Page 1

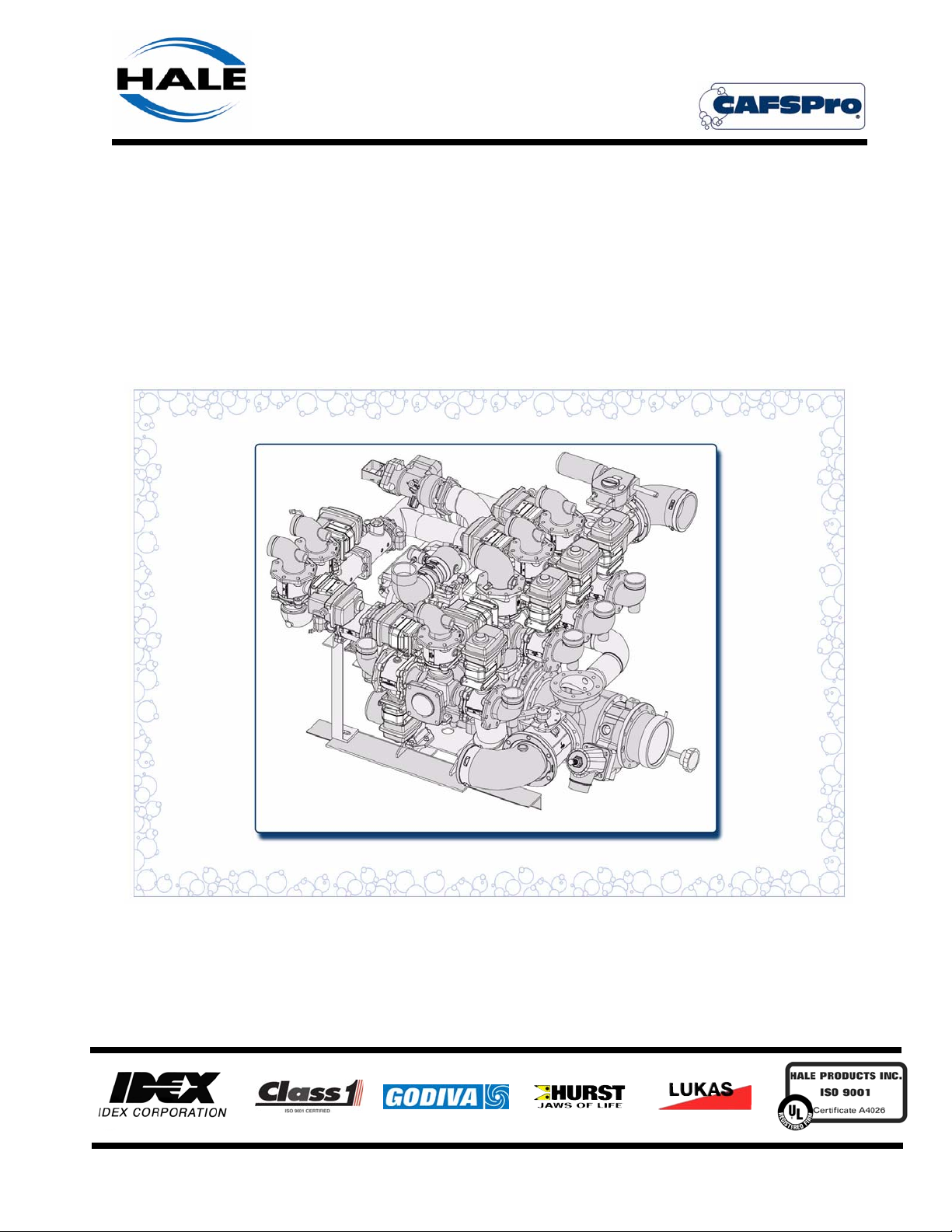

SMR-AC Addendum “A”

Compressed Air Foam System

CAFSPro

Hale Products Inc. ◆ A Unit of IDEX Corporation

700 Spring Mill Avenue

Telephone: 610-825-6300

Web............www.haleproducts.com

◆ Conshohocken, PA 19428 U.S.A.

◆ FAX: 610-825-6440

Manual p/n: 029-0020-78-0

Page 2

NOTICE !

Class1 cannot assume responsibility for product failure resulting from improper

maintenance or operation. Class1 is responsible only to the limits stated in the

product warranty. Product specifications contained in this manual are subject to

change without notice.

All Class1 products are quality components -- ruggedly designed, accurately

machined, precision inspected, carefully assembled and thoroughly tested. In

order to maintain the high quality of your unit, and to keep it in a ready condition, it

is important to follow the instructions on care and operation. Proper use and good

preventive maintenance will lengthen the life of your unit.

ALWAYS INCLUDE THE UNIT SERIAL NUMBER

IN YOUR CORRESPONDENCE.

ECO NO REV CHANGE FROM BY DATE APVD

0032 A INITIAL RELEASE LwH 07/29/2005 MAL

? B SMR-AC CAFSPro Addendum LwH 06/30-2006 MAL

HALE PRODUCTS, INC.

A Unit of IDEX Corporation

Conshohocken, PA 19428 USA

Manual p/n: 029-0020-78-0, Rev. -B

Printed in U.S.A.

DRAWN BY LwH ISSUE DATE COPYRIGHT ©

CHECKED BY PW 06/30/2005

NOT TO BE REPRODUCED OR USED TO

MAKE OTHER DRAWINGS OR MACHINERY.

© Hale Products, Inc. 2006

All Rights Reserved

Page 3

Addendum - Table of Contents ❑

Contents Page

SMR-AC CAFSPro Installation Addendum

Addendum: SMR-AC Installation........................................................................ 5

A.1 Unpacking........................................................................................................................... 5

Lifting the System ...............................................................................................................................5

Figure A-1: Lifting the SMR-AC system................................................................................6

A.2 SMR-AC System Mounting ................................................................................................ 6

SMR-AC CAFSPro Main Pump System Assembly.............................................................................6

Figure A-2: Shock Mounting .................................................................................................7

Oil Separator Tank Assembly .............................................................................................................7

Figure A-3: Separator Tank Mounting Bracket .....................................................................7

Panel Strainer, Water Cooling ............................................................................................................ 8

A.3 Plumbing Connections ......................................................................................................8

Figure A-4: Overview, SMR-AC System Connections (FRONT View) .................................8

Figure A-5: Overview, SMR-AC System Connections (REAR View)....................................9

A.4 Oil Separator Tank ............................................................................................................. 9

Figure A-6: Separator Tank Installation Overview ..............................................................10

Figure A-7: Depressurizing Valve Assembly ......................................................................11

A.5 Air Filter.............................................................................................................................12

Figure A-8: Typical Air Filter Installation.............................................................................12

A.6 Electrical Connections..................................................................................................... 12

Harness Connections ......................................................................................................................12

Table A-9: Harness Connections........................................................................................12

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

3

Page 4

❑ Addendum - Table of Contents

Contents - continued Page

Notes

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

4

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

Page 5

SMR-AC Installation and Setup ❑

Addendum: SMR-AC Installation

This SMR-AC Installation Addendum is in addition to and is to be used in conjunction with the CAFSPro Installation Guide, Hale p/n: 029-0020-78-0. Additional

installation is required by the builder / installer as the Oil Separator Tank must be

externally mounted, requiring additional plumbing.

A.1 UNPACKING

The SMR-AC CAFSPro system is shipped primarily assembled on two

skids. One skid contains the main SMR-AC CAFSPro pump, manifold and

valve assembly. The second skid contains the FoamLogix Pump Unit, Air

Separator Tank, Gearbox, along with all supplied loose items.

Use care when removing the SMR-AC CAFSPro from its packaging (skid) to

prevent injury and/or damage to the system, especially the external system

connecitons.

IMPORTANT!

EXERCISE CARE DURING UNPACKING AND INSTALLATION TO PREVENT

INJURY AND/OR DAMAGE TO THE SYSTEM AND TO ENSURE THAT THE

IDENTIFICATION TAGS ARE NOT REMOVED BEFORE THE CONNECTIONS

ARE MADE.

DO NOT REMOVE OR ALTER ANY HYDRAULIC OR PNEUMATIC CONNECTIONS WITHOUT WRITTEN APPROVAL FROM HALE PRODUCTS. ALSO SEE

SECTION “1 SAFETY PRECAUTIONS” BEGINNING ON PAGE 7.

Lifting the System

WARNING !

THE SMR-AC CAFSPRO PUMP SYSTEM IS HEAVY AND BULKY, POSSIBLY

WEIGHING OVER 2,000 LBS. (907 KGS.). CHECK BILL OF LADING FOR

APPROXIMATE WEIGHT. USE PROPER LIFTING SUPPORT DEVICES (OVERHEAD CRANE, STRAPS/CHAINS, ETC.) CAPABLE OF HANDLING THE LOAD

WHEN MOVING OR INSTALLING THE SYSTEM.

DO NOT ATTACH LIFTING APPARATUS TO THE SYSTEM MANIFOLDING.

ATTACH DIRECTLY TO THE FRAME.

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

51

Page 6

❑ SMR-AC Installation and Setup

WARNING - continued !

PLACE A BRACE, APPROXIMATELY 3’ (1 METER) BETWEEN THE LIFTING

STRAPS / CHAINS TO PREVENT APPLYING EXCESSIVE PRESSURE TO THE

MANIFOLDS AS THE SYSTEM IS LIFTED INTO PLACE. APPLY A STRAP

AROUND THE FRONT SUCTION INLET AS SHOWN TO DEVELOP A THREEPOINT LIFT, MAKING SURE THE SYSTEM IS BALANCED. ALSO SEE FIGURE A-1: “LIFTING THE SMR-AC SYSTEM (THREE-POINT LIFT).”

Figure A-1: Lifting the SMR-AC System (Three-Point Lift)

A.2 SMR-AC SYSTEM MOUNTING

SMR-AC CAFSPro Main Pump System Assembly

When installing the SMR-AC CAFS System to the apparatus chassis, use

accepted practices for mounting. Review previous Section 3 “Receiving

and Inspection” beginning on page 13. Also see Figure A-2: “Shock Mounting” on page 53.

52

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

Page 7

SMR-AC Installation and Setup ❑

Whether mounting directly to the chassis, or constructing a separate bracket,

accepted brackets must be used.

Shock absorption is provided and must

be included in any mounting modification. (See Figure A-2: “Shock Mounting.”)

All mounting brackets must be constructed from structural angled steel,

having minimum dimensions of 4” x 36”

x 1/2” (102 x 914 x 13 mm). Use mini-

Figure A-2: Shock Mounting

mum 5/8”, Grade 8 bolts with flat

washers and lock nuts.

Installation diagrams are located at the back of this manual to assist with

overall dimensions and clearances required for the various mounting configurations. Also see Section “ Drawing Package” beginning on page 67.

Oil Separator Tank Assembly

Mount the oil separator tank assembly at a convenient and accessible location, enabling a clear view of the oil level sight gauge and oil fill cap. (See

Figure A-3: “Separator Tank Mounting Bracket.”).

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

Figure A-3: Separator Tank Mounting Bracket

53

Page 8

❑ SMR-AC Installation and Setup

Attach female eye-bolts, 12 mm, to the

top cross bracket mounting studs for

lifting. Mount the separator tank having the inlet port sightly BELOW the

compressor discharge port to ensure

back-flush does not enter the compressor, which would severely damage

the unit. (See Figure A-4: “Lifting Separator Tank.”)

Mount the tank using 7/16”-14, Grade

8 screws, flat and lock washers and

nuts. For a separator tank mounting

overview schematic, see Section

“Drawing Package” on page 67.

Figure A-4: Lifting Separator

Tan k

Panel Strainer, Water Cooling

For mounting instructions, see Section 4.4 “Panel Strainer” on page 21.

A.3 PLUMBING CONNECTIONS

(See Figure A-5: “Overview, SMR-AC System Connections,” on page 55.)

The following connections are made by the system builder/installer:

❑ Truck air to solenoid manifold

❑ Gearbox cooler return line to booster tank

❑ Pressure lines (3/8” tube) to PM control

❑ Control line (3/8” tube) from PM control to sensing valve

❑ Switch and truck air to pump master drain

❑ Water and air to duplex master gauge

❑ TRV electrical and discharge connections

❑ TPM electrical connections

54

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

Page 9

SMR-AC Installation and Setup ❑

Figure A-5: Over-

view, SMR-AC Sys-

tem Connections

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

55

Page 10

❑ SMR-AC Installation and Setup

A.4 OIL SEPARATOR TANK

For a general overview of the oil separator tank connection, see Section

“Drawing Package” on page 67. (See Figure A-6: “Separator Tank Installation Overview.”)

56

Figure A-6: Separator Tank Installation Overview

The following connections are made by the system builder/installer:

❑ (#1) Compressor discharge air / oil mixture to oil separator tank INLET.

Use 1-1/2” (38 mm), wire reinforced hose. For example, Aeroquip

FC350-24. (See Figure A-6: “Separator Tank Installation Overview.”)

❑ (#2) Oil separator tank DISCHARGE to CAFSPro manifold (air INLET).

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

Page 11

SMR-AC Installation and Setup ❑

Use 1-1/4” (32 mm), wire reinforced hose for maximum air flow. For

example, Aeroquip FC350-20.

Note: Two check valves are provided in this discharge line to ensure water is not

back-flushed into the oil separator tank.

❑ (#3) Oil separator tank DISCHARGE to heat exchanger.

Use 7/8” (22 mm), wire reinforced hose. For example, Aeroquip FC350-

16. (See Figure A-6: “Separator Tank Installation Overview,” on page

56.)

❑ (#4) Air sensing valve to duplex gauge.

Use DOT approved red 1/4” (6 mm) tubing

❑ (#5) Oil separator tank to compressor control line.

Provided - 3/8” (10 mm), wire reinforced high pressure hose. For example, Aeroquip FC332-06.

❑ (#6) Oil separator

tank “discharge”

air feed to air filter

line (blow-down

line). (See Figure

A-7: “Depressurizing Valve Assembly.”)

Use DOT

approved low

pressure tubing

(1/4” / 6 mm).

❑ (#7) Oil separator

tank to compressor, oil scavenge

line. Use DOT

approved air supply tubing. (See

Figure A-7: Depressurizing Valve Assembly

Figure A-6: “Separator Tank Installation Overview,” on page 56.)

❑ Oil / water separator tank drain and shut-off vavle.

❑ An auxiliary air outlet for rescue tools and testing is provided. A fitting is

available, with JIC cap, on the outlet of the separator tank.

Remove the protective cap, and install an appropriate hose. Use 3/4”

(19 mm) to 1” (25.4 mm), wire reinforced hose for maximum air flow. For

example, Aeroquip FC350-16, 1” (25.4 mm) wire reinforced hose.

A quick disconnect and ball valve should be installed on the panel, as

required.

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

57

Page 12

❑ SMR-AC Installation and Setup

Note: A minimum 1” (25.4 mm) connection is required to test the system per

NFPA standards.

A.5 AIR FILTER

For reliable operation, the CAFS air filter must be located in a clean, freshair environment, usually in the dunnage area above the pump compartment.

DO NOT damage the filter during

assembly and be sure the mounting area offers protection.

Mount the air filter 6” (152 mm)

MINIMUM above the decking platform to prevent standing water from

being sucked into the filter and possibly back into the system. (See

Figure A-8: “Typical Air Filter Installation,” on page 58.)

Use 3” (76.2 mm) CPVC pipe and

rubber connections. Support the

piping with brackets as needed.

Figure A-8: Typical Air Filter Installation

A.6 ELECTRICAL CONNECTIONS

Harness Connections

To From

Separator Tank Air Sensing Valve C14

Vent Valve C7

Oil temperature Sensor C15

Oil Salvage (Blow-Down) C17

Gearbox Pump Engaged Switch C9

Tachometer Sender C13

Labeled Apparatus Power C16

Connector

Number

58

Table A-9: Harness Connections

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

Page 13

(See Figure A-6: “Separator Tank Installation Overview,” on page 56.) Also

see Figure A-7: “Depressurizing Valve Assembly” on page 57.

A.7 FLUID LEVELS

To meet various shipping regulations, oil within the pump gearbox and separator tank assemblies is drained prior to shipping from the factory.

AT INSTALLATION AND BEFORE OPERATION, ALL FLUIDS MUST BE ADDED

TO THE APPROPRIATE LEVELS.

Before operation, refill and check as necessary -

SMR-AC Installation and Setup ❑

IMPORTANT !

❑ Separator tank - see page 35.

❑ Hot shift clutch option - see page 36.

❑ Pump gearbox reservoir - see separate pump service manual.

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

59

Page 14

❑ SMR-AC Installation and Setup

Notes

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

60

Addendum - SMR-AC CAFSPro Installation Guide

p/n: 029-0020-78-0

Loading...

Loading...