Page 1

Table of contents

Service Manual

Circuit Diagrams

Adjustment Procedure

HM303-5

Y-Preamplifier CH I (YP-Board) .................................. 4

Y-Preamplifier CH II (YP-Board) ................................. 5

Y-Intermediate Amplifier and Trigger Amplifier

(YP-Board) ................................................................. 6

YPA-Board (Bottom side) .......................................... 7

YPA-Board (Top side)................................................. 8

XY-Board (X-Amplifier) ............................................... 9

XY-Board (Y-Amplifier) ............................................. 10

XY-Board (Top side) ................................................. 11

Sync.-Amplifier ........................................................ 12

Timebase ................................................................. 13

Sweep-Generator .................................................... 14

TB-Board ................................................................. 15

CRT-Board ............................................................... 16

CRT-Board (Top and Bottom side) ........................... 17

Power Supply (PS-Board) ........................................ 18

PS-Board (Bottom side) .......................................... 19

PS-Board (Top side) ................................................. 20

Component tester, Calibrator .................................. 21

CCT-Board (Top and Bottom side) ........................... 22

Front-Controlboard .................................................. 23

Front-Controlboard (Top and Bottom side) .............. 24

Adjustment procedure .......................................... 25

Interface commands ............................................. 43

St. 010998. Hüb/goRR

Subject to change without notice

1

Page 2

2

Subject to change without notice

Page 3

Technische Daten

Vertikal-Ablenkung

Betriebsarten: Kanal I oder II einzeln,

Kanal I und Kanal II alternierend oder chop.,

(Chopperfrequenz ca. 0,5MHz)

Summe oder Differenz von KI und KII,

(beide Kanäle invertierbar),

XY-Betrieb: über Kanal I und Kanal II

Frequenzbereich: 2xDC bis 35MHz (−3dB)

Anstiegszeit: <10ns

Überschwingen: ≤ 1%

Ablenkkoeffizienten: 12 kalibrierte Stellungen

von 5mV/cm bis 20V/cm (1-2-5 Teilung)

variabel 2,5:1 bis mindestens 50V/cm

Genauigkeit der kalibrierten Stellungen: ±3%

Y-Dehnung x5 (kalibriert) bis 1mV/cm ±5%

im Frequenzbereich 0 - 10MHz (–3dB)

Eingangsimpedanz: 1MΩ II 20pF

Eingangskopplung: DC-AC-GD (Ground)

Eingangsspannung: max. 400V (DC + Spitze AC)

Triggerung

Automatik (Spitzenwert):

Normal mit Level-Einstellung: DC-

LED-Anzeige für Triggereinsatz

Flankenrichtung: positiv oder negativ,

Alternierende Triggerung von KI und KII,

Quellen: Kanal I, Kanal II, Netz, extern

Kopplung: AC (10Hz bis 100MHz),

Extern: ≥0,3V

Aktiver TV-Sync-Separator (pos. und neg.)

DC (0 bis 100MHz),

LF (0 bis 1,5kHz)

ss

<20Hz-100MHz

>

100MHz (≤5mm)

von 30Hz bis 30MHz

(≤5mm)

Horizontal-Ablenkung

Zeitkoeffizienten: 20 kalibrierte Stellungen

von 0,2s/cm - 0,1µs/cm mit 1-2-5 Teilung

Genauigkeit der kalibrierten Stellungen: ±3%

variabel 2.5:1 bis max. 0,5s/cm

mit X-Mag. x10 ±5%; 10ns/cm: ±8%

Holdoff: variabel bis ca. 10:1

Bandbreite X-Verstärker: 0-3MHz (−3dB)

Eingang X-Verstärker über Kanal II,

Empfindlichkeiten wie Kanal II

X-Y Phasendifferenz: <3° unter 220kHz

Komponententester

Testspannung: ca. 6V

Teststrom: ca. 5mA

Testfrequenz: ca. 50Hz

Testkabelanschluß: 2 Steckbuchsen 4mm ∅

Prüfkreis liegt einpolig an Masse (Schutzleiter)

(Leerlauf)

eff

(Kurzschluß)

eff

Verschiedenes

Röhre: D14-364GY/123 oder ER151-GH/-,

Rechteckform (8x10cm), Innenraster

Beschleunigungsspannung: ca. 2000V

Strahldrehung: auf Frontseite einstellbar

Kalibrator: Rechteckgenerator (t

≈1kHz / 1MHz; Ausgang: 0,2V ±1% und 2V

Netzanschluß: 100-240V ~±10%, 50/60Hz

Leistungsaufnahme: ca. 36 Watt bei 50Hz

Zul. Umgebungstemperatur: 0°C...+40°C

Schutzart: Schutzklasse I (IEC1010-1/VDE 0411)

Gewicht: ca. 5,6kg, Farbe: techno-braun

Gehäuse: B 285, H 125, T 380 mm

Mit verstellbarem Aufstell-Tragegriff

<4ns)

a

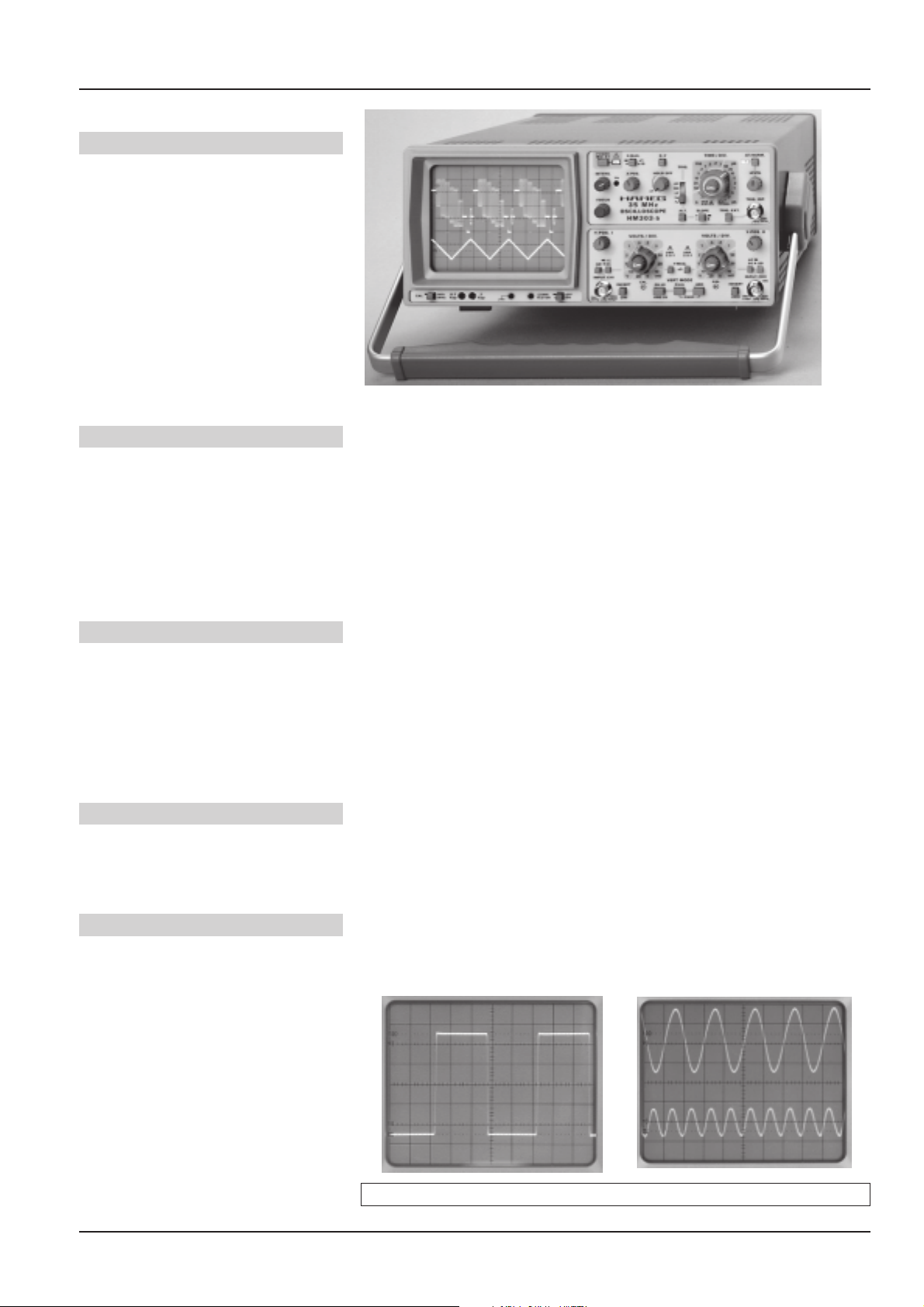

35MHz Standard Oszilloskop HM 303

,

Vertikal: 2 Kanäle, 5mV – 50V/cm, mit Dehnung x5 ab 1mV/cm

Zeitbasis: 0.5s – 0,1µs/cm, mit Dehnung x10 bis 10ns/cm

Triggerung: DC – 100MHz, TV-Sync-Separator, Altern. Triggerung

Komponenten-Tester, 1kHz/1MHz Kalibrator

Der neue HM303 ist der Nachfolger des bisher weltweit mehr als 180000mal

verkauften HM203. Wesentliche Neuerungen betreffen vor allem die Erhöhung

der Bandbreite von 20 auf 35MHz, die Erweiterung des horizontalen Ablenkbereiches bis max. 10ns/cm und eine nochmalige Verbesserung der schon seit

Jahren einzigartigen Triggerung. In seiner jetzigen Ausführung eignet sich der

HM303 f ür die Darstellung von Signalen im Frequenzbereich von DC bis ca. 100

MHz.

Ein wesentliches Qualitätsmerkmal dieses Oszilloskops ist vor allem die

hohe Übertragungsgüte der Meßverstärker mit max. 1% Überschwingen.

Damit diese – von der Tastspitze bis zum Bildschirm – ständig kontrollierbar ist,

besitzt der HM303 als erster seiner Preisklasse einen Kalibrator mit geringer

Anstiegszeit.

Wirklich außergewöhnlich ist die Triggerung des HM303. Bereits ab 5mm

Bildhöhe kann sie noch Signale bis über 100MHz triggern. Für die exakte

Darstellung von TV-Signalen wird ein aktiver Sync-Separator verwendet. In

alternierender Betriebsart ist auch die Triggerung von zwei Signalen mit

unterschiedlicher Frequenz möglich. Wie sein Vorgänger ist das Gerät ebenfalls

mit dem bewährten Komponententester ausgestattet. Seine Meßspannung ist

jetzt amplitudenstabilisiert. Vorbildlich ist auch die Stromversorgung. Das eingebaute Schaltnetzteil arbeitet ohne Netzspannungsumschaltung immer mit dem

geringstmöglichen Leistungsverbrauch. Gegen magnetische Einwirkungen von

außen ist die Strahlröhre des HM303 mit Mumetall abgeschirmt.

Alles in allem hat HAMEG mit diesem Gerät wieder einmal Maßstäbe

gesetzt, die entsprechend seinem Preis-/Leistungs-Standard einfach beispiellos

sind. Kenner werden von den Eigenschaften des neuen HM303 begeistert sein.

Foto: 1MHz Rechteck-Signal

Foto: 50MHz und 100MHz Sinus-Signal

mit alternierender Triggerung

Subject to change without notice

01/98

Inkl. Zubehör: Netzkabel, Betriebsanleitung, 2 Tastköpfe 1:1/10:1

3

Page 4

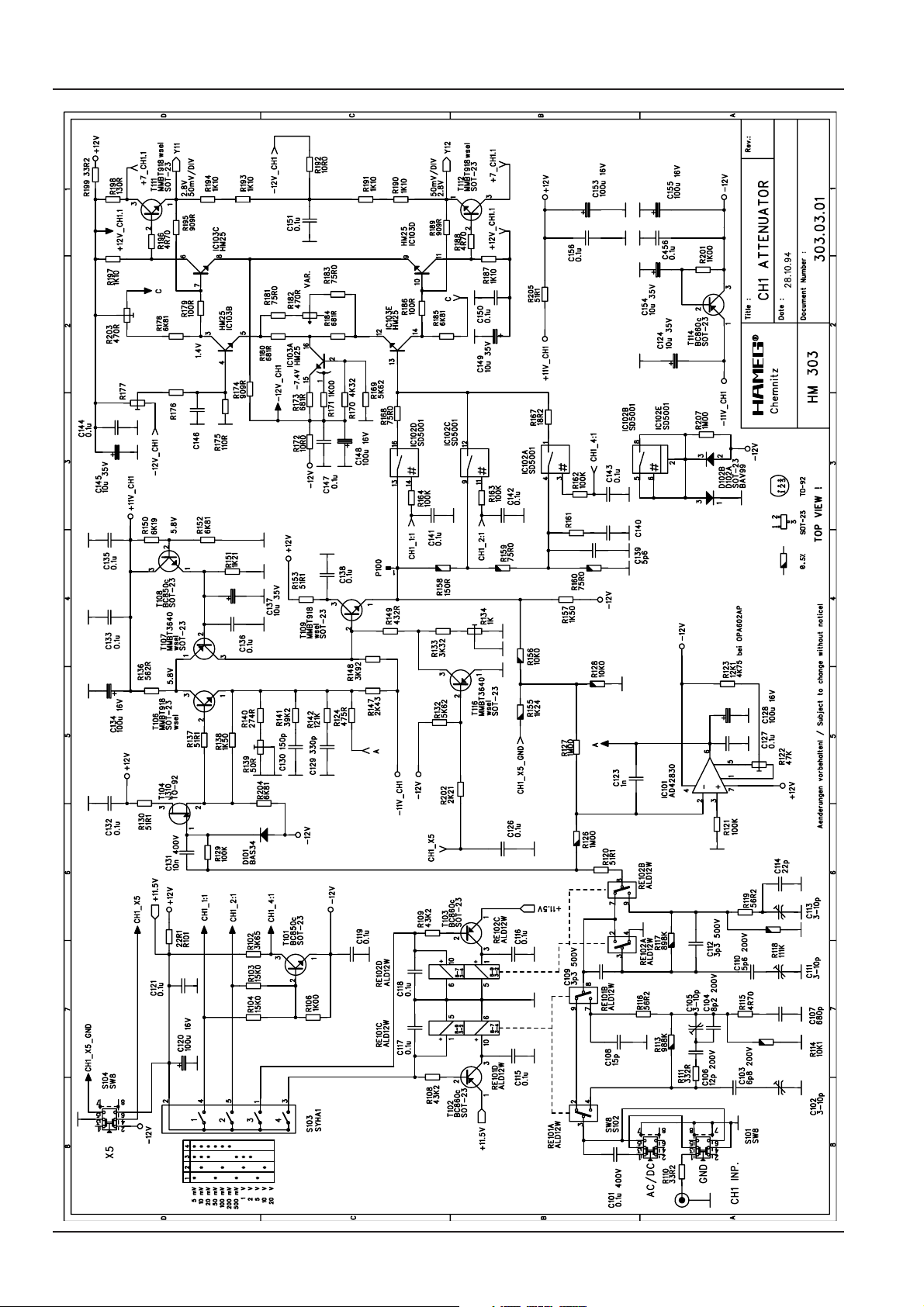

Y-Preamplifier CH I (YP-Board)

4

Subject to change without notice

Page 5

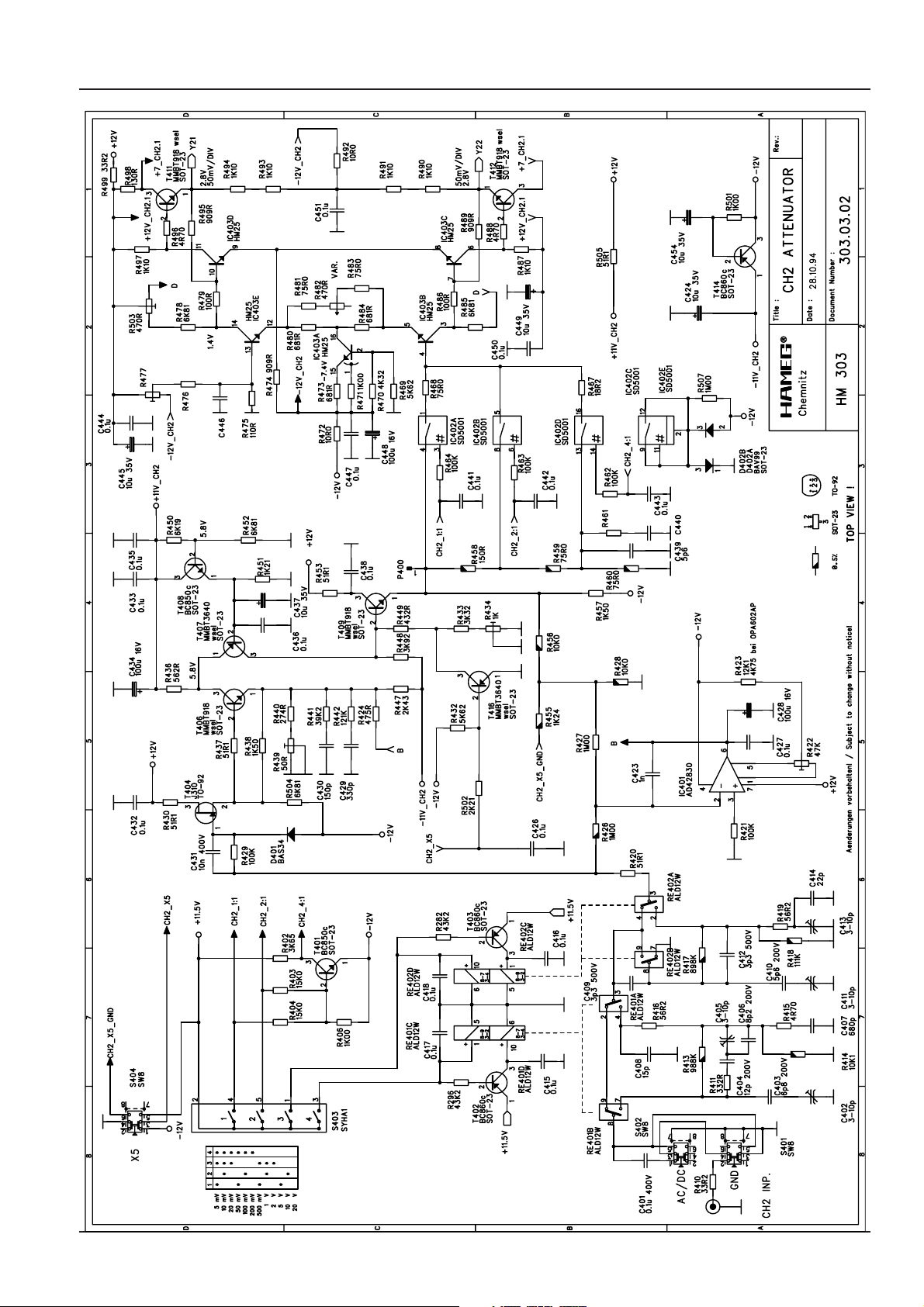

Y-Preamplifier CH II (YP-Board)

Subject to change without notice

5

Page 6

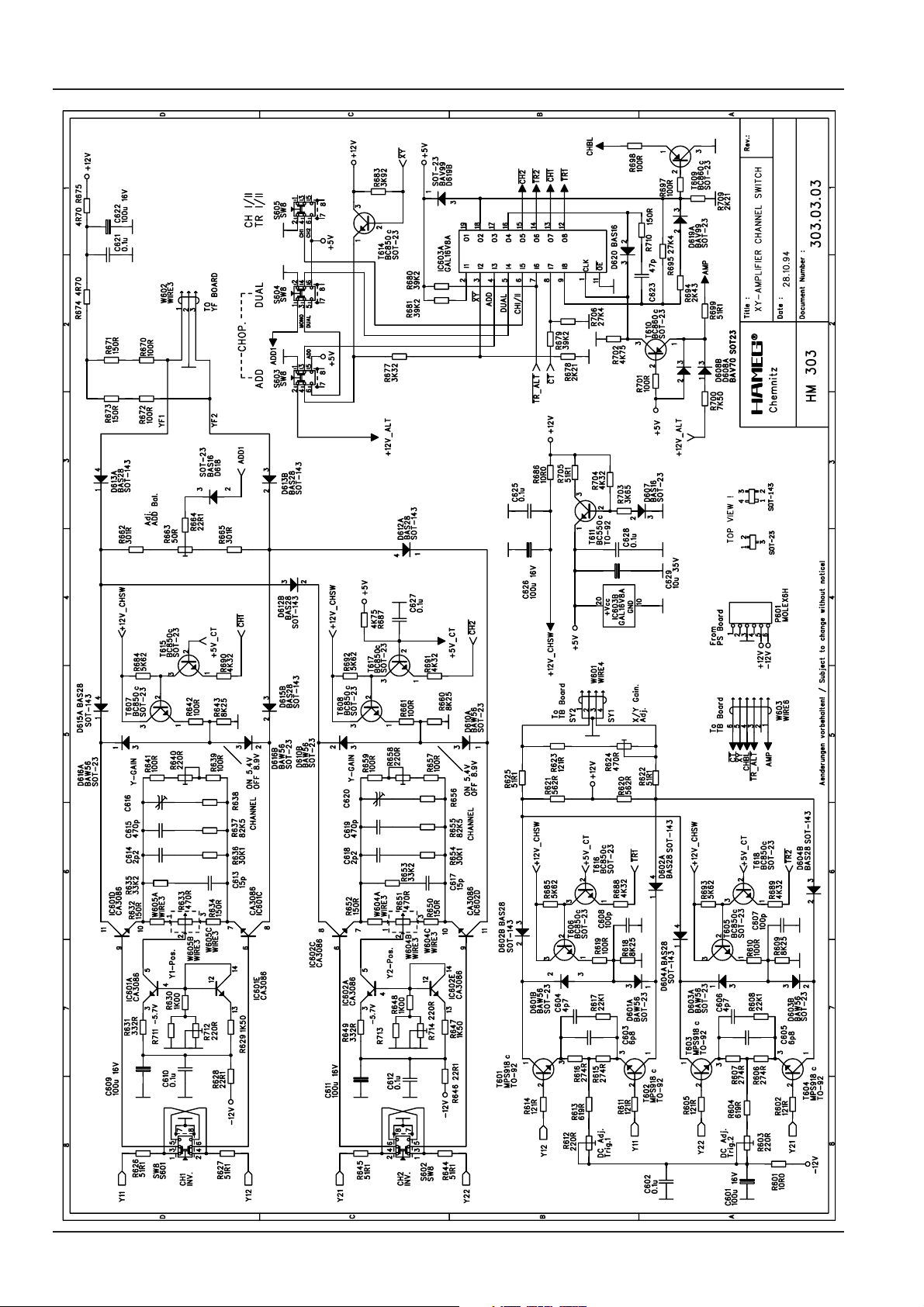

Y-Intermediate Amplifier and Trigger Amplifier (YP-Board)

6

Subject to change without notice

Page 7

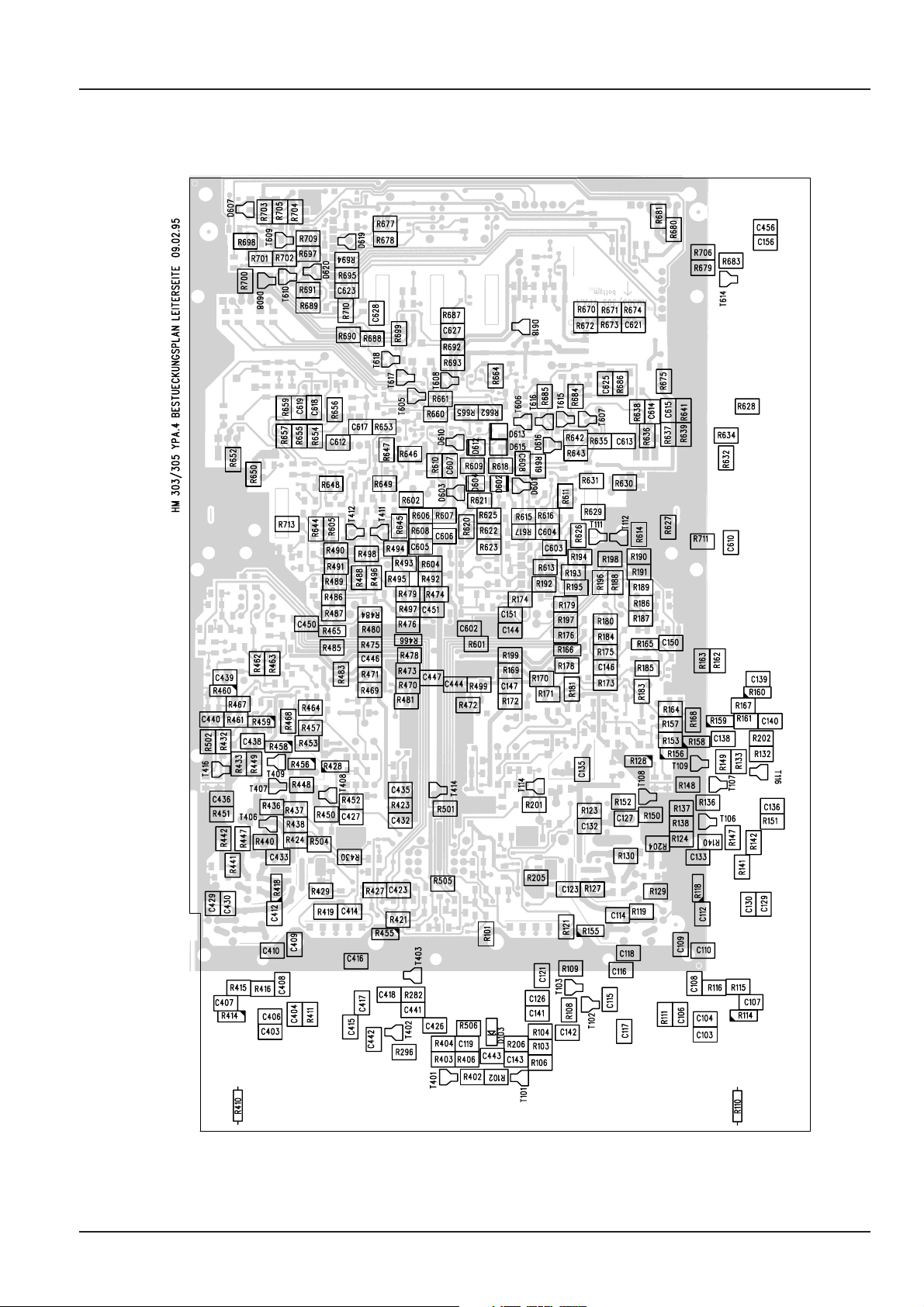

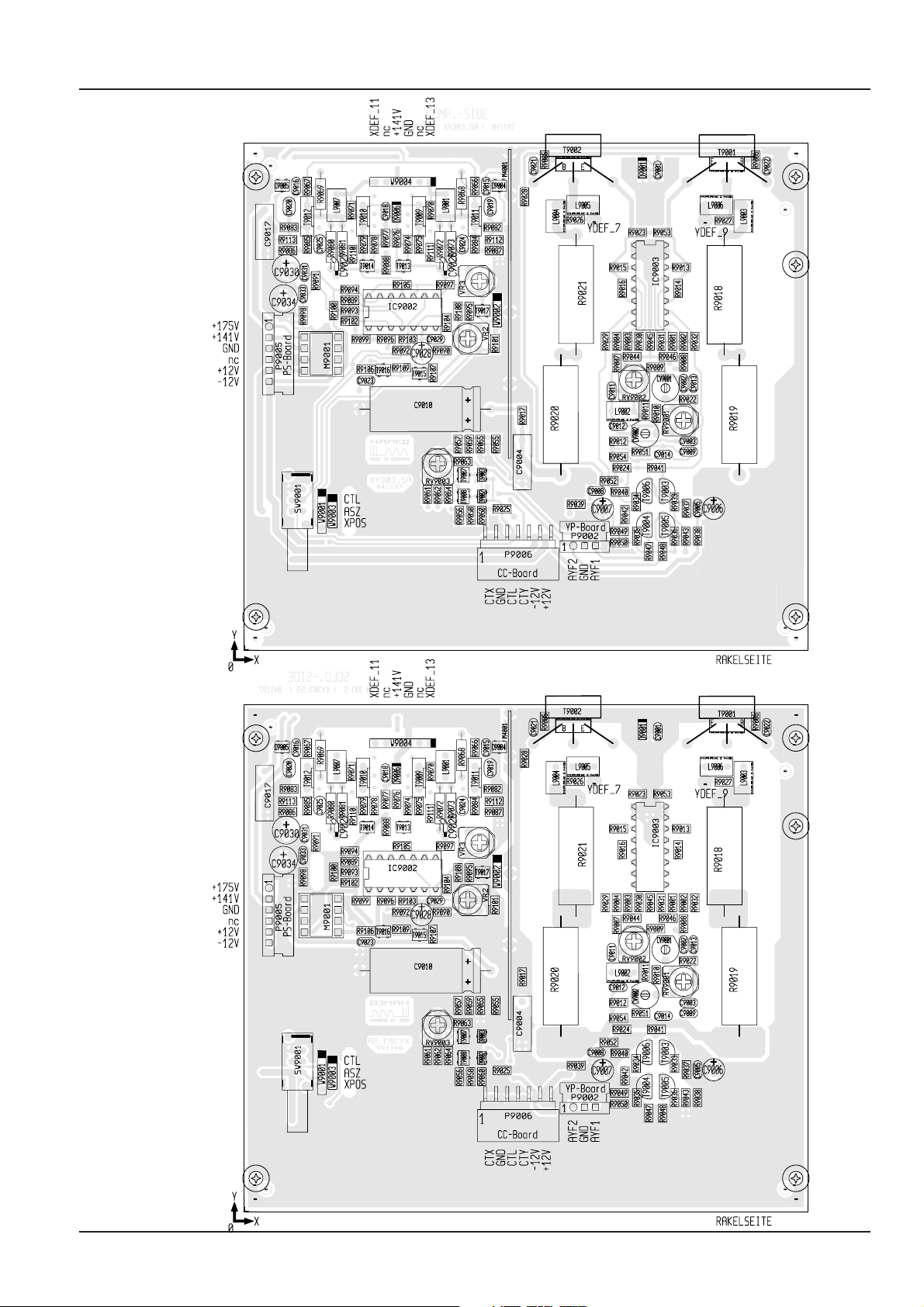

YPA-Board (Bottom side)

Subject to change without notice

7

Page 8

YPA-Board (Top side)

8

Subject to change without notice

Page 9

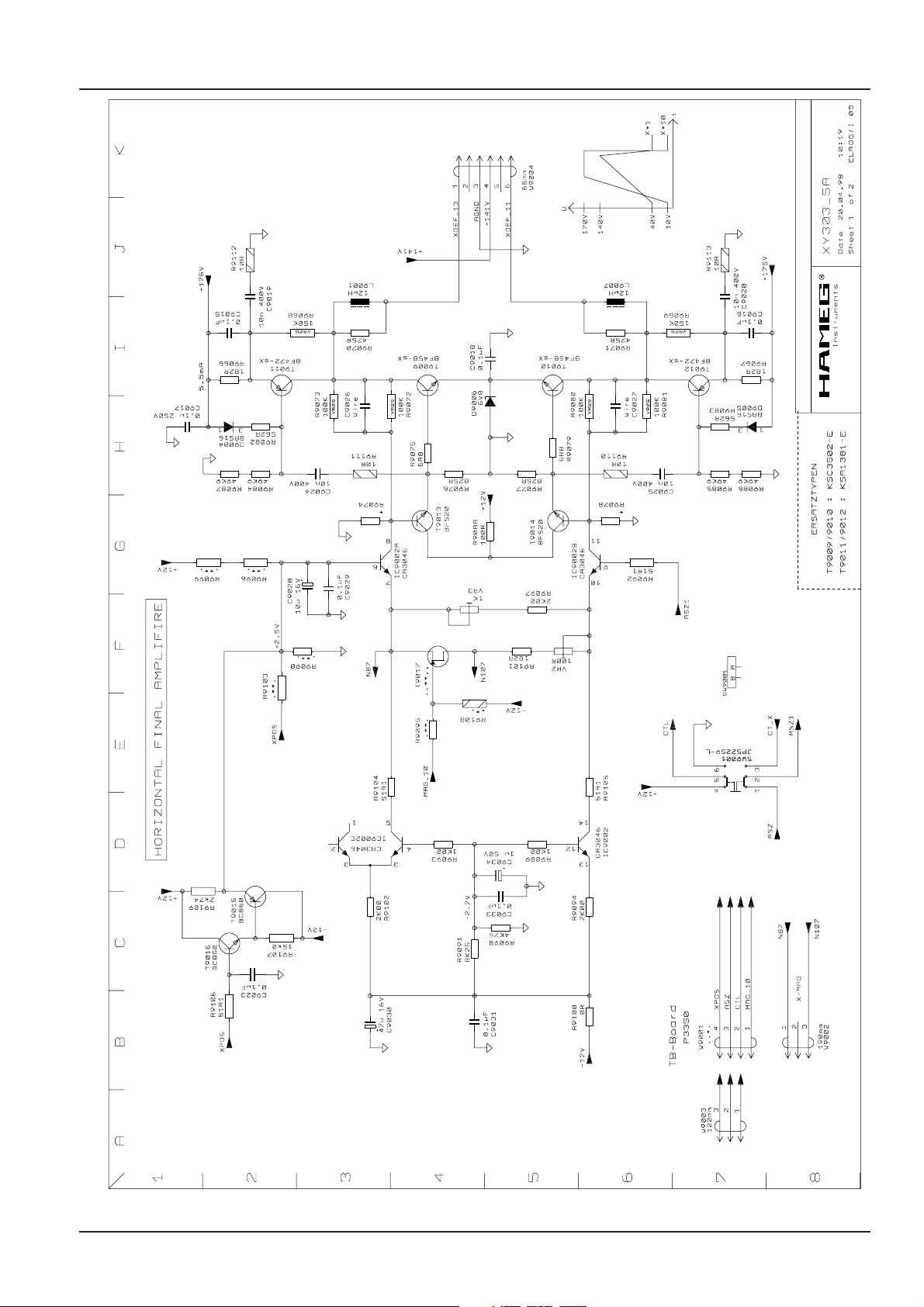

XY- Amplifier

Subject to change without notice

9

Page 10

XY Board (Y Amplifier)

10

Subject to change without notice

Page 11

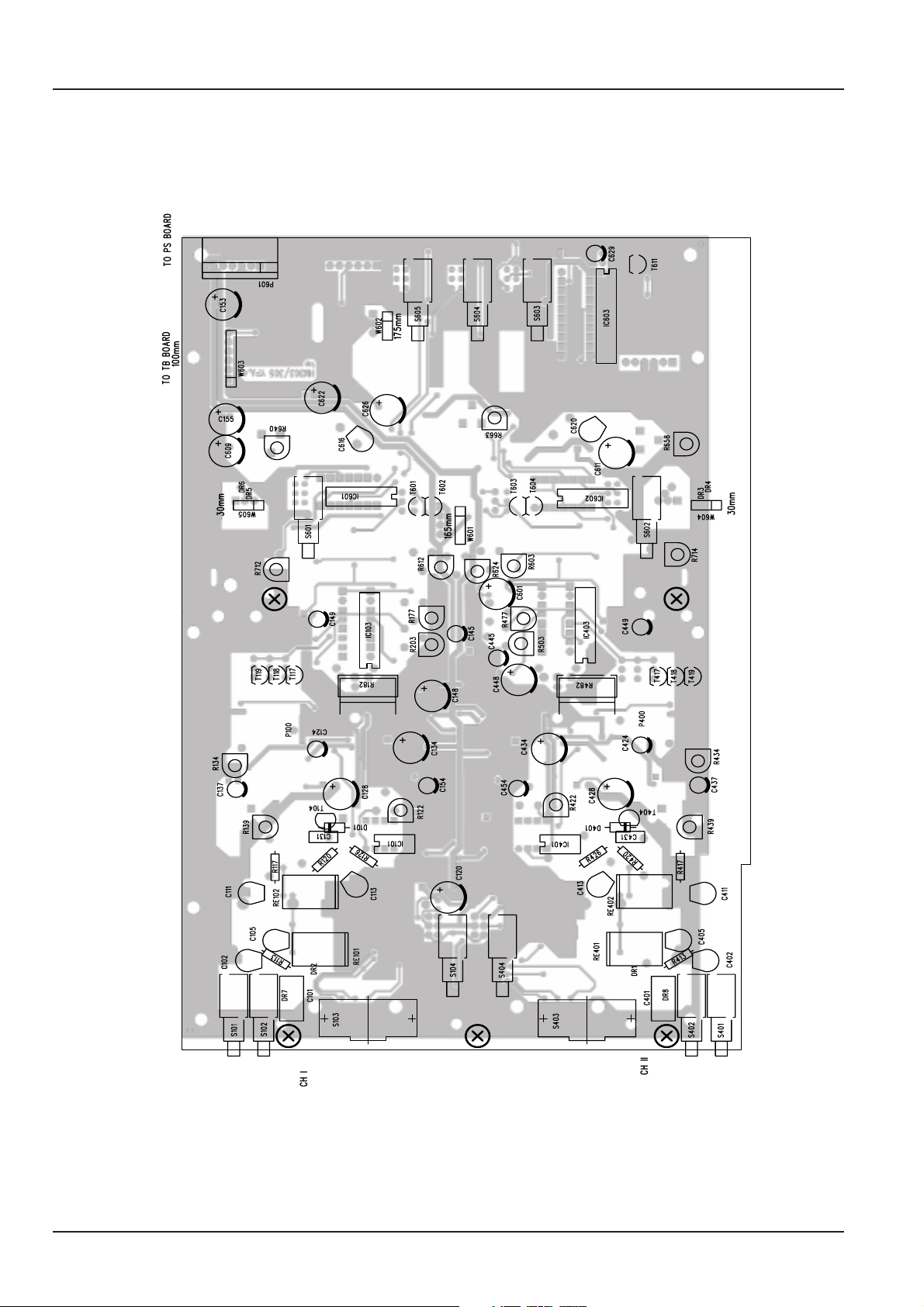

XY Board (Top and Bottom side)

Subject to change without notice

11

Page 12

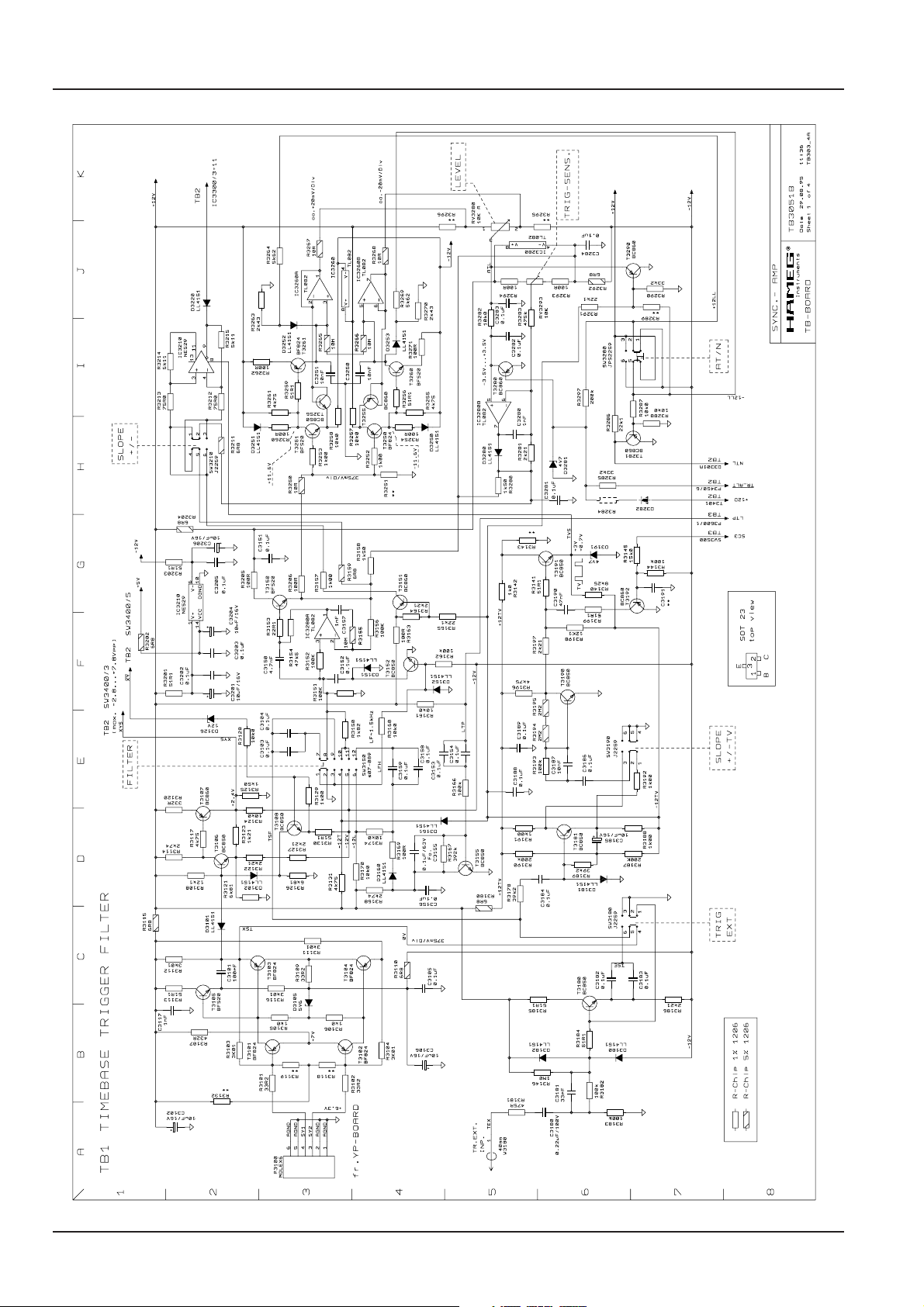

Sync.- Amplifier

12

Subject to change without notice

Page 13

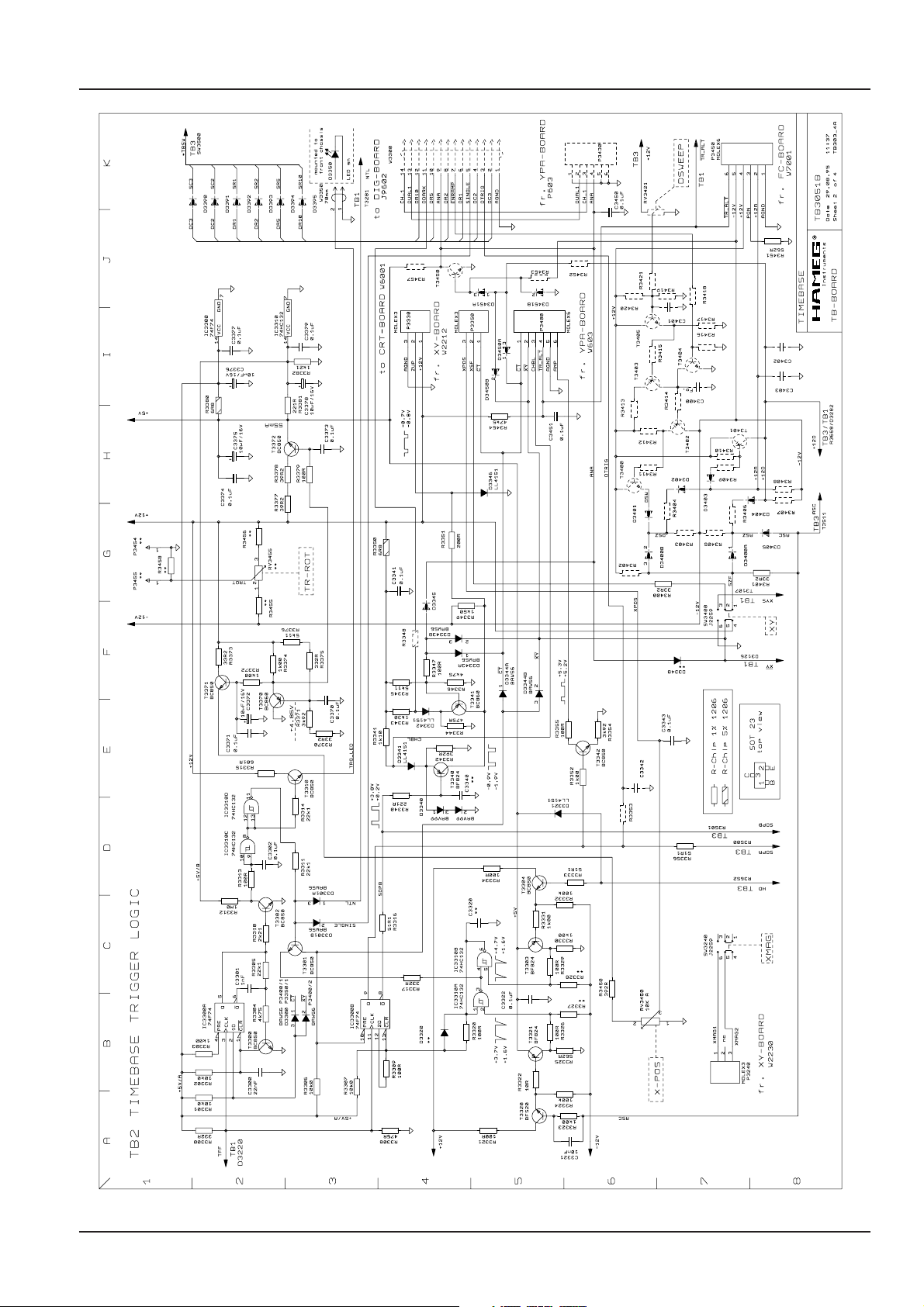

Timebase

Subject to change without notice

13

Page 14

Sweep- Generator

14

Subject to change without notice

Page 15

TB Board

Subject to change without notice

15

Page 16

CRT- Board

16

Subject to change without notice

Page 17

CRT Board (Top and Bottom side)

Subject to change without notice

17

Page 18

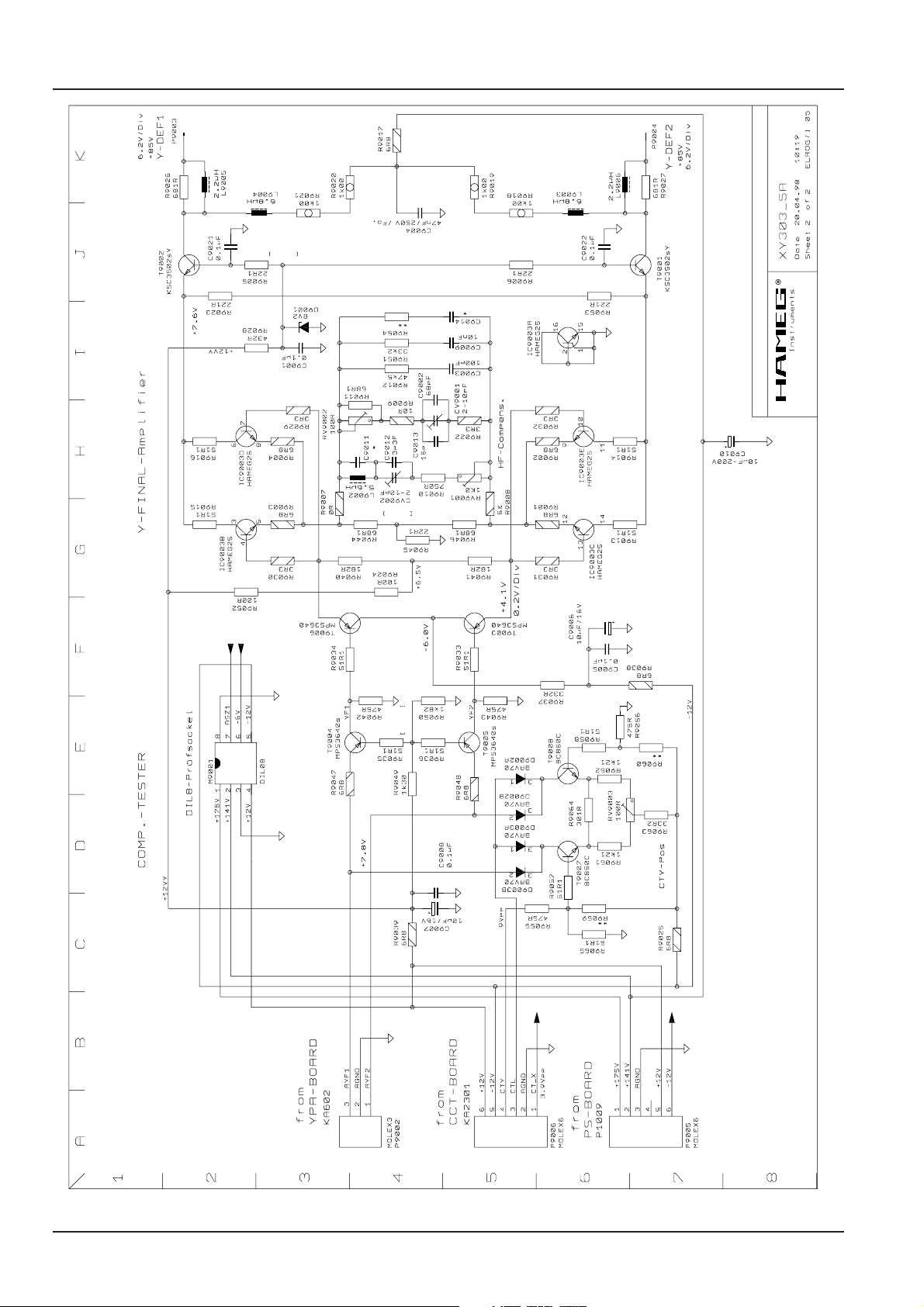

Power Supply (PS-Board)

+12V

9

MPT

B1011

2

1

5

MPT

C1036

10u 250V

L1007

68uH 1.5A

BYD37M

D1020

6

+

1K0

R1016

R1070

D1023

LL4151

T1004

R1066

+185V

6

MPT

L1006

BYD37M

D1021

100u 16V

C1032

C1045

1K00

R1063

TO-126

BD434

3

3

7K50

+141V

+

+

68uH 1.5A

7

0.1u 50V

2k21

2

c

T1012

BC850

C1030

10u 250V

+

+

C1028

22u 160V

D

R1072

3K32

IC1005

1

SOT-23

C1037

0.1u 250V

C1031

22u 160V

1K0

R1071

3

21

TO-92A

TL431C

619R

R1062

MKT

7

MPT

L1005

8

+12V

C1029

+13.5V

+

68uH 1.5A

C1026

+

D1004

BYV27-100

9

R1061

10K0

R1054

3K01

D1015

LL4151

R1053

619R

1000u 16V

330u 25V

8

IC1004A

TL082CN

R1055

1

T1008

c

T1010

BC850

SOT-23

3

+

1

511R

2

c

BC860

31

C1046

0.1u 50V

2

-

3

SOT-23

2

10

100u 16V

C1034

+

R1056

10K0

C1042

T1002

3

R1043

R1052

C1023

+

C1022

+

C

-12V

1n 50V

21

TO-126

BD433

7K50

R1014

511R

1000u 16V

L1004

330u 25V

10

MPT

12K1

R1051

0R39

8

MPT

-13.5V

68uH 1.5A

BYV27-100

D1003

13

MPT

P1002

12

MPT

HT1

D1009

BYD37M

MOLEX6S

1

2

HT1

BLV

3

+

R1022

+

4

G1

C1009

6

5

HT14

-1950V

100u 35V

1K82

R1073

100u 16V

C1015

BLV

31V

BYT01-400

D1012

21

16

MPT

C1038

R1025

11

MPT

2

R1074

27k4

1K0

HT14

31

75K

+

1u 50V

R207

WIRE6

P1003

P1010

WIRE6

6.3V

20

T1006

BF822

R1029

3

2

C1016

12345

1

2

BYD37M

D1014

19

FOKUS

1M00

B1001

1

T1005

R1006

470K

0.1u 100V

6

6

3

4

5

DD1400

D1016

B

C1007

R1024

LL4151

D1005

c

BC860

SOT-23

D1010

13

10n 400V

1M00

R1036

R1003

470K

R1004

BZV55C75

HVC

-2025V

1M00

R1028

750K

R1023

750K

C1010

0.1u 100V

470K

14

MPT

141516

17

R1042

-1950V

15

MPT

G1

C1019

10n 2kV

17

MPT

DD1400

D1024

750K

R1007

1M00

C1043

R1041

R1040

0R0

VR37

R1012

6M81

C1024

68p 3KV

10n 50V

475K

10K0

R1027

R1044

3

1M00

750K

R1058

5

6

+

7

475K

2

BYD37M

D1027

DD1400

D1025

R1034

R1064

-

IC1004B

TL082CN

R1057

4K32

T1007

BF822

1

C1018

10n 400V

18

10M0

VR37

47K5

D1018

LL4151

R1067

1K00

R1046

22K1

SOT-23

BYD37M

D1026

R1011

C1004

47n 2kV

R1069

8K25

A

+12V

WIRE6

P1008

P1009

WIRE6

Title : Rev.:

6

+185V

6

R

5

+141V

5

2

3

4

2

3

4

Date :

Document Number :

1

+12V

-12V

1

12345678

BYD77G

D1022

D1017

220p 400V

C1027

D1019

BYD77G

BYD37M

5

DR1001

ETD39/303

4

B1010

R1018

R1065

1K3

1K3

R1068

100K

411

10n 400V

MKT

C1035

R1017

C1033

0.1u 400V

MKT

100K

411

R1047

R207

56K2

R1013

R1049

200K

R1037

332K

301K

R1050

1

+

C1025

68u 400V

+

3

2

D1001

R1048

68u 400V

C1011

FL406

F1001

0.5AF

L1003

220uH 1A

1

MPT

87654321

C1001

4700p

Y 250V

D

8K25

1

D1006

LL4151

5

1K00

R1019

LINE

4

0.1u

C1002

X2 250V

3

MPT

STHV82FI

T1003

1

2

22K1

B1007

IC1001

6

32

14

L1001

2x33mH 1A

C1021

100p 2kV

32

1

c

ISOWATT 218

T1009

BC860

SOT-23

3

2

3

T1011

BC850c

2

4

C1005

2200p

Y 250V

C

R1015

R1059

1K00

1

SOT-23

2

CNY17-2Z

R1021

R1031

200K

0.33u

C1003

X2 250V

2W

0R22

C1044

C1039

4n7 50V

T1001

BUX86

3

75K

R1001

U

R1005

R1060

4K99

1n 50V

TO-126

1

R1020

NTC 8

S14K275

1

2

MPT

R1030

75K

D1013

LL4151

R1035

22R

12.9V

681R

VR37

R1002

3

332K

2

3

6

R1010

90R9

R207

C1006

R1009

R1045

10K0

851

IC1003

2200p

Y 250V

90R9

R207

D1011

BAS20

1K0

R1008

R1033

R1026

R1032

R1038

D1007

BZV55B16

B

23

1K82

47K5

5K11

0R0

S1001

2

3

IC1002

21

4

0.4V

4

7

NT

C1012

+

C1017

1u 50V

TO-92A

TL431C

MPT

R1039

+

1n 250V

200R

C1040

0.1u 50V

C1041

0.1u 50V

C1020

220u 16V

P1001

Power Recept.

P1005

+13.5V

B1013

A

WIRE6

6

B1003

LINE

8

5

+Vcc

3

4

IC1004C

-12V

+12V

1

2

B1009

B1008

-12V

+12V

4

-Vcc

TL082CN

-13.5V

18

Subject to change without notice

Page 19

PS-Board (Top side)

Subject to change without notice

19

Page 20

PS Board (Bottom side)

20

Subject to change without notice

Page 21

Component tester, Calibrator

Subject to change without notice

21

Page 22

CCT Board (Top and Bottom side)

22

Subject to change without notice

Page 23

Front- control board

Subject to change without notice

23

Page 24

Front Control board (Top and Bottomside)

24

Subject to change without notice

Page 25

Adjustment

Procedure

Subject to change without notice

25

Page 26

ADJUSTMENT PROCEDURE

30MHz Standard Oscilloscope HM303-5

WARNING

The Instrument must be disconnected from the mains power supply whenever you open

the case, repair or exchange parts.

HIGH VOLTAGE WARNING!

Hazardous High Voltage of up to 2,000 Volts is present inside this Instrument. The areas particularly

affected by High Voltage are the high voltage circuit on the PS-board, the CRT-board and the CRTsocket.

SERVICE AND ADJUSTMENT

• of this instrument should only be performed in accordance and in conjunction with the operating

manual and the WARNINGS contained therein.

• should only be performed by suitable qualified and experienced service personnel, or should be

referred to one of the HAMEG companies listed on the rear cover of the manual.

Test Instruments required:

1) Scope Tester HZ60-2.

2) Constant amplitude sinewave generator, 20Hz - 250MHz, output 5mV - 5V into 50Ω,

preferably with 20dB attenuation (e.g. HM8133, TEK SG502 + TEK SG503).

3) Amplitude Calibrator with 1kHz squarewave output and 600Ω impedance, risetime faster than

150ns.Output voltage 2mV - 20Volts in 1-2-5 sequence for 4 divisions display amplitude

(e.g. HZ62, TEK PG506).

4) Time mark generator from 5ns/div to 5s/div. Output min. 10mV into 50Ω

(e.g. HZ62, TEK TG501).

5) Pre-attenuator 2:1 (1MΩ , 12-48pF), e.g. HZ20.

6) 50Ω BNC through termination, e.g. HZ22.

7) 2 BNC-cables, 50Ω, e.g. HZ34.

8) BNC-T-connector.

9) Oscilloscope probe 10:1, with exactly 9MΩ series resistance and compensated

for test oscilloscope mentioned under 10).

10) Oscilloscope 100MHz, 5mV/div to 5V/div, e.g. HM1005.

11) Trimming/adjusting tool.

12) Variable output safety insulation transformer.

13) Video signal generator with positive and negative signal output.

14) Yt-EPROM HM1007.

26

This procedure covers all adjustments and the most important - but not all - performance checks.

The correct sequence of all adjustment steps must be strictly followed.

Exact adjustment is only possible when any influence of the earths‘ magnetic field has been

compensated with the trimmer marked TR (trace rotation).

All adjustments should only be performed by qualified and experienced personnel. This is particularly

important for adjustments in the high voltage section of the instrument.

Subject to change without notice

Page 27

Table of Contents

(1) R1008: +141 Volt supply............................................................................. 29

(2) R1016: +12 Volt supply............................................................................... 29

(3) VR7000: Trace Rotation Check. .................................................................. 29

(4) R1004 : CRT minimum intensity................................................................. 29

(5) R712RT maximum intensity........................................................................ 29

(6) R712: Mean Y-plate Potential Channel I. .................................................... 29

(7) R714: Mean Y-plate Potential Channel II. ................................................... 29

(8) RV6021 : Astigmatism correction. .............................................................. 31

(9) R640: Y-Gain CH I. ...................................................................................... 31

(10) R122: FET operating point CH I. ................................................................. 31

(11) R203: Invert-Balance CH I. ......................................................................... 31

(12) R177: Variable-Balance CH I. ...................................................................... 31

(13) R139: 100Hz Squarewave 5mV/div CH I. ................................................... 32

(14) R134: 100Hz Squarewave 1mV/div Adjustment CH I. ............................... 33

(15) R658: Y-Gain CH II. ..................................................................................... 33

(16) R422: FET operating point CH II. ................................................................ 33

(17) R503: Invert-Balance CH II. ........................................................................ 33

(18) R477: Variable-Balance CH II. ..................................................................... 33

(19) R439: 100Hz Squarewave 5mV/div CH II. .................................................. 33

(20) R434: 100Hz Squarewave 1mV/div CH II. .................................................. 33

(21) RV2005 (A), RV2006 (C), CV2000 (D) and CV2001 (B): Y-Final Amplifier. .. 35

(22) Y-Amplifier Bandwidth Check. .................................................................... 35

(23) C113/111/102/105: Attenuator Compensation CH I. .................................. 35

(24) C413/411/402/405: Attenuator Compensation CH II. ................................. 35

(25) R663: ADDition/Offset................................................................................ 37

(26) RV2417 (A), RV2418 (B): Overscan. ........................................................... 37

(27) RV3519: Sweep start voltage. .................................................................... 37

(28) RV2225: X-Magnification x1. ...................................................................... 37

(29) RV2260: X-Symmetry. ................................................................................ 37

(30) RV3591 (A)/3589 (C), CV3511 (B): Time base. ........................................... 37

(31) RV2234: X-Magnification x10. .................................................................... 39

(32) R624: XY-Gain ............................................................................................. 39

(33) RV3293: Trigger-Symmetry......................................................................... 39

(34) R612: DC-Triggering CH I. .......................................................................... 39

(35) R603: DC-Triggering CH II. ......................................................................... 39

(36) RV2301 (A), 4322 (B): Component Tester Y-Position and Tilt. .................... 41

(37) VR8940: Calibrator Output. ........................................................................ 41

(38) Trigger Filter Check. .................................................................................... 41

(39) Triggerbandwidth Check. ............................................................................ 41

(40) External Trigger Check................................................................................ 41

(41) Video Trigger Check. ................................................................................... 42

NOTE

The adjustment procedures assume that the instrument had once been properly adjusted in the

factory and adjustments are required due to temperature drift or the replacement of defective

components.

Before starting each adjustment procedure, set the oscilloscope to the following basic settings:

• Press POWER pushbutton (in!).

• Release all other pushbuttons (out!) except AC/DC input coupling.

• Rotate the three variable controls (TIME/DIV. and VOLTS/DIV.) to

• Set TIME/DIV. switch to 50µs/div.

• Set both VOLTS/DIV switches to 5mV/div.

• Rotate the HOLD OFF knob fully counterclockwise.

• Trigger coupling set to AC.

• Set all other controls to their midrange positions.

If different settings are required, they are mentioned particularly for each subject.

Subject to change without notice

their (calibrated) detent positions.

27

Page 28

PS-Board

3

Front panel

1

7

2

YPA-Board

6

PS-Board XY-Board

28

5

4

Pin 2 Pin 4

Subject to change without notice

Page 29

(1) R1008: +141 Volt supply.

WARNING: To avoid damage use a fully insulated screwdriver!

Locate and identify R1008 (1) on PS-Board (screened section).

Locate 8 pole checkpoint socket on XY-Board and identify pin 2.

Adjust R1008 (1) for exactly +141Volts (± 0.1 Volt).

(2) R1016: +12 Volt supply.

Locate and identify R1016 (2) on PS-Board.

Locate 8 pole checkpoint socket on XY-Board and identify pin 4.

Adjust R1016 (2) for exactly +12Volts (± 10mV). All other voltages +185V (pin 1), -12V (pin 5)

and -1950V on cathode of CRT depend on the correct +12 Volt adjustment. All these

voltages must be checked and verified.

(3) VR7000: Trace Rotation Check.

Locate and identify VR703 (3) „TR“ on the front panel.

Using Y-Pos.I and X-Pos. controls, move baseline to the center of the graticule.

Press channel I GD pushbutton (in!).

When turning VR703 (3), check that the range of inclination of the baseline is at least 1mm at both

horizontal limits of the graticule.

Readjust baseline exactly parallel to the horizontal center line of the graticule.

(4) R1004 : CRT minimum intensity.

Locate and identify R1004 (4) on PS-Board.

Set INTENS. control to fully left position.

Press XY pushbutton (in!).

Adjust R1004 (4) so that the dot just disappears.

Release XY pushbutton.

(5) R1003 : CRT maximum intensity.

Locate and identify R1003 (5) on PS-Board.

Set INTENS. control to fully right position.

Set FOCUS knob on the front panel for optimum sharpness.

Adjust R1004 (5) so that the beam diameter is 1.5mm.

Repeat adjustment 4 and 5 until optimum is obtained!

(6) R712: Mean Y-plate Potential Channel I.

Locate and identify R712 (6) on YPA-Board.

Press DUAL pushbutton (in!).

Set both beams to the horizontal center line of the graticule by using Y-position I and II knobs

on the front panel. The Y-position knob settings must not be changed during the following

procedure until item 7) is finished.

Release DUAL pushbutton (out!).

Switch the oscilloscope OFF.

Locate and identify both lines from the Y-final amplifier to the Y-plates of the CRT.

Connect both lines (short)galvanically.

Switch the oscilloscope ON.

Measure the DC voltage at the Y-plates in respect to ground.

Adjust R712 (6) for +85Volt Y-plate voltage.

Note: Do not remove the short at the Y-plates until item 7) is finished.

(7) R714: Mean Y-plate Potential Channel II.

Note: Do not start item 7) until item 6) is finished.

Locate and identify R714 (7) on YPA-Board.

Press CHI/II pushbutton (in!) for channel II mode.

Measure the DC voltage at the Y-plates in respect to ground.

Adjust R714 (7) for +85Volt Y-plate voltage.

Switch the oscilloscope OFF.

Remove the connection between both Y-plates.

Switch the oscilloscope ON.

Subject to change without notice

29

Page 30

7

12

11 9

YPA-Board

30

10

PS-Board

8

Subject to change without notice

Page 31

(8) RV6021 : Astigmatism correction.

Locate and identify RV6021 (8) on CRT-Board.

Connect a 1MHz squarewave signal with 25mVpp at 50Ω (HZ22) to input CHI.

Set time base to 0.1µs/div.

Adjust FOCUS control for optimum sharpness.

Adjust RV6021 (8) until leading edge and top of signal have equal sharpness.

Recheck range of FOCUS control.

Adjust FOCUS control for optimum sharpness.

(9) R640: Y-Gain CH I.

Locate and identify R640 (9) on YPA-Board.

Connect a 25mV/1kHz squarewave signal via 50Ω cable and 50Ω through terminator

to input channel I.

Set time base to 1ms/div.

Adjust R640 (9) for 5 division signal height.

(10) R122: FET operating point CH I.

Locate and identify R122 (10) in CH I section of the YPA-Board.

Release all pushbuttons (out!) for channel I mode.

Press Y x5 channel I (in!) for 1mV/div.

Press GD pushbutton channel I (in!).

Switch the attenuator channel I constantly between 5mV/div (1mV) and 10mV/div (2mV).

Adjust R122 (10) until no Y-position change occurs.

Do not change the operating conditions.

(11) R203: Invert-Balance CH I.

Press GD pushbutton channel I (in!).

Press Y x5 channel I (in!) for 1mV/div.

Using Y-POS.I control set trace to the horizontal center line.

Locate and identify R203 (11) on YPA-Board.

Adjust R203 (11) so that the baseline will not move, when pressing and releasing the

INVERT CH I pushbutton.

(12) R177: Variable-Balance CH I.

Locate and identify VR177 (12) in CH I section of the YPA-Board.

Press channel I Y-MAG. x5 pushbutton for 1mV/div.

Press channel I GD pushbutton (in!).

Adjust VR177 (12) so that the baseline will not move when turning the channel I Y-variable

control through the entire range.

Check adjustment 11) again and repeat it if required.

Subject to change without notice

31

Page 32

181715

YPA-Board

20

19

16 13

(13) R139: 100Hz Squarewave 5mV/div CH I.

Locate and identify R139 (13) in CH I section of the YPA-Board.

Connect a 25mV/100Hz squarewave signal via 50Ω cable and 50Ω through

terminator to input channel I.

Set time base to 2ms/div.

Check that DC input coupling is selected.

Adjust R139 (13) for flat top.

14

32

Subject to change without notice

Page 33

(14) R134: 100Hz Squarewave 1mV/div Adjustment CH I.

Locate and identify R134 (14) in CH I section of the YPA-Board.

Connect a 5mV/100Hz squarewave signal via 50Ω cable and 50Ω through

terminator to input channel I.

Press Yx5 channel I (in!) for 1mV/div.

Set time base to 2ms/div.

Check that DC input coupling is selected.

Adjust R134 (14) for flat top.

(15) R658: Y-Gain CH II.

Locate and identify R658 (15) on YPA-Board.

Connect a 25mV/1kHz squarewave signal via 50Ω cable and 50Ω through

terminator to input channel II.

Check that DC input coupling is selected.

Set time base to 1ms/div.

Adjust R658 (15) for 5 division signal height.

(16) R422: FET operating point CH II.

Locate and identify R422 (16) in CH II section of the YPA-Board.

Press CHI/II pushbutton (in!) for channel II mode.

Press Y x5 channel II (in!) for 1mV/div.

Press GD pushbutton channel II (in!).

Switch the attenuator channel II constantly between 5mV/div (1mV) and 10mV/div (2mV).

Adjust R422 (16) until no Y-position change occurs.

(17) R503: Invert-Balance CH II.

Press GD pushbutton channel II (in!).

Press Y x5 channel II (in!) for 1mV/div.

Using Y-POS.II control set trace to the horizontal center line.

Locate and identify R503 (17) on YPA-Board.

Adjust R503 (17) so that the baseline will not move, when pressing and releasing the

INVERT CH II pushbutton.

(18) R477: Variable-Balance CH II.

Locate and identify VR477 (18) in CH II section of the YPA-Board.

Press channel II Y-MAG. x5 pushbutton for 1mV/div.

Press channel II GD pushbutton (in!).

Adjust VR477 (18) so that the baseline will not move when turning the channel I Y-variable control

through the entire range.

Check adjustment 17) again and repeat it if required.

(19) R439: 100Hz Squarewave 5mV/div CH II.

Locate and identify R439 (19) in CH II section of the YPA-Board.

Connect a 25mV/100Hz squarewave signal via 50Ω cable and 50Ω through terminator

to input channel II.

Set time base to 2ms/div.

Check that DC input coupling is selected.

Adjust R439 (19) for flat top.

(20) R434: 100Hz Squarewave 1mV/div CH II.

Locate and identify R434 (20) in CH II section of the YPA-Board.

Connect a 5mV/100Hz squarewave signal via 50Ω cable and 50Ω through terminator

to input channel II.

Press Yx5 channel II (in!) for 1mV/div.

Set time base to 2ms/div.

Check that DC input coupling is selected.

Adjust R434 (20) for flat top.

Subject to change without notice

33

Page 34

XY-Board

ACD B

24

YPA-Board

BDCA

23

34

Subject to change without notice

Page 35

(21) RV2005 (A), RV2006 (C), CV2000 (D) and CV2001 (B):

Y-Final Amplifier.

Connect a 1MHz squarewave signal of 25mV via 50Ω cable and 50Ω through termination

to input CH I.

Check that DC input coupling is selected.

Set time base to 0.2µs/div.

Locate and identify the adjustment points RV2005 (21A), RV2006 (21B), CV2000 (21C) and

CV2001 (21D) on XY-Board.

As the capacitive influence of the cabinet is of importance, a metal sheet above the Y-final

amplifier section is required.

Adjust RV2005 (21A) and CV2001 (21B) for flat top, RV2006 (21C) and CV2000 (21D) for fast

leading edge with minimum overshoot.

Repeat until optimum is obtained.

Check channel II under the same conditions.

(22) Y-Amplifier Bandwidth Check.

Connect a 40mVpp/50kHz sinewave signal from a constant amplitude generator via

a 50Ω throughtermination to the input of channel I.

Adjust the generator amplitude for 8 div. display height on the screen.

Increase the generator frequency until the signal is displayed with 5.6 div. height ( -3dB).

Repeat the adjustment under item 21), if the frequency reading on the generator shows a value

less than 30MHz.

Press CHI/II-TRIGI/II pushbutton (in!).

Connect a 40mVpp/50kHz sinewave signal from a constant amplitude generator via

a 50Ω throughtermination to the input of channel II.

Adjust the generator amplitude for 8 div. signal height displayed on the screen.

Increase the generator frequency until the signal is displayed with 5.6 div. height ( -3dB).

Repeat the adjustments under item 21), if the frequency reading on the generator shows

a value less than 30MHz.

(23) C113/111/102/105: Attenuator Compensation CH I.

Locate and identify trimmers VC102-113 for CH I on YPA-Board.

Check that DC input coupling is selected.

Check that input attenuator CH I is in 5mV/div setting.

Set time base switch to 0.5ms/div.

Set amplitude calibrator to 1kHz and connect a 2:1 pre-attenuator via 50Ω cable to input of CH I.

Set calibrator output voltage to 80mVpp (40mVpp at the 2:1 pre-attenuator output,

if terminated with 1MΩ).

Adjust trimmer in pre-attenuator for flat squarewave top. This adjustment must not be changed

during the following procedure.

Adjust compensation as listed in the table below:

Scope Input Adjustment

Input Atten. CH I

250mVpp 50mV/div A (VC111) flat top + B (VC113) leading edge

2.5Vpp 0.5V/div C (VC102) flat top + D (VC105) leading edge

(24) C413/411/402/405: Attenuator Compensation CH II.

Locate and identify trimmers VC402-413 for CH II on YPA-Board.

Check that DC input coupling is selected.

Check that input attenuator CH II is in 5mV/div setting.

Set time base switch to 0.5ms/div.

Set amplitude calibrator to 1kHz and connect a 2:1 pre-attenuator via 50Ω cable to input of CH II.

Set calibrator output voltage to 80mVpp (40mVpp at the 2:1 pre-attenuator output,

if terminated with 1MΩ).

Adjust trimmer in pre-attenuator for flat squarewave top. This adjustment must not be

changed during the following procedure.

Adjust compensation as listed in the table below:

Scope Input Adjustment

Input Atten. CH II

250mVpp 50mV/div A (VC411) flat top + B (VC413) leading edge

2.5Vpp 0.5V/div C (VC402) flat top + D (VC405) leading edge

Subject to change without notice

35

Page 36

YPA-Board

25

XY-Board

TB-Board

36

27

B30A

Subject to change without notice

C

Page 37

(25) R663: ADDition/Offset.

Press DUAL pushbutton (in!).

Locate and identify R663 (25) on YPA-Board.

Set input coupling CH I and II to GD.

Move both baselines with Y-POS. I and II controls to the horizontal center line of the graticule.

Release DUAL pushbutton (out!).

Press ADD pushbutton (in!).

Adjust R663 (25) for the same signal position as before in DUAL mode.

(26) RV2417 (A), RV2418 (B): Overscan.

Locate and identify RV2417 (26A) and RV2418 (26B)on XY-Board.

Press channel I and channel II GD pushbuttons (in!).

Press DUAL pushbutton (in!).

Set baseline with Y-POS.I control to the top line of the graticule.

Set baseline with Y-POS.II control to the bottom line of the graticule.

Adjust RV2417 (26A) for just lighting up of the upper LED.

Adjust RV2418 (26B) for just lighting up of the lower LED.

Repeat both procedures until both adjustments are correct.

(27) RV3519: Sweep start voltage.

Locate and identify RV3519 (27) on TB-Board.

Set time base to .2ms/div.

Locate and identify pin 7 of test socket on XY-Board.

Use a control oscilloscope with a x10 (10:1) probe and measure under DC input coupling

conditions the sawtooth voltage at pin 7.

Adjust RV3519 (27) for 0 volts DC at the sawtooth start (end of the hold off time).

(28) RV2225: X-Magnification x1.

Locate and identify RV2225 (28) on XY-Board.

Set time base to .2ms/div.

Adjust RV2225 (28) for 10.2 div sweep length.

(29) RV2260: X-Symmetry.

Locate and identify RV2260 (29) on XY-Board.

Set the X-POS. knob to the mechanical center position.

Adjust RV2260 (29) for a symmetrical trace position in respect to the graticule.

(30) RV3591 (A)/3589 (C), CV3511 (B): Time base.

a) Locate and identify RV3591 (A) on TB-Board.

Set time mark generator to f= 20kHz and connect signal to CH I input.

Set time base to 50µs/div.

Move trace with X-Pos. control so that the first time mark coincides with the first left

graticule line of the screen.

Adjust RV3591 (30A) so that the 11th time mark coincides with the last right graticule line.

Rotate time base variable control to fully left position.

Now more than 2.5 time marks per division should be displayed.

b) Locate and identify CV3511 (30B) on TB-Board.

Set time base to 0.5µs/div. and time base variable control to CAL position.

Set time mark generator to f= 2MHz.

Move trace with X-POS. control so that the first time mark coincides with the first left

graticule line of the screen.

Adjust CV3511 (30B) so that the 11th time mark coincides with the last right graticule line.

c) Locate and identify RV3589 (30C) on TB-Board.

Set time base to 5ms/div. and time base variable control to CAL position.

Set time mark generator to f= 200Hz.

Move trace with X-POS. control so that the first time mark coincides with the first left

graticule line of the screen.

Adjust RV3589 (30C) so that the 11th time mark coincides with the last right graticule line.

Check all time base settings with suitable time mark signals.

Subject to change without notice

37

Page 38

YPA-Board

35 32 34

TB-Board

XY-Board

33

38

Subject to change without notice

Page 39

(31) RV2234: X-Magnification x10.

Locate and identify RV2234 (31) on XY-Board.

Press pushbutton X-Mag. x10.

Set time base to 50µs/div.

Set time mark generator to f= 20kHz and connect signal to CH I input.

Set X-POS control to mechanical center.

Using X-POS control, move the visible time mark to the first left graticule line.

Adjust RV2234 (31) so that the next time mark coincides with the last (right) graticule line.

Release X-MAG. x10 pushbutton (out!).

(32) R624: XY-Gain

Connect a 1kHz squarewave signal of 25mVpp amplitude (HZ60-2) to input CH II.

Check that the CH II input sensitivity is 5mV/div.

Check that DC input coupling is selected.

Locate and identify R624 (32) on YPA-Board.

Press XY pushbutton.

Set X-POS control that the left dot coincides with the graticule center.

Adjust R624 (32) for a distance of 5 division between left and right dot.

(33) RV3293: Trigger-Symmetry

Locate and identify RV3293 (33) on TB-Board.

Connect a 50kHz sinewave signal of 40mVpp amplitude to input CH I.

Set input coupling CH I to AC.

Check that trigger coupling is in AC position.

Set attenuator switch CH I to 0.1V/div (calibrated position).

Press AT/NORM. pushbutton (in!).

Turn LEVEL control for triggering (center position).

Reduce signal height and correct LEVEL setting for just triggering with a minimum signal height.

Press and release the trigger SLOPE ± pushbutton and adjust RV3293 (33) for stable triggering

in both SLOPE conditions.

(34) R612: DC-Triggering CH I.

Locate and identify R612 (34) on YPA-Board.

Connect a 50kHz sinwave signal to input CH I.

Set generator amplitude to 8cm.

Set time base to 10µs/div.

Press AT/NORM. pushbutton (in!).

Turn LEVEL control to the center position.

Release AC/DC input coupling pushbutton CH I (out!).

Constantly switch between AC and DC trigger coupling and watch the trace start position.

Adjust R612 (34) so that there is no difference regarding the signal start position on the signal

slope between DC and AC trigger coupling.

(35) R603: DC-Triggering CH II.

Locate and identify R603 (35) on YPA-Board.

Connect a 50kHz sinwave signal to input CH II.

Press CH I/II-TRIG I/II pushbutton (in!).

Set generator amplitude to 8cm.

Set time base to 10µs/div.

Press AT/NORM. pushbutton (in!).

Turn LEVEL control to the center position.

Release AC/DC input coupling pushbutton CH II (out!).

Constantly switch between AC and DC trigger coupling and watch the trace start position.

Adjust R603 ( 35) so that there is no difference regarding the signal start position on the signal

slope between DC and AC trigger coupling.

Subject to change without notice

39

Page 40

XY-Board

Pin 1

CT-Board

37

Pin 14

36B

40

Subject to change without notice

Page 41

(36) RV2301 (A), 4322 (B): Component Tester Y-Position and Tilt.

Release all pushbuttons (out!).

Press COMPONENT TESTER pushbutton (in!).

Locate and identify RV2301 (36A) on XY-Board.

Adjust RV2301 (36A) to shift the approx. 8 div. horizontal component tester trace to the

horizontal center of the CRT graticule.

Locate and identify RV4322 (36B) on CC-Board.

Set up the instrument on a table in normal operating conditions to avoid misadjustment due

to the influence of the earth magnetic field.

Adjust RV4322 (36B) in such a way that the trace is parallel to the horizontal graticule center line

and not tilt. This adjustment

(37) VR8940: Calibrator Output.

Locate and identify VR8940 (37) on CC-Board.

Connect a digital multimeter to the 0.2Vpp calibrator output.

Set up the digital multimeter for DC measurement in a suited sensitivity setting.

Locate and identify IC8903 on CC-Board.

Connect pin 1 and pin 14 of IC8903 galvanically together.

Adjust VR8940 (37) for exactly 0.2V DC.

Check 2V calibrator output.

Remove the connection between pin 1 and pin 14 of IC8903.

Connect a 10:1 probe to the 0.2Vpp calibrator output and connect it to the CH I input of the scope.

Release all pushbuttons (out!).

Select CH I DC input coupling.

Set attenuator CH I to 5mV/div (calibrated detent).

Set time base to 0.2ms/div.

Now approximately 2 signal periods should be visible on the screen.

Press 1kHz/1MHz pushbutton (in!).

Set time base to 0.5µs position.

Check 1MHz calbrator signal.

Please note: Neither the calibrator frequency nor the pulse duty factor are specified.

(38) Trigger Filter Check.

Set time base to 1ms/div.

Connect a 1kHz sinewave signal of 40mVpp amplitude to input CH I and check for full

screen deflection.

Set input attenuator CH I to 50mV/div and check for 8mm display height.

Select trigger coupling from AC to DC and LF. The signal must always trigger .

Set sinewave generator to 50kHz and 40mV output amplitude and check for 8mm display height.

Select trigger coupling from AC to DC. The signal must always trigger.

Select LF trigger coupling. Now the signal should not trigger.

(39) Triggerbandwidth Check.

Set time base to 0.05µs/div, time base variable to CAL position.

Set input coupling switch CH I to DC.

Set trigger coupling to AC.

Release AUTO/NORM pushbutton (out!).

Set input attenuator CH I to 5mV/div.

Connect a 100MHz sinewave signal to input CH I.

Adjust generator output for 5mm display height.

The signal must be triggered.

(40) External Trigger Check.

Set time base to 20µs/div.

Set input attenuator CH I to 0.1V/div.

Connect a 50 kHz sinewave signal via a 50-Ohm through terminator with an amplitude of

280mVpp (100mVrms) to input CH I and check for 2.8div display height.

Set LEVEL to midrange position.

Check that the Trigger-LED is ON.

Press EXT. pushbutton. The Trigger-LED (TR) should now be OFF.

Subject to change without notice

41

Page 42

Set input coupling CH I to GD.

Remove signal cable from input CH I and connect it to TRIG.INP. socket. Do not change

generator settings.

Now the Trigger-LED should be ON again.

(41) Video Trigger Check.

Set CH I input coupling switch to DC.

Connect video signal with positiv sync. pulses to input CH I.

Adjust input attenuator switch CH I for 1 div display amplitude of video signal.

Set time base to 5ms/div ( time base ≥ 1ms/div = frame triggering).

Set trigger coupling switch to TV.

Check that trigger starts with vertical sync. pulses.

Now approx. 2.5 frames should be visible.

Change polarity of video signal.

Press SLOPE pushbutton (in!).

Again approx. 2.5 frames should be displayed triggered.

Set time base to 20µs/div ( time base range 0.5ms/div - 0.1µs/div = line triggering).

Recheck trigger SLOPE pushbutton procedure, using video signal with polarity change.

Note:Note:

Note: Invert pushbutton does not affect trigger polarity.

Note:Note:

42

Subject to change without notice

Loading...

Loading...