Page 1

ENGLISH

®

Instruments

Oscilloscope

HM 1004-3 .01/.02/.03

MANUAL•HANDBUCH•MANUEL

Page 2

MANUAL•HANDBUCH•MANUEL

Page 3

General information regarding the CE marking .......... 4

General Information ........................................................ 6

Symbols ......................................................................... 6

Use of tilt handle ............................................................ 6

Safety ............................................................................. 6

Intended purpose and operating conditions ................. 6

EMC ............................................................................... 7

Warranty......................................................................... 7

Maintenance .................................................................. 7

Protective Switch-Off .................................................... 7

Power supply ................................................................. 7

Table of contents

Type of signal voltage ..................................................... 8

Amplitude Measurements ............................................. 8

Total value of input voltage ............................................ 9

Time Measurements ..................................................... 9

Connection of Test Signal ............................................ 10

Controls and Readout .................................................... 11

Menu ................................................................................ 21

First Time Operation...................................................... 21

Trace Rotation TR ........................................................ 21

Probe compensation and use ...................................... 21

Adjustment at 1kHz ..................................................... 22

Adjustment at 1MHz ................................................... 22

Operating modes of the

vertical amplifiers in Yt mode ...................................... 23

X-Y Operation ............................................................... 23

Phase comparison with Lissajous figures .................. 23

Phase difference measurement

in DUAL mode (Yt) ....................................................... 24

Phase difference measurement in DUAL mode ........ 24

Measurement of amplitude modulation ..................... 24

Triggering and timebase .............................................. 25

Automatic Peak (value) -Triggering .............................. 25

Normal Triggering ......................................................... 25

Slope ...................................................................... 25

Trigger coupling ............................................................ 26

Triggering of video signals ........................................... 26

Line triggering (~) ........................................................ 26

Alternate triggering ...................................................... 27

External triggering........................................................ 27

Trigger indicator “TR” .................................................. 27

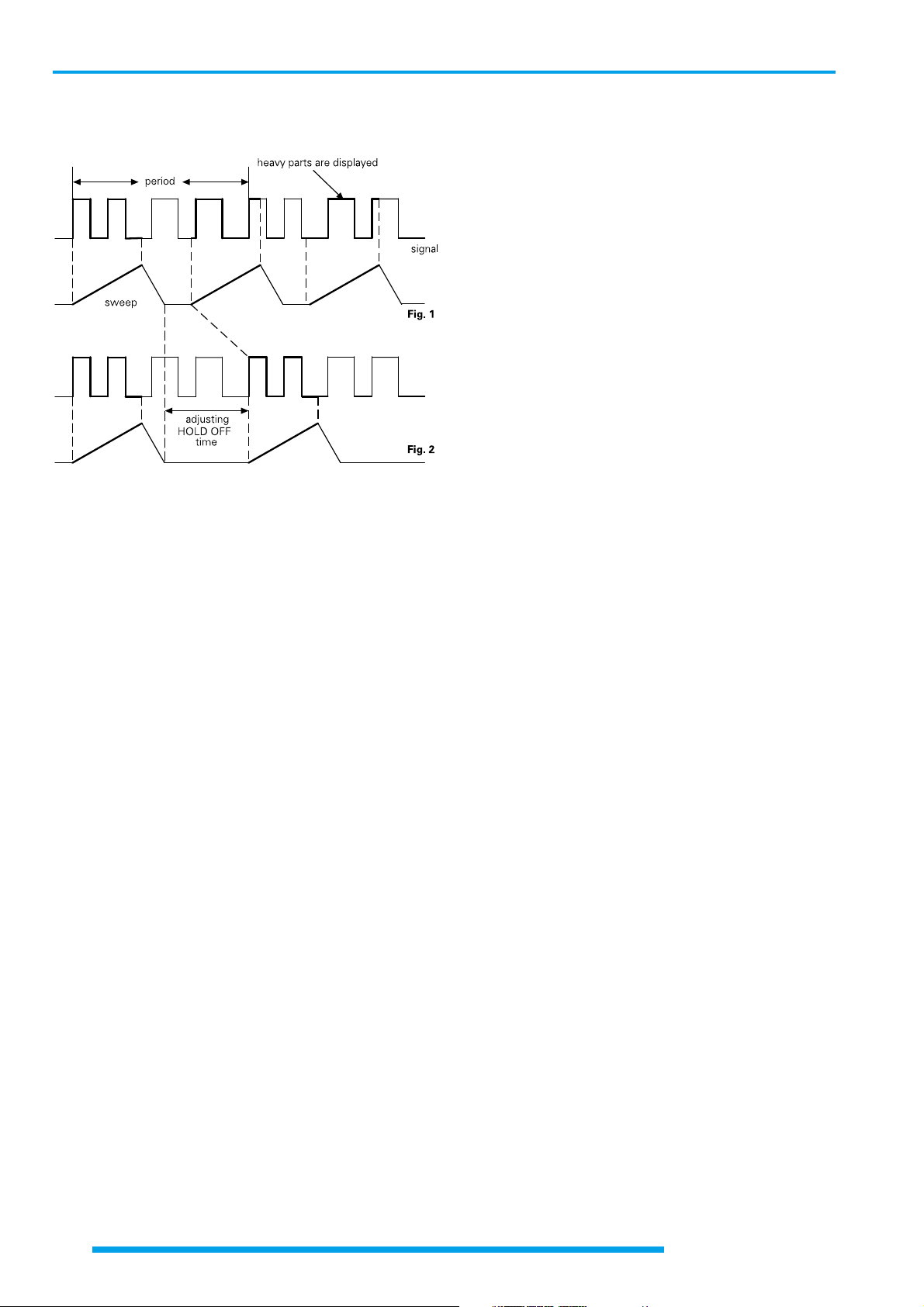

HOLD OFF-time adjustment ....................................... 27

B-Timebase (2nd Timebase)/

Triggering after Delay .................................................. 28

St.190601-Hüb/tke

Auto Set........................................................................... 28

Component Tester .......................................................... 29

General ......................................................................... 29

Using the Component Tester ...................................... 29

Test Procedure ............................................................. 29

Test Pattern Displays ................................................... 29

Testing Resistors ......................................................... 29

Testing Capacitors and Inductors ................................ 29

Testing Semiconductors .............................................. 29

Testing Diodes ............................................................. 30

Testing Transistors ....................................................... 30

In-Circuit Tests ............................................................. 30

Adjustments.................................................................... 31

RS232 Interface - Remote Control ............................... 31

Safety ........................................................................... 31

Operation ..................................................................... 31

Baud-Rate Setting ........................................................ 31

Data Communication ................................................... 31

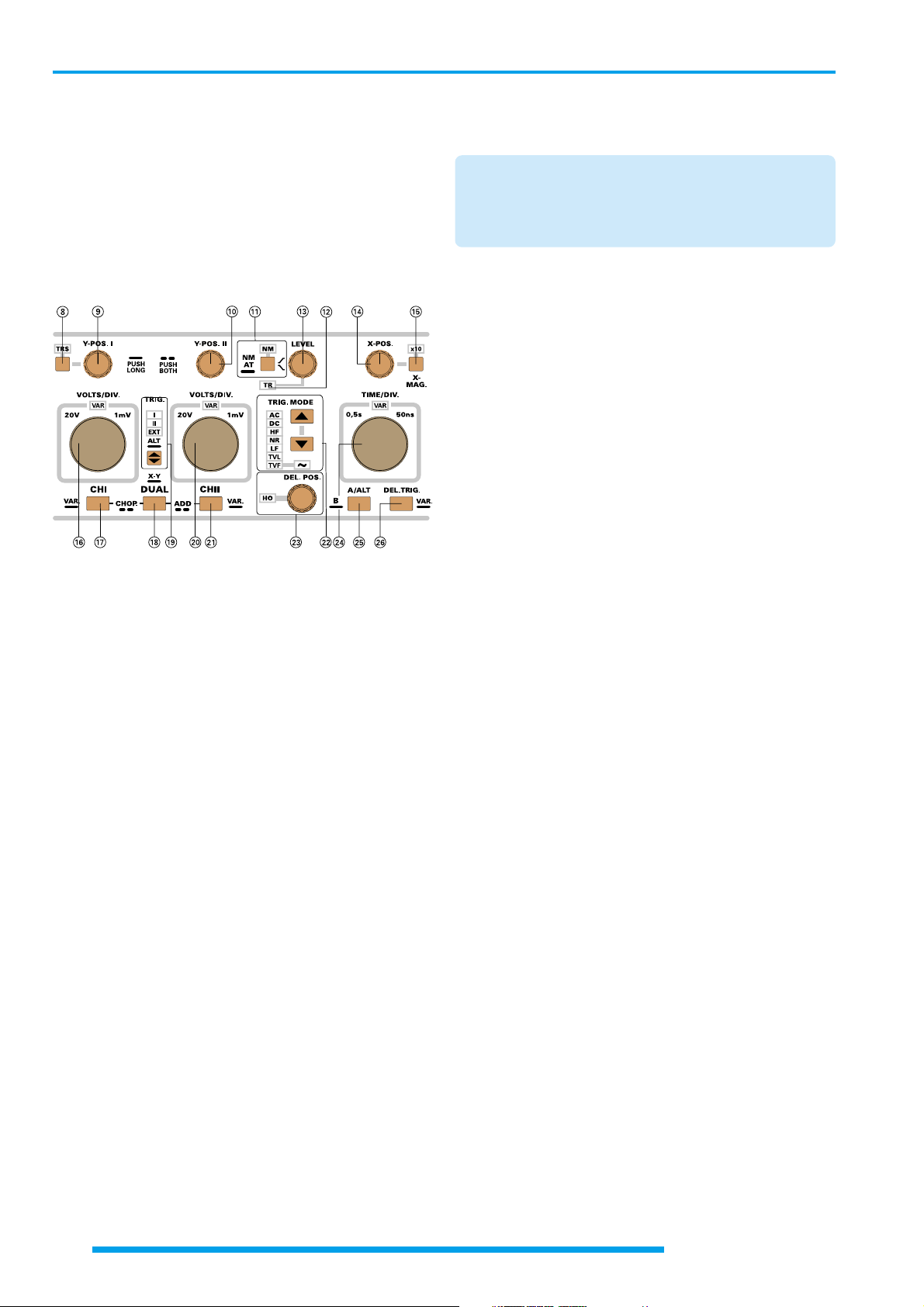

Front Panel HM1004-3 ................................................... 32

Subject to change without notice

3

Page 4

KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE

Herstellers HAMEG GmbH

Manufacturer Kelsterbacherstraße 15-19

Fabricant D - 60528 Frankfurt

Bezeichnung / Product name / Designation:

Oszilloskop/Oscilloscope/Oscilloscope

Typ / Type / Type: HM1004-3

mit / with / avec: -

Optionen / Options / Options: -

mit den folgenden Bestimmungen / with applicable regulations / avec les

directives suivantes

EMV Richtlinie 89/336/EWG ergänzt durch 91/263/EWG, 92/31/EWG

EMC Directive 89/336/EEC amended by 91/263/EWG, 92/31/EEC

Directive EMC 89/336/CEE amendée par 91/263/EWG, 92/31/CEE

Niederspannungsrichtlinie 73/23/EWG ergänzt durch 93/68/EWG

Low-Voltage Equipment Directive 73/23/EEC amended by 93/68/EEC

Directive des equipements basse tension 73/23/CEE amendée par 93/68/CEE

Angewendete harmonisierte Normen / Harmonized standards applied / Normes

harmonisées utilisées

Sicherheit / Safety / Sécurité

EN 61010-1: 1993 / IEC (CEI) 1010-1: 1990 A 1: 1992 / VDE 0411: 1994

EN 61010-1/A2: 1995 / IEC 1010-1/A2: 1995 / VDE 0411 Teil 1/A1: 1996-05

Überspannungskategorie / Overvoltage category / Catégorie de surtension: II

Verschmutzungsgrad / Degree of pollution / Degré de pollution: 2

Elektromagnetische Verträglichkeit / Electromagnetic compatibility /

Compatibilité électromagnétique

EN 61326-1/A1

Störaussendung / Radiation / Emission: Tabelle / table / tableau 4; Klasse / Class /

Classe B.

Störfestigkeit / Immunity / Imunitee: Tabelle / table / tableau A1.

EN 61000-3-2/A14

Oberschwingungsströme / Harmonic current emissions / Émissions de courant

harmonique: Klasse / Class / Classe D.

EN 61000-3-3

Spannungsschwankungen u. Flicker / Voltage fluctuations and flicker /

Fluctuations de tension et du flicker.

Datum /Date /Date Unterschrift / Signature /Signatur

27.03.2001

E. Baumgartner

Technical Manager /Directeur Technique

Instruments

General information regarding the CE marking

HAMEG instruments fulfill the regulations of the EMC directive. The conformity test made by HAMEG is based on the actual generic- and product

standards. In cases where different limit values are applicable, HAMEG applies the severer standard. For emission the limits for residential,

commercial and light industry are applied. Regarding the immunity (susceptibility) the limits for industrial environment have been used.

The measuring- and data lines of the instrument have much influence on emmission and immunity and therefore on meeting the acceptance

limits. For different applications the lines and/or cables used may be different. For measurement operation the following hints and conditions

regarding emission and immunity should be observed:

1. Data cables

For the connection between instruments resp. their interfaces and external devices, (computer, printer etc.) sufficiently screened cables must be

used. Without a special instruction in the manual for a reduced cable length, the maximum cable length of a dataline must be less than 3 meters

and not be used outside buildings. If an interface has several connectors only one connector must have a connection to a cable.

Basically interconnections must have a double screening. For IEEE-bus purposes the double screened cables HZ72S and HZ72L from HAMEG are

suitable.

2. Signal cables

Basically test leads for signal interconnection between test point and instrument should be as short as possible. Without instruction in the manual

for a shorter length, signal lines must be less than 3 meters and not be used outside buildings.

Signal lines must screened (coaxial cable - RG58/U). A proper ground connection is required. In combination with signal generators double

screened cables (RG223/U, RG214/U) must be used.

3. Influence on measuring instruments.

Under the presence of strong high frequency electric or magnetic fields, even with careful setup of the measuring equipment an influence of such

signals is unavoidable.

This will not cause damage or put the instrument out of operation. Small deviations of the measuring value (reading) exceeding the instruments

specifications may result from such conditions in individual cases.

4. RF immunity of oscilloscopes.

4.1 Electromagnetic RF field

The influence of electric and magnetic RF fields may become visible (e.g. RF superimposed), if the field intensity is high. In most cases the

coupling into the oscilloscope takes place via the device under test, mains/line supply, test leads, control cables and/or radiation. The device under

test as well as the oscilloscope may be effected by such fields.

Although the interior of the oscilloscope is screened by the cabinet, direct radiation can occur via the CRT gap. As the bandwidth of each amplifier

stage is higher than the total –3dB bandwidth of the oscilloscope, the influence RF fields of even higher frequencies may be noticeable.

4.2 Electrical fast transients / electrostatic discharge

Electrical fast transient signals (burst) may be coupled into the oscilloscope directly via the mains/line supply, or indirectly via test leads and/or

control cables. Due to the high trigger and input sensitivity of the oscilloscopes, such normally high signals may effect the trigger unit and/or may

become visible on the CRT, which is unavoidable. These effects can also be caused by direct or indirect electrostatic discharge.

HAMEG GmbH

4

Subject to change without notice

Page 5

Analog Oscilloscope HM1004-3 (100MHz)

Autoset, Save / Recall, Readout / Cursor and RS-232 Interface

Specifications

Vertical Deflection

Operating modes: Channel I or II separate,

Chopper Frequency: approx. 0.5MHz

Sum or difference: from CH I and CH II

Invert: both channels

XY-Mode: via channel I (Y) and channel II(X)

Frequency range: 2x DC to 100MHz (-3dB)

Risetime: <3.5ns

Overshoot: ≤1%

Deflection coefficients: 14 calibrated steps

Input impedance: 1MΩ II 15pF.

Input coupling: DC-AC-GD (ground).

Input voltage: max. 400V (DC + peak AC).

Delay line: approx. 70ns

Triggering

Automatic (peak to peak): ≤20Hz-200MHz (≥ 0.5div.)

Normal with level control:DC-200MHz (≥0.5div.)

Indicator for trigger action: LED

Slope: positive or negative

Sources: Channel I or II,

ALT. Triggering: CH I/CH II (≥0.8div.)

Coupling:

DC (0 to 200MHz), HF (50kHz – 200MHz),

LF (0 to 1.5kHz), NR(noise reject):0-50MHz (≥ 0.8div.)

Triggering time base B: normal with level

Active TV Sync. Separator: field & line, + / –

External: ≥0.3V

Horizontal Deflection

Time base A: 22 calibrated steps (±3%)

X-Mag. x10: 5ns/div. (±5%)

Holdoff time: variable to approx. 10:1

Time base B: 18 calibrated steps (±3%)

Operating modes: A or B, alternate A/B

Bandwidth X-amplifier: 0 to 3MHz (-3dB)

Input X-amplifier: via Channel II

Sensitivity: see Ch II

X-Y phase shift: <3° below 220kHz.

Manual (front panel switches)

Auto Set (automatic parameter selection)

Save/Recall: 9 user-defined parameter settings

Readout: Display of parameter settings

Cursor measurement: ∆V, ∆t or ∆1/t (frequ.)

Remote control: with built in RS-232 interface

Component Tester

Test voltage: approx. 7V

Test current: approx. 7mA

General Information

CRT: D14-375GH, 8x10div., internal graticule

Acceleration voltage: approx 14kV

Trace rotation: adjustable on front panel

Calibrator:

Line voltage: 100-240V AC ±10%, 50/60Hz

Power consumption: approx. 38 Watt at 50Hz

Min./Max. ambient temperature: 0°C...+40°C

Protective system: Safety class I (IEC1010-1)

Weight: approx. 5.9kg. Color: techno-brown

Cabinet: W 285, H 125, D 380 mm

Subject to change without notice. 08/00

Channel I and II: alternate or chopped

1mV to 2mV/div.: ±5% (DC – 10MHz (-3dB))

5mV/div. to 20V/div.: ±3% in 1-2-5 sequence,

from 0.5s/div. – 50ns/div. in 1-2-5 sequence

from 20ms/div. to 50ns/div. in 1-2-5 sequence

with variable 2.5:1 up to 50V/div.

line and external.

AC (10Hz – 200MHz),

control and slope selection (0 – 200 MHz)

(0 – 100MHz)

pp

variable 2.5:1 up to 1.25s/div.,with

Operation / Control

(open circuit).

rms

(shorted).

rms

0,2V ±1%, ≈ 1kHz/1MHz (t

<4ns)

r

2 Channels, 1mV – 20V/div, Delay Line, 14kV CRT

Time Base A: 0.5s – 5ns/div., B: 20ms–5ns/div. , 2

nd

Trigger

Triggering DC–200MHz, Automatic Peak to Peak,

Alternate Trigger, Calibrator and Component Tester

This microprocessor controlled oscilloscope has been designed for a wide

multitude of applications in service and industry. For ease of operation the

„Autoset“ function allows for signal related automatic setup of measuring

parameters. On screen alphanumeric readout and cursor functions for

voltage, time and frequency measurement provide extraordinary operational

convenience. Nine different user defined instrument settings can be saved and

recalled without restriction. The built-in RS-232 serial interface allows for

remote controlled operation by a PC .

The outstanding features of the HM1004-3 include two vertical input channels

and the second time base with the ability to magnify, over 1000 times, extremely

small portions of the input signal. The second time base has its own triggering

controls, including level and slope selection,to allow a stable and precisely

referenced display of asynchronous or jittery signal segments. The trigger circuit

is designed to provide reliable triggering to over 200MHz at signal levels as low

as 0.5div.. An active TV Sync Separator for TV-signal tracing ensures accurate

triggering even with noisy signals. Signals are solid and distortion free even at

the upper frequency limit. The built in Y delay line allows for leading edge display

of even low repetition rate signals, supported by the 14kV CRT with its high

intensity. Both instruments are equipped with a built in COMPONENT TESTER.

Because it is so important to be able to trust the accuracy of the display when

viewing pulse or square signals, the HM1004-3 has a built-in switchable

calibrator, which checks the instrument’s transient response characteristics from probe tip to CRT screen. The essential high frequency compensation of

wide band probes can be performed with this calibrator, which features a rise

time of less than 4ns.

The instrument offers the right combination of triggering control, frequency

response, and time base versatility to facilitate measurements in a wide range

of applications - in laboratory as well as in field service use. It is another example

of HAMEG’s dedication to engineering excellence.

Accessories supplied:

Line Cord, Operators Manual on CD-ROM, 2 Probes 10:1

Subject to change without notice

5

Page 6

General Information

General Information

This oscilloscope is easy to operate. The logical arrangement

of the controls allows anyone to quickly become familiar with

the operation of the instrument, however, experienced users

are also advised to read through these instructions so that all

functions are understood.

Immediately after unpacking, the instrument should be

checked for mechanical damage and loose parts in the

interior. If there is transport damage, the supplier must be

informed immediately. The instrument must then not be put

into operation.

Symbols

ATTENTION - refer to manual

Danger - High voltage

Protective ground (earth) terminal

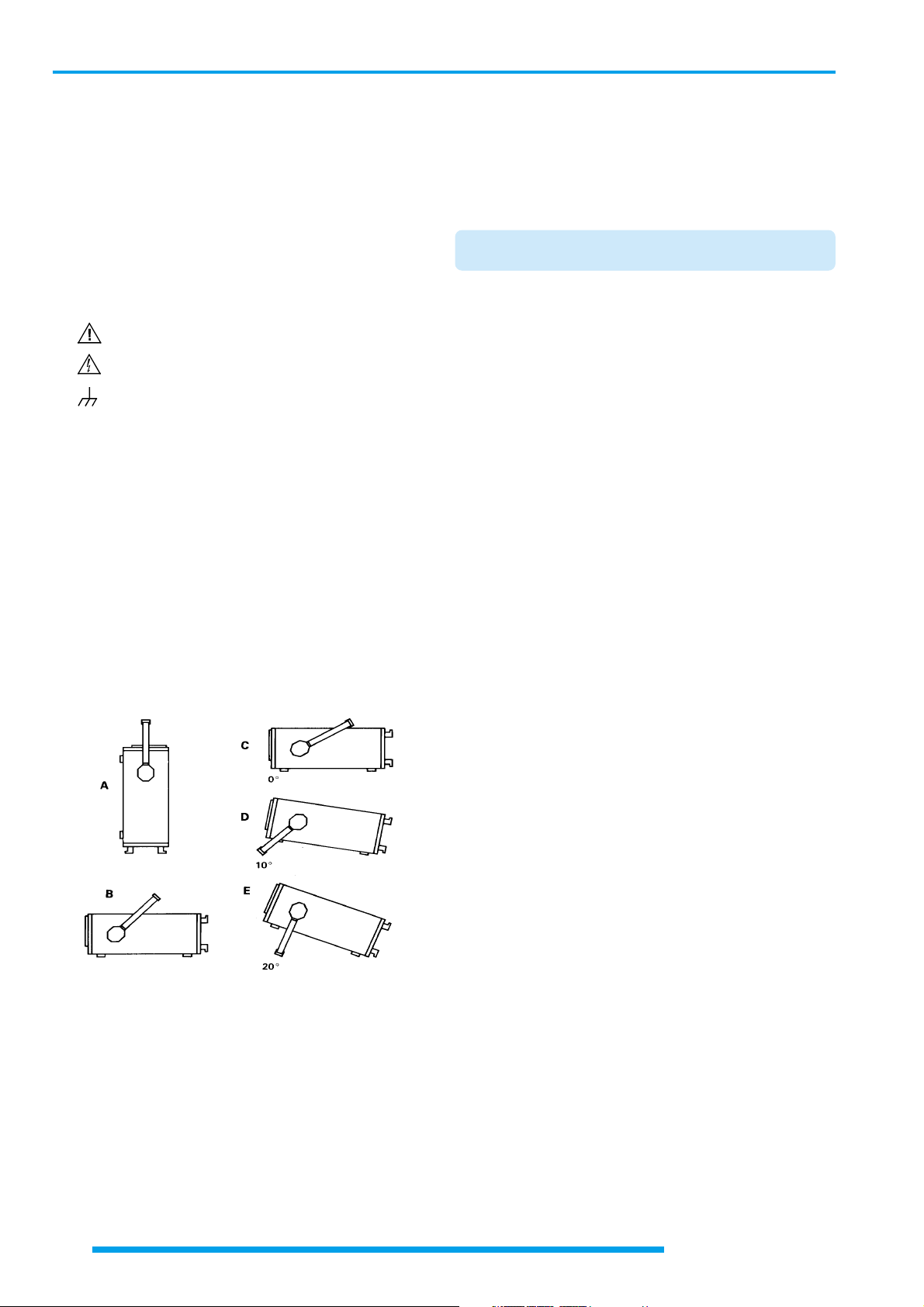

Use of tilt handle

To view the screen from the best angle, there are three

different positions (C, D, E) for setting up the instrument. If

the instrument is set down on the floor after being carried, the

handle automatically remains in the upright carrying position

(A). In order to place the instrument onto a horizontal surface,

the handle should be turned to the upper side of the oscilloscope (C). For the D position (10° inclination), the handle

should be turned to the opposite direction of the carrying

position until it locks in place automatically underneath the

instrument. For the E position (20° inclination), the handle

should be pulled to release it from the D position and swing

backwards until it locks once more. The handle may also be

set to a position for horizontal carrying by turning it to the

upper side to lock in the B position. At the same time, the

instrument must be lifted, because otherwise the handle will

jump back.

instrument operates according to Safety Class I (threeconductor power cord with protective earthing conductor and

a plug with earthing contact).

The mains/line plug shall only be inserted in a socket outlet

provided with a protective earth contact. The protective

action must not be negated by the use of an extension cord

without a protective conductor.

The mains/line plug must be inserted before connections are made to measuring circuits.

The grounded accessible metal parts (case, sockets, jacks)

and the mains/line supply contacts (line/live, neutral) of the

instrument have been tested against insulation breakdown

with 2200V DC.

Under certain conditions, 50Hz or 60Hz hum voltages can

occur in the measuring circuit due to the interconnection with

other mains/line powered equipment or instruments. This can

be avoided by using an isolation transformer (Safety Class II)

between the mains/line outlet and the power plug of the

device being investigated.

Most cathode-ray tubes develop X-rays. However, the dose

equivalent rate falls far below the maximum permissible

value of 36pA/kg (0.5mR/h).

Whenever it is likely that protection has been impaired, the

instrument shall be made inoperative and be secured against

any unintended operation. The protection is likely to be

impaired if, for example, the instrument

• shows visible damage,

• fails to perform the intended measurements,

• has been subjected to prolonged storage under unfavourable conditions (e.g. in the open or in moist environments),

• has been subject to severe transport stress (e.g. in poor

packaging).

Safety

This instrument has been designed and tested in accordance

with IEC Publication 1010-1 (overvoltage category II, pollu-

tion degree 2), Safety requirements for electrical equipment

for measurement, control, and laboratory use. The CENELEC

regulations EN 61010-1 correspond to this standard. It has left

the factory in a safe condition. This instruction manual contains important information and warnings which have to be

followed by the user to ensure safe operation and to retain the

oscilloscope in a safe condition.

The case, chassis and all measuring terminals are connected

to the protective earth contact of the appliance inlet. The

Intended purpose and operating conditions

This instrument must be used only by qualified experts who

are aware of the risks of electrical measurement.

The instrument is specified for operation in industry, light

industry, commercial and residential environments.

Due to safety reasons the instrument must only be connected

to a properly installed power outlet, containing a protective

earth conductor. The protective earth connection must not be

broken. The power plug must be inserted in the power outlet

while any connection is made to the test device.

The instrument has been designed for indoor use. The

permissible ambient temperature range during operation is

+10°C (+50°F) ... +40°C (+104°F). It may occasionally be

subjected to temperatures between +10°C (+50°F) and -10°C

(+14°F) without degrading its safety. The permissible ambient temperature range for storage or transportation is -40°C

(-40°F) ... +70°C (+158°F). The maximum operating altitude is

up to 2200m (non-operating 15000m). The maximum relative

humidity is up to 80%.

If condensed water exists in the instrument it should be

acclimatized before switching on. In some cases (e.g. extremely cold oscilloscope) two hours should be allowed

before the instrument is put into operation. The instrument

should be kept in a clean and dry room and must not be

operated in explosive, corrosive, dusty, or moist environments. The oscilloscope can be operated in any position, but

the convection cooling must not be impaired. The ventilation

6

Subject to change without notice

Page 7

General Information

holes may not be covered. For continuous operation the

instrument should be used in the horizontal position, preferably tilted upwards, resting on the tilt handle.

The specifications stating tolerances are only valid if

the instrument has warmed up for 30minutes at an

ambient temperature between +15°C (+59°F) and +30°C

(+86°F). Values without tolerances are typical for an

average instrument.

EMC

This instrument conforms to the European standards regarding the electromagnetic compatibility. The applied standards

are: Generic immunity standard EN50082-2:1995 (for industrial environment) Generic emission standard EN50081-1:1992

( for residential, commercial und light industry environment).

This means that the instrument has been tested to the

highest standards.

Please note that under the influence of strong electromagnetic fields, such signals may be superimposed on

the measured signals.

Under certain conditions this is unavoidable due to the

instrument’s high input sensitivity, high input impedance and

bandwidth. Shielded measuring cables, shielding and earthing

of the device under test may reduce or eliminate those effects.

Warranty

HAMEG warrants to its Customers that the products it

manufactures and sells will be free from defects in materials

and workmanship for a period of 2 years. This warranty shall

not apply to any defect, failure or damage caused by improper

use or inadequate maintenance and care. HAMEG shall not be

obliged to provide service under this warranty to repair

damage resulting from attempts by personnel other than

HAMEG representatives to install, repair, service or modify

these products.

In order to obtain service under this warranty, Customers

must contact and notify the distributor who has sold the

product. Each instrument is subjected to a quality test with 10

hour burn-in before leaving the production. Practically all early

failures are detected by this method. In the case of shipments

by post, rail or carrier the original packing must be used.

Transport damages and damage due to gross negligence are

not covered by the guarantee.

In the case of a complaint, a label should be attached to the

housing of the instrument which describes briefly the faults

observed. If at the same time the name and telephone number

(dialing code and telephone or direct number or department

designation) is stated for possible queries, this helps towards

speeding up the processing of guarantee claims.

ether) can be used to remove greasy dirt. The screen may be

cleaned with water or washing benzine (but not with spirit

(alcohol) or solvents), it must then be wiped with a dry clean

lint-free cloth. Under no circumstances may the cleaning fluid

get into the instrument. The use of other cleaning agents can

attack the plastic and paint surfaces.

Protective Switch Off

This instrument is equipped with a switch mode power supply.

It has both over voltage and overload protection, which will

cause the switch mode supply to limit power consumption to

a minimum. In this case a ticking noise may be heard.

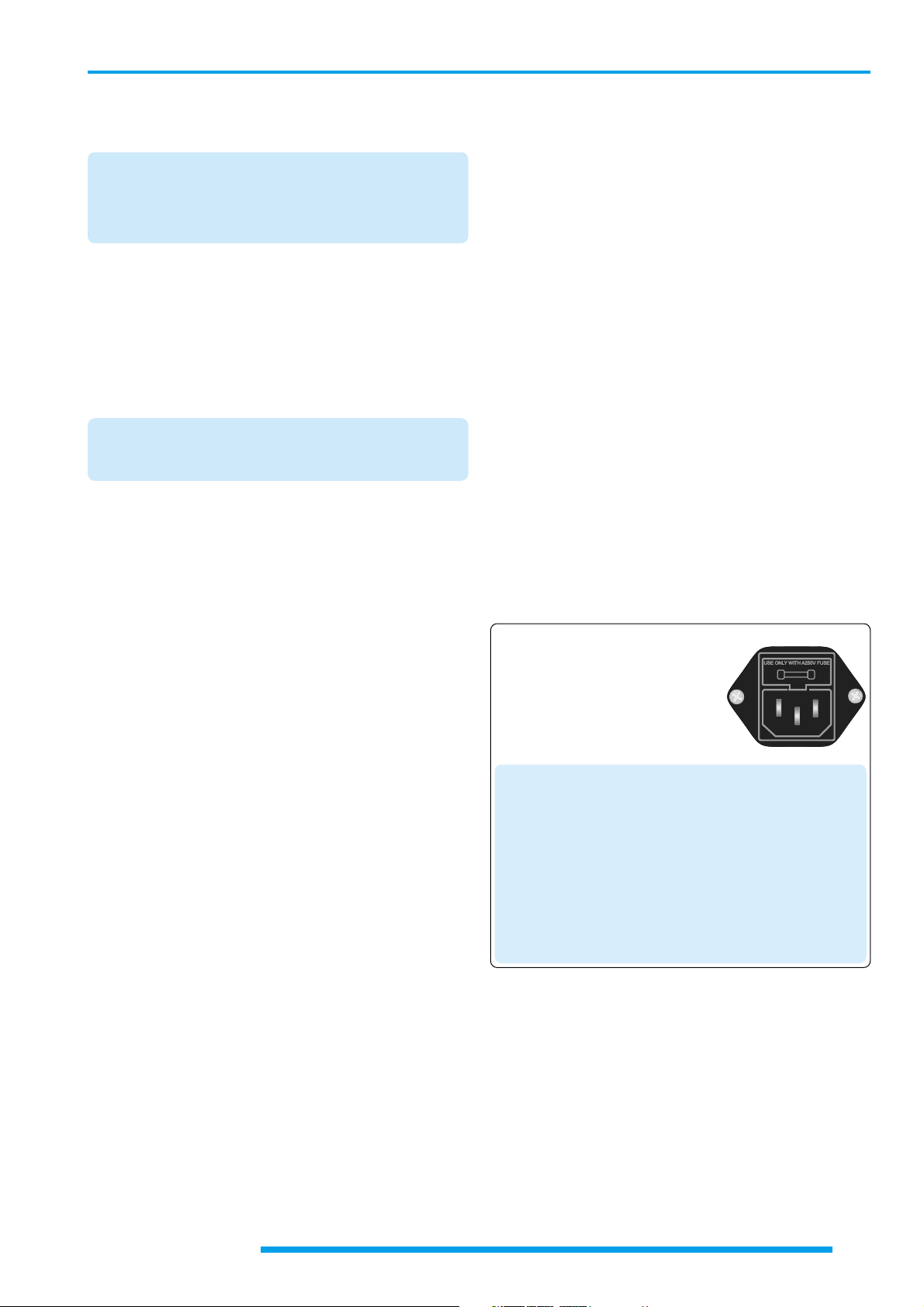

Power supply

The instrument operates on mains/line voltages between

and 240VAC. No means of switching to different input

100V

AC

voltages has therefore been provided.

The power input fuse is externally accessible. The fuse holder

and the 3 pole power connector is an integrated unit. The

power input fuse can be exchanged after the rubber connector

is removed. The fuse holder can be released by lever action

with the aid of a screwdriver. The starting point is a slot located

on contact pin side. The fuse can then be pushed out of the

mounting and replaced.

The fuse holder must be pushed in against the spring pressure

and locked. Use of patched fuses or short circuiting of the fuse

holder is not permissible;

whatsoever for any damage caused as a result, and all warranty

claims become null and void.

Fuse type:

Size 5x20mm; 0.8A, 250V AC fuse;

must meet IEC specification 127,

Sheet III (or DIN 41 662

or DIN 41 571, sheet 3).

Time characteristic: time lag.

Attention!

There is a fuse located inside the instrument within the

switch mode power supply:

Size 5x20mm; 0.8A, 250V AC fuse;

must meet IEC specification 127,

Sheet III (or DIN 41 662

or DIN 41 571, sheet 3).

Time characteristic: fast (F).

The operator must not replace this fuse!

HAMEGHAMEG

HAMEG assumes no liability

HAMEGHAMEG

Maintenance

Various important properties of the oscilloscope should be

carefully checked at certain intervals. Only in this way is it

largely certain that all signals are displayed with the accuracy

on which the technical data are based. Purchase of the

HAMEG scope tester HZ 60, which despite its low price is

highly suitable for tasks of this type, is very much

recommended. The exterior of the oscilloscope should be

cleaned regularly with a dusting brush. Dirt which is difficult

to remove on the casing and handle, the plastic and aluminium

parts, can be removed with a moistened cloth (99% water

+1% mild detergent). Spirit or washing benzine (petroleum

Subject to change without notice

7

Page 8

Type of signal voltage

Type of signal voltage

The oscilloscopes HM1004-3 and HM1505-3 allow examination of DC voltages and most repetitive signals in the frequency range up to at least 100MHz (-3dB) in case of

HM1004-3 or 150MHz for the HM1505-3.

The vertical amplifiers have been designed for minimum overshoot and therefore permit a true signal display. The display of

sinusoidal signals within the bandwidth limits causes no problems, but an increasing error in measurement due to gain

reduction must be taken into account when measuring high

frequency signals. These errors become noticeable at approx.

40MHz (HM1004-3) or 70MHz (HM1505-3). At approx. 80

MHz (HM1505-3: 110 MHz) the reduction is approx. 10% and

the real voltage value is 11% higher. The gain reduction error

can not be defined exactly as the -3dB bandwidth of the

amplifiers differ between 100MHz and 140MHz (HM1004-3);

and 150MHz and 170MHz (HM1505-3).

For sine wave signals the -6dB limits are approx.

160MHz for the HM1004-3 and 220MHz in the case of

the HM1505-3.

When examining square or pulse type waveforms, attention

must be paid to the harmonic content of such signals. The

repetition frequency (fundamental frequency) of the signal

must therefore be significantly smaller than the upper limit

frequency of the vertical amplifier.

Displaying composite signals can be difficult, especially if they

contain no repetitive higher amplitude content which can be

used for triggering. This is the case with bursts, for instance.

To obtain a well-triggered display in this case, the assistance

of the variable holdoff function or the second timebase may

be required. Television video signals are relatively easy to

trigger using the built-in TV-Sync-Separator (TV).

For optional operation as a DC or AC voltage amplifier, each

vertical amplifier input is provided with a DC/AC switch. DC

coupling should only be used with a series-connected

attenuator probe or at very low frequencies or if the measurement of the DC voltage content of the signal is absolutely

necessary.

When displaying very low frequency pulses, the flat tops may

be sloping with AC coupling of the vertical amplifier (AC limit

frequency approx. 1.6 Hz for 3dB). In this case, DC operation

is preferred, provided the signal voltage is not superimposed

on a too high DC level. Otherwise a capacitor of adequate

capacitance must be connected to the input of the vertical

amplifier with DC coupling. This capacitor must have a sufficiently high breakdown voltage rating. DC coupling is also

recommended for the display of logic and pulse signals,

especially if the pulse duty factor changes constantly. Otherwise the display will move upwards or downwards at each

change. Pure direct voltages can only be measured with DCcoupling.

tions in oscilloscope measurements, the peak-to-peak voltage (Vpp) value is applied. The latter corresponds to the real

potential difference between the most positive and most

negative points of a signal waveform.

If a sinusoidal waveform, displayed on the oscilloscope screen,

is to be converted into an effective (rms) value, the resulting

peak-to-peak value must be divided by 2x√2 = 2.83. Con-

versely, it should be observed that sinusoidal voltages indicated in Vrms (Veff) have 2.83 times the potential difference

in Vpp. The relationship between the different voltage

magnitudes can be seen from the following figure.

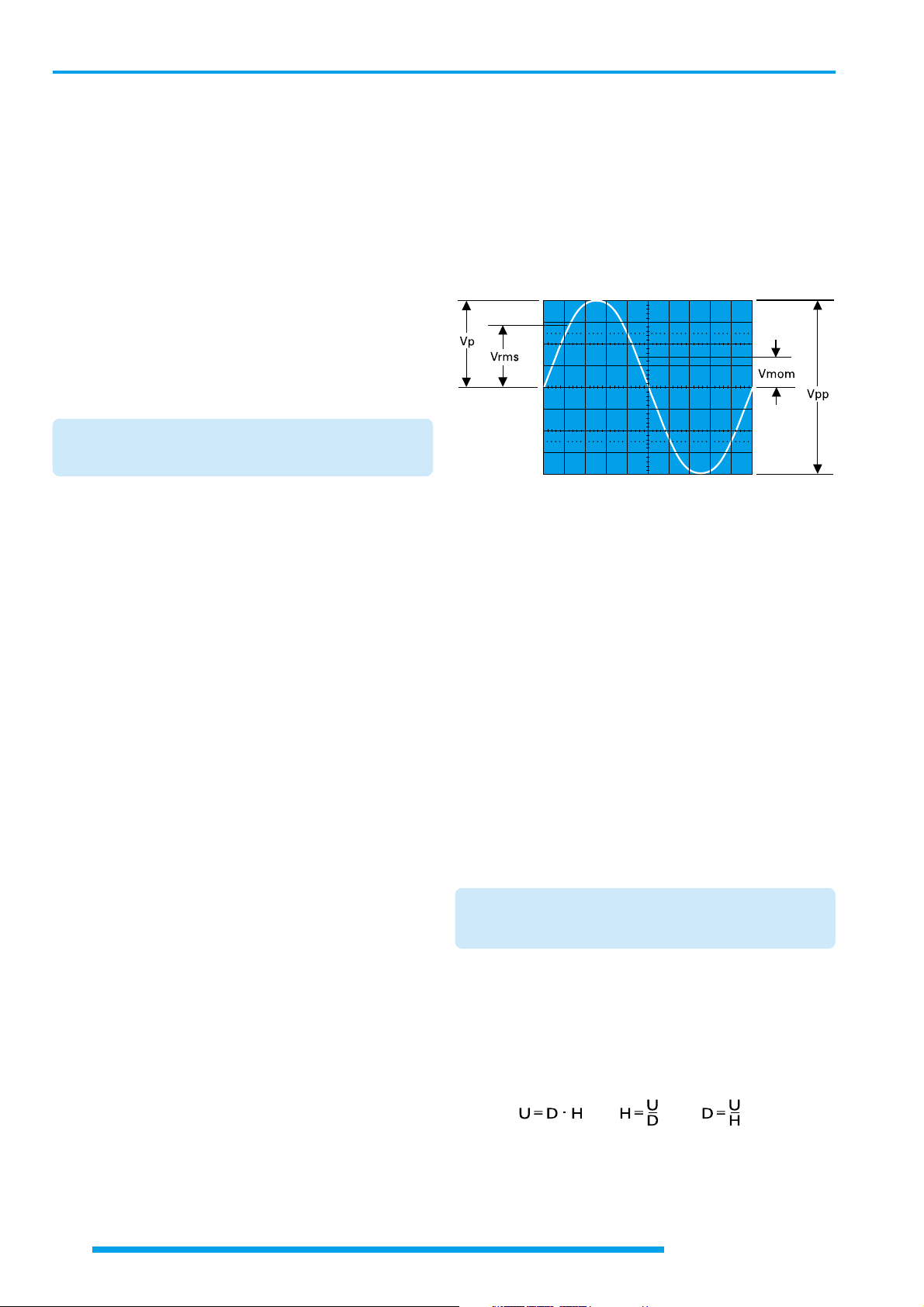

Voltage values of a sine curve

Vrms = effective value; Vp = simple peak or crest value;

Vpp = peak-to-peak value; Vmom = momentary value.

The minimum signal voltage which must be applied to the Y input

for a trace of 1div height is 1mVpp (± 5%) when this deflection

coefficient is displayed on the screen (readout) and the vernier

is switched off (VAR-LED dark). However, smaller signals than

this may also be displayed. The deflection coefficients are

indicated in mV/div or V/div (peak-to-peak value).

The magnitude of the applied voltage is ascertained by

multiplying the selected deflection coefficient by the vertical

display height in div. If an attenuator probe x10 is used, a

further multiplication by a factor of 10 is required to ascertain

the correct voltage value.

For exact amplitude measurements, the variable control

(VAR) must be set to its calibrated detent CAL position.

With the variable control activated the deflection sensitivity

can be reduced up to a ratio of 2.5 to 1 (please note “controls

and readout”). Therefore any intermediate value is possible

within the 1-2-5 sequence of the attenuator(s).

With direct connection to the vertical input, signals up

to 400Vpp may be displayed (attenuator set to 20V/

div, variable control to 2.5:1).

With the designations

H = display height in div,

U = signal voltage in Vpp at the vertical input,

D = deflection coefficient in V/div at attenuator switch,

The input coupling is selectable by the AC/DC pushbutton.

The actual setting is displayed in the readout with the “ = “

symbol for DC- and the “ ~ “ symbol for AC coupling.

Amplitude Measurements

In general electrical engineering, alternating voltage data

normally refers to effective values (rms = root-mean-square

value). However, for signal magnitudes and voltage designa-

8

the required value can be calculated from the two given

quantities:

However, these three values are not freely selectable. They

have to be within the following limits (trigger threshold,

accuracy of reading):

Subject to change without notice

Page 9

H between 0.5 and 8div, if possible 3.2 to 8div,

U between 0.5mVpp and 160Vpp,

D between 1mV/div and 20V/div in 1-2-5 sequence.

Examples:

Set deflection coefficient D = 50mV/div 0.05V/div,

observed display height H = 4.6div,

required voltage U = 0.05x4.6 = 0.23Vpp.

Input voltage U = 5Vpp,

set deflection coefficient D = 1V/div,

required display height H = 5:1 = 5div.

√

Signal voltage U = 230Vrmsx2

(voltage > 160Vpp, with probe 10:1: U = 65.1Vpp),

desired display height H = min. 3.2div, max. 8div,

max. deflection coefficient D = 65.1:3.2 = 20.3V/div,

min. deflection coefficient D = 65.1:8 = 8.1V/div,

adjusted deflection coefficient D = 10V/div.

2 = 651Vpp

Type of signal voltage

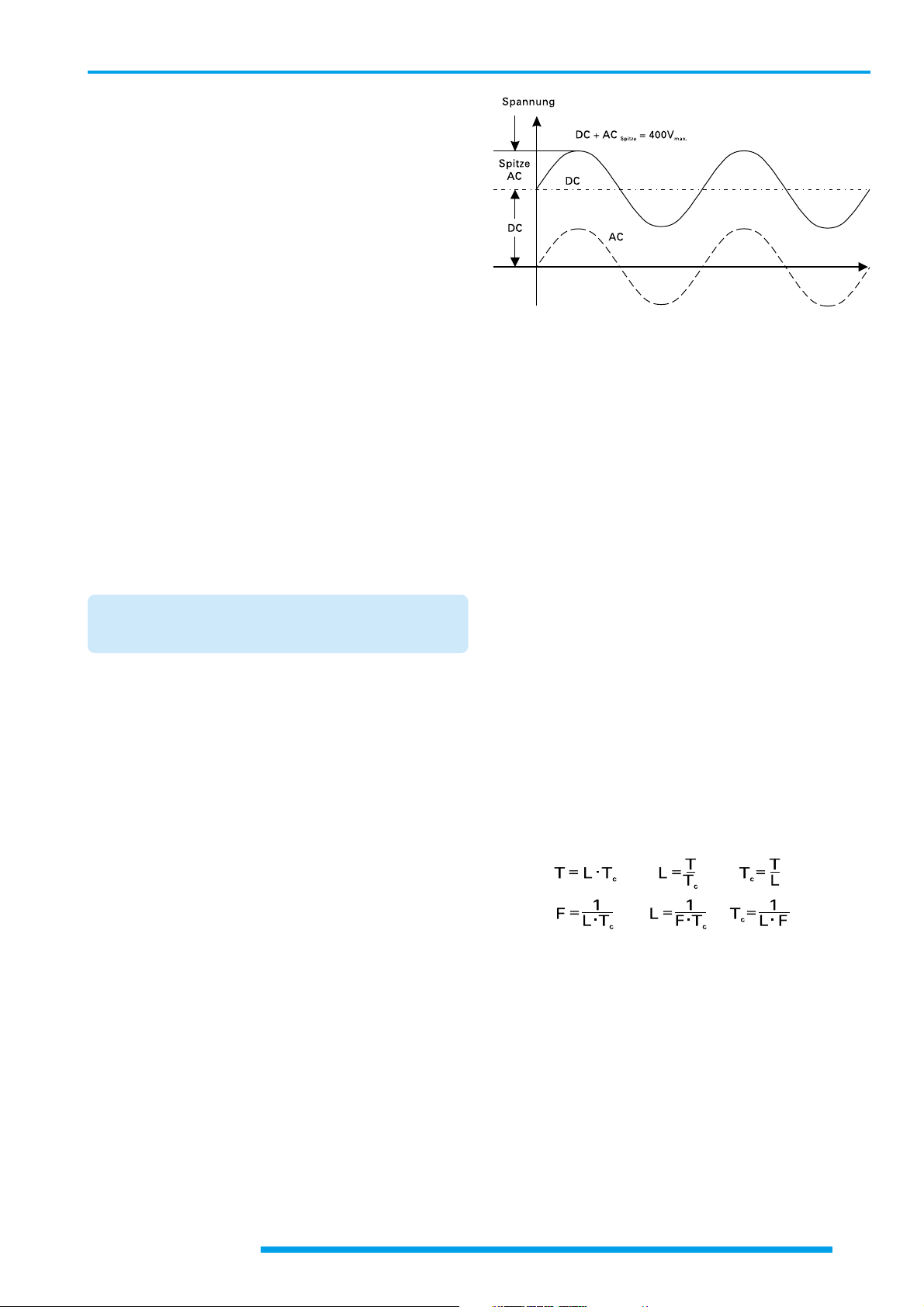

Total value of input voltage

The dotted line shows a voltage alternating at zero volt level.

If superimposed on a DC voltage, the addition of the positive

peak and the DC voltage results in the max. voltage (DC +

ACpeak).

The previous examples are related to the crt graticule reading.

The results can also be determined with the aid of the ∆V

cursor measurement (please note “controls and readout”).

The input voltage must not exceed 400V, independent from

the polarity.

If an AC voltage which is superimposed on a DC voltage is

applied, the maximum peak value of both voltages must not

exceed + or -400V. So for AC voltages with a mean value of

zero volt the maximum peak to peak value is 800Vpp.

If attenuator probes with higher limits are used, the

probes limits are valid only if the oscilloscope is set to

DC input coupling.

If DC voltages are applied under AC input coupling conditions

the oscilloscope maximum input voltage value remains 400V.

The attenuator consists of a resistor in the probe and the 1MΩ

input resistor of the oscilloscope, which are disabled by the

AC input coupling capacity when AC coupling is selected. This

also applies to DC voltages with superimposed AC voltages.

It also must be noted that due to the capacitive resistance of

the AC input coupling capacitor, the attenuation ratio depends

on the signal frequency. For sinewave signals with frequencies higher than 40Hz this influence is negligible.

With the above listed exceptions HAMEG 10:1 probes can be

used for DC measurements up to 600V or AC voltages (with

a mean value of zero volt) of 1200Vpp. The 100:1 probe HZ53

allows for 1200V DC or 2400Vpp for AC.

Time Measurements

As a rule, most signals to be displayed are periodically

repeating processes, also called periods. The number of

periods per second is the repetition frequency. Depending on

the timebase setting (TIME/DIV.-knob) indicated by the

readout, one or several signal periods or only a part of a period

can be displayed. The time coefficients are stated in ms/div,

µs/div or ns/div. The following examples are related to the

crt graticule reading. The results can also be determined with

the aid of the ∆T and 1/∆T cursor measurement (please note

“ Controls and Readout”).

The duration of a signal period or a part of it is determined by

multiplying the relevant time (horizontal distance in div) by the

(calibrated) time coefficient displayed in the readout .

Uncalibrated, the timebase speed can be reduced until a

maximum factor of 2.5 is reached. Therefore any intermediate value is possible within the 1-2-5 sequence.

With the designations

L = displayed wave length in div of one period,

T = time in seconds for one period,

F = recurrence frequency in Hz of the signal,

Tc = time coefficient in ms, µs or ns/div and the relation

F = 1/T, the following equations can be stated:

It should be noted that its AC peak value is derated at higher

frequencies. If a normal x10 probe is used to measure high

voltages there is the risk that the compensation trimmer

bridging the attenuator series resistor will break down causing damage to the input of the oscilloscope.

However, if for example only the residual ripple of a high

voltage is to be displayed on the oscilloscope, a normal x10

probe is sufficient. In this case, an appropriate high voltage

capacitor (approx. 22-68nF) must be connected in series with

the input tip of the probe. With Y-POS. control (input coupling

to GD) it is possible to use a horizontal graticule line as

reference line for ground potential before the measurement. It can lie below or above the horizontal central line

according to whether positive and/or negative deviations

from the ground potential are to be measured.

Subject to change without notice

However, these four values are not freely selectable. They

have to be within the following limits:

L between 0.2 and 10div, if possible 4 to 10div,

T between 5ns and 5s,

F between 0.5Hz and 100MHz,

Tc between 50ns/div and 500ms/div in 1-2-5 sequence

(with X-MAG. (x10) inactive), and

Tc between 5ns/div and 50ms/div in 1-2-5 sequence

(with X-MAG. (x10) active).

Examples:

Displayed wavelength L = 7div,

set time coefficient Tc = 100ns/div,

required period T = 7x100x10-9 = 0.7µs

required rec. freq. F = 1:(0.7x10-6) = 1.428MHz.

Signal period T = 1s,

9

Page 10

Type of signal voltage

set time coefficient Tc = 0.2s/div,

required wavelength L = 1:0.2 = 5div.

Displayed ripple wavelength L = 1div,

set time coefficient Tc = 10ms/div,

required ripple freq. F = 1:(1x10x10-3) = 100Hz.

TV-Line frequency F = 15625Hz,

set time coefficient Tc = 10µs/div,

required wavelength L = 1:(15 625x10-5) = 6.4div.

Sine wavelength L = min. 4div, max. 10div,

Frequency F = 1kHz,

max. time coefficient Tc = 1:(4x103) = 0.25ms/div,

min. time coefficient Tc = 1:(10x103) = 0.1ms/div,

set time coefficient Tc = 0.2ms/div,

required wavelength L = 1:(103x0.2x10-3) = 5div.

Displayed wavelength L = 0.8div,

set time coefficient Tc = 0.5µs/div,

pressed X-MAG. (x10) button: Tc = 0.05µs/div,

required rec. freq. F = 1:(0.8x0.05x10-6) = 25MHz,

required period T = 1:(25x106) = 40ns.

If the time is relatively short as compared with the complete

signal period, an expanded time scale should always be applied

(X-MAG. (x10) active). In this case, the time interval of interest

can be shifted to the screen center using the X-POS. control.

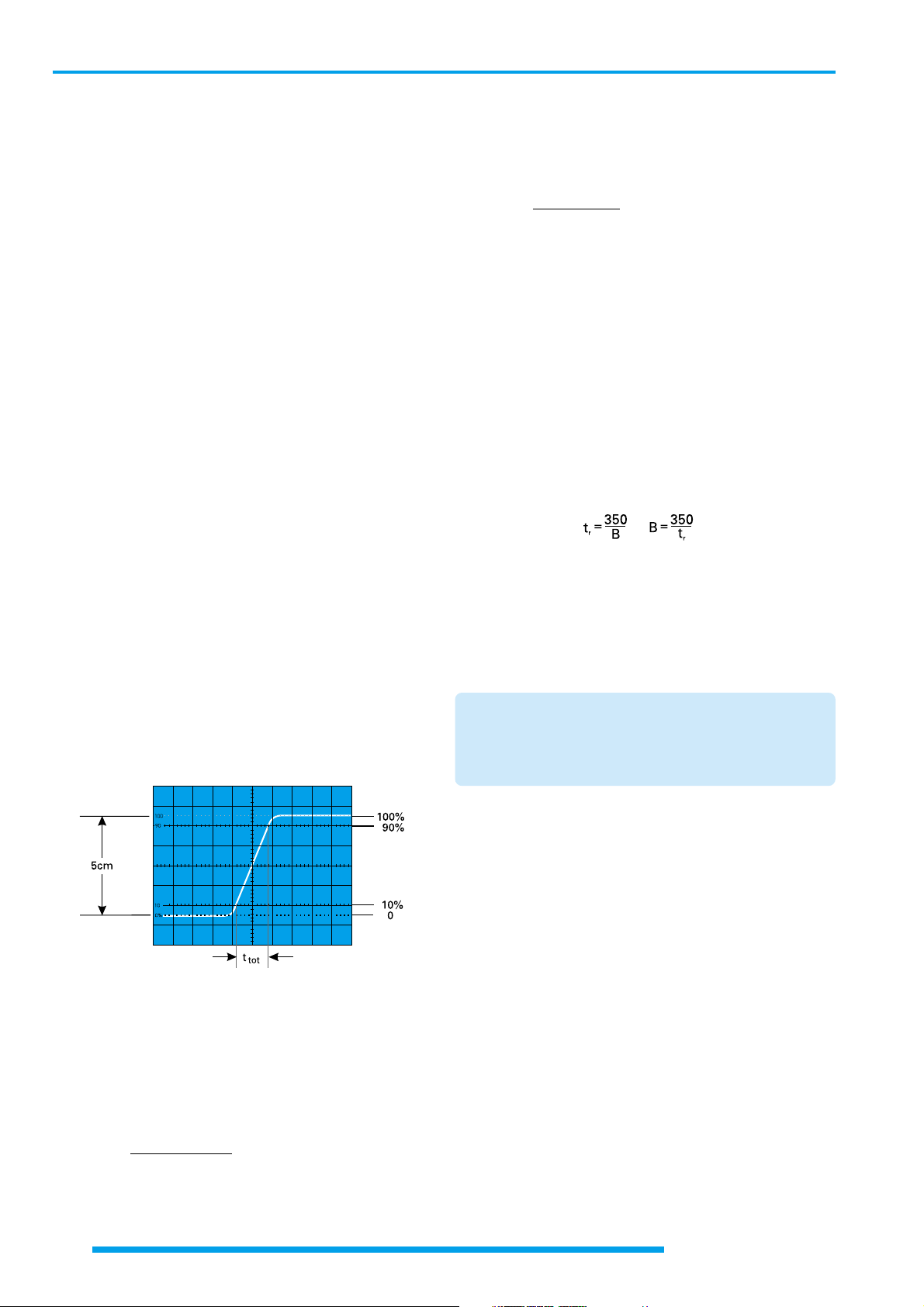

When investigating pulse or square waveforms, the critical

feature is the risetime of the voltage step. To ensure that

transients, ramp-offs, and bandwidth limits do not unduly

influence the measuring accuracy, the risetime is generally

measured between 10% and 90% of the vertical pulse height.

For measurement, adjust the Y deflection coefficient using its

variable function (uncalibrated) together with the Y-POS.

control so that the pulse height is precisely aligned with the

0% and 100% lines of the internal graticule. The 10% and

90% points of the signal will now coincide with the 10% and

90% graticule lines. The risetime is given by the product of the

horizontal distance in div between these two coincident

points and the calibrated time coefficient setting. The fall time

of a pulse can also be measured by using this method.

The following figure shows correct positioning of the oscilloscope trace for accurate risetime measurement.

the risetime of the probe (e.g. = 2ns). If t

34ns, then t

calculation is unnecessary.

can be taken as the risetime of the pulse, and

tot

is greater than

tot

Calculation of the example in the figure above results in a

signal risetime

2

t

r

- 3,52 - 22 = 6,9ns

= √ 8

The measurement of the rise or fall time is not limited to the

trace dimensions shown in the above diagram. It is only

particularly simple in this way. In principle it is possible to

measure in any display position and at any signal amplitude.

It is only important that the full height of the signal edge of

interest is visible in its full length at not too great steepness

and that the horizontal distance at 10% and 90% of the

amplitude is measured. If the edge shows rounding or overshooting, the 100% should not be related to the peak values

but to the mean pulse heights. Breaks or peaks (glitches) next

to the edge are also not taken into account. With very severe

transient distortions, the rise and fall time measurement has

little meaning. For amplifiers with approximately constant

group delay (therefore good pulse transmission performance)

the following numerical relationship between rise time tr (in

ns) and bandwidth B (in MHz) applies:

Connection of Test Signal

In most cases briefly depressing the AUTO SET causes a

useful signal related instrument setting. The following explanations refer to special applications and/or signals, demanding a manual instrument setting. The description of the

controls is explained in the section “controls and readout”.

Caution:

When connecting unknown signals to the oscilloscope

input, always use automatic triggering and set the

input coupling switch to AC (readout). The attenuator

should initially be set to 20V/div.

With a time coefficient of 5ns/div (X x10 magnification active),

the example shown in the above figure results in a total

measured risetime of

t

= 1.6div x 5ns/div = 8ns

tot

When very fast risetimes are being measured, the risetimes

of the oscilloscope amplifier and of the attenuator probe has

to be deducted from the measured time value. The risetime

of the signal can be calculated using the following formula.

2

2

= √ t

t

r

In this t

of the oscilloscope amplifier (HM1004-3 approx. 3.5ns) and t

tot

- t

tot

osc

is the total measured risetime, t

- t

2

p

is the risetime

osc

10

Sometimes the trace will disappear after an input signal has

been applied. Then a higher deflection coefficient (lower input

sensitivity) must be chosen until the vertical signal height is

only 3-8div. With a signal amplitude greater than 160Vpp and

the deflection coefficient (VOLTS/DIV.) in calibrated condition, an attenuator probe must be inserted before the vertical

input. If, after applying the signal, the trace is nearly blanked,

the period of the signal is probably substantially longer than

the set time deflection coefficient (TIME/DIV.). It should be

switched to an adequately larger time coefficient.

The signal to be displayed can be connected directly to the Yinput of the oscilloscope with a shielded test cable such as

HZ32 or HZ34, or reduced through a x10 or x100 attenuator

probe. The use of test cables with high impedance circuits is

only recommended for relatively low frequencies (up to

approx. 50kHz). For higher frequencies, the signal source

must be of low impedance, i.e. matched to the characteristic

resistance of the cable (as a rule 50Ω). Especially when

transmitting square and pulse signals, a resistor equal to the

characteristic impedance of the cable must also be connected

across the cable directly at the Y-input of the oscilloscope.

When using a 50Ω cable such as the HZ34, a 50Ω through

termination type HZ22 is available from HAMEG. When

transmitting square signals with short rise times, transient

phenomena on the edges and top of the signal may become

p

Subject to change without notice

Page 11

Controls and Readout

visible if the correct termination is not used. A terminating

resistance is sometimes recommended with sine signals as

well. Certain amplifiers, generators or their attenuators maintain the nominal output voltage independent of frequency only

if their connection cable is terminated with the prescribed

resistance. Here it must be noted that the terminating resistor

HZ22 will only dissipate a maximum of 2Watts. This power is

reached with 10V

or x100 attenuator probe is used, no termination is necessary.

In this case, the connecting cable is matched directly to the high

impedance input of the oscilloscope. When using attenuators

probes, even high internal impedance sources are only slightly

loaded (approx. 10MΩ II 12pF or 100MΩ II 5pF with HZ53).

Therefore, if the voltage loss due to the attenuation of the

probe can be compensated by a higher amplitude setting, the

probe should always be used. The series impedance of the

probe provides a certain amount of protection for the input of

the vertical amplifier. Because of their separate manufacture,

all attenuator probes are only partially compensated, therefore

accurate compensation must be performed on the oscilloscope (see Probe compensation ).

Standard attenuator probes on the oscilloscope normally

reduce its bandwidth and increase the rise time. In all cases

where the oscilloscope bandwidth must be fully utilized (e.g.

for pulses with steep edges) we strongly advise using the

probes HZ51 (x10) HZ52 (x10 HF) and HZ54 (x1 and x10). This

can save the purchase of an oscilloscope with larger bandwidth.

The probes mentioned have a HF-calibration in addition to low

frequency calibration adjustment. Thus a group delay correction to the upper limit frequency of the oscilloscope is possible

with the aid of an 1MHz calibrator, e.g. HZ60.

or at 28.3Vpp with sine signal. If a x10

rms

adapter, should be used. In this way ground and matching

problems are eliminated. Hum or interference appearing in

the measuring circuit (especially when a small deflection

coefficient is used) is possibly caused by multiple grounding

because equalizing currents can flow in the shielding of the

test cables (voltage drop between the protective conductor

connections, caused by external equipment connected to the

mains/line, e.g. signal generators with interference protection capacitors).

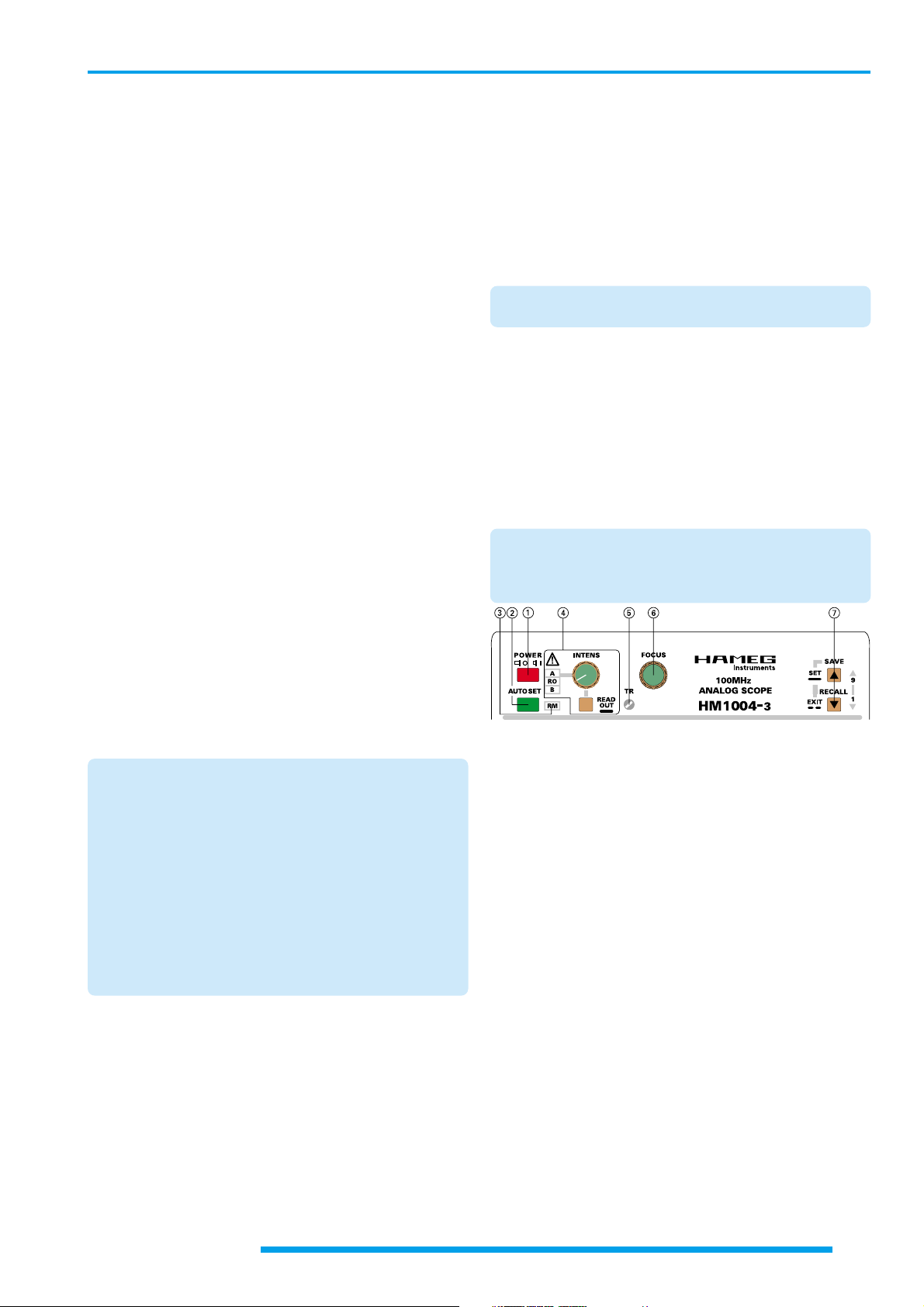

Controls and Readout

The following description assumes that the instrument is not set to “COMPONENT TESTER” mode.

If the instrument is switched on, all important settings are

displayed in the readout. The LED´s located on the front panel

assist operation and indicate additional information. Incorrect

operation and the electrical end positions of control knobs are

indicated by a warning beep.

Except for the power pushbutton (POWER), the calibrator

frequency pushbutton (CAL. 1kHz/1MHz), the focus control

(FOCUS) and the trace rotation control (TR) all other controls

are electronically selected. All other functions and their settings can therefore be remote controlled and stored.

The front panel is subdivided into sections.

On the top, immediately to the right of the CRT screen,

the following controls and LED indicators are placed:

In fact the bandwidth and rise time of the oscilloscope are not

noticably changed with these probe types and the waveform

reproduction fidelity can even be improved because the probe

can be matched to the oscilloscopes individual pulse response.

If a x10 or x100 attenuator probe is used, DC input

coupling must always be used at voltages above 400V.

With AC coupling of low frequency signals, the attenuation is no longer independent of frequency, pulses

can show pulse tilts. Direct voltages are suppressed

but load the oscilloscope input coupling capacitor

concerned. Its voltage rating is max. 400 V (DC + peak

AC). DC input coupling is therefore of quite special

importance with a x100 attenuation probe which usually has a voltage rating of max. 1200 V (DC + peak AC).

A capacitor of corresponding capacitance and voltage

rating may be connected in series with the attenuator

probe input for blocking DC voltage (e.g. for hum

voltage measurement).

With all attenuator probes, the maximum AC input voltage

must be derated with frequency usually above 20kHz. Therefore the derating curve of the attenuator probe type concerned must be taken into account.

The selection of the ground point on the test object is

important when displaying small signal voltages. It should

always be as close as possible to the measuring point. If this

is not done, serious signal distortion may result from spurious

currents through the ground leads or chassis parts. The

ground leads on attenuator probes are also particularly critical.

They should be as short and thick as possible. When the

attenuator probe is connected to a BNC-socket, a BNC-

(1) POWER - Pushbutton and symbols for ON (I) and OFF

(O).

After the oscilloscope is switched on, all LEDs are lit and

an automated instrument test is performed. During this

time the HAMEG logo and the software version are

displayed on the screen. After the internal test is completed succesfully, the overlay is switched off and the

normal operation mode is present. Then the last used

settings become activated and one LED indicates the ON

condition.

Some mode functions can be modified (SETUP) and/or

automated adjustment procedures (CALIBRATE) can be

called if the “MAIN MENU” is present. For further

information please note “MENU”.

(2) AUTO SET -

Briefly depressing this pushbutton (please note “AUTO

SET”) automatically selects Yt mode. The instrument is

set to the last used Yt mode setting (CH I, CH II or DUAL).

Even if alternating timebase mode or B timebase mode

was active before, the instrument is switched automatically to A timebase mode. Please note “AUTO SET”.

Automatic CURSOR supported voltage measurement

If CURSOR voltage measurement is present, the CURSOR lines are automatically set to the positive and

negative peak value of the signal. The accuracy of this

function decreases with higher frequencies and is also

influenced by the signal‘s pulse duty factor.

Subject to change without notice

11

Page 12

Controls and Readout

In DUAL mode the CURSOR lines are related to the signal

which is used for internal triggering.

If the signal height is insufficient, the CURSOR lines do

not change.

(3) RM -

The remote control mode can be switched on or off via

the RS232 interface. In the latter case the “RM” LED is

lit and the electronically selectable controls on front panel

are inactive. This state can be left by depressing the

AUTO SET pushbutton provided it was not deactivated

via the interface.

(4) INTENS - READOUT

Knob with associated pushbutton and LEDs.

This control knob is for adjusting the A and B traces and

readout intensity. Turning this knob clockwise increases

and turning it counterclockwise decreases the intensity.

The READOUT pushbutton below is for selecting the

function in two ways.

Depending on the actual timebase mode and with the

readout (RO) not switched off, briefly pressing the

READOUT pushbutton switches over the INTENS knob

function indicated by a LED in the sequences:

A - RO - A in condition A timebase,

A - RO - B - A if alternate timebase mode is present and

B - RO - B in condition B timebase.

XY mode: A - RO - A.

Component Test: A - RO - A.

Pressing and holding the READOUT pushbutton switches

the readout on or off. In readout off condition the INTENS

knob function can consequently not be set to RO. Briefly

pressing the pushbutton causes the following sequences:

condition sequence

A timebase A - A

Alternate A/B A - B - A

B timebase B - B

XY mode A - A

Component Test A - A

Switching the readout off, may be required if interference

is visible on the signal(s). Such interference may also

originate from the chopper generator if the instrument is

operated in chopped DUAL mode.

With the exception of the letters “CT” all other READOUT information is switched off in COMPONENT TEST

mode.

All INTENS settings are stored after the instrument is

switched off.

The AUTOSET function switches the readout on and

selects A timebase mode (A-LED lit). The INTENS setting

for each function is automatically set to the mean value,

if less intensity was previously selected.

(5) TR

The trace rotation control can be adjusted with a small

screwdriver (please note “trace rotation TR”)

(6) FOCUS

This control knob effects both the trace and the readout

sharpness.

(7) SAVE / RECALL

The instrument contains 9 non volatile memories. These

can be used by the operator to save instrument settings

and to recall them. This relates to all settings with the

exception of FOCUS, TR (trace rotation) and the calibrator

frequency pushbutton.

Press the SAVE pushbutton briefly to start the save

procedure. The readout then indicates the letter “S”

followed by a cipher between 1 and 9, indicating the

memory location. If the instrument settings stored in this

memory location must not be overwritten, briefly press

the SAVE or the RECALL pushbutton to select another

memory location. Each time the SAVE pushbutton is

briefly pressed the memory location cipher increases

until the location number 9 is reached. The RECALL

pushbutton function is similar but decreases the memory

location cipher until 1 is reached. Press and hold SAVE for

approx. 3 seconds to write the instruments settings in the

memory and to switch the associated readout information (e.g. “S8”) off.

To recall a front panel setup, start that procedure by

briefly pressing the RECALL pushbutton. The readout

then indicates the letter “R” and the memory location

number. If required, select a different memory location as

described above. Recall the settings by pressing and

holding the RECALL pushbutton for approx. 3 seconds.

Attention:

Make sure that the signal to be displayed is similar to

the one that was present when the settings were

stored. If the signal is different (frequency, amplitude)

to the one during storage then a distorted display may

result.

If the SAVE or the RECALL pushbutton was depressed

inadvertently, briefly press both pushbuttons at the same

time or wait approx. 10 seconds without pressing either

pushbutton to exit that function.

Switching the instrument off automatically stores the

actual settings in memory location 9, with the effect that

different settings previously stored in this location get

lost. To prevent this, RECALL 9 before switching the

instrument off.

Attention!

Both pushbuttons have a second function if the

instrument is switched to menu operation. Please

note "MENU".

The setting controls and LED’s for the Y amplifiers,

modes, triggering and timebases are located underneath the sector of the front panel described before.

12

Subject to change without notice

Page 13

(8) TRS

The instrument contains a trace separation function which

is required in the alternate timebase mode to separate

the B timebase trace from the A timebase in Y direction.

Consequently this function is only available in alternate

timebase mode. After the TRS pushbutton was pressed

once the LED related to that pushbutton is lit.

The Y-POS. I control knob is then operative as vertical

position control for the trace of the B timebase. The

maximum position shift is approx. +/- 4 div. Without a

change of the Y-POS. I control the trace separation

function is switched off automatically after approx. 10

seconds. The trace separation function can also be left by

pressing the TRS pushbutton.

(9) Y-POS. I - Control knob with a double function.

Controls and Readout

XY and ADD (addition) mode.

(10)Y-POS. II - Control knob.

The vertical trace position of channel II can be set with

this control knob. In ADD (addition) mode both (Y-POS. I

and Y-POS. II) control knobs are active. If the instrument

is set to XY mode this control knob is inactive and the XPOS. knob must be used for a horizontal position shift.

DC voltage measurement:

If no signal is applied at the INPUT CHII (31), the vertical

trace position represents 0 Volt. This is the case if INPUT

CHII (31) or in addition (ADD) mode, both INPUT CHI (27)

and INPUT CHII (31), are set to GD (ground) and automatic triggering (AT (11)) is present to make the trace

visible. The trace then can be set to vertical position

which is suited for the following DC voltage measurement.

After switching GD (ground) off and selecting DC input

coupling, a DC signal applied at the input changes the

trace position in vertical direction. The DC voltage then

can be determined by taking the deflection coefficient,

the probe factor and the trace position change in respect

to the previous 0 Volt position into account.

”0 Volt” Symbol:

The determination of the ”0 Volt” position is not necessary if the readout is switched on and the software

setting ”DC Ref. = ON” is selected in the ”SETUP”

submenu ”Miscellaneous”. Then the ”

left of the screen‘s vertical center line always indicates

the ”0 Volt” trace position in CHI and DUAL mode.

⊥⊥

⊥” symbol to the

⊥⊥

Y-Position channel I:

The vertical trace position of channel I can be set with this

control knob. In ADD (addition) mode both (Y-POS. I and

Y-POS. II) control knobs are active.

Y-Position B-trace in alternate timebase mode:

In alternate timebase mode, this control knob can be

used to separate the B timebase trace from the A

timebase trace. Please note TRS (8).

DC voltage measurement:

If no signal is applied at the INPUT CHI (27), the vertical

trace position represents 0 Volt. This is the case if INPUT

CHI (27) or in addition (ADD) mode, both INPUT CHI (27)

and INPUT CHII (31), are set to GD (ground) and automatic triggering (AT (11)) is present to make the trace

visible. The trace then can be set to vertical position

which is suited for the following DC voltage measurement.

After switching GD (ground) off and selecting DC input

coupling, a DC signal applied at the input changes the

trace position in vertical direction. The DC voltage then

can be determined by taking the deflection coefficient,

the probe factor and the trace position change in respect

to the previous 0 Volt position into account.

”0 Volt” Symbol:

The determination of the ”0 Volt” position is not necessary if the readout is switched on and the software

setting ”DC Ref. = ON” is selected in the ”SETUP”

submenu ”Miscellaneous”. Then the ”

left of the screen‘s vertical center line always indicates

the ”0 Volt” trace position in CHI and DUAL mode.

The ”0 Volt” position symbol (

⊥⊥

⊥) will not be displayed in

⊥⊥

⊥⊥

⊥” symbol to the

⊥⊥

The ”0 Volt” position symbol (

XY and ADD (addition) mode.

(11)NM - AT -

Pushbutton with a double function and associated NMLED.

NM - AT selection:

Press and hold the pushbutton to switch over from

automatic (peak value) to normal triggering (NM LED

above the pushbutton lit) and vice versa. If the LED is

dark, automatic (peak value) triggering is selected. Whether

the peak value detection in automatic trigger mode is

automatically activated or not, depends on the trigger

coupling setting (TRIG.MODE). The way the trigger point

symbol in the readout responds on different LEVEL

control knob settings indicates the situation:

1. If the trigger symbol can not be shifted in the vertical

direction when a signal is not applied or the signal

height is not sufficient, the peak value detection is

active.

2. Under the condition that the trigger point symbol

cannot be shifted in such a way that it leaves the signal

display on the screen, the peak value detection is

active.

3. The peak value detection is switched off if the trigger

point can be set outside the maximum peak values of

the signal, thus causing an untriggered signal display.

Slope selection:

Briefly pressing this pushbutton selects which slope of

the signal is used for triggering the timebase generator.

(SLOPE)

⊥⊥

⊥) will not be displayed in

⊥⊥

Subject to change without notice

13

Page 14

Controls and Readout

Each time this pushbutton is briefly pressed, the slope

direction switches from falling edge to rising edge and

vice versa.

The current setting is displayed in the readout under item

“TR: source, SLOPE, coupling”. The last setting in A

timebase mode is stored and still active if the alternate (A

and B) or B timebase are selected. This allows for a

different slope setting regarding the B timebase if the

DEL. TRIG. function is active. The slope direction chosen

for the B timebase is indicated in the readout under “DTr:

SLOPE, coupling”.

results in a higher timebase speed (lower time deflection

coefficient), all time and frequency relevant information in

the readout is switched over.

Please note that in alternate timebase mode the intensified sector may become invisible due to the X position setting.

This pushbutton is not operative in XY mode.

(16) VOLTS/DIV.

This control knob for channel I has a double function.

The following description relates to the input attenuator

function (VAR LED dark).

Turning the control knob clockwise increases the sensitivity in a 1-2-5 sequence and decreases it if turned in the

opposite direction (ccw.). The available range is from

1mV/div up to 20V/div. The knob is automatically switched

inactive if the channel related to it is switched off, or if the

input coupling is set to GD (ground).

The deflection coefficients and additional information

regarding the active channels are displayed in the readout,

e.g. “Y1: deflection coefficient, input coupling”. The “:”

symbolizes calibrated measuring conditions and is replaced by the “>” symbol in uncalibrated conditions.

(12)TR - Trigger indicator LED.

The TR LED is lit in Yt mode if the triggering conditions are

met. Whether the LED flashes or is lit constantly depends

on the frequency of the trigger signal.

(13)LEVEL - Control knob.

Turning the LEVEL knob causes a different trigger point

setting (voltage). The trigger unit starts the timebase

when the edge of a trigger signal (voltage) crosses the

trigger point. In most Yt modes the trigger point is

displayed in the readout by the symbol on the left vertical

graticule line. If the trigger point symbol would overwrite

other readout information or would be invisible when

being set above or below the screen, the symbol changes

and an arrow indicates in which vertical direction the

trigger point has left the screen.

The trigger point symbol is automatically switched off in

those modes where there is no direct relation between

the trigger signal and the displayed signal. The last setting

in A timebase mode is stored and still active if alternate

(A and B) or B timebase mode are selected.

This allows for a different level setting for the B timebase

if the DEL. TRIG. function is active. Under this condition

the letter “B” is added to the trigger point symbol.

(14)X-POS. - Control knob.

This control knob enables an X position shift of the

signal(s) in Yt and XY mode. In combination with X

magnification x10 this function makes it possible to shift

any part of the signal on the screen.

(17)CH I - VAR. - Pushbutton with several functions.

CH I mode:

Briefly pressing the CHI button sets the instrument to

channel I (Mono CH I) mode. The deflection coefficient

displayed in the readout indicates the current conditions

(“Y1...”). If neither external nor line (mains) triggering

was active, the internal trigger source automatically

switches over to channel I (“TR:Y1...”). The last function

setting of the VOLTS/DIV (16) knob remains unchanged.

All channel I related controls are active if the input (27) is

not set to GD (29).

VAR.:

Pressing and holding this pushbutton selects the VOLTS/

DIV. (16) control knob function between attenuator and

vernier (variable). The current setting is displayed by the

VAR-LED located above the knob.

After switching the VAR-LED (16) on, the deflection

coefficient is still calibrated. Turning the VOLTS/DIV.

(16) control knob counter clockwise reduces the signal

height and the deflection coefficient becomes

uncalibrated.

The readout then displays e.g. “Y1>...” indicating the

uncalibrated condition instead of “Y1:...”. Pressing and

holding the CHI pushbutton again switches the LED off,

sets the deflection coefficient into calibrated condition

and activates the attenuator function. The previous vernier setting will not be stored.

(15)X-MAG. x10 - Pushbutton and LED.

Each time this pushbutton is pressed the x10 LED located

above is switched on or off. If the x10 LED is lit, the signal

display in all Yt and timebase modes is expanded 10 fold

and consequently only a tenth part of the signal curve is

visible. The interesting part of the signal can be made

visible with aid of the X-POS. control. As the X expansion

14

The CHI pushbutton can also be pressed simultaneously

with the DUAL(18) button. Please note item (18).

(18)DUAL - XY - Pushbutton with multiple functions.

DUAL mode:

Briefly pressing this button switches over to DUAL mode.

Subject to change without notice

Page 15

Controls and Readout

Both deflection coefficients are then displayed. The previous trigger setting stays as it was, but can be changed.

All controls related to both channels are active, if the

inputs (27) and (31) are not set to GD (29) (33).

Whether alternated or chopped channel switching is

present depends on the actual timebase setting, and is

displayed in the readout.

ALT

displayed in the readout, indicates alternate channel

switching. After each timebase sweep the instrument

internally switches over from channel I to channel II and

vice versa. This channel switching mode is automatically

selected if any time coefficient from 200µs/div to 50ns/

div is active.

CHP

indicates chopper mode, whereby the channel switching

occurs constantly between channel I and II during each

sweep. This channel switching mode occurs when any

timebase setting between 500ms/div and 500µs/div has

been chosen.

The actual channel switching can be changed to the

opposite mode by briefly pressing both CHI (17) and

DUAL (18) simultaneously. If afterwards the time coefficient is changed, the channel switching is automatically

set to the time coefficient related mode.

ADD mode:

Addition mode can be selected by briefly pressing the

DUAL (18) and CHII (21) buttons simultaneously. Whether

the algebraic sum (addition) or the difference (subtraction) of both input signals is displayed, depends on the

phase relationship and the INV (29) (33) setting(s). As a

result both signals are displayed as one signal. For correct

measurements the deflection coefficients for both channels must be equal.

Please note “Operating modes of the vertical amplifiers

in Yt mode”.

In XY mode the deflection coefficients are displayed as

“Y...” for channel I and “X...” for channel II, followed by

“XY”. Except the cursor lines which may be active, all

other readout information including the trigger point

symbol are switched off. In addition to all trigger and

timebase related controls, the Y-POS. II (10) knob and

INV (33) button are deactivated. For X position alteration,

the X-POS. (14) knob can be used.

(19)TRIG.

Pushbutton with double function for trigger source selection and associated LEDs.

The button and the LEDs are deactivated if line (mains)

triggering is selected or XY operation is chosen.

With the aid of this button, the trigger source can be

chosen. There are three trigger sources available:

channel I, channel II (both designated as internal trigger

sources) and the TRIG. EXT. (34) input for external

triggering.

The availability of the internal sources depends on the

actual channel mode. The actual setting is indicated by

the associated LED(s).

Briefly pressing the button switches over in the following

sequence:

I - II - EXT - I in DUAL and ADD (addition) mode,

I - EXT - I if mono channel I is present,

II - EXT - II under mono channel II conditions.

Each condition is indicated by the associated LED and

displayed by the readout (“TR:Y1...”, “TR:Y2...” and

“TR:EXT...”). The trigger point symbol is switched off in

external trigger condition.

ALT:

Pressing and holding the button selects alternate triggering in DUAL mode. Under these conditions both I and II

LEDs are lit and the readout displays “TR:ALT...”. As

alternate triggering requires alternate channel operation,

alternate channel switching is set automatically. A change

of the time coefficient then has no affect regarding the

channel switching mode. In addition to the deflection

coefficients display, “ALT” is displayed by the readout

instead of “CHP”.

The readout indicates this mode by a “+” sign located

between both channel deflection coefficients. While the

trigger mode is not affected, the trigger point symbol is

switched off. The Y-position of the signal can be influenced by both Y-POS controls (9) and (10).

XY mode:

This mode can be switched on or off by pressing and

holding the DUAL button (18).

Subject to change without notice

In alternate trigger mode the trigger point symbol is

switched off.

Alternate triggering is not available or automatically

switched off under the following conditions:

ADD (addition) mode,

alternate (A & B) timebase mode,

B timebase mode,

TVL, TVF and line (mains) trigger coupling.

(20) VOLTS/DIV. -

This control knob for channel II has a double function.

The following description relates to the input attenuator

function (VAR LED dark).

Turning the control knob clockwise increases the sensitivity in a 1-2-5 sequence and decreases it if turned in the

opposite direction (ccw.). The available range is from

15

Page 16

Controls and Readout

1mV/div up to 20V/div. The knob is automatically switched

inactive if the channel related to it is switched off, or if the

input coupling is set to GD (ground).

The deflection coefficients and additional information

regarding the active channels are displayed in the readout,

e.g. “Y2: deflection coefficient, input coupling”. The “:”

symbolizes calibrated measuring conditions and is replaced by the “>” symbol in uncalibrated conditions.

(21)CH II - VAR. - Pushbutton with several functions.

CH II mode:

Briefly pressing the button sets the instrument to channel

II (Mono CH II) mode. The deflection coefficient displayed

in the readout indicates the current conditions (“Y2...). If

neither external nor line (mains) triggering was active, the

internal trigger source automatically switches over to

channel II (“TR:Y2...). The last function setting of the

VOLTS/DIV (20) knob remains unchanged.

AC (DC content suppressed),

DC (peak value detection inactive),

HF (high-pass filter cuts off frequencies below

approx. 50kHz), trigger point symbol switched off

NR (high frequency noise rejected),

LF (low-pass filter cuts off frequencies above

approx. 1.5kHz),

TVL (TV signal, line pulse triggering)

trigger point symbol switched off,

TVF (TV signal, frame pulse triggering)

trigger point symbol switched off.

~ (line/mains triggering) trigger point symbol

and TRIG. LED (19) are switched off.

Please note:

In delay trigger mode (B timebase) the instrument is

automatically set to normal triggering mode and DC

trigger coupling. Neither setting is indicated by the

NM- (11) or the “DC” TRIG. MODE-LED. The previous

trigger settings regarding the A timebase remain unchanged and are indicated by the LEDs (11) and (22).

In some trigger modes such as alternate triggering, some

trigger coupling modes are automatically disabled and

can not be selected.

(23)DEL.POS. - HO

Control knob with a double function and associated LED.

This control knob has two different functions depending

on the timebase mode.

A timebase:

In A timebase mode, the control knob applies to the hold

off time setting. If the HO-LED associated with the knob

is dark, the hold off time is set to minimum.

All channel related controls are active if the input (31) is

not set to GD (33).

VAR.:

Pressing and holding this pushbutton selects the VOLTS/

DIV. (20) control knob function between attenuator and

vernier (variable). The current setting is displayed by the

VAR-LED located above the knob.

After switching the VAR-LED (20) on, the deflection

coefficient is still calibrated. Turning the VOLTS/DIV.

(20) control knob counter clockwise reduces the signal

height and the deflection coefficient becomes

uncalibrated.

The readout then displays “Y2>...” indicating the

uncalibrated condition instead of “Y2:...”. Pressing and

holding the CHII pushbutton again switches the LED off,

sets the deflection coefficient into calibrated condition

and activates the attenuator function. The previous vernier setting will not be stored.

The CHII pushbutton can also be pressed simultaneously

with the DUAL (18) button. Please note item (18).

(22)TRIG. MODE - Pushbuttons and indicator LEDs.

Pressing the upper or lower button selects the trigger

coupling. The actual setting is indicated by a LED and by

the readout (“TR: source, slope, AC”).

Each time the lower TRIG. MODE pushbutton is pressed

the trigger coupling changes in the sequence:

Turning the control knob clockwise switches the LED on

and extends the hold off time until the maximum is

reached (please note “Hold Off-time adjustment”).

The hold off time is automatically set to minimum (LED

dark), if the A timebase setting is changed. The (A) hold

off time setting is stored and active if alternate (A and B)

or B timebase mode is selected.

Alternate (A and B) and B timebase: