HALE SmartFOAM 1.7AHP, SmartFOAM 2.1A, SmartFOAM 6.5, SmartFOAM 3.3, SmartFOAM 5.0 Description, Installation And Operation Manual

Page 1

SmartFOAM

Electronic Foam Proportioning Systems

Models:

Class A only – 1.7AHP, 2.1A

Class A/B – 3.3, 5.0, 6.5

Description, Installation, and Operation

Manual

FSG-MNL-00158

HALE PRODUCTS, INC / CLASS 1

607 NW 27th Avenue ● Ocala, FL 34475

U.S.A. Telephone: 352-629-5020

Charles Street ● Warwick, England CV34 5LR

FAX: 800-533-3569

GODIVA LTD.

Phone: 44-1-926-623600

Page 2

SmartFOAM

Hale SmartFOAM System Serial Number

In Service Date

Fire Department

Engine Number

Calibration Factors:

Water Flow – high calibration point

Water flow

Pulses

Water Flow – low calibration point

Water flow

Pulses

Class A Foam Factor

NOTICE!

REV

Date

Page

Description

A

DEC 2015

All

New Issue

B

FEB 2018

6

12, 13

22, 34, 35, 47

23, 53, 54

36

82

83-84

87, 90

State all foam models not just 1.7/2.1

Add new Motor Driver drawings

Add pictures of piston and gear pump w/ new motor driver

Add new harness part numbers and information

Add new mounting information

Updated closed loop control diagram and system overview

Add new motor driver information

Add new Assembly drawings

APPARATUS INFORMATION

Page 1

Hale Products does not assume responsibility for product failure resulting from improper maintenance or operation.

Hale Products is responsible only to the limits stated in the product warranty. Product specifications contained in this

manual are subject to change without notice.

All Hale products are quality components -- ruggedly designed, accurately machined, precision inspected, carefully

assembled and thoroughly tested. In order to maintain the high quality of your unit, and to keep it in a ready condition, it

is important to follow the instructions on care and operation. Proper use and good preventive maintenance will lengthen

the life of your unit.

REVISION RECORD

Page 3

Page 2

SmartFOAM

NOTES

Page 4

Page 3

SmartFOAM

Contents

APPARATUS INFORMATION ........................................................................................................ 1

REVISION RECORD ...................................................................................................................... 1

NOTES ........................................................................................................................................... 2

SAFETY ......................................................................................................................................... 6

GUIDELINES ...................................................................................................................................................................... 6

SYSTEM OVERVIEW ..................................................................................................................... 9

ROTARY PLUNGER PUMP (1.7 AHP, 2.1A) ...................................................................................................................... 9

ROTARY GEAR PUMP (3.3, 5.0, 6.5) ................................................................................................................................. 9

SMARTFOAM CONTROL UNIT ......................................................................................................................................... 9

WATER FLOW SENSOR .................................................................................................................................................... 9

FEEDBACK SENSOR ........................................................................................................................................................ 9

LOW PRESSURE STRAINER .......................................................................................................................................... 10

HIGH PRESSURE STRAINERS (FS SERIES) ................................................................................................................... 10

TANK SELECTOR VALVES ............................................................................................................................................. 10

HALE FOAM SYSTEM SPECIFICATIONS ....................................................................................................................... 11

HALE FOAM PUMP DIMENSIONS .................................................................................................................................. 12

SYSTEM DIAGRAM ......................................................................................................................................................... 14

CONTROLLER AND BASE PUMP ................................................................................................................................... 22

SINGLE CONCENTRATE TANK OPTIONS ..................................................................................................................... 24

DUAL CONCENTRATE TANK OPTIONS ........................................................................................................................ 24

STRAINER OPTIONS ....................................................................................................................................................... 25

LOW TANK SENSOR OPTIONS ...................................................................................................................................... 26

FLOW SENSOR OPTIONS .............................................................................................................................................. 26

CHECK VALVE MANIFOLDS, FLANGES AND GASKETS .............................................................................................. 27

ELBOWS AND MANIFOLDS ............................................................................................................................................ 28

REMOTE START OPTION ............................................................................................................................................... 29

INSTALLATION ........................................................................................................................... 30

FOAM PUMP AND MOTOR ASSEMBLY ......................................................................................................................... 30

FOAM CONCENTRATE STRAINER ................................................................................................................................ 30

CONTROL UNIT AND INSTRUCTION / SYSTEM DIAGRAM PLACARD ........................................................................ 31

INSTALLER SUPPLIED COMPONENTS ......................................................................................................................... 31

FOAM CONCENTRATE SUCTION HOSE ....................................................................................................................... 31

FOAM CONCENTRATE DISCHARGE HOSE .................................................................................................................. 32

FOAM CONCENTRATE BYPASS HOSE ......................................................................................................................... 32

CHECK VALVES .............................................................................................................................................................. 32

FLUSHING WATER HOSE ............................................................................................................................................... 32

FOAM DISCHARGE DRAINS ........................................................................................................................................... 33

APPARATUS DESIGN/BUILD FOR COLD WEATHER (BELOW FREEZING) DUTY ..................................................... 33

ELECTRICAL REQUIREMENTS ...................................................................................................................................... 33

FOAM CONCENTRATE TANK ......................................................................................................................................... 34

FOAM PUMP MOUNTING ................................................................................................................................................ 34

PLUMBING INSTALLATION ............................................................................................................................................. 37

WATER AND FOAM SOLUTION PLUMBING .................................................................................................................. 37

CHECK VALVE MANIFOLD ............................................................................................................................................. 37

OPTIONAL HALE PIPING COMPONENTS ...................................................................................................................... 38

WATERWAY CHECK VALVES ........................................................................................................................................ 40

FLOW SENSOR ................................................................................................................................................................ 40

SADDLE CLAMP INSALLATION ...................................................................................................................................... 41

FOAM PUMP FLUSH SYSTEM ........................................................................................................................................ 42

Page 5

Page 4

SmartFOAM

FOAM CONCENRATE PLUMBING .................................................................................................................................. 42

FOAM STRAINER CONNECTION ................................................................................................................................... 42

IN-LINE STRAINER VALVE .............................................................................................................................................. 43

FS SERIES STRAINER .................................................................................................................................................... 44

CHECK VALVE / INJECTOR FITTING .............................................................................................................................. 46

FOAM CONCENTRATE INJECTION HOSE ..................................................................................................................... 47

BYPASS HOSE CONNECTION ....................................................................................................................................... 48

ADT OPTION AIR CONNECTIONS .................................................................................................................................. 49

ELECTRICAL CONNECTIONS ........................................................................................................................................ 51

CONTROLLER UNIT ........................................................................................................................................................ 52

CONTROLLER UNIT POWER AND GROUND CONNECTIONS ..................................................................................... 53

MOTOR GROUND / PRIMARY POWER .......................................................................................................................... 55

GROUND CONNECTION ................................................................................................................................................. 55

PRIMARY POWER SUPPLY CONNECTION ................................................................................................................... 55

RFI / EMI ........................................................................................................................................................................... 55

FOAM TANK LOW LEVEL SENSOR INSTALLATION ..................................................................................................... 56

FOAM TANK LOW LEVEL SENSOR WIRING .................................................................................................................. 60

REMOTE ACTIVATION SWITCH OPTION ...................................................................................................................... 61

START-UP CHECKLIST .............................................................................................................. 62

ELECTRICAL .................................................................................................................................................................... 62

LIQUID .............................................................................................................................................................................. 62

FOAM PUMP .................................................................................................................................................................... 62

SYSTEM INSTALLER START-UP ................................ ............................................................... 63

INITIAL SYSTEM POWER CHECK ................................................................................................................................... 63

INITIAL SYSTEM CHECK ................................................................................................................................................. 63

INSTALLATION AND DELIVERY CHECKLIST .......................................................................... 66

INSTALLATION ................................................................................................................................................................ 66

DELIVERY ........................................................................................................................................................................ 66

NOTES .............................................................................................................................................................................. 67

USER CALIBRATION .................................................................................................................. 68

ENTERING PASSWORDS ............................................................................................................................................... 68

WATER FLOW CALIBRATION ......................................................................................................................................... 68

FOAM FLOW CALIBRATION ........................................................................................................................................... 69

SETTING PRESETS ......................................................................................................................................................... 70

UNIT OF MEASURE ......................................................................................................................................................... 70

RELIEF VALVE ................................................................................................................................................................. 71

OPERATION ................................................................................................................................ 72

DESCRIPTION ................................................................................................................................................................. 72

PRESET SCREEN ............................................................................................................................................................ 72

OPERATION SCREEN ..................................................................................................................................................... 72

DISPLAYED INFORMATION ............................................................................................................................................ 73

RESET WATER/FOAM TOTALS ...................................................................................................................................... 73

FOAM CONCENTRATE INJECTION RATE ..................................................................................................................... 73

WARNING MESSAGES ................................................................................................................................................... 73

PRIMING THE FOAM PUMP ............................................................................................................................................ 74

NORMAL OPERATION SUMMARY ................................................................................................................................. 74

SIMULATED FLOW OPERATION ............................................................................................... 75

SIMULATED FLOW SEQUENCE ..................................................................................................................................... 75

TO END SIMULATED FLOW ............................................................................................................................................ 75

DUAL TANK SYSTEM SELECTION ............................................................................................ 76

FLUSHING THE SMARTFOAM SYSTEM ................................................................ ................... 77

Page 6

Page 5

SmartFOAM

REMOTE ON/OFF SWITCH OPERATION .................................................................................. 78

NOTES .............................................................................................................................................................................. 79

MAINTENANCE ........................................................................................................................... 80

MAINTENANCE PROCEDURES ..................................................................................................................................... 80

ON-SCREEN MAINTENANCE MINDER .......................................................................................................................... 80

FREEZE PROTECTION .................................................................................................................................................... 81

TROUBLESHOOTING ................................................................................................................. 82

USER DIAGNOSTICS ...................................................................................................................................................... 82

PROBLEM ISOLATION .................................................................................................................................................... 85

ILLUSTRATED PARTS BREAKDOWN ....................................................................................... 86

GENERAL ......................................................................................................................................................................... 86

ABBREVIATIONS ............................................................................................................................................................. 86

FOAM PUMP ASSEMBLY – 1.7AHP AND 2.1A ............................................................................................................... 87

FLOW METER ASSEMBLY – 1.7AHP AND 2.1A (115497) .............................................................................................. 88

PUMP REPAIR KIT – 1.7AHP AND 2.1A .......................................................................................................................... 89

FOAM PUMP ASSEMBLY – 3.3, 5.0, AND 6.5 ................................................................................................................... 90

FLOW METER ASSEMBLY – 3.3, 5.0, AND 6.5 ................................................................................................................ 91

Page 7

SmartFOAM

IMPORTANT!

WARNING!

SAFETY

ALL HALE SMARTFOAM MODELS ELECTRONIC

FOAM PROPORTIONING SYSTEMS ARE

DESIGNED FOR OPTIMUM SAFETY OF ITS

OPERATORS AND TO PROVIDE RELIABLE AND

SAFE FOAM CONCENTRATE INJECTION. FOR

ADDED PROTECTION AND BEFORE ATTEMPTING

INSTALLATION OR OPERATION PLEASE FOLLOW

THE SAFETY GUIDELINES LISTED IN THIS

SECTION AND ADHERE TO ALL WARNING,

DANGER, CAUTION AND IMPORTANT NOTES

FOUND WITHIN THIS GUIDE.

THIS SECTION ON SAFETY MUST BE CAREFULLY

READ, UNDERSTOOD AND ADHERED TO

STRICTLY BY ALL INSTALLERS AND OPERATORS

BEFORE ATTEMPTING TO INSTALL OR OPERATE

THE SMARTFOAM PROPORTIONING SYSTEM.

INCORPORATE THE WARNINGS AND CAUTIONS

AS WRITTEN WHEN DEVELOPING

DEPARTMENTAL APPARATUS OPERATING

PROCEDURES.

SmartFOAM is a trademark of Hale Products,

Incorporated. All other brand and product names

are the trademarks of their respective holders.

GUIDELINES

READ ALL INSTRUCTIONS THOROUGHLY BEFORE

BEGINNING ANY INSTALLATION OR OPERATION

PROCESS.

❑ Installation should be performed by a trained and

qualified installer, or your authorized Hale

Products service representative.

❑ Be sure the installer has sufficient knowledge,

experience and the proper tools before attempting

any installation.

❑ Make sure proper personal protective equipment is

used when operating or servicing apparatus.

Page 6

❑ A foam tank low level sensor must be utilized to

protect the Hale Foam proportioner from dry

running. Failure to use a low level sensor with the

Hale Foam system voids warranty.

❑ DO NOT permanently remove or alter any

guard or insulating devices, or attempt to

operate the system when these guards are

removed.

❑ Make sure all access/service panels and covers

are installed, closed and latched tight, where

applicable.

❑ DO NOT remove or alter any hydraulic or

pneumatic connections, electrical devices, etc.

DO NOT tamper with or disconnect safety

features or modify protective guards (such as

covers or doors). DO NOT add or remove

structural parts. Doing so voids the warranty.

Any of the above could affect system capacity and/or

safe operation of the system and is a serious safety

violation which could cause personal injury, could

weaken the construction of the system or could affect

safe operation of the SmartFOAM Proportioning

System.

NO MODIFICATIONS OR ADDITIONS MA Y BE

MADE TO THE SMARTFOAM PORPORTIONING

SYSTEM WITHOUT PRIOR WRITTEN PERMISSION

FROM:

HALE PRODUCTS, INC

607 NW 27th Avenue

Ocala, Florida 34475 USA

Telephone: 352-629-5020

FAX: 800-533-3569

Page 8

SmartFOAM

❑ All electrical systems have the potential to

cause sparks during service. Take care to

eliminate explosive or hazardous environments

during service and/or repair.

❑ To prevent electrical shock always disconnect the

primary power source before attempting to service

any part of the Hale Foam system.

❑ To prevent system damage or electrical shock

the main power supply wire is the last

connection made to the Hale Foam motor

controller.

❑ Release all pressure then drain all concentrate and

water from the system before servicing any of its

component parts.

❑ Do not operate system at pressures higher than the

maximum rated pressure.

❑ Use only pipe, hose, and fittings from the foam

pump outlet to the injector fitting, which are rated at

or above the maximum pressure rating at which the

water pump system operates.

❑ Hale Foam proportioning systems are designed for

use on negative ground direct current electrical

systems only.

❑ Do not mount radio transmitter or transmitter

cables in direct or close contact with the

SmartFOAM control unit.

❑ Before connecting the cord sets and wiring

harnesses, inspect the seal washer in the female

connector. If the seal washer is missing or damaged,

water can enter the connector causing corrosion of

the pins and terminals. This could result in possible

system failure.

❑ Always disconnect the power cable, ground

straps, electrical wires and control cables from

the control unit or other Hale Foam system

equipment before electric arc welding at any point

on the apparatus Failure to do so could result in a

power surge through the unit that could cause

irreparable damage.

❑ DO NOT connect the main power lead to small leads

that are supplying some other device, such as a light

bar or siren.

❑ When operating the Hale SmartFOAM in Simulated

Flow mode, an outlet for the foam concentrate must

be provided to prevent excessive pressure build up

in the discharge piping or hoses.

❑ Make sure the foam tank and foam concentrate

suction hoses are clean before making final

connection to foam pump. If necessary, flush tank

and hoses prior to making connection.

Page 7

❑ Check all hoses for weak or worn conditions after

each use. Ensure that all connections and fittings

are tight and secure.

❑ Ensure that the electrical source of power for

unit is a negative (–) ground DC system, of

correct input voltage, with a reserve minimum

current available to drive the system.

❑ The in-line strainer/valve assembly is a low

pressure device and WILL NOT withstand

flushing water pressure in excess of 45 PSI (3

BAR).

❑ When determining the location of Hale Foam

system components keep in mind piping runs,

cable routing and other interferences that could

hinder or interfere with proper system

performance.

❑ Always position the check valve/injector fitting at

a horizontal or higher angle to allow water to

drain away from the fitting. This avoids the

possibility of sediment deposits or the formation

of an ice plug.

❑ The cord sets provided with each Hale Foam

system are indexed to ensure correct receptacle

installation (they insert one way only). When

making cord set connections DO NOT force

mismatched connections as damage can result in

improper system operation.

❑ Make sure all connections are sound, and that

each connection is correct.

❑ The cables shipped with each Hale Foam system

are 100% tested at the factory with that unit.

Improper handling and forcing connections can

damage these cables which could result in other

system damage.

❑ There are no user serviceable parts inside Hale

Foam system electrical/electronic components.

Opening of the motor controller or controller unit

voids the warranty.

❑ Use mounting hardware that is compatible with all

foam concentrates to be used in the system. Use

washers, lock washers and cap screws made of

brass or 300 series stainless steel.

❑ When making wire splice connections, make sure

they are properly insulated and sealed using an

adhesive filled heat shrink tubing.

❑ ALWAYS connect the primary positive power lead

from the terminal block to the master switch

terminal or the positive battery terminal.

❑ Use a minimum 8 AWG type SGX (SAE J1127)

chemical resistant battery cable and protect with

wire loom.

the

Page 9

Page 8

SmartFOAM

❑ Prevent corrosion of power and ground connections

by sealing these connections with silicone sealant

provided.

❑ Prevent possible short circuit by using the rubber

boot provided to insulate the primary power

connection at the Hale SmartFOAM motor

controller.

Page 10

SmartFOAM

SYSTEM OVERVIEW

The Hale SmartFOAM Foam Proportioning Systems are

completely engineered, factory matched foam

proportioning systems that provides reliable, consistent

foam concentrate injection for Class “A” AND Class “B”

foam operations. The 1.7AHP and 2.1A systems are for

Class “A” only while the 3.3, 5.0, and 6.5 systems can

use Class “A” and Class “B”.

Hale SmartFOAM Foam systems accurately deliver from

0.1% to 10.0% (up to the capacity of the foam pump)

foam concentrate through a check valve/ injector fitting,

directly into the water discharge stream. It is then fed as

foam solution into a standard fog nozzle, an air aspirated

nozzle, or CAFS equipment, through the apparatus

discharge piping. A properly configured and installed

foam system with Hale recommended components

virtually eliminates contamination of the booster tank, fire

pump and relief valve with foam concentrate.

ROTARY PLUNGER PUMP (1.7 AHP, 2.1A)

The heart of the Hale SmartFOAM 2.1A and 1.7AHP

systems are an electric motor driven rotary plunger

pump. The pump is constructed of anodized aluminum

and stainless steel and is compatible with most Class

“A” foam concentrates. The pump is close coupled to the

electric motor thereby eliminating maintenance of an oil

filled gearbox.

A relief valve mounted on the foam pump and

constructed of brass, protects the foam pump and foam

concentrate discharge hoses from over pressurization

and damage.

ROTARY GEAR PUMP (3.3, 5.0, 6.5)

The heart of the Hale SmartFOAM 3.3, 5.0, and 6.5

systems is an electric motor driven rotary gear pump.

The pump is constructed of bronze and stainless steel

and is compatible with almost all foam concentrates. The

pump is close coupled to the electric motor thereby

eliminating maintenance of an oil-filled gearbox. A relief

valve mounted on the foam pump and constructed of

stainless steel, protects the foam pump and foam

concentrate discharge hoses from over pressurization

and damage.

SMARTFOAM CONTROL UNIT

The control unit, mounted on the operator panel, is the

single control point for the SmartFOAM system. Press

one of the preset buttons to enable foam concentrate

Page 9

injection once water flow has been established. The 4.5”

direct sunlight viewable color display shows:

❑ Water flow rate

❑ Foam concentrate injection percentage

❑ Total water flowed

❑ Total foam concentrate used

❑ Foam pump capacity

The SmartFOAM control unit also provides plain-text

information and warnings as well as tutorials for

calibration. The user interface can be configured for the

modern SmartFOAM look or the classic FoamLogix look.

WATER FLOW SENSOR

Foam concentrate injection rate is controlled by a

computer chip in the control unit for accurate,

repeatable, reliable foam concentrate injection. A water

flow sensor constantly monitors water flow through the

discharge piping. The information from the flow sensor is

provided to the control unit by a shielded cable. When

the SmartFOAM system is activated at the control unit a

signal is sent through the control cable to the motor

controller to begin foam concentrate injection. The motor

controller then provides power to the electric motor. The

electric motor rotates the foam pump and foam

concentrate flows through the foam pump discharge to

the one piece check valve/injector fitting into the water

discharge stream.

Note: All Hale SmartFOAM Foam systems require a flow

sensor for operation.

FEEDBACK SENSOR

A feedback sensor in the foam pump discharge

measures foam concentrate flow. The water flow rate

and foam concentrate flow rate are constantly compared

by the computer chip in the control unit.

The motor speed is constantly adjusted to maintain the

operator selected foam concentrate injection rate. Since

the system is flow based, injection rate remains constant

regardless of changes in system pressure or the number

of discharges that are open (within the limits of the

system).

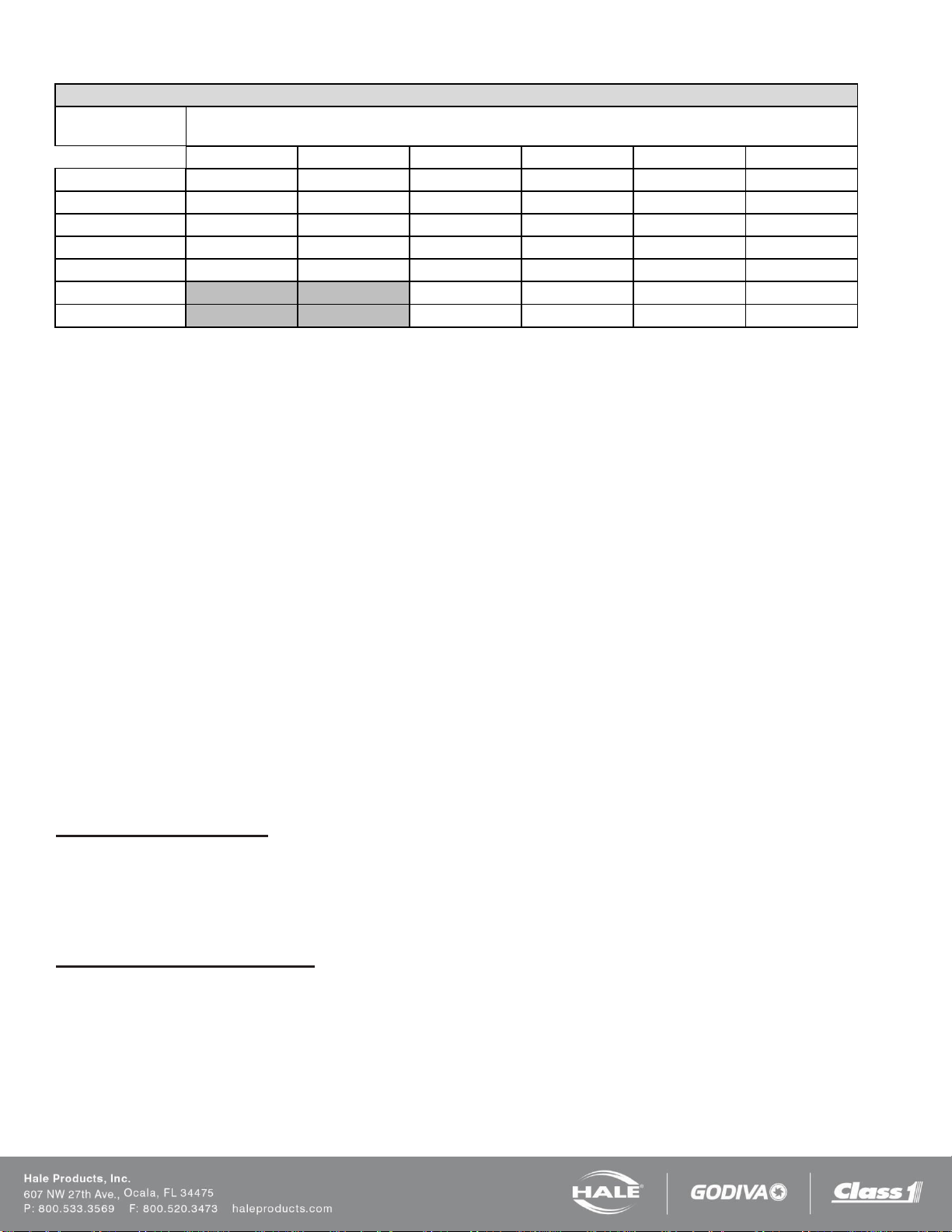

The maximum rated foam concentrate flow, in gallons

per minute, is denoted by the model number. Table 1:

Maximum Foam Solution Flows shows the system

capacity at various foam concentrate injection rates for

the Hale SmartFOAM systems.

Page 11

Page 10

SmartFOAM

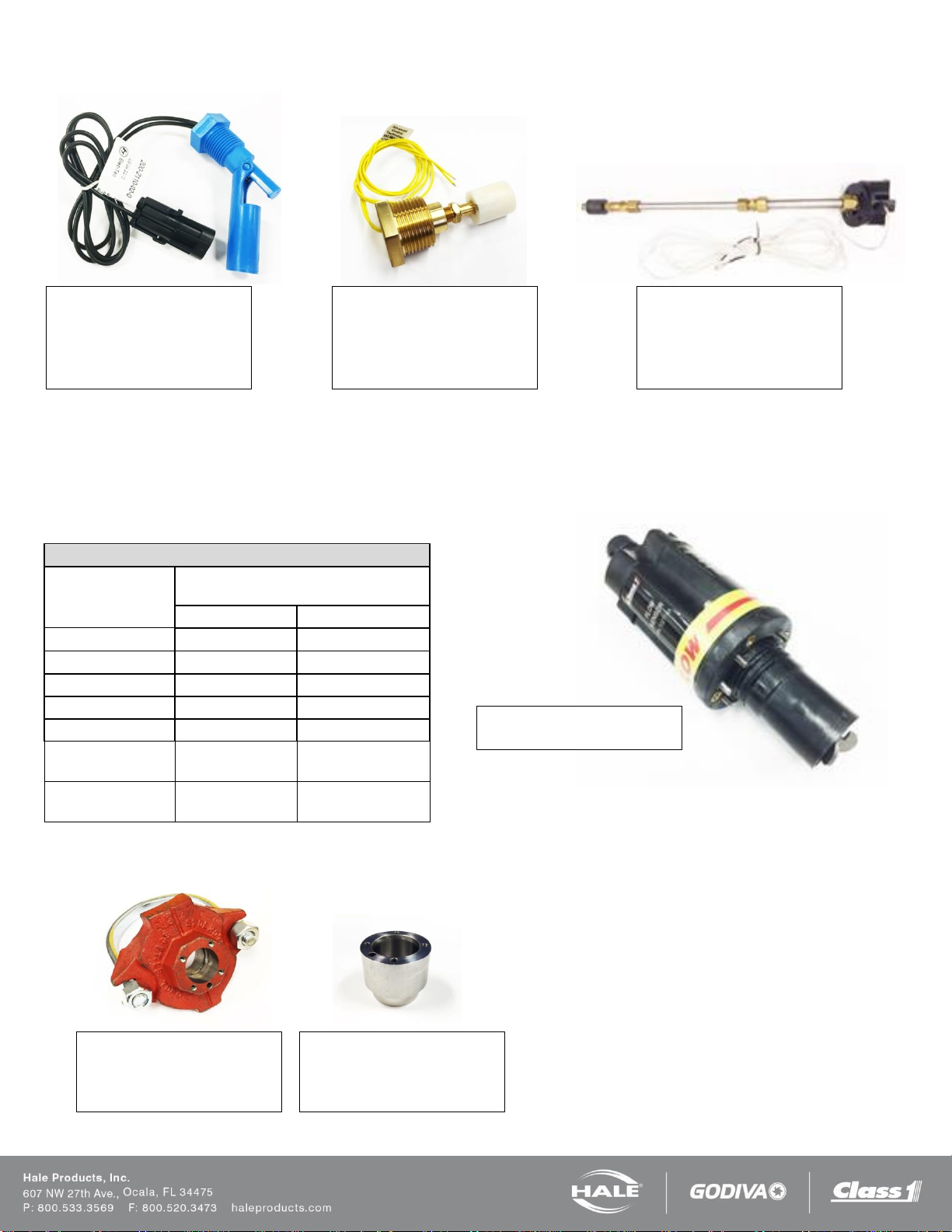

Maximum Foam Solution Flow

Injection Rate

Percent (%)

Flow rate in GPM [LPM]

1.7AHP

2.1A

3.3

5.0

6.5

Dual 6.5

0.1

1,700 [6,426]

2,100 [7,949]

3,300 [12,492]

5,000 [18,927]

6,500 [24,606]

13,000 [49,213]

0.2

850 [3,213]

1,050 [3,974]

1,650 [6,245]

2,500 [9,464]

3,250 [12,303]

6,500 [24,606]

0.3

567 [2,143]

700 [2,650]

1,100 [4,164]

1,667 [6,310]

2,167 [8,202]

4,333 [16,404]

0.5

340 [1,285]

420 [1,590]

660 [2,498]

1,000 [3,785]

1,300 [4,921]

2,600 [9,843]

1.0

170 [643]

210 [795]

330 [1,249]

500 [1,893]

650 [2,461]

1,300 [4,921]

3.0

110 [416]

167 [632]

217 [820]

433 [1,640]

6.0

55 [208]

83 [314]

108 [410]

217 [820]

Table 1: Maximum Foam Solution Flows

LOW PRESSURE STRAINER

A low pressure foam concentrate strainer is mounted at the inlet of the foam pump. The strainer protects the pump from

debris that might accumulate in the foam concentrate tank. The strainer/valve assembly has a composite non-metallic

housing with stainless steel mesh strainer element and includes a service shut-off valve.

The valve inlet offers 1/2” NPT (13 mm) threads, with a fitting to connect a 1/2” (13 mm) ID foam concentrate suction

hose.

The strainer and valve are low pressure devices and are designed for installations where the strainer IS NOT subject to

HIGH pressure flushing water.

HIGH PRESSURE STRAINERS (FS Series)

Hale FS series strainers (FS15 and FS25) are panel mounted with a 500 PSIG (34 BAR) pressure rating, suitable for use

where flushing water pressure must pass through the strainer.

The FS15 strainer uses 3/4” (19mm) NPT connection ports and a 1-1/2” NST cap. It is suitable for use with Class “A” and

low viscosity Class “B” foam concentrates.

The FS25 strainer uses 1” (25mm) NPT connection ports and a 2-1/2” NST cap. It is suitable for use with both Class “A”

and Class “B” foam concentrates.

TANK SELECTOR VALVES

SmartFOAM models 3.3, 5.0, and 6.5 may use dual foam tanks for A and B foam concentrates. Selection of the desired

foam concentrate tank with the ADT panel mounted toggle switch or MDT II selector automatically changes the foam

concentrate injection rate to the preset default rate for the selected foam tank. No further operator Intervention is required.

The ADT, MDT II and MST include the check valves and connection points to provide foam pump flushing capabilities.

Air Dual Tank Selector (ADT)

The Air Dual Tank (ADT) valve is an air operated foam tank selector valve that enables selection of foam concentrate

dependent on fire ground operational demands.

The ADT is an integral part of the foam pump and provides an electrical interlock for the low tank level sensors and

concentrate injection rate. A panel mounted selector toggle switch with indicator lights controls foam concentrate tank

selection and shows which foam concentrate tank is in use.

Manual Dual Tank Selector (MDT II)

The Manual Dual Tank (MDT II) selector valve is available for the Hale Foam systems with dual tanks. The MDT II is a

panel mounted, manually operated selector that provides selection of foam concentrate dependent on fire ground

operational demands.

The MDT II also provides an electrical interlock for the low tank level sensors and concentrate injection rate. The MDT II is

not suitable for top mount operator panel installations and some side operator panels due to gravity feed requirements of

foam concentrate to the foam pump.

Page 12

Page 11

SmartFOAM

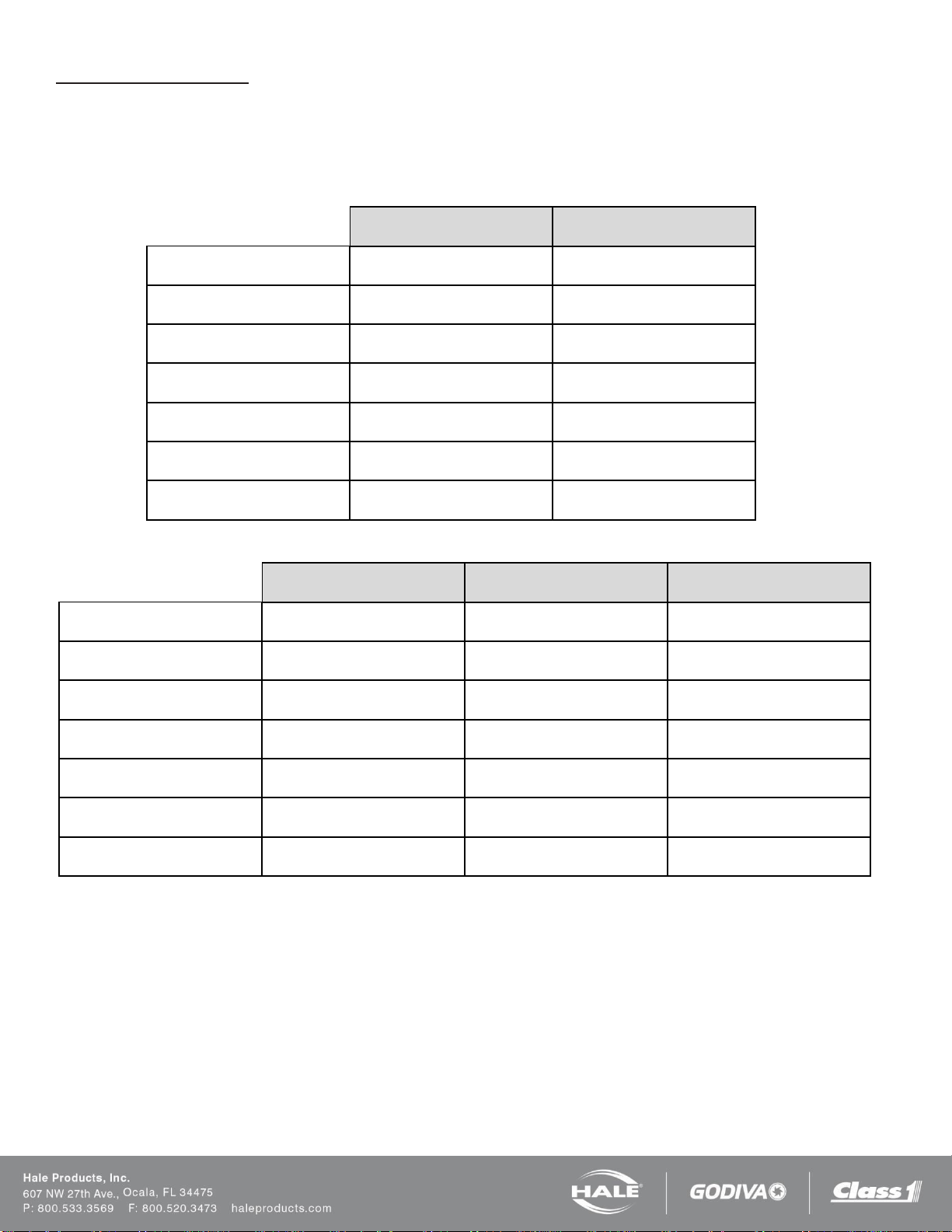

1.7AHP

2.1A

Foam Pump Type

Piston Pump, Dual Plunger

Piston Pump, Dual Plunger

Maximum Foam Concentrate

Output

1.7 GPM (6.5 LPM)

2.1 GPM (8 LPM)

Maximum System Operating

Pressure

400 PSI (27.5 BAR)

250 PSI (17 BAR)

Maximum Operating

Temperature

160°F (71°C)

160°F (71°C)

Pump Motor

0.44 HP (0.3 Kw), 12 VDC

0.44 HP (0.3 Kw), 12 VDC

Operating Ampere Draw

30 AMPS @ 12 VDC

25 AMPS @ 12 VDC

Maximum Ampere Draw

40 AMPS @ 12 VDC

40 AMPS @ 12 VDC

3.3

5.0

6.5

Foam Pump Type

Rotary Gear Positive

Displacement

Rotary Gear Positive

Displacement

Rotary Gear Positive

Displacement

Maximum Foam Concentrate

Output

3.3 GPM (13 LPM)

5.0 GPM (19 LPM)

6.5 GPM (24.6 LPM)

Maximum System Operating

Pressure

400 PSI (27.5 BAR)

250 PSI (17 BAR)

200 PSI (13.8 BAR)

Maximum Operating

Temperature

160°F (71°C)

160°F (71°C)

160°F (71°C)

Pump Motor

0.75 HP (0.6 Kw), 12 VDC

0.75 HP (0.6 Kw), 12 VDC

1.25 HP (0.9 Kw), 12 VDC

Operating Ampere Draw

30 AMPS @ 12 VDC

30 AMPS @ 12 VDC

40 AMPS @ 12 VDC

Maximum Ampere Draw

60 AMPS @ 12 VDC

60 AMPS @ 12 VDC

80 AMPS @ 12 VDC

Manual Single Tank (MST)

Single tank foam systems can be configured with a Manual Single Tank (MST) selector, which provides a flush function

connection to the foam system electronic controls.

HALE FOAM SYSTEM SPECIFICATIONS

Table 2: Specifications – 1.7 and 2.1

Table 3: Specifications – 3.3, 5.0, and 6.5

Page 13

Page 12

SmartFOAM

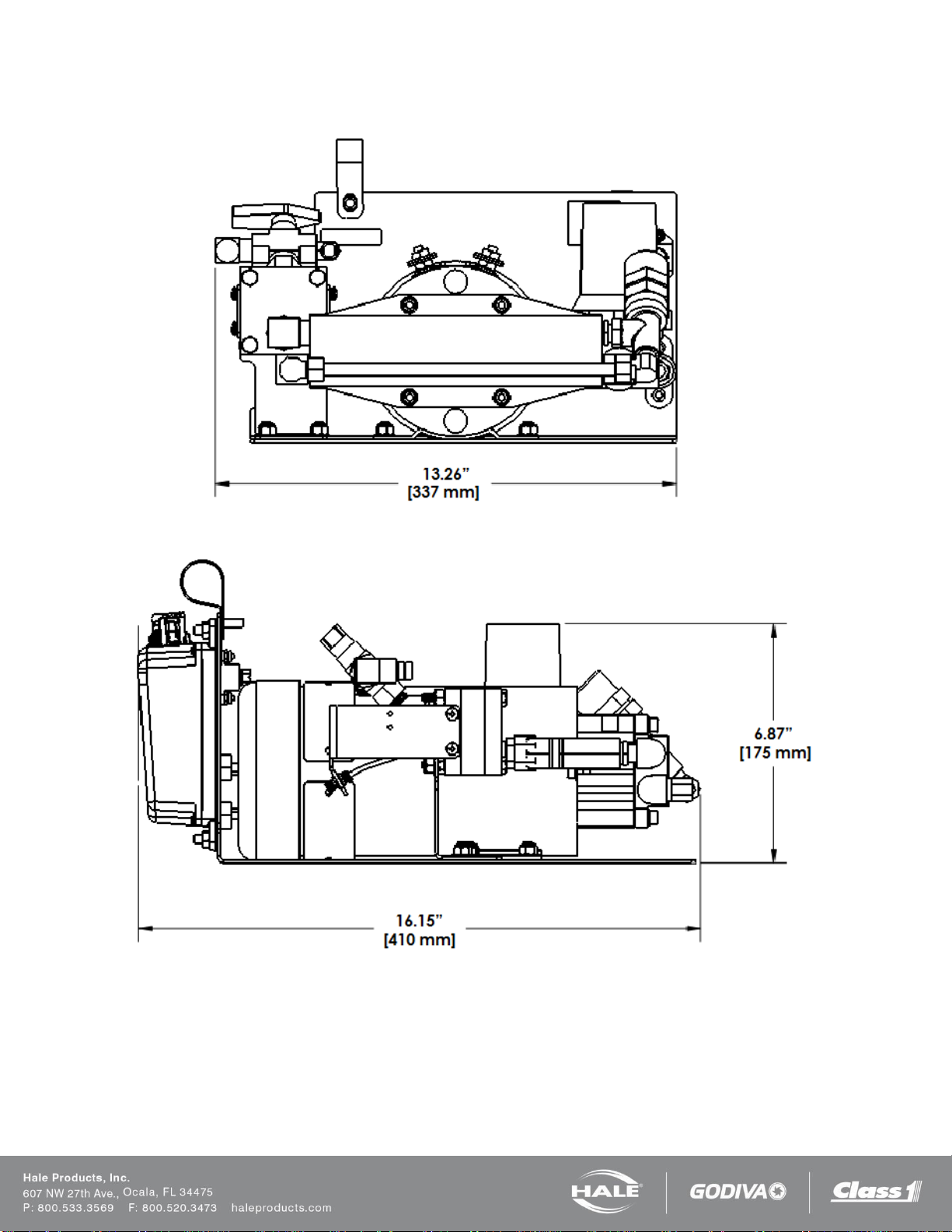

HALE FOAM PUMP DIMENSIONS

Figure 1: 1.7 and 2.1 Foam Pump Installation Envelope Dimensions

Page 14

Page 13

SmartFOAM

Figure 2: 3.3 and 5.0 Foam Pump Installation Envelope Dimensions

Page 15

Page 14

SmartFOAM

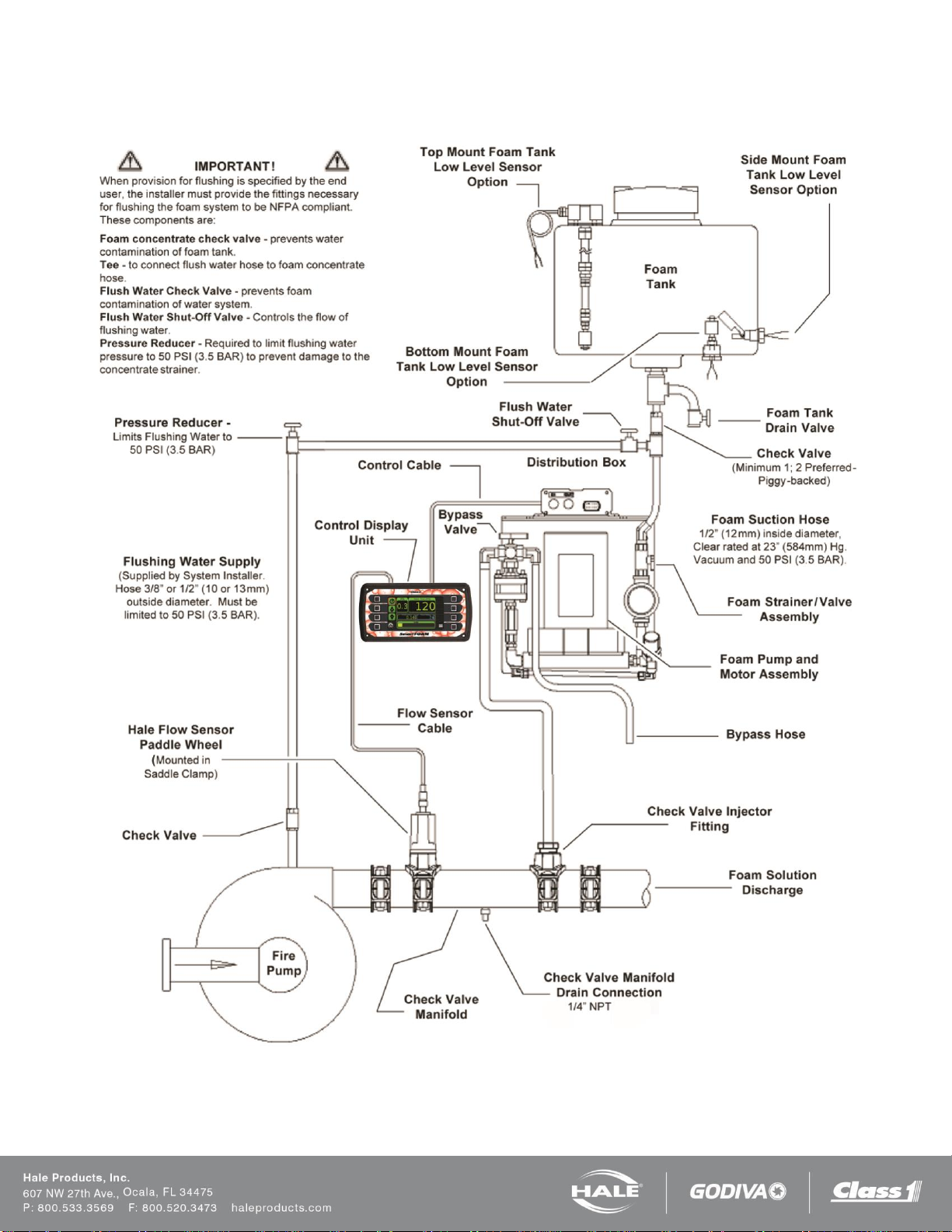

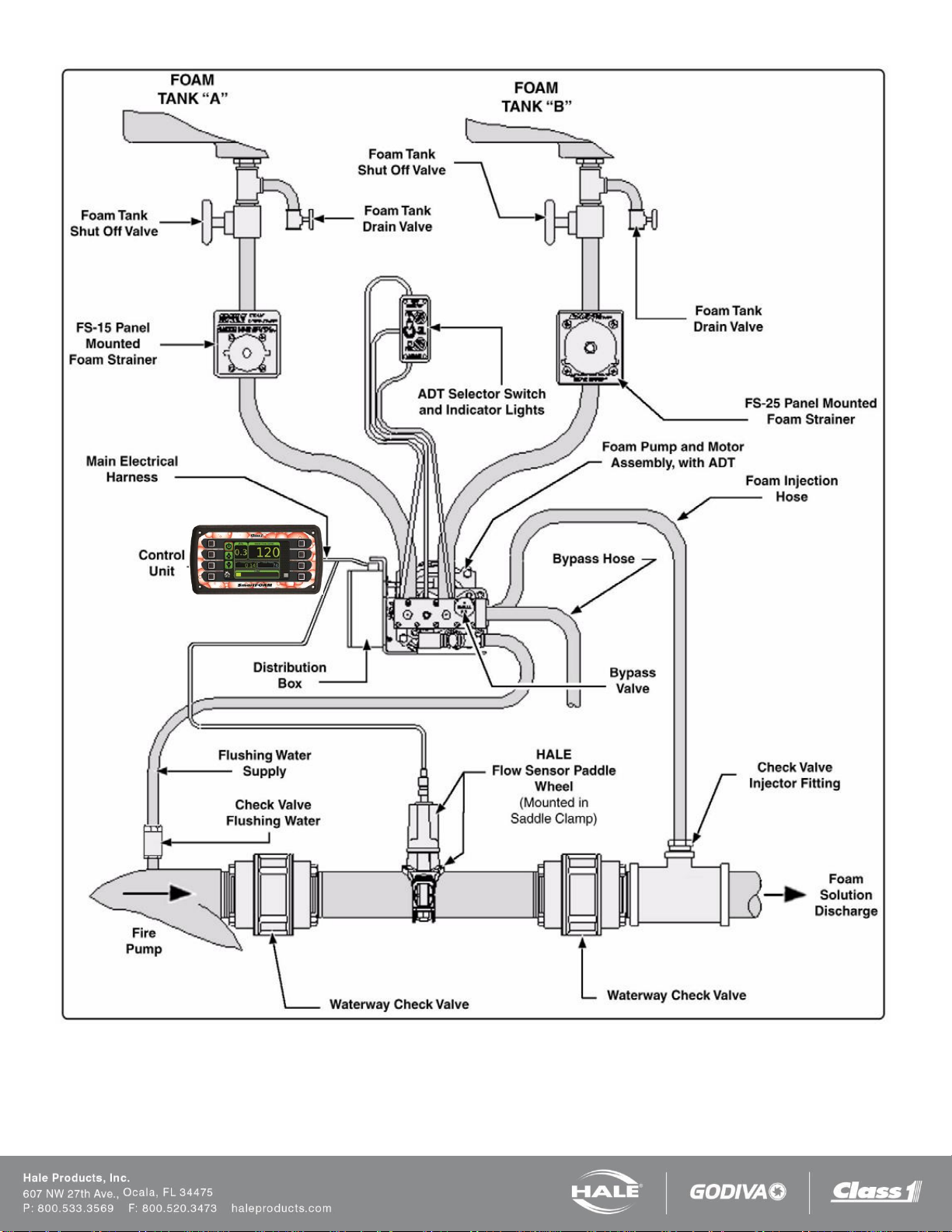

SYSTEM DIAGRAM

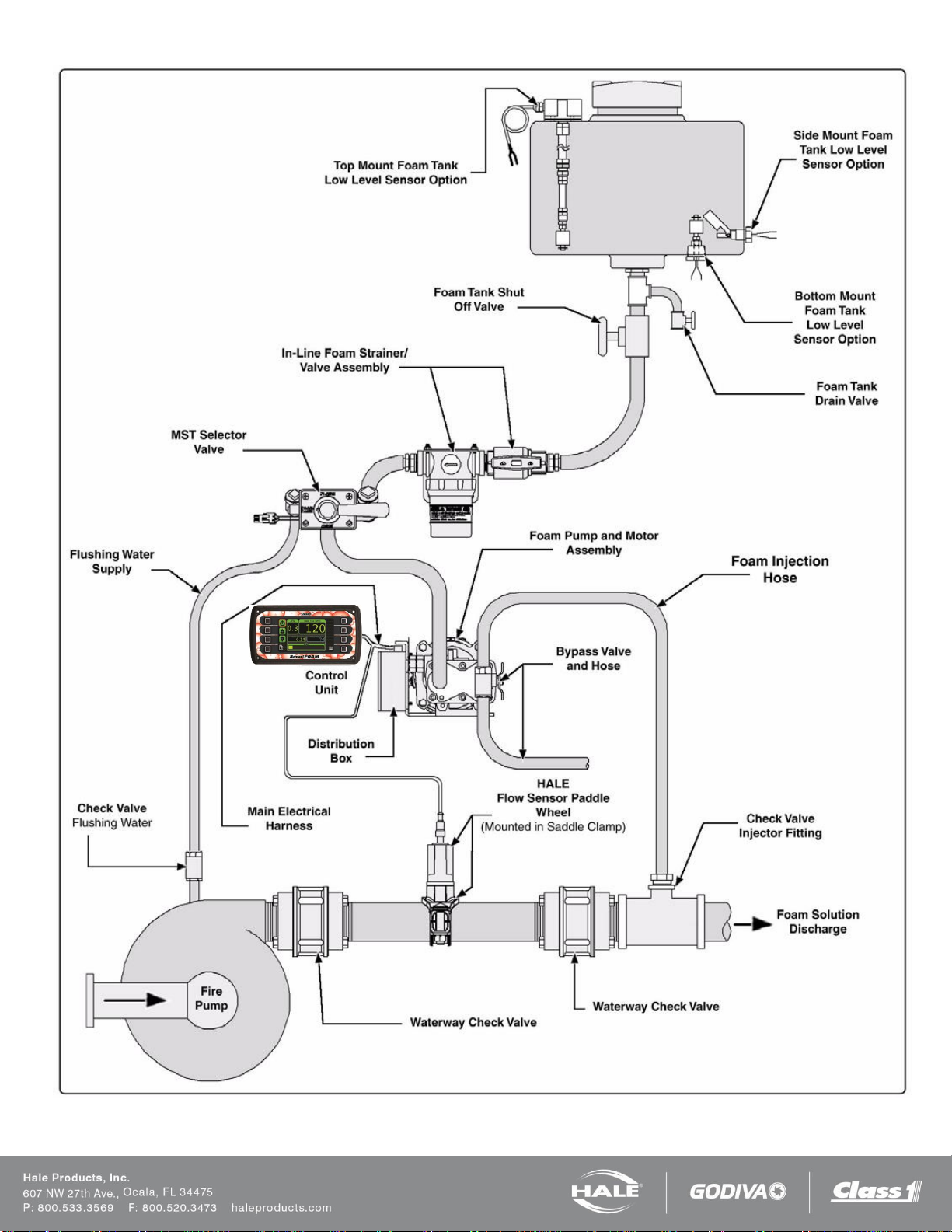

Figure 3: Typical Hale SmartFOAM 2.1A and 1.7AHP System

Page 16

Page 15

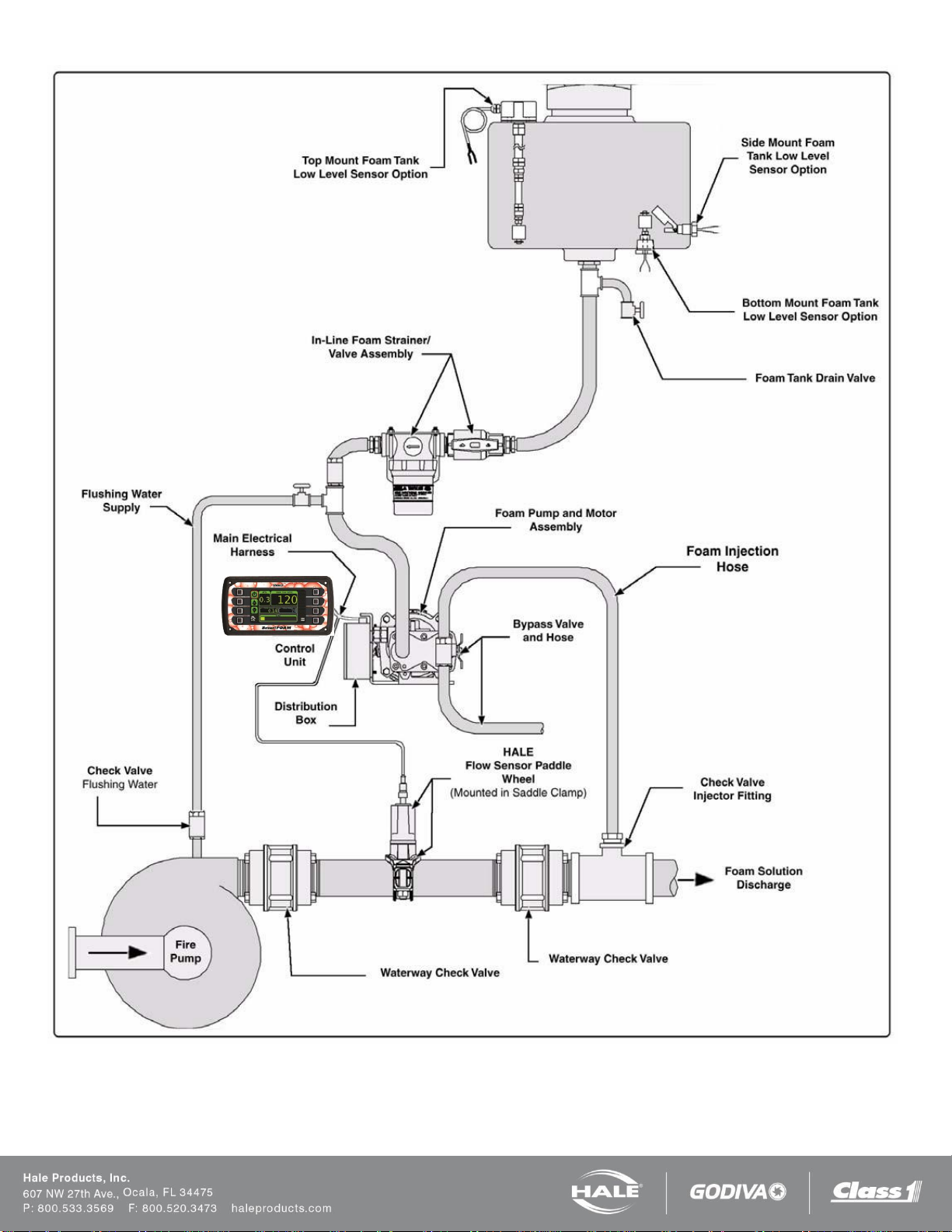

SmartFOAM

Figure 4: SmartFOAM 3.3, 5.0, 6.5 Single Tank System with In-line Strainer

Page 17

Page 16

SmartFOAM

Figure 5: SmartFOAM 3.3, 5.0, 6.5 Single Tank with MST and In-line Strainer

Page 18

Page 17

SmartFOAM

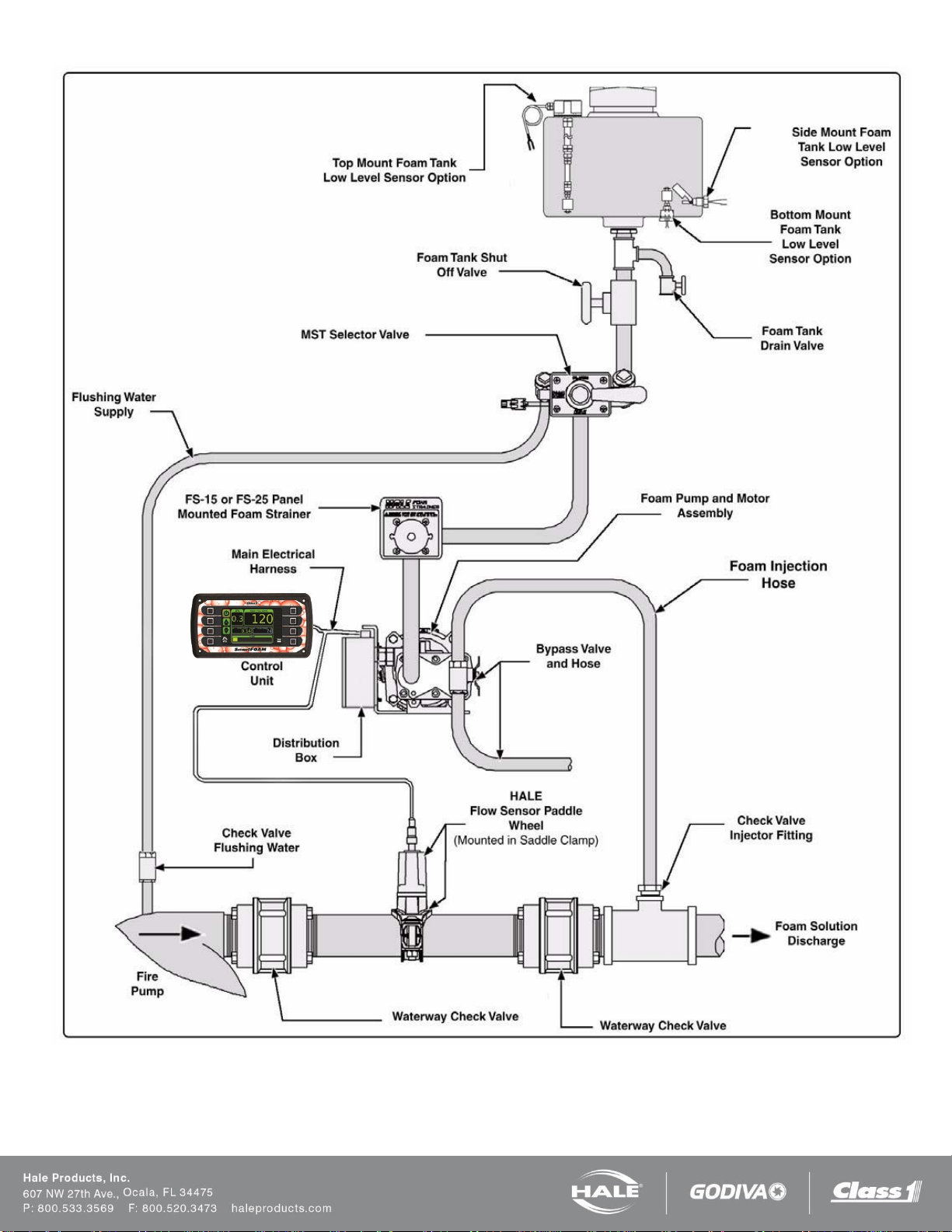

Figure 6: SmartFOAM 3.3, 5.0, 6.5 Single Tank with MST and FS Series Strainer

Page 19

Page 18

SmartFOAM

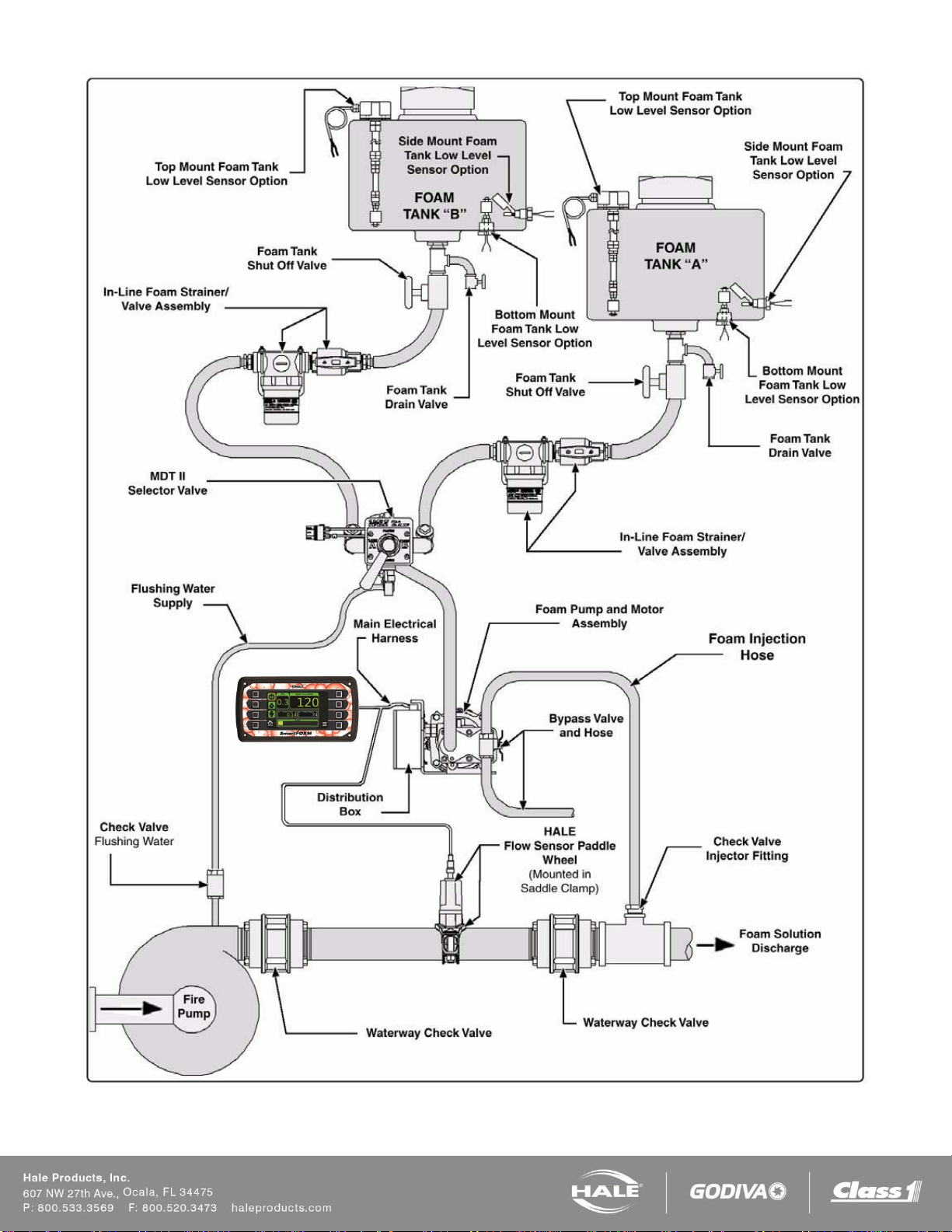

Figure 7: SmartFOAM 3.3, 5.0, 6.5 Dual Tank with MDTII and In-line Strainer

Page 20

Page 19

SmartFOAM

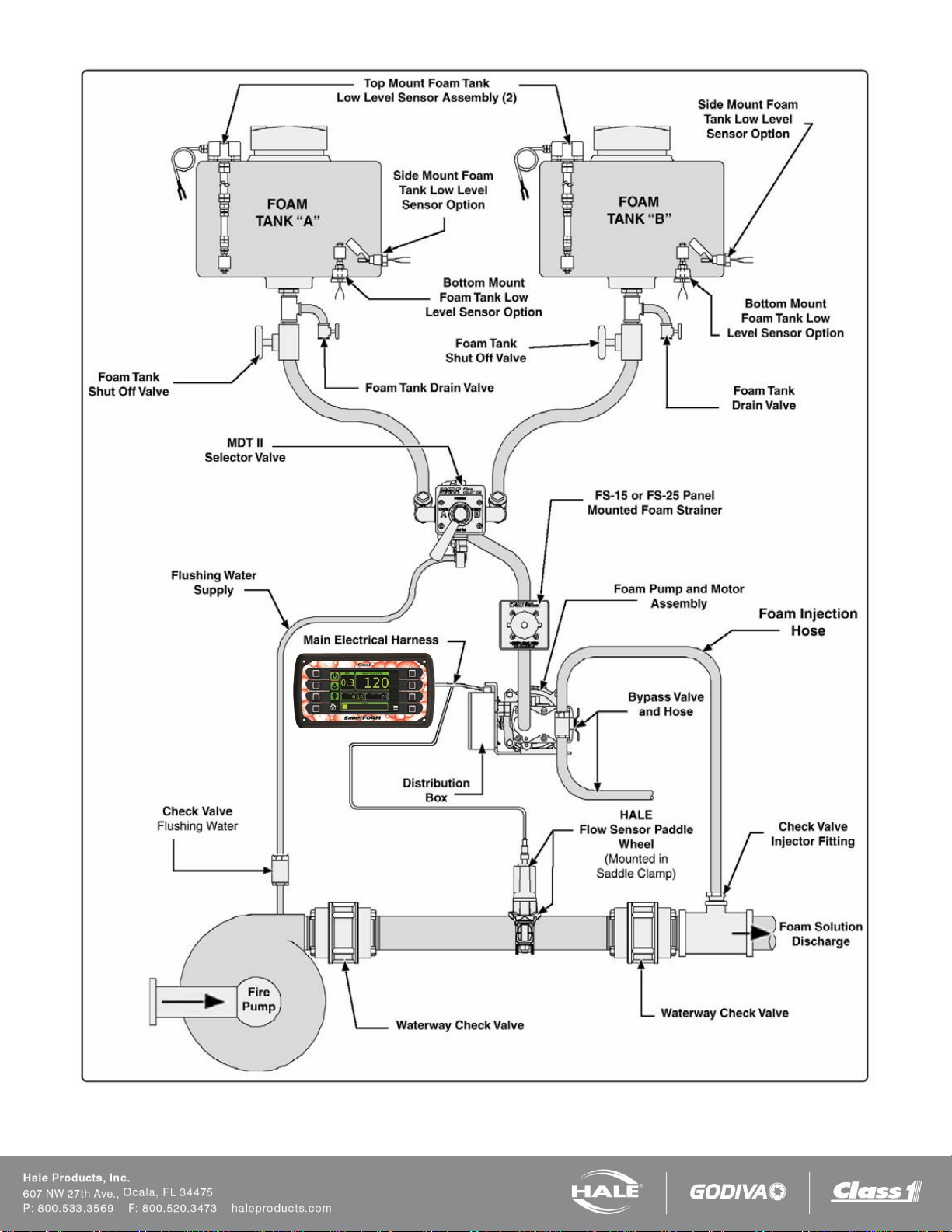

Figure 8: SmartFOAM 3.3, 5.0, 6.5 Dual Tank with MDTII and FS Series Strainer

Page 21

Page 20

SmartFOAM

Figure 9: SmartFOAM 3.3, 5.0, 6.5 Dual Tank with ADT and In-line Strainer

Page 22

Page 21

SmartFOAM

Figure 10: SmartFOAM 3.3, 5.0, 6.5 Dual Tank with ADT and FS Series Strainer

Page 23

Page 22

SmartFOAM

SmartFOAM controller

610-00039

SmartFOAM Base Unit, Foam

Pump/Motor Assembly

2.1A – 12V: 115498

2.1A – 24V: 115499

1.7AHP – 12V: 119276

1.7AHP – 24V: 119277

SmartFOAM Base Unit, Foam

Pump/Motor Assembly

3.3 – 12V: 501-3120-05-0

3.3 – 24V: 501-3120-06-0

5.0 – 12V: 501-3130-05-0

5.0 – 24V: 501-3130-06-0

6.5 – 24V: 501-4480-04-0

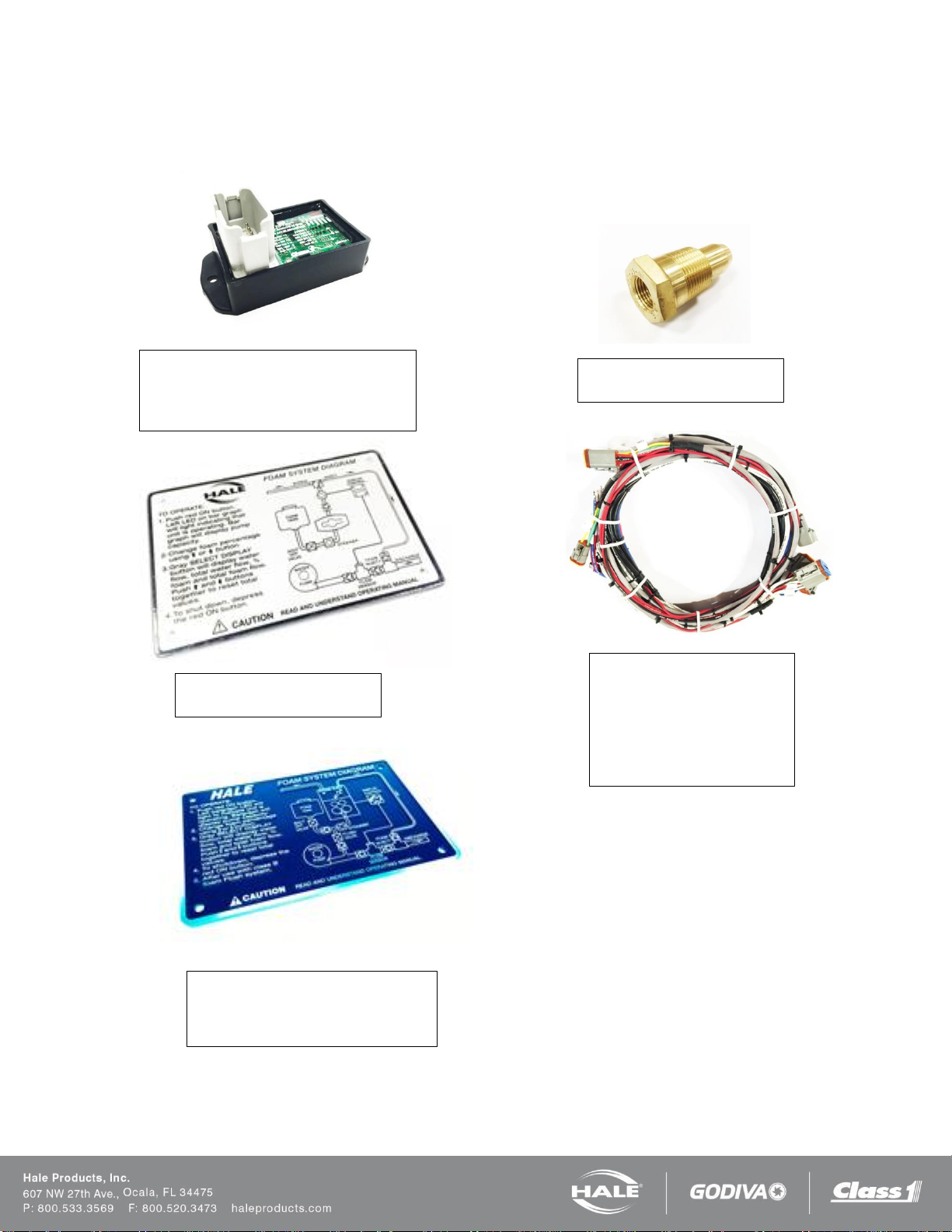

CONTROLLER AND BASE PUMP

Page 24

SmartFOAM

Check valve / Injector fitting

038-1790-00-0

SmartFOAM controller

harness

Single pump (10’x14’)

513-00101-200

Single pump (15’x19’)

513-00101-201

Dual pump

513-00074-200

Water Flow sensor input module

610-00033

(NOT REQUIRED WITH 610-00044)

1.7, 2.1 Foam system placard

101-1630-70-0

3.3, 5.0, 6.5 Foam system placard

Inline strainer - 101-1630-58-0

MST and FS strainer – 101-1631-12-0

MDTII and FS strainer – 101-1631-07-0

Page 23

Page 25

Page 24

SmartFOAM

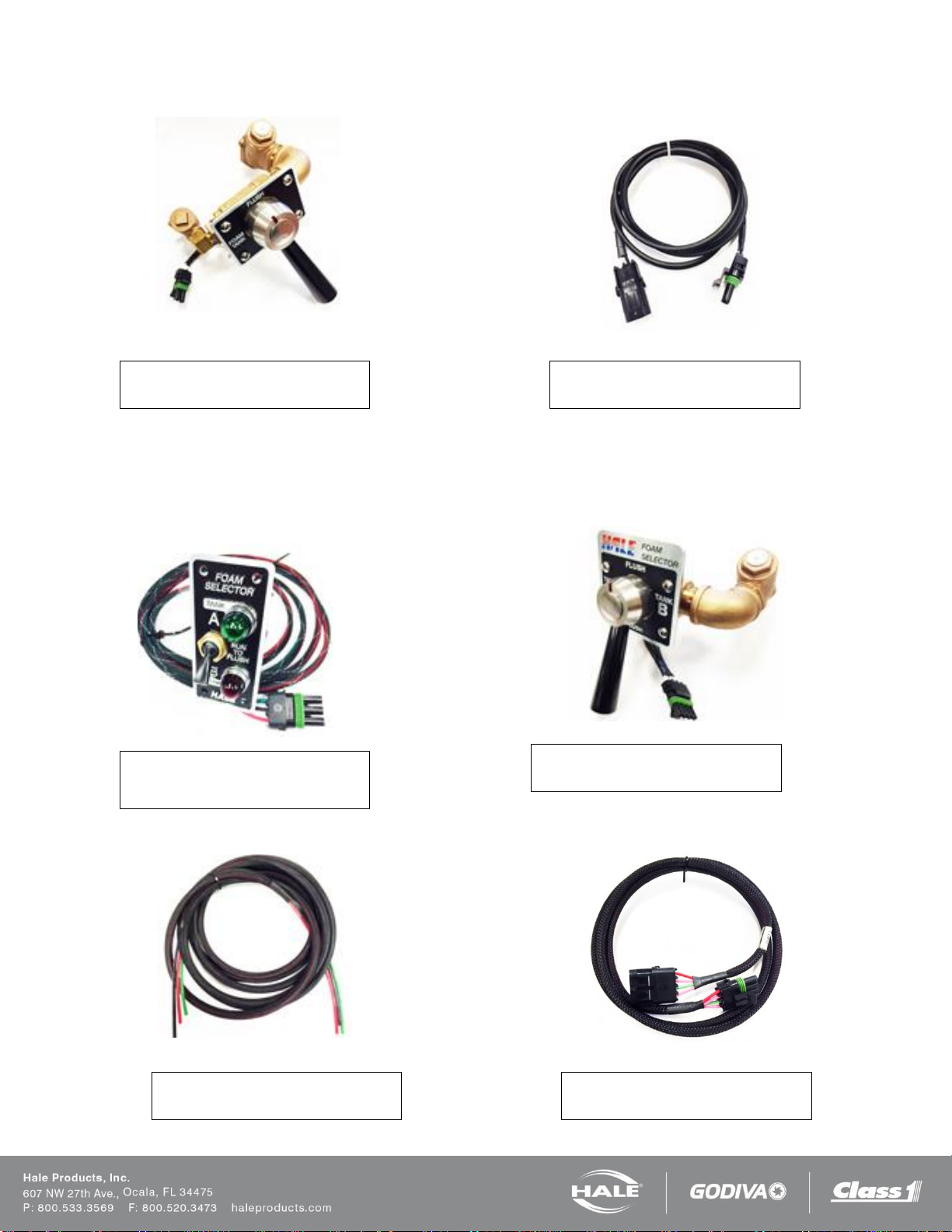

MDTII (Manual Dual Tank)

538-1490-14-0

ADT (Air Dual Tank)

12V – 538-1640-05-0

24V – 538-1640-06-0

MDTII harness extension (6 feet)

513-0320-02-0

ADT color-coded air tubing extension

507-0380-00-0

MST harness extension (6 feet)

513-0320-07-0

MST (Manual Single Tank)

538-1490-12-0

SINGLE CONCENTRATE TANK OPTIONS

DUAL CONCENTRATE TANK OPTIONS

Page 26

SmartFOAM

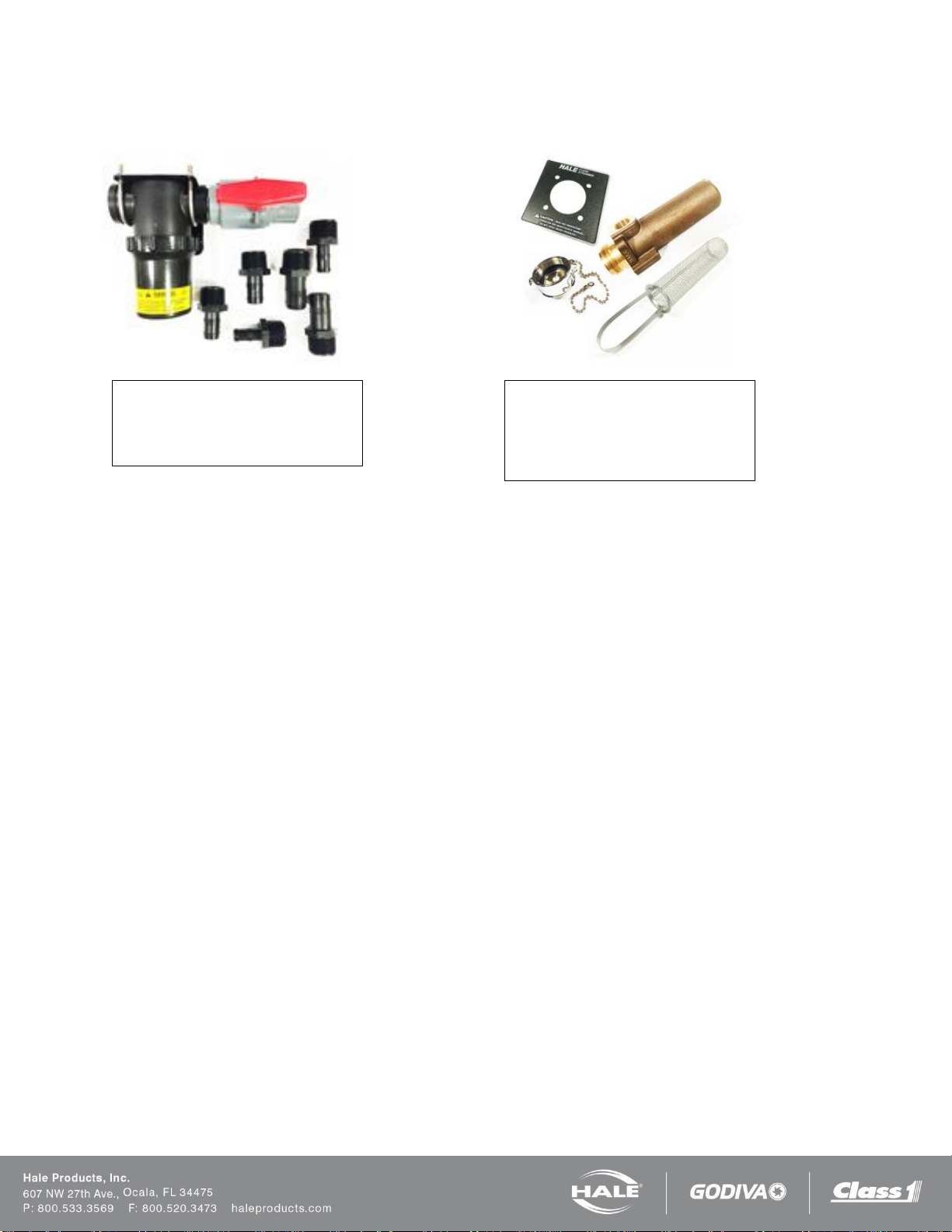

In-line strainer/valve assembly

510-0190-01-0

(Do not use if subject to flushing water

pressure)

FS panel mount strainers

FS-15 – 510-0150-00-0

¾” NPT threads

FS-25 – 510-0180-00-0

1” NPT threads

STRAINER OPTIONS

Page 25

Page 27

Page 26

SmartFOAM

Pipe Size vs. Flow Range

Pipe size

Flow Range

GPM

LPM

1.5”

10 – 350

38 – 1,219

2.0”

20 – 550

76 – 2,082

2.5”

30 – 800

114 – 3,028

3.0”

50 – 1,250

189 – 4,731

4.0”

75 – 1,800

284 – 6,813

3” Single Check

Valve (SCV)

30 - 750

114 – 2,839

3” Dual Check Valve

(DCV)

30 - 750

114 – 2,839

Side mount (1/2 inch NPT)

200-2110-02-0

½ inch NPT threaded bushing to

mount from outside foam tank.

Bottom mount (1 inch NPT)

200-2100-04-0

1 inch NPT threaded bushing to

mount from outside foam tank

Top mount

200-2110-06-0

Extends from 2.5 feet to 5 feet –

may be cut shorter if required.

Flow sensor weld fitting

Stainless steel – 082-3060-00-0

Steel – 309020

Aluminum - 309010

Flow sensor saddle clamp

2.0 inch – 4842010

2.5 inch – 4843010

3.0 inch – 4844010

Flow sensor paddlewheel

102714

LOW TANK SENSOR OPTIONS

FLOW SENSOR OPTIONS

Each Hale foam system requires a flow sensor for operation. Pipe size must be selected based on the minimum and

maximum water flow in the foam capable discharge. Following is a list of pipe size and rated flow ranges, along with flow

sensor saddle clamp part number. In all instances, a weld fitting may be substituted for the saddle clamp.

Table 4: Pipe Size versus Flow Range

Page 28

Page 27

SmartFOAM

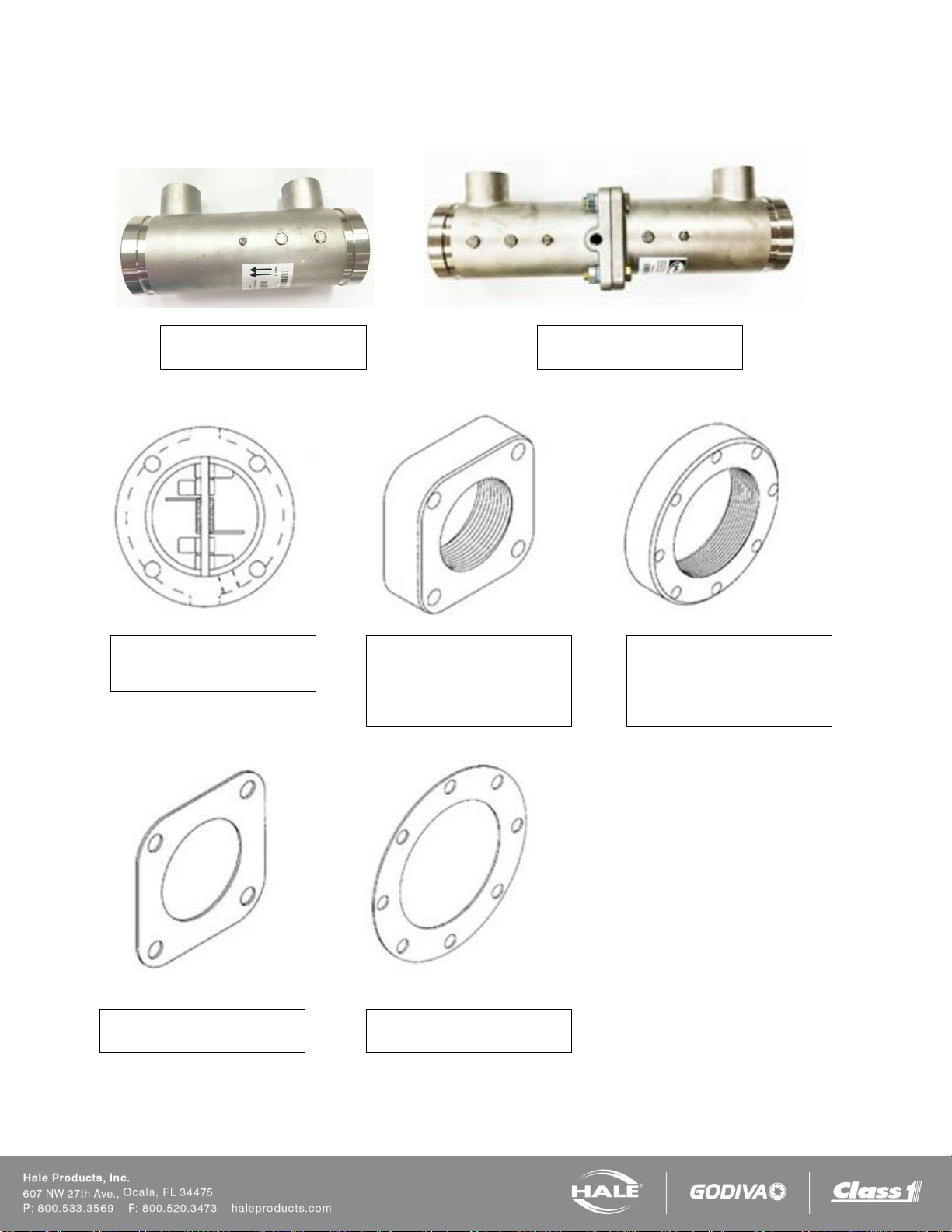

Single Check Valve (SCV)

3.0” 538-1850-00-0

Dual Check Valve (DCV)

3.0” 538-1840-00-0

Wafer Check Valve

3.0” 038-1570-06-0

4.0” 038-1570-08-0

Type 115 Flange

3.0” NPT 115-0080-00-0

2.5” NPT 115-0070-00-0

2.0” NPT 115-0060-00-0

BLANK 115-0050-00-0

Type 2433D Flange

4.0” NPT 115-0040-00-0

3.0” NPT 115-0030-00-0

2.5” NPT 115-0020-00-0

BLANK 115-0010-00-0

115 Flange Gasket

046-0050-00-0

2433D Flange Gasket

046-0040-00-0

CHECK VALVE MANIFOLDS, FLANGES AND GASKETS

The check valve manifolds include flow sensor, check valve/injector fitting and a single or dual waterway check valve

flappers. End connections for the manifolds are 3 inch Victaulic.

Page 29

Page 28

SmartFOAM

Close Fit Flanged Elbow

098-0140-00-0

115 flange inlet with 3” Victaulic

output

Close Fit Flanged Elbow

098-0190-00-0

2433D flange inlet with 3” NPT

female and 4” Victaulic output

Close Fit Flanged Elbow

098-0050-00-0

115 flange inlet with 2.5” NPT

female output

Close Fit Flanged Elbow

098-0020-00-0

115 flange inlet with 115 flange

output

Mini-Manifold

178-0320-02-0

ELBOWS AND MANIFOLDS

Page 30

Page 29

SmartFOAM

Switch with indicator

513-0330-01-0

Harness

513-0680-00-0

REMOTE START OPTION

Page 31

Page 30

SmartFOAM

IMPORTANT!

CAUTION!

INSTALLATION

The following guidelines are offered to assist the system

installer with a complete system installation.

Carefully review the procedures that follow to ensure the

system is properly designed. This section lists

components that have been tested with Hale SmartFOAM

and provide the best system performance. Use of the

recommended materials and specified parts ensures a

virtually maintenance free installation.

Differences in apparatus plumbing and foam system

configuration make it impractical to show exactly how the

Hale SmartFOAM systems are installed on a particular

apparatus.

The information contained in this section, however, applies

to most situations and should be used when designing

and installing Hale SmartFOAM systems. A system

plumbing and electrical diagram is provided at the end of

this section to assist with installation.

Before proceeding with system installation, carefully

review the procedures that follow to ensure the system is

properly designed.

The Hale SmartFOAM system is supplied with five major

components that must be located on the apparatus:

❑ Foam pump motor and assembly

❑ Control unit

❑ Instructions/system diagram placard

❑ Flow sensor

❑ Check valve injector fitting

Notes: The flow sensor and check valve injector fitting

may be pre-mounted, if a manifold or pre-configured

package is ordered.

Optional components that require mounting on the

apparatus include:

❑ Mini manifold

❑ Flanged elbows

❑ Manual Single Tank (MST) selector valve

❑ Manual Dual Tank (MDTII) selector valve

❑ Air Dual Tank (ADT) operating switches and

indicator lights

❑ Foam tank(s)

❑ FS Series panel mounted foam strainers

❑ Remote activation switch and indicator

WHEN DETERMINING THE LOCATIONS OF HALE

SMARTFOAM COMPONENTS BEING INSTALLED KEEP

IN MIND PIPING RUNS, CABLE ROUTING AND OTHER

INTERFERENCES THAT COULD HINDER OR

INTERFERE WITH PROPER SYSTEM PERFORMANCE.

FOAM PUMP AND MOTOR ASSEMBLY

The foam pump and motor assembly must be located in an

area that is protected from road debris and excessive heat

build-up. The back of a compartment or a compartment

shelf is often an ideal location. The foam system, bypass

valve, strainer and shut-off valve are located on the foam

pump and motor assembly and access to these components

must be provided.

The foam pump and motor assembly must be mounted

below the discharge of the foam tank to provide for gravity

feed to the foam pump. The foam tank must be located

where refilling can be easily accomplished with 5 gallon (19

liters) pails and other methods suitable to the end user. Most

water tank manufacturers build the foam tank into the

booster tank.

When specifying a foam tank, make sure provisions are

made for:

❑ Installation of the low tank level sensor

❑ Foam suction connections

❑ Tank drainage

❑ Proper fill openings, per NFPA requirements

In addition, a foam tank refill system may be required. See

Hale EZFill system for installation requirements.

FOAM CONCENTRATE STRAINER

Determine a location on the apparatus to mount the foam

strainer.

THE IN-LINE STRAINER/VALVE ASSEMBLY IS A LOW

PRESSURE DEVICE THAT WILL NOT WITHSTAND

FLUSHING WATER PRESSURE. WHEN INSTALLING

THE IN-LINE STRAINER IN SYSTEMS EQUIPPED WITH

HALE “MDT II” OR HALE “MST,” MAKE SURE THE INLINE STRAINER/VALVE ASSEMBLY IS IN THE HOSE ON

THE INLET SIDE OF THE VALVE.

IF THE STRAINER IS SUBJECT TO FLUSHING WATER

PRESSURE, USE HALE “FS” SERIES STRAINERS.

Mount the in-line foam strainer/valve assembly in the foam

concentrate hose from the foam tank to the foam pump

suction connection, ADT, MDT II or MST.

Page 32

SmartFOAM

IMPORTANT!

If panel mounted FS series strainers are installed, mount

the strainer in the foam concentrate hose that supplies

concentrate to the ADT, MDT II or MST. The FS series

strainer may also be mounted in the outlet hose of the

MDT II or MST.

WHEN DETERMINING THE STRAINER LOCATION

KEEP IN MIND THE REQUIREMENT FOR GRAVITY

FEED OF FOAM CONCENTRATE TO THE FOAM PUMP

THROUGH THE STRAINER AND AVOID AIR TRAPS IN

THE HOSES. ALSO, CLEARANCE MUST BE

PROVIDED TO ALLOW REMOVAL OF THE BOWL

ASSEMBLY TO CLEAN THE STAINLESS STEEL

MESH, TO MAKE HOSE CONNECTIONS TO THE

STRAINER AND FOR OPERATION OF THE SERVICE

VALVE.

The installer must provide a strainer service isolation valve

in the foam concentrate hose to prevent spillage during

service. An MST or MDT II can serve this purpose.

CONTROL UNIT AND INSTRUCTION /

SYSTEM DIAGRAM PLACARD

Determine a location on the operator panel of the

apparatus for the control unit and instruction/ system

diagram placard, if provided. These components must be

located at the main pump operator position in close

proximity to each other. Consideration must be given for

routing the control cable from the control unit to the motor

controller on the foam pump and motor assembly. If

necessary, order longer or shorter cable assemblies to suit

the location demands.

INSTALLER SUPPLIED COMPONENTS

Due to the many differences in apparatus configurations

and design requirements the Hale SmartFOAM system

installer must supply components such as:

❑ Mounting brackets

❑ Piping

❑ Hoses

❑ Fittings

❑ Electrical wiring

❑ Foam tank(s)

The following guidelines are recommendations for

selection of additional components for a complete system

installation. These recommendations reflect materials and

components that are tested extensively with Hale

SmartFOAM systems and provide proven reliable

performance.

Page 31

FOAM CONCENTRATE SUCTION HOSE

SmartFOAM 2.1A and 1.7 AHP Foam systems

These systems are provided with 15’ (4.6 meters) of 1/2”

(13mm) ID reinforced PVC foam concentrate suction hose.

The system installer may need to supply additional fittings

and hose from the foam tank to the inlet of the foam pump.

All components selected transfer foam concentrate;

therefore they must be compatible with the foam

concentrates being used in the system.

SmartFOAM 3.3, 5.0, and 6.5 Foam systems

Hoses for Class “A” foam concentrates have minimum 3/4”

(19mm) inside diameter. Hoses for Class “B” foam

concentrates must have a minimum 1” (25.4mm) inside

diameter due to higher viscosity of the concentrate.

Note: Certain types of Class “B” AFFF-ARC or ATC

concentrates require a 1-1/4” or 1-1/2” (32mm or 38mm) ID

foam concentrate supply line.

Hoses for the foam concentrate suction that are not subject

to high pressure, i.e. flushing water or foam concentrate

discharge, must have a rating of 23” (584.2mm) Hg vacuum

and 50 PSI (3.5 BAR) pressure or greater.

Note: NFPA requires that foam concentrate suction hose be

clear to observe foam concentrate flow during foam pump

operation.

Recommended components

Hose: PVC, Kuriyama Kuri-Tec K3130 or K7130 series.

Fittings: Hose Barb Type; Brass, Stainless Steel or Nylon.

Foam concentrate suction hose subjected to flushing water

pressure must be rated for 23 in (584.2mm) Hg vacuum and

the maximum discharge pressure of the fire pump (500 PSI

[34 BAR] minimum). These hoses include the hose from the

outlet of the MDT II or MST to the foam pump inlet.

Recommended components

Hose: Aeroquip 2580 series or Equivalent Reinforced

Hydraulic Hose.

Fittings: Brass or Stainless Steel Hose End Crimp or

Reusable Type (Aeroquip 412 series or

Equivalent).

A foam tank shut-off valve and drain valve should be

provided in the foam tank suction hose to allow strainer

service, tank drainage and easier priming.

These components are subject to the same material

characteristics and pressure ratings as stated above. When

the In-line strainer/valve assembly option is installed the

shut-off valve is included. A separate valve is not required.

Page 33

Page 32

SmartFOAM

FOAM CONCENTRATE DISCHARGE HOSE

The system installer must supply fittings and hoses from

the foam pump inject connection to the check

valve/injector fitting inlet. All components selected transfer

foam concentrate, therefore they must be compatible with

the foam concentrates being used in the system.

The foam pump discharge connection is a 1/2” (13 mm)

compression fitting. The check valve injector fitting

connection has 1/2” NPT threads. Hoses and fittings of

1/2” minimum diameter rated at 500 PSI (34.5 BAR)

working pressure or maximum discharge pressure of the

fire pump must be used. Fittings and hoses must be

compatible with all foam agents to be used.

Recommended components

Hose: Aeroquip 2580-8 or Equivalent Reinforced

Hydraulic Hose.

Fittings: Brass or Stainless Steel Hose End Crimp or

Reusable Type (Aeroquip 412-9-8 or

Equivalent).

Note: Although air brake tubing has been used for foam

concentrate discharge hose, it is not as flexible as the

hydraulic hose and readily kinks during installation.

Additionally, the air brake tubing may not meet NFPA 500

PSI (34 BAR) test requirements.

FOAM CONCENTRATE BYPASS HOSE

The foam concentrate bypass hose connection is a 1/2”

(13mm) hose barb connection. Hoses and fittings of

nominal 1/2” diameter must be used as bypass hose.

Since the bypass hose is used for calibration and draining

the system it does not see high operating pressures;

therefore, a hose with a lower pressure rating than the

inject hose may be used.

Fittings and hoses used must be compatible with all foam

agents expected to be used. Use fittings made of brass or

300 series stainless steel compatible with all foam

concentrates.

Recommended components

Hose: Low Pressure Hydraulic Hose or Air Brake

Tubing.

Fittings: Brass or Stainless Steel.

It is recommended that the foam concentrate bypass hose

be long enough to extend past the apparatus running

board to reach five (5) gallon (19 liter) containers, making

foam pump setup and calibration simpler.

CHECK VALVES

Check valves must be installed on the apparatus with foam

systems to prevent contamination of the foam concentrate

with water and contamination of the fresh water tank with

foam. When a Hale SmartFOAM foam Injection system and

related components are properly installed the required check

valves are integral parts of the system.

NFPA standards require a check valve in the foam

concentrate injection line at the injection point. The Hale part

number 038-1790-00-0 Integral Check Valve/ Injector Fitting,

a standard component included with the Hale SmartFOAM

system and installed when a manifold kit is ordered, meets

these requirements and threads directly into the foam

injection port on Hale manifolds.

Check valves must be installed in all water piping locations

where foam concentrate could drain back into pumps or

other components of the fire apparatus.

As a minimum one check valve must be installed where the

water piping that supplies foam solution connects to the fire

pump discharge. To more effectively keep foam

contamination out of the fire pump and water tank, double

check valves are recommended.

Separate two check valves by at least 6” to 8” (152 to

203mm) of piping to form a dead zone between the check

valves. Individual drain lines should be used on each check

valve. The waterway check valves must be rated for 500

PSIG (34.5 BAR) test pressure.

FLUSHING WATER HOSE

Flushing water connections for the Hale ADT, MDT II or

MST require using 1/2” (13mm) inside diameter tubing and

appropriate fittings. The tubing and fittings used must be

capable of withstanding the maximum fire pump discharge

pressure (500 PSI [34 BAR] minimum) and must be

compatible with foam concentrates being used in the

system.

When the ADT, MDT II or MST is installed, a check valve is

used integral to the flushing water line connection. This

provides protection against water system contamination with

foam concentrate.

Note: The installer/builder should provide an additional

check valve and shut-off valve where the flushing water

hose connects to the water pump.

Hale recommends the use of one of the above selector

options to provide foam system flushing capabilities.

However, if the Hale SmartFOAM system is ordered with the

“no tank” option the system installer must maintain NFPA

compliance.

Page 34

SmartFOAM

IMPORTANT!

Models 1.7 and 2.1

Maximum length

8 AWG (8.4mm2)

6 ft (1.8M) or less

4 AWG (21.2mm2)

6 ft (1.8M) to 15 ft (4.6M)

0 AWG (53.5mm2)

15 ft (4.8M) or Longer

Models 3.3, 5.0, 6.5

Maximum length

4 AWG (21.2mm2)

6 ft (1.8M) or less

0 AWG (53.5mm2)

6 ft (1.8M) to 15 ft (4.6M)

00 AWG (67.5mm2)

15 ft (4.8M) or Longer

To be NFPA compliant, when flushing is required, the

system installer must provide proper:

❑ Hoses

❑ Shut-off valves

❑ Check valves

❑ Reducer/regulator

❑ Connections for flushing water for the system

FOAM DISCHARGE DRAINS

Drains must be provided from foam capable discharge

piping components to prevent freezing in cold weather.

When designing the drain system care must be taken to

prevent contamination of the water system with foam and

the foam concentrate with water. Some multiple drain

systems that allow individual drain lines to communicate

also allow foam to bypass the installed check valves

causing contamination of fire pump and the water or foam

concentrate storage tanks.

Hale offers an optional manual or air-operated 6-port drain

valve, Class1 Model MMD6 (p/n: 104961). The valve

provides individual drains with a single control and is use

for applications where a single point for multiple drains is

required. If a Hale MMD6 drain valve is not used,

individual drain lines and valves for foam capable

discharge piping is recommended.

APPARATUS DESIGN/BUILD FOR COLD

WEATHER (BELOW FREEZING) DUTY

If the end-user will use the fire apparatus in sub- freezing

temperatures, the onus is on the fire truck builder to build

into the apparatus design an appropriate ambient

temperature operating environment for the envelope

where the SmartFOAM system will be located. This

routinely takes on the form and function of mounting the

SmartFOAM system in a limited ventilation area that is

served by an appropriate pump house auxiliary heater.

Simply, the fire truck builder must keep ambient air

temperature above 32°F (0°C) in the envelope around the

SmartFOAM hardware, including the base foam pump

unit, foam strainer, foam concentrate injection line, etc.

There are several best practices in the fire industry that

can be employed to meet this criteria and the fire truck

builder/designer can choose the best choice for their

specific installation. Note that there must be ventilation

available to cool the area around the unit also, to prevent

electric motor overheating when the unit is operating in

high temperature ambient environments.

ELECTRICAL REQUIREMENTS

The system installer must provide the primary power wire

and a ground strap for the Hale SmartFOAM system.

Primary power must be supplied from the main apparatus

battery to the motor controller box on the foam pump and

motor assembly. The Hale SmartFOAM 2.1A and 1.7AHP

Page 33

systems require a minimum of a 40 AMP electrical service.

The Hale SmartFOAM 3.3 and 5.0 systems require a

minimum of a 60 AMP electrical service. The Hale

SmartFOAM 6.5 system requires a minimum of a 80 AMP

electrical service

Primary electrical power must be supplied directly from the

battery, the battery master disconnect switch, or solenoids to

the Hale SmartFOAM system.

OTHER ELECTRICAL COMPONENTS MUST NOT BE

SUPPLIED FROM THIS WIRE. DO NOT CONNECT THE

PRIMER AND HALE SMARTFOAM TO THE SAME

POWER WIRE.

The primary power connection must be made so that power

is supplied to the Hale SmartFOAM when the main

apparatus electrical system is energized and the pump is in

gear. Use of a solenoid with a 150 AMP peak, 85 AMP

continuous rating is recommended. Figure 11:

Recommended Relay Wiring Schematic shows the

recommended wiring for this relay.

Note: This ensures immediate operation when the operator

places the apparatus in PUMP mode, and to prevent battery

power drain when the apparatus is not running.

Make certain that the recommended wire gage is selected

for the primary power connection based on the run length

(see Table 5: Recommended Primary Power Cable

Sizes). Use solder lugs on cable ends with a 5/16” (8mm)

diameter hole.

Table 5: Recommended Primary Power Cable Sizes

Page 35

Page 34

SmartFOAM

IMPORTANT!

Figure 11: Recommended Relay Wiring Schematic

When planning cable runs make sure the primary wires

are routed by the shortest most direct route.

A braided flat ground strap connected to the apparatus

chassis is recommended for the ground connection.

This limits the RFI/EMI interference encountered with

radios, computers or other sensitive electronic equipment.

The ground strap should be a minimum of 1-1/4” (32mm)

wide and no longer than 18” (457mm). It must have

soldered flat lug ends with 3/8” (10mm) diameter holes. If

the ground strap length exceeds 18” (457mm), a wider

ground strap should be used or use a double thickness of

1-1/4” (32mm) wide ground strap. The ground strap must

be connected to the chassis. Use minimum 5/16” (8 mm)

diameter bolt or mounting to secure the strap.

Power and ground must also be provided for the display

unit using the 2 pin Packard connector. The power must

be a minimum 5 amp dedicated and fused circuit. The

ground must be connected to the chassis ground stud and

protected from corrosion. Make sure the ground is

attached directly to the chassis frame and not to the

apparatus body work.

FOAM CONCENTRATE TANK

A foam concentrate tank must be supplied to suit the

capacity required for the apparatus application. The tank

must meet NFPA minimum standards for its design capacity,

including:

❑ Filler size

❑ Vapor pressure venting

❑ Baffling

❑ Drain facilities

FOAM PUMP MOUNTING

Position the foam pump and motor assembly in the desired

location on the apparatus. When installing the foam pump

and motor assembly, the assembly should be kept in a

HORIZONTAL position with the base plate on the bottom

(See Figure 12: SmartFOAM Piston Pump Installation).

BEFORE MAKING GROUND CONNECTIONS REMOVE

ALL PAINT, GREASE AND COATINGS FROM THE

CONNECTION AREA. AFTER MAKING CONNECTION,

SEAL AGAINST CORROSION. WHEN A FLAT GROUND

STRAP IS NOT AVAILABLE USE A BATTERY CABLE

ONE SIZE LARGER THAN THE POWER CABLE USED.

Figure 12: SmartFOAM Piston Pump Installation

Page 36

SmartFOAM

Figure 13: SmartFOAM Gear Pump Installation

Although the system is sealed and designed to be

resistant to the harsh environment of fire-fighting

apparatus, a compartment with easy operator access is

recommended.

The base plate of the foam pump and motor assembly

must be anchored to a surface or structure that is rigid and

of adequate strength to withstand the vibration and

stresses of apparatus operation.

The base of the foam pump and motor assembly includes

5/16” (8mm) diameter predrilled mounting holes. The

apparatus mounting location must to be drilled

accordingly. The base plate may be used as a template to

mark mounting hole locations.

Page 35

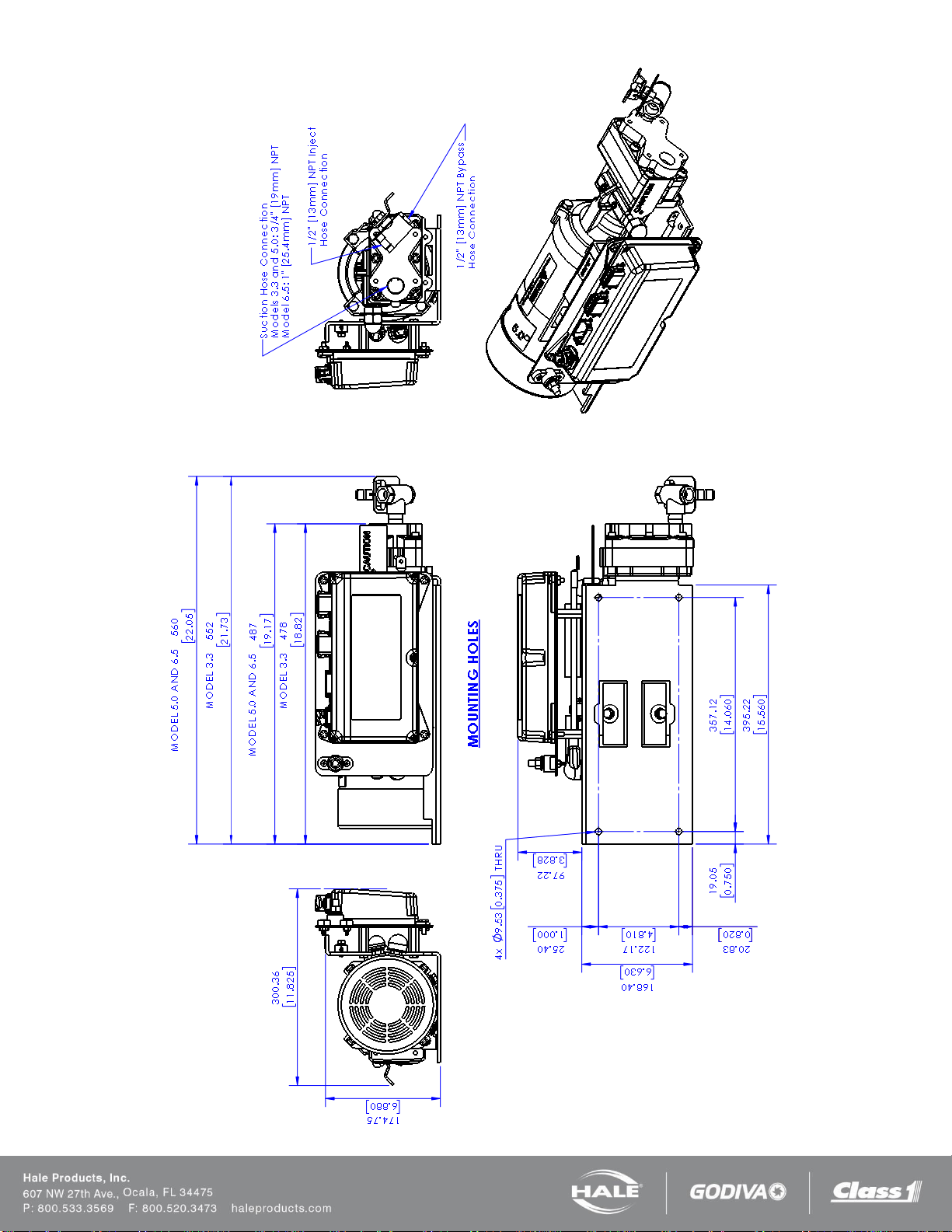

Figure 14: Base Plate Mounting Hole Locations – 1.7 and

2.1 provides the mounting base dimensions for the

SmartFOAM 1.7AHP and 2.1A foam pump and motor

assembly.

Figure 15: Base Plate Mounting Hole Locations – 3.3, 5.0,

and 6.5 provides the mounting base dimensions for the

SmartFOAM 3.3, 5.0, and 6.5 foam pump and motor

assembly.

Make sure the foam concentrate hoses are properly routed

to the inlet and outlet on the foam pump.

Foam concentrate must gravity feed to the foam pump inlet

from the foam tank(s). The foam pump must be mounted in

an area to avoid excessive engine exhaust system heat or

accessory heat build-up.

Page 37

Page 36

SmartFOAM

Figure 14: Base Plate Mounting Hole Locations – 1.7 and 2.1

Figure 15: Base Plate Mounting Hole Locations – 3.3, 5.0, and 6.5

Page 38

Page 37

SmartFOAM

IMPORTANT!

PLUMBING INSTALLATION

Hale SmartFOAM System plumbing diagram is located below. The diagram provides recommended guidelines for the

installation of system components that handle water, foam concentrate and foam solution. The sequence in which the

plumbing installation is completed depends on your individual installation requirements.

AFTER INSTALLATION, MAKE SURE ALL PIPES, HOSES AND TUBES ARE PROPERLY SUPPORTED USING THE

BEST INDUSTRY PRACTICES. USE A SUITABLE PIPE SEALING COMPOUND AT ALL JOINTS.

WATER AND FOAM SOLUTION PLUMBING

Use best industry practices when installing the water and foam solution piping runs. Use a suitable pipe sealing compound

at all joints.

CHECK VALVE MANIFOLD

Hale pre-made stainless steel foam manifolds are recommended. The manifolds are available in kits and eliminate the extra

labor and leaks from large pipe thread connections. The manifolds use 3” (76mm) Victaulic connections and are available in

single or dual check valve configurations. Figure 16: Check Valve Manifold Installation shows a typical check valve

manifold installation.

Figure 16: Check Valve Manifold Installation

Note: When the manifold is installed the drain tap that must be placed in the “down” position and plumbed to an individual

drain.

Page 39

Page 38

SmartFOAM

When properly mounted, the flow sensor and check

valve/injector fitting are on the side of the manifold and one

of the drain ports is on the bottom. The flow sensor should

point upwards slightly to allow drainage of water and

sediment. See Figure 19: Flow Sensor Tee Position

Range.

OPTIONAL HALE PIPING COMPONENTS

Hale piping components, such as 3” (76mm) and 4”

(102mm) wafer-type check valves, 115 and 2433 series

flanges, mini manifold, etc. are available to simplify

installation of water and foam solution discharge piping.

The arrangement shown in Figure 17: Typical Midship

Pump Installation provides accurate proportioning across

a wide range for up to four discharges from the mini

manifold.

The Hale mini manifold provides a 1” NPT tap for

installation of the check valve/injector fitting.

The Hale mini manifold and elbow components offer 4-3/8”

diameter bolt circles and minimize fabrication and pipe

work. After installation, make sure all pipes, hoses and

tubes are supported using the best industry practices.

Figure 18: Typical 4 Inch Check Valve Installation

(Midship Pump) shows a suggested installation

arrangement using Hale 4” (102mm) check valves, pipe

and Hale 2433 flanges.

Figure 17: Typical Midship Pump Installation

Page 40

Page 39

SmartFOAM

Figure 18: Typical 4 Inch Check Valve Installation (Midship Pump)

Page 41

Page 40

SmartFOAM

Pipe Size

Minimum Recommended

Straight Run Pipe

1-1/2 in (38.1 mm)

9 in (228.6 mm)

2 in (50.8 mm)

12 in (304.8 mm)

2-1/2 in (63.5 mm)

15 in (381 mm)

3 in (76.2 mm)

18 in (457.2 mm)

4 in (101.6 mm)

24 in (609.6 mm)

WATERWAY CHECK VALVES

Check valves in the waterway, rated at 500 PSI (34.5

BAR), are required to keep foam solution out of the main

pump and allow pump priming without drawing foam into

the piping.

Using double check valves, separated by at least 6” to 8”

(152 to 203mm) of pipe before the foam injection point,

ensures that the pump and tank water remain

uncontaminated.

FLOW SENSOR

The Hale SmartFOAM flow sensor is specially designed

to enable quick and easy sensor inspection and

maintenance. The flow sensor paddle wheel is installed

on a saddle clamp or weld fitting to the foam-capable

discharge piping of the apparatus.

In horizontal piping runs, the flow sensor is mounted

within the range shown in Figure 19: Flow Sensor Tee

Position Range.

Figure 19: Flow Sensor Tee Position Range

When selecting a flow sensor, it is important to consider

the minimum and maximum flow requirements during

operation. Refer to the Table 4: Pipe Size versus Flow

Range, for the proper pipe size for flow range desired.

The flow sensor is installed in the piping before the foam

concentrate injection point.

This is true in applications where the foam system needs

to supply a 3” (76mm) deck gun, as well as a 1”

(25.4mm) booster line.

Table 6: Pipe Size versus Minimum Straight Run

Pipe size for flow sensor mounting must be selected to

provide accuracy at the lowest flow rate. Mounting the

flow sensor in a short section of pipe, one pipe size

smaller (e.g., 4” to 3”; 3” to 2-1/2”, etc.), provides better

accuracy at the lower flows.

Refer to the Table 13: “Pipe Size vs. Minimum Straight

Run” for pipe size. Selecting the next smaller pipe

permits reducing the straight pipe run the required

distance prior to the flow sensor paddle wheel.

In the short length of reduced pipe pressure loss is

minimal and there is minimal pressure loss through

elbows and fittings. See Figure 20: Typical Reduced

Size Sensor Piping Arrangement.

Excessive turbulence in the flow sensor may produce

unstable and inaccurate flow readings. The length of

straight pipe prior to the flow sensor must be sufficient to

reduce any turbulence in the pipe.

The following guidelines help attain the best readings,

and maintain Hale SmartFOAM system accuracy.

1. A minimum of 6 times the pipe diameter of

straight run pipe without any fittings is necessary

prior to the flow sensor paddle wheel. (See

Figure 21: Flow Sensor Placement).

2. The downstream piping length is not as critical,

but there must be a short length of straight pipe

with no fittings or valves immediately after the

flow sensor paddlewheel. Two to three times the

pipe diameter is recommended.

3. Do not mount a flow sensor directly after an

elbow or valve. Valves create severe turbulence

when they are “Gated”.

Page 42

Page 41

SmartFOAM

Figure 20: Typical Reduced Size Sensor Piping Arrangement

Figure 21: Flow Sensor Placement

SADDLE CLAMP INSALLATION

See Figure 22: Flow Sensor/Saddle Clamp

Installation.

Installation of the paddlewheel flow sensor using a

saddle clamp requires a 1.385/1.390 inch (35/35.3 mm)

bored hole in the pipe.

A minimum of six times the pipe diameter of straight run

pipe without any fittings is necessary prior to the position

of this hole.

Figure 22: Flow Sensor/Saddle Clamp Installation

The flow sensor requires a spacer and eight stainless

steel internal hex head screws. These are supplied with

the sensor.

Four 6-32 x1/2 inch screws attach the spacer to the

saddle clamp mount and four 6-32 x 3/4 inch screws with

lock washers attach the paddlewheel to the spacer.

Page 43

Page 42

SmartFOAM

CAUTION!

CAUTION!

CAUTION!

Align the indexing pin of the saddle clamp to the

indexing hole of the spacer to align the saddle clamp

mount.

Secure with four 1/2” machine screws, no lock washers.

Torque to 8.5 in.-lbs. (1.0 N-m).

Align the paddle wheel indexing pin to the indexing hole

in the spacer and secure using four 3/4” screws and lock

washers. Torque to 7.5 in.-lbs. (0.9 N-m).

Apply a small amount of grease to the saddle clamp

gasket before the final installation of the assembly onto

the pipe. Firmly tighten the saddle clamp onto the pipe.

FOAM PUMP FLUSH SYSTEM

Dual Tank System

Flushing water must be provided to flush the system of

foam concentrate after each use. This prevents adverse

reactions of some foam concentrates should they mix

together. The Hale ADT and MDT II each have

provisions for connecting flushing water to the foam

concentrate injection system.

Single Tank System

The Hale MST provides a selector valve and gives the

system flush capabilities for NFPA compliance. A fitting

provided on the Hale MST simplifies the flushing water

connection.

No Tank Option

The system installer must provide a flushing water

supply to comply with NFPA standards.

The flushing water hose must be a minimum of 1/2” (12

mm) inside diameter and capable of withstanding the

maximum fire pump discharge pressure, 500 PSI (34

BAR) minimum. The flush water supply should be

provided from one of the pressure taps on the discharge

of the fire pump.

It is recommended that a check valve be installed at the

pressure tap to prevent contamination. Flush water

thread connections are:

❑ ADT - 1/2” (13mm) NPT

❑ MDT II and MST - 1/4” (6.4mm) NPT

The system installer must provide proper fittings for

these connections.

FOAM CONCENRATE PLUMBING

MAKE SURE THE FOAM TANK AND FOAM

CONCENRATE SUCTION HOSES ARE CLEAN

BEFORE MAKING A FINAL CONNECTION TO FOAM

PUMP. FLUSH TANK(S) AND HOSES PRIOR TO

MAKING CONNECTIONS. MAKE SURE THE FOAM

CONCENRATE IS GRAVITY FED FROM THE TANK

TO THE PUMP.

Foam concentrate plumbing consists of:

❑ Foam concentrate suction hose

❑ Foam strainer

❑ Foam concentrate discharge hose

❑ Check valve/injector fitting

FOAM STRAINER CONNECTION

THE FOAM CONCENTRATE STRAINER ASSEMBLY,

MOUNTED ON THE FOAM PUMP INLET, IS A LOW

PRESSURE DEVICE. IT WILL NOT WITHSTAND

FLUSHING WATER PRESSURE. IF FLUSHING

WATER IS TO BE PROVIDED THE PRESSURE MUST

BE LIMITED TO 50 PSI (3.5 BAR).

The strainer/valve assembly has 1/2” (12mm) NPT

female threaded ports. A 1/2” hose barb fitting is

supplied to connect the 1/2” ID hose, provided with the

Hale SmartFOAM 2.1A installation kit.

The hose from the foam tank to the strainer must have

adequate wall stiffness to withstand the vacuum of the

foam pump while it is operating (23” [584 mm] Hg and

50 PSI [3 BAR], Kuriyama, Kuri-tec K-3130 or K-7130

series or equal).

After the foam pump is mounted on the apparatus,