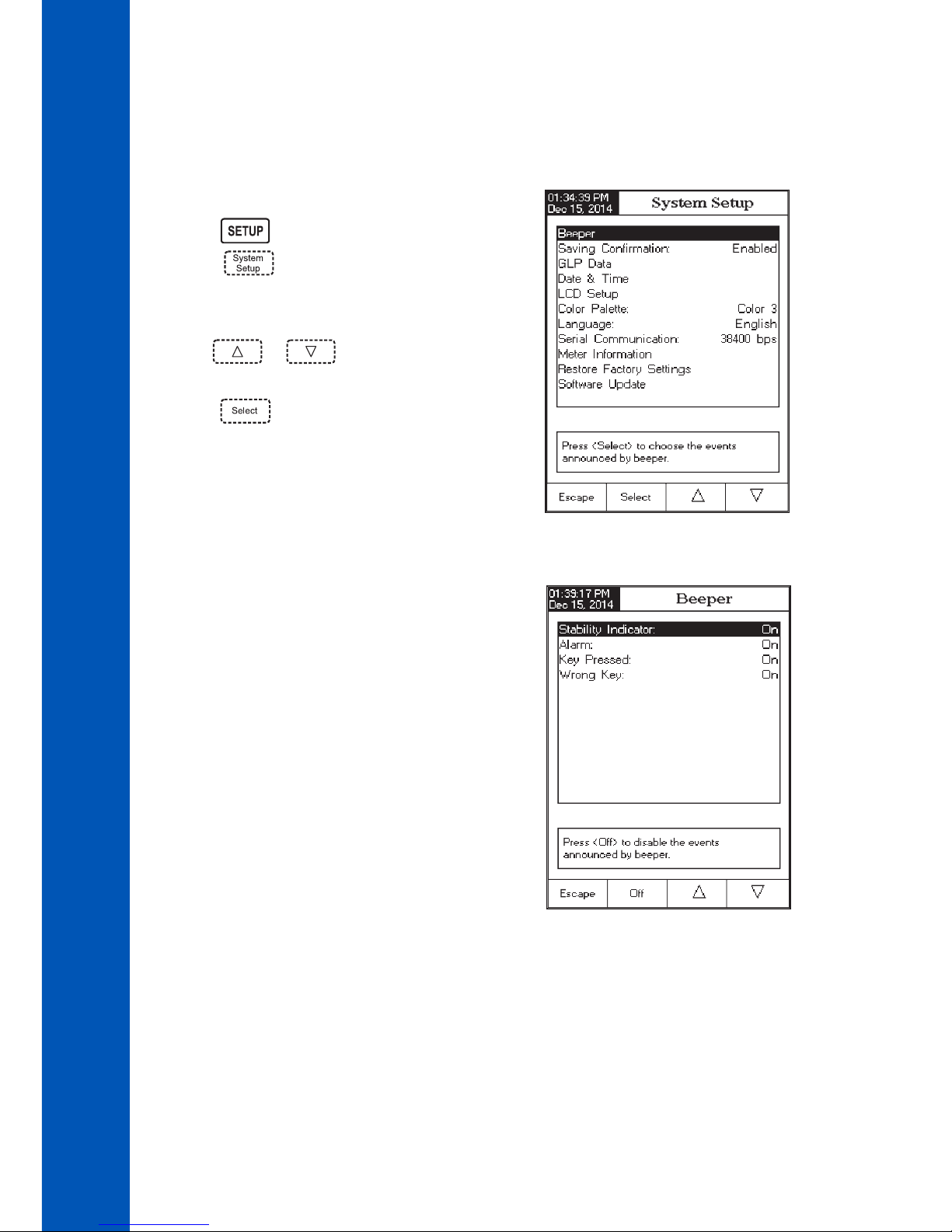

The System Setup menu allows the user to customize the user interface, view meter information,

set the external serial communication interface and to restore the manufacturer settings.

Accessing System Setup

• Press while in Measure mode.

• Press . The system setup options will be

displayed on the LCD.

To access a System Setup option:

• Use or to highlight the desired op‑

tion.

• Press to access the selected option.

The following is a detailed description of the System

Setup option screen.

Beeper

This option allows the user to turn an acoustic warning

signal on or off. This function can be used to signal 4 dif‑

ferent events: a stable signal, an alarm state, when every

key is pressed or when an incorect key is pressed. Enable

(or disable) the Beeper for these events. Disabling the

Beeper will stop audible signals.

SYSTEM SETUP

Page 15

15

Saving Confirmation

Enable this option to force verification of a change made

to a “GLP Data Option field” or a Sample ID name. If

Saving Confirmation is enabled, the user will have to

accept the change with a key stroke.

If Saving Confirmation is disabled, the changes made

to these fields change automatically without verification.

GLP Data

Use this option to customize log GLP information with specific identification data. When enabled, these

ID tags will be included in the GLP section of all data logs. Each data field can use up to 10 characters.

The five available fields are:

Operator ID : used to add the name of the operator.

Instrument ID : used to name an instrument with a discrete name, location or number.

Company Name : used to include the Company ID to the GLP data field.

Additional Info : two data fields are available for general notes or notations.

SYSTEM SETUP

Page 16

16

To add the GLP Data:

• Press while in Measure mode.

• Press .

• Use or to select the GLP Data option.

• Press and use or to highlight

the desired option.

• Press to edit the desired information. The Text

Editor menu will be displayed on the LCD.

• Enter the desired information by accepting the

highlighted character which is added to the text bar,

using . The and keys help the

user select the desired character. It is also possible to

delete the last character by positioning the cursor on

the Backspace character ( ) and pressing .

• Press to return to the GLP Data options. If the Saving Confirmation is enabled, press

to accept the modified option, to escape without saving or to return to

the editing mode. Otherwise, the modified options are saved automatically.

Date & Time

Set the current date & time and the format in which they appear. These parameters will be displayed

on the Measure screens and also when storing measured data.

Set Date and Time

This option allows the user to set the current date (year/month/day) and time (hour/minute/second).

Notes: Only years starting with 2000 are accepted.

The time is set using the selected time format. For 12 Hour time format only, the AM/PM

can also be selected with or .

Set Time Format

Choose between 12 Hour (AM/PM) time format or 24 Hour time format.

Set Date Format

Choose the desired date format from 7 available options: DD/MM/YYYY; MM/DD/YYYY; YYYY/MM/DD;

YYYY‑MM‑DD; Mon DD,YYYY; DD‑Mon‑YYYY or YYYY‑Mon‑DD.

To set the Date & Time:

• Press while in Measure mode.

• Press .

SYSTEM SETUP

Page 17

17

• Use or to select the Date & Time option.

• Press and use or to highlight the

Set Date and Time.

• Press to confirm your selection.

Use / to select next/previous entry to be

edit.

Press and use or to set the desired

value, then press to save the modified value (for

Set Date and Time option).

• For the other two options press to confirm your

selection and select one of the displayed options.

• Press to return to previous menu. If the Saving Confirmation is enabled, press to

accept the modified option, to escape without saving or to return to the editing

mode. Otherwise, the modified option is saved automatically.

Note: If the time is changed with more than one hour before last calibration, a pop-up

warning will appear on the LCD, notifying the user that a date/time conflict has occured

and some time-dependent modes could work improperly (e.g. Measure, GLP, Log).

LCD Setup

This option allows the user to set the Contrast, the Backlight of the LCD and the Backlight Saver. The

Contrast parameter can be adjusted within 7 steps, while the Backlight parameter within 8 steps.

The Backlight Saver can be set from 1 to 60 minutes or it can be OFF (disabled). All the changes are

visible on the LCD for each parameter.

Note: If the instrument backlight turnes off after the time period set, press any key to turn it

back on.

To set the LCD Setup:

• Press while in Measure mode.

• Press .

• Use or to select the LCD Setup option.

• Press and use key to highlight the desired

parameter.

• Use or to adjust the contrast / backlight

or to set the desired backlight saver time.

• Press to confirm the modified options and return

to the System Setup menu.

SYSTEM SETUP

Page 18

18

Language

This option allows the user to choose the desired language in which all information will be displayed.

To select the Language:

• Press while in Measure mode.

• Press .

• Use or to select the Language option.

• Press and use or to highlight

the desired language.

• Press to confirm your selection and return to

the System Setup menu or press to return to

the System Setup menu without changing.

Color Palette

This option allows the user to choose a desired color palette.

To select the Color Palette:

• Press while in Measure mode.

• Press .

• Use or to select the Color Palette

option.

• Press and use or to highlight the desired color.

• Press to confirm your selection and return to the System Setup menu or press to

return to the System Setup menu without changing.

Color 1 White background blue text

Color 2 Blue background white text

Color 3 White background black text

Color 4 Black background white text

SYSTEM SETUP

Page 19

19

Meter Information

This option provides general information about the instrument serial number (each instrument has

an unique identification serial number), the software version and the factory calibration date and

time (for mV and temperature).

Note: All instruments are factory calibrated for conductivity and temperature. One year after

factory calibration, the warning message “Factory Calibration Expired” will be displayed when

powering up instrument. The instrument will still function, however, it should be taken to the

nearest Hanna Customer Service for factory calibration.

To view the Meter Information:

• Press while in Measure mode.

• Press .

• Use or to select the Meter Information

option.

• Press to acces the Meter Information menu.

• Press to return to the System Setup menu.

Serial Communication

This option allows the user to set the desired speed for the

serial communication (baud rate) in bps. The meter and the

PC program must have the same baud rate.

To set the Serial Communication:

• Press while in Measure mode.

• Press .

• Use or to select the Serial Commu-

nication option.

• Press and use or to highlight

the desired baud rate.

• Press to confirm your selection and return to

the System Setup menu or press to return to the System Setup menu without changing.

SYSTEM SETUP

Page 20

20

Software update

This function allows the user to update instrument

software. In order to start the PC upgrade application, you

need to select the proper baud rate, the software update

package and start the update.

Restore Factory Settings

This option allows the user to erase all user settings and reset the instrument to the default factory

settings.

To restore the Factory Settings:

• Press while in Measure mode.

• Press .

• Use or to select the Restore Factory

Settings option.

• Press to confirm your selection. A pop‑up menu

will be displayed, asking for confirmation.

• Press to confirm your selection and return to

the System Setup or press to return to the

System Setup menu without restoring defaults.

• Press to return to Measure mode.

SYSTEM SETUP

Page 21

21

The Conductivity Setup menu allows the user to set the parameters related to the conductivity

measurement and calibration.

Accessing Conductivity Setup

• Press while in Measure mode and then

to select the Conductivity measurement

mode.

• Press and then to access

Conductivity Setup menu.

To access a conductivity setup options:

• Use or to highlight the desired op‑

tion.

• Press to access the selected option or

to exit setup.

The following is a detailed description of the Conductivity

Setup option screens.

Profile

This option opens the Profile manager. Enabling Profile allows the user to Save, Load or Delete

an application Profile. The Profile option allows the user to store up to ten separate profile

applications. Each Profile can be named and recalled at a moment’s notice. A profile is a sensor

setup complete with measurement units, logging and display preferences, calibration standards

(Standards including custom), setup of the Display screen for measurement (i.e. graphing, GLP)

and any other sensor configuration. Once saved, the exact same profile can be used at another

time. This is a handy feature if the meter is used occasionally for additional applications because

it saves time in the setup of the meter and ensures the same procedure will be used.

To save the measurement configuration for Conductivity mode:

• Press , then and use or to highlight Profile option.

• Press / to enable / disable this feature.

The available options are:

Profile Feature: enable or disable the profile feature.

Save Profile: save the current profile.

Save Profile As...: save current profile using a specific name.

Load Profile: load from available profiles.

Delete Profile: delete a profile.

CONDUCTIVITY SETUP

Page 22

22

Save Profile

To save a profile:

• Press while in Conductivity mode.

• Press .

• Use or to highlight Profile option.

• Press and then use or to

highlight Save Profile.

• Press . The existing configuration will be saved

in current profile.

Save Profile As...

To create a new profile:

• Press while in Conductivity mode.

• Press .

• Use or to highlight Profile option.

• Press and then use or to highlight Save Profile As....

• Press . The Text Editor box will be displayed on the LCD.

• Enter the desired profile name by using and to highlight the desired character

and then press to add it to the text bar. It is also possible to delete the last character by

positioning the cursor on the Backspace character ( ) and pressing .

• Press to return to the previous menu. If the Saving Confirmation is enabled, press

to accept the modified option, to escape without saving or to return to the editing

mode. Otherwise, the modified option is saved automatically.

Note: The saved profile will automatically become

the current profile.

Load Profile

To load one profile:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Profile option.

• Press and then use or to

highlight the Load Profile option.

CONDUCTIVITY SETUP

Page 23

23

Temperature

From the Temperature menu the user can choose the Temperature Source and Units, as well as the

Temperature Compensation mode, Reference Temperature, Compensation Coefficient and Compensation

Coefficient.

To access a Temperature option:

• Press while in Conductivity mode.

Delete Profile

To delete one of the existing profiles:

• Use or to highlight the Profile option.

• Press and then use or to highlight

the Delete Profile option.

• Press . A list with all customised profiles will appear

on the screen.

• Use or to select the desired profile and

press .

• Press to return to the previous menu.

Reading Mode

This option allows the user to select between Direct, Direct/AutoHold or Direct/USP conductivity

reading modes.

Note: All three selections permit conductivity to be changed to resistivity, TDS and salinity via

the key.

To set the reading mode:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Reading Mode

option.

• Press and then use or to highlight

the desired option.

• Press to confirm your selection or press to

cancel operation.

• Press . A list with all customized profiles will be displayed on the screen.

• Use or to select the desired profile and press to confirm or to

exit without selecting.

CONDUCTIVITY SETUP

Page 24

24

• Use or to highlight the Temperature option from the Conductivity Setup menu.

• Press to access the Temperature option.

Temperature Source

To set the temperature source:

Note: The HI76312 sensor has an integrated temperature sensor and will provide the best

conductivity measurement. Use Automatic to use sensor or Manual. When manual, the value

will have to be adjusted using when in measurement mode.

• Use or to highlight the Temperature

Source option.

• Press to select Manual or to select

Automatic temperature source.

Temperature Compensation

The user can choose from the following options:

Linear - the meter will automatically compensate the

conductivity using the following formula:

where:

C

ref

‑ conductivity at reference temperature

CI ‑ conductivity at temperature of measurement

α ‑ compensation coefficient

TI ‑ temperature in °C

T

ref

‑ reference temperature

Non-Linear - recommended for measuring the conductivity of the natural water in accordance with the

ISO‑788‑1985. It provides compensation in the range of 60 to 1000 µS/cm over a temperature

range of 0 ‑ 35 °C.

Disabled - the meter will display the Absolute conductivity with no temperature compensation.

C

ref

=

C

I

1 + α (TI - T

ref

)

100

To set the temperature compensation mode:

• Use or to highlight the Temperature Compensation option.

• Press and then use or to select Linear, Non-Linear or Disabled

option.

CONDUCTIVITY SETUP

• Press .

Page 25

25

Temperature Unit

The user can choose from the Celsius, Fahrenheit or Kelvin

temperature units.

To set the temperature unit:

• Press and then use or to high‑

light the Temperature Unit option.

• Press and then use or to select

Celsius, Fahrenheit or Kelvin unit.

• Press to confirm your selection or press to

cancel operation.

Reference Temperature

(Linear or Non‑Linear temperature compensation only)

Note: ISO -7888-1985 requires a reference temperature

of 25 °C.

To set the reference temperature:

• Use or to highlight the Temperature

option.

• Press and then use or to high‑

light the Reference Temperature option.

• Press and then use or to

increase / decrease the value.

• Press to save or press to cancel operation.

• Press to confirm your selection or press to

cancel operation.

Note: Whatever form of compensation is used,

the reading will not be as accurate as taking a

reading of the sample’s conductivity at the reference

temperature.

CONDUCTIVITY SETUP

Page 26

26

Compensation Coefficient (Linear temperature compensation only)

The temperature coefficient is a factor used to express the rate a solution’s conductivity increases

with an increase in temperature and is expressed as a % increase in conductivity, for a temperature

change of 1 °C. The coefficient differs for different binary solutions. For typical aqueous dilute salt

mixtures, 1.90 %/°C is used. Ultrapure water is 5.50 %/°C.

To set the compensation coefficient:

• Use or to highlight the Temperature

option.

• Press and then use or to

highlight the Compensation Coefficient option.

• Press and set the desired compensation coef‑

ficient using or to increase/decrease

the value.

• Press to save the current value or press

to cancel operation.

Calibration

The conductivity probe can be calibrated using the con‑

ductivity standards or by entering the cell constant of the

probe by the user.

Using standard solutions:

The probe and the meter can be calibrated with a single standard or with multiple standards (up to four

points), choosing from 6 Hanna standards (84 µS/cm, 1413 µS/cm, 5.0 mS/cm,12.88 mS/cm,

80.0 mS/cm, 111.8 mS/cm) or using the custom standards. Multiple point calibrations are used to

increase accuracy when measurements are made over an extended range. Choose standards that are

in the sample measurement range of interest. Use only one standard at each measurement range.

Measurement Range Calibration Standards

0 ‑ 200 µS/cm 84.00 µS/cm

200 ‑ 2000 µS/cm 1413 µS/cm

2 ‑ 20 mS/cm 5.000 or 12.88 mS/cm

20 ‑ 1000 mS/cm 80.0 or 111.8 mS/cm

CONDUCTIVITY SETUP

Page 27

27

Calibration Points

The user can choose between Single Point and Multi Points calibration.

To set the calibration points:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Calibration

option.

• Press and then use or to

highlight the Calibration Points option.

• Press to choose Multiple Points calibration.

• Press to choose Single Point calibration.

The following options are available for calibration:

Standard Recognition

The user can choose between Automatic recognition (from 6 Hanna standards available) or User

Standard (when custom standards are used for calibration).

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Calibration

option.

• Press and then use or to

highlight the Standard Recognition option.

• Press to choose Automatic recognition mode.

• Press to choose User Standard mode.

CONDUCTIVITY SETUP

Page 28

28

Calibration Reminder

This option allows the user to set the calibration reminder as Daily, Periodic or Disabled.

To set the calibration reminder:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Calibration

option.

• Press and then use or to

highlight the Calibration reminder option.

• Press to confirm your selection and then use

or to choose the desired option.

• Press to confirm your selection or press

to cancel operation.

Set Reminder Period

Daily reminder ‑ the user can set the time of day when the reminder is to appear.

Periodic reminder ‑ the user can set the time from the last calibration (days, hours and minutes)

after which the reminder appears.

To set the reminder period:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Calibration

option.

• Use or to highlight the Set Reminder

Period option.

• Press and use / to select

next / previous entry to be edited.

• Press and use or to set the

desired value, then press to save the modified

value or press to cancel operation.

• Press to return to the previous menu.

CONDUCTIVITY SETUP

Page 29

29

Clear Calibration

Accessing this option, the existent conductivity calibration can be cleared. If the calibration is cleared,

another calibration has to be performed.

To clear calibration:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Calibration option.

• Use or to highlight the Clear Calibration option.

• Press to clear calibration. A pop‑up menu will be displayed asking for confirmation (if

calibration is available).

• Press to confirm or press to escape without saving and return to the Calibration

options.

Cell Constant

Cell constant manual editing:

The conductivity probe can also be calibrated by entering the cell constant value.

To edit the cell constant value:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Cell Constant

option.

• Press to reset the cell constant value to default

(1.0000/cm).

• Use / to increase / decrease the

value.

• Press to confirm the new value or press

to exit without modifying.

Probe Type

This option allows the user to obtain some information about the connected conductivity probe: name,

default cell constant, range and rings number. The HI76312 probe is recognized by the meter.

CONDUCTIVITY SETUP

Page 30

30

Units

The user can select the desired measurement unit. The available options are: µS/cm, mS/cm or

AutoRanging.

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Units option.

• Press and then use or to

select µS/cm, mS/cm or AutoRanging.

• Press to confirm your selection or press

to cancel operation.

Sample ID

This option allows the user to assign an identification number/name to sample logs. Two Sample ID

parameters are available: ID Increment mode and Edit Sample ID.

ID Increment

Choose None to identify a sample with a text tag.

Choose Automatic to identify a sample with a numeric tag. This number will be incremented by

one for each new lot log but it can also be altereted manually here. This number does not increment

for each manual log sample. This will be automatically

incremented when a New Lot will be selected.

To select the ID increment mode:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Sample ID

option.

• Use or to highlight the ID Increment

option.

• Press or as desired.

• Press to return to previous menu.

CONDUCTIVITY SETUP

Page 31

31

Edit Sample ID

This option allows the user to edit the sample ID. If ID increment is None, a Text Editor screen is

displayed. If ID increment is Automatic, a Numeric Editable screen is displayed.

To access the Sample ID:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Sample ID

option.

• Press and use or to highlight

the Edit Sample ID option.

• Press to confirm your selection.

• For text editing use and to highlight

the desired character and then press to add

it to the text bar. It is also possible to delete the last

character by positioning the cursor on the Backspace

character ( ) and pressing .

• Press to return to Sample ID option.

If the Saving Confirmation is enabled, press to

accept the modified option, to escape without

saving, or to return to the editing mode. Other‑

wise, the modified options are saved automatically.

• For numeric editing use or keys.

• Press to save the current value or press

to cancel operation.

Log

Note: See Logging section for available types of logging.

This option allows the user to edit the log settings: Logging Type, Logging Data Configuration, Sampling

Period and New Lot.

Logging Type

Three logging types are available: Automatic, Manual and Auto Hold.

CONDUCTIVITY SETUP

Page 32

32

Automatic ‑ the measurement data is logged automatically at constant time intervals.

Manual ‑ a snapshot of the displayed measurement data is logged with time stamp when the user

manually depresses Log.

Auto Hold ‑ this is configured along with the Direct/AutoHold reading mode to take a snapshot of

stable measurement data. Press to initiate a logging session. Press to

initiate an Auto Hold event. The log occurs automatically once measurement stability is

reached. This type log removes subjective data, as it only captures stable measurements.

To set the Logging Type:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Log option.

• Press and use or to highlight

the Logging Type option.

• Press and use or to highlight

the desired option.

• Press to confirm your selection or press

to cancel operation.

Logging Data Configuration

This option allows the user to select which parameters will accompany a log file: Date/Time,

Calibration Data, Sample ID, Instrument ID, Operator ID, Company Name, Additional Info 1 and

Additional Info 2.

To set the Logging Data Configuration:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Log option.

• Press and use or to highlight

the Logging Data Configuration option.

• Press and use or to highlight

the desired parameter to be logged in file.

• Press to enable the parameter or to

disable it.

• Press to return to previous menu.

CONDUCTIVITY SETUP

Page 33

33

Sampling Period

This option allows the user to select the desired sampling period for automatic logs.

To set the Sampling Period:

• Press while in Conductivity mode.

• Press .

• Use or to highlight the Log option.

• Press and use or to highlight

the Sampling Period option.

• Press and use or to select the

desired option.

• Press to confirm your selection or press

to cancel operation.

New Lot

This option is used to create a new lot when manual logging is used.

Note: If New Lot option is accessed and the Logging Type is Automatic, a warning message

appears on the LCD informing the user that a new lot can be created only if the Logging Type

is set as Manual.

To generate a New Lot:

• Press while in Conductivity mode.

• Press .

• Use or to select the Log option.

• Press and use or to highlight the New Lot option.

• Press to generate a new manual lot. A pop‑up menu will be displayed asking for

confirmation.

• Press to confirm or press to escape without saving and return to the Log options.

Alarm

This option allows the user to select the alarm settings: Alarm State and Alarm Limits. If the Alarm

option is enabled, a continuous double beep will be heard, along with the “Alarm” indicator blinking

on the LCD, each time the set limits in Measure mode are exceeded.

Note: Alarm Beeper must be set On for audible beep to be heard. See: System Setup →

Beeper → Alarm.

CONDUCTIVITY SETUP

Page 34

34

Alarm State

Three settings are available for the Alarm State option:

Disabled ‑ the alarm will be disabled.

Inside Limits ‑ the alarm state will trigger when the

measured value is inside the set limits.

Outside Limits ‑ the alarm state will trigger when the

measured value is outside the set limits.

To set the Alarm State:

• Press while in Conductivity mode.

• Press .

• Use or to select the Alarm option.

• Press and use or highlight

the Alarm State option.

• Press and use or to highlight the desired option.

• Press to confirm your selection or press to cancel operation.

Alarm Limits

This option allows the user to set the alarm limits for the measured value.

Note: The Alarm High value can not be lower than the Alarm Low value.

• Press while in Conductivity mode.

• Press .

• Use or to select the Alarm option.

• Press and use or highlight

the Alarm Limits option.

• Press and then use or to

set the desired value, then press to save the

modified value or press to cancel operation.

• Press to return to the Alarm options.

CONDUCTIVITY SETUP

Page 35

35

The Resistivity Setup menu allows the user to set the parameters related with the resistivity

measurements.

Accessing Resistivity Setup

• Press and then to select resistivity

measurement mode.

• Press and then to access Resistivity

Setup menu.

To access a Resistivity Setup option:

• Use or to select the desired option.

• Press to confirm your selection.

The following is a description of the Resistivity Setup

option screens.

Profile ‑ see Conductivity Setup section.

Reading Mode

This option allows the user to select between Direct and Direct/AutoHold resistivity reading modes.

To set the Reading Mode:

• Use or to highlight the Reading Mode

option.

• Press / to select Direct /

Direct/AutoHold option as desired.

• Press to cancel operation.

RESISTIVITY SETUP

Page 36

36

Temperature - see Conductivity Setup section.

Units

The user can choose between Ω.cm, KΩ.cm, MΩ.cm or AutoRanging units.

To select the units:

• Press while in Resistivity mode.

• Press .

• Use or to highlight the Units option.

• Press to confirm and then use or

to highlight the desired unit.

• Press to confirm or press to cancel

operation.

Sample ID - see Conductivity Setup section.

Log - see Conductivity Setup section.

Alarm - see Conductivity Setup section.

RESISTIVITY SETUP

Page 37

37

The TDS Setup menu allows the user to set the parameters related to the TDS measurement.

Accessing TDS Setup

• Press and then to select TDS (Total Dissolved Solids) measurement mode.

• Press and then to access TDS Setup menu.

To access a TDS Setup option:

• Use or to highlight the desired op‑

tion.

• Press to access the selected option.

The following is a description of the TDS Setup option

screens.

Profile - see Conductivity Setup section.

Reading Mode ‑ see Resistivity Setup section.

Temperature - see Conductivity Setup section.

Units

This option allows the user to set the TDS measuring unit ppm (mg/L), ppt (g/L) or AutoRanging units.

To select the suitable unit:

• Press while in TDS mode.

• Press .

• Use or to highlight the Units option.

• Press to confirm and then use or

to highlight the desired unit.

• Press to confirm your selection or press

to cancel operation.

TDS SETUP

Page 38

38

TDS factor

TDS factor is a conversion factor used to convert conductivity to TDS by the equation:

TDS = Factor x EC25. The TDS conversion factor can be set from 0.40 to 1.00. A typical TDS conver‑

sion factor for a strong ionic solutions is 0.50, while for a weak ionic solutions (e.g. fertilizers) is 0.70.

Example:

TDS factor

0.5 µS/cm x 0.41 = 0.205 ppm NaCl

The default value is 0.50.

This option allows the user to set the TDS factor:

• Press while in TDS mode.

• Press .

• Use or to highlight the TDS Factor

option.

• Press to confirm your selection and use

or to increase / decrease the value.

• Press to confirm your selection or press

to cancel operation.

Sample ID - see Conductivity Setup section.

Log - see Conductivity Setup section.

Alarm - see Conductivity Setup section.

TDS SETUP

Page 39

39

Salinity measurements are related to the salt in ocean water.

The Salinity Setup menu allows the user to set the parameters related to Salinity measurement

and calibration.

Accessing Salinity Setup

• Press and then to select Salinity measurement mode.

• Press and then to access Salinity Setup menu.

To access a Salinity Setup option:

• Use or to highlight the desired

option.

• Press to access the selected option.

The following is a description of the Salinity Setup

option screens.

Profile - see Conductivity Setup section.

Reading Mode - see Resistivity Setup section.

Temperature - see Conductivity Setup section.

To set one of the Temperature options:

• Press while in Salinity mode.

• Press .

• Use or to highlight the Temperature option.

• Press and then use or to highlight the desired Temperature option you

wish to modify.

• Press and then use or to highlight the desired option (for Temperature

Source & Unit options) or use or to adjust the temperature value between the

displayed limits (for Manual Temperature option).

• Press to confirm your selection (for Temperature Source & Unit options) or press

to save the current value (for Manual Temperature option). Otherwise, press to cancel

operation.

SALINITY SETUP

Page 40

40

Clear Calibration

This function only works for the Percent Scale.

To clear calibration:

• Press while in Salinity mode.

• Press .

• Use or to highlight the Clear Calibration option.

• Press to clear calibration. A pop‑up menu will be displayed asking for confirmation

(if calibration is available).

• Press to confirm or press to cancel operation.

Salinity Scale

Note: See Salinity Measurement for a description of these scales.

The meter has three ocean salinity scales: Natural Sea Water 1966, Practical Scale 1978, Percent

Scale [%].

To select the desired salinity measurement scale:

• Press while in Salinity measure mode.

• Press .

• Use or to highlight the Salinity Scale

option.

• Press and use or to highlight

the desired option.

• Press to confirm your selection or press

to cancel operation.

Sample ID - see Conductivity Setup section.

Log - see Conductivity Setup section.

Alarm - see Conductivity Setup section.

SALINITY SETUP

Page 41

41

For optimum measurements:

• Insert probe in the center of the beaker away from container bottom or walls.

• Fix the probe so it does not move during measurements and add sufficient solution to cover top

vent holes on probe.

• Gently stir solution and wait for probe to reach thermal equilibrium and verify no bubbles are

entrapped within probe electrodes.

It is recommended to calibrate the instrument frequently, especially if high accuracy is required.

The conductivity range should be recalibrated:

• Whenever the conductivity probe is replaced.

• At least once a week.

• Before USP measurements.

• After testing aggressive chemicals.

• When calibration reminder is activated (“Conductivity Cal Expired”).

• If the readings are far from the calibration point.

Note: TDS, Resistivity and Natural Sea Water and Practical Sea Water Salinity readings are

automatically derived from the conductivity readings so conductivity calibration is required.

OFFSET CALIBRATION

The meter allows the user to calibrate the probe for an offset.

• Press and then press .

• Select the automatic standard recognition (see Conductivity Setup → Calibration).

• Leave the dry probe in the air (infinite resistance).

• Enter in calibration mode by pressing .

• Clear any previous calibrations by pressing .

• Wait to stabilize. The 0.000 µS/cm calibration point will appear on the screen.

• Press to finish the probe offset calibration.

• Press to exit calibration mode or continue calibration in the other standard solutions.

Note: The offset calibration can be performed only if it is performed first (no other calibration

points present). Clear the old calibration if it is present.

CELL CONSTANT CALIBRATION (in solution)

Single-Point Calibration

• Select the single point calibration (see Conductivity Setup → Calibration).

CONDUCTIVITY CALIBRATION

Page 42

42

• Pour a small quantity of the standard solution into a clean beaker. If possible, use plastic

beakers to minimize any EMC interferences.

• For accurate calibration and to minimize cross‑contamination, use two beakers for each standard

solution. One for rinsing the probe and one for calibration.

• Insert the probe in the rinse beaker.

• Swirl probe in this solution. Raise and lower 3 times to fill cell with solution.

• Insert the probe in the second beaker.

• Swirl and tap probe to remove air bubbles. Raise and lower 3 times to ensure representative

sample.

• Enter calibration mode by pressing . Wait to stabilize.

• If automatic standard recognition was selected in Setup, a calibration point will be auto‑

matically displayed from the Hanna standard list (84 µS/cm, 1413 µS/cm, 5.0 mS/cm,

12.88 mS/cm, 80.0 mS/cm, 111.8 mS/cm). The user can also select another standard value

by using and .

• If User Standard was selected in Setup, a pop‑up will prompt for the custom standard value.

• Press to finish the calibration or to abort calibration.

• The probe should be rinsed in deionized water.

• Shake off excess water.

Note: The calculated cell constant will be used for the whole range.

Multi-Point Calibration

• Up to 4 calibration points can be performed in order to

increase the measurement accuracy over a larger measure‑

ment range.

• Select the multi point calibration (see Conductivity Setup

→ Calibration).

• Repeat the steps from the single point calibration for

each measurement range. The meter will calculate a cell

constant corresponding to each calibration point.

• Press to exit calibration mode.

Note: For each range the corresponding cell constant

will be displayed.

CELL CONSTANT CALIBRATION (edited by the user)

• A known value of the probe cell constant can be set by the user for the whole range (see

Conductivity Setup → Cell Constant section). Using a known cell constant is another way to

calibrate the meter/probe system.

CONDUCTIVITY CALIBRATION

Page 43

43

CALIBRATION MESSAGES

• Wrong standard solution. Check the standard solution. This message appears when the

difference between the reading and the value of the selected standard is significant. If this

message is displayed, check if you have selected the appropriate calibration standard.

• Wrong standard temperature. This message appears if the standard temperature is out of

the allowable standard temperature range (0 ‑ 60 °C).

• The current range was already calibrated. Change the standard solution. The calibration

for this conductivity range was already done. Please change the standard.

• Press <Clear Offset> to clear old calibration. Clear the offset of the electrode calibration.

• Press <Clear Cal> to clear old calibration. Clear all old calibrated standards.

Make sure the instrument has been calibrated before taking conductivity measurements.

DIRECT MEASUREMENT

To measure the conductivity of a sample using the Direct reading mode:

• Press and then to select conductivity measure mode.

• Select the Direct reading mode (see Conductivity Setup).

• The conductivity probe should be rinsed with deionized water.

• Shake off excess water.

• If possible rinse probe with a sample of solution to be tested. Swirl and raise and lower probe

in this rinse solution.

• Insert probe in center of a beaker with the sample,

away from the wall or bottom of beaker. The upper

vent holes must be covered with solution.

• Gently stir solution and wait for probe to reach thermal

equilibrium with the sample.

• Tap probe repeatedly to dislodge any air bubbles that

may be trapped inside the sleeve. Allow time for the

reading to stabilize.

• The measured conductivity value will be displayed on

the screen.

Note: When a cell constant value is used, the solution calibration will be cleared. A solution

calibration can still be made after entering a cell constant value.

CONDUCTIVITY MEASUREMENT

Page 44

44

The United States Pharmacopoeia Regulations establishes limits and calibration requirements for

WFI (Water For Injection). The HI5321 meter supports conductivity measurements that are needed

for off line measurements in a Stage 2 of the regulation. Stage 1 verification may be carried out in

a container but the regulation requires an in‑line measurement. The meter provides prompts and

instructions to make the measurements easily. Calibrate an EC probe prior to starting USP analysis.

To access the USP menu:

• Select from the basic display to select

• Press then .

• Select the Direct/USP reading mode (see Conductivity

Setup).

• Return to measure mode by pressing .

• Verify conductivity probe has been calibrated in

conductivity standards in the lowest measurement

range.

• Press and then select the desired USP stage.

In this measure mode the user can check for water

quality using the United States Pharmacopeia standard

(USP <645>) guidelines for water for injection.

This USP standard consists of three stages (one in‑line and two off‑line tests) as followings:

DIRECT/AUTOHOLD MEASUREMENT

To measure conductivity of a sample using the

Direct/AutoHold reading mode:

• Follow sample and probe directions found under

Direct Measurement.

• Select the Direct/AutoHold reading mode(see Con‑

ductivity Setup).

• If pressing , the “AutoHold” indicator will start

blinking on the display until the stability criterion is

reached. The conductivity value will be frozen on the

display, along with “AutoHold” indicator.

• To return to normal measure mode press .

CONDUCTIVITY MEASUREMENTUSP EVALUATION

Page 45

45

Stage 1 ‑ this is an in‑line test.

The procedure follows:

• Measure the temperature of the water and the absolute

conductivity readings. The measurement must be an

in‑line measurement. Results may be verified using a

laboratory method.

• The temperature should be rounded down to the

nearest 5 °C. Look up the corresponding conductivity

value in the table on the next page.

• If the measured conductivity is lower than the

conductivity in the table, then the water meets the

USP requirements.

• Otherwise, proceed to Stage 2 testing.

Stage 1 steps:

Press from the keypad.

• An instruction prompt will pop up.

• Using measurement technique outlined in direct measurement, place probe into sample.

• Press .

• The user may edit the USP factor by pressing (to provide a margin of error) or compare

measurement results directly to the standard (100%). “Please wait ...” will appear on display

and the measurement is compared to the standard values.

• At the conclusion of the test period the results will be displayed.

• The user may view the results as a report. Press .

• A copy of the sample results may also be saved. Press . This may be printed using HI92000

software.

USP EVALUATION

Temperature

(°C)

Conductivity

(µS/cm)

Temperature

(°C)

Conductivity

(µS/cm)

Temperature

(°C)

Conductivity

(µS/cm)

0 0.6 35 1.5 70 2.5

5 0.8 40 1.7 75 2.7

10 0.9 45 1.8 80 2.7

15 1.0 50 1.9 85 2.7

20 1.1 55 2.1 90 2.7

25 1.3 60 2.2 95 2.9

30 1.4 65 2.4 100 3.1

Page 46

46

Stage 2 steps:

Note: A temperature bath at 25.0 ±1.0 °C is required

for this measurement.

• Press from the keypad.

• An instruction prompt will pop up with instructions for

sample preparation.

• Using measurement technique outlined in direct measure‑

ment, place probe into sample.

• Press .

• The meter will begin to evaluate stability of the conductivity measurement. At the conclusion of

the test period the results will be displayed. If the sample has passed the evaluation the testing

is finished and the water may be used.

• Press to store a copy of the sample results. This

may be printed using HI92000 software.

Note: A separate pH meter and sensor is required.

Stage 3 ‑ this is an off‑line test that studies the pH and CO2.

If the water sample has failed Stage 1 and Stage 2 tests,

Stage 3 testing must be conducted.

To perform this test pH measurement is required. Have a

calibrated pH sensor.

Stage 2 ‑ this is an off‑line test.

To perform this test:

• Store the water sample in an enclosed clean container

that has been rinsed previously with water of the same

quality.

• Adjust the sample’s temperature to 25 °C and agitate the

sample to ensure that it has equilibrated with ambient

CO2.

• If the measured conductivity is less than 2.1 µS/cm, then

the sample has met the USP requirements.

• Otherwise, proceed to Stage 3 testing.

USP EVALUATION

Page 47

47

Note: A temperature bath at 25.0 ±1.0 °C is required

for this measurement.

• Take the water sample from the stage 2 test and increase

its ionic strength for a pH measurement at 25 °C.

• Use 100 mL of Stage 2 water and add 300 µL saturated

KCl to the sample.

• Calibrate a pH sensor in pH 4.01 and pH 6.86 (or 7.01)

buffers.

• Thermally equilibrate the sample to 25.0 ±1.0 °C.

• Measure sample with the calibrated pH sensor.

• The pH of sample must be between 5.0 and 7.0 pH.

• Record the pH and round it to the nearest 0.1 pH.

• Find the measured pH and corresponding conductivity in the stage 3 table.

• Compare the conductivity value determined in stage 2 to the conductivity value found in the

stage 3 table.

• If the stage 2 conductivity is lower than the conductivity from the table below, the sample has

meet the USP requirements. Otherwise, the water didn’t meet the USP requirements.

USP EVALUATION

pH Conductivity

(µS/cm)

pH Conductivity

(µS/cm)

pH Conductivity

(µS/cm)

5.0 4.7 5.7 2.5 6.4 2.3

5.1 4.1 5.8 2.4 6.5 2.2

5.2 3.6 5.9 2.4 6.6 2.1

5.3 3.3 6.0 2.4 6.7 2.6

5.4 3.0 6.1 2.4 6.8 3.1

5.5 2.8 6.2 2.5 6.9 3.8

5.6 2.6 6.3 2.4

Page 48

48

Make sure the TDS factor has been set before taking TDS measurements (see TDS Setup section).

Also the TDS calibration is made in Conductivity mode.

DIRECT MEASUREMENT

To measure the TDS of a sample using the Direct reading

mode:

• Press and then to select TDS measure

mode.

• Select the Direct reading mode (see TDS Setup section).

• Proceed the same as for the conductivity measurement

(see Conductivity Measurement section).

DIRECT/AUTOHOLD MEASUREMENT

To measure resistivity of a sample using the Direct/

AutoHold reading mode:

• Select the Direct/AutoHold reading mode (see

Resistivity Setup section).

• Proceed the same as for the conductivity measurement

(see Conductivity Measurement section).

• Press and then to select resistivity

measure mode.

• Select the Direct reading mode (see Resistivity Setup

section).

• Proceed the same as for the conductivity measurement

(see Conductivity Measurement section).

Make sure the instrument and probe has been calibrated in conductivity mode before taking

resistivity measurements.

DIRECT MEASUREMENT

To measure the resistivity of a sample using the Direct

reading mode:

RESISTIVITY MEASUREMENT

TDS MEASUREMENT

Page 49

49

Note: Salinity calibration is made in conductivity mode when using Natural Sea Water or

Practical Sea Water measurement. Direct salinity calibration is only possible when using the

older percent scale.

Salinity calibration is a single‑point calibration procedure at 100.0%. Use the HI7037 calibration

solution (salinity solution) as a 100% seawater solution.

To enter salinity calibration:

• Set the meter for salinity range.

• Select the Percent Scale (see Salinity Setup section).

• Rinse the probe with some of the calibration solution or deionized water.

• Immerse the probe in HI7037 solution. The sleeve holes must be completely submerged. Tap

the probe repeatedly to remove any air bubbles that may be trapped inside the sleeve. Position

probe away from the wall or bottom of the container.

• Enter in calibration mode by pressing .

• Wait for measurement to stabilize.

• Press to finish salinity calibration or press to cancel calibration.

CALIBRATION MESSAGES

• Wrong standard solution. Check the standard solution. This message appears when the

difference between the reading and the value of the selected standard is significant. If this

message is displayed, check if you have selected the appropriate calibration standard.

• Wrong standard temperature. This message appears if the standard temperature is out of

the allowable standard temperature range (0 ‑ 60 °C).

• Press <Clear Cal> to clear old calibration.: Clear the old calibration.

DIRECT/AUTOHOLD MEASUREMENT

To measure TDS of a sample using the Direct/AutoHold

reading mode:

• Select the Direct/AutoHold reading mode (see TDS Setup

section).

• Proceed the same as for the conductivity measurement.

(see Conductivity Measurement section).

SALINITY CALIBRATION

Page 50

50

S = - 0.08996 + 28.2929729R15 + 12.80832R

15

2

- 10.67869R

15

3

+ 5.98624R

15

4

- 1.32311R

15

5

Note: The formula can be applied for temperatures between 10 °C and 31 °C.

PRACTICAL SALINITY SCALE (UNESCO 1978)

The PSU scale extends from 0.00‑42.00 PSU. The Practical salinity (S) of seawater relates the ratio

of electrical conductivity of a normal seawater sample at 15 °C and 1 atmosphere to a potassium

chloride solution (KCl) with a mass of 32.4356 g/kg water at the same temperature and pressure.

Under these conditions the ratio is equal to 1 and S=35. The Practical salinity scale may be

applied to values 2 through 42.00 PSU at temperature between ‑2 °C to 35 °C.

S is defined in terms of the ratio K

15

.

S = 0.0080-0.1692K

15

1/2

+25.3851K15+14.0941K

15

3/2

-7.0261K

15

2

+2.7081K

15

5/2

Where C is Conductivity;

C(35,15,0)=0.042933 S/cm

The simplified equation above is derived from

With the following coefficients and k = 0.0162 and

Seawater temperature coefficient r

T

= c0 + c1·T + c2·T2 + c3·T3 + c4·T

4

S = a0 + a1·R

T

1/2

+ a2·RT + a3·R

T

3/2

+ a4·R

T

2

+ a5·R

T

5/2

+

(T - 15)

·

[b0 + b1·R

T

1/2

+ b2·RT + b3·R

T

3/2

+ b4·R

T

2

+ b5·R

T

5/2

]

1 + k(T-15)

R =

C

(S,T,P)

= (RP·RT·rT)

C

(35,15,10)

K

15

=

C(S,15,0)

C(KCl,15,0)

C(35,15)·r

T

R15=

CT(sample)

RT=

R

RP·r

T

RP=1+

P·(A1 + A2·P + A3·P2)

1+B1·T + B2·T2 + B3·R + B

4

·R·T

;

where R15 is the conductivity ratio, and Salinity is defined by the following

equation.

NATURAL SEA WATER SCALE (UNESCO 1966)

The Natural Sea Water Scale extends from 0.00 ‑ 80.00 ppt. It determines salinity based upon a

conductivity ratio of sample to “standard seawater” at 15 °C.

Three methods for calculating seawater salinity are supported (Natural Sea Water Scale, Practical

Salinity Scale and Percent Scale).

PERCENT SCALE (1902)

This salinity scale extends from 0.0 to 400.0%. The formula followed is: S

%

= 1.805Cl + 0.03

where salinity is defined as the total amount of solid materials in grams dissolved in one kilogram

of seawater. 100% Salinity has ~10% solids and is considered normal seawater.

SALINITY MEASUREMENT

Page 51

51

The user temperature calibration menu can be accessed during meter startup by simultaneously

pressing three keys as shown in the drawing below. Press the keys after the short beep is heard at

the meter power on. Keep all three keys pressed until Temp. Calibration menu appear.

Note: The user temperature calibration is performed at three points: around 0 °C, 50 °C

and 100 °C.

To perform the user temperature calibration:

• Press to start the temperature calibration.

Adjust the temperature preset value using

or when necessary.

• Insert the EC probe into the beaker with water at

0 °C.

• Wait for measurement to stabilize and then press

to confirm the calibration point.

• Repeat the previous steps for 50 °C and 100 °C.

• Save the calibration.

• Press to return to measure mode.

Note: Press if you want to clear the

temperature user calibration.

a0=0.008 b0=0.0005 A1=2.070·10

‑5

c0=6.766097·10

‑1

a1=‑0.1692 b1=‑0.0056 A2=-6.370·10

‑10

c1=2.00564·10

‑2

a2=25.3851 b2=‑0.0066 A3=3.989·10

‑15

c2=1.104259·10

‑4

a3=14.0941 b3=‑0.0375 B1=3.426·10

‑2

c3=-6.9698·10

‑7

a4=‑7.0261 b4=0.0636 B2=4.464·10

‑4

c4=1.0031·10

‑9

a5=2.7081 b5=‑0.0144 B3=4.215·10

‑1

B4=-3.107·10

‑3

TEMPERATURE CALIBRATION

Page 52

52

Reading Mode Log log Recall

Automatic (1) Automatic Log

Direct Manual (2) Manual Log

Auto Hold (NA) Not Applicable

Automatic (3) Automatic Log

Direct/AutoHold Manual (4) Manual Log

Auto Hold (5) Manual Log

There are 5 ways the Reading Mode and Log may be configured together. The table below shows

the combinations and indicates where the completed log will be stored.

2) Direct Reading Mode and Manual Log:

Real time continuous measurements are on display and snapshots

of measurement data are stored in the Manual log when

the user presses . Subsequent snapshots will be

added to the same Manual Lot every time the is

depressed unless New Lot is selected under Log options.

Note: When the is pressed the lot ID along

with the current record number will appear for short

time on the selected channel window on the top/left

corner (e.g. L001_EC 4 - this means lot ID L001_EC

and recod number 4).

1) Direct Reading Mode and Automatic Log:

Real time continuous measurements are on display and

continuous logs to meter memory. These are sometimes referred

as interval logs. Press .

LOGGING

Page 53

53

3) Direct/AutoHold Reading Mode and Automatic Log

Press and then keys must be pressed on

front display to initiate this function. Real time continuous

measurements are on display with “AutoHold” flashing and

real time continuous logging into meter memory, until the

meter reaches the stability criteria to go into Auto Hold

mode. The stored sample logs will be marked with an “H”

to indicate the Auto Hold mode. The virtual key

returns operation to real time continuous measurements

and stops the logging session.

4) Direct/AutoHold Reading Mode and Manual Log

Press in order to add one new record in the log

report. The manual log is working even if it is in Auto Hold or Continuous reading mode. Press

to initiate the Auto Hold event. “AutoHold” will flash until the stability criteria is reached

and then the screen freezes in Auto Hold mode, the data is marked with an “H”.

5) Direct/AutoHold Reading Mode and Auto Hold Log

Press and then keys to initiate and automate the capture of stable data which is

stored in the Recall Manual Log file. During the process, “AutoHold” will flash until the stability

criteria is reached and then the screen freezes in Auto Hold mode, the data is logged and marked

with an “H”. The virtual key returns operation to Real time continuous measurement.

Press again to log a second stable data point. The lot ID along with the record index will

appear for short time on the top/left corner on the selected channel window, every time a record

will be added to the lot.

LOG RECALL

This feature allows the user to view all stored data. If no

data were logged, the “No records were found.” message

will be displayed on the LCD in the Log Recall screen.

Otherwise, the instrument will display all the memorized

lots in accordance with the selected option: Automatic Log,

Manual Log or USP Reports.

To view the memorized data:

• Press while in Measure mode.

• Press and then select the log report type.

LOGGING

Page 54

54

• Press , or to select the desired

Log Report type. All logged lots for the selected Log

Report type will be displayed on the LCD.

• To filter the displayed lots, press and then the

desired parameter. Only the selected measurement

parameter lots will be displayed on the LCD.

• Select the desired lot with or and

press to display the logged data from the

highlighted lot. The “Please wait...” message will

be displayed on the LCD for one second. The se‑

lected Logging Data Configuration options will be

displayed on the LCD, together with GLP information

(last calibration date and calibrated standards) if a

calibration has been performed on the selected mode

and the logged values (measured value, temperature

value, temperature compensation mode and the

logging time).

Note: For automatic logging only, it is possible to view

the plotted graph.

Press to display the graph.

By pressing it is possible to move the graph

along the X or Y axis with the arrow keys.

If pressing while the graph is displayed, the

zoom menu for the X and Y axes will be accessed.

Press , or / / /

to switch between the active zooming axes

and then zoom in or out on the selected axis by

pressing the appropriate virtual key.

Press to return to the previous menu at

any time.

LOGGING

Page 55

55

To delete lots:

• Press while in Log Recall mode.

• Press or to access delete or delete

all mode.

Otherwise, press to return to Log Recall

view mode.

• After selecting one of the Delete keys, use

or to select one lot and then press

or to delete the selected lot or all lots.

The “Please wait...” message will be displayed on

the LCD until the selected lot or all lots are deleted.

• Press and then press to exit delet‑

ing mode and return to Log Recall view mode.

• Press to exit Log Recall mode and return to Measure mode.

Note: Logged lots should also be deleted whenever “Limited Automatic Logging Space” or

“Automatic Log Is Full” message appears on the LCD, in the Reminder messages area.

Data transmission from the instrument to the PC can be done with the HI92000 Windows®

compatible software (optional). HI92000 also offers graphing and on‑line help features.

Data logged on the HI5321 meter can be exported to the most popular spreadsheet applications

for further analysis.

The instrument has an USB interface.

Use a standard USB cable to connect your instrument to the PC.

Make sure that the instrument and the HI92000 software have the same baud rate and the

appropriate communication port.

The PC software may also be used for real time logging.

LOGGING

PC INTERFACE

Page 56

56

MEASURE

• Rinse conductivity probe with deionized water and shake off excess water.

• To avoid cross‑contamination, rinse probe with a sample of solution to be tested.

The measurement solution is that contained within the sleeve.

• Insert probe into the center of the beaker with sample. Position it so it is away from the walls

or bottom of the beaker. The vent holes must be covered with solution.

• Tap the probe repeatedly to dislodge any air bubbles that may be trapped inside the sleeve.

Allow time for the reading to stabilize and reach thermal equilibrium.

• If you are adjusting the conductivity of the solution, stir the solution, then raise and lower the

probe to ensure representative sample is measured within the sleeve of the probe.

• If required, wait for the probe to reach thermal equilibrium with the sample.

PERIODIC MAINTENANCE