100 MHz CombiScope

HM1008

Manual

English

®

Hersteller HAMEG Instruments GmbH KONFORMITÄTSERKLÄRUNG

Manufacturer Industriestraße 6 DECLARATION OF CONFORMITY

Fabricant D-63533 Mainhausen DECLARATION DE CONFORMITE

Die HAMEG Instruments GmbH bescheinigt die Konformität für das Produkt

The HAMEG Instruments GmbH herewith declares conformity of the product

HAMEG Instruments GmbH déclare la conformite du produit

Bezeichnung / Product name / Designation:

Oszilloskop

Oscilloscope

Oscilloscope

Typ / Type / Type: HM1008

mit / with / avec: –

Optionen / Options / Options: –

mit den folgenden Bestimmungen / with applicable regulations / avec les

directives suivantes

EMV Richtlinie 89/336/EWG ergänzt durch 91/263/EWG, 92/31/EWG

EMC Directive 89/336/EEC amended by 91/263/EWG, 92/31/EEC

Directive EMC 89/336/CEE amendée par 91/263/EWG, 92/31/CEE

Niederspannungsrichtlinie 73/23/EWG ergänzt durch 93/68/EWG

Low-Voltage Equipment Directive 73/23/EEC amended by 93/68/EEC

Directive des equipements basse tension 73/23/CEE amendée par 93/68/CEE

Angewendete harmonisierte Normen / Harmonized standards applied / Normes

harmonisées utilisées:

General information regarding the CE marking

HAMEG instruments fulfi ll the regulations of the EMC directive. The

conformity test made by HAMEG is based on the actual generic- and

product standards. In cases where different limit values are applicable,

HAMEG applies the severer standard. For emission the limits for

residential, commercial and light industry are applied. Regarding the

immunity (susceptibility) the limits for industrial environment have

been used.

The measuring- and data lines of the instrument have much infl uence

on emmission and immunity and therefore on meeting the acceptance

limits. For different applications the lines and/or cables used may

be different. For measurement operation the following hints and

conditions regarding emission and immunity should be observed:

1. Data cables

For the connection between instruments resp. their interfaces and

external devices, (computer, printer etc.) suffi ciently screened cables

must be used. Without a special instruction in the manual for a reduced

cable length, the maximum cable length of a dataline must be less than

3 meters and not be used outside buildings. If an interface has several

connectors only one connector must have a connection to a cable.

Basically interconnections must have a double screening. For IEEE-bus

purposes the double screened cables HZ72S and HZ72L from HAMEG

are suitable.

2. Signal cables

Basically test leads for signal interconnection between test point and

instrument should be as short as possible. Without instruction in the

manual for a shorter length, signal lines must be less than 3 meters

and not be used outside buildings.

Sicherheit / Safety / Sécurité: EN 61010-1:2001 (IEC 61010-1:2001)

Überspannungskategorie / Overvoltage category / Catégorie de surtension: II

Verschmutzungsgrad / Degree of pollution / Degré de pollution: 2

Elektromagnetische Verträglichkeit / Electromagnetic compatibility /

Compatibilité électromagnétique

EN 61326-1/A1 Störaussendung / Radiation / Emission:

Tabelle / table / tableau 4; Klasse / Class / Classe B.

Störfestigkeit / Immunity / Imunitée: Tabelle / table / tableau A1.

EN 61000-3-2/A14 Oberschwingungsströme / Harmonic current emissions /

Émissions de courant harmonique:

Klasse / Class / Classe D.

EN 61000-3-3 Spannungsschwankungen u. Flicker / Voltage fl uctuations and fl icker /

Fluctuations de tension et du fl icker.

Datum /Date /Date

24. 02. 2005

Unterschrift / Signature / Signatur

Manuel Roth

Manager

This will not cause damage or put the instrument out of operation. Small

deviations of the measuring value (reading) exceeding the instruments

specifi cations may result from such conditions in individual cases.

4. RF immunity of oscilloscopes.

4.1 Electromagnetic RF fi eld

The infl uence of electric and magnetic RF fi elds may become visible

(e.g. RF superimposed), if the fi eld intensity is high. In most cases

the coupling into the oscilloscope takes place via the device under

test, mains/line supply, test leads, control cables and/or radiation.

The device under test as well as the oscilloscope may be effected by

such fi elds.

Although the interior of the oscilloscope is screened by the cabinet,

direct radiation can occur via the CRT gap. As the bandwidth of

each amplifi er stage is higher than the total –3dB bandwidth of the

oscilloscope, the infl uence RF fi elds of even higher frequencies may

be noticeable.

4.2 Electrical fast transients / electrostatic discharge

Electrical fast transient signals (burst) may be coupled into the

oscilloscope directly via the mains/line supply, or indirectly via test

leads and/or control cables. Due to the high trigger and input sensitivity

of the oscilloscopes, such normally high signals may effect the trigger

unit and/or may become visible on the CRT, which is unavoidable.

These effects can also be caused by direct or indirect electrostatic

discharge.

HAMEG Instruments GmbH

Signal lines must screened (coaxial cable - RG58/U). A proper ground

connection is required. In combination with signal generators double

screened cables (RG223/U, RG214/U) must be used.

3. Infl uence on measuring instruments

Under the presence of strong high frequency electric or magnetic fi elds,

even with careful setup of the measuring equipment an infl uence of

such signals is unavoidable.

2

Subject to change without notice

Contents

General information regarding the CE marking 2

100 MHz CombiScope HM1008 4

Specifi cations 5

Important hints 6

List of symbols used: 6

Positioning the instrument 6

Safety 6

Proper operation 6

CAT I 6

Environment of use. 6

Environmental conditions 7

Warranty and repair 7

Maintenance 7

Line voltage 7

Description of the controls 8

Basic signal measurement 10

Signals which can be measured 10

Amplitude of signals 10

Values of a sine wave signal 10

DC and ac components of an input signal 11

Timing relationships 11

Connection of signals 11

AUTOSET 19

Component tester 19

CombiScope 21

DSO Operation 22

DSO operating modes 22

Memory resolution 22

Memory depth 23

Horizontal resolution with X magnifi er 23

Maximum signal frequency in DSO mode 23

Display of aliases 23

Vertical amplifi er operating modes 23

Data transfer 23

HO710: RS-232 Interface. Remote control 24

Selection of Baud rate 24

Data transmission 24

Loading of new fi rmware 24

General information concerning MENU 25

Controls and Readout 26

First time operation and initial adjustments 12

Trace rotation TR 12

Probe adjustment and use 12

1 kHz adjustment 12

1 MHz adjustment 13

Operating modes of the vertical amplifi er 13

XY operation 14

Phase measurements with Lissajous fi gures 14

Measurement of phase differences in dual

channel Yt mode 14

Measurement of amplitude modulation 15

Triggering and time base 15

Automatic peak triggering (MODE menu) 15

Normal trigger mode (See menu MODE) 16

Slope selection (Menu FILTER) 16

Trigger coupling (Menu: FILTER) 16

Video (tv triggering) 16

Frame sync pulse triggering 17

Line sync pulse triggering 17

LINE trigger 17

Alternate trigger 17

External triggering 17

Indication of triggered operation (TRIG’D LED) 17

Hold-off time adjustment 17

Time base B (2nd time base). Delaying,

Delayed Sweep. Analog mode. 18

Alternate sweep 18

Subject to change without notice

3

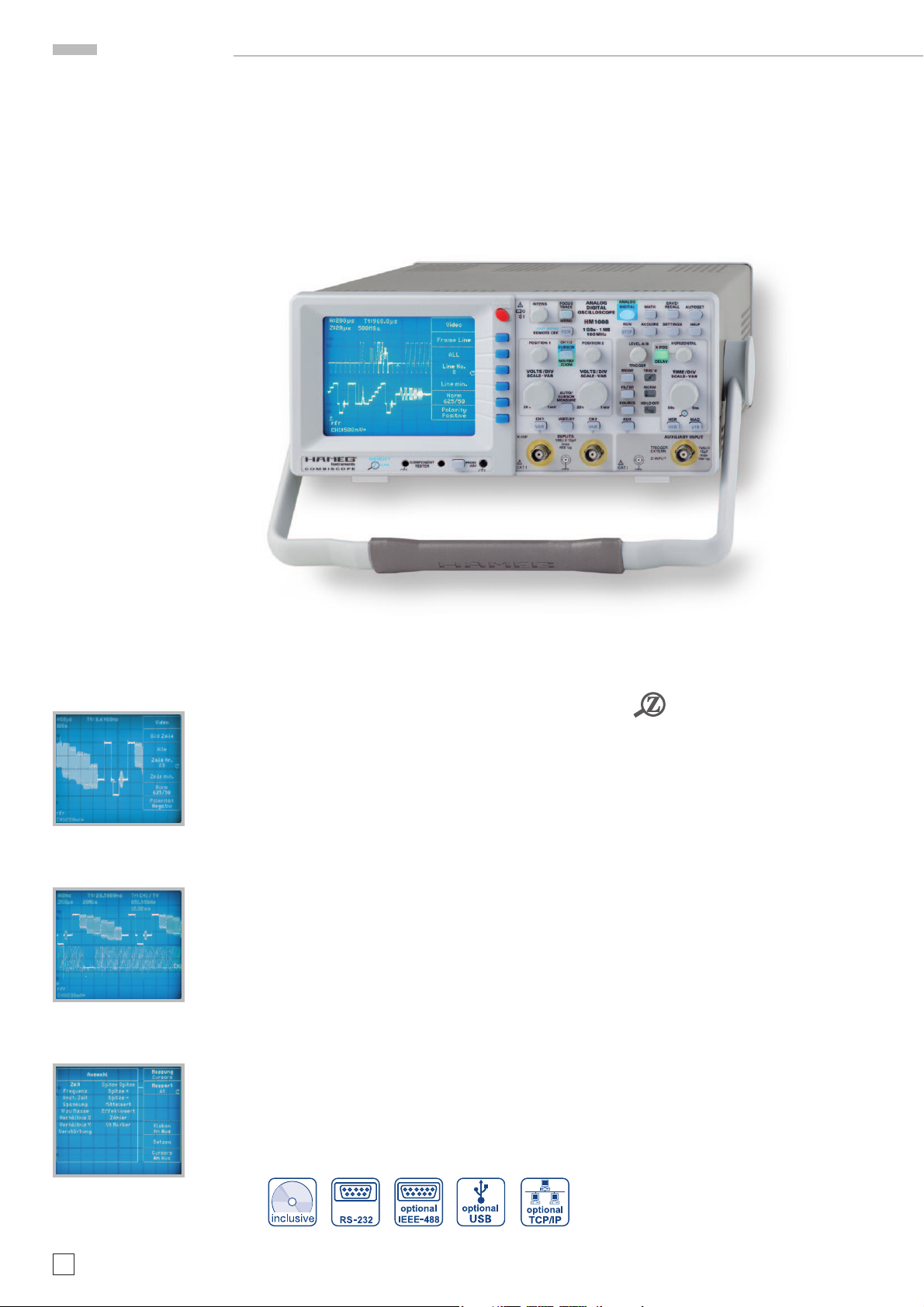

HM1008

1 GSa/s Real Time Sampling, 10 GSa/s Random Sampling

1 MPt memory per channel allows Memory oom

up to 50,000:1

Two Channels 1mV – 20 V/cm

8-Bit Low Noise Flash A/D Converters

Pre/Post Trigger -100 % to +400 %

Time Base 50 s/cm – 5 ns/cm

Acquisition modes: Single Event, Refresh, Average, Envelope,

Roll, Peak-Detect

RS-232 Interface, optional: USB/RS-232, IEEE-488,

Ethernet/USB

Signal display: Yt and XY;

Interpolation: Sinx/x, Pulse, Dot Join (linear)

Analog Mode: see HM1000-2

100 MHz CombiScope

®

HM1008

Cursor measurement

choices in digital mode

Digital Mode: TV field and

zoomed display of one

selected line

Either PAL or NTSC: Line

triggering with line counter

4

Subject to change without notice

Technische Daten

100 MHz CombiScope®HM1008

Valid at 23 °C after a 30 minute warm-up period

Vertical Deflection

Channels:

Analog: 2

Digital: 2

Operating Modes:

Analog: CH 1 or CH 2 separate, DUAL (CH 1 and

CH 2 alternate or chopped), Addition

Digital: CH 1 or CH 2 separate, DUAL (CH 1 and

CH 2), Addition

X in XY-Mode: CH 1

Invert: CH 1, CH 2

Bandwidth (-3 dB): 2 x 0 - 100 MHz

Rise time: ‹ 3.5 ns

Overshoot: max. 1 %

Bandwith limiting (selectable): about 20 MHz (5 mV/cm - 20V/cm)

Deflection Coefficients(CH 1, 2):14 calibrated steps

1mV – 2mV/cm (10MHz) ±5% (0 - 10 MHz (-3dB))

5 mV – 20 V/cm ±3% (1-2-5 sequence)

variable (uncalibrated): › 2.5 :1 to › 50V/cm

Inputs CH 1, 2:

Input Impedance: 1 MΩ II 15 pF

Coupling: DC, AC, GND (ground)

Max. Input Voltage: 400 V (DC + peak AC)

Y Delay Line (analog): 70 ns

Measuring Circuits: Measuring Category I

Anal

og mode only:

Auxiliary input:

Function (selectable): Extern Trigger, Z (unblank)

Coupling: AC, DC

Max. input voltage: 100 V (DC +peak AC)

Triggering

Analog and Digital Mode

Automatic (Peak to Peak):

Min. signal height: 5mm

Frequency range: 10Hz - 200 MHz

Level control range: from Peak- to Peak+

Normal (without peak): Slope/Video

Min. signal height: 5mm

Frequency range: 0 - 200MHz

Level control range: –10 cm to +10cm

Operating modes: Slope/Video

Slope: positive, negative, both

Sources: CH 1, CH 2, alt. CH 1/2 (≥ 8mm), Line, Ext.

Coupling: AC: 10 Hz-200MHz

DC: 0 -200 MHz

HF: 30 kHz–200 MHz

LF: 0-5kHz

Noise Rej. switchable

Video: pos./neg. Sync. Impulse

Standards: 525 Line/60Hz Systems

625 Line/50Hz Systems

Field: even/odd /both

Line: all/line number selectable

Source: CH 1, CH 2, Ext.

Indicator for trigger action: LED

External Trigger via: Auxiliary Input (0.3Vpp, 100 MHz)

Coupling: AC, DC

Max. input voltage: 100 V (DC +peak AC)

Digital mode

Pre/Post Trigger: -100 % to +400% related to complete memory

Analog mode

2nd Trigger

Min. signal height: 5mm

Frequency range: 0 - 200MHz

Coupling: DC

Level control range: –10 cm to +10cm

Horizontal Deflection

Analog mode

Operating modes: A, ALT (alternating A/B), B

Time base A: 0.5s/cm - 50 ns/cm (1-2-5 sequence)

Time base B: 20 ms/cm – 50 ns/cm (1-2-5 sequence)

Accuracy A and B: ±3%

X Magnification x10: to 5 ns/cm

Accuracy: ±5%

Variable time base A/B: cont. 1:2.5

Hold Off time: var. 1:10 (LED-Indication)

Bandwidth X-Amplifier: 0 - 3 MHz (-3dB)

X Y phase shift ‹ 3°: ‹ 220kHz

Digit

al mode

Time base range (1-2-5 sequence)

Refresh Mode: 20 ms/cm - 5 ns/cm

with Peak Detect: 20ms/cm – 2 ms/cm (min. Pulse Width 10 ns)

Roll Mode: 50s/cm – 50 ms/cm

Accuracy time base

Time base: 50 ppm

Display: ±1%

MEMORY ZOOM: max. 50,000:1

Bandwidth X-Amplifier: 0 - 100 MHz (-3dB)

X Y phase shift ‹ 3°: ‹ 100 MHz

Digital Storage

Sampling rate (real time): 2x 500 MSa/s, 1 GSa/s interleaved

Sampling rate (random sampling): 10GSa/s

Bandwidth: 2 x 0 - 100 MHz (random)

Memory: 1 M-Samples per channel

Operating modes: Refresh, Average, Envelope/

Roll: Free Run/Triggered, Peak-Detect

Resolution (vertical): 8 Bit (25 Pts/cm)

Resolution (horizontal):

Yt: 11 Bit (200 Pts/cm)

XY: 8 Bit (25 Pts /cm)

Interpolation: Sinx/x, Dot Join (linear)

Delay: 1 Million x 1/Sampling Rate to

4 Million x 1/Sampling Rate

Display refresh rate: max.170 /s at 1 MPts

Display: Dots (acquired points only), Vectors (partly

interpolated), optimal (complete memory

weighting and vectors)

Reference Memories: 9 with 2 kPts each (for recorded signals)

Display: 2 signals of 9 (free selectable)

Operation/Measuring/Interfaces

Operation: Menu (multilingual), Autoset,

help functions (multilingual)

Save/Recall (instrument parameter settings): 9

Signal display: max. 4 traces

analog: CH 1, 2 (Time Base A) in combination with

CH 1, 2 (Time Base B)

digital: CH1,2 and ZOOM or Reference or

Mathematics)

Frequency counter:

6 digit resolution: ›1 MHz – 200MHz

5 digit resolution: 0.5 Hz – 1MHz

Accuracy: 50ppm

Auto Measurements:

Analog mode: Frequency, Period, Vdc, Vpp, Vp+, Vp-

also in digital mode: V

rms

, V

avg

Cursor Measurements:

Analog mode: Δt, 1/Δt (f), tr, ΔV, V to GND, ratio X, ratio Y

plus in digital mode: V

pp

, Vp+, Vp-, V

avg

, V

rms

, pulse count

Resolution Readout/Cursor: 1000 x 2000Pts, Signals: 250 x 2000

Interfaces (plug-in): RS-232 (HO710)

Optional: IEEE-488, Ethernet, Dual-Interface

RS-232/USB

Mathematic functions

Number of Formula Sets: 5 with 5 formulas each

Sources: CH 1, CH 2, Math 1-Math 5

Targets: 5 math. memories, Math 1-5

Functions: ADD, SUB, 1/X, ABS, MUL, DIV, SQ, POS,

NEG, INV

Display: max. 2 math. memories (Math 1-5)

Display

CRT: D14-375GH

Display area (with graticule): 8cm x 10cm

Acceleration voltage: approx. 14 kV

General Information

Component tester

Test voltage: approx. 7V

rms

(open circuit), approx. 50 Hz

Test current: max. 7 mA

rms

(short circuit)

Reference Potential : Ground (safety earth)

Probe ADJ Output: 1 kHz/1 MHz square wave signal 0.2 V

pp

(tr ‹ 4 ns)

Trace rotation: electronic

Line voltage: 105 – 253 V, 50/60 Hz ±10 %, CAT II

Power consumption: 42 Watt at 230V, 50Hz

Protective system: Safety class I (EN61010-1)

Weight: 5.6 kg

Cabinet (W x H x D): 285 x 125 x 380mm

Ambient temperature: 0° C ...+40° C

Accessories supplied: Line cord, Operating manual, 2 Probes 10:1 with at tenuation ID, Windows Software for control and data transfer

Optional accessories: HO720 Dual-Inter face RS-232/USB, HO730 Dual-Inter face Ethernet/ USB, HO740 Interface IEEE-488 (GPIB), HZ70 Opto-Interface (with

optical fi ber cable)

Subject to change without notice

5

Important hints

Important hints

Please check the instrument for mechanical damage or loose

parts immediately after unpacking. In case of damage we advise

to contact the sender. Do not operate.

List of symbols used:

Consult the manual High voltage

Important note Ground

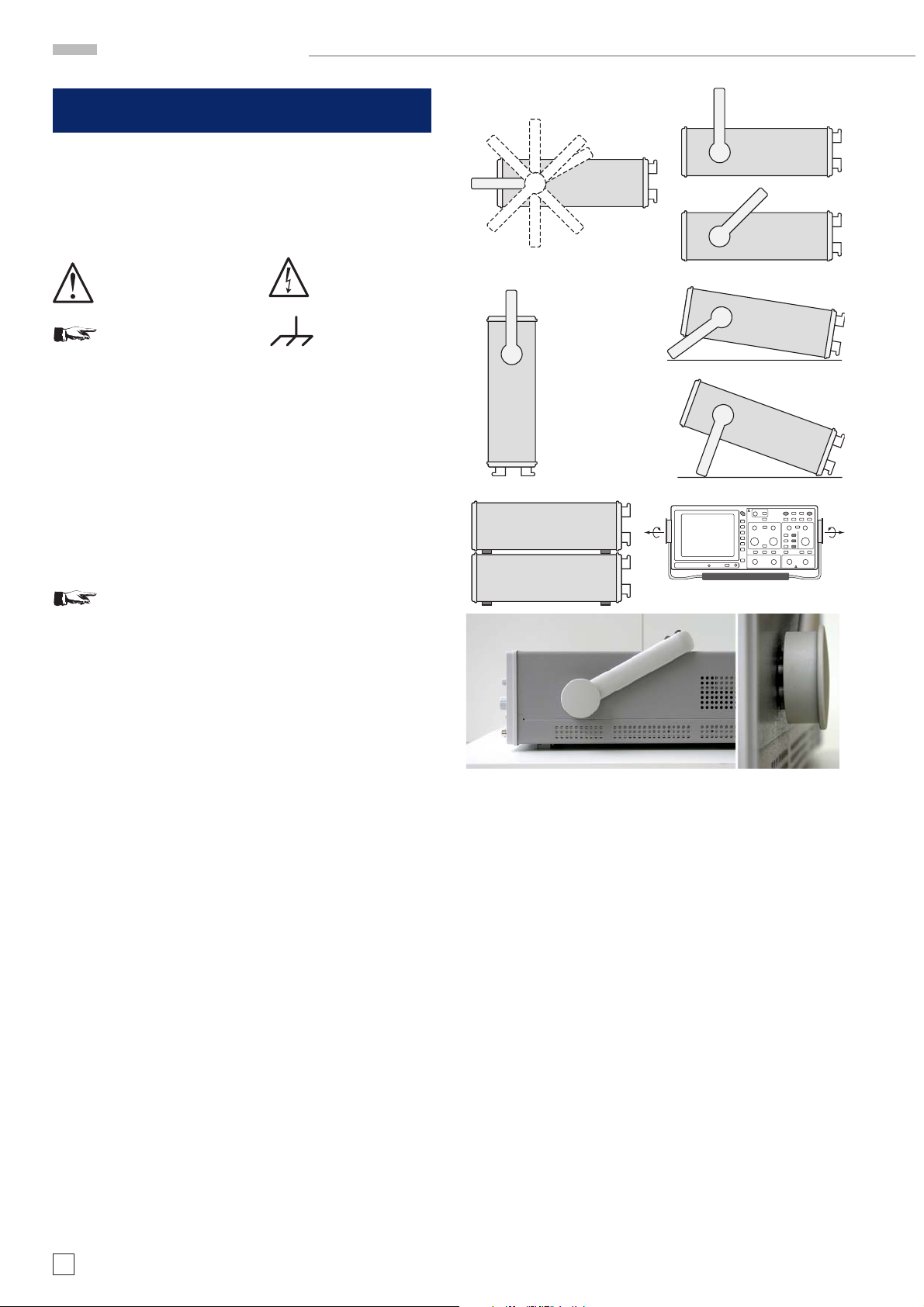

Positioning the instrument

As can be seen from the fi gures, the handle can be set into

different positions:

A = carrying

B = handle removal and horizontal carrying

C = horizontal operating

D and E = operating at different angles

F = handle removal

T = shipping (handle unlocked)

B

C

B

T

A

C

D

F

E

D

E

A

PUkT

PUOGkT

PUkT

ANALOG

PUOPFGkT

PUkT

HGOFFD

PUOPFGkT

PUOPFGkT

HGOPFFD

DIGITAL

MIXED SIGNAL

COMBISCOPE

PUkT

HM1508

PUOPFGkT

PUOPFGkT

PFGkT

PUkT

1 GSa · 1MB

PUkT

150 MHz

PUOPFGkT PUOPFGkT

PUOPFGkT

VOLTS/DIVV

HGOPFFD

B

HAMEG

C O M B I S C O P E

PUk PUk

PUkT

PUkT

PUOPFGkT

PUOPFGkT

PUkT

PUOPF

PUOPF

PUkT

PUOPF

HGOPFFD

PUkT

PUkT

VOLTS/DIVV

VOLTS/DIVV

HGOPFFD

HGOPFFD

PUkT

PUOPFGkT

PUkT

HGOPFFD

PUkT

PUOPFGkT

PUk PUk

PUk PUk

PUOPFGkT

PGkT

PUkT PUkT

PUOPFGkT

PUOPFGkT

PUOPF PUOPF

PUOPFGkT

INPUTS

PUkTKl

PUkTKl

15pF

15pF

max

max

400 Vp

400 Vp

PUkT

Attention!

When changing the handle position, the instrument

must be placed so that it can not fall (e.g. placed

on a table). Then the handle locking knobs must be

simultaneously pulled outwards and rotated to the

required position. Without pulling the locking knobs

they will latch in into the next locking position.

Handle mounting/dismounting

The handle can be removed by pulling it out further, depending

on the instrument model in position B or F.

Safety

The instrument fulfi ls the VDE 0411 part 1 regulations for

electrical measuring, control and laboratory instruments and

was manufactured and tested accordingly. It left the factory in

perfect safe condition. Hence it also corresponds to European

Standard EN 61010-1 resp. International Standard IEC 1010-1.

In order to maintain this condition and to ensure safe operation

the user is required to observe the warnings and other directions

for use in this manual. Housing, chassis as well as all measuring terminals are connected to safety ground of the mains.

All accessible metal parts were tested against the mains with

2200 V

The oscilloscope may only be operated from mains outlets with

a safety ground connector. The plug has to be installed prior to

connecting any signals. It is prohibited to separate the safety

ground connection.

Most electron tubes generate X-rays; the ion dose rate of this instrument remains well below the 36 pA/kg permitted by law.

. The instrument conforms to safety class I.

DC

T

T

Safe operation may be endangered if any of the following

was noticed:

– in case of visible damage.

– in case loose parts were noticed

– if it does not function any more.

– after prolonged storage under unfavourable conditions (e.g.

like in the open or in moist atmosphere).

– after any improper transport (e.g. insuffi cient packing not

conforming to the minimum standards of post, rail or transport fi rm)

Proper operation

Please note: This instrument is only destined for use by personnel well instructed and familiar with the dangers of electrical

measurements.

For safety reasons the oscilloscope may only be operated from

mains outlets with safety ground connector. It is prohibited

to separate the safety ground connection. The plug must be

inserted prior to connecting any signals.

CAT I

In case safe operation may not be guaranteed do not use the

instrument any more and lock it away in a secure place.

6

Subject to change without notice

This oscilloscope is destined for measurements in circuits not

connected to the mains or only indirectly. Direct measurements,

Important hints

i.e. with a galvanic connection to circuits corresponding to the

categories II, III, or IV are prohibited!

The measuring circuits are considered not connected to the

mains if a suitable isolation transformer fulfi lling safety class

II is used. Measurements on the mains are also possible if

suitable probes like current probes are used which fulfi l the

safety class II. The measurement category of such probes must

be checked and observed.

Measurement categories

The measurement categories were derived corresponding to

the distance from the power station and the transients to be

expected hence. Transients are short, very fast voltage or current excursions which may be periodic or not.

Measurement CAT IV:

Measurements close to the power station, e.g. on electricity

meters

Measurement CAT III:

Measurements in the interior of buildings (power distribution

installations, mains outlets, motors which are permanently

installed).

Measurement CAT II:

Measurements in circuits directly connected to the mains

(household appliances, power tools etc).

Environment of use.

The oscilloscope is destined for operation in industrial, business,

manufacturing, and living sites.

Environmental conditions

check all operating modes and fulfi lment of specifi cations. The

latter is performed with test equipment traceable to national

measurement standards.

Statutory warranty regulations apply in the country where the

HAMEG product was purchased. In case of complaints please

contact the dealer who supplied your HAMEG product.

Maintenance

Clean the outer shell using a dust brush in regular intervals.

Dirt can be removed from housing, handle, all metal and plastic

parts using a cloth moistened with water and 1 % detergent.

Greasy dirt may be removed with benzene (petroleum ether) or

alcohol, there after wipe the surfaces with a dry cloth. Plastic

parts should be treated with an antistatic solution destined

for such parts. No fl uid may enter the instrument. Do not use

other cleansing agents as they may adversely affect the plastic

or lacquered surfaces.

Line voltage

The instrument has a wide range power supply from 105 to 253

V, 50 or 60 Hz ±10%. There is hence no line voltage selector.

The line fuse is accessible on the rear panel and part of the line

input connector. Prior to exchanging a fuse the line cord must

be pulled out. Exchange is only allowed if the fuse holder is

undamaged, it can be taken out using a screwdriver put into the

slot. The fuse can be pushed out of its holder and exchanged.

The holder with the new fuse can then be pushed back in place

against the spring. It is prohibited to ”repair“ blown fuses or to

bridge the fuse. Any damages incurred by such measures will

void the warranty.

Operating ambient temperature: 0 to + 40 degrees C. During

transport or storage the temperature may be –20 to +55 degrees C.

Please note that after exposure to such temperatures or in case

of condensation proper time must be allowed until the instrument has reached the permissible range of 0 to + 40 degrees

resp. until the condensation has evaporated before it may be

turned on! Ordinarily this will be the case after 2 hours. The

oscilloscope is destined for use in clean and dry environments.

Do not operate in dusty or chemically aggressive atmosphere

or if there is danger of explosion.

The operating position may be any, however, suffi cient ventilation must be ensured (convection cooling). Prolonged operation

requires the horizontal or inclined position.

Do not obstruct the ventilation holes!

Specifi cations are valid after a 20 minute warm-up period

between 15 and 30 degr. C. Specifi cations without tolerances

are average values.

Warranty and repair

HAMEG instruments are subjected to a rigorous quality control.

Prior to shipment each instrument will be burnt in for 10 hours.

Intermittent operation will produce nearly all early failures.

After burn in, a fi nal functional and quality test is performed to

Type of fuse:

Size 5 x 20 mm; 250V~, C;

IEC 127, Bl. III; DIN 41 662

(or DIN 41 571, Bl. 3).

Cut off: slow blow (T) 0,8A.

Subject to change without notice

7

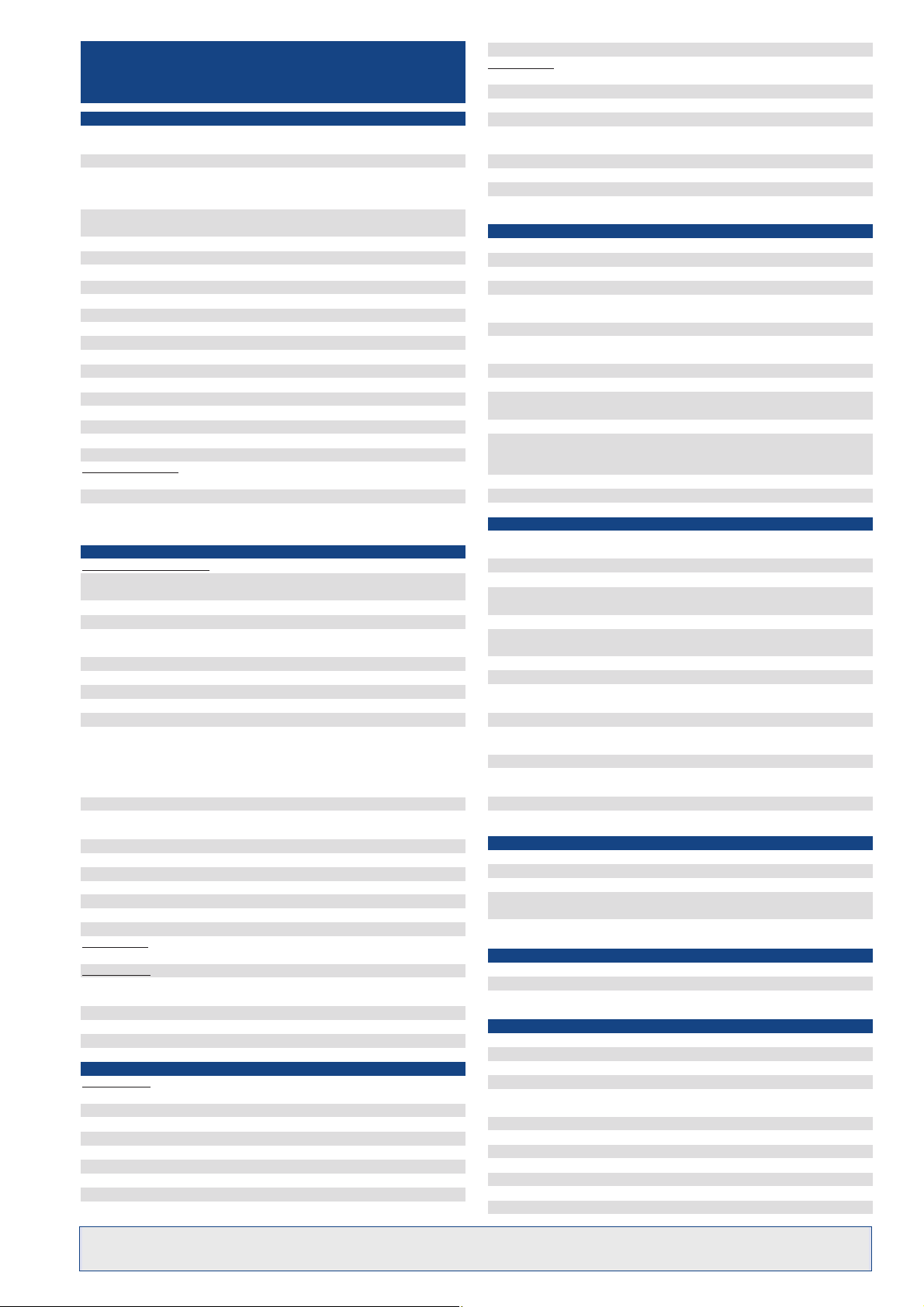

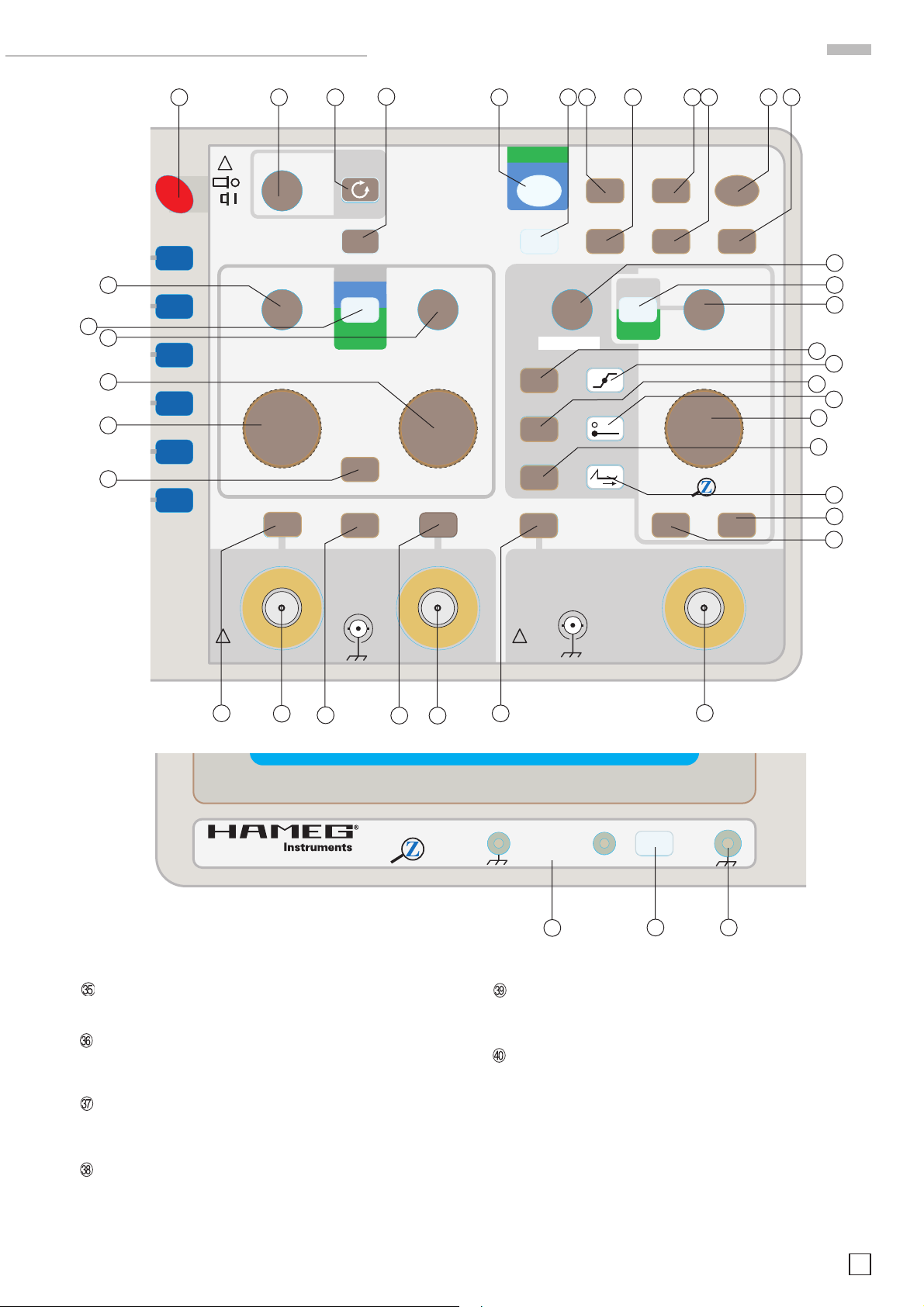

Front Panel Elements – Brief Description

Front Panel Elements – Brief Description

The fi gures indicate the page for complete discriptions

POWER (pushbutton switch) 26

Turns scope on and off.

INTENS (knob) 26

Intensity for trace- and readout brightness, focus and trace

rotation control.

FOCUS, TRACE, MENU (pushbutton switch) 26

Calls the Intensity Knob menu to be displayed and enables

the change of different settings by aid of the INTENS knob.

See item 2.

REM (pushbutton switch) 26

Switches the displayed menu, the remote mode (REM lit)

off.

ANALOG/DIGITAL (pushbutton switch) 27

Switches between analog (green) and digital mode (blue).

STOP / RUN (pushbutton switch) 27

RUN: Signal data acquisition enabled.

STOP: Signal data acquisition disabled. The result of the last

acquisition is displayed.

MATH (pushbutton switch) 27

Calls mathematical function menu if digital mode is pre-

sent.

ACQUIRE (pushbutton switch) 28

Calls the signal capture and display mode menu in digital

mode.

SAVE/RECALL (pushbutton switch) 29

Offers access to the reference signal (digital mode only) and

the instrument settings memory.

SETTINGS (pushbutton switch) 30

Opens menu for language and miscellaneous function; in

digital mode also signal display mode.

AUTOSET (pushbutton switch) 30

Enables appropriate, signal related, automatic instrument

settings.

in the chapter CONTROLS AND READOUT

▼

VOLTS/DIV-SCALE-VAR (knob) 32

Channel 2 Y defl ection coeffi cient, Y variabel and Y scaling

setting.

AUTO / CURSOR MEASURE (pushbutton switch) 33

Calls menus and submenus for automatic and cursor sup-

ported measurement.

LEVEL A/B (knob) 34

Trigger level control for time base A and B.

MODE (pushbutton switch) 34

Calls selectable trigger modes.

FILTER (pushbutton switch) 35

Calls selectable trigger fi lter (coupling) and trigger slope

menu.

SOURCE (pushbutton switch) 35

Calls trigger source menu.

TRIG’d (LED) 36

Lit on condition that time base is triggered.

NORM (LED) 36

Lit on condition that NORMAL or SINGLE triggering is pre-

sent.

HOLD OFF (LED) 36

Lit if a hold off time > 0% is chosen in time base menu (HOR

pushbutton

X-POS / DELAY (pushbutton switch) 36

Calls and indicates the actual function of the HORIZONTAL

knob

HORIZONTAL (knob) 37

Changes the X position resp. in digital mode the delay time

(Pre- resp. Post-Trigger).

TIME/DIV-SCALE-VAR (knob) 37

Time base A and B defl ection coeffi cient, time base variable

and scaling control.

MAG (pushbutton switch) 37

10 fold expansion in X direction in Yt mode, with simulta-

neous change of the defl ection coeffi cient display in the

readout.

).

, (X-POS = dark).

HELP (pushbutton switch) 30

Switches help texts regarding controls and menus on and

off.

POSITION 1 (knob) 30

Controls position of actual present functions: Signal (cur-

rent, reference or mathematics), Cursor and ZOOM (digital).

POSITION 2 (knob) 31

Controls position of actual present functions: Signal (current,

reference or mathematics) Cursor and ZOOM (digital).

CH 1/2-CURSOR-CH3/4-MA/REF-ZOOM (pushbutton) 32

Calls the menu and indicates the current function of

POSITION 1 and 2 controls.

VOLTS/DIV-SCALE-VAR (knob) 32

Channel 1 Y defl ection coeffi cient, Y variabel and Y scaling

setting.

8

Subject to change without notice

HOR / VAR (pushbutton switch) 38

Calls ZOOM function (digital) and analog time base A and

B, time base variable and hold off control.

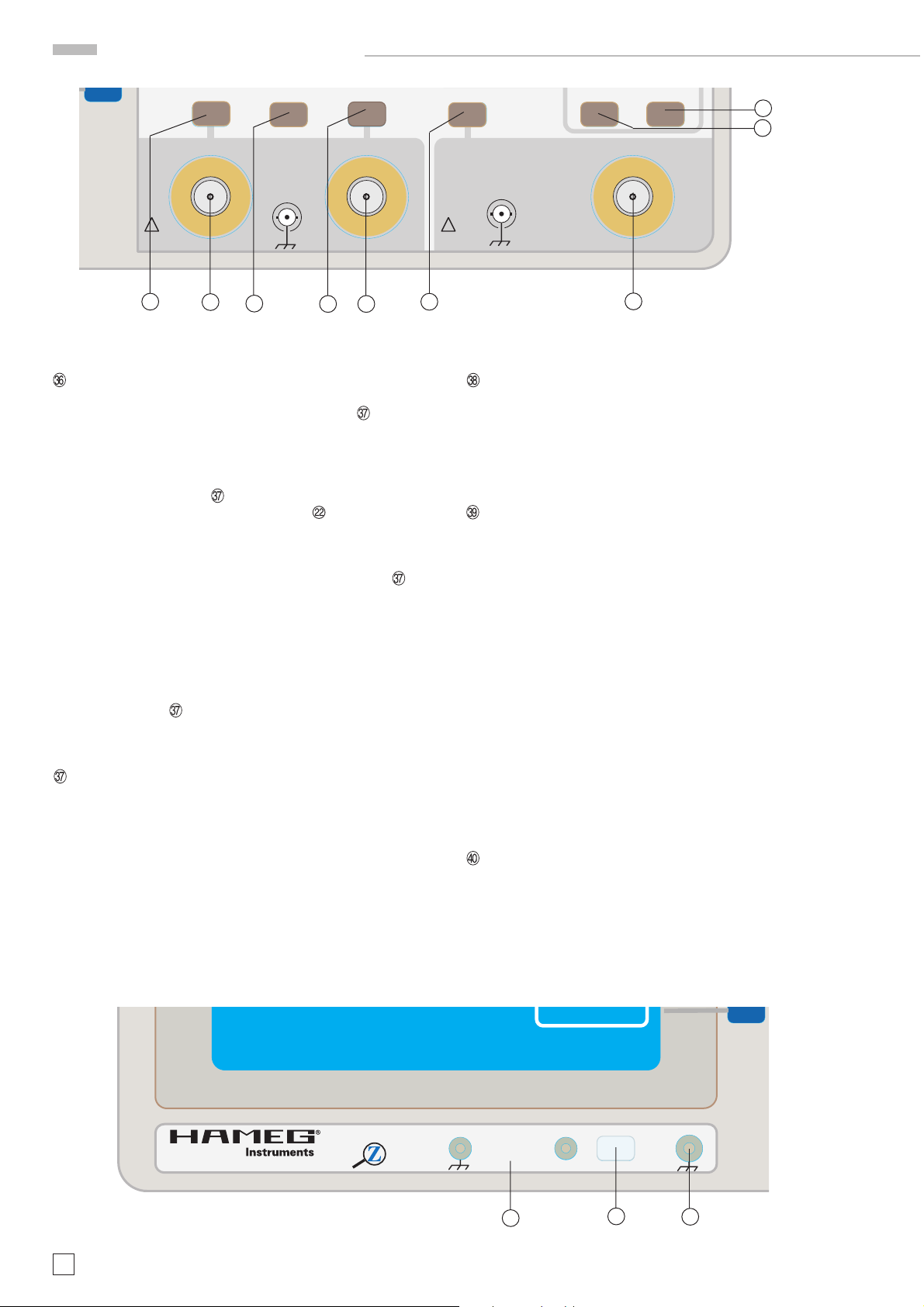

CH1 (pushbutton switch) 39

Calls channel 1 menu with input coupling, inverting, probe

and Y variable control.

VERT/XY (pushbutton switch) 39

Calls vertical mode selection, addition, XY mode and band-

width limiter.

CH2 (pushbutton switch) 41

Calls channel 1 menu with input coupling, inverting, probe

and Y variable control.

CH1 (BNC-socket) 41

Channel 1 signal input and input for horizontal defl ection in

XY mode.

Front Panel Elements – Brief Description

POWER

POWER

15

13

14

17

16

18

1 2 3

INTENS

POWER

!

EXIT MENU

REMOTE OFF

POSITION 1 POSITION 2

VOLTS / DIV

SCALE · VAR

20 V 1 mV 20 V 1 mV

CH 1

VAR

X-INP

!

CAT I

FOCUS

TRACE

MENU

REM

CH 1/2

CURSOR

MA/REF

ZOOM

AUTO/

CURSOR

MEASURE

VERT/XY

INPUTS

1MΩII15pF

max

400 Vp

4

ANALOG

DIGITAL

5 6 7 8 9 10 11 12

ANALOG

DIGITAL

MATH

RECALL

OSCILLOSCOPE

HM1008

·

1 MB

1 GSa

100 MHz

VOLTS / DIV

SCALE · VAR

CH 2 HOR MAG

RUN ACQUIRE SETTINGS HELP

STOP

LEVEL A/B

TRIGGER

MODE

FILTER

SOURCE

AUX

X-POS

DELAY

TRIG ’d

NORM

HOLD OFF

VAR

AUXILIARY INPUT

TRIGGER

EXTERN

!

CAT I

Z-INPUT

SAVE/

AUTOSET

HORIZONTAL

TIME / DIV

SCALE · VAR

50s 5ns

VAR

x10

1MΩ II

15pF

max

100 Vp

19

26

27

20

23

21

24

28

22

25

29

30

3431

32

33

35

MEMORY

COMBISCOPE

oom

CH2 (BNC-socket) 41

Channel 2 signal input.

AUX (pushbutton switch) 41

Calls AUXILIARY INPUT menu with intensity modulation (Z)

and external triggering selectable.

AUXILIARY INPUT (BNC-socket) 41

Input for external trigger or intensity (Z) modulation si-

gnal.

36

37

COMPONENT

TESTER

40

PROBE

ADJ

3839

PROBE / COMPONENT (pushbutton switch) 42

Calls COMPONENT TESTER mode settings and frequency

selection of PROBE ADJ signal.

COMPONENT TESTER (2 sockets with 4 mm Ø) 42

Connectors for test leads of the Component Tester. Left

socket is galvanically connected with protective earth.

PROBE / ADJ (socket) 42

Square wave signal output for frequency compensation of

x10 probes.

Subject to change without notice

9

Basic signal measurement

Basic signal measurement

Signals which can be measured

The following description pertains as well to analog as to

DSO operation. The different specifi cations in both operating

modes should be kept in mind.

The oscilloscope HM1008 can display all repetitive signals

with a fundamental repetition frequency of at least 100 MHz.

The frequency response is 0 to 100 MHz (-3 dB). The vertical

amplifi ers will not distort signals by overshoots, undershoots,

ringing etc.

Simple electrical signals like sine waves from line frequency

ripple to hf will be displayed without problems. However,

when measuring sine waves, the amplitudes will be displayed

with an error increasing with frequency. At 80 MHz the amplitude error will be around –10 %. As the bandwidths of individual instruments will show a certain spread (the 100 MHz

are a guaranteed minimum) the actual measurement error

for sine waves cannot be exactly determined.

Pulse signals contain harmonics of their fundamental frequency which must be represented, so the maximum useful

repetition frequency of nonsinusoidal signals is much lower

than 100 MHz. The criterion is the relationship between the

rise times of the signal and the scope; the scope’s rise time

should be <1/3 of the signal’s rise time if a faithful reproduction without too much rounding of the signal shape is to

be preserved.

The display of a mixture of signals is especially diffi cult

if it contains no single frequency with a higher amplitude

than those of the other ones as the scope’s trigger system

normally reacts to a certain amplitude. This is e.g. typical of

burst signals. Display of such signals may require using the

HOLD-OFF control.

Composite video signals may be displayed easily as the instrument has a tv sync separator.

The maximum sweep speed of 5 ns/cm allows suffi cient time

resolution, e.g. a 100 MHz sine wave will be displayed one

period per 2 cm.

The vertical amplifi er inputs may be dc or ac coupled. Use dc

coupling only if necessary and preferably with a probe.

Low frequency signals when ac coupled will show tilt (ac low

frequency – 3 dB point is 1.6 Hz), so if possible use dc coupling.

Using a probe with 10:1 or higher attenuation will lower the

–3 dB point by the probe factor. If a probe cannot be used

due to the loss of sensitivity dc coupling the scope and an

external large capacitor may help which, of course, must have

a suffi cient dc rating. Care must be taken, however, when

charging and discharging a large capacitor.

Amplitude of signals

In contrast to the general use of rms values in electrical engineering oscilloscopes are calibrated in Vpp as that is what is

displayed.

Derive rms from V

: divide by 2.84. Derive Vpp from rms: mul-

pp

tiply by 2.84.

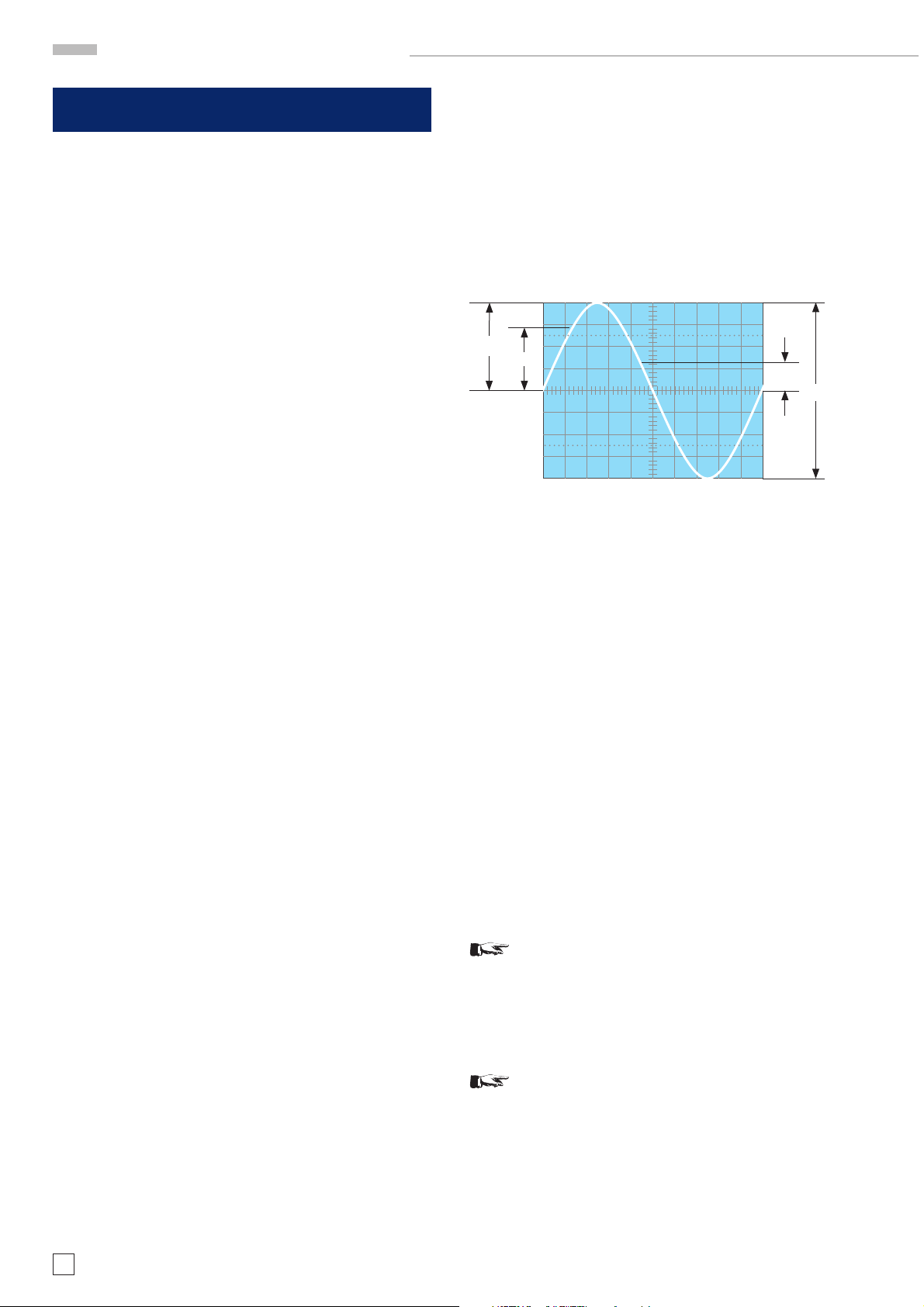

Values of a sine wave signal

V

p

V

rms

V

mom

V

pp

V

= rms value

rms

V

= pp – value

PP

V

= momentary value, depends on time vs. period.

mom

The minimum signal for a one cm display is 1 mV

ded 1 mV/cm was selected and the variable is in the calibrated

position.

The available sensitivities are given in mV

pp

allow to indicate the amplitudes of the signals immediately on

the readout as the attenuation of probes is automatically taken

into account. Even if the probe attenuation was selected manually this will be overridden if the scope identifi es a probe with

an identifi cation contact as different. The readout will always

give the true amplitude.

It is important that the variable be in its calibrated position. The

sensitivity may be continuously decreased by using the variable

(see Controls and Readout). Each intermediate value between

the calibrated positions 1–2–5 may be selected. Without using

a probe thus a maximum of 400 V

may be displayed (20 V/div

PP

x 8 cm screen x 2.5 variable).

Amplitudes may be directly read off the screen by measuring

the height and multiplying by the V/div. setting.

Please note: Without a probe the maximum permis-

sible voltage at the inputs must not exceed 400 V

irrespective of polarity.

In case of signals with a dc content the peak value DC + AC

peak must not exceed + or – 400 V

. Pure AC of up to 800 VPP

P

is permissible.

If probes are used their possibly higher ratings are

only usable if the scope is dc coupled.

±5 % provi-

pp

or Vpp. The cursors

p

Dc coupling is preferable with all signals of varying duty cycle, otherwise the display will move up and down depending

on the duty cycle. Of course, pure dc can only be measured

with dc coupling.

The readout will show which coupling was chosen: = stands

for DC, ~ stands for AC.

10

Subject to change without notice

In case of measuring dc with a probe while the scope input is

ac coupled the capacitor in the scope input will see the input

dc voltage as it is in series with the internal 1 MΩ resistor.

This means that the maximum dc voltage (or DC + peak AC) is

that of the scope input, i.e. 400 V

! With signals which contain

P

dc and ac the dc content will stress the input capacitor while

the ac content will be divided depending on the ac impedance

of the capacitor. It may be assumed that this is negligible for

frequencies >40 Hz.

Considering the foregoing you may measure dc signals of up

to 400 V or pure ac signals of up to 800 V

with a HZ200 probe.

PP

Probes with higher attenuation like HZ53 100:1 allow to measure

dc up to 1200 V and pure ac of up to 2400 V

. (Please note the

PP

derating for higher frequencies, consult the HZ53 manual).

Stressing a 10:1 probe beyond its ratings will risk destruction of

the capacitor bridging the input resistor with possible ensuing

damage of the scope input!

In case the residual ripple of a high voltage is to be measured a

high voltage capacitor may be inserted in front of a 10:1 probe, it

will take most of the voltage as the value of the probe’s internal

capacitor is very low, 22 to 68 nF will be suffi cient.

If the input selector is switched to Ground the reference trace

on the screen may be positioned at graticule center or elsewhere.

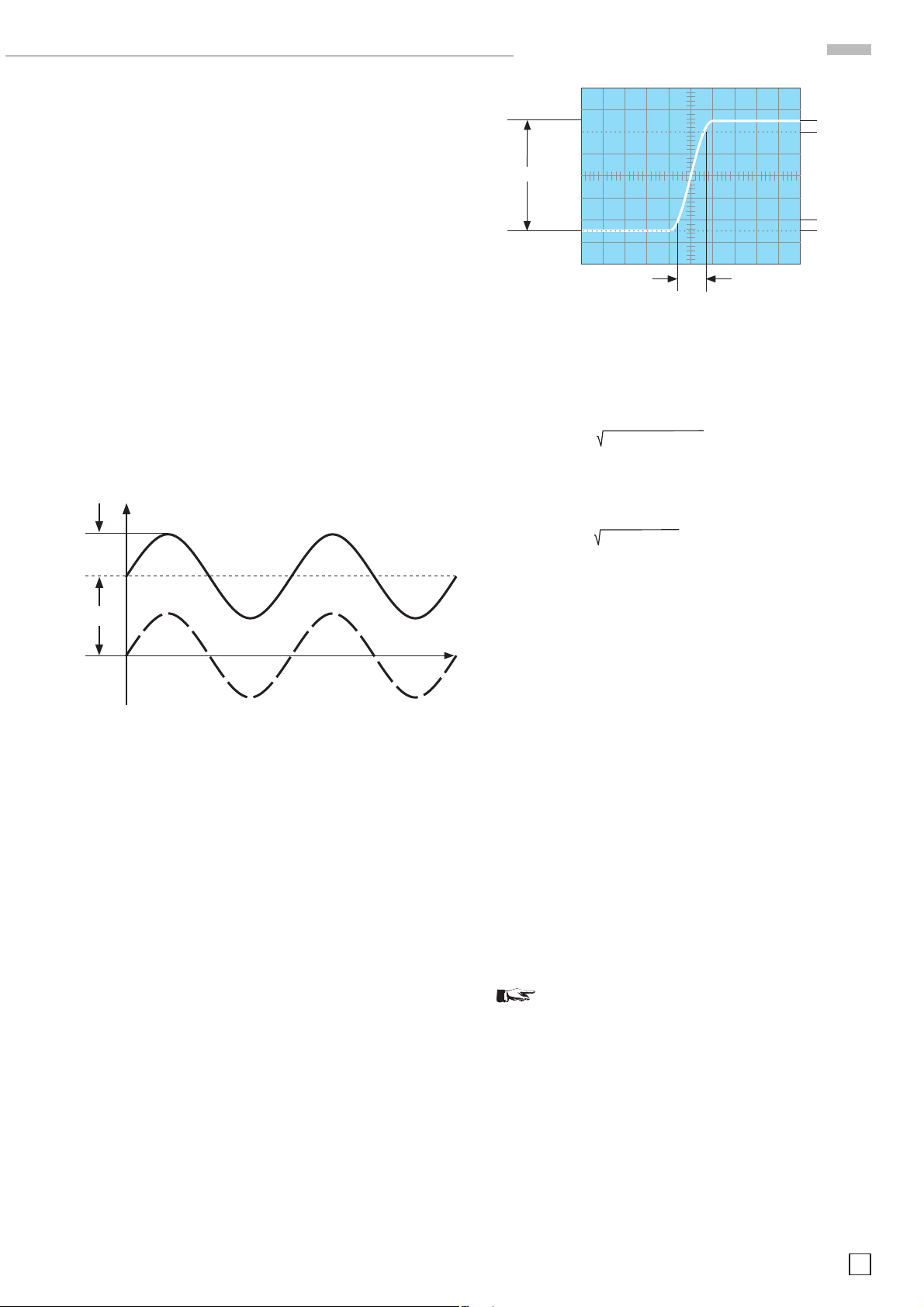

DC and ac components of an input signal

voltage

peak

AC

DC

DC + AC

DC

AC

peak

= 400 V

max

The dashed curve shows an ac signal symmetrical to zero.

If there is a dc component the peak value will be dc + ac peak.

Timing relationships

The repetition frequency of a signal is equal to the number of

periods per second. Depending on the TIME/DIV setting one or

more periods or part of a period of the signal may be displayed.

The time base settings will be indicated on the readout in s/cm,

ms/cm, μs/cm and ns/cm. Also the cursors may be used to

measure the frequency or the period.

If portions of the signal are to be measured use delayed sweep

(analog mode) or zoom (DSO mode) or the magnifi er x 10. Use

the HORIZONTAL positioning control to shift the portion to be

zoomed into the screen center.

Pulse signals are characterized by their rise and fall times

which are measured between the 10 % and 90 % portions. The

following example uses the internal graticule of the crt, but also

the cursors may be used for measurement.

Measurement:

– Adjust the rising portion of the signal to 5 cm.

– Position the rising portion symmetrically to the graticule

centre line, using both Y and X positioning controls.

– Notice the intersections of the signal with the 10 and 90 %

lines and project these points to the centre line in order to

read the time difference.

Basic signal measurement

100%

90%

5 cm

10%

0%

t

tot

In the example it was 1.6 cm at 5 ns/cm equals 8 ns rise time.

When measuring very short rise times coming close to the scope

rise time it is necessary to subtract the scope’s (and if used the

probe’s) rise times geometrically from the rise time as seen on

the screen. The true signal rise time will become:

2

2

ta= t

t

is the rise time seen, t

tot

– t

tot

(3.5 ns with the HM1008), t

2

– t

osc

t

is the scope’s own rise time

osc

is the rise time of the probe, e.g.

t

2 ns. If the signal’s rise time is > 34 ns, the rise times of scope

and probe may be neglected.

ta= 82 - 3.52 - 22 = 6.9 ns

For the measurement of rise times it is not necessary to proceed

as outlined above. Rise times may be measured anywhere on

the screen. It is mandatory that the rising portion of the signal

be measured in full and that the 10 to 90 % are observed. In

case of signals with over- or undershoot the 0 and 100 % levels

are those of the horizontal portions of the signal, i.e. the overresp. undershoots must be disregarded for rise and fall time

measurements. Also, glitches will be disregarded. If signals

are very distorted, however, rise and fall time measurements

may be of no value.

For most amplifi ers, even if their pulse behaviour is far from

ideal, the following relationship holds:

350 350

t

=

——

a

B t

B =

——

a

tr/ns = 350/Bandwidth/MHz

Connection of signals

In most cases pressing the AUTOSET button will yield a satisfactory display (see AUTOSET). The following relates to special

cases where manual settings will be advisable. For a description

of controls refer to ”Controls and Readout“.

Take care when connecting unknown signals to the

inputs!

It is recommended to use probes whenever possible. Without

a probe start with the attenuator set to its 20 V/cm position.

If the trace disappears the signal amplitude may be too large

overdriving the vertical amplifi er or/and its dc content may be

too high. Reduce the sensitivity until the trace will reappear

onscreen. If calibrated measurements are desired it will be

necessary to use a probe if the signal becomes >160 Vp. Check

the probe specifi cations in order to avoid overstressing. If the

time base is set too fast the trace may become invisible, then

reduce the time base speed.

If no probe is used at least screened cable should be used,

such as HZ32 or HZ34. However, this is only advisable for low

Subject to change without notice

11

First time operation and initial adjustments

impedance sources or low frequencies (<50 kHz). With high

frequencies impedance matching will be necessary.

Nonsinusoidal signals require impedance matching, at both

ends preferably. At the scope input a feed through – 50 Ω-termination will be required. HAMEG offers a HZ22 termination. If

proper terminations are not used sizeable pulse aberrations will

result. Also sine wave signals of > 100 kHz should be properly

terminated. Most generators control signal amplitudes only if

correctly terminated.

HZ22 may only be used up to 7 V

or 20 VPP i.e. 1 W.

rms

For probes terminations are neither required nor allowed, they

would ruin the signal.

Probes feature very low loads at fairly low frequencies: 10 MΩ in

parallel to a few pF, valid up to several hundred kHz. However,

the input impedance diminishes with rising frequency to quite

low values. This has to be borne in mind as probes are, e.g.,

entirely unsuitable to measure signals across high impedance

high frequency circuits such as bandfi lters etc.! Here only FET

probes can be used. Use of a probe as a rule will also protect

the scope input due to the high probe series resistance (9 MΩ).

As probes cannot be calibrated exactly enough during manufacturing individual calibration with the scope input used is

mandatory! (See Probe Calibration).

Passive probes will, as a rule, decrease the scope bandwidth

resp. increase the rise time. We recommend to use HZ200 probes in order to make maximum use of the combined bandwidth.

HZ200 features 2 additional hf compensation adjustments.

First time operation and initial adjustments

Prior to fi rst time operation the connection between the instrument and safety ground must be ensured, hence the plug must

be inserted fi rst.

Use the red pushbutton POWER to turn the scope on. Several

displays will light up. The scope will then assume the set-up,

which was selected before it was turned off. If no trace and

no readout are visible after approximately 20 sec, push the

AUTOSET button.

As soon as the trace becomes visible select an average intensity with INTENS, then select FOCUS and adjust it, then select

TRACE ROTATION and adjust for a horizontal trace.

With respect to crt life use only as much intensity as necessary

and convenient under given ambient light conditions, if unused

turn the intensity fully off rather than turning the scope off and

on too much, this is detrimental to the life of the crt heater.

Do not allow a stationary point to stay, it might burn the crt

phosphor.

With unknown signals start with the lowest sensitivity 20 V/cm,

connect the input cables to the scope and then to the measuring object which should be deenergized in the beginning. Then

turn the measuring object on. If the trace disappears, push

AUTOSET.

Whenever the DC content is > 400 V

coupling must be used in

DC

order to prevent overstressing the scope input capacitor. This is

especially important if a 100:1 probe is used as this is specifi ed

for 1200 V

+ peak AC.

DC

AC coupling of low frequency signals may produce tilt.

If the dc content of a signal must be blocked it is possible to

insert a capacitor of proper size and voltage rating in front of the

probe, a typical application would be a ripple measurement.

When measuring small voltages the selection of the ground

connection is of vital importance. It should be as close to voltage

take-off point as possible, otherwise ground currents may deteriorate the measurement. The ground connections of probes

are especially critical, they should be as short as possible and

of large size.

If a probe is to be connected to a BNC connector use

a probe tip to BNC adapter.

If ripple or other interference is visible, especially at high sensitivity, one possible reason may be multiple grounding. The

scope itself and most other equipment are connected to safety

ground, so ground loops may exist. Also, most instruments will

have capacitors between line and safety ground installed which

conduct current from the live wire into the safety ground.

Trace rotation TR

The crt has an internal graticule. In order to adjust the defl ected

beam with respect to this graticule the Trace Rotation control

is provided. Select the function Trace Rotation and adjust for a

trace which is exactly parallel to the graticule.

Probe adjustment and use

In order to ensure proper matching of the probe used to the

scope input impedance the scope contains a calibrator with

short rise time and an amplitude of 0.2 V

± 1 %, equivalent to

pp

4 cm at 5 mV/cm when using 10:1 probes.

The inner diameter of the calibrator connector is 4.9 mm and

standardized for series F probes. Using this special connector is the only way to connect a probe to a fast signal source

minimizing signal and ground lead lengths and to ensure true

displays of pulse signals.

1 kHz adjustment

This basic adjustment will ensure that the capacitive attenuation

equals the resistive attenuation thus rendering the attenuation

of the probe independent of frequency. 1:1 probes can not be

adjusted and need no such adjustment anyway.

12

Subject to change without notice

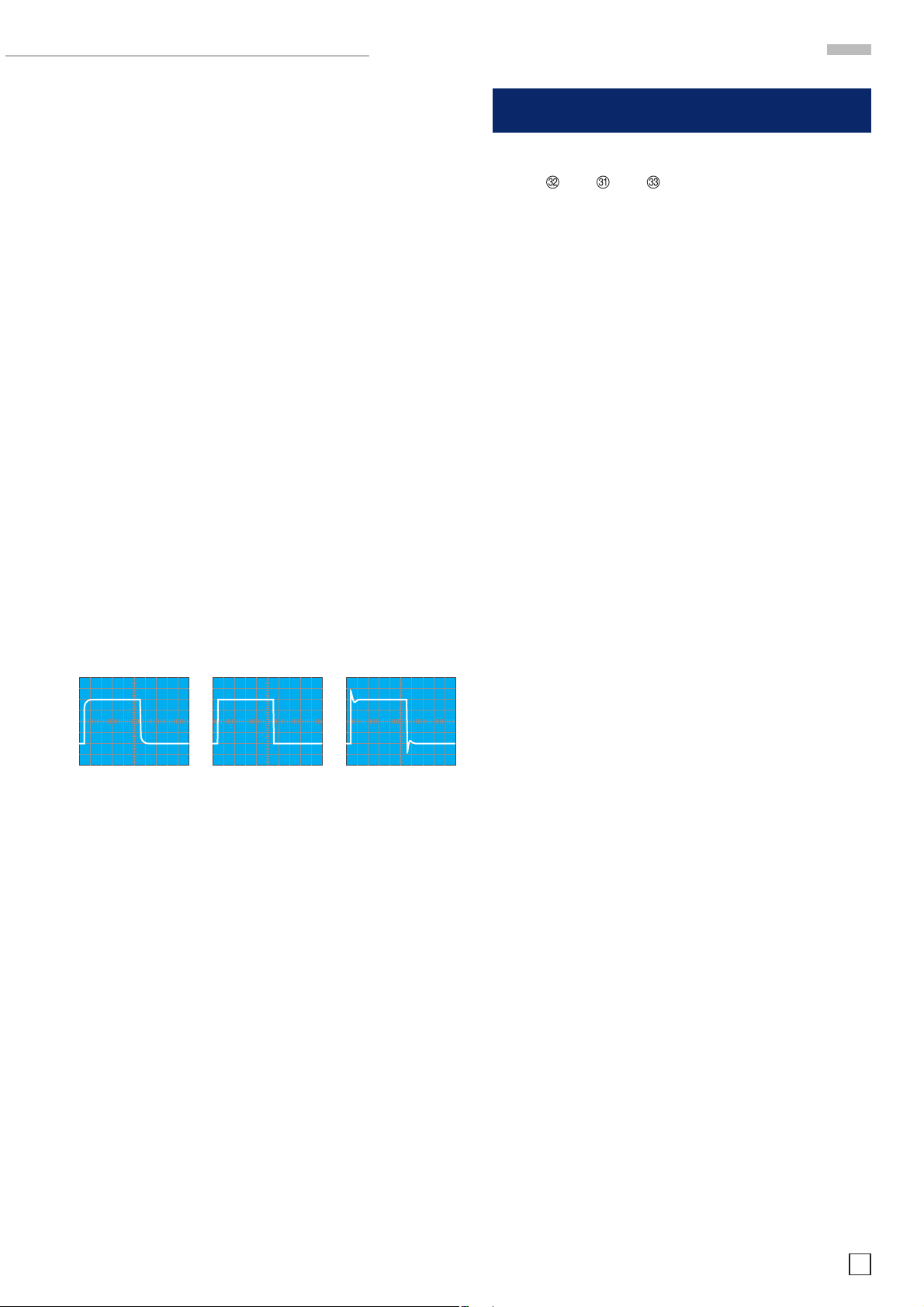

incorrect correct incorrect

Operating modes of the vertical amplifier

Prior to adjustment make sure that the trace rotation adjustment was performed.

Connect the 10:1 probe to the input. Use dc coupling. Set

the VOLTS/DIV to 5 mV/cm and TIME/DIV to 0.2 ms/cm, both

calibrated. Insert the probe tip into the calibrator connector

PROBE ADJ.

You should see 2 signal periods. Adjust the compensation capacitor (see the probe manual for the location) until the square

wave tops are exactly parallel to the graticule lines (see picture

1 kHz). The signal height should be 4 cm ±1.6 mm (3% oscilloscope and 1% probe tolerance). The rising and falling portions

of the square wave will be invisible.

1 MHz adjustment

The HAMEG probes feature additional adjustments in the

compensation box which allow to optimise their hf behaviour.

This adjustment is a precondition for achieving the maximum

bandwidth with probe and a minimum of pulse aberrations.

This adjustment requires a calibrator with a short rise time (typ.

4 ns) and a 50 Ω output, a frequency of 1 MHz, an amplitude

of 0.2 V

requirements.

Connect the probe to the scope input to which it is to be adjusted.

Select the PROBE ADJ. signal 1 MHz. Select dc coupling and

5 mV/cm with VOLTS/DIV. and 0.1 μs/cm with TIME/DIV., both

calibrated. Insert the probe tip into the calibrator output connector. The screen should show the signal, rise and fall times will

be visible. Watch the rising portion and the top left pulse corner,

consult the manual for the location of the adjustments.

. The PROBE ADJ. output of the scope fulfi ls these

PP

Operating modes of the vertical amplifi er

The controls most important for the vertical amplifi er are:

VERT/XY

containing the operating modes and the parameters of the

individual channels.

Changing the operating mode is described in the chapter:

”Controls and Readout“.

Remark: Any reference to ”both channels“ always refers to

channels 1 and 2.

Usually oscilloscopes are used in the Yt mode. In analog mode

the amplitude of the measuring signal will defl ect the trace

vertically while a time base will defl ect it from left to right.

The vertical amplifi ers offer these modes:

– One signal only with CH1.

– One signal only with CH2.

– Two signals with channels 1 and 2 (DUAL trace mode)

In DUAL mode both channels are operative. In analog mode

the method of signal display is governed by the time base (see

also ”Controls and Readout“). channel switching may either

take place after each sweep (alternate) or during sweeps with

a high frequency (chopped).

The normal choice is alternate, however, at slow time base settings the channel switching will become visible and disturbing,

when this occurs select the chopped mode in order to achieve

a stable quiet display.

, CH1 , CH2 . They give access to the menus

incorrect correct incorrect

The criteria for a correct adjustment are:

– short rise time, steep slope.

– clean top left corner with minimum over- or undershoot,

fl at top.

After adjustment check the amplitude which should be the

same as with 1 kHz.

It is important to fi rst adjust 1 kHz, then 1 MHz. It may be necessary to check the 1 kHz adjustment again.

Please note that the calibrator signals are not calibrated with

respect to frequency and thus must not be used to check the

time base accuracy, also their duty cycle may differ from 1:1.The

probe adjustment is completed if the pulse tops are horizontal

and the amplitude calibration is correct.

In DSO mode no channel switching is necessary as each input

has its own A/D converter, signal acquisition is simultaneous.

In ADD mode the two channels 1 and 2 are algebraically added (±CH1 ±CH2). With + polarity the channel is normal, with

– polarity inverted. If + Ch1 and – CH2 are selected the difference

will be displayed or vice versa.

Same polarity input signals:

Both channels not inverted: = sum

Both channels inverted: = sum

Only one channel inverted: = difference

Opposite polarity input signals:

Both channels not inverted: = difference

Both channels inverted: = difference

One channel inverted: = sum.

Please note that in ADD mode both position controls will be

operative. The INVERT function will not affect positioning.

Often the difference of two signals is to be measured at signal

take-offs which are both at a high common mode potential.

While this one typical application of the difference mode one

important precaution has to be borne in mind: The oscilloscope vertical amplifi ers are two separate amplifi ers and do not

constitute a true difference amplifi er with as well a high CM

rejection as a high permissible CM range! Therefore please

observe the following rule: Always look at the two signals in

the one channel only or the dual modes and make sure that

they are within the permissible input signal range; this is the

case if they can be displayed in these modes. Only then switch

to ADD. If this precaution is disregarded grossly false displays

Subject to change without notice

13

Operating modes of the vertical amplifier

may result as the input range of one or both amplifi ers may

be exceeded.

Another precondition for obtaining true displays is the use of

two identical probes at both inputs. But note that normal probe

tolerances (percent) will cause the CM rejection to be expected

to be rather moderate. In order to obtain the best possible results proceed as follows: First adjust both probes as carefully

as possible, then select the same sensitivity at both inputs and

then connect both probes to the output of a pulse generator

with suffi cient amplitude to yield a good display. Readjust one

(!) of the probe adjustment capacitors for a minimum of overor undershoot. As there is no adjustment provided with which

the resistors can be matched a residual pulse signal will be

unavoidable.

When making difference measurements it is good practice

to fi rst connect the ground cables of the probes to the object

prior to connecting the probe tips. There may be high potentials

between the object and the scope. If a probe tip is connected

fi rst there is danger of overstressing the probe or/and the scope

inputs! Never perform difference measurements without both

probe ground cables connected.

XY operation

This mode is accessed by VERT/XY > XY. In analog mode

the time will be turned off. The channel 1 signal will defl ect in X

direction (X-INP. = horizontal input), hence the input attenuators,

the variable and the POSITION 1 control will be operative. The

HORIZONTAL control will also remain functional.

Channel 2 will defl ect in Y direction.

Please note:

– As the trigonometric functions are

periodic limit the calculation to

angles <90 degrees. This is where

this function is most useful.

– Do not use too high frequencies,

because, as explained above, the

two amplifi ers are not identical,

their phase difference increases with frequency. The spec

gives the frequency at which the phase difference will stay

<3 degrees.

– The display will not show which of the two frequencies does

lead or lag. Use a CR combination in front of the input of the

frequency tested. As the input has a 1 MΩ resistor it will be

suffi cient to insert a suitable capacitor in series. If the ellipse

increases with the C compared to the C short-circuited the

test signal will lead and vice versa. This is only valid <90

degrees. Hence C should be large and just create a barely

visible change.

If in XY mode one or both signals disappear, only a line or a point

will appear, mostly very bright. In case of only a point there is

danger of phosphor burn, so turn the intensity down immediately; if only a line is shown the danger of burn will increase the

shorter the line is. Phosphor burn is permanent.

a

sin ϕ =

b

a

cos ϕ = 1 – (—

b

a

ϕ = arc sin

b

—

2

)

—

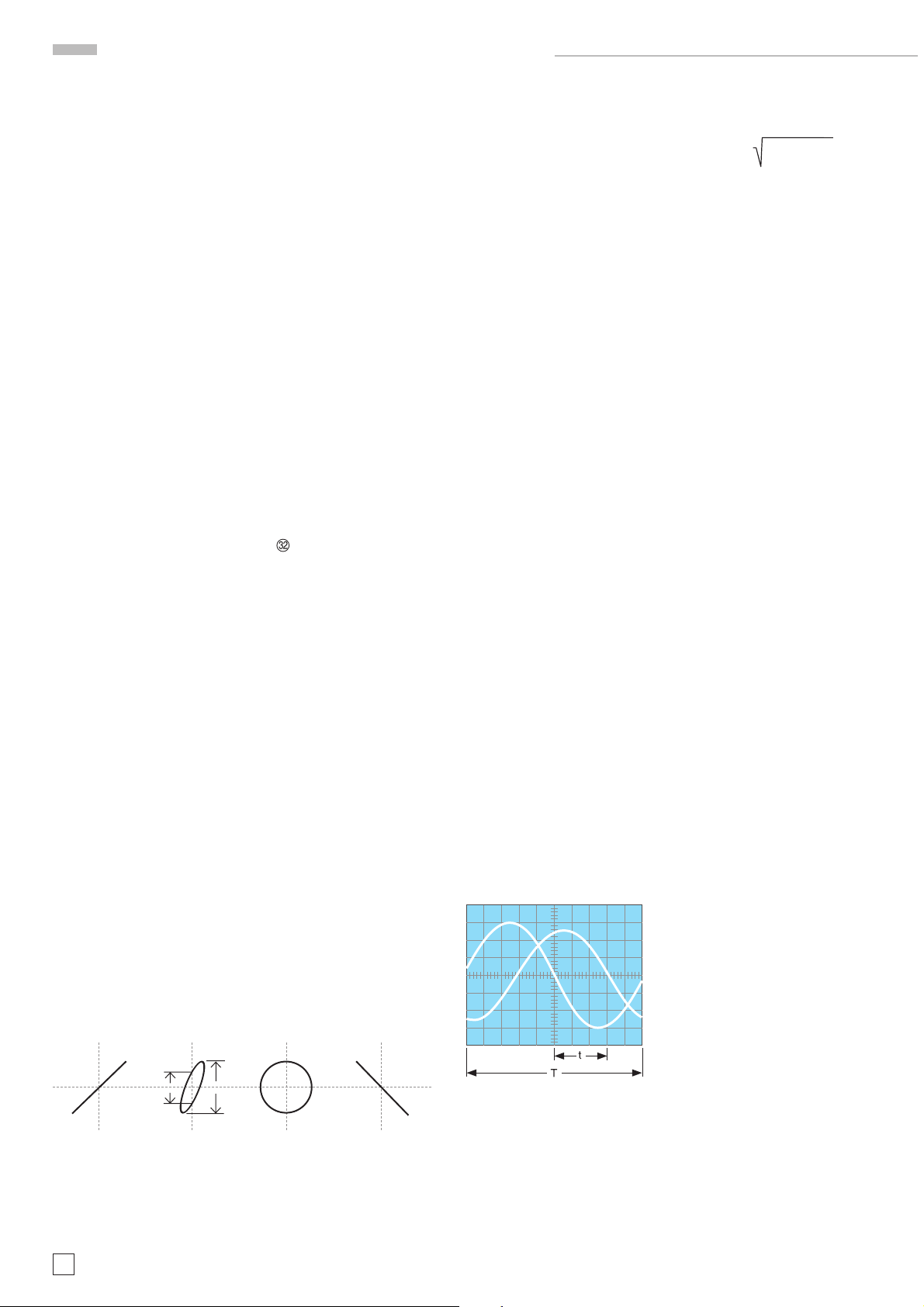

Measurement of phase differences in dual channel

Yt mode

Please note: Do not use ”alternate trigger“ because the time

differences shown are arbitrary and depend only on the respective signal shapes! Make it a rule to use alternate trigger only

in rare special cases.

The x 10 magnifi er will be inoperative in XY mode. Please note

the differences in the Y and X bandwidths, the X amplifi er has

a lower – 3 dB frequency than the Y amplifi er. Consequently

the phase difference between X and Y will increase with frequency.

In XY mode the X signal (CH1 = X-INP). can not be inverted.

The XY mode may generate Lissajous fi gures which simplify

some measuring tasks and make others possible:

– Comparison of two signals of different frequency or adju-

stment of one frequency until it is equal to the other resp.

becomes synchronized.

– This is also possible for multiples or fractions of one of the

frequencies.

Phase measurements with Lissajous fi gures

The following pictures show two sine waves of equal amplitude

and frequency but differing phase.

ab

0° 35° 90° 180°

Calculation of the phase angle between the X- and Y-signals (after reading a and b off the screen) is possible using the following

formulas and a pocket calculator with trigonometric functions.

This calculation is independent of the signal amplitudes:

The best method of measuring time or phase differences is using

the dual channel Yt mode. Of course, only times may be read off

the screen, the phase must then be calculated as the frequency

is known. This is a much more accurate and convenient method

as the full bandwidth of the scope is used, and both amplifi ers

are almost identical. Trigger the time base from the signal

which shall be the reference. It is necessary to position both

traces without signal exactly on the graticule center (POSITION

1 and 2). The variables and trigger level controls may be used,

this will not infl uence the time difference measurement. For

best accuracy display only one period at high amplitude und

observe the zero crossings. One period equals 360 degrees.

It may be advantageous to use ac coupling if there is an offset

in the signals.

t = horizontal spacing of the

zero transitions in div

T= horizontal spacing for one

period in div

In this example t = 3 cm and T = 10 cm, the phase difference in

degrees will result from:

5 3

ϕ° =

—

T 10

or in angular units:

t 3

arc ϕ° =

T 10

· 360° = — · 360° = 108°

—

· 2π = — · 2π = 1,885 rad

14

Subject to change without notice

Triggering and time base

Very small phase differences with moderately high frequencies

may yield better results with Lissajous fi gures.

However, in order to get higher precision it is possible to switch

to higher sensitivities – after accurately positioning at graticule

centre – thus overdriving the inputs resulting in sharper zero

crossings. Also, it is possible to use half a period over the full

10 cm. As the time base is quite accurate increasing the time

base speed after adjusting for e.g. one period = 10 cm and

positioning the fi rst crossing on the fi rst graticule line will also

give better resolution.

Measurement of amplitude modulation

Please note: Use this only in analog mode because in DSO mode

alias displays may void the measurement! For the display of

low modulation frequencies a slow time base (TIME/DIV) has

to be selected in order to display one full period of the modulating signal. As the sampling frequency of any DSO must be

reduced at slow time bases it may become too low for a true

representation.

The momentary amplitude at time t of a hf carrier frequency

modulated by a sinusoidal low frequency is given by:

u = UT · sinΩt + 0,5 m · UT · cos (Ω - ω) t - 0,5 m · UT · cos (Ω - ω) t

where: UT = amplitude of the unmodulated carrier

Ω = 2πF = angular carrier frequency

ω = 2πf = modulation angular frequency

m = modulation degree (≤1

In addition to the carrier a lower side band F – f and an upper

side band F + f will be generated by the modulation.

U

T

v100%)

Set the scope controls as follows in order to display the picture

2 signal:

CH1 only, 20 mV/cm, AC

TIME/DIV: 0.2 ms/cm

Triggering: NORMAL, AC, internal.

Use the time base variable or external triggering.

Reading a and b off the screen the modulation degree will

result:

a – b a – b

m =

——

a + b a + b

(1 + m) and b = UT (1 – m)

a = U

T

bzw. m =

—— · 100 [%]

When measuring the modulation degree the amplitude and time

variables can be used without any infl uence on the result.

Triggering and time base

The most important controls and displays for these functions

are to be found in the shaded TRIGGER area, they are described

in „Controls and Readout“.-

In YT mode the signal will defl ect the trace vertically while the

time will defl ect it horizontally, the speed can be selected.

In general periodic voltage signals are displayed with a periodically repeating time base. In order to have a stable display

successive periods must trigger the time base at exactly the

same time position of the signal (amplitude and slope).

0,5 m · U

T

0,5 m · U

T

F – f F F + f

Picture 1: Amplitudes and frequencies with AM (m = 50 %) of

the spectra

As long as the frequencies involved remain within the scope’s

bandwidth the amplitude-modulated hf can be displayed. Preferably the time base is adjusted so that several signal periods

will be displayed. Triggering is best done from the modulation

frequency. Sometimes a stable displayed can be achieved by

twiddling with the time base variable.

m · U

T

U

T

ba

Pure DC can not trigger the time base, a voltage

change is necessary.

Triggering may be internal from any of the input signals or

externally from a time-related signal.

For triggering a minimum signal amplitude is required which

can be determined with a sine wave signal. With internal triggering the trigger take-off within the vertical amplifi ers is directly

following the attenuators. The minimum amplitude is specifi ed

in mm on the screen. Thus it is not necessary to give a minimum

voltage for each setting of the attenuator.

For external triggering the appropriate input connector is used,

the amplitude necessary there is given in V

. The voltage for

pp

triggering may be much higher than the minimum, however, it

should be limited to 20 times the minimum. Please note that

for good triggering the voltage resp. signal height should be a

good deal above the minimum. The scope features two trigger

modes to be described in the following:

Automatic peak triggering (MODE menu)

Consult the chapters MODE > AUTO, LEVEL A/B , FILTER

and SOURCE in ”Controls and Readout“. Using AUTOSET

this trigger mode will be automatically selected. With DCcoupling and with alternate trigger this mode will be left while

the automatic triggering will remain.

Picture 2: Amplitude modulated HF. F = 1 MHz, f = 1 kHz,

m = 50 %, U

= 28,3 mV

T

rms

Automatic triggering causes a new time base start after the end

of the foregoing and after the hold-off time has elapsed even

Subject to change without notice

15

Triggering and time base

without any input signal. Thus there is always a visible trace in

analog mode, and in DSO mode the trace will also be shown.

The position of the trace(s) without any signal is then given by

the settings of the POSITION controls.

As long as there is a signal scope operation will not need more

than a correct amplitude and time base setting. With signals

< 20 Hz their period is longer than the time the auto trigger

circuit will wait for a new trigger, consequently the auto trigger

circuit will start the time base then irrespective of the signal so

that the display will not be triggered and free run, quite independent of the signal’s amplitude which may be much larger

than the minimum.

Also in auto peak trigger mode the trigger level control is active.

Its range will be automatically adjusted to coincide with the

signal’s peak-to-peak amplitude, hence the name. The trigger

point will thus become almost independent of signal amplitude.

This means that even if the signal is decreased the trigger will

follow, the display will not loose trigger. As an example: the

duty cycle of a square wave may change between 1:1 and 100:1

without loosing the trigger.

Depending on the signal the LEVEL A/B control may have to be

set to one of its extreme positions.

The simplicity of this mode recommends it for most uncomplicated signals. It is also preferable for unknown signals.

negative portion of a signal. This is valid in automatic and

normal modes.

Trigger coupling (Menu: FILTER)

Consult chapters: MODE > AUTO, LEVEL A/B , FILTER

and SOURCE

coupling will be used unless ac coupling was selected before.

The frequency responses in the diverse trigger modes may be

found in the specifi cations.

With internal dc coupling with or without LF fi lter use normal

triggering and the level control. The trigger coupling selected

will determine the frequency response of the trigger channel.

AC:

This is the standard mode. Below and above the fall-off of the

frequency response more trigger signal will be necessary.

DC:

With direct coupling there is no lower frequency limit, so this

is used with very slowly varying signals. Use normal triggering

and the level control. This coupling is also indicated if the signal

varies in its duty cycle.

HF:

A high pass is inserted in the trigger channel, thus blocking low

frequency interference like fl icker noise etc.

in ”Controls and Readout“. In AUTOSET DC

This trigger mode is independent of the trigger source and

usable as well for internal as external triggering. But the signal

must be > 20 Hz.

Normal trigger mode (See menu MODE)

Consult the chapters: MODE > AUTO, LEVEL A/B , FILTER

and SOURCE in ”Controls and Readout“. Information

about how to trigger very diffi cult signals can be found in the

HOR menu

VAR, HOLD-OFF time setting, and time base B operation are

explained.

With normal triggering and suitable trigger level setting triggering may be chosen on any point of the signal slope. Here, the

range of the trigger level control depends on the trigger signal

amplitude. With signals <1 cm care is necessary.

In normal mode triggering there will be no trace visible in the

absence of a signal or when the signal is below the minimum

trigger amplitude requirement!

Normal triggering will function even with complicated signals. If

a mixture of signals is displayed triggering will require repetition

of amplitudes to which the level can be set. This may require

special care in adjustment.

where the functions time base fi ne adjustment

Slope selection (Menu FILTER)

After entering FILTER the trigger slope may be selected using

the function keys. See also ”Controls and Readout“. AUTOSET

will not change the slope.

Noise Reject:

This trigger coupling mode or fi lter is a low pass suppressing

high frequencies. This is useful in order to eliminate hf interference of low frequency signals. This fi lter may be used in

combination with dc or ac coupling, in the latter case very low

frequencies will also be attenuated.

LF:

This is also a low pass fi lter with a still lower cut-off frequency

than above which also can be combined with dc or ac coupling.

Selecting this fi lter may be more advantageous than using dc

coupling in order to suppress noise producing jitter or double

images. Above the pass band the necessary trigger signal will

rise. Together with ac coupling there will also result a low

frequency cut-off.

Video (tv triggering)

Selecting MODE > Video will activate the TV sync separator

built-in. It separates the sync pulses from the picture content

and enables thus stable triggering independent of the changing

video content.

Composite video signals may be positive or negative. The

sync pulses will only be properly extracted if the polarity

is right. The definition of polarity is as follows: if the video

is above the sync it is positive, otherwise it is negative. The

polarity can be selected after selecting FILTER. If the polarity is wrong the display will be unstable resp. not triggered

at all as triggering will then initiated by the video content.

With internal triggering a minimum signal height of 5 mm

is necessary.

Positive or negative slope may be selected in auto or normal

trigger modes. Also, a setting ”both“ may be selected which will

cause a trigger irrespective of the polarity of the next slope.

Rising slope means that a signal comes from a negative potential and rises towards a positive one. This is independent

of the vertical position. A positive slope may exist also in the

16

Subject to change without notice

The PAL sync signal consists of line and frame signals which

differ in duration. Pulse duration is 5 μs in 64 μs intervals. Frame

sync pulses consist of several pulses each 28 μs repeating each

half frame in 20 ms intervals.

Both sync pulses differ hence as well in duration as in their

repetition intervals. Triggering is possible with both.

Triggering and time base

Frame sync pulse triggering

Remark:

Using frame sync triggering in dual trace chopped mode may

result in interference, then the dual trace alternate mode

should be chosen. It may also be necessary to turn the readout off.

In order to achieve frame sync pulse triggering call MODE,

select video signal triggering and then FILTER to select frame

triggering. It may be selected further whether ”all“, ”only even“

or ”only odd“ half frames shall trigger. Of course, the correct tv

standard must be selected fi rst of all (625/50 or 525/60).

The time base setting should be adapted, with 2 ms/cm a complete half frame will be displayed. Frame sync pulses consist

of several pulses with a half line rep rate.

Line sync pulse triggering

In order to choose line snyc triggering call MODE and select

VIDEO, enter FILTER, make sure that the correct video standard

is selected (625/50 or 525/60) and select Line.

If ALL was selected each line sync pulse will trigger. It is also

possible to select a line number ”LINE No.“.

In order to display single lines a time base setting of TIME/DIV.

= 10 μs/cm is recommended, this will show 1½ lines. In general

the composite video signal contains a high dc component which

can be removed by ac coupling, provided the picture is steady.

Use the POSITION control to keep the display within the screen.

If the video content changes like with a regular tv program only

dc coupling is useful, otherwise the vertical position would

continuously move.

The sync separator is also operative with external triggering.

Consult the specifi cations for the permissible range of trigger

voltage. The correct slope must be chosen as the external

trigger may have a different polarity from the composite video.

In case of doubt display the external trigger signal.

LINE trigger

Consult SOURCE in ”Controls and Readout“ for specifi c

information.

If the readout shows Tr:Line the trigger signal will be internally

taken from the line (50 or 60 Hz).

Alternate trigger

This mode is selected with SOURCE > Alt. 1/2. The readout will display Tr:alt, but no more the trigger point symbol

indicating level and time position. Instead an arrow pointing

upwards will indicate the trigger time position if this lies within

the screen area.

This trigger mode is to be used with greatest care and should be

an exception rather than the rule, because the time relationships

visible on the screen are completely meaningless, they depend

only on the shape of the signals and the trigger level!

In this mode the trigger source will be switched together with

the channel switching, so that when CH1 is displayed in the

dual channel alternate mode the trigger is taken from CH1

and when CH2 is displayed the trigger is taken from CH2. This

way two uncorrelated signals can be displayed together. If this

mode is inadvertently chosen the time relationships between

the signals will also be lost when both signals are correlated!

(Except for the special case that both happen to be square waves

with extremely fast rise times). Of course, this trigger mode is

only possible in the dual channel alternate mode and also not

with external or line trigger. Ac coupling is recommended for

most cases.

External triggering

In analog mode this trigger mode may be selected with SOURCE

> Extern. In DSO mode it is only possible if channels 3 and

4 are turned off. The readout will display Tr:ext. CH4

the input for the external trigger, all internal sources will be

disconnected. In this mode the trigger point symbol (level and

time position) will not be displayed, only the trigger time position

will be indicated. External triggering requires a signal of 0.3 to

3 V

, synchronous to the vertical input signal(s).

PP

Triggering will also be possible within limits with multiples or

fractions of the vertical input signal frequency. As the trigger

signal may have any polarity it may happen that the vertical

input signal will start with a negative slope in spite of having

selected positive slope; slope selection refers now to the external trigger.

will be

Indication of triggered operation (TRIG’D LED)

Refer item in ”Controls and Readout“. The LED labelled

TRIG’D indicates triggered operation provided:

– Suffi cient amplitude of the internal or external trigger signal.

– The trigger point symbol is not above or below the signal.

This trigger signal is independent of the scope input signals and

is recommended for all signals synchronous with the line. Within

limits this will also be true for multiples or fractions of the line

frequency. As the trigger signal is taken off internally there is

no minimum signal height on the screen for a stable display.

Hence even very small voltages like ripple or line frequency

interference can be measured.

Please note that with line triggering the polarity switching will

select either the positive or negative half period of the line, not

the slope. The trigger level control will move the trigger point

over most of a half wave.

Line frequency interference may be checked using a search

coil which preferably should have a high number of turns and

a shielded cable. Insert a 100 Ω resistor between the center

conductor and the BNC connector. If possible the coil should

be shielded without creating a shorted winding.

If these conditions are met the trigger comparator will output

triggers to start the time base and to turn on the trigger indication. The trigger indicator is helpful for setting the trigger

up, especially with low frequency signals (use normal trigger)

resp. very short pulses.

The trigger indication will store and display triggers for 100 ms.

With signals of very low rep rate the indicator will fl ash accordingly. If more than one signal period is shown on the screen

the indicator will fl ash each period.

Hold-off time adjustment

Consult ”Controls and Readout“ HOR > Hold-off time for

specifi c information.

After the time base defl ected the trace from left to right the trace

will be blanked so the retrace is invisible. The next sweep will,

however, not immediately start. Time is required to perform

Subject to change without notice

17

Triggering and time base

internal switching, so the next start is delayed for the so called

hold-off time, irrespective of the presence of triggers. The

hold-off time can be extended from its minimum by a factor of

10:1. Manipulation of the hold-off time and thus of the time for

a complete sweep period from start to start can be useful e.g.

when data packets are to be displayed. It may seem that such

signals can not be triggered. The reason is that the possible

start of a new sweep does not conincide with the start of a data

packet, it may start anywhere, even before a data packet. By