Page 1

pH • EC • DO

®

www.GlobalTestSupply.com

Page 2

Dear

Customer

Thank you for choosing a Hanna Instruments product.

Please read this instruction manual carefully before using this instrument. This

manual will provide you with the necessary information for correct use of this

instrument, as well as a precise idea of its versatility.

Table of

Contents

Included ...............................................................................................................................................3

Safety Measures

Description

Diagram

Product Diagram ..................................................................................................................................................................4-5

Probe Diagram .......................................................................................................................................................................... 6

Keypad Function .......................................................................................................................................................................7

Guide to Indicators ..................................................................................................................................................................8

..............................................................................................................................3

.........................................................................................................................................4

..........................................................................................................................................4-8

Setup/Installation ....................................................................................................................9-19

Setting Up edge® .................................................................................................................................................................... 9

Electrode & Probe Connections ......................................................................................................................................10

Setting Up edge® ..................................................................................................................................................................10

General Setup ...................................................................................................................................................................11-12

Basic Mode ............................................................................................................................................................................... 13

Logging Function ...........................................................................................................................................................13-15

Viewing Logged Data ................................................................................................................................................... 15-17

PC & Storage Interface .................................................................................................................................................18-19

Operational Guide .................................................................................................................20-53

Basic vs Standard pH Mode ...............................................................................................................................................20

pH Meter Congurations .............................................................................................................................................21-27

Calibration Messages ................................................................................................................................................... 27-29

pH GLP Information ......................................................................................................................................................29-30

pH Measurement ............................................................................................................................................................31-32

Basic vs Standard EC Mode ...............................................................................................................................................33

EC Meter Conguration ............................................................................................................................................... 33-36

EC/TDS Calibration ........................................................................................................................................................ 36-37

NaCl % Calibration ...............................................................................................................................................................38

Calibration Messages ...................................................................................................................................................38-39

EC/TDS GLP Information ............................................................................................................................................39-40

NaCl % GLP Information .............................................................................................................................................41-42

EC/TDS Measurements ...............................................................................................................................................42-43

Salinity Measurements ...............................................................................................................................................43-45

Dissolved Oxygen Setup ............................................................................................................................................46-47

Dissolved Oxygen Probe Diagram ..................................................................................................................................47

Dissolved Oxygen Meter Conguration ...............................................................................................................48-49

Dissolved Oxygen Calibration...................................................................................................................................49-50

Dissolved Oxygen Calibration Messages .....................................................................................................................51

Dissolved Oxygen GLP Information ........................................................................................................................51-52

Dissolved Oxygen Measurements ...........................................................................................................................52-53

Maintenance ...........................................................................................................................54-59

pH Probe Maintenance ...............................................................................................................................................54-55

EC Probe Maintenance ........................................................................................................................................................56

Dissolved Oxygen Probe Maintenance .........................................................................................................................57

Troubleshooting Guide ...............................................................................................................................................58-59

Specications .........................................................................................................................60-61

Accessories

Warranty

............................................................................................................................. 62-63

..........................................................................................................................................64

2

www.GlobalTestSupply.com

Page 3

Remove the instrument and accessories from the packaging and verify damage

has not occurred during shipping. Remove protective lm from meter. Notify

your nearest Hanna Customer Service Center if damage is observed.

Each instrument is supplied with:

edge®

Bench cradle

Wall cradle

Electrode holder

USB cable

5 Vdc Power Adapter

Instruction Manual

Quality Certicate

Model Specic Components include:

HI 2020 (pH) HI 2030 (EC) HI 2040 (DO)

Included

HI 11310: Digital pH Electrode

with integrated temperature

sensor

pH 4.01, 7.01 & 10.01 Buer

Sachets

HI 700601 General Purpose

Cleaning Solution

HI 763100: Digital 4 ring

conductivity probe with

integrated temperature

sensor

1413 µS/cm and 12.88 mS/cm

Conductivity Standard

Sachets

HI 764080: Digital

polarographic dissolved

oxygen probe with integrated

temperature sensor

HI 7041S Electrolyte

for DO probe

2 DO membrane caps for

HI 764080 DO probe

2 replacement O-rings for

membrane caps

Note: Save all packing material until you are sure that the instrument works

correctly. Any defective item must be returned in its original packing.

Before using this product, make sure that it is entirely suitable for your specic

application and for the environment in which it is used.

Operation of this instrument may cause interference to other electronic

equipment, requiring the operator to take steps to correct interference. Any

variation introduced by the user to the supplied equipment may degrade the

instrument’s EMC performance.

To avoid damages or burns, do not put the instrument in microwave ovens.

For your and the instrument’s safety, do not use or store the instrument in

hazardous environments.

Safety

Measures

www.GlobalTestSupply.com

3

Page 4

Description

Product

Diagram

edge® enables the user to make fast, accurate measurements of commonly

measured laboratory parameters using one of the Hanna edge® digital sensors

for pH, Conductivity or Dissolved Oxygen. Each digital sensors has a unique

serial number and the parameter that is measures is automatically identied

by the meter. Once connected to the meter, the sensor(s) are ready to measure

their parameter along with temperature.

The user interface permits you to adapt edge® to your exact measurement

requirements. The intuitive design simplies conguration, calibration,

measurement, data logging and transfer of data to a USB thumb drive

or computer. edge® also oers a basic operation mode that streamlines

measurement conguration and is useful for many routine applications. (Every

feature and measurement detail is designed to give you an edge in measurement

technology.)

edge® is versatile in many ways. The slim meter and probe can be used as

a portable device (using its rechargeable battery) or used in its bench or wall

cradles (that also power the meter) as a line-powered laboratory instrument.

• Sleek, clean, intuitive design

• Internal clock and date

• Adjustable resolution for pH and EC measurements

• Auto parameter recognition

• Dedicated GLP key

• GLP data included with logged data

• Basic mode for simplied operation

• Simplied data transfer to a PC

• Up to 8 hour battery life when used as a portable device

Side & Back

Diagram

4

View

www.GlobalTestSupply.com

Page 5

Product

Diagram

1. Liquid Crystal Display (LCD)

2. Capacitive Touch Keypad

3. 3 mm jack input for edge® digital

probes

4. Top mounted ON/OFF button

www.GlobalTestSupply.com

5. Micro USB device connection for

power or PC interface

6. Standard USB host connection

for data transfer to a USB

thumb-drive

Diagram 5

Page 6

Probe

Diagram

Probes

pH Electrode

• Probes process signal directly for noise free measurements

• Auto sensor recognition

• Store calibration specic data from the last calibration

• Are built with materials suitable for use in chemical analysis

• Have integrated temperature measurement

• Incorporate a 3 mm jack termination

• Unique serial ID in every probe for traceability

Diagram

6

EC Electrode DO Electrode

www.GlobalTestSupply.com

Page 7

Keypad

Function

1. CAL/MODIFY - Used to enter

and exit calibration mode. In

SETUP, used to initiate changes of a

conguration setting.

2. GLP/CFM - Used to display GLP

calibration information. In SETUP,

used to conrm change made. In

calibration, used to accept calibration

points.

3. RANGE/u - Used to select

measurement range. In SETUP, used

to move to right in pick list. In log RCL,

used to view GLP data for a data point.

4. SETUP/CLR - Used to enter/exit

SETUP mode. During calibration, used

to clear previous calibration data. In

log RCL, used to clear log records.

www.GlobalTestSupply.com

5. / - Used to scroll through

SETUP menu. Used to change

selection when modifying a

parameter in SETUP.

6. RCL (Recall) - Used to view

logged records or view % log memory

used.

7. LOG - Used to log data by

manual log on demand or manual log

on stability or to start/stop interval

logging.

Note: You can increase/

decrease the speed to

change the value of a

parameter.

Proceed as follows:

Press and hold down the

p or q key, then slide the

nger toward the double

apex to increase the speed

that a value changes.

Diagram 7

Page 8

Guide to

Indicators

1. Mode tags

2. Conrm tag

3. USB connection status

4. pH electrode diagnostics

5. Probes symbol

6. Battery symbol

7. Arrow tags, displayed when they

are available

8. pH calibration buers used

The third line of the LCD (9) is a dedicated message line. During measurement

the user may use the pq arrows to select desired message. Options include

date, time, calibration data, battery charge or no message. If a measurement

error or log status change occurs during measurement, the third line will display

a pertinent message.

Diagram

8

9. Third LCD line, message area

10. Labels

11. Second LCD line, temperature

measurement

12. Temperature units

13. Temp. Compensation status

14. Measurement line

15. Measurement units

16. Stability Indicator

www.GlobalTestSupply.com

Page 9

The main operating modes of edge® are setup, calibration, measurement,

data logging, and data export. Follow this general outline of steps to get you

started. The following topics are expanded upon in the sections that follow in

this manual.

1. Familiarize yourself with the design features of this unique meter.

2. Decide how the meter will be used and set up the wall or bench cradle in a

clean area near line power.

3. Turn edge® on using the ON/OFF button located on the top of the meter.

4. Plug in the probe required for measurement.

5. SETUP the measurement parameters required for the measurement you

will be making.

6. Calibrate the sensor/probe.

You are now ready for measurements.

Bench Cradle Setup

Insert electrode holder arm into the

post on the pivoting base.

Connect the probe connector to the

socket located at the bottom of the

instrument.

Setting Up

edge®

Slide edge® into the cradle while

positioning the probe cable behind the

cradle. Put the probe/sensor into the

electrode holder and secure cable in clips.

Connect the power adapter cable to the

rear socket of the bench cradle. Connect

the other end to the power adapter and

plug into line power. Verify the battery

icon indicates charging.

Wall Cradle Setup

Choose suitable wall location. (Use 2.5 mm

or US #3 bit). Fasten the wall cradle using

the provided screws. Snap cover over

screw heads.

www.GlobalTestSupply.com

Setup/Installation 9

Page 10

Setting Up

edge®

Connect the power adapter cable to the

bottom socket of the wall cradle. Connect

the other end to the power adapter and

plug into line power.

Connect the 3 mm probe jack to the socket

located at the bottom of edge®.

Slide edge® into the wall cradle. Verify the

battery icon indicates charging.

Power Connection

Alternatively to using the cradle for

power, edge® can be powered by micro

USB socket at the top. Plug the 5 VDC

adapter into the power supply socket or by

connecting directly to a PC.

Note: edge® is supplied with a rechargeable

battery inside, which provides about 8

hours of continuous use. Whenever edge®

i s connected to the power adapter or to a PC,

the battery is charging.

Electrode

& Probe

Connections

Setup/Installation

10

Connect the 3 mm probe jack to the probe

input located on the bottom of edge®.

Make sure the probe is completely

connected. If the probe is recognized,

“CONNECTING” message is displayed along

with sensor model.

If the probe is not connected or not

recognized, “NO PROBE” message is

displayed.

www.GlobalTestSupply.com

Page 11

The following General Setup options are displayed regardless of the sensor

being used. These settings remain when switching to another probe type or

when no probe is attached. Options are tabulated in the table below with choices

and default values. Options are accessed by pressing SETUP. Loop through the

options by using the pq arrows. To modify a setting, press MODIFY. The option

may be modied by using u, p and q keys. Press CFM to conrm the change. To

exit SETUP press SETUP.

Option Description Choices Default

*Only seen

when cable

connection

between micro

USB and PC is

made.

Log

Set Calibration

Expiration

Warning

Probe Specic

Set Date

Select if PC is being

used for charging

battery (and meter

will be used for

logging) or if Data

will be exported to

the PC.

Select log type to be

used from 3 types of

logging:

Manual log on

demand

Manual log on

stability (3 types

of stability criteria

available)

Timed interval lot

logging

Meter will indicate

“CAL DUE” when

set time in this

parameter has been

exceeded.

Parameters that are specic to a measurement type are inserted here in the

SETUP list.

Press MODIFY key

to Set current date,

displayed in ISO

format. Press CFM to

save changes.

LOG ON EDGE or

EXPORT TO PC

Manual Log

Stability Log:

Fast, Medium,

Accurate;

Interval Log:

Seconds: 5, 10,

30; Interval Log

Minutes: 1, 2, 5,

15, 30, 60, 120,

180.

1, 2, 3, 4, 5, 6, 7

days or OFF

YYYY/MM/DD

Date

LOG ON EDGE Available

Interval

(5 Sec)

7 days Not available

Set date Available

Basic mode

(pH and EC)

Manual log

or

Stability log:

Medium

General

Setup

Set Time

Set Auto O

Press MODIFY key

to Set current time,

displayed in ISO

format. Press CFM to

save changes.

Used to save battery

life by automatically

turning o when no

key press is detected

for time set and

meter is not in active

logging or calibration

mode.

www.GlobalTestSupply.com

24hr:MM:SS

Time

5, 10, 30, 60 Min

or O

Set time Available

10 MIN Available

Setup/Installation 11

Page 12

General

Setup

Option Description Choices Default

If enabled, a short

audible tone is

Sound

Temperature

Unit

LCD Contrast

Flash Format*

Only seen when

log errors are

present.

Message

Transition

Reset Cong

To Default

Instrument

Firmware/

Probe

Firmware

produced for key

stroke or calibration

conrmation and

a longer tone for

wrong key.

Select degree

Celsius or Fahrenheit

scale for displayed

and logged

temperatures.

Permits modication

of the display

contrast for various

lighting conditions.

Permits formatting

the ash drive.

User may choose

how messages are

displayed on third

LCD line of display.

Press the MODIFY key and CFM (when prompted) to reset

parameters.

Displays rmware

version of meter.

Using the u

key switches to

Probe rmware (if

connected) and

diagnostic made for

troubleshooting.

On or O On Available

ºC or ºF ºC Available

1 to 8 3 Available

On or O OFF Available

Word scroll

messages or

letter scroll

messages

View only

Letter scroll

messages

Current

rmware

version.

Basic mode

(pH and EC)

Available

Available:

RESETS with

Basic Mode

OFF.

Available

Setup/Installation

12

User ID and Serial

Meter ID/

Meter SN/

Probe SN

CSV le

separator

Number of meter

and probe (if

connected). Use

u to change

between the three

parameters.

Used to separate

columns in the CSV

le..

Meter ID is user

selectable

Comma (,) or

Semicolon (;)

0000/ Serial

Number

Comma Available

*Note: Options that are seen under special conditions only.

www.GlobalTestSupply.com

Available

Page 13

edge® oers a basic operation mode that streamlines measurement

conguration for pH and EC measurements and is useful for many routine

applications. Basic pH SETUP reduces parameter selection to the basic set.

The meter limits calibration to 5 standard pH buers; 6.86, 7.01, 4.01, 9.18

and 10.01 buers. All pH measurements will display, log and export with 0.01

pH resolution. Interval logging is also eliminated. Manual and Manual medium

stability log on demand are still functional. pH CONDITION, RESPONSE graphs

are not displayed, giving the display a “Basic” measurement screen with just pH

data and temperature. Basic EC reduces specic EC SETUP parameters to 3. The

meter defaults settings to common parameters and auto ranges measurements

automatically. The Basic EC meter may be used for conductivity and TDS

measurements (salinity is not available). Interval logging is also eliminated.

Manual and Manual medium stability Log on demand are still functional.

Note

:

• If powering edge® through the micro USB connector to a PC, a SETUP

option will require the choice “LOG ON EDGE” or “EXPORT TO PC“.

• 1000 log records can be stored into edge® memory. This memory is shared

between all measurement types (pH, EC, DO) and all logging types (Manual,

Manual Stability, Interval logs).

• The maximum number of records for an Interval lot is 600 records (provided

log space is available).

• A record is a stored reading and a lot is a group of records.

Each time an Interval log is initiated, a new lot is

created. The maximum number of Interval lots that

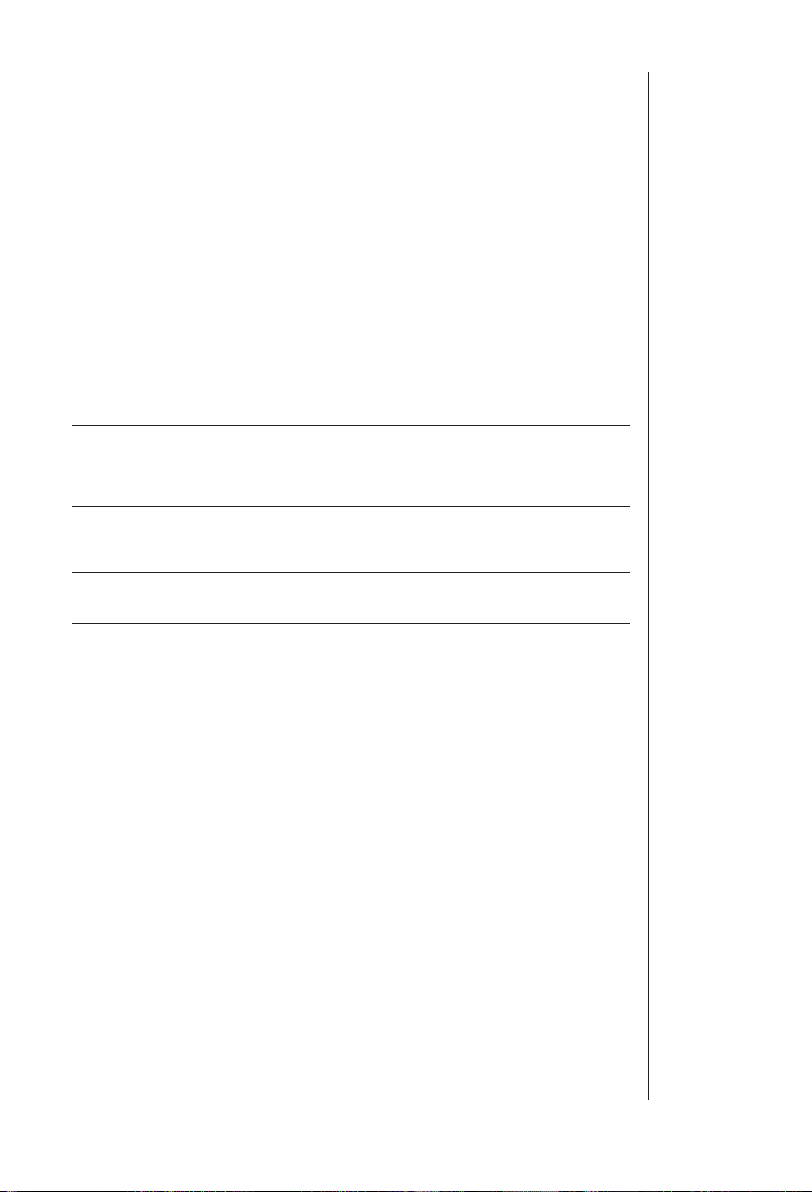

may be stored is 100. If a 101

LOTS” will be displayed. Some lots will need to be

deleted. The lot numbering is up to 999 and restarts if

all lot logs are deleted. All log on demand and stability

log on demand are stored in a single lot. The maximum

number of records that may be stored in a Manual or

Stability lot is 200 records.

st

lot is attempted, “MAX

Basic

Mode

Logging

Function

If the log memory is full during any logging session,

the “LOG FULL“ message will be displayed on the

third LCD line for a brief moment and logging will

cease. The display will return to the measurement

screen.

Logging type is congured in SETUP.

Types of Logging

Interval logging: A continuous log recorded using a user-selected timed period.

(This is not available in Basic mode).

Manual log on demand: Readings are logged each time LOG key is pressed. All

of the records are stored in a single Manual lot for the measurement type. New

records made on dierent days are stored in the same Manual lot.

Manual Stability log on demand: A log on demand that is made each time LOG

key is pressed and the stability criteria is reached. Stability criteria may be set to

Fast, Medium or Accurate settings.

Setup/Installation 13

www.GlobalTestSupply.com

Page 14

Logging

Function

In Setup mode, choose log parameter, press MODIFY then use the u arrow to

select between Interval, Manual, or Stability. When Interval is displayed, use the

p and q arrows to select the setting for the timed interval. When Stability is

displayed, use the p and q to select the measurement stability setting.

A complete set of GLP information including date, time, range selection,

temperature reading, calibration information and probe serial number is stored

with each log made.

Interval Logging

Select Interval and sampling period in the SETUP menu (Not available in Basic

mode). To start Interval logging, press the LOG key while the instrument is in

measurement mode.

A “PLEASE WAIT” message will be displayed followed

by the number of free spaces. During active interval

logging, lot information is displayed on the third

LCD line. The line indicates in which lot the data will

be placed and keeps track of the number of logged

records taken. The “LOG“ tag is on continuously during

active logging.

Pressing u during an interval log will display the

number of logs available.

Setup/Installation

14

Pressing the LOG key again will stop the Interval

logging session. The “LOG STOPPED“ message will be

displayed for a few seconds.

If a sensor failure occurs during interval logging, the

message “OUT OF SPEC.” will alternate with logging

information.

Manual Logging

Select Manual in the SETUP menu. To initiate a

Manual log, press the LOG key while the instrument

is in measurement. The “PLEASE WAIT” screen will

be displayed briey followed by a screen indicating

the measurement has been saved and then a screen

indicating the log record number.

The “LOG” tag will be displayed on all 3 screens.

“PLEASE WAIT”

“SAVED” with the log record number

“FREE” with the number of free spaces available

www.GlobalTestSupply.com

Page 15

Stability Logging

Select Stability and choose measurement stability

criteria in the SETUP menu. Only Stability Medium

is available in Basic mode. To initiate the Stability

log, press the LOG key while the instrument is in

measurement.

The “PLEASE WAIT” screen will be displayed briey

followed by a screen showing the stability tag, “LOG”

tag and a “WAITING” message. The log can be stopped

while the “WAITING” message is displayed by pressing

LOG again.

When the stability selected criteria has been met,

a “SAVED” message will be displayed followed by a

screen indicating how much log space is available. The

“LOG” tag will be displayed on all 4 screens.

“PLEASE WAIT”

“WAITING”

“SAVED” with the log record number

“FREE” with the number of free spaces available

Logging

Function

All log records stored on edge® may be viewed on the meter by pressing the RCL

key. The log records are grouped according to measurement (pH, EC, DO).

The parameter displayed rst is based on the probe/

sensor connected. The display also indicates the

percentage of log memory used. Press CFM to display

those logs.

If no sensor or probe is connected, use the u arrow

to select the desired measurement type. Press CFM to

display those logs.

Once a parameter is selected by pressing CFM, use the

pq keys to chose the type of logging records to view.

Choices are:

• Manual log on demand lot,

• Manual log on stability lot,

• Individual Interval logging lots.

Setup/Installation 15

www.GlobalTestSupply.com

Viewing

Logged

Data

Page 16

Viewing

Logged

Data

If no data was logged for the selected measurement

range, the instrument displays the following

messages (ex. for pH range):

“NO MANUAL LOGS”

“NO STABILITY LOGS”

Press CFM to enter inside lot information to view recorded data.

Use the ARROW keys to toggle between dierent records.

Use u to display GLP data including calibration information, date, time, etc.

Press CLR then CFM when deleting records or lots.

Press RCL to exit the logging type.

Press RCL to exit the parameter selection screen.

Press RCL to return to the measurement screen.

Delete Logging Type/Lot

Press RCL and select the parameter log.

Use the pq keys to select the Manual/Stability

records or Interval lots to delete. Press CLR. The

instrument will display “CLEAR MANUAL” for Manual

Records, “CLEAR STAB” for Stability Records.

For Interval lots, the message “CLEAR”, followed by the

selected lot will be displayed with “CFM” tag blinking.

Press the pq keys to select a dierent lot. Press CFM.

The instrument will display “PLEASE WAIT”.

Setup/Installation

16

“CLEAR DONE” is displayed for a few seconds after the

selected Interval lot is deleted.

Delete Records (Manual and Stability log on demand)

To delete individual records (Manual and Stability logs only), enter Manual

(Stability) log by pressing CFM when Manual (Stability) is displayed. Use the

ARROW keys to select the record to be deleted and then press CLR.

The instrument will display “CLEAR REC.“ and record

number along with “CFM” tag blinking. Use the ARROW

keys to select another record if necessary.

Press CFM. The instrument will display “PLEASE WAIT” and then “CLEAR

DONE” message. When individual logs are deleted within saved MANUAL or

STABILITY logs, the logs will renumber, lling in the deleted data but staying in

chronological order.

www.GlobalTestSupply.com

Page 17

To delete all records of the MANUAL (STABILITY) log, proceed as described on

page 16 for LOTS.

Select the Manual (Stability) lot and press CLR.

The ”CLEAR” message will be displayed along with

”MANUAL” or “STABILITY” and CFM tag blinking on

the LCD. Press the CFM key to conrm the deleting of

the selected lot (MANUAL or STABILITY) or all records.

Press CLR to exit without deleting.

The lot number is used to identify particular sets of data. The lot numbers

are allocated successively until 100, even if some lots were deleted. The total

number of lots that can be saved is 100. If some are deleted (for example 1-50),

fty additional logs may be stored. These will be numbered 101-150. The lots are

allocated successively (provided available memory space) until 999 is reached.

After this, it is necessary to delete all the LOT logs to start over the numbering.

Delete All

All pH logs, (or all EC, all DO logs) may be deleted in a single clear. This function

will delete all MANUAL, STABILITY and INTERVAL logs for the measurement type

selected.

Press the RCL key. The pH, EC, or DO type will be

blinking. Use u to select desired measurement

parameter log data to delete.

While the measurement type is blinking and message

states “LOG RECALL”, press CLR.

“CLEAR ALL” and measurement type will be displayed

with “CFM” tag blinking. Press CFM.

Viewing

Logged

Data

“PLEASE WAIT” and the percent cleared will be

displayed until completed. The procedure can be

repeated for the other measurement modes.

Note: If CLR is pressed in error, press CLR again to exit

without deleting.

www.GlobalTestSupply.com

Setup/Installation 17

Page 18

PC & Storage

Interface

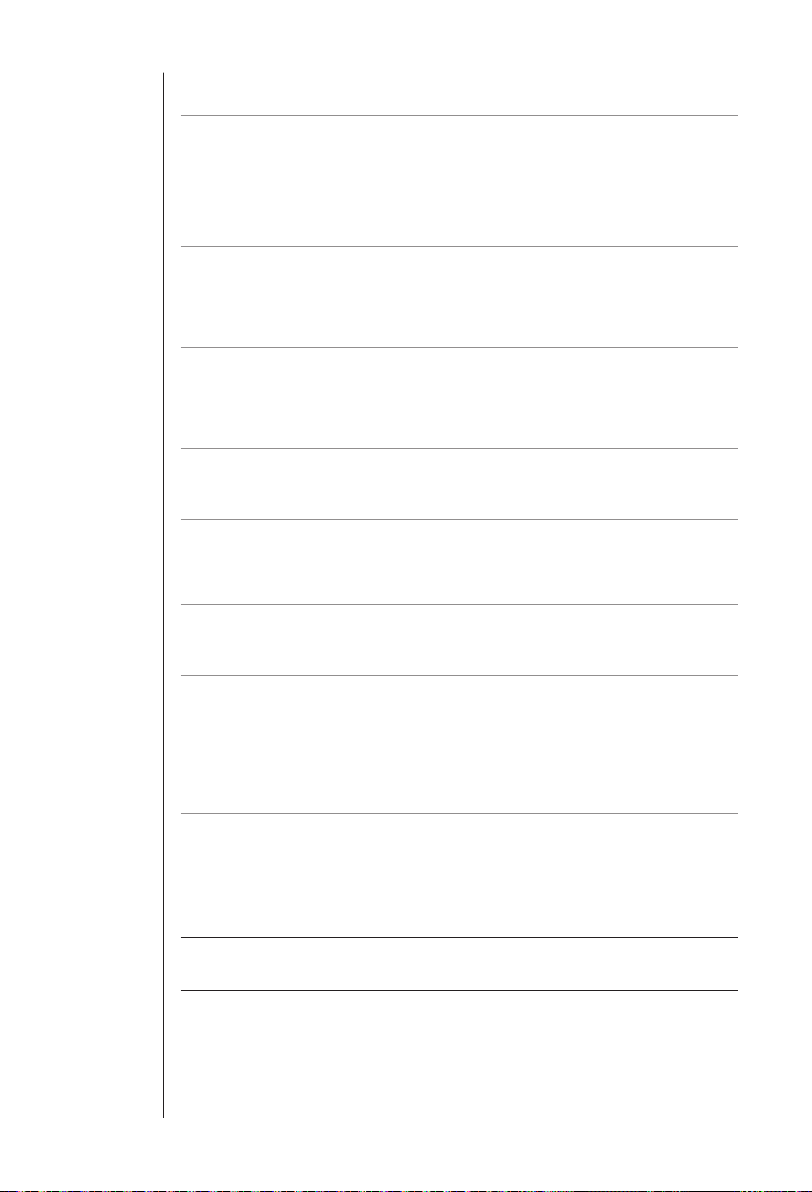

Logged data on edge® can be transferred from the meter to a USB ash drive

by using the log recall function. The minimum requirement for the drive is USB

2.0. Select the pH, EC or DO record you wish to export and follow the simple

steps below.

Connect USB ash drive to the USB port, located on

the top of the meter. Press the RCL key and select

the parameter to view (pH, EC, or DO). Press the CFM

key. Select Manual, Stability, or interval lots by using

the pq keys. Press the LOG key (not CFM). The “USB

HOST” tag should come on.

“PLEASE WAIT” message appears followed by

“EXPORT”. Press CFM to export the selected record or

lot. If CFM is not pressed in 10 seconds, the USB host

will become inactive.

The meter will display the percentage of export.

The export percentage should go to 100%. Remove

USB ash drive.

Setup/Installation

18

If the selected le is already saved on the ash drive,

edge® will ask for conrmation of overwriting the

existing le. The message “OVERWRITE” and “CFM”

tag will blink. Press CFM for overwriting the existing

le or CAL to exit without exporting.

After exporting the display will return to the

selected le. Press the RCL key twice to return to

measurements.

Note: Do not remove USB ash drive during an active export transfer.

www.GlobalTestSupply.com

Page 19

Logged data on the edge® can be transferred from the meter to a PC by

following these simple directions. Suitable operating systems include Windows

(Xp minimum), OS X or Linux.

1. Connect edge® to the PC using the supplied micro USB cable.

2. Turn on edge®.

3. Press SETUP and select “LOG ON EDGE”

4. Press MODIFY then use pq keys to change to “EXPORT TO USB”

5. Press CFM and the USB/PC Tag is displayed.

6. Press SETUP to exit

The PC should detect the USB as a removable drive. Open the drive to view the

stored les. Log les are formatted as Comma separated values (*.CSV) and can

be opened with any text editor or spreadsheet program. (Note: Field separator

may be set as comma or semicolon depending upon region preferences, see

Setup.)

Note:

• Western Europe (ISO-88859-1) character set and English language are

suggested settings.

• Other les may be visible depending upon computer settings. All les

stored will appear in this folder.

• Adjust Font or column width appropriately. Adjust the decimal places if the

pH was logged with 0.001 resolution.

• All conductivity measurements will be displayed as μS/cm.

Interval logs are designated as pH, EC or DO Lots. ie. PHLOT001, ECLOT002,

DOLOT003.

PC & Storage

Interface

The Manual Lots are PHLOTMAN, ECLOTMAN, and DOLOTMAN.

The Stability Lots are PHLOTSTA, ECLOTSTA, and DOLOTSTA. All stability logs,

regardless of stability setting, are located in the same stability le for that

measurement.

Click on the desired log to view data.

Note:

• If “ºC !” appears in log data, the electrode/probe was used beyond it’s

operation specications and the data is not considered reliable.

• If “ºC !!” appears in log data, the temperature sensor within the probe or

electrode is broken and the device should be replaced. Logged data should

not be considered reliable.

Setup/Installation 19

www.GlobalTestSupply.com

Page 20

Basic vs

Standard

pH Mode

For optimum pH measurements, follow these steps:

1. Understand the benets and features of Standard and Basic Operation.

2. Set up edge® meter by conguring preferences.

3. Calibration

4. Measurement

The “Standard” pH operation includes up to a 5-point buer calibration, use

of custom buers, choice of displaying 0.001 pH resolution, use of the full

diagnostic features of Calibration Check™ (that includes buers used, probe

condition, response time and messages indicating a contaminated buer or pH

sensor requiring maintenance during calibration). Additional Sensor Check™

indicators are available if using HI 11311 or HI 12301 pH electrodes. These

include a continuous diagnostic to detect if the electrode is broken and at the

time of calibration, a diagnostic to indicate the reference junction has been

compromised or fouled by sample contamination. The Standard pH operation

also includes full logging capability including Interval, Manual log on demand

and Manual log on stability.

“Basic” pH operation provides a simplied SETUP menu; there are no decisions

to make regarding the pH measurement itself. The meter will display 0.01 pH

resolution and permit a 3-point buer calibration from the following pH buers;

4.01, 6.86, 7.01, 9.18 or 10.01. Calibration Check™ and Sensor Check™ features

are limited to messages during calibration. Calibration reminders are also not

available. The GLP will still provide oset, slope, buers used and a calibration

date. The Basic pH operation includes Manual log on demand and Manual log on

stability (medium setting).

: When changing from Standard to Basic operation in SETUP, previous

Note

calibration data will be cleared. A prompt will force the user to facilitate this.

Operational Guide

20

Major dierences between Standard and Basic modes are shown below.

Standard Basic*

Calibration

Diagnostics

Log types

Recommended pH electrodes:

5 points including 2 custom

buers

Cal Check™ Feature

Sensor Check™ Feature

Error messages

GLP

Manual Log on demand

Manual Log on stability

(Fast, Medium, Accurate)

Interval Logging

HI 11310, HI 12300

HI 11311, HI 12301

HI 10530, HI 10430

3 points

Basic error messages

GLP basic

Manual Log on demand

Manual Log on stability

(Medium)

HI 11310*

HI 12300

* All Sensors work in this mode, but diagnostic and all buers will not be

available.

www.GlobalTestSupply.com

Page 21

edge’s pH meter operation is congured by using the SETUP key with a pH probe

connected to the meter. The parameter-specic options will be seen inserted

into the menu. If Basic mode is “On”, the pH parameter list will not be displayed.

See Basic mode for a description of this operation before choosing how to

SETUP the meter.

Option Description Choices Default Basic mode

When “On”, a limited set of

Basic Mode

Information

parameters and calibration

buers are available for

use.

Visual indication of buers

used, Probe Condition

and Response times are

determined and displayed

when calibration uses 7 and

4 and/or 10 pH buers.

O or

On

O or

On

O Available

Buers used, probe

On

conditions, and

response times are

not displayed.

pH Meter

Congurations

First Custom

Buer

Second

Custom Buer

First

Calibration

Point

Resolution

Set Out Of

Calibration

Range

When “On”, it permits the

user to enter a custom pH

buer value to use during

electrode calibration.

When “On”, it permits the

user to enter a custom pH

buer value to use during

electrode calibration.

Allows the user to choose

how the rst point in

calibration will be made.

Allows the user to select

between 0.01 and 0.001 pH

resolution.

When set to “On”, a

measurement that is

outside the calibrated

range (buers used) will

trigger a warning message.

O or

value

O or

value

Oset

or point

0.01 or

0.001 pH0.01 pH

O or

On

O Not Available

O Not Available

Oset

On

Not Available

(automatically uses

Oset).

Not Available

(automatically uses

0.01 pH resolution).

Not Available, No

Error messages

displayed.

Calibration in Standard Mode

pH operation in standard mode oers full function of edge®. This includes

seven standard buers and two custom ones. Five pH buers may be used for

calibration.

The instrument should be recalibrated whenever:

• High accuracy and sensor verication are required.

• The pH electrode is replaced.

• At least once a week.

• After testing aggressive chemicals.

• If ”CAL DUE” is displayed on the third LCD line.

pH

Calibration

Every time you calibrate the instrument use fresh buers and perform electrode

maintenance as required. It is advised to choose calibration buers that bracket

the sample pH.

Operational Guide 21

www.GlobalTestSupply.com

Page 22

pH

Calibration

Preparation

Pour small quantities of the buer solutions into clean beakers. If possible,

use plastic to minimize any EMC interferences. For accurate calibration and to

minimize cross-contamination, use two beakers for each buer solution; one

for rinsing the electrode and one for calibration. If you are measuring in the

acidic range, use pH 7.01 or 6.86 as the rst buer and pH 4.01 (or 3.00*) as the

second buer. If you are measuring in the alkaline range, use pH 7.01 or 6.86 as

rst buer and pH 10.01 or 9.18 as the second buer.

* pH 3.00 is only visible when using specic pH electrodes and will replace 4.01

pH buer.

Procedure

Calibration can be performed using up to ve calibration buers. For accurate

measurements, a minimum of a three-point calibration is recommended. The

calibration buer can be selected from the calibration buer list that includes

the custom buers and the standard buers:

pH 1.68, 4.01 (pH 3.00), 6.86, 7.01, 9.18, 10.01 and 12.45.

The custom buers allow the user to calibrate in a buer solution dierent from

a standard one. Two custom buers can be set in SETUP menu. See page 23 for

more information about using custom buers.

The instrument will automatically skip custom buers which are in a ±0.2 pH

window of an already calibrated buer.

Submerse the pH electrode approximately 3 cm (1¼”) into a buer solution and

stir gently. Press CAL to enter calibration.

Operational Guide

22

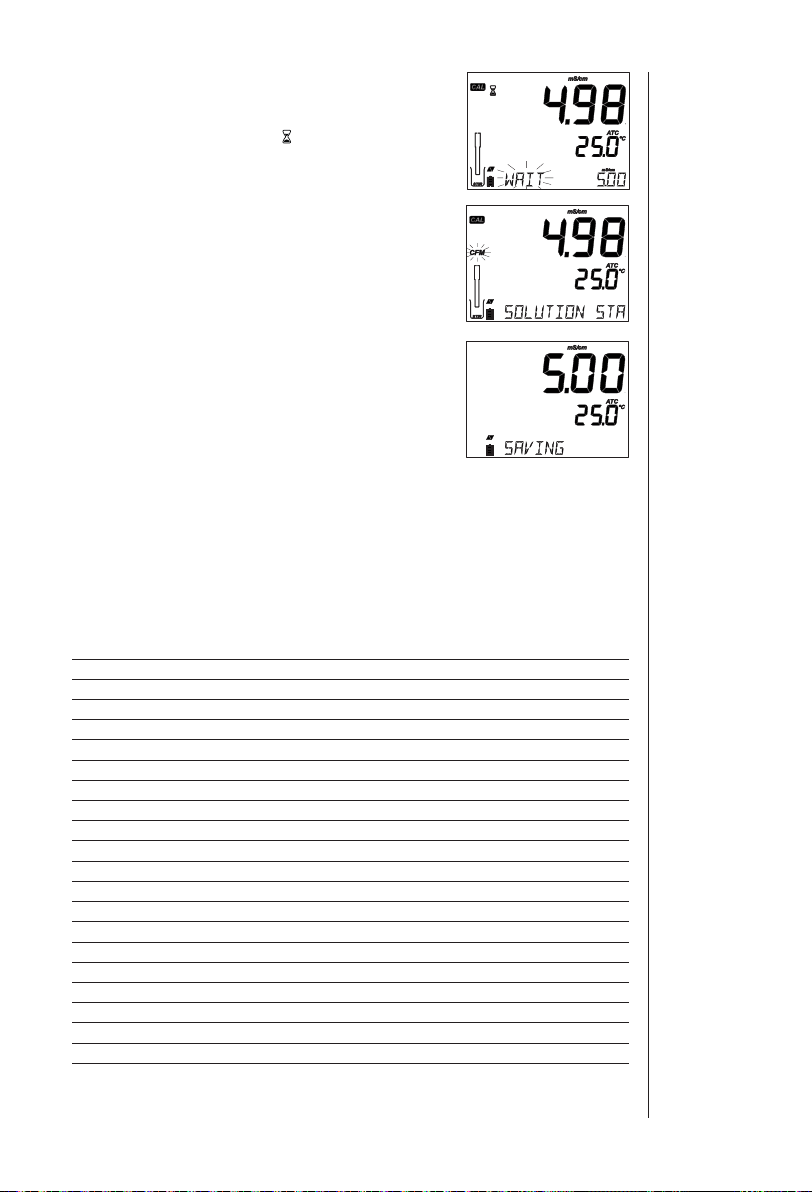

The “CAL” tag will appear and the “7.01” buer will be

displayed on the third LCD line. If necessary, press the

ARROW keys to select a dierent buer value. The “ ”

along with “STIR” tag will be displayed and “WAIT” will

blink on the LCD until the reading is stable.

When the reading is stable and close to the selected

buer, “CFM” tag will blink. Press CFM to conrm

calibration.

After conrming the rst point, the calibrated value

will be displayed on the rst LCD line and the second

expected buer value on the third LCD line (i.e. pH

4.01).

www.GlobalTestSupply.com

Page 23

Rinse and submerse the pH electrode approximately 3 cm (1¼”) into the second

buer solution and stir gently. If necessary, press the ARROW keys to select a

dierent buer value.

The “

” along with “STIR” tag will be displayed and “WAIT” will blink on the LCD

until the reading is stable.

When the reading is stable and close to the selected buer, “CFM” tag will blink.

Press CFM to conrm calibration.

Repeat procedure with additional pH buers. A total of ve pH buers can be

utilized.

After conrming the last desired buer calibration

points, press CAL (or if all ve buer values were

calibrated) the instrument will automatically display

“SAVING” as it stores information. It will then return to

normal measurement mode.

Each time a buer is conrmed, the new calibration

data replaces the old data for the corresponding

buer or for any buer in the proximity of ±0.2 pH.

If current buer has no previous data stored and the

calibration is not full (ve buers), the current buer

is added to the existing calibration. If the existing

calibration is full, the instrument asks which buer to

replace.

Press the ARROW keys to select another buer to be replaced.

Press CFM to conrm the buer that will be replaced.

Press CAL to leave calibration without replacing.

pH

Calibration

Note: If the replaced buer is outside the ±0.2 pH window of the calibrated

buers, it is possible to select this buer during the next calibration.

Working With Custom Buers

If a custom buer was set in SETUP menu, it can be selected during calibration

by pressing the ARROW keys. The “C1” or “C2” tag will be displayed once selected.

Press u if you want to modify the custom buer

value. The buer value will start blinking.

Use the ARROW keys to change the buer value.

After 5 seconds, the buer value is updated. Press u

if you want to change it again.

Operational Guide 23

www.GlobalTestSupply.com

Page 24

pH

Calibration

Note: Custom buer values can be adjusted ±1.00 pH around the set

value during calibration. When a custom buer is displayed, the “C1” or “C2”

tag is displayed.

First Calibration Point

When performing a new calibration, or adding to an existing one, the user has

a choice of how the rst new calibration point will be treated in reference to

the existing calibration point. This is selected in SETUP by the option FIRST

CALIBRATION POINT. The two SETUP selectable options are “POINT” or “OFFSET”.

Point: A buer value can be recalibrated and added to the previous calibration

set. The electrode slope of the other calibration points will be reevaluated with

the recalibrated buer value.

Oset: The new buer calibration point can create a constant oset to all

existing pH calibration data (existing calibration must have a minimum of two

pH buers)

.

Recalibrating a pH sensor or adding to an existing calibration is simple and

follows the PROCEDURE outlined on page 22.

Press CAL. Place sensor in desired buer and select buer from choices. When

sensor has equilibrated, the CFM tag will turn on and blink. Press the CFM key.

Press CAL to escape the calibration. Alternately continue calibrating in

additional buers. The latest calibration point will be added to the existing data.

GLP will reect the latest calibration data. Older calibration buers will be seen

as blinking buers.

Note: Each time a buer is conrmed, the new

calibration data replaces the old data for the

corresponding buer or for any buer in the proximity

of ±0.2 pH. If the current buer has no previous data

stored and the calibration has not used ve buers,

the current buer is added to the existing calibration.

If the existing calibration is full, the instrument asks

which buer to replace.

Operational Guide

24

Note: When using Standard mode, the user can choose if they want the display

to show the CONDITION and RESPONSE gauges on the display. These are part of

the Cal Check™ system and are selected in SETUP by the option INFORMATION.

The choice is ON or OFF.

Electrode Condition and Electrode Response Time

edge® pH Calibration Check™ feature will assess electrode condition and

response time during each calibration and display it for the rest of the day.

The condition gauge shows the electrode’s condition that is based on the oset

and slope characteristics of the pH electrode at the time of calibration. The

response gauge is a function of the stabilization time between the rst and

second calibration buers, when calibration is performed between a pair of

4.01, 7.01, or 10.01 buers. These gauges reect the electrode’s performance

and should be expected to slowly decrease over the life of the electrode .

www.GlobalTestSupply.com

Page 25

If the instrument is not calibrated the calibration history has been deleted, or it

has been calibrated only at one point, the electrode condition and the electrode

response gauges will be empty.

For a continuous display of the electrode’s condition and response, daily

calibration is necessary. This information can also be viewed in the GLP data.

Junction Condition (HI 11311 and HI 12301 Only)

edge’s pH Sensor Check™ feature assess the health of the pH electrode’s

reference junction during each calibration. The junction gauge may be viewed

directly in GLP but will also blink a warning on the display if the junction is

compromised (not 100%). Should this happen, the junction condition will

appear on the display with the junction blinking. The Junction Condition is a

function of the electrode’s reference impedance which should be kept low. If the

reference junction becomes fouled from a precipitate or coating, the impedance

will rise and cause the pH measurement to drift. This diagnostic feature serves

as a warning to clean the sensor.

pH

Calibration

Calibration in Basic Mode

Procedure

Basic mode operation permits up to three-point buer calibration.

For accurate measurements, at least a two-point calibration is recommended.

However, a single point calibration can also be used.

The calibration buers can be selected from the calibration buer list that

includes the standard buers, pH 4.01, 6.86, 7.01, 9.18 and 10.01.

Three-Point Calibration

Submerse the pH electrode approximately 3 cm (1¼”) into a buer solution and

stir gently. Press CAL. The “CAL” tag will appear and the “7.01” buer will be

displayed on the third LCD line. If necessary, press the

ARROW keys to select a dierent buer value.

The “ ” along with “STIR” tag will be displayed and

“WAIT” will blink on the LCD until the reading is stable.

Operational Guide 25

www.GlobalTestSupply.com

Page 26

pH

Calibration

When the reading is stable and close to the selected

buer, the “CFM” tag will blink. Press CFM to conrm

calibration.

After conrming the rst calibration point, the

calibrated value will be displayed on the rst LCD line

and the second expected buer value on the third LCD

line. (i.e. pH 4.01)

Rinse and submerse the pH electrode approximately

3 cm (1¼”) into the second buer solution and stir

gently.

If necessary, press the ARROW keys to select a dierent buer value.

The “

” along with “STIR” tag will be displayed and “WAIT” will blink on the LCD

until the reading is stable. When the reading is stable and close to the selected

buer, the “CFM” tag will blink. Press CFM to conrm calibration.

The calibrated value is then displayed on the rst LCD line and the third expected

buer value on the third LCD line.

After the second calibration point is conrmed, rinse and submerse the pH

electrode approximately 3 cm (1¼”) into the last buer solution and stir gently.

If necessary, press the ARROW keys to select a dierent buer value.

The “ ” along with “STIR” tag will be displayed and “WAIT” will blink on the LCD

until the reading is stable.

Operational Guide

26

When the reading is stable and close to the selected buer, the “CFM” tag will

blink. Press CFM to conrm calibration.

At the end of calibration the instrument displays “SAVING”, stores the calibration

value and returns to normal measurement mode.

The calibration sequence may be reduced to two buer values or a single one.

Press CAL to return to measurement mode after the desired number of buers

have been calibrated.

Note:

• When performing a new calibration or adding to an existing calibration the

rst calibration point will be treated as an oset. See page 24 for details.

• Press CAL after the rst or second calibration point are conrmed and

the instrument will store the calibration data. Then it will return to

measurement mode.

• If the value measured by the instrument is not close to the selected buer,

“WRONG BUFFER” will blink. Check if the correct buer has been used or

selected.

www.GlobalTestSupply.com

Page 27

• If the buer temperature exceeds the temperature limits of the buer,

“WRONG BUFFER TEMPERATURE” will be displayed.

• Press CLR after entering calibration to clear previous calibrations stored on

probe. “CLEAR CALIBRATION” message will be displayed. Press CFM. The

instrument will return to measurement mode displaying the “CAL DUE”

message.

• If measured value diers more than expected “CHECK ELECTRODE CHECK

BUFFER“ will be displayed. Take appropriate action, cleaning the probe if

necessary or refreshing the pH buer.

pH Buer Temperature Dependence

Calibration buers are aected by temperature. During calibration with standard

pH buers (not Custom), the instrument will display the pH buer value at 25 ºC,

however, it will use the appropriate value for that buer at the temperature of

the buer for the calibration. Immediately after exiting calibration, the buer

will read its value at the temperature of measurement.

TEMP pH BUFFERS

ºC ºF 1.679 3.000 4.010 6.862 7.010 9.177 10.010 12.454

0 32 1.670 3.072 4.007 6.982 7.130 9.459 10.316 13.379

5 41 1.670 3.051 4.002 6.949 7.098 9.391 10.245 13.178

10 50 1.671 3.033 4.000 6.921 7.070 9.328 10.180 12.985

15 59 1.673 3.019 4.001 6.897 7.046 9.273 10.118 12.799

20 68 1.675 3.008 4.004 6.878 7.027 9.222 10.062 12.621

25 77 1.679 3.000 4.010 6.862 7.010 9.177 10.010 12.450

30 86 1.683 2.995 4.017 6.851 6.998 9.137 9.962 12.286

35 95 1.688 2.991 4.026 6.842 6.989 9.108 9.919 12.128

40 104 1.693 2.990 4.037 6.837 6.983 9.069 9.881 11.978

45 113 1.700 2.990 4.049 6.834 6.979 9.040 9.847 11.834

50 122 1.707 2.991 4.062 6.834 6.978 9.014 9.817 11.697

55 131 1.715 2.993 4.076 6.836 6.979 8.990 9.793 11.566

60 140

65 149 1.734 2.998 4.107 6.844 6.987 8.948 9.757 11.323

70 158 1.744 3.000 4.123 6.850 6.993 8.929 9.746 11.211

75 16 7 1.755 3.002 4.139 6.857 7.001 8.910 9.740 11.104

80 176 1.767 3.003 4.156 6.865 7.010 8.891 9.738 11.003

85 185 1.780 3.002 4.172 6.873 7.019 8.871 9.740 10.908

90 194 1.793 3.000 4.187 6.880 7.029 8.851 9.748 10.819

95 203 1.807 2.996 4.202 6.888 7.040 8.829 9.759 10.734

1.724 2.995 4.091 6.839 6.982 8.969 9.773 11.442

pH

Calibration

Calibration

Messages

The Calibration Check™ feature may ag diagnostic messages during a

calibration. As electrode aging is normally a slow process, substantial changes

from previous calibrations are likely due to a temporary problem with the probe

or buers that can be addressed easily. These messages are seen in Standard

and Basic modes.

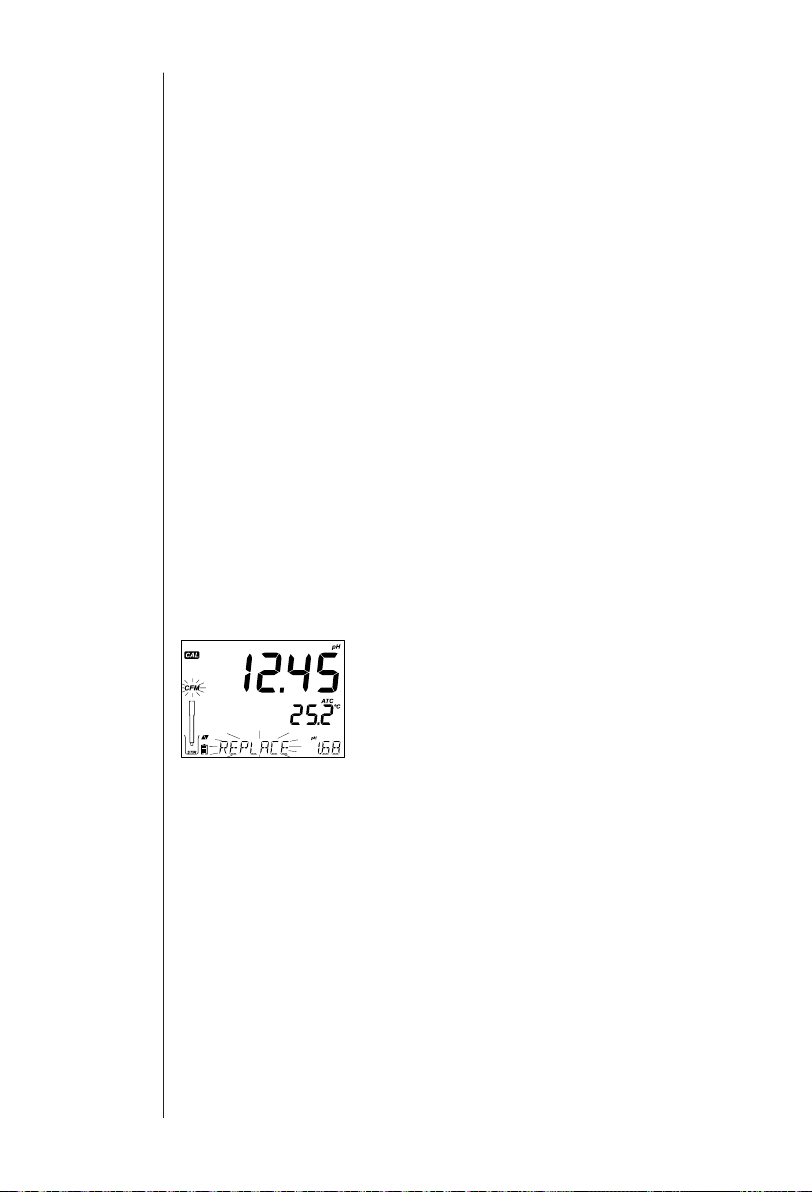

Wrong Buer

This message appears when the dierence between

the pH reading and the value of the selected buer

is too great. If this error message is displayed, check

if you have selected the proper calibration buer and

have poured the desired buer.

Operational Guide 27

www.GlobalTestSupply.com

Page 28

Calibration

Messages

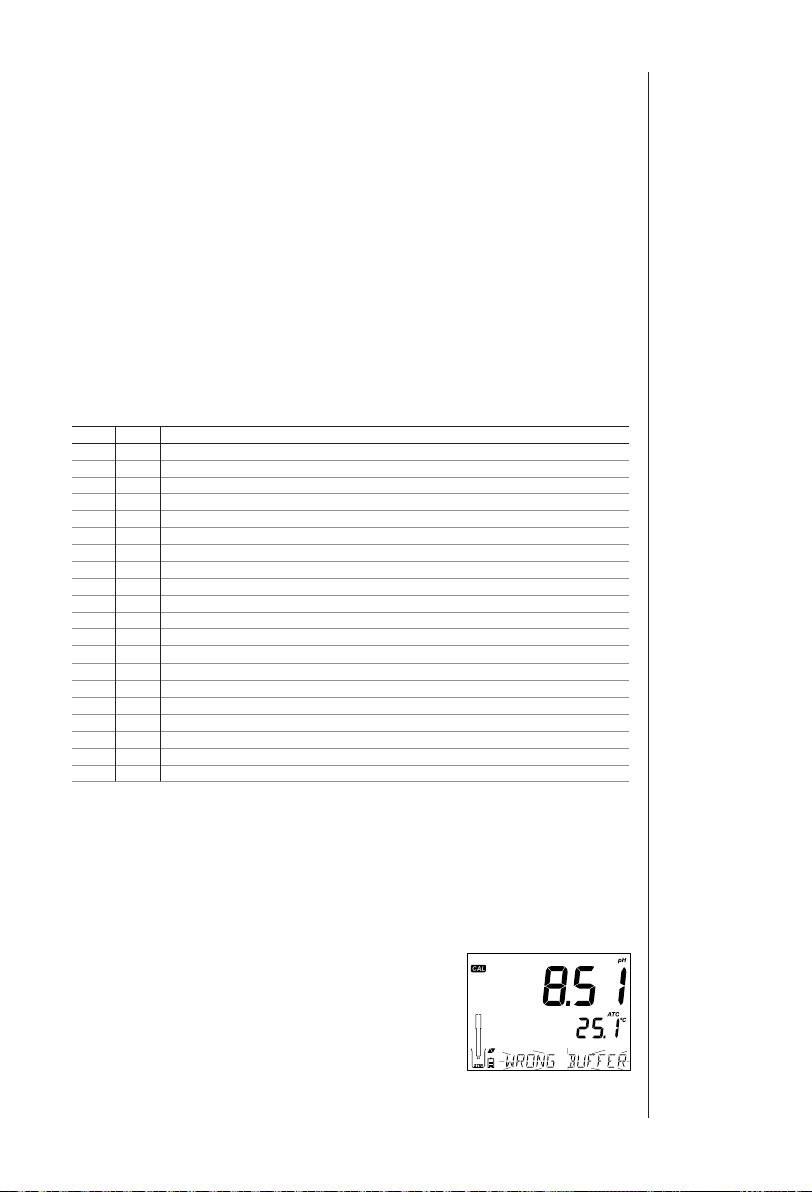

Wrong Old Points Inconsistency

“WRONG OLD POINTS INCONSISTENCY” is displayed if

the new calibration diers signicantly from the last

value of that probe in that buer. In this case it may

be best to clear the previous calibration and attempt a

new calibration with fresh buers.

To clear calibration information, press CAL then

press CLR. The “CLEAR CALIBRATION” message will

be displayed. Either press the CFM key and clear all

calibration information or press CAL to exit. The probe

may retain a single point calibration if rst point was

accepted.

Once calibration information is cleared, the message

“CAL DUE” will be displayed

Clean Electrode

“CLEAN ELECTRODE” indicates poor electrode

performance (oset out of accepted window, or

slope under the accepted lower limit). Often, cleaning

the probe will improve the pH electrodes response.

See pH Electrode Conditioning and Maintenance for

details. Repeat calibration after cleaning.

Check Electrode Check Buer

“CHECK ELECTRODE CHECK BUFFER” appears when

electrode slope exceeds the highest accepted slope

limit. You should check your probe and use fresh

buer. Cleaning may also improve this response.

Operational Guide

28

Bad Electrode

“BAD ELECTRODE” appears if the cleaning procedure

performed as a result of the above two messages is

found to be unsuccessful. In this case it is advised to

replace the probe.

Wrong Buer Temperature

“WRONG BUFFER TEMPERATURE” appears if the

temperature of the buer is outside the dened

buer temperature range. The calibration buers are

aected by temperature changes in a dened manner.

During calibration, the instrument will automatically

calibrate to the pH value corresponding to the measured temperature but

display it to the value at 25 ºC. Immediately after calibration, the buer should

read the value of the buer at the temperature of measurement.

Note: Temperature limits will be reduced to actual sensor specications.

www.GlobalTestSupply.com

Page 29

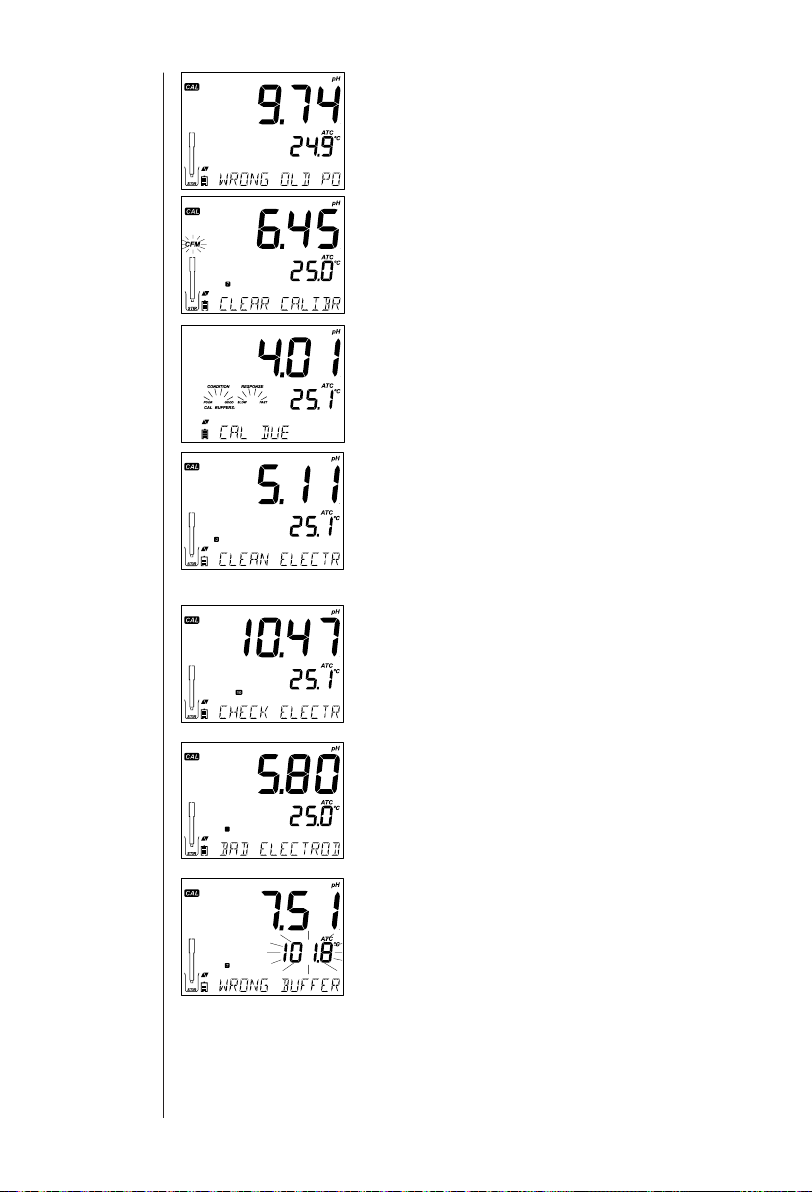

Contaminated Buer

“CONTAMINATED BUFFER” appears in order to alert

that the buer could be contaminated. Refresh your

buer and continue the calibration procedure.

Broken Temperature Sensor

If the temperature sensor should malfunction or break at any time, a temperature

of “25.0 ºC” will blink on the second LCD line and the

message “BROKEN TEMPERATURE SENSOR” will

appear on the third LCD line after leaving calibration.

The calibration will have the compensation at 25 ºC.

Replace probe if this occurs.

Note: If this occurs during logging “25 ºC !” will appear in the CSV le.

Calibration

Messages

Good Laboratory Practice (GLP) refers to a quality control function used to

ensure uniformity of sensor calibrations and measurements. The dedicated

GLP key opens a le of the latest calibration information. Use the qp keys to

scroll the stored information. This includes the buers used, temperature of the

buer, time and date of the last calibration, the sensor serial number and the

calculated oset and percent slope. This information is available in Basic and

Standard Modes. This information is also included with every data log. Newest

calibration points report as a solid number, older calibration data (that is still

used) will be displayed blinking.

If calibration has not been performed, the instrument

displays a blinking “NO CAL” message.

The pH calibration oset and slope (the GLP slope is

the average of the calibration slopes; the percentage

is referenced to the ideal slope value at 25 ºC). The

condition and response indicators displayed are from

the last calibration.

Pressing the qp keys, the last calibration date (yyyy.

mm.dd) together with the current reading is displayed.

pH GLP

Information

www.GlobalTestSupply.com

Operational Guide 29

Page 30

pH GLP

Information

Note: If a custom buer was used in calibration, the “C1” and “C2” tags will be

displayed. If only the one custom buer is used in calibration, the tag will be “C1”

and the value will be displayed.

If disabled, “EXPIRATION WARNING DISABLED” is

displayed.

Or if enabled the number of days until the calibration

alarm “CAL DUE” will be displayed. (i.e. “CAL EXPIRES

IN 2 DAYS”)

The number of days since the calibration expired. (i.e.

“CAL EXPIRED 2 DAYS AGO”).

The probe serial number together with the current

reading.

If a buer is not from the last calibration, the buer

tag will be displayed blinking.

Operational Guide

30

In Standard Mode, Condition and Response gauges are visible on the day of

calibration (See Electrode Condition And Electrode Response Time page 24).

If congured in SETUP, a countdown message displays the number of days

remaining until a new Calibration is due.

If using a HI 11311 or HI 12301 sensor, the glass

impedance is continuously monitored, updated and

reported here and the Junction Condition Gauge is

fully visible.

www.GlobalTestSupply.com

Page 31

When an edge® pH probe is connected, the instrument

will recognize it and a the cap removal message will be

displayed along with “PH”. Press any key to skip the

message. The instrument will enter measurement

mode. Make sure the electrode has been calibrated

before taking measurements.

Rinse the pH sensor with water and a sample if

possible. Submerse the electrode tip approximately 3 cm

(1¼”) into the sample to be tested and stir sample

gently. Allow time for the electrode to stabilize.

The pH is displayed on the rst LCD line and the temperature on the second LCD

line. Using the ARROWS, date, time, battery status and oset with slope can be

displayed on the third LCD line. If the reading is out of measurement range, the

closest full scale value will be displayed blinking on the rst LCD line.

If measurements are taken successively in dierent samples, it is recommended

to rinse the electrode thoroughly with deionized water or tap water and then

with some of the next sample to prevent cross-contamination. The pH reading is

aected by temperature. The temperature eect is compensated for using the

temperature sensor inside the probe. The resulting measurement is the actual

pH at the temperature of measurement.

Error Messages During Measurement

If the pH or temperature exceeds the limits of the

sensor, the message “ELECTRODE OUT OF SPEC”

will scroll on the third LCD line. The temperature will

continue to be displayed. If temperature exceeds

the meter specication of 120 ºC, then “120 ºC” will

blink on the display. If interval logging, the message

“OUT OF SPEC.” will alternate with the LOG specic

message. In both these cases the Log le will indicate

a “ºC!” next to the data.

pH

Measurement

In case the temperature sensor is damaged, “BROKEN

TEMPERATURE SENSOR” message will be displayed

with “25.0 ºC” blinking on the second LCD line. The Log

le will indicate “ºC!!” next to the data.

mV Reading Of The pH

The mV reading of the measured pH can be displayed

on the LCD by pressing the RANGE key.

www.GlobalTestSupply.com

Operational Guide 31

Page 32

pH

Measurement

Third Line Messages Displayed During Measurement

All the messages described in General Setup (page 11)

are displayed in pH range.

Temperature Sensor Problem (if there is one)

Cal Due or Oset and Slope Value

Time

Date

Battery or Charge Status

Logging Messages

Out of Calibration Range

Operational Guide

32

www.GlobalTestSupply.com

Page 33

Steps To Optimize EC Measurement

Follow these steps to optimize measurement using an EC probe:

1. Determine what measurement you wish to make with the EC probe. (See

below)

2. Determine if Standard or Basic mode is best for your measurement.

3. Connect the Probe and congure your measurement using the SETUP

menu.

4. Calibrate the EC probe.

5. Take measurements using an EC probe.

Measurements Available With The EC Probe

The four-ring EC probe may be used for 3 dierent measurement applications

with edge®.

• It may be used for temperature compensated or absolute conductivity

measurements (with units of μS/cm or mS/cm).

• TDS (Total Dissolved Solids) measurements (a calculated measurement

derived from the ionized particles in a sample and the conductivity

measurement). This has measurement units of mg/L, ppm or g/L.

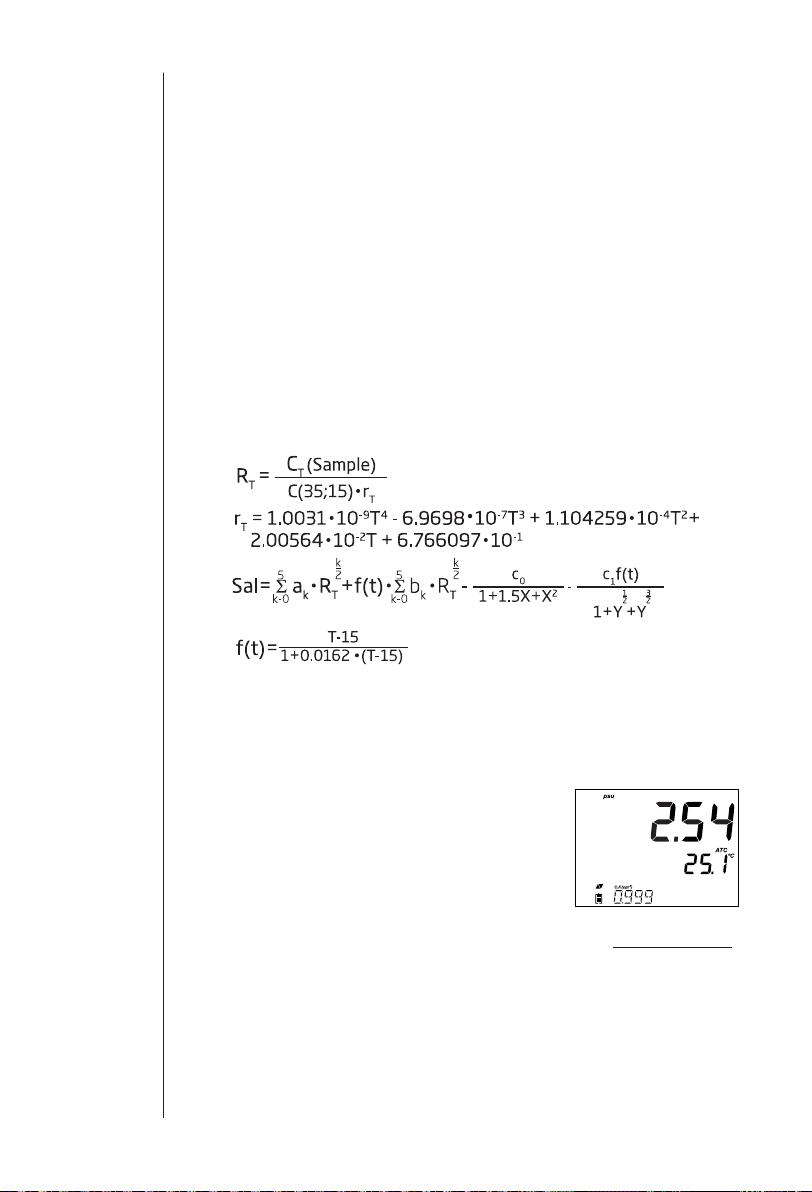

• Salinity (not available in basic mode): 3 dierent seawater salinity scales

are supported; Practical Salinity (PSU), the Natural Seawater Scales (g/L),

and the NaCl %.

The RANGE key is used to change from conductivity to TDS (and to Salinity

available in standard mode only).

Basic Versus Standard EC Mode

Standard operation mode allows complete conguration of all options for the

measurement of Conductivity, TDS or Salinity measurements. Measurement data

can be logged using Manual log on demand, Manual Log on Stability or Interval

logs. All logged data can be exported to a thumb drive or PC. Basic operation

mode is used for conductivity and TDS measurements. Common default values

are used for Cell Factor (C.F.), temperature compensation coecient and TDS

conversion factor. Measurement units are user-selectable for TDS. The meter

uses continuous auto-ranging to simplify the measurement experience.

Basic vs

Standard

EC Mode

Standard Basic

Measurement Conductivity, TDS, Salinity Conductivity, TDS

Set up Parameters Fully selectable Default values used

Log types

Manual Log on demand

Manual Log on stability

(Fast, Medium, Accurate)

Interval Logging

Manual Log on demand

Manual Log on stability

(Medium)

EC (Electrolytic Conductivity) meter operation is congured using the SETUP

key with an EC probe connected to the meter. The EC-specic parameters will

be seen inserted into the menu. If Basic mode is “On”, the EC parameter list will

be simplied, limiting the options the user can change. See Basic mode for a

description of this operation before choosing how to SETUP the meter.

Operational Guide 33

www.GlobalTestSupply.com

EC Meter

Conguration

Page 34

EC Meter

Conguration

Option Description Choices Default Basic mode

Basic Mode O or On O Available

Temperature

Compensation

-1

) User may

C.F (cm

T.Coef. (%/ºC) This parameter

T.Ref. (ºC) The user may

TDS Conversion

Factor.

View T.Ref. or

T.Coef.

The user

may select

Automatic

Temperature

Compensation

or No TC to

congure

absolute

conductivity.

enter actual

Cell factor

value Manual

calibration. (see

page 35)

is related to the

solution being

measured at

temperatures

other than 20

or 25 ºC. It is

used to correct

measured

conductivity

to a reference

temperature by

applying a xed

factor for linear

compensation.

select either

20 ºC or 25 ºC

reference

temperature for

temperature

corrected

conductivity.

This factor

is used to

mathematically

convert

conductivity to a

TDS value.

The user may

choose whether

to display the

reference

temperature

(T.Ref) or the

Temperature

coecient on

the display

with the

measurement.

No TC or ATC ATC Not available.

0.01 to 9.999

-1

cm

0.00 to 6.00

(%/ºC) Note:

Setting to 0.00

is the same as

using No TC.

20 ºC or 25 ºC 25 ºC Available

0.40 to 0.80 0.50 Not Available.

T.Ref.(ºC) or

T.Coef.(%/ºC)

1.000 cm

1.90 (%/ºC)

Close for natural

waters or salt

solutions.

T.Ref (ºC) T.Ref (ºC)

-1

ATC is

automatically

used.

Not available.

Automatically

determined

during

calibration.

Not available.

Automatically

set to 1.90%/ºC.

Automatically

set to 0.50.

automatically

displayed during

measurement.

Operational Guide

34

www.GlobalTestSupply.com

Page 35

Option Description Choices Default Basic mode

EC Range If AUTO is used,

TDS Range If AUTO is used,

TDS Unit Select units of

EC Salinity Scale Three

edge® will

automatically

nd the correct

conductivity

range and

unit. If a xed

value is used,

measurements

made outside

the ranges are

considered

Out of Range,

but units will

remain xed

throughout the

measurement.

edge® will

automatically

nd the

correct TDS

measurement

range and

units. If a xed

value is used,

measurements

made outside

the ranges are

considered

Out of Range,

but units will

remain xed

throughout the

measurement.

measurement

for TDS

measurement.

measurement

scales are

available

for salinity

measurement

in Seawater.

(Practical

Salinity Scale,

Percent Scale

and Natural

Seawater Scale).

AUTO,

29.99 μS/cm,

299.9 μS/cm,

2999 μS/cm,

29.99 mS/cm,

200.0 mS/cm,

500.0 mS/cm

AUTO,

14.99 mg/L,

149.9 mg/L,

1499 mg/L,

14.99 g/L,

100.0 g/L,

400 g/L

mg/L or ppm ppm Available to

PSU, NaCl%, g/L NaCl% Not available.

AUTO Not available but

AUTO Not available but

measurement

autoranges as

needed.

measurement

autoranges as

needed.

select.

EC Meter

Conguration

Cell Factor (cm-1) Manual Calibration

This option may be used to perform a manual calibration in a custom standard.

1. Rinse the pro be with a aliquot of standard and shake o excess solution.

2. Place the probe in the standard. The sleeve holes must be covered with

solution.

3. Press SETUP and use the ARROW keys to get to C.F. (cm-1)

4. Press MODIFY.

5. Use the pq keys to change C.F. (cm-1) until the display reads the Custom

Standard value.

Operational Guide 35

www.GlobalTestSupply.com

Page 36

EC Meter

Conguration

6. Press CFM. The message “MANUAL CALIBRATION CLEARS PREVIOUS

CALIBRATIONS” will be displayed on the third line LCD. “CAL” and “CFM” tags

will blink. Press CFM to conrm the manual calibration.

Note: GLP will display “Manual” for a standard. Using this calibration technique

will erase any previous calibrations done in CAL. Log les will indicate “MANUAL”

as standard.

User Selectable EC/TDS Range (Not Available In Basic Mode)

The EC and TDS measurements may be congured in SETUP as AUTO (meaning

auto ranging, the measurement automatically nds the correct conductivity

or TDS unit and resolution), or it may be congured with a user-selected

measurement range and resolution (if you know ahead of time where your

samples will fall). If AUTO is selected, the meter will select the scale with

the highest possible resolution, but may change in the middle of a series of

measurements changing units and displayed resolution.

Note: The selected range is only active during measurements. Auto ranging is

used during calibration. If a xed range is selected and during measurement

goes beyond the range limits, the full scale value of that range will ash on the

display. All log data in the CSV les will be displayed in uS/cm.

EC/TDS

Calibration

General Guidelines

Calibrate the instrument frequently, especially if high accuracy is required.

The instrument should be recalibrated:

• Whenever the EC probe is replaced.

• At least once a week.

• After testing aggressive chemicals.

• If “CAL DUE” is displayed on the third LCD line.

Every time you calibrate the instrument use fresh standard and perform

electrode maintenance as required. It is recommended to choose a calibration

standard that is close to the sample.

Preparation

Pour small quantities of the standard solutions into a beaker. If possible, use a

plastic beaker to minimize any EMC interferences. For accurate calibration and to

minimize cross-contamination, use two beakers for the standard solution; one

for rinsing the probe and one for calibration.

Procedure

Select standard to be used for calibration. 0.00 μS (probe in air) may be used for

an oset calibration. This should be done rst. Hanna Conductivity standards

are available at 84 μS/cm, 1413 μS/cm, 5.00 mS/cm, 12.88 mS/cm, 80.0 mS/cm,

111.8 mS/cm and are used for the cell factor calibration.

Rinse the probe with calibration solution or deionized water. Shake o excess

solution. Submerse the probe in the calibration solution. The sleeve holes must

be completely submersed. If possible, center the probe in the beaker away from

the bottom or beaker walls.

Raise and lower the probe to rell the center cavity and tap the probe repeatedly

to remove any air bubbles that may be trapped inside the sleeve.

Operational Guide

36

www.GlobalTestSupply.com

Page 37

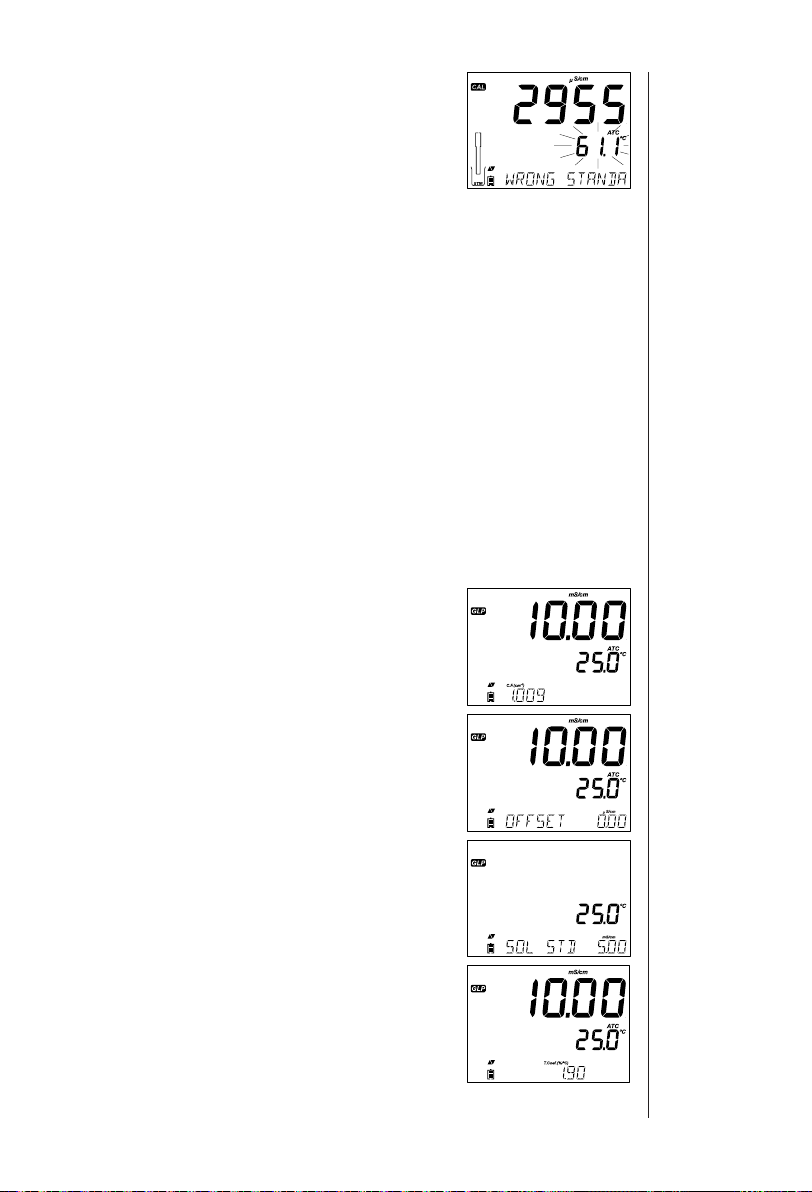

Press CAL to enter calibration. The “CAL” tag and the

recognized standard value will appear on the third LCD

line. If necessary, press the ARROW keys to select a

dierent standard value. The “

“ along with “STIR” tag

will be displayed and “WAIT” will blink on the LCD until

the reading is stable.

When the reading is stable and close to the selected

standard, “CFM” tag will blink, the message “ SOL STD”

and the value will be displayed.

Press CFM to conrm calibration. The instrument

displays “SAVING”, stores the calibration values and

returns to measurement mode.

Conductivity vs Temperature Chart

The following table lists the temperature dependence of Hanna EC calibration

standards. edge® uses these values and their temperature coecients during

calibration.

EC/TDS

Calibration

ºC ºF

0 32 7150 776 64 48300 65400 2760

5 41 8220 896 65 53500 74100 3180

10 50 9330 1020 67 59600 83200 3615

15 59 10480 1147 68 65400 92500 4063

16 60.8 10720 1173 70 67200 94400 4155

17 62.6 10950 1199 71 68500 96300 4245

18 64.4 11190 1225 73 69800 98200 4337

19 66.2 11430 1251 74 71300 100200 4429

20 68 11670 1278 76 72400 102100 4523

21 69.8 11910 1305 78 74000 104000 4617

22 71.6 12150 1332 79 75200 105900 4711

23 73.4 12390 1359 81 76500 107900 4805

24 75.2 12640 1386 82 78300 109800 4902

25 77 12880 1413 84 80000 111800 5000

26 78.8 13130 1440 86 81300 113800 5096

27 80.6 13370 1467 87 83000 115700 5190

28 82.4 13620 1494 89 84900 117700 5286

29 84.2 13870 1521 90 86300 119700 5383

30 86 14120 1548 92 88200 121800 5479

31 87.8 14370 1575 94 90000 123900 5575

HI7030

HI8030

(μS/cm)

HI7031

HI8031

(μS/cm)

HI7033

HI8033

(μS/cm)

HI7034

HI8034

(μS/cm)

HI7035

HI8035

(μS/cm)

HI7039

HI8039

(μS/cm)

Operational Guide 37

www.GlobalTestSupply.com

Page 38

NaCl %

Calibration

Preparation

Pour a small quantity of the calibration solution into a beaker. If possible, use a

plastic beaker to minimize any EMC interferences.

Before pressing CAL verify in SETUP:

• Basic mode is o.

• Salinity Scale is set to NaCl%.