Page 1

Instruction Manual

BL 983314-0

BL 983314-1

Panel-Mounted

Resistivity

Indicators & Controllers

Dear Customer,

Thank you for choosing a Hanna product.

This manual will provide you with the necessary information

for the correct operation of the meter. Please read it carefully

before using the instrument.

If you need additional technical information, do not hesitate

to e-mail us at tech@hannainst.com.

These instruments are in compliance with the directives.

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and

examine it carefully. If any damage has occurred during

shipment, immediately notify your Dealer or the nearest

Hanna Customer Service Center.

Each meter is supplied with:

• HI 3314 resistivity probe

• Mounting brackets

• Instruction manual

Note: Conserve all packing material until the instrument

has been observed to function correctly. Any defective

item must be returned in its original packing.

SPECIFICATIONS

Range 0.00 to 19.90 MΩ/cm

Resolution 0.10 MΩ/cm

Accuracy (@ 20°C/68°F) ±2% f.s.

Typical EMC Deviation ±2% f.s.

Probe HI 3314 resistivity probe (included)

Temp. Compensation Automatic and Linear

from 5 to 50°C (41 to 122°F)

Temperature Coefficient β=2.4 ; 3.5 ; 4.5 %/°C

User-selectable through rear jumper

Calibration Factory calibrated

Dosing Contact Maximum 2A (fuse protected), 250 Vac, 30 Vdc

Contact close when measure < setpoint

Setpoint Adjustable, from 0 to 19.90 MΩ/cm

Overtime Adjustable, typically from 5 to approx. 30 minutes

Power Consumption 10 VA

Installation Category II

Power supply: External (fuse protected)

BL983314-0 12 Vdc

BL983314-1 115/230 Vac ; 50/60Hz

Dimensions 83 x 53 x 99 mm (3.3x2.1x3.9”)

CE DECLARATION OF CONFORMITY

WARRANTY

These instruments are warranted for two years against defects in workmanship and materials when used for their intended purpose and

maintained according to instructions. Probes are warranted for six months.

This warranty is limited to repair or replacement free of charge. Damages

due to accident, misuse, tampering or lack of prescribed maintenance are

not covered. If service is required, contact the dealer from whom you

purchased the instrument. If under warranty, report the model number,

date of purchase, serial number and the nature of the failure. If the repair

is not covered by the warranty, you will be notified of the charges incurred.

If the instrument is to be returned to Hanna Instruments, first obtain a

Returned Goods Authorization Number from the Customer Service department and then send it with shipment costs prepaid. When shipping any

instrument, make sure it is properly packaged for complete protection.

Recommendations for Users

Before using these products, make sure that they are entirely suitable for the environment

in which they are used. Operation of these instruments in residential areas could cause

unacceptable interferences to radio and TV equipment. The metal band at the end of the

probe is sensitive to electrostatic discharges. Avoid touching this metal band at all times.

During operation, ESD wrist straps should be worn to avoid possible damage to the probe by

electrostatic discharges. Any variation introduced by the user to the supplied equipment may

degrade the instrument’s EMC performance. To avoid electrical shock, do not use these

instruments when voltages at the measurement surface exceed 24 Vac or 60 Vdc. To avoid

damages or burns, do not perform any measurement in microwave ovens.

GENERAL DESCRIPTION

BL983314-0 and BL983314-1 resistivity indicators and

controllers have been designed for continuous monitoring of

process solutions.

The setpoint value can be fixed by acting on the trimmer on

the front panel, and after selection of the required limit, the

output relay allows to control an external dosing device.

Connections and wiring to probe, power supply and contacts

are made via the terminal blocks on the rear panel.

The probe is easy to clean and requires little maintenance.

Other features include: user-selectable temperature coefficient

for readings compensation, overtime control system, multicolour LED for indicating if the meter is in measurement/

dosing/alarm condition, possibility to set (Off-Auto-On switch)

dosing action mode.

Two models are available:

• BL 983314-0 powered at 12 Vdc

• BL 983314-1 powered at 115 or 230 Vac

ASSEMBLING VIEW

ACCESSORIES

HI 3314 Resistivity probe

HI 710005 12 Vdc power adapter, US plug

HI 710006 12 Vdc power adapter, European plug

HI 710012 12 Vdc power adapter, Australian plug

HI 710013 12 Vdc power adapter, South African plug

HI 710014 12 Vdc power adapter, UK plug

HI 731326 Calibration screwdriver (20 pcs)

HI 740146 Mounting brackets

Page 2

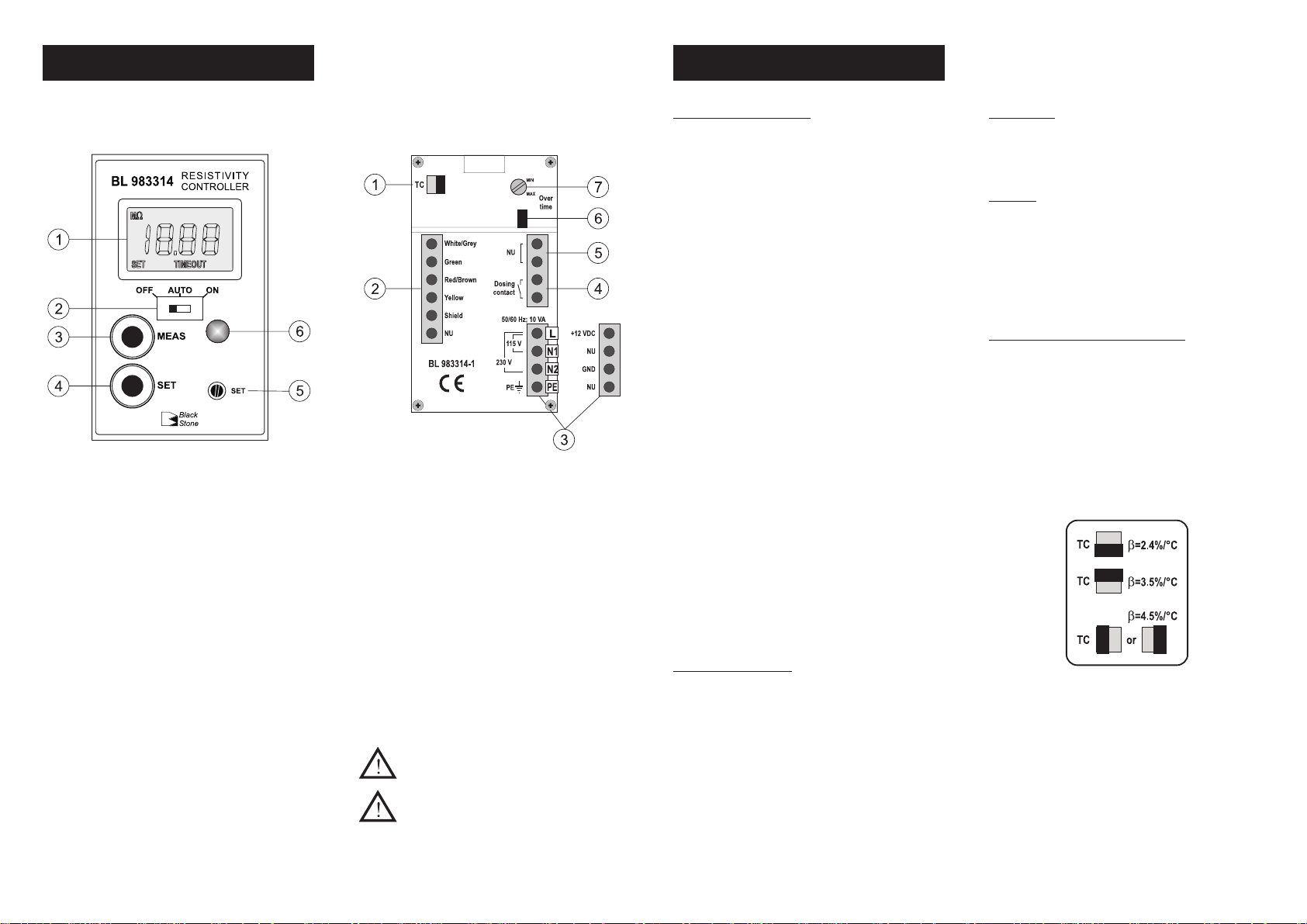

FUNCTIONAL DESCRIPTION

OPERATIONS

Front panel Rear panel

1. Liquid Crystal Display

2. Switch for selecting dosing mode:

• OFF = dosing disabled

• Auto = automatic dosage, depending on setpoint value

• ON = dosing always active

3. “MEAS” key to set the instrument to measurement mode

4. “SET” key to display and set the setpoint value

5. “SET” trimmer to adjust the setpoint value

6. 3-colour LED indicator:

• Green = meter in measurement mode

• Orange/Yellow = dosing in progress

• Red, blinking = indicates an alarm condition

1. TC jumper for selection of temperature coefficient (β)

2. Connections for HI 3314 resistivity probe

3. Power supply terminal:

• for BL983314-0 model: 12 Vdc adapter

• for BL983314-1 model: 115 Vac or 230 Vac option

4. This contact acts as a switch for driving the dosing system (e.g.

dosing pump)

5. Not used contact

6. Jumper for enabling (jumper in) or disabling (jumper

removed) the overtime control

7. Trimmer for overtime setting (typically from 5 to 30 minutes)

All external cables connected to the rear panel

should end with cable lugs.

A circuit breaker (rated 6A max.) must be

connected in close proximity to the equipment, and in a position easy to reach by the

operator, for disconnection of the instrument

and of all the devices connected to the relays.

REAR PANEL CONNECTIONS

Terminals #1: Probe

• Connect the supplied HI3314 probe by following the wires

colour indications.

Terminals #2: Power Supply

• Model BL983314-0: connect the 2 wires of a 12 Vdc

power adapter to the terminals +12 Vdc and GND.

• Model BL983314-1: connect a 3-wire power cable to the

terminals while paying attention to the correct earth (PE),

line (L) and neutral (N1 for 115 V or N2 for 230 V) contacts.

Terminals #3: Dosing Contact

• This contact drives the dosing system, accordingly to the

selected setpoint.

Note: The setpoint has a typical hysteresis value comparable

to the meter accuracy.

Terminals #4: Not Used Contact

Overtime system: jumper (#5) and trimmer (#6)

• This system allows the user to set a maximum dosing

period, by adjusting the rear trimmer from 5 (min) to

approx. 30 (max) minutes.

• When the set time is exceeded, any dosing action stops,

the LED indicator on the front panel will blink Red and the

LCD will show the “TIMEOUT” warning message. To exit

the overtime condition, set the OFF/Auto/ON switch to

“OFF” position, and then to “Auto” again.

• For disabling the overtime feature, simply remove the

jumper on the rear panel.

Note: The overtime system works only if the OFF/Auto/ON

switch is in “Auto” position.

OPERATING THE METER

Attach the resistivity probe to the meter and immerse it in

the solution to be monitored while making sure that the

metal pins are completely submerged.

Press the “MEAS” key (if necessary) and wait for a few

seconds to allow stabilization of reading.

The LCD will display the resistivity value of the solution in

MΩ/cm unit. The LED indicator will light up Green when the

meter is in measurement mode and dosing is not active,

while will light up Orange/Yellow for signaling that a dosing

action is in progress.

CALIBRATION

The meter is factory calibrated.

If recalibration is needed, please contact your dealer or the

nearest Hanna Service Center.

SETPOINT

Press the “SET” key: the display will show the default or

previously adjusted value, together with the “SET” indication.

Using a small screwdriver adjust the “SET” trimmer until the

desired setpoint value is displayed.

After 1 minute the meter automatically returns to the normal

mode; or press the “MEAS” key.

SELECTING TEMPERATURE COEFFICIENT

The reading is automatically corrected for temperature variations by using the linear compensation method:

R25=R

(1+β(t-25))

t

where Rt is the resistivity at the temperature t.

The reference temperature is 25ºC.

The coefficient β is user-selectable through the “TC” jumper on

the rear panel.

Three values are available: 2.4, 3.5 or 4.5%/ºC.

Follow the below diagram to set the desired coefficient.

Note: If the coefficient 4.5%/ºC is selected, a minimum

measurement temperature of 10ºC is suggested to

maintain the best accuracy of the meter.

ISTBL3314R2 04/05

Loading...

Loading...