Page 1

OPERATING AND

MAINTENANCE MANUAL

MODEL: HFM

SERIAL NO._______________

Failure to follow the operating, lubrication,

and maintenance requirements set forth in

the operating and instruction manual may

result in serious personal injury and/or damage to equipment.

A Hale pump is a quality product; ruggedly designed, accurately machined, carefully assembled and thoroughly tested. In order to maintain

the high quality of your pump and to keep it in a ready condition, it is important to follow the instructions on care and operation. Proper use and

good preventive maintenance will lengthen the life of your pump.

ALWAYS INCLUDE THE PUMP SERIAL NUMBER IN CORRESPONDENCE

n

HALE PRODUCTS INC.

A Unit of IDEX Corporation

700 Spring Mill Avenue

610/825-6300

www.haleproducts.com

n

Fax: 610/825-6440

Fire Suppression Division

n

Conshohocken, PA 19428

Page 2

WARRANTY

REGISTRATION

RETURN OF THIS WARRANTY REGISTRATION IS REQUIRED TO EFFECT THE LIMITED WARRANTY ON

THIS PRODUCT. THE UNDERSIGNED ACKNOWLEDGES RECEIPT OF THE OPERATION AND MAINTENANCE MANUAL FOR THE PUMP AND FURTHER ACKNOWLEDGES READING AND UNDERSTANDING

THE BASIC OPERATION OF THE PUMP DESIGNATED BELOW.

SIGNATURE______________________________ DATE _________

READ INSTRUCTIONS CAREFULLY FOR OPERATING PROCEDURES

Pump Model________ Serial Number __________

Apparatus Manufacturers Name:

________________________________________

Date place in service: Month _____ Year ______

Engine Model_____________ HP _____ RPM _____

Transmission Model___________________________

Make and Model of Chassis_____________________

Type of Vehicle:

Pumper______ Aerial ______ Tanker Pumper ______

Tanker_____ Mini Pumper ___Rescue Pumper_____

Fill in top portion and mail. Retain lower portion for your records.

COMPANY/DEPARTMENT

____________________________________________

Address_____________________________________

City___________________________ State _________

Country_______________________ Zip ___________

PURCHASED FROM (Apparatus Dealer)

____________________________________________

Purchased From__________________________________________ Date______________________

Apparatus Manufacturers Name:

________________________________________________________________

Date Placed in Service: Month_______________ Year _________________

Hale Products Inc., A Unit of IDEX Corporation

700 Spring Mill Avenue Conshohocken, PA 19428

Tel: (610) 825-6300 Fax: (610-825-6440

www.haleproducts.com

Page 3

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO. 13 CONSHOHOCKEN PA 19428

HALE PRODUCTS INC.

A Unit of IDEX Corp.

700 Spring Mill Avenue

P. O. Box 849

Conshohocken, PA 19428

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

LIMITED WARRANTY

PUMPS

EXPRESS WARRANTY. Hale Products Inc. (Hale) hereby

warrants to the original buyer that pump parts products manufactured by it are free of defects in material and workmanship for one

(2) years or 2000 hours usage, whichever shall first occur. An

exception will be split-shaft midship type pumps which will be

warranted for two (2) years or 2000 hours, whichever shall first

occur. The Warranty Period commences on the date the Product

is first placed in service.

LIMITATIONS. HALES obligations is expressly conditioned on

the Product being:

• Subjected to normal use and service;

• Properly maintained in accordance with HALES Instruction

Manual as to recommended services and procedures;

• Not damaged due to abuse, misuse, negligence or accidental

causes;

• Not altered, modified, serviced (non-routine) or repaired other

than by an Authorized Service Facility;

• Manufactured per design and specifications submitted by the

original Buyer.

THE ABOVE EXPRESS LIMITED WARRANTY IS EXCLUSIVE.

NO OTHER EXPRESS WARRANTIES ARE MADE. SPECIFICALLY EXCLUDED ARE ANY IMPLIED WARRANTIES,

INCLUDING WITHOUT LIMITATIONS, THE IMPLIED WARRANTIES OF MERCHANTABILITY; FITNESS FOR A PARTICULAR

PURPOSE OR USE, QUALITY; COURSE OF DEALING; USAGE

OF TRADE; OR PATENT INFRINGEMENT FOR A PRODUCT

MANUFACTURED TO ORIGINAL BUYERS DESIGN AND

SPECIFICATION.

EXCLUSIVE REMEDIES. If Buyer promptly notifies HALE upon

discovery of any such defect (within the Warranty Period), the

following terms shall apply:

• Any notice to HALE must be in writing, identifying the

Product (or component) claimed defective and circumstances

surrounding its failure;

· HALE reserves the right to physically inspect the Product

and require Buyer to return same to HALES plant or other

Authorized Service Facility;

• In such event, HALE will provide a Returned Goods

Authorization and Buyer must return the Product F.O.B.

within thirty (30) days thereof.

• If determined defective HALE shall, at its option, repair or

replace the Product , or refund the purchase price (less

allowance for depreciation);

• Absent proper notice within the Warranty Period,

HALE shall have no further liability or obligation

to Buyer therefore.

THE REMEDIES PROVIDED ARE THE SOLE AND EXCLUSIVE

REMEDIES AVAILABLE. IN NO EVENT SHALL HALE BE

LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES

INCLUDING, WITHOUT LIMITATION, LOSS OF LIFE; PERSONAL INJURY; DAMAGE TO REAL OR PERSONAL PROPERTY DUE TO WATER OR FIRE; TRADE OR OTHER COMMERCIAL LOSSES ARISING, DIRECTLY OR INDIRECTLY,

Page 4

Limited Warranty

EXPRESS WARRANTY: Hale Products Inc. (“Hale”) hereby warrants to the original buyer that products manufactured by it are free of defects in material and workmanship for two (2) years or 2000 hours usage whichever

shall first occur. The “Warranty Period” commences on the date the original buyer takes delivery of the product

from the manufacturer.

LIMITATIONS: HALE’S obligation is expressly conditioned on the Product being:

• Subjected to normal use and service.

• Properly maintained in accordance with HALE’S Instruction Manual as to recommended services and

procedures.

• Not damaged due to abuse, misuse, negligence or accidental causes.

• Not altered, modified, serviced (non-routine) or repaired other than by an Authorized Service Facility.

• Manufactured per design and specifications submitted by the original Buyer.

THE ABOVE EXPRESS LIMITED WARRANTY IS EXCLUSIVE. NO OTHER EXPRESS WARRANTIES ARE

MADE. SPECIFICALLY EXCLUDED ARE ANY IMPLIED WARRANTIES INCLUDING, WITHOUT

LIMITATIONS, THE IMPLIED WARRANTIES OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR

PURPOSE OR USE; QUALITY; COURSE OF DEALING; USAGE OF TRADE; OR PATENT INFRINGEMENT

FOR A PRODUCT MANUFACTURED TO ORIGINAL BUYER’S DESIGN AND SPECIFICATIONS.

EXCLUSIVE REMEDIES: If Buyer promptly notifies HALE upon discovery of any such defect (within the War-

ranty Period), the following terms shall apply:

• Any notice to HALE must be in writing, identifying the Product (or component) claimed defective

and circumstances surrounding its failure.

• HALE reserves the right to physically inspect the Product and require Buyer to return same to

HALE’S plant or other Authorized Service Facility.

• In such event, Buyer must notify HALE for a Returned Goods Authorization number and Buyer

must return the Product F.O.B. within (30) days thereof.

• If determined defective, HALE shall, at its option, repair or replace the Product, or refund the

purchase price (less allowance for depreciation).

• Absent proper notice within the Warranty Period, HALE shall have no further liability or obligation

to Buyer therefore.

THE REMEDIES PROVIDED ARE THE SOLE AND EXCLUSIVE REMEDIES AVAILABLE. IN NO EVENT

SHALL HALE BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGE’ INCLUDING, WITHOUT

LIMITATION, LOSS OF LIFE; PERSONAL INJURY; DAMAGE TO REAL OR PERSONAL PROPERTY DUE TO

WATER OR FIRE; TRADE OR OTHER COMMERCIAL LOSSES ARISING, DIRECTLY OR INDIRECTLY, OUT

OF PRODUCT FAILURE.

Hale Products Inc. • A Unit of IDEX Corporation

700 Spring Mill Avenue • Conshohocken, PA. 19428

Phone: 610-825-6300 • Fax: 610-825-6440

IDEX CORPORATION

www.haleproducts.com

Page 5

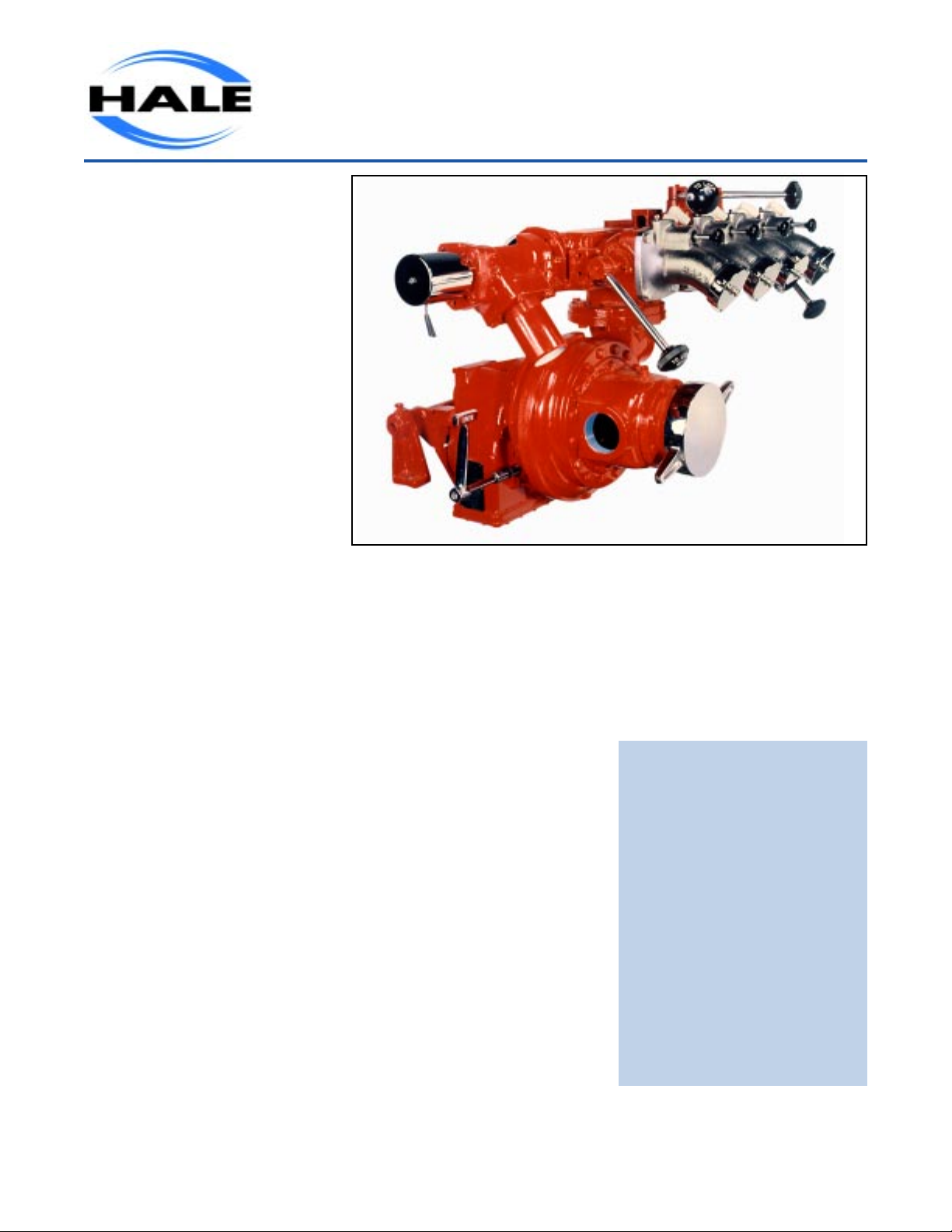

Hale Front Mounts provide

pump-and-roll capability with full

NFPA 1901 complialnce. They

have single-stage design for

ease of operation. Best of all,

theyre built by Hale.

For pump-and-roll grass fire

fighting or drafting from ponds

and streams, there are no

pumps like Hale Front Mounts.

They are extremely rugged, with

a range of capacities to meet

your needs. And they are built

with the same unique design

features that have made Hale

the leader in the fire-fighting

industry.

STANDARD FEATURES

Bronze impeller,

individually balanced and

matched with renewable

bronze clearance rings.

Electric rotary vane,

positive displacement

priming system with single

panel control activation.

Bronze fitted ball-type

droop discharge valves

with twist-to-lock handle

feature to gate valve in any

position.

Front Mount Fire Pumps

Corrosion-resistant stainless

steel pump shaft.

Oversized deep-groove ball

bearings for maximum

efficiency and long life.

Maintenance-free, self-

adjusting mechanical seal.

Oversized relief valve with

pressure control valve and

light.

Other standard features include

chrome-plated discharge and

suction caps, speed counter

connection and throttle indicator

lights.

HFM Series

Hale pumps go where the action

is. And when they get there,

they deliver. Thats why more

firefighters around the world rely

on Hale Front Mounts.

NFPA 1901 STANDARD RATINGS

HFM 75 750 GPM @ 150 PSI

2850 LPM @ 10.3 BAR

HFM 100 1000 GPM @ 150 PSI

3785 LPM @ 10.3 BAR

HFM 125 1250 GPM @ 150 PSI

4730 LPM @ 10.3 BAR

HFM 150 1750 GPM @ 150 PSI

5678 LPM @ 10.3 BAR

(GPM U.S. gallons per minute)

Page 6

Technical Specifications

Pump

Rated Capacities: 750,1000,

1250,1500 GPM ~ 150 PSI,

(2850, 3785, 4732, 5675 L/min

10.3 bar).

Type: Single-stage,

single-suction, gear-driven

centrifugal pump designed for

crankshaft-driven application,

with an integrated clutch for

engagement.

Impeller: Fine-grain bronze,

closed type, single-suction

mixed flow design, 10 inch (254

mm) diameter, accurately

machined and individually

balanced.

Clearance Rings: Bronze, front

and rear of impeller, easily

renewable.

Pump Shaft: Heat-treated

electric furnace

corrosion-resistant stainless

steel.

Packing: Maintenance-free,

self-adjusting mechanical seal.

Pump Casing: Fine-grain cast

iron with a minimum tensile

strength of 30,000 PSI. Tested

at 600 PSI hydrostatically by

Hale.

Suction Manifold: Fine-grain

cast iron with a minimum tensile

strength of 30,000 (206,842 kpa)

PSI. Tested at 600 PSI (41 bar),

hydrostatically and equipped

with fluid jacket for engine

coolant connection. Two 2-1/2

inch or 3 inch NPT pipe

connections are available.

Suction tube: Fine-grain cast

iron 4-1/2 inch NST (750 GPM),

5 inch NST (1000 GPM); 6 inch

NST (1250,1500 GPM).

Discharge Manifold: Fine-grain

cast iron with a minimum tensile

strength of 30,000 (206,842 kpa)

PSI tested at 600 PSI (41 bar)

hydrostatically. Designed with

six -3 inch cored openings to

accommodate discharge

requirements. Optional

manifolds available.

Discharge Valves: Hale Model

25BDT Valves (standard)

supplied as follows: three (750

GPM); four (1000,1250,1500

GPM). Hale Model 25BDT

Valves available as optional

equipment.

Gearbox

Drive Shaft: Heat-treated 1-1/4

in ten spline designed to accept

commercially available universal

joints.

Bearings: Heavy-duty ball

bearings, precision-ground to

size and lubricated from central

oil reservoir.

Gears: Both drive and pump

gears manufactured from the

highest quality steel alloy and

case hardened to provide

maximum strength and long life.

Ratios: Five ratios available to

provide maximum pump

performance and broaden

engine selection (gasoline and

diesel). Ratios: 1.40:1, 1.59:1,

1.81:1, 2.16:1, or 2.37:1.

Clutch: Integrated two-stage,

positive drive, wet-clutch design,

splash-lubricated from central

reservoir.

Mounting: Adjustable mounting

brackets provided for

standardization and to assist in

proper angularity requirements.

Pressure Control Device:

3 inch relief valve with control

standard (750,1000 and 1250

GPM); 3-1/2 inch relief valve with

control standard (1500 GPM).

Priming System: Hale Model

Electric Rotary Vane Priming

System, includes priming valve.

Meets or exceeds NFPA

1901standards.

Testing: Pump dynamometer

pretested by the Hale to ensure

compliance with NFPA 1901

standards.

Optional Accessories

Model TRV120 thermal Relief

Valve:

Automatically protects against

pump overheating.

TPM/P35 relief valve system.

Discharge and Suction Valves

Full-flow, quarter turn, ball-type with

locking handle.

Inline Valves: 1 inch through 3 inch,

full-flow, quarter turn, ball-type.

Drain Valves: Push-pull hose

bleeder valve and multi-port master

drain valve.

Strainers: Full-flow, basket-type

Shift: Air power shift system for

clutch.

Hale Products

A Unit of IDEX Corp.

700 Spring Mill Avenue

Conshohocken, PA 19428

USA

TEL: 610/825-6300

FAX: 610/825-9615

www.haleproducts.com

Note: Hale Products Inc. cannot assume responsibility for product failure resulting

from improper maintenance or operation. Hale is responsible only to the limits stated

in the product warranty. Product specifications contained in this material are subject

to change without notice. Bulletin 482 10/00 , rev 3 ©2000 Hale Products Inc.

Hale Products Europe

Charles Street

Warwick, CV34 5LR

England

TEL: (44) 01926 623000

FAX: (44) 01926 623666

www.haleeurope.com

Hale Products

Europe GmbH

Industriegebiet-Nord

Benzstrasse 4

64807 Dieburg Germany

TEL: (49) 06071 /92665

FAX: (49) 06071 /926677

MADE IN THE USA

Hale Products Asia

Singapore Rep. Office

63 Hillview Ave. #07-08

Lam Soom Industrial Bldg.

Singapore 669569

TEL: (65) 764-3575

FAX: (65) 764-4020

Page 7

Page 8

Page 9

Page 10

Page 11

Hale Model HFM

Front Mount Pump Operation Instructions

Pumping from Hydrant

1. Position chassis near hydrant and set parking brake. Shift truck transmission

to neutral position. Caution: Make sure that truck transmission shift quadrant

lock is used. Place wheel chocks in front and behind tires.

2. Attach one end of the suction hose to the hydrant and the other end to the

pump suction connection. Be sure the inlet strainer is installed and all drain

valves are closed.

3. Maintain engine idle speed, open hydrant, and slowly engage clutch in pump

transmission.

Caution: If clutch does not shift easily through its 180 degree travel,

do not force it, as this may cause serious damage to the pump

transmission. Instead, back the clutch off and re-engage it.

4. When discharge gauge registers pressure, open discharge line.

Note: It is not necessary to use primer when pumping from hydrant.

5. Accelerate engine and adjust discharge valves to obtain desired pressure and

volume.

6. When using soft suction hose between pump and hydrant, do not use

nozzles of larger capacity than the hydrant will supply.

Pumping from Booster Tank

1. Position chassis and set parking brake. Shift truck transmission to neutral

position. Caution: Make sure that truck transmission shift quadrant lock is

used. Place wheel chocks in front and behind tires.

2. Close all drain valves.

3. Maintain engine idle speed, open tank to pump supply line valve, and slowly

engage clutch in pump transmission.

Page 12

Caution: If clutch does not shift easily through its 180 degree travel, do

not force it, as this may cause serious damage to the pump

transmission. Back the clutch off and reengage it.

4. Pull out primer valve handle. When discharge gauge registers pressure, open

discharge line and release primer handle.

5. Accelerate engine and adjust discharge valves to obtain desired pressure and

volume. Caution: Do not try to pump a large volume of water, as suction line from

the tank will not handle it.

Pumping From Draft

1. Position chassis as dose to water source as possible and set parking brake.

Shift truck transmission to neutral position.

Caution: Make sure that truck transmission shift quadrant lock is used.

Place wheel chocks in front and behind tires. The pump will exceed the

rated capacity on a ten foot vertical lift, however, as the lift increases,

performance and capacity will decrease.

2 Attach hard suction hose to the suction nipple on pump and attach the hose

strainer to the other end. Be sure suction hose gasket and inlet strainer are in

place and all drain valves are dosed.

3. For best results, submerge suction strainer two feet or more in the water and

avoid pumping large volumes from shallow water.

4. Maintain engine idle speed, pull out primer handle, and slowly engage clutch in

pump transmission.

Caution: If clutch does not shift easily through its 180 degree travel, do not

force it, as this may cause serious damage to the pump transmission.

Instead, back the clutch off and re engage it.

5. When discharge gauge registers pressure, open discharge line, and release

primer handle. Caution: Care must be exercised not to operate pump without

water as this can seriously damage pump.

6. Accelerate engine and adjust discharge valves to obtain desired pressure and volume.

7. When suction hose must be carried over some obstruction such as a bridge rail, or if for

any reason the hose does not slope from pump to the water, the best results will be

obtained by priming with the discharge valve wide open

.

Page 13

One Last Word

The Hale Model HFM fire pump is an extremely rugged, dependable and

versatile unit. Its transmission housing, gears, shafts, bearings, pump casings,

and impeller are made of only the finest materials. Years of engineering

experience in hydraulic design and pump manufacturing stand behind each unit,

and are, in fact, the very reasons for its efficiency as a hydraulic machine.

Careful individual attention is given to each component as it is machined to exact

tolerances. Each pump is assembled by hand as a single unit. After assembly

and inspection, it is thoroughly tested under all phases of actual pumping

conditions.

In order that you may realize the full value and advantages of this

pump, it is suggested that a few practices be carefully followed. All men who

will be responsible for the actual operation of the pump should be thoroughly

familiar with it and its operation, both in theory and practice. This should

include regular drills in pumping from draft, hydrant and booster tank. Careful

instruction and practical experience will enable the men and their equipment

to work together as an effective fire-fighting team.

Regular and proper care of the pump itself and its related equipment

(suction and discharge hoses, gaskets, valves, etc.) is most important. A

periodical schedule for maintenance should be set up and strictly observed.

Page 14

Trouble Shooting Guide

Pump Fails to Prime or Loses Prime

1. Restriction at the Suction Strainer

a. Remove all leaves, dirt and other foreign material from the strainer.

b. Use extra caution when drafting from shallow water sources with mud, sand or gravel

bottom.

c Keep the strainer off bottom by placing it inside a barrel with the top cut down,

or use a similar method.

2. Suction Lift too High

a. Suction lift should not be attempted over 20 feet, except at low altitudes with the

equipment in new condition.

3. Suction Strainer too Near the Surface.

a. When pumping large volumes of water, the strainer should be submerged at least two feet

below the surface.

4. High Point in Suction Line.

a. Suction hose should slope from pump to source.

b. If a high point cannot be avoided, re-prime several times to avoid air pockets.

5. Primer Not Operated Long Enough.

a. A normal prime should be accomplished within 20 seconds at a 10-foot lift.

6. Defective Priming Line.

a. Check hose from pump to priming valve and also hose from priming

priming pump. Check for leaks or accumulations of foreign material.

b. If necessary, refer to the electric priming pump operation instructions supplied elsewhere in

this manual.

.

valve to the electric

Pump Will Not Deliver Capacity

1. Insufficient Horsepower

a. Check engine according to manufacturer's instructions, supplied with truck. b. See local

truck service garage.

2. Engine RPM too Low at Full Throttle.

a. Engine operated at hig h altitudes, engine horsepower decreases about 3 percent per 1000

feet above sea level. Consult manufacturer's instructions. Also due to insufficient

horsepower.

Page 15

3. Pump Wear Rings excessively Worn.

a. Excessive wear will allow severe internal leakage from the pressure side of the pump back to

the suction side, reducing the net pump capacity and pressure.

Engine RPM Higher than Necessary for Desired Volume in Pressure

1. Restriction in Suction Hose Strainer or Impeller Valves.

a. Inspect strainer to dear away all debris.

b. Pressure backwash will usually dear impeller vane when pump is topped.

c. Check condition of the suction hose. On an old, or defective hose, the liner may be pulled

loose when pumping, thus reducing the inside diameter of the hose itself.

2. Undersize Suction Hose.

a. When pumping at higher than normal lifts, or altitudes, use a larger suction.

3. Truck Transmission in Too Low a Gear.

a. Proper pumping gear is usually high, or direct drive. Consult apparatus instructions.

Pump Will Not Develop Sufficient Pressure

1. Often the remedies for low pump capacity will also correct low pressure.

2. Pump RPM too Low

a. Use a tachometer to check engine speed. Governor adjustment maybe required.

3. Pump Capacity Limits Pump Pressure.

a. Do not attempt to pump a greater volume of water at a given pressure than the pump was

designed to handle. Cavitation will result. Pump efficiency will be seriously impaired.

(NOTE: Prolonged pumping while pump is cavitating will damage impeller.)

b. Reduce volume by restricting discharge until the desired pressure is obtained.

Volume and Pressure

100% Capacity at 150 PSI 70% Capacity at 200 PSI 50% Capacity at 250 PSI

Page 16

Many Centrifugal Pump Troubles are Due to Air Leaks

Procedure to follow to detect possible air leaks

A. Start engine with pump disengaged and with pump drained.

B. Tightly close pump drain valve as well as booster tank suction and discharge

valves (if connected to a booster tank). Tighten caps on suction and discharge

openings. Then pull out primer handle.

C. With engine running at idling speed, observe hand on vacuum gauge until it

reaches a stationary position. This should be 20 inches or over, depending on

vacuum producing capacity of engine.

D. Release primer handle and carefully watch vacuum gauge hand. If hand drops

back rapidly, it indicates a leak, which must be located and corrected. If it stands

stationary, or moves back very slowly, it indicates either "no leak", or a minor leak,

which will not interfere with satisfactory operation.

E. Should test indicate a leak in pump proper, the stuffing box may need adjustment.

F Now remove discharge cap. If vacuum gauge hand returns toward zero, more

rapidly than before cap was removed, it indicates that the self-closing poppet valve

within the discharge manifold is not properly seated and this condition should be

corrected. G. When difficulty is experienced in locating an air leak, it may be found

by connecting pump suction to a hydrant. With hydrant pressure on pump, look for

water leaks, any one of which indicates a possible air leak. When connected to a

booster tank, there may be an air leak in booster line valves - in valve proper, or

around valve stem. The former may necessitate replacement of complete valve

while the latter may be corrected by replacing valve stem.

H. Do not overlook possibility of air leaks in suction hose or couplings. To test for

such leaks, connect suction hose to pump suction, place pump suction cap over

the end of the suction hose, and test in the same manner as described above as to

the motion of the vacuum gauge hand.

I. It is a very good idea to make periodic tests for air leaks.

NOTE: Excessive air leakage may delay, or even prevent priming

.

:

Page 17

Hale Model HFM

Recommended Preventive Maintenance Procedure

1. Lubrication.

The Hale pumps utilize oil-bath type lubrication of all gears and bearings in

the pump transmission. Oil level in the transmission should be maintained even with the

oil level plug, which is located on the lower left hand side of the gear case.

WARNING: Insufficient oil will result in serious damage to the all bearings and other

internal parts. An excessive amount of oil will cause the transmission to run at an

unusually high temperature, which may cause an oil breakdown.

WARNING: It is normal practice to ship pump to builder without oil, oil must be

added before operating.

It is recommended that the oil be changed every three months and after any prolonged

period of pumping. A good grade of SAE 30 non-detergent motor oil should be used in the

transmission. DO NOT use heavier oil. Check oil level at regular intervals.

Should your department be fortunate enough to have only a few calls during the year, it

will be beneficial to operate the pump once a week - perhaps during drill work.

2. Drafting. When pumping large volumes of water, the strainer should be submerged at least

two feet below the surface. Use extra caution when drafting from shallow water sources

with mud, sand or gravel bottom. Keep the strainer off bottom by placing it inside a barrel

with the top cut down, or use a similar method.

3. Salt Water Use. After pumping salt water, pump from a hydrant for a few minutes to flush

out the pump. Also, follow this procedure after pumping excessively dirty water.

4. Cold Weather. It is recommended that during cold weather the pump should be drained at

all times, except when kept in a heated fire house.

CAUTION: If long runs in very cold weather are expected (such as in rural areas), it

is wise to maintain a dry pump regardless of storage conditions.

Page 18

5. Final Test Before Housing Engine after a Fire or Drill. In addition to regular lubrication and

maintenance to the pump, the following pr ocedure is recommended to assur e proper

operation under emergency conditions:

a) Open discharge valves and remove caps.

b) Close drain valve(s).

c) Tighten suction caps.

d) Pull a prime until the compound gauge reaches about 20 inches of vacuum.

e) Watch gauge - if vacuum drops more than 10 inches in 10 minutes, an air lea k is prese nt.

All air leaks must be corrected before th e pump m ay be considered fully ser viceable.

Page 19

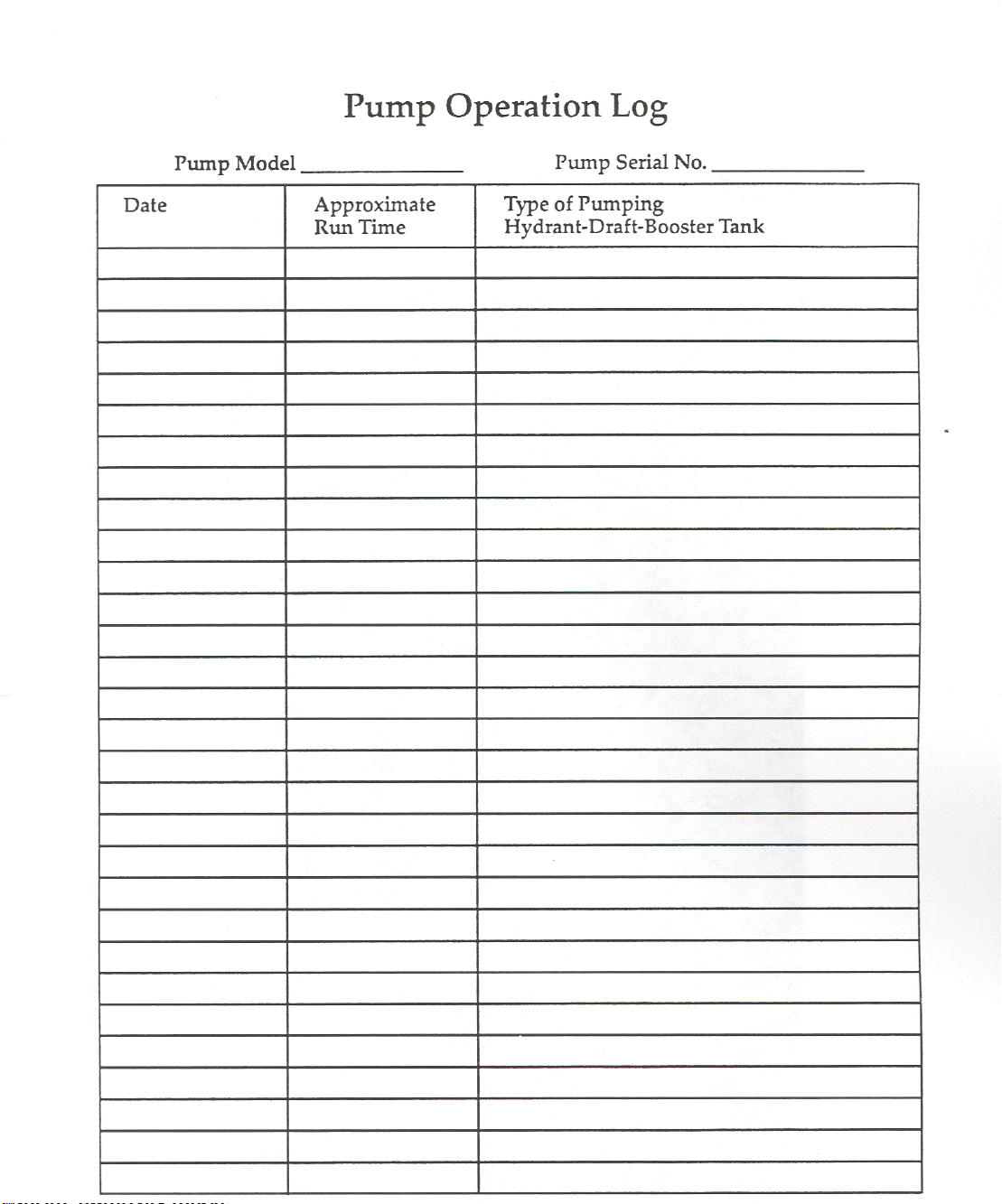

Pump Service Record

Pump Model ___________________ Pump Serial Number___________________

Check oil in gear case every 3 months; use SAE 20 non-detergent oil.

Change oil in gear case every 24 running hours.

Gear Case Oil Primer OIl Reservoir Comments or other Date/

Changed (Need Oil) Maintenance Performed Initials

YES NO YES NO

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

HOSE FRICTON LOSS (PSI PER 100 FEET)

G.P.M Flowing

3/4 Booster

1 Booster

1-1/2 Hose

G.P.M Flowing

1-1/2 Couplings

1-3/4Hose with

1-1/2 Couplings

2 Hose with

2-1/2 Hose

3 Hose with

2-1/2 Couplings

10 13.5 3.5 95 14 8

20 44 6 125 24 13

30 99 14 150 35 18

40 176 24 4 175 47 25 6

50 38 7 200 62 32 8

60 54 9 225 10

70 12 250 13 5 4

80 15 275 15

95 22 300 18

125 38 325 22 8

150 54 350 25 8

500 20 17

750 45 38

1000

NOTE: Add 5 PSI for each story of building and each wye orNOTE: Add 5 PSI for each story of building and each wye or

NOTE: Add 5 PSI for each story of building and each wye or

NOTE: Add 5 PSI for each story of building and each wye orNOTE: Add 5 PSI for each story of building and each wye or

siamese.siamese.

siamese.

siamese.siamese.

FF

riction Loss Calculariction Loss Calcula

F

riction Loss Calcula

FF

riction Loss Calculariction Loss Calcula

tions Courtions Cour

tions Cour

tions Courtions Cour

tesy IFSTtesy IFST

tesy IFST

tesy IFSTtesy IFST

A.A.

A.

A.A.

80

3 Hose

68

HALE PRODUCTS INC.

A UNIT OF IDEX CORPORATION

Page 38

HOSE FRICTON LOSS (PSI PER 100 FEET)

s

GPM FlowingGPM Flowing

GPM FlowingGPM Flowing

GPM Flowing

3/4" Booster3/4" Booster

3/4" Booster3/4" Booster

1" Booster

3/4" Booster

GPM FlowingGPM Flowing

GPM FlowingGPM Flowing

1-1/2" Hose1-1/2" Hose

1-1/2" Hose1-1/2" Hose

GPM Flowing

1-1/2" Hose

1-3/4" Hose with1-3/4" Hose with

1-3/4" Hose with1-3/4" Hose with

1-1/2" Couplings1-1/2" Couplings

1-1/2" Couplings1-1/2" Couplings

2" Hose with2" Hose with

2" Hose with2" Hose with

1-1/2" Couplings1-1/2" Couplings

1-3/4" Hose with

1-1/2" Couplings1-1/2" Couplings

1-1/2" Couplings

2" Hose with

1-1/2" Couplings

2-1/2" Hose

3" Hose with

3" Hose

2-1/2" Coupling

10 13.5 3.5 95 14 8 500

20 44 6 125 24 13 750

30 99 14 150 35 18 1000

40 176 24 4 175 47 25 6 1250

50 38 7 200 62 32 8 1500

60 54 9 225 10 1750

70 12 2 50 13 5 4 2000

80 15 2 75 15

95 22 3 00 18

125 38 325 22 8

150 54 350 25 8

500 20 17

750 45 38

3-1/2" Hose

GPM Flowing

4" Hose

5" Hose

1000 80 68

NOTE: Add 5 PSI for each story of building and each wye or siamese.NOTE: Add 5 PSI for each story of building and each wye or siamese.

NOTE: Add 5 PSI for each story of building and each wye or siamese.

NOTE: Add 5 PSI for each story of building and each wye or siamese.NOTE: Add 5 PSI for each story of building and each wye or siamese.

FF

riction Loss Calculariction Loss Calcula

F

riction Loss Calcula

FF

riction Loss Calculariction Loss Calcula

tions Courtions Cour

tions Cour

tions Courtions Cour

tesy IFSTtesy IFST

tesy IFST

tesy IFSTtesy IFST

A.A.

A.

A.A.

HALE PRODUCTS INC.

A UNIT OF IDEX CORPORATION

Page 39

DATA FOR PRACTICAL USE

WATER HORSE POWER =

GALLONS PER MINUTE X TOTAL HEAD IN POUNDS PER SQUARE INCH

1712

ONE GALLON WATER WEIGHS 8.33 POUNDS

ONE GALLON = 231 CUBIC INCHES

ONE CUBIC FOOT = 7.48 GALLONS

ONE POUND PER SQUARE INCH OF HEAD = 2.31 FEET HEAD OF WATER

ONE INCH OF MERCURY = 1.132 FEET OF WATER

ONE POUND PER SQUARE INCH = 2.0178 INCHES OF MERCURY = 27.68

INCHES OF WATER

POUNDS PER SQUARE INCH = FEET HEAD X .433

FEET HEAD = POUNDS PRESSURE X 2.31

ONE GALLON PER MINUTE X 3.785 = ONE LITER PER MINUTE

ONE CUBIC METER = 1000 LITERS

ONE IMPERIAL GALLON = 1.2 GALLONS

ONE POUND PER SQUARE INCH X .0690 = ONE BAR = .001 KPA

ONE BAR = 14.50 PSI

HALE PRODUCTS INC.

A UNIT OF IDEX CORPORATION

700 Spring Mill Avenue

Conshohocken, PA 19428

(610) 825-6300

Page 40

HOSE FRICTON LOSS (PSI PER 100 FEET)HOSE FRICTON LOSS (PSI PER 100 FEET)

HOSE FRICTON LOSS (PSI PER 100 FEET)

HOSE FRICTON LOSS (PSI PER 100 FEET)HOSE FRICTON LOSS (PSI PER 100 FEET)

G.P.M Flowing

500

750

1000

1250

1500

1750

2000

3-1/2 Hose

9.5

20

34

53

74

4 Hose

3

6

10

16

23

31

5 Hose

5

8

13

18

25

32

NOTE: Add 5 PSI for each story of building and each wye or siamese.

Friction Loss Caclulations Courtesy IFSTA.

700 Spring Mill Avenue

Conshohocken, PA 19428

HALE PRODUCTS INC.

A UNIT OF IDEX CORP.

(610) 825-6300

Page 41

HALE PRODUCTS INC.

A UNIT OF IDEX CORPORATION

GPM AT VARIOUS NOZZLE SIZES

1/2" 5/8" 3/4" 7/8" 1" 1-1/8" 1-1/4" 1-3/8"

PRESS.

NOZZLE

30 41 64 92 125 163 206 254 308

35 44 69 99 135 176 222 275 332

40 47 73 106 144 188 238 294 355

45 50 78 112 153 199 252 311 377

50 53 82 118 161 210 266 328 397

55 55 86 124 169 220 279 344 417

60 58 90 130 176 230 291 360 435

62 58 91 132 179 234 296 366 442

64 59 93 134 182 238 301 371 449

66 60 94 136 185 241 305 377 456

68 61 96 138 188 245 310 383 463

70 62 97 140 190 248 315 388 470

72 63 99 142 193 252 319 394 477

74 64 100 144 196 255 323 399 483

76 65 101 146 198 259 328 405 490

78 66 103 148 201 262 332 410 496

80 66 104 150 203 266 336 415 502

85 68 107 154 210 274 347 428 518

90 70 110 159 216 282 357 440 533

95 72 113 163 222 289 366 452 547

100 74 116 167 228 297 376 464 562

105 76 119 171 233 304 385 476 575

110 78 122 175 239 311 394 487 589

115 80 125 179 244 319 403 498 602

120 81 127 183 249 325 412 509 615

Page 42

HALE PRODUCTS INC.

A UNIT OF IDEX CORPORATION

700 Spring Mill Avenue

Conshohocken, PA 19428

(610) 825-6300

GPM AT VARIOUS NOZZLE SIZES

1-1/2" 1-5/8" 1-3/4" 1-7/8" 2" 2-1/4" 2-1/2" 3"

PRESS.

NOZZLE

30 366 430 498 572 651 824 1017 1464

35 395 464 538 618 703 890 1098 1581

40 423 496 575 660 751 951 1174 1691

45 448 525 610 700 797 1009 1245 1793

50 473 555 643 738 840 1063 1313 1890

55 496 582 675 774 881 1115 1377 1982

60 518 608 705 809 920 1165 1438 2071

62 526 618 716 822 935 1184 1462 2105

64 535 628 728 835 950 1203 1485 2138

66 543 637 739 848 965 1222 1508 2172

68 551 647 750 861 980 1240 1531 2204

70 559 656 761 874 994 1258 1553 2236

72 567 666 772 886 1008 1276 1575 2268

74 575 675 783 898 1022 1293 1597 2299

76 583 684 793 910 1036 1311 1618 2330

78 590 693 803 922 1049 1328 1639 2361

80 598 702 814 934 1063 1345 1660 2391

85 616 723 839 963 1095 1386 1711 2465

90 634 744 863 991 1127 1427 1761 2536

95 651 765 887 1018 1158 1466 1809 2605

100 668 784 910 1044 1188 1504 1856 2673

105 685 804 932 1070 1217 1541 1902 2739

110 701 823 954 1095 1246 1577 1947 2803

115 717 841 976 1120 1274 1613 1991 2867

120 732 859 997 1144 1301 1647 2034 2928

Loading...

Loading...