Page 1

MUSCLE (Midship) Pumps

(“Q” Series)

Installation, Operation and

Maintenance Manual

Part 1

Hale Products Inc. u A Unit of IDEX Corporation

700 Spring Mill Avenue

Telephone: 610-825-6300

Web..........www.haleproducts.com

u Conshohocken, PA 19428 U.S.A.

u FAX: 610-825-6440

Manual p/n: 029-0020-63-0

Page 2

NOTICE !

Hale Products, Inc. (Hale) cannot assume responsibility for product f ailure resulting from improper maintenance or operation. Hale is responsibl e only to the limits

stated in the product warranty. Product specifications contained in this manual are

subject to change without notice.

All Hale products are quality components -- ruggedly designed, accurately

machined, precision inspected, carefully assembled and thoroughly tested. In

order to maintain the high quality of your unit, and to keep it in a re ady condition, it

is important to follow the instructions on ca re and operation. Proper use and go od

preventive maintenance will lengthen the life of your unit.

ALWAYS INCLUDE THE UNIT SERIAL NUMBER

IN YOUR CORRESPONDENCE.

ECO NO REV CHANGE FROM BY DATE APVD

0956 C Series Upgrade LwH 01/20/2006 MAL

Manual p/n: 029-0020-63-0, Rev. -C

Printed in U.S.A.

HALE PRODUCTS, INC.

A Unit of IDEX Corporation

Conshohocken, PA 19428 USA

DRAWN BY LwH ISSUE DATE

CHECKED BY PRW 01/20/2006

© Hale Products, Inc. 2009

NOT TO BE REPRODUCED OR USED TO

MAKE OTHER DRAWINGS OR MACHINERY.

COPYRIGHT ©

All Rights Reserved

Page 3

Table of Contents

Contents Page

MUSCLE Pump (Midship) Operation and Maintenance

1 Safety Precautions................................................................................................. 13

1.1 Definitions.........................................................................................................................13

1.2 Guidelines.........................................................................................................................14

2 Introduction...........................................................................................................19

2.1 Description........................................................................................................................19

2.2 Principle of Operation......................................................................................................19

Centrifugal Force ............. .... ... ............................................................. ... .... ... ... ................................19

Figure 2-1: Centrifugal Force - Rotating Disk.....................................................................19

Pump Stages ....................................................................................................................................20

Single-Stage...............................................................................................................................20

Figure 2-2: Water Flow, Typical Hale Single-Stage Pump .................................................20

Figure 2-3: Single-Stage Pump Overview..........................................................................21

Two-Stage..................................................................................................................................22

Volume (Parallel) Operation.......................................................................................................22

Figure 2-4: Two-Stage Pump VOLUME Operation.............................................................22

Figure 2-5: Two-Stage Pump Overview..............................................................................23

Pressure (Series) Operation ......................................................................................................24

Figure 2-6: Two-Stage Pump PRESSURE Operation........................................................24

Volume vs. Pressure Operation .................................................................................................24

Transfer Valve............................................ ... ... ... .... ...................................................................25

Choosing Volume or Pressure Operation ..................................................................................25

General Guidelines ....................................................................................................................25

2.3 Muscle Pump Components .............................................................................................26

Pump Body .......................................................................................................................................26

Qmax, Qmid, and Qtwo Pumps .................................................................................................26

Figure 2-7: Typical Midship Two-Stage Centrifugal Pump .................................................27

Qpak, Qflo and Qflo-Plus Pumps...............................................................................................27

Impeller.............................................................................................................................................27

Figure 2-8: Impeller Operation............................................................................................28

Clearance Rings ...............................................................................................................................28

2.4 Pump Seals.......................................................................................................... .............28

Packing Seals................................................................... ... ... .... ... ...................................................29

Figure 2-9: Pump Packing Seal Assembly ......................................................... ... .... ... ... ...29

Mechanical Seal .................................................. ............................................................. ................30

Figure 2-10: Mechanical Seal Assembly ............................................................................30

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

3

Page 4

Table of Contents

Auto Lube ®......................................... ... ... ... .............................................................. ... . ..................31

Figure 2-11: AutoLube Feature....... ... .............................................................. ... ... ... .......... 31

2.5 Pump Drives ..................................................................................................................... 31

Table 2-1: Pump vs. Gearbox / Gear Ratio Comparison....................................................32

2.6 Gearbox ............................................................................................................................ 32

Figure 2-12: Typical Gearbox Overview .......................................................................... ...33

A-Series............................................................................................................................................33

G-Series............................................................................................................................................34

K-Series............................................................................................................................................34

J-Series.............................................................................................................................................34

R-Series............................................................................................................................................34

Power Shift - Optional.......................................................................................................................34

Engine Rotation Option - Qmax-U and Qtwo-U................................................................................34

Figure 2-13: Pump/Engine Rotation ...................................................................................35

HALE Power Takeoff (PTO) Driven Midship Pumps.........................................................................35

2.7 Serial Number Identification ...........................................................................................35

Figure 2-14: Typical Midship Pump Serial Number Location..............................................36

3 Accessories / Options.............................................................................................37

3.1 Anodes.............................................................................................................................. 37

Figure 3-1: Hale 1-1/4” NPT Anode....................................................................................37

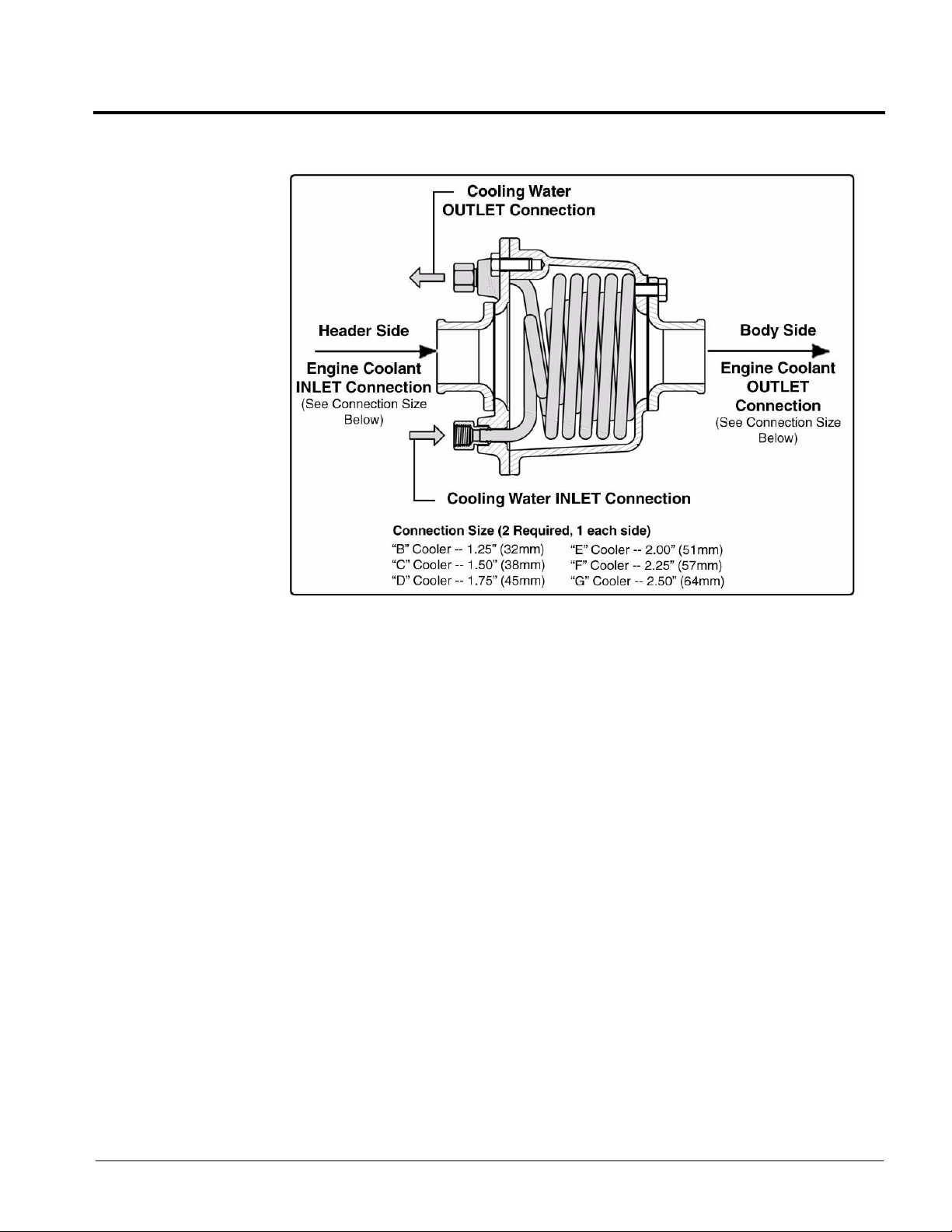

3.2 Auxiliary Cooling.............................................................................................................. 38

Heat Exchanger, “K” Series ..............................................................................................................38

Figure 3-2: Model “K” Heat Exchanger...............................................................................38

3.3 Pressure and Relief Valve Control .................................................................................39

Relief Valve System..........................................................................................................................39

Figure 3-3: PMD Series Relief Valve Control (Shown).......................................................39

Thermal Relief Valves (TRV) ............................................................................................................39

Figure 3-4: Thermal Relief Valve, TRV...............................................................................40

TRV-L Kit................ ... .............................................................. ... ... ... ..........................................40

3.4 Priming Systems......................................................................................... ........... ..........41

Figure 3-5: Rotary Vane ESP Priming Pump......................................................................41

Priming Valves........................... ... ... .... ... ............................................................. ... .... ... ...................41

Figure 3-6: SPVR Priming Valve (Shown)..........................................................................42

Figure 3-7: PVG Priming Valves.........................................................................................42

3.5 Pump Shift, Automatic (VPS / KPS)................................................................................ 42

Figure 3-8: Automatic Pump Shift Overview.......................................................................43

Figure 3-9: Pump Shift Control Valve.................................................................................43

3.6 Torrent SVS Valves.......................................................................................................... 44

Figure 3-10: Typical SVS Valve Primary Components......................................................44

3.7 Additional Midship Accessories.....................................................................................44

Auxiliary Heat Exchanger / Cooler, Model K.....................................................................................44

Figure 3-11: Model “K” Heat Exchanger.............................................................................45

4

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 5

Table of Contents

Booster Pump Option, 2HP.............................................................................................................. 45

Figure 3-12: 2HP Booster Pump Option ............................... .... ......................................... 4 5

In-Line / Discharge Valves ...............................................................................................................45

Drain Valves..................................................................................................................................... 46

Suction Valves........... .............................................................. ... ... ... ................................................ 46

Figure 3-13: Master Intake Valve (MIV)............................................................................. 47

Tank Suction Valves......................................................................................................................... 47

Total Pressure Master (TPM) Relief Valve System................. ... ...................................................... 47

Figure 3-14: Hale (TPM) Total Pressure Master Relief Valve S yste m............................... 48

How the TPM Works............................................ ... ... ... .... ......................................................... 48

Figure 3-15: Typical TPM Relief Valve System, Condition 1 ....................... ...................... 50

Figure 3-16: Typical TPM Relief Valve System, Condition 2 ....................... ...................... 51

Figure 3-17: Typical TPM Relief Valve System, Condition 3 ....................... ...................... 52

4 Basic Operation .....................................................................................................53

4.1 Overview ...........................................................................................................................53

4.2 Fluid Levels ......................................................................................................................54

4.3 Stationary Pumping Operations .....................................................................................54

Pumping From a Hydrant, General Operation.................................................................................. 54

Figure 4-1: Driver’s Compartment Indicator Lights ............................................................55

Figure 4-2: Pump Operator’s Panel ................................... ................................................ 56

TPM Operation from a Hydrant ........................................................................ .... ... ... ...................... 57

Draft Limiting Factors ....................................................................................................................... 57

Pumping From Draft......................................................................................................................... 58

Pumping from On Board Water Tank (Split-Shaft PTO)................................................................... 60

4.4 Pumping In Relay.............................................................................................................62

Relay Procedures............................................................................................................................. 62

4.5 Tandem (Series) Pumping...............................................................................................64

Tandem Procedures......................................................................................................................... 64

4.6 Pump-To-Road Shift Procedures....................................................................................65

4.7 Pump and Roll............................................................................................................ ......65

4.8 Relief Valve Procedures ..................................................................................................66

Standard Relief Valve Procedures ................................................................................................... 66

TPM Relief Valve Procedures .......................................................................................................... 66

Figure 4-3: TPM / PMD Relief Valve Control ..................................................................... 67

TPM System with Engine Governor.................................................................................................67

Increasing Pressure................................................................................................................... 68

Decreasing Pressure ................................................................................................................. 68

4.9 Emergency Pump Shift Procedures...............................................................................69

4.10 Post Operation Procedures.............................................................................................69

5 Preventive Maintenance........................................................................................71

5.1 Overview ...........................................................................................................................71

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

5

Page 6

Table of Contents

5.2 Post Operation ................................................................................................................. 71

5.3 Extreme Conditions ......................................................................................................... 71

During Freezing Weather.............................................. .... ... ... ... .......................................................71

Pumping Salt Water, Contaminated Water, or Foam Solution...................................................72

5.4 Weekly...............................................................................................................................72

Relief Valve and TPM Test...............................................................................................................73

Governor Test...................................................................................................................................73

Transfer Valve Test (Two-Stage Pumps Only).................................................................................73

Priming System Test......................................................... ... ... ... .......................................................74

Pump Shift Warning Lights ...............................................................................................................74

Valve Maintenance ....... ... ... .... ............................................................. ... ... .... ... ................................74

Intake Strainers.................................................................................................................................75

Verify All Gauges are in Working Order............................................................................................75

Operate Pump Controls ....................................................................................................................75

Inspect Water and Foam Tanks........................................................................................................75

Check Auxiliary Engine.....................................................................................................................75

5.5 Monthly ............................................................................................................................. 75

Valve Lubrication .......... ... ... .... ............................................................. ... ... .... ... ................................76

Suction Check Valve Testing, Two-Stage Pumps............................................................................76

Gearbox Lubrication .........................................................................................................................76

Packing Gland Adjustment ..................................... ............................................................. ... ..........77

Adjustment .................................................................................................................................77

Pump, Drive Line and Flange Bolts ..................................................................................................77

Priming System Test (Dry Vacuum Test)..........................................................................................78

Figure 5-1: Priming Valve Handle.......................................................................................78

5.6 Annual............................................................................................................................... 79

Replace Gearbox Oil ........................................................................................................................80

Relief Valve System Check ..............................................................................................................80

Check Drain Lines to Multi-Drain......................................................................................................81

Clean Priming Pump.........................................................................................................................81

MIV Relief Valve Test and Adjustment.............................................................................................81

Performance Testing Overview ....................... .... ... ... ... .... ........................................................... .....82

Table 5-1: Pump Ratings (GPM / LPM)..............................................................................82

Tank-to-Pump Flow Rate Test ...................................................................................................82

Performance Testing Equipment and Mater ials............................. ... ... .............................................83

Performance Testing ................................. ... ... .... ... ... .......................................................................84

Thermal Relief Valve Test ...............................................................................................................85

Table 5-2: Maximum Pump Run Time................................................................................85

Repacking the Seal...........................................................................................................................85

Figure 5-2: Pump Packing Seal Assembly ............................................... .... ... ... ... ... .......... 86

Worn Clearance Rings and Impeller Hubs.... ... .... ... ... ............................................................. .... ... ...86

Anode Check ............. ... ... ... .............................................................. ... ... ... .... ...................................87

Figure 5-3: Hale 1-1/4” NPT Anode....................................................................................87

Figure 5-4: Muscle Pump Service Chart, Part 1 of 3..........................................................88

6

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 7

Table of Contents

Figure 5-5: Muscle Pump Service Chart, Part 2 of 3.......................................................... 89

Figure 5-6: Muscle Pump Service Chart, Part 3 of 3.......................................................... 90

Midship Pump Maintenance Check List.............................................................91

Recommended “Weekly” Procedures......................................................................................91

Recommended “Annual” Procedures......................................................................................92

6 Troubleshooting.....................................................................................................93

Table 6-1: Muscle (Midship) Pump Troubleshooting........................................................ 93

PTO Will Not Engage. ...................................................................................................... 93

Pump Will Not Engage.....................................................................................................93

Pump Loses Prime or Will Not Prime............................................................................... 94

Insufficient Pump Capacity, Single Stage. ....................................................................... 96

Leak at Pump Packing. .................................................................................................... 97

Remote Control Difficult to Operate. ................................................................................ 97

Engine Speeds Too HIGH for Required Capacity or Pressure. ....................................... 98

Cavitation .........................................................................................................................99

Relief Valve Does Not Relieve Pressure When Relief Valves are Closed.......................99

Relief Valve Does Not Recover and Return to Original Pressure Setting After Opening

Valves............................................................................................................................... 99

Relief Valve Opens When Control Valves are Locked Out..............................................99

Unable to Obtain Proper Setting on Relief Valves. ................................. ... ... .................100

Discharge Valves Are Difficult to Operate.................................. ... ................................. 100

Water/Moisture in Pump Gearbox.................................................................................. 101

Rotation Symptoms........................................................................................................ 101

7 Repair and Corrective Maintenance .................................................................103

7.1 Overview .........................................................................................................................103

7.2 General Repair Guidelines ............................................................................................103

Before You Begin... ........................................................................................................................ 103

Table 7-1: Typical Torque Values Chart ............................... .... ... ... ... .............................. 105

Remove the Gearbox Assembly..................................................................................................... 105

7.3 Cleaning and Inspection Guidelines ............................................................................ 106

Bearings......................................................................................................................................... 106

Tools Required...............................................................................................................................107

7.4 Removing the Pump Assembly ....................................................................................108

Figure 7-1: Typical Muscle (Midship) Pump Overview.....................................................108

Figure 7-2: Lifting Eyebolt Attachment Layout................................................................. 109

Installing the Assembly to the Apparatus .......................................................................................110

7.5 Removing the Gearbox..................................................................................................110

G Series Gearbox...... ... .... ... ............................................................. ... .... ... ... ................................. 110

Figure 7-3: Typical G Series Gearbox Removal .............................................................. 111

Removal - G Series .................................................................................................................111

Installation - G Series ............................................................. ................................................. 112

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

7

Page 8

Table of Contents

J Series Gearbox............................................................................................................................112

Removal - J Series...................................................................................................................112

Figure 7-4: Typical J Series Gearbox Removal................................................................113

Installation - J Series................................. .... ... ... ............................................................. ........113

K Series Gearbox ...........................................................................................................................114

Removal - K Series ..................................................................................................................114

Installation - K Series .................... ... ... ............................................................. .... ... ... ... ...........115

7.6 QMID/QMAX/QTWO AutoLube ® Service .................................................................... 115

Figure 7-5: AutoLube Assembly Overview.......................................................................116

7.7 Impeller Assembly ......................................................................................................... 118

QMID/QMAX/QTWO Removing Impeller and Clearance Rings.....................................................118

Figure 7-6: Qmax / Qtwo Assembly Overview..................................................................119

Disassembly - QMAX/QMID Single-Stage Pump...........................................................................120

Assembly - QMAX/QMID Single-Stage Pump................................................................................121

Disassembly - QTWO Two-Stage Pump........................................................................................122

Assembly - QTWO Two-Stage Pump .............................................................................................123

Inspection – Clearance Rings.........................................................................................................124

Figure 7-7: Clearance Ring and Impeller ID / OD Measurement......................................124

Installing the Impeller and Clearance Rings ...................................................................................125

8 Packing and Mechanical Seal Maintenance......................................................127

8.1 Packing Seal Replacement............................................................................................ 127

Figure 8-1: Pump Packing Seal Overview............................................. ... .... ... .................127

Figure 8-2: Packing / Mechanical Seal Assembly Overview.............................................128

8.2 Mechanical Seal Replacement...................................................................................... 129

Qmax and Qtwo Pumps with G Series Gearbox.............................................................................129

Figure 8-3: Qmax, Qmid, and Qtwo Mechanical Seal Assembly Overview......................130

Removing the Seal...................................................................................................................130

Figure 8-4: Mechanical Seal Overview / Replacement.....................................................131

Installing the Seal.....................................................................................................................132

Qmax and Qtwo Pumps with K Series Gearbox.............................................................................134

Removing the Seal...................................................................................................................134

Figure 8-5: QmaxK and QtwoK Mechanical Seal Assembly Overview.............................135

Figure 8-6: Mechanical Seal Overview / Replacement.....................................................135

Installing the Seal.....................................................................................................................136

Impeller Assembly and Mechanical Seal Qflo, Qflo-Plus and Qpak Pump.....................................138

Removing the Mechanical Seal................................................................................................138

Figure 8-7: Qflo / Qflo-Plus / Qpak Mechanical Seal Assembly Overview .......................139

Figure 8-8: Mechanical Seal Overview / Replacement.....................................................140

Installing the Seal ...........................................................................................................................140

K-Gearbox Mechanical Seal............................ .... ... ............................................................. ... ........142

Figure 8-9: Housing on shaft ............................................................................................143

Figure 8-10: Retaining ring .......................... ... .... ............................................................. .143

Figure 8-11: Seal seat into cover........................................ ... ... ........................................144

8

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 9

Table of Contents

Figure 8-12: Pump shaft gear and top space installed..................................................... 145

Figure 8-13: Install bearing lock nut................................................................................. 146

9 Gearbox Maintenance.........................................................................................149

9.1 G Series Gearbox Maintenance ....................................................................................149

Disassembly................................................................................................................................... 149

Intermediate and Sliding Gear Shaft Assemblie s ................................................................... . 149

Figure 9-1: Intermediate Shaft and Sliding Gear, Typical G Series Gearbox .................. 149

Tail Shaft Assembly................................................................................................................. 150

Figure 9-2: Tail Shaft Assembly .......................................................................................150

Power Gearshift Assembly ...................................................................................................... 151

Figure 9-3: Power Gearshift Assembly ............................................................................152

Sliding Gear and Fork..............................................................................................................152

PTO Drive Option, Qflo / Qflo Plus / Qpak Series Pump......................................................... 153

Figure 9-4: PTO Drive Option ..........................................................................................154

Assembly........................................................................................................................................ 154

Gearshift Cap........................................................................................................................... 154

Sliding Gear Assembly ............................................................................................................ 154

Tail Shaft and Gear Shift Assemblies...................................................................................... 155

PTO Drive Option .................................................................................................................... 156

Intermediate Shaft Assembly...................................................................................................156

9.2 J Series Gearbox Maintenance .....................................................................................157

Disassembly................................................................................................................................... 157

Idler Shaft Disassembly.......... ... ... ............................................................. .... ... ... ... .................157

Figure 9-5: Typical J Series Gearbox Assembly.............................................................. 158

Input Shaft Disassembly..........................................................................................................159

Assembly and Installation...............................................................................................................159

Input Shaft Assembly...............................................................................................................159

Idler Shaft Assembly............................................ ... ... .............................................................. 160

9.3 K Series Gearbox Maintenance ....................................................................................161

Oil seals (Input/Tail Shafts) .............. ... ... ... .... ............................................................. ... ... .... ..........161

Figure 9-6: Oil Seal Replacement.................................................................................... 161

Tail Shaft Assembly.......... ... ... ... .............................................................. ... ... ... .... .......................... 162

Figure 9-7: Tail Shaft Assembly .......................................................................................162

Removal And Disassembly............................................................................................... ... ... . 162

Inspection ................................................................................................................................163

Reassembly and Installation....................................................................................................163

Figure 9-8: Shaft End Gap ............................................................................................... 164

Input Shaft.............. ............................................................. .... ... ... ... .............................................. 165

Figure 9-9: Input Shaft Assembly..................................................................................... 165

Removal and Disassembly ..................... ... ............................................................. ... .... ... ... ....165

Inspection ................................................................................................................................166

Reassembly and Installation....................................................................................................166

KPS Power Shift Assembly............................................................................................................ 167

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

9

Page 10

Table of Contents

Figure 9-10: KPS Shift Cylinder Assembly.......................................................................167

Removal...................................................................................................................................167

Installation................................................................................................................................168

KPS Shift CAP and Switch .............................................................................................................169

Figure 9-11: KPS Shift Cap Assembly..............................................................................169

Removal...................................................................................................................................169

Installation................................................................................................................................169

Gear Shift Fork ...............................................................................................................................170

Removal...................................................................................................................................170

Installation................................................................................................................................170

Idler Shaft......................................... ... ............................................................. .... ... ... . .............171

Figure 9-12: Idler Shaft Assembly....................................................................................171

Removal...................................................................................................................................171

Inspection.................................................................................................................................172

Installation................................................................................................................................172

10 Installation............................................................................................................173

10.1 Overview......................................................................................................................... 173

10.2 Mounting.........................................................................................................................173

Mounting Holes...............................................................................................................................173

Figure 7-1: Lifting Eyebolt Attachment Layout..................................................................174

10.3 Driveline Issues.............................................................................................................. 175

Drive Line and Flange Bolts............................................................................................................175

Issues .............................................................................................................................................175

Table 10-1: Maximum Recommended Driveline Lengths.................................................176

10.4 Plumbing Connections..................................................................................................177

10.5 Panel Mounted Accessories ......................................................................................... 177

10.6 Fluid Levels .................................................................................................................... 177

Appendix A:Glossary.................................................................................................179

Appendix B: Measurements and Conversions .........................................................183

Table B-1: Conversion Chart ............................................................................................183

Appendix C:Alternate Lubricant Manufacturers...................................................185

Table C-1: Alternate Lubricant Manufacturers..................................................................185

Appendix D:Lube and Sealant Specifications ........................................................187

10

Table D-1: Oil Capacity and Recommendation ................................................................187

Grease............................................................................................................................................188

Loctite Sealant................................................................................................................................188

Oil ...................................................................................................................................................188

Recommended Cleaners.............................. ... .... ............................................................. ... ... ........188

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 11

Table of Contents

Appendix E: Hose Friction Loss ...............................................................................189

Table E-1: Hose Friction Loss (PSI (kPa) / 100 Feet)......................................................189

Appendix F: Nozzle Size vs. Pressure .......................................................................191

Table F-1: Nozzle Flow and Pressure Ratings (Part 1).................................................... 191

Table F-2: Nozzle Flow and Pressure Ratings (Part 2).................................................... 192

Appendix G:Cavitation..............................................................................................193

Figure G-1: Sample, Cavitation Regions.......................................................................... 193

G.1 Process of Cavitation ....................................................................................................193

G.2 Warning Signs of Cavitation (Discharge and Gauges)...............................................194

Discharge Pressure........................................................................................................................ 194

Vacuum Compound Gauge............................................................................................................ 194

G.3 Eliminating Cavitation ...................................................................................................194

During Operations .................. ... .... ... ............................................................. ... .... ... ... .................... 195

Table G-1: Lift Loss from Elevation.................................................................................. 195

Table G-2: Lift Loss from Temperature............................................................................ 195

Table G-3: Lift Loss from Barometric Reading................................................................. 196

Preventive Measures......................................................................................................................196

Table G-4: Hose Size vs. Pump Rating Capacity ............................................................ 196

Strainers.........................................................................................................................................197

Appendix H:Midship Flow Rates..............................................................................199

Table F-1: Midship Flow Rates ........................................................................................199

Express Warranty ...............................................................................................201

Drawing Package .......................................................................................................203

Part 2 (Section 8) ........................................................................................................203

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

11

Page 12

Table of Contents

12

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 13

1 Safety Precautions

IMPORTANT!

DANGER!

W ARNING!

CAUTION!

HALE PUMPS ARE DESIGNED FOR OPTIMUM SAFETY OF ITS OPERATORS. FOR

ADDED PROTECTION, PLEASE FOLLOW THE SAFETY GUIDELINES LISTED IN THIS

SECTION AND ADHERE TO ALL WARNING, DANGER, CAUTION AND IMPORTANT

NOTES FOUND WITHIN THIS MANUAL.

ALL SUPPLIED DOCUMENTATION MUST BE CAREFULLY READ, UNDERSTOOD AND

STRICTLY ADHERED TO BY ALL INSTALLERS AND OPERATORS BEFORE ATTEMPTING TO INSTALL OR OPERATE THE PUMP.

WHEN DEVELOPING DEPARTMENTAL APPARATUS OPERATING PROCEDURES,

INCORPORATE THE WARNINGS AND CAUTIONS AS WRITTEN.

Safety Precautions

Hale is a registered trademark of Hale Products, Incorporated. All other brand and product names are

the trademarks of their respective holders.

1.1 DEFINITIONS

DANGER - IMMEDIATE HAZARD WHICH WILL RESULT IN SE VERE PERSONAL INJURY

OR DEATH IF THE WARNING IS IGNORED.

WARNING - HAZARD S OR UNSAFE PRACTICES WHICH COULD RESULT IN SEVERE

PERSONAL INJURY OR DEATH IF THE WARNING IS IGNORED.

CAUTION - HAZARDS OR UNSAFE PRACTICES WHICH COULD RESULT IN MINOR OR

MODERATE PERSONAL INJURY IF THE WARNING IS IGNORED.

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

13

Page 14

Safety Precautions

IMPORTANT!

IMPORTANT!

IMPORTANT - PRACTICES WHICH COULD RESULT IN DAMAGE TO THE APPARATUS

OR OTHER PROPERTY.

1.2 GUIDELINES

THE PROCEDURES IN THIS MANUAL ARE GENERAL OPERATING PROCEDURES.

THEY DO NOT REPLACE THE PROCEDURES, POLICIES, OR GUIDELINES ESTABLISHED BY THE AUTHORITY HAVING JURISDICTION, NOR DO THEY REPLACE THE

RECOMMENDATIONS AND PROCEDURES PROVIDED IN THE APPARATUS MANUFACTURER'S MANUAL.

REFER TO THE PROCEDURES PR OVIDED BY THE AUTHORITY HAVING JURISDICTION

ON SETTING WHEEL CHOCKS (TO PREVENT ANY MOVEMENT OF THE APPARATUS),

AS WELL AS LAYOUT AND CONNECTION OF HOSES, VALVES AND DRAIN COCKS.

ALL FASTENERS ON THE HALE PUMP AND GEARBOX ASSEMBLY ARE SELECTED

FOR THEIR APPLICATION. HALE PRODUCTS DOES NOT RECOMMEND REPLACING

FASTENERS WITH ANYTHING OTHER THAN HALE PART NUMBERS PROVIDED.

REPLACING WITH A WEAKER ALTERNATIVE POSES A SERIOUS SAFETY RISK.

ALL FASTENERS MUST BE INSTALLED WITH A LOCKING ANAEROBIC ADHESIVE/

SEALANT, SUCH AS LOCTITE

Use care when removing the pump assembly from its packaging to prevent per-

®

#242 OR EQUIVALENT.

sonal injury and/or damage to the system.

Use all mounting bolt holes provided on the gearbox and/or the pump to support

the assembly. See the pump assembly plate drawing, located at the back of this

manual, for additional installation information.

Installation should be performed by a trained and qualified installer, such as your

authorized Hale representative. Be sure the installer has sufficient knowledge,

experience and the proper tools before attempting any installation.

14

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 15

Safety Precautions

W ARNING!

W ARNING!

THE HALE PUMP AND GEARBOX ASSEMBLY CAN BE HEAVY AND BULKY. ADDING

ACCESSORIES TO THE SYSTEM ALSO INCREASES THE WEIGHT. CHECK YOUR BILL

OF LADING FOR THE APPROXIMATE WEIGHT.

BE CERTAIN TO USE PROPER LIFTING SUPPORT DEVICES (I.E., OVERHEAD CRANE,

JACKS, CHAINS, STRAPS, ETC.) CAPABLE OF HANDLING THE LOAD WHEN REMOVING OR INSTALLING THE HALE PUMP AND GEARBOX ASSEMBLY.

The installer is responsible for observing all instructions and safety preca utions in

his or her daily routine as dictated by regional safety ordinances or departmental

procedures.

Fluids - To meet various shipping regulations, oil is drained from the gearbox res-

ervoir prior to shipping from the factory.

At installation and before operation, oil must be added to the appropriate levels.

(See Section 4, heading “ Gearbox Lubrication,” on page 76.)

See separate documentation provided with the engine and pump and gearbox

assemblies for proper fluids to use and quantities required.

DO NOT permanently remove or alter an y protectiv e f eature , guard or insulating

devices, or attempt to operate the system when these guards are removed.

Doing so voids the Hale pump warranty. Also see heading “Express Warranty” on

page 201.

Any of the above could aff ect system capacity and/or saf e opera tion of the system

and is a serious safety violation which could cause personal injury or could affect

safe operation of the pump.

NO MODIFICATIONS MAY BE MADE TO THE HALE PUMP AND GEARBOX ASSEMBLY

WITHOUT PRIOR WRITTEN PERMISSION FROM:

Hale Products, Incorporated

Fire Suppression Division

700 Spring Mill Avenue

Conshohocken, PA 19428 U.S.A.

Telephone: 610-825-6300

Fax: 610-825-6440

Web: www.haleproducts.com

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

15

Page 16

Safety Precautions

W ARNING!

Rotating drive line parts can cause injury. Be extremely careful that NO part of

your body (head, feet, arms, legs, fingers, hair, etc.) is in an area of rotating parts

where you could be subject to injury.

Make sure everyone is clear of the apparatus before shifting to the PUMP posi-

tion. Verify the parking brake is set and the wheels are chocked to prevent any

movement of the apparatus.

Make sure proper personal protective equipment is used when operating or ser-

vicing the apparatus.

BE SURE TO WEAR SAFETY GLASSES WHEN REMOVING AND/OR INSTALLING

FORCE (PRESS) FITTED PARTS. WEAR PROTECTIVE, HEAT-RESISTANT GLOVES

WHEN HANDLING PARTS THAT REQUIRE HEATING FOR INSTALLATION AND/OR

REMOVAL. FAILURE TO COMPLY MAY RESULT IN SERIOUS EYE OR HAND INJURY.

DO NOT OVERHEAT PARTS CONSTRUCTED OF BRONZE (E.G. IMPELLER). OVERHEATING (PART TURNS RED OR BLUE) CAN WEAKEN THE PART AND IT MUST THEN

BE REPLACED.

DO NOT operate the system at pressures higher than the maximum rated pres-

sure. Alwa ys use the lo west possib le relief v alv e settings to enhance operator and

equipment safety. Also see Section 2 “Introduction” on page 19 for additional information.

Relieve all system pressure, then drain all water from the system before servicing

any of its component parts.

Use only pipe, hose and fittings which are rated at or above the maximum pres-

sure rating at which the water pump system operates.

Per NFPA 1962 requirements, large diameter hose, marked “supply Hose 3-1/2” to

5” (89 - 127 mm) diameter” shall not be used at operating pressures exceeding

185 PSI (1,276 kPa). Large diameter hose, marked “Supply Hose 6” (150 mm)

diameter” shall not be used at operating pressures exceeding 135 PSI (931 kPa).

If leakage from the drain hole in the pump head is noticed or suspected, the

mechanical seal must be inspected and/or replaced.

If a pump is operated without water for extended periods, or without discharging

water, it could overheat. This can damage the mechanical seal, impeller or the

drive mechanism.

16

DO NOT attempt to pump until all the GREEN pump indicators in the cab and

panel are ON. Also see Section 4 “Basic Operation” on page 53 for additional

information.

DO NOT advance the throttle unless the OK TO PUMP indicator is ON. Also see

Section 4 “Basic Operation” on page 53 for additional

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 17

Safety Precautions

information.

DO NOT leav e the cab , after selecting the PUMP mode , until all the GREEN pump

indicators in the cab and panel are ON. Also see Section 4 “Basic Operation” on

page 53 for additional info rmation.

DO NOT attempt emergency manua l shift procedures while the engin e is running.

Also see Section 4 “Basic Operation” on page 53 for additional information.

Never attempt to shift the pump (PUMP-to-R OAD, vise versa) while the app aratus

transmission is in gear. Always shift the transmission to NEUTRAL (N) and verify

the speedometer is at ZERO (0) before shifting the pump. Also see Section 4

“Basic Operation” on page 53 for additional information.

DO NOT reduce the pressure on the INTAKE gauge below zero (0). Serious dam-

age to the water main could result.

Some vehicles maintain air on the shift cylinder continuously regardless of trans-

mission setting, and some only have air applied when the vehicle transmission is

in NEUTRAL.

Use caution when servicing.

Use only PAC-EASE Rubber Lubricant Emulsion (or equal) on the rubber

mechanical seal parts to ease installation. DO NOT use other lubricant types as

damage to the mechanical seal and seat could occur.

Before connecting any cord sets or wiring harnesses, inspect the seal washer in

the connector.

If the seal washer is missing or damaged, water can enter the connector causing

corrosion. This could resulting in possible system failure.

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

17

Page 18

Safety Precautions

NOTES

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

18

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 19

2 Introduction

Figure 2-1: Centrifu-

gal Force - Rotating

Disk

2.1 DESCRIPTION

Hale single-stage and two-stage Midship MUSCLE Pumps cover a range of capacities from 750 Gallons Per Minute (GPM) (3,000 Liters Per Minute, LPM) up to 2,250

GPM (9,000 LPM). Hale single and two-stage pumps are designed to mount on the

chassis rails of commercial and custom apparatus. The pump is driven from the

truck’s main driveline.

Various models of the single-stage muscle pumps and one model of the two-stage

muscle pump are offered. The use and position on the apparatus determines the

model selected as well as the drive unit. Flow capacities (or rates) are shown in

Appendix H: “Midship Flow Rates” on page 199, located at the back of this manual.

Introduction

2.2 PRINCIPLE OF OPERATION

Centrifugal Force

Hale pumps are centrifugal pumps that operate on the principle

of centrifugal force created by a rapidly spinning disk. (See Figure 2-1: “Centrifugal Force - Rotating Disk.”)

As the disk rotates, it throws water from the center toward the

outer circumference of the disk. The velocity at which the water

travels from the center directly relates to the diameter of the

disk and the speed of rotation.

When water is confined in a closed container, such as the

volute (pump body), the velocity of the water is converted to

pressure that rises to a level dependent on the speed of rotation.

There are three interrelated factors that regulate the performance of a centrifugal pump:

SPEED (RPM) If the speed of rotation increases with flow held constant, fluid

pressure increases.

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

PRESSURE If pressure changes with speed held constant, the flow, measured in

gallons or liters per minute (GPM/LPM), changes in versely; if pressure increases,

flow decreases. Pressure is measured in pounds per square inch (PSI) or pascals

(kPa).

19

Page 20

Introduction

FLOW If the pressure (kPa) is held constant, the flow increases with an increase

in the speed of rotation. Flow is measured in the number of gallons of fluid per

minute (GPM or LPM) that a pump can deliver when supplied from draft.

A centrifugal pump has the ability to fully utilize any positive suction inlet pressure,

reducing the amount of work done by the pump.

For example, if the required discharge pressure is 120 PSI (827 kPa) and the inlet

pressure is 45 PSI (310 kPa), the pump must only produce the difference in pressure

or 75 PSI (517 kPa). This contributes to improved performance with reduced maintenance. Additionally, decreased maintenance is aided by a centrifugal pump having

few moving parts.

Pump Stages

The number of impellers on a common shaft determines the number of pump stages.

The Hale single-stage pumps provide the same normal operating and r ating test pressures as the Hale two-stage pumps. The two-stage pump provides an additional level

of operating pressures if required.

Single-Stage

Hale single-stage pumps use a one (1) impeller to develop the required volume and

pressure. (See Figure 2-2: “Water Flow, Typical Hale Single-Stage Pump.”)

Figure 2-2: Water Flow, Typical Hale Single-Stage Pump

20

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 21

Introduction

Figure 2-3: Single-Stage Pump Overview

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

21

Page 22

Introduction

Water enters the suction channels on both sides of the impeller, thereby maintaining

1

axial balance. Dual cutwaters

on the Qmax and Qmid strip water from the rotating

impeller and direct it to the discharge path. Radial hydraulic balance in the Qmax,

Qmid, and Qtwo is maintained by the opposed discharge volute cutwaters.

The Qflo, Qflo Plus, and Qpak series pumps utilize an impeller with a single suction

channel where water enters. The impeller develops discharge pressure and directs

the water to a single cutwater* and then to the discharge valves. The impellers are

radially and axially balanced.

Two-Stage

Hale two-stage pumps use two (2) impellers and a transfer valve / switch to develop

the required volume and pressure. (See Figure 2-5: “Two-Stage Pump Overview” on

page 23.)

Note: The transfer valve is a two-positi on valve that permits the impellers to be operated in

parallel (volume) or series (pressure).

Volume (Parallel) Operation

In Volume operation, the pressure at the pump intake is added to the pressure developed by both impellers, and the amount of water deliv ered to the discharge is the sum

of the flows of the two impellers . (See Figu re 2-4: “Two-Stage Pump VOLUME Operation.”)

22

Figure 2-4: Two-Stage Pump VOLUME Operation

1. The cutwater is a wedge that divides the water between the volute (pump body) and the pump

discharge.

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 23

Introduction

Figure 2-5: Two-Stage Pump Overview

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

23

Page 24

Introduction

For example, if the inlet pressure is 30 PSI (207 kPa) and the flow of each impeller is

500 GPM (1,892 LPM) at 150 PSI (1034 kPa), the pressure and volume at the discharge is: 180 PSI (1241 kPa).

Pressure (Series) Operation

For Pressure operation the impellers are connected in series. The output of the impeller supplied from the pump intake is added to the input of the next impeller. (See Figure 2-6: “Two-Stage Pump PRESSURE Operation.”).

Figure 2-6: Two-Stage Pump PRESSURE Operation

The pressure at the pump discharge is the sum of the pressure of the two impellers,

plus the pressure of the intake. The amount of water delivered to the discharge is the

same amount that entered the first impeller. Using the preceding example, when in

series operation, the discharge pressure is 330 PSI, (2275 kPa) and the discharge

volume is 500 GPM (1,892 LPM)

Volume vs. Pressure Operation

Selection of volume versus pressure operation is determined by three factors:

Generally, the pump should be operated so that the it provides the desired perfor-

mance at the LOWEST engine speed.

Set to VOLUME (parallel) operation for higher flows. (See Figure 2-4: “Two-Stage

Pump VOLUME Operation” on page 22.)

Set to PRESSURE (series) operation when higher water pressures are required.

(See Figure 2-6: “Two-Stage Pump PRESSURE Operation” on page 24.)

24

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 25

Introduction

IMPORTANT!

Transfer Valve

A transfer valve, controlled from the apparatus pump control panel, allows the operator to select VOLUME or PRESSURE operations.

The valve tr ansf ers betw een pumping modes with two and one-half turns of its control

hand wheel. The position of the valve is indicated on the apparatus pump control

panel via a positive mechanical indicator . As an optio n, Hale also off ers a pow er transfer valve.

Choosing Volume or Pressure Operation

In deciding which range to use (pressure or vo lume), choose the one that provides the

desired flow and pressure at the LOWEST engine speed.

REFER TO YOUR FIRE DEPARTMENT POLICY FOR WHEN TO USE “VOLUME” OR

“PRESSURE” OPERATIONS. IF YOUR FIRE DEPARTMENT DOES NOT HAVE A POLICY ,

REFER TO THE FOLLOWING HEADING, “GENERAL GUIDELINES.”

General Guidelines

1. Hale pumps are designed to pump up to 200 PSI (1379 kPa) net pressure in vol-

ume operation and at reasonable engine speeds.

2. The pump should be operated so that engine speed is within its best operating

range.

3. Generally, v olume oper ation should be used at a ny net pump pre ssure under 150

PSI (1034 kPa), especially when pumping from a hydrant.

4. When pumping from draft or a water tank, pressure operation may be used when

the volume is less that one-half the pump capacity and when the desired pressure is over 150 PSI (1034 kPa).

5. Set to VOLUME operation if the pump has to discharge more than 50 percent of

its rated capacity. Be certain to warn everyone involved before switching

between volume and pressure operation.

6. Reduce the pump pressure to between 50 to 60 PSI (345 to 414 kPa) before

switching. The engine speed should especially be reduced when switching from

volume to pressure operation with hand held hoses in use.

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

25

Page 26

Introduction

2.3 MUSCLE PUMP COMPONENTS

Note: When shifting the transfer valve from volume to pressure, pressure (PSI / kPa) is dou-

bled. You may hear a metallic click indicating as the check valve closes. If the clicking is too

loud or somewhat violent, the pum ping pressure is to o HIGH for switching. Ease back on the

engine throttle to reduce IDLE speed.

Hale muscle pumps are manifolded-type pumps. The pump volute, suction manifolding, and discharge manifolding are cast as one piece to simplify installation. (See Figure 2-7: “Typical Midship Two-Stage Centrifugal Pump” on page 27.)

Pump Body

The standard pump body and related parts are constructed from fine grain alloy cast iron,

with a minimum tensile strength of 30 ,000 PS I (207 N/mm²). All moving parts subject to

water contact.

A bronze body, for use with saltwater or harsh water applications, is also available.

Qmax, Qmid, and Qtwo Pumps

The Qmax, Qmid, and Qtwo pump body is split horizontally on a single plane in two

sections for easy removal of the impeller assembly, including clearance rings and

bearings.

The impeller assembly is removed from the bottom of the pump to avoid interference

with the surrounding piping and pump mounting on the apparatus chassis. (See Figure 2-7: “Typical Midship Two-Stage Centrifugal Pump” on page 27.)

Two tank suction valve locations are available to allow higher flows from the booster

tank. Optional built-in check valves are available to prevent tank over-pressurization.

Both pumps include two large suction inlets on th e left and right side. Option ally, additional front and rear inlets may be added as needed. Impeller inlets are on opposite

sides of the pump to balance axial forces; discharges are on opposite sides to balance radial forces.

26

Page 27

Introduction

Figure 2-7: Typical Midship Two-Stage Centrifugal Pump

Qpak, Qflo and Qflo-Plus Pumps

The pump bodies are a single piece construction. To avoid disturbing discharge or

suction piping, the gearbox and rear pump head / bearing housing must be removed

to service the impeller, clearance rings and mechanical seal.

The pumps include two large suction inlets on the left and right sides. The incoming

water is directed to the impeller through the suction passages.

A tank suction valve opening, located on the rear of the pump, allows for high flows

from the booster tank. An optional built-in check valve is available to prevent tank

over-pressurization.

Discharge valves in the basic pump configuration are mounted at either side of the

pump body. However, the manifolded pump body provides several additional discharge locations (facing front, back, or up) to accommodate additional discharge

valves.

Impeller

The impeller provides velocity to the water. Water enters the rotating impeller at the

intake (or eye), and is confined by the shrouds and the vanes to build pressure. (See

Figure 2-8: “Impeller Operation” on page 28.)

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

27

Page 28

Introduction

The vanes guide water from the inlet to the discharge and reduce the turbulence of

the spinning water.

Figure 2-8: Impeller Operation

As water discharges from the impeller, it enters the volute (pump body). The volute

increases in size from the cutwater to its full capacity at the volute throat.

This gradual increase maintains a constant average velocity through the volute. Figure 2-8: “Impeller Operation,” traces a drop of water from the intake of the impeller to

the discharge outlet.

Clearance Rings

Clearance rings preven t pressurized water that is lea ving the pump v olute from returning to the intake of the impeller. Clearance rings at the impeller intake also prevent

leakage, accomplished by limiting the radial clearance between the spinning impeller and

the stationary clearance ring. Also see Figure 2-7: “Typical Midship Two-Stage Centrifugal Pump” on page 27.

Typically , a ne w clearance ring has a radi al clearance of about 0.005” (0.127 mm) or a

0.008” (0.203 mm) diameter. However, due to foreign material found in the water,

this clearance increases over time as the pump is operated. Clearance rings are

designed for replacement when wear limits exceed NFPA satisfactory performance.

2.4 PUMP SEALS

28

Two types of seals are used - a packing seal or a mechanical seal.

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 29

Introduction

IMPORTANT!

Packing Seals

Packing, available on Qmax, Qmid, and Qtwo pumps, forms a watertight seal at the

point where the shaft passes from the inside to the outside of the pump. The packing

material is cooled with pump water . (See Figure 2-9: “Pump Packing Seal Assembly. ”)

Figure 2-9: Pump Packing Seal Assembly

The single packing gland is located on the low-pressure side of the pump. The packing rings are made of a combination of unique materials and have sacrificial zinc separators to protect the pump shaft from galvanic corrosion.

THE PACKING GLAND SHOULD NOT BE OVER TIGHTENED, OR THE MATERIAL WILL

LOSE ITS BUILT-IN LUBRICATION AND DRY OUT, WHICH MAY DAMAGE THE PUMP.

PACKING MATERIAL MAY ALSO DETERIORATE IF THE PUMP IS KEPT DRY FOR LONG

PERIODS OF TIME (FOR EXAMPLE, TO PREVENT FREEZING). IN THIS CASE, CHARGING THE PUMP WITH WATER AT LEAST ONCE WEEKLY WILL PREVENT DETERIORATION. ALSO SEE SECTION 6 “TROUBLESHOOTING” ON PAGE 93.

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

29

Page 30

Introduction

W ARNING!

Mechanical Seal

The mechanical seal is used on the Qpak, Qflo and Qflo-Plus pumps and is available

as an option on the Qmax, Qmid, and Qtwo pumps. (See Figure 2-10: “Mechanical

Seal Assembly.”)

Figure 2-10: Mechanical Seal Assembly

A stationary seal seat is in constant contact with a rotating carbon face to prevent

leakage. The sealing diaphragm is made of a rubber elastomer specifically designed

for high-temperature oper ations. Also see dr awing Plate No . 757A, locate d at the back

of this manual, for additional information and a detailed illustration.

IF A PUMP IS OPERATED WITHOUT WATER FOR EXTENDED PERIODS, OR WITHOUT

DISCHARGING WATER, IT COULD O VERHEAT. THIS CAN DAMAGE THE MECHANICAL

SEAL OR THE DRIVE MECHANISM.

30

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Page 31

Auto Lube ®

Figure 2-11: AutoLube Feature

A patented centrifugal pump is

built into the shaft of Qmax,

Qmid, and Qtwo pumps. (See

Figure 2-11: “AutoLube Feature.”)

This pump continuously forces

oil from the reservoir, through

the bearing, and back again. A

balancing chamber, behind the

oil reservoir, maintains the pressure in the oil reservoir equal to

water pressure – whether you

are pumping at high inlet pressure or pulling vacuum.

Introduction

The pump adds enough extra

pressure to maintain oil flow a

few PSI higher than water pressure. Thus, oil pressure inside

the double lip-type seal is

always slightly higher than w ater

pressure outside. Dirt and water are repelled by this higher pressure.

Auto-Lube also ensures continuous lubrication, even when you are pumping dry. A