FYR-PAK

OPERATING AND MAINTENANCE MANUAL

(Models: 2006 to Present)

MODEL NO. SERIAL NO.

Failure to follow the operating, lubrication, and

maintenance requirements set forth in the operating and instruction manual may

result in serious personal injury and/or damage to equipment.

A Hale pump is a quality product; ruggedly designed, accurately machined,

carefully assembled and thoroughly tested. In order to maintain the high quality

of your pump and to keep it in a ready condition, it is important to follow the

instructions on care and operation. Proper use and good preventive maintenance

will lengthen the life of your pump.

ALWAYS INCLUDE THE PUMP SERIAL NUMBER IN CORRESPONDENCE

Hale Products Inc.

A Unit of IDEX Corporation

700 Spring Mill Avenue

Phone: 610.825.6300

www.haleproducts.com

l

l

Fax: 610.825.6440

Conshohocken, PA 19428

l

800.220.4253

Class 1®

607 NW 27th Avenue l Ocala, FL 34475

Phone: 352.629.5020 l Fax: 352.629.2902

www.class1.com

l

800.533.3569

P/N 029-9100-01-0, Rev B, 8/2010

Fyr Pak

Operation and Maintenance Manual

2

Fyr Pak

Operation and Maintenance Manual

LIMITED WARRANTY

Hale Products Inc., herein referred to as “Hale,” warrants products of its manufacture to be free from

defects in material and workmanship, under normal use and service, for a period of two (2) years

or 400 hours of usage, whichever comes rst and the engine for up to one (1) year or 200 hours of

usage. The “Warranty Period” commences on the date the original buyer takes delivery of the product

from the manufacturer, or two and a half (2-1/2) years from date of shipment from Hale, whichever

period shall be the rst to expire. Products used for rental or contracting purposes are warranted for

a period of six months or 150 hours of usage, whichever comes rst. This limited warranty is effective

only if the equipment or apparatus is used as directed, is not subjected to misuse, negligence or

accident, and is not altered, treated or repaired by someone other than Hale or its designee. Items not

manufactured by Hale shall bear only the limited warranties offered by their respective manufacturers.

The exclusive remedy for breach of this warranty shall be to give Hale written notice thereof and to

request a Returned Goods Authorization. Upon receipt of the Returned Goods Authorization, the

buyer will return the nonconforming material to Hale F.O.B. its plant within thirty days after the buyer

has received the Returned Goods Authorization. Thereupon Hale at its own election shall repair

or replace the same or repay the price thereof. No proximate, incidental, consequential or other

damages shall be recoverable. Hale shall not be liable for consequential damages or contingent

liabilities including; but not limited to, loss of life, personal injury, loss of crops, loss due to re or

water property damage, and consequential trade or other commercial loss arising out of the failure of

Manufacturer’s product.

HALE MAKES NO WARRANTIES OF FREEDOM FROM PATENT INFRINGEMENT, OF

MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE OR ARISING FROM A

COURSE OF DEALING OR USAGE OF TRADE OR OTHER LIKE OR DIFFERENT EXPRESS

OR IMPLIED WARRANTIES EXCEPT AS MADE ABOVE.

Hale Products Inc.

A Unit of IDEX Corp.

Conshohocken, PA. 19428

3

Fyr Pak

Operation and Maintenance Manual

NOTE: The Hale Fyr-pak is equipped with a United States Motor Power Inc., Power Bee Engine.

The engine is warranted by the manufacturer. Information on the engine should be referred to the

manufacturer or an authorized service center.

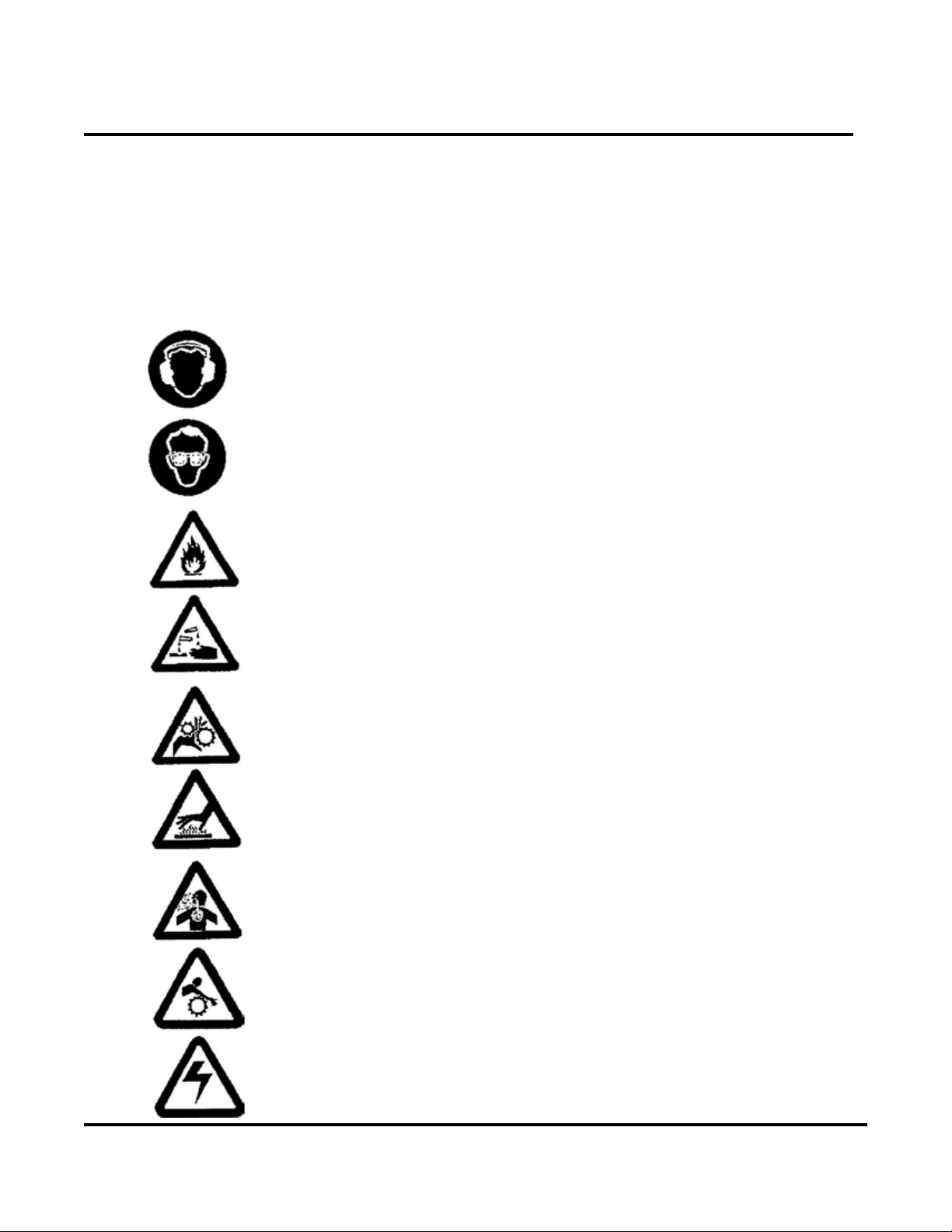

WARNING LABEL IDENTIFICATION

The equipment described in this manual contains one or more of the following warning labels.

The following chart identies the label and provides an explanation of the hazard associated

with the label.

HEARING PROTECTION REQUIRED WHEN OPERATING

EQUIPMENT

EYE PROTECTION REQUIRED WHEN OPERATING EQUIPMENT

EQUIPMENT CONTAINS FLAMMABLE FUEL

CORROSIVE HAZARD

ROTATING COMPONENTS

HOT SURFACES

DANGER OF CARBON MONOXIDE POISONING WHEN

EQUIPMENT IS OPERATING

OPERATING EQUIPMENT PRESENTS A DRAW-IN HAZARD

4

Fyr Pak

Operation and Maintenance Manual

ELECTRICAL SHOCK HAZARD

SAFETY PRECAUTIONS

Failure to follow the operating, maintenance and lubrication requirements set forth In this operating and

Instruction manual may result in serious personnel injury and/or damage to equipment. These “WARNING”

statements indicate potentially hazardous conditions for operator or equipment.

TAKE NECESSARY STEPS TO PROTECT PERSONNEL AND EQUIPMENT.

1 Carefully read “Engine Operating Instructions,” before attempting to operate, service, or

disassemble the engine or any of its parts.

2 Warning - Gasoline is a highly combustible fuel. The Improper use, handling, or storage of gasoline can

be dangerous. Prevent accidents by following these safety rules:

A. Use gasoline only as a fuel, never as a cleaning uid.

B. Use only an approved container to hold or store gasoline. Never store gasoline in familiar

containers such as milk containers or soda pop bottles.

C. Store gasoline in a cool location, out of the reach of children. Never store gasoline near heat or an

open ame.

D. Do not refuel with the engine running. Add fuel to a cool engine only. Spilled fuel on a hot engine

or mufer may cause a re or an explosion. Fill fuel tank out-of-doors and wipe up any spills.

E. Make sure all fuel lines and connectors are secure.

F. Provide a re extinguisher nearby when working with gasoline. Be sure extinguisher is

in operating condition; check the pressure gauge or indicator. Be familiar with its proper

use. Consult local re department for the correct type of extinguisher for your application.

Extinguishers rated ABC by the NATIONAL FIRE PROTECTION ASSOCIATION are

appropriate for most applications.

G. POSITIVELY NO SMOKING!!

3 DO NOT RUN THE ENGINE IN AN ENCLOSED AREA!! Exhaust fumes contain carbon monoxide that is

an odorless poisonous gas. If equipment is located in an enclosed area with an exhaust line to the outside,

regularly check the exhaust system for leaks. Be sure the area is well ventilated.

4 Do not operate equipment when mentally or physically fatigued.

5 Stay away from moving parts, avoid wearing loose tting clothes that could get caught in the equipment.

6 Keep the equipment and surrounding area clean. Cluttered areas invite accidents. Remove all oil deposits

from equipment and surrounding area. Accumulations of grease and oil may present a hazard.

7 All visitors should be kept at a safe distance from work area. Keep children away from equipment and

discharge hose. Do not allow children to hold discharge hose.

8 Be careful not to touch the exterior of a hot engine, especially the mufer and the surrounding area.

The engine is hot enough to be painful or cause injury.

9 Keep power shields and guards in place. Do not make adjustments and repairs while engine is running,

unless specied for in repairs. Use extreme caution around hot manifolds and moving parts.

10 Prevent accidental starting by always removing spark plug or by disconnecting and grounding spark plug

5

Fyr Pak

Operation and Maintenance Manual

wire before working on engine or the equipment driven by engine.

11 Maximum speed of the engine is set. Do not tamper with the controls to adjust to run at higher speeds.

Excessive speed increases the hazard of personal injury and reduces engine life

12 Familiarize yourself with all controls, learn how to stop engine quickly in a emergency.

13 When shutting off a gasoline engine, be sure It is completely stopped before leaving the work area.

14 For proper handling, storing and transporting fuel, follow fuel tank manufacturer’s instructions sheet and/or

instructions printed on tank.

15 If tank is equipped with a closing vented cap, open when pumping.

16 Check engine fuel level before initial start-up each day.

17 Flush pump with fresh, clear water if pump has been used to pump salt water or water containing sand.

18 During freezing weather, drain the pump, throttle actuator tubing, and discharge lines after each use.

19 The pump must be primed with the hand pump and the priming valve closed before starting engine.

20 Do not operate the unit while it is being carried.

21 Wear hearing protection when operating the unit.

6

Fyr Pak

Operation and Maintenance Manual

OPERATION AND INSTRUCTION MANUAL FOR ENGINE DRIVEN,

BACKPACK CENTRIFUGAL PUMPING UNIT

Introduction

PURPOSE

This operation and instruction manual is published to guide and assist in the installation, operation, lubrication,

maintenance, and repair of the Hale FYR PAK pumping unit. The installer and operator should understand this

manual before attempting to install or operate the unit.

IDENTIFICATION

Whenever a question arises regarding your pumping unit, contact your Hale Dealer for the latest available

information. This dealer will also be able to advise you of the nearest authorized engine dealer who can provide

service for the engine in your pumping unit. Finally, if additional help is needed, contact the Service Department

of Hale Products Inc.

Please supply the complete pump model and serial numbers when requesting information or ordering parts.

The pump model and serial numbers are stamped (not cast) on the Hale nameplate. For your convenience, ll

in the information on the Hale nameplate below.

Also always mention both the model number and serial number of your engine when ordering engine parts.

These numbers are found on the engine identication plate attached to the engine.

To help identify the pump parts used in your FYR-PAK, a pump parts catalog is included toward the back of this

manual. To identify the engine parts used in your pumping unit refer to the engine manufacturer’s parts catalog.

DESCRIPTION GENERAL

The FYR-PAK is a lightweight portable centrifugal pump mounted on a modern adjustable backpack frame.

It consists of a Hale type 20FP single stage, centrifugal pump close coupled to an air-cooled, 2-cycle, single

cylinder, engine overspeed control switch, priming pump and priming valve. The unit will deliver discharge

pressures to 220 PSIG and ows to 75 GPM from draft

7

The FYR PAK pumping unit consists of 6 major subassemblies; the engine, pump, priming system, mounting

Fyr Pak

base, overspeed control switch and backpack frame.

Operation and Maintenance Manual

ENGINE

The lightweight engine is a single cylinder, two cycle, air-cooled version producing 8 hp (6 kW) from its

8.2 cu. inch (134 cc) displacement using a gasoline/oil fuel mixture. The engine is equipped with water resistant

solid state ignition, a pressure carburetor with built-in fuel pump, and an on/off ignition toggle switch.

The engine’s interior is protected from impurities by the use of a wire mesh element air ler, a 75 micron in-line

fuel ller, and an integral fuel strainer built into the fuel pump.

PUMP

The engine crankshaft extension serves as the pump shaft with an enclosed type bronze impeller mounted

directly on the shaft. The shaft is protected against corrosion by a bronze sleeve, an “O”-ring, and a mechanical

type, self-lubricating and adjusting seal. The impeller is hydraulically sealed by a replaceable, patented oating,

bronze clearance ring located in the suction of the aluminum volute body. The volute body is attached

to the cast aluminum pump head by four mounting scr

The pump head serves as the mounting bracket for the pump/engine assembly. It is attached to the mounting

base with rubber vibration shock mounts. It also incorporates a handle for positioning the unit of carrying short

distances.

ews.

PRIMING SYSTEM

The priming pump is a hand operated piston pump. Its purpose is to remove air from the pump allowing

atmospheric pressure to push water through the inlet hose into the pump. A priming valve is included which

controls air ow through the priming line.

MOUNTING BASE

The mounting base is an intermediate part to which the engine is attached with three shock vibration isolation

mounts. The base is attached to the backpack frame with four vinyl clad tubing clamps. The mounting base has

the overspeed control switch, priming pump mounting clamps and Hale nameplate attached to it.

OVERSPEED CONTROL

The overspeed switch control assembly is an added safeguard against overspeeding of the engine. The

overspeed switch is attached to the mounting base of the pumping unit below the carburetor. Attached to the front

of the overspeed switch is a exible transparent hose that is connected to the nozzle plate (riveted to the engine

fan housing). Connected to the back of the overspeed switch are two wires one goes to the engine’s ignition coil,

the other goes to ground (engine). The switch senses the air pressure generated by the engine’s cooling fan.

When the engine reaches a speed in excess of that which would normally occur the fan air pressure generated

will be sufcient to cause the switch to close thereby grounding the solid state ignition. The engine speed will

then decrease until the air pressure reaches a lower trip point, reactivating the ignition system and the engine will

accelerate. The engine will decelerate and accelerate alternately until the operating conditions are returned to

their normal mode.

BACKPACK FRAME

The backpack frame serves as a convenient means for transporting the FYR PAK unit over long distances. The

backpack frame is of conventional design incorporating adjustable shoulder straps and hip belt. The addition of

8

Fyr Pak

Operation and Maintenance Manual

a hip belt allows part of the weight to be carried on the hips.

PREPARATION

INSPECTION OF NEW UNIT

When unpacking unit do not discard cushioning materials, carton, or case until you are certain everything is

correct. Inspect carefully, perfect condition of the outside shipping container does not guarantee undamaged

contents. Check for loose, missing, or damaged parts. Also, check the packing slip for any additional parts.

After inspection proves satisfactory, discard all shipping material in a proper manner.

The idle speed, idle and main fuel mixture adjustment screws have been factory set. However, the idle and main

fuel mixture adjustment screws may require readjustment, especially for cold weather or high altitudes (see

“Engine Operating Instructions,” for adjustment procedure).

IDENTIFICATION OF CONTROLS

Air Cleaner: Low restriction cleanable expanded aluminum foil type element

Carburetor Fuel Strainer: Provides secondary fuel ltering for engine.

Carrying Handle: This is incorporated into the pump head

Choke: Reduces the amount of air entering the engine to correct the fuel-air ratio for cold start-up.

Discharge Hose Connection: Located on the air cleaner side of the unit for connection. Pump supplied with

1-1/2” female NPT, 1-1/2” Male NH or 1-1/2” Male ISO

Exhaust mufer: This is a spark arrested type that also reduces the amount of combustion noise emitted by

the engine.

Flexible Transparent Hose: Connected between the nozzle plate and the overspeed switch control. Allows

for visual inspection of dirt and water which may clog hose and reduce amount of pressure reaching switch.

Check regularly, be sure hose is not cracked, crimped, or kinked.

Fuel Line Connector: Connect the fuel line from the fuel caddie here.

Ignition Toggle Switch: When ipped to the “ON” position, opens circuit to ground allowing the magneto

to develop a spark for the ignition of combustion. Flipped to the “OFF” position, closed the circuit to ground

magneto.

In-Line Fuel Filter: Provides primary fuel ltering for engine.

Nozzle Plate: Riveted to the engine fan housing, directs air pressure to exible, transparent hose and

overspeed control.

Overspeed Control: For description refer to “Description -Overspeed Control”

Priming Valve: For description refer to “Description - Priming System”

Priming Pump: For description refer to “Description - Priming System”

Pump Inlet: Located at the end of the pump, tted with either 2” Female NPT, 2” Male ISO or 1-1/2” Male NH

thread.

9

Fyr Pak

Operation and Maintenance Manual

GENERAL COMPONENT IDENTIFICATION

NOZZLE PLATE

FLEXIBLE

TRANSPARENT HOSE

FUEL LINE

CONNECTOR

AIR CLEANER

OVERSPEED CONTROL

PRIMING PUMP

INLINE

FUEL FILTER

PRIMING VALVE

DISCHARGE

HOSE CONNECTION

10

Fyr Pak

Operation and Maintenance Manual

GENERAL COMPONENT IDENTIFICATION

BACKPACK FRAME

IGNITION

TOGGLE SWITCH

THROTTLE

CHOKE

CARRYING HANDLE

PUMP INLET

EXHAUST MUFFLER

BASE PLATE

11

Fyr Pak

Operation and Maintenance Manual

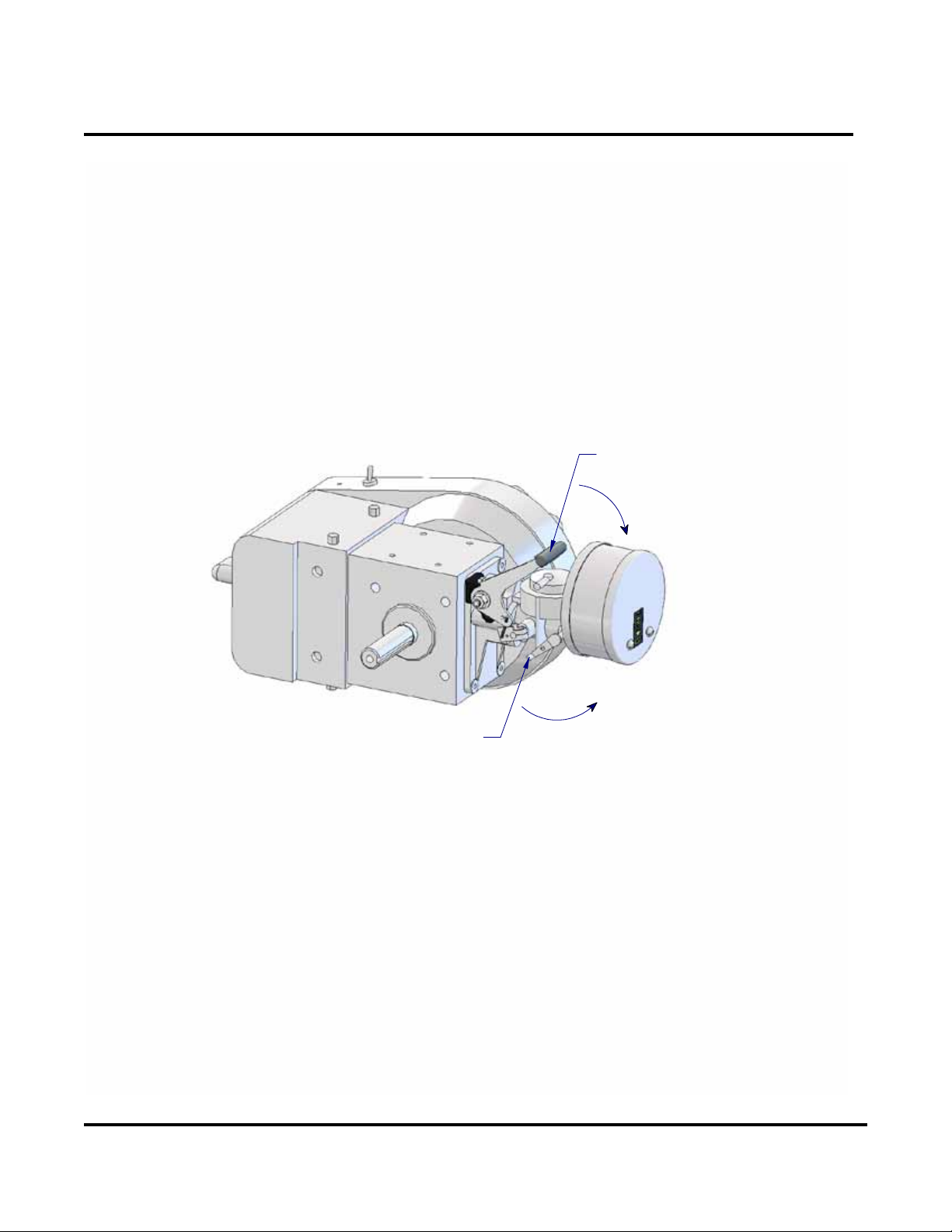

ENGINE CONTROLS

THROTTLE

CHOKE

INCREASE

CLOSE

12

Fyr Pak

Operation and Maintenance Manual

TRANSPORTING WARNING

Before transporting the FYR PAK, the fuel caddie MUST be disconnected from the engine and

the fuel drained as instructed under “STOPPING PROCEDURE” . Also, allow engine to cool.

The FYR PAK has a handle for moving and positioning the unit. Care should be taken not to drop or strike the

engine or pump as damage may result.

When transporting the unit by motor vehicle, care should be taken to fasten it down securely. Follow the

manufacturer’s instructions for transporting the fuel caddie.

When carrying the unit as a backpack, the hip belt and shoulder straps should be adjusted to satisfy the

individual.

There are two sets of holes in the frame for adjusting the hip belt.

The top end of the shoulder straps has three positions for attaching to the frame. Position the shoulder straps so

that they are horizontal from the shoulders to the fame. Adjustments are made by moving the adjustment pins on

one of the three holes found in the frame.

INSTALLATION

1. Choose a suitable location, as near to the source of water as possible, to place the FYR PAK and

attach intake and discharge hoses. When operating from draft, the inlet hose should slope continuously downward from the pump to the water.

2. Attach fuel line from remote tank.

CAUTION: Make sure connections on Intake and Discharge hoses match those supplied on the

pump or damage to threads will result. Damage may impede pump performance by allowing

leakage or preventing priming of the pump.

PRIME PUMP

It is recommended that the pump be primed before starting the engine.

a) Priming Procedure

1. The discharge must be closed either with a discharge valve, shutoff nozzle or by pinching the

discharge hose (use a pinch clamp if available.)

2. Open priming valve

3. Operate priming valve until water is discharged from priming pump

4. Close priming valve

5. Start engine. See starting procedures

6. Slowly open discharge valve until a steady stream is discharged

7. If an unsteady stream is discharged (incomplete prime) open priming valve and operate hand

primer to purge remaining air until a steady stream is discharged. Then, close priming valve

13

Fyr Pak

Operation and Maintenance Manual

and adjust throttle for desired output.

b) Alternate Priming Method: If the inlet hose is tted with a foot valve, the pump may be primed

by jabbing the end of the inlet hose in and out of the water until water expands the discharge

hose. The discharge line MUST be open when this method is used. Be sure the priming valve is

closed before starting engine.

OPERATION STARTING PROCEDURE

WARNING: DO NOT RUN THE ENGINE IN AN ENCLOSED AREA! Exhaust

fumes contain carbon monoxide which is an odorless and poisonous gas. Be

sure the area is well ventilated.

1. Make sure there is a FRESH mixture of gasoline and oil in the tank. Refer to “Fuel Specications,” for proper

amounts and type.

WARNING: Do not change or ll fuel while the engine running. Fill fuel tank out-of-

doors and away from any source of ignition. Wipe up any spills.

2. Connect fuel caddie to fuel line connector on engine base. Squeeze and release the priming bulb until

resistance is felt, indicating the fuel line is full. Further action will pump fuel past the check valve into the

carburetor, ooding it.

3. Close Choke

4. Open throttle slightly (1/4). Closed is down

5. Move ignition switch to “ON” position

6. Place foot on frame to prevent movement

7. Pull the starting handle slowly to bleed off some compression, then pull with a quick short stroke. Repeat as

necessary.

8. When engine starts, slowly open choke

9. Slowly open discharge valve

10. Set throttle to desired operating point.

NOTE: When operating from draft, especially on high lifts, do not increase engine speed

without a corresponding increase in pump pressure. If the engine speed increases with

no further increase in ow or pressure, reduce the throttle setting until the pressure or

ow decreases slightly and operate at that point.

14

Fyr Pak

Operation and Maintenance Manual

STOPPING PROCEDURE

1. Idle engine by pushing throttle lever down.

2. Move ON/OFF switch to OFF position.

3. Disconnect fuel caddie quick disconnect coupling, close cap and store fuel line.

4. Restart engine with water owing through pump and allow to idle until it stops from lack of fuel.

5. Allow lines to drain. Disconnect hoses.

CAUTION: Be careful not to touch the exterior of the engine, especially the mufer

and the surrounding area. The engine is hot enough to cause injury.

6. Without inlet and discharge caps in place, drain pump by tilting inlet end of pump downward. When pump is

drained, replace caps to prevent damage to threads.

RELAY PROCEDURE

For pumping water over long distances or up high vertical rises, it may be necessary to use several pumps in

series. When this is done, pressure (not exceeding 100 PSI) should be maintained at the inlet of the second and

subsequent pumps.

PREPARATION FOR STORAGE

WARNING: Prevent accidental starting by always removing spark plug or by disconnecting and

grounding spark plug wire before working on engine or pump.

NOTE: Replace the spark plug or wire only after all preparation is completed on both pump and engine.

1. Fuel System: If the unit is to be stored for any length of time, drain the fuel system by running until it stops as

instructed in “STOPPING PROCEDURE.”

2. Engine: See ENGINE MANUAL for storage instructions

3. Pump:

a. Follow the procedure under “Maintenance - Daily or Every 8 Hours” item 2, “Pump Inlet.”

b. Drain water from pump thoroughly. After the ow has ceased, pump should be turned over a few

revolutions so all water will drain from impeller.

c. While turning the pump over (using the starting handle), spray into the pump inlet and discharge

connections using either a white lithium or silicone type lubricant.

This treatment coats the inside of the pump and tends to prevent the clearance ring

and impeller hub from sticking due to corrosion.

d. Spray the threads of the inlet and discharge connections with either a while lithium or

silicone type lubricant.

15

Fyr Pak

Operation and Maintenance Manual

LUBRICATION AND MAINTENANCE

FUEL AND LUBRICANT SPECIFICATIONS:

Gasoline: Use clean, fresh, “regular grade unleaded” or “low lead” type. When “regular” or “low-lead” is

unavailable, an “unleaded” type fuel may be used; however, it should be limited to emergency use only. Oil

must be mixed with the gasoline. Refer to fuel mixture below.

Oil: Use a good quality Outboard motor oil or equivalent. The oil should meet or exceed the following typical

specications: TC-W3TM, NMMA, [API] TC, JASO FC, or ISO-L-EGO. Gasoline must be mixed with the oil,

refer to the fuel mixture below.

FUEL MIXTURE:

The engine used in the FYR-PAK requires that oil be mixed with the gasoline. For ease of starting, it is

desirable to have a fresh mixture of fuel; therefore, mix only an amount of fuel you anticipate using in the near

future. As a guide, the engine consumes approximately one gallon (3.8 L) per hour at full throttle (depending on

load), less at partial throttle.

To mix fuel, add oil to a small amount of gasoline in a clean container, then add the rest of the gasoline and

shake well.

NOTE: Do not mix oil and gasoline in the FYR-PAK fuel tank, it will be difcult to get good mixing.

Also if the fuel container has been still for an extended period, shake container before lling fuel tank.

The correct ratio of oil to gasoline is one (1) part oil to 24 parts gasoline (1:24). Table 1 shows various quantities

of fuel mixture and the amount of oil and gasoline required.

Approximate Quantity of

Fuel Desired Oil Gasoline

One Gallon (plus)

(3.9 Liters)

Three Gallons (plus)

(11.8 Liters)

Five Gallons (plus)

(19.7 Liters)

5 oz.

(158 ml.)

16 oz.

(473 ml.)

27 oz.

(789 ml.)

1 Gallon

(3.8 L.)

3 Gallons

(11.4 L.)

5 Gallons

(18.9 L.)

TABLE 1

SAFETY PRECAUTIONS:

1. DO NOT RUN THE ENGINE IN AN ENCLOSED AREA Be sure the area is well ventilated.

2. Stay away from moving parts. Avoid wearing loose clothing that could pose a catch risk.

3. Keep the equipment and surrounding area clean. Cluttered areas invite accidents.

4. Keep power shields and guards in place. Do not make adjustments and repairs while the engine is running,

unless specied for in repairs.

16

Fyr Pak

Operation and Maintenance Manual

5. Do not run the pump more than two minutes without water in the pump

6. Be careful not to touch the exterior of a hot engine, especially the mufer and the surrounding area.

7. Prevent accidental starting by always removing spark plug or by disconnecting and grounding spark plug wire

before working on engine or pump.

8. When working on any part of the fuel system be sure the unit is cool. Remove any sources of heat or ame.

ABSOLUTELY NO SMOKING!

Reassembly Note:

Before reassembly begins, visually inspect parts. See that parts are clean; all sealing surfaces are free of

corrosion and nicks. Remove any metal chips from casting cavities and tapped holes. Also, inspect for

any damaged or excessively worn parts which should be replaced.

MAINTENANCE SCHEDULE

DAILY OR EVERY 8 HOURS:

1. Leaks - (gaskets, fuel, seals, washers, and water): Check for any leaks before operating unit. These leaks

must be repaired before operating.

2. Pump Inlet: Remove any debris that might collect in the inlet, impeller eye, or the inlet hose strainer.

MONTHLY OR EVERY 25 HOURS:

1. Clean Air Filter aluminum foil element as follows:

NOTE: Service air cleaner more often under dusty conditions.

a) Remove (2) screws and washers so foil element and end plates can be removed

b) Wash foil element in kerosene or liquid detergent and water

c) Dry foil element by shaking out excess water. Use compressed air if available.

d) Install foil element, end plates, screws and washers on carburetor.

2. Spark Plug: Clean and regap at .030 inch (.8 mm). Spark plug type is champion #RL 86C,

NGK #BR5HS, AC #R46FF Motorcraft #AER6, and FramAutolite #426.

CAUTION: Do not blast clean spark plug. Blasting material could lodge in recesses of plug and

eventually work loose, permanently damaging aluminum bore. Spark plug should be cleaned

by scraping or wire brushing and washing with a commercial solvent.

3. Fuel Filters

General

a. Place the unit in a horizontal position.

b. Disconnect fuel caddie

c. Place a rag under the carburetor and fuel line to catch any fuel spillage.

d. Refer to lter maintenance below.

e. Wipe up any additional fuel spillage and discard rag in an approved safety container.

17

Fyr Pak

Operation and Maintenance Manual

In-Line Fuel Filter:

a. Remove the two clamps from both sides of lter and pull hoses using a slight twisting motion.

b. Observe hoses for any signs of cracking or deterioration and replace if necessary.

c. Install a new lter with the word “IN” toward fuel tank. Replace clamps.

Carburetor Fuel Strainer:

a. Remove the screw holding the plastic cover in place (where the fuel line connects to carburetor).

Gently remove the cover, gasket and strainer screen.

b. Clean screen in a nonammable solvent and blow dry.

c. Replace strainer screen, gasket, cover and screw.

4. Hoses, Fittings and Tubes: Clean and check all hoses, ttings and tubes for signs of cracks, kinks,

deterioration, etc. They should have uniform bends; if any are kinked or collapsed they should be

replaced. Fittings and clamps should be tight, but not over tight

SEASONAL OR AS REQUIRED:

1. Engine Cooling System: Clean the starter screen, ywheel (fan), and engine cooling ns. Foreign

matter may clog cooling system after prolonged service. Continued operation with a clogged cooling

system causes severe overheating and possible engine damage.

a. Remove the four screws that fasten the fan housing to the support plate and remove the two

screws that fasten the fan housing to the sheet metal cylinder cover.

b. Remove the exible transparent hose from nozzle plate and the spark plug wire from spark plug.

c. Carefully lift the fan housing from engine, push the spark plug and overspeed switch wires rubber

grommet from housing. Reach inside of housing and disconnect the magneto wire from ignition

switch. The fan housing can now be completely removed and cleaned.

d. Remove the four screws that fasten the sheet metal cylinder cover to engine; be careful, the

lower two holes have small spacers between the cover and engine.

e. To reassemble engine; reverse above procedures.

2. Pump: Except for draining the casing during freezing weather, the pump requires only an occasional

cleaning.

3. Removal of Pump/Engine Assembly:

WARNING: When working on any part of the fuel system, be sure the unit is cool. Remove any

sources of heat or ame.

ABSOLUTELY NO SMOKING!

3a. Removal of pump/Engine housing from Mounting Base

a) Place the unit in a horizontal position.

b) Remove the fuel line from the fuel line connector. Catch any fuel spillage with a rag. Dispose of the

rag in an approved safety container.

18

Fyr Pak

Operation and Maintenance Manual

c) Disconnect the overspeed switch wire at the connector. Disconnect the short overspeed switch

ground wire by pulling spade connector from the overspeed switch.

d) Remove the overspeed switch tubing from the overspeed switch.

e) Remove the three locknuts from the vibration isolators that fasten them to the pump mounting base.

f) Lift the pump/engine assembly from the mounting base.

4. Assembly of Pump/Engine to Mounting Base

Assembly is the reverse of the removal procedure above.

5. Repair or Replacement of Any Components in Pump (Replacing mechanical Seal):

a) Remove pump/engine assembly from mounting base. Refer to item 3 “Removal of Pump/Engine

assembly.”

b) Remove the four screws that fasten the volute body to the pump head. Remove the volute body

c) Remove the impeller retaining screw and washer.

ATTENTION: The impeller screw is left hand threaded.

NOTE: To prevent the engine from rotating, when removing the impeller screw, place a long 3/8” screw

or 3/8” diameter bar through one of the pump head mounting holes and a at bar in one of the impeller

cavities.

d. Remove impeller by putting hardwood wedges on each side of impeller, between impeller

and pump head. The wedges should bear against impeller disc directly behind impeller

vanes to prevent damaging the impeller; refer to gure 4. Tap end of engine shaft with

a Soft (rawhide, rubber) headed mallet, while maintaining pressure with wedges until

impeller comes off.

DO NOT PUT TOO MUCH PRESSURE ON WEDGES

e) With impeller removed, remove the impeller key.

f) Remove the spring and carbon section (sealing washer) of mechanical seal from engine crankshaft

sleeve. Observe the ceramic seal seat and carbon sealing washer. If they are scored or lip on the

sealing washer is worn or cracked, replace complete assembly.

g) If further disassembly is required beyond mechanical seal replacement, remove the four 5/16-18 x

2-1/2 Lg. screws and 5/16 at brass washers that fasten pump head to engine.

h) If mechanical seal ceramic seal was not removed previously, remove from head.

i) Pull engine crankshaft brass sleeve from shaft,

j) There is a replaceable clearance or wear ring used in this pump. Inspect impeller hub and clearance

ring bore, replace if any of these surfaces are scored or worn excessively.

19

Fyr Pak

Operation and Maintenance Manual

Pump Head

Bent or Cracked

Impeller disc

Impeller Disc

Impeller Cavity

Wedge

Impeller Vane

CORRECT INCORRECT

Wedge

Reassembly Note:

Before Reassembly visually inspect parts. See that parts are clean and all sealing surfaces are free of corrosion

and nicks. Remove any metal chips from casting cavities and tapped holes. Also inspect for any damaged or

excessively worn parts which should be replaced.

a. Coat the engine crankshaft with a thin layer of gasket sealer, such as, Loctite Gasket Eliminator 504

b. Lubricate the groove in the pump shaft sleeve using a multipurpose grease and install “O”-ring in

groove. Slide this assembly on engine crankshaft.

c. Position pump head on engine and align holes. If original screws are in good condition, reuse, but

apply a thread locking adhesive, such as Loctite Threadlocker 242 or equal to threads. If original

screws were damaged, or corroded, replace with four new screws. When installing screws use a new

brass sealing washer under the head of each screw.

Note: Hale has available small tubes of Loctite Threadlocker 242 adhesive (0.5 cc). Hale

P/N: 029-0010-01-0.

d. Coat rubber cup of mechanical seal seat with dish soap or Pac Ease and press into pump head

with polished surface toward you.

e. Coat rubber on inside of mechanical seat carbon sealing washer with dish soap or Pac Ease.

Using a turning motion, push onto shaft sleeve until carbon lip comes into contact with the seat

installed in step d.

20

Fyr Pak

Operation and Maintenance Manual

CAUTION: Keep the seal seat and carbon sealing washer surfaces clean. Be careful not to crack

or chip seal surfaces.

g. Line up keyway of impeller with keyway of shaft. Push impeller on shaft. Insert impeller key until

ush with face of impeller

f. Line up keyway of impeller with keyway of shaft; push impeller on shaft. Insert impeller key until

ush with face of impeller.

g. Coat end of shaft and impeller with a thin layer of gasket sealer.

h. Coat threads of a new impeller screw with a thread locking adhesive (Loctite 2440 or equal).

i. Mount impeller washer and impeller screw. Torque impeller screw to 10 ft/lbs

ATTENTION: The impeller screw is left hand thread.

If impeller clearance ring requires replacement proceed with the following steps. If impeller

clearance ring is in good condition, proceed to step “m”.

j. With the clearance ring removed from volute body, inspect clearance ring pins. If

these are damaged replace.

k. Apply a thin coat of oil or multipurpose grease to groove of impeller clearance ring

and install O-ring into groove. Coat the outside of clearance ring and O-ring with oil or

multipurpose grease.

l. Aligning the holes in impeller clearance ring with pins in volute body, press clearance

ring into volute body.

m. Coat the inside of clearance ring bore and outside of impeller hub with oil.

n. Install O-ring on pump head pilot and coat O-ring and pump head pilot diameter with

either oil or a multipurpose grease.

o. Mount volute body with clearance ring to pump head.

p. Install the pump/engine assembly to mounting base. Refer to item 4, “Assembly of

Pump/ Engine to Mounting Base”

21

Fyr Pak

Operation and Maintenance Manual

Appendix A

Parts Breakdown

22

Fyr Pak

Operation and Maintenance Manual

108-0620-06-0

REMOTE TANK, 6 GALLON

2

3

1

4

5

1

ITEM PART DESCRIPTION QTY UNIT

1 108-0620-05-0 TANK , FUEL, 6 GAL 1 EA

2 110192 SPACER, FUEL TANK, 6 GAL 1 EA

3 044-0260-00-0 VENT, AIR 1/8" MPT 1 EA

4 088-0250-00-0 COUPLING, MALE 1 EA

5 340-0061-02-0 HOSE, 1/4" FUEL 1 17"

6 010-0390-00-0 FILTER, 1/4" FUEL HOSE 1 EA

7 101-0640-00-0 DECAL, FUEL MIXTURE (NOT SHOWN) 1 EA

6

23

Fyr Pak

168-5160-00-0

Operation and Maintenance Manual

ENGINE CONTROL PARTS, FYR-PAK/PORT

4

2

3

1

9

7

11

10

8

5

6

ITEM PART DESCRIPTION QTY

1 019-0961-00-0 THROTTLE BRACKET 1

2 097-2260-00-0 WASHER, POLY 2

3 012-0770-00-0 THROTTLE LEVER 1

4 012-0160-03-0 HANDLE, T-KNOB 1

5 012-0850-00-0 LINKAGE, THROTTLE 1

6 101-0650-00-0 DECAL, CHOKE 1

7 097-6020-01-0 WASHER, SPRING 1

8 097-0020-02-0 WASHER, FLAT 1/4" 1

9 018-1210-02-0 SCREW, HEX HEAD 1/4-20 X 1" 1

10 110-1206-02-0 NUT, NYLOCK, 1/4-20 1

11 018-1205-02-0 SCREW, HEX HEAD 1/4-20 X 5/8" 1

1

1 SUPPLIED WITH ENGINE

ENGINE SHOWN FOR

ILLUSTRATIVE PURPOSES ONLY

24

Fyr Pak

Operation and Maintenance Manual

178-55XX-01-0

INTAKE/DISCHARGE ADAPTER KIT

METRIC (ISO)

1

2

3

4

9

8

FASTENING RIVET

INCLUDED WITH

ASSEMBLY 547-0191-40-0

9

178-5580-01-0 (INTAKE)

QTYITEM PART DESCRIPTION

1 007-0470-01-0 ADAPTER, 2" MPT X 2" ISO 1

2 008-0100-08-0 CAP, 2" ISO(BSP) 1

8 368-0010-01-0 CHAIN, PLATED 1

9 102521 SCREW, PAN PH 8-32 X 3/8" 1

1

178-5590-01-0 (DISCHARGE)

ITEM PART DESCRIPTION QTY

3 007-0480-01-0 ADAPTER, 1-1/2" MPT X 1-1/2" ISO 1

4 008-0100-07-0 CAP, 1-1/2" ISO(BSP) 1

8 368-0010-01-0 CHAIN, PLATED 1

9 102521 SCREW, PAN PH 8-32 X 3/8" 1

1

1 INCLUDED WITH CAP

PUMP AND BASE ASSEMBLY SHOWN

FOR ILLUSTRATIVE PURPOSES ONLY

25

Fyr Pak

178-55XX-00-0

Operation and Maintenance Manual

INTAKE/DISCHARGE ADAPTER KIT

STANDARD (NH)

5

7

6

7

9

8

9

FASTENING RIVET

INCLUDED WITH

ASSEMBLY 547-0191-40-0

178-5580-00-0 (INTAKE)

ITEM PART DESCRIPTION QTY

5 007-0470-00-0 ADAPTER, 2" MPT X 1-1/2" MALE NH 1

7 008-0100-06-0 CAP, 1-1/2" NH 1

8 368-0010-01-0 CHAIN, PLATED 1

9 102521 SCREW, PAN PH 8-32 X 3/8" 1

1

178-5590-00-0 (DISCHARGE)

ITEM PART DESCRIPTION QTY

6 007-0480-00-0 ADAPTER, 1-1/2" MPT X 1-1/2" MALE NH 1

7 008-0100-06-0 CAP, 1-1/2" NH 1

8 368-0010-01-0 CHAIN, PLATED 1

9 102521 SCREW, PAN PH 8-32 X 3/8" 1

1

1 INCLUDED WITH CAP

PUMP AND BASE ASSEMBLY SHOWN

FOR ILLUSTRATIVE PURPOSES ONLY

26

Fyr Pak

Operation and Maintenance Manual

200-0722-55-0

OVERSPEED PRESSURE SWITCH ASSEMBLY

FYR-PAK/PORT

2

4

6

VIEW FROM TOP

OF ENGINE

3

*

5

10

9

7

8

1

ITEM PART DESCRIPTION QTY UNIT

1 H013-0931-00-0-A GROUND WIRE, OVERSPEED SWITCH 1 EA

2 505-0070-00-0 PLATE, OVERSPEED SWITCH 1 EA

3 340-0380-01-0 HOSE, PVC CLEAR 3/8" OD X 3/16" ID 1 7"

4 064-7100-00-0 RIVET, 1/8" DIA 2 EA

5 097-0750-01-0 WASHER, FLAT #10 2 EA

6 102460 SCREW, SH 10-32 X 5/8" 2 EA

7 101662 WASHER, LOCK #10 2 EA

8 102537 NUT, HEX 10-32 2 EA

9 200-0722-01-0 SWITCH ASY, OVERSPEED 1 EA

10 018-1205-02-0 SCREW, HEX HEAD 1/4-20 X 5/8" 1 EA

1

1 SUPPLIED WITH ENGINE

* ITEMS SHOWN FOR

ILLUSTRATIVE PURPOSES ONLY

27

Fyr Pak

Operation and Maintenance Manual

340-0060-04-0

FUEL HOSE ASSEMBLY

2

3

4

FLOW

DIRECTION

1

3

5

2

TANK ASSEMBLY SHOWN FOR

ILLUSTRATIVE PURPOSES ONLY

ITEM PART DESCRIPTION QTY UNIT

1 003-0080-00-0 PRIMING BULB 1 EA

2 088-0310-01-0 COUPLER, HOSE TANK 2 EA

3 242-0620-01-0 CLAMP, 1/2" 2 EA

4 340-0061-02-0 HOSE, 1/4" FUEL 1 35.5"

5 340-0061-02-0 HOSE, 1/4" FUEL 1 17"

28

Fyr Pak

Operation and Maintenance Manual

340-5000-00-0

FUEL LINE ASSEMBLY, FYR-PAK

*

2

5

1

3

ITEM P ART DESCRIPTION QTY UNIT

1 010-0340-00-0 FILTER, FUEL 1 EA

2 340-0061-02-0 HOSE, 1/4" FUEL 1 5.5"

3 340-0061-02-0 HOSE, 1/4" FUEL 1 5.5"

4 088-0250-00-0 COUPLING, MALE 1 EA

5 242-0620-01-0 CLAMP, 1/2" 4 EA

44

* ITEMS SHOWN FOR

ILLUSTRATIVE PURPOSES ONLY

29

Fyr Pak

501-1990-04-0

Operation and Maintenance Manual

PUMP, 20FP-C8 (PRESSURE PUMP)

12

6

ENGINE SHOWN FOR

ILLUSTRATIVE PURPOSES ONLY

9

14

16

4

11

10

20

7

3

5

19

21

8

2

15

17

13

1

18

ITEM PART DESCRIPTION QTY

1 002-0510-00-0 HEAD, PUMP 1

2 048-0770-00-0 SHAFT SLEEVE 1

3 016-0261-01-0 IMPELLER 1

4 001-0220-XX-X VOLUTE BODY 1

5 296-5240-00-0 MECHANICAL SEAL 1

6 217-0201-04-0 PLUG, PIPE 1/4 MPT 3

7 097-0381-00-0 WASHER, IMPELLER 1

8 040-0180-00-0 O-RING 1

9 064-0309-12-0 PIN, CLEARANCE RING 2

10 321-0121-00-0 RING, CLEARANCE 1

11 040-2320-00-0 O-RING 1

12 064-1024-01-0 PIN, SUCTION 1

13 040-1590-00-0 O-RING 1

14 102669 PLUG, PIPE 1/8 MPT 1

15 097-0810-00-0 WASHER, FLAT BRASS 4

16 018-1424-07-0 SCREW, HEX HEAD 5/16-18 X 2.5" 4

17 097-0140-01-0 WASHER, LOCK SPLIT 3/8" 4

18 018-1607-12-0 SCREW, HEX HEAD 3/8-16 X 7/8" 4

19 017-0060-01-0 KEY, IMPELLER 1

20 018-9350-00-0 SCREW, HEX HEAD 5/16-18 X 1" 1

21 217-0001-11-0 PLUG, PIPE 1/16 MPT 1

30

Fyr Pak

Operation and Maintenance Manual

503-5010-10-0

HAND PRIMER KIT - FYR PAK/PORT

10

9

8

PUMP AND BASE ASSEMBLY SHOWN

FOR ILLUSTRATIVE PURPOSES ONLY

9

ITEM PART DESCRIPTION QTY UNIT

1 003-1050-00-0 PRIMING PUMP 1 EA

2 082-0225-01-0 NIPPLE, 1/4 MPT X 1.5" GALV 1 EA

3 242-0550-00-0 CLAMP 1 EA

4 038-1130-00-0 VALVE, BALL 1/4 FPT 1 EA

5 082-0214-02-0 REDUCER BSHG, 1/4" MPT x 1/8" FPT BRASS 2 EA

6 082-0119-02-0 ADAPTER, 1/8 MPT X 3/8" HOSE 2 EA

7 340-0490-00-0 HOSE, 3/8" ID 1 10"

78

5

6

4

31

Fyr Pak

Operation and Maintenance Manual

510-0320-00-0

AIR INTAKE ASSEMBLY

FYR-PAK/PORT/FLOTE

ENGINE SHOWN FOR

ILLUSTRATIVE PURPOSES ONLY

ITEM PART DESCRIPTION QTY

1 010-0320-02-0 AIR FILTER 1

2 097-0160-01-0 WASHER, LOCK SPLIT #10 2

3 2718863 SCREW, RD SL 10-32 X 2.25" 2

1

2

3

32

Fyr Pak

Operation and Maintenance Manual

524-0051-30-0

EXHAUST ASSEMBLY - FYR-PAK/FLOTE

1

2

3

ENGINE SHOWN FOR

ILLUSTRATIVE PURPOSES ONLY

ITEM PART DESCRIPTION QTY

1 024-0330-01-0 EXHAUST MUFFLER 1

2 110-1406-02-0 NUT, NYLOCK 5/16-18 2

3 USM-247279 GASKET, MUFFLER 1

1

1 SUPPLIED WITH ENGINE

33

Fyr Pak

Operation and Maintenance Manual

529-5810-00-0

BACK PACK ASSEMBLY - FYR-PAK

6

4

BASE SHOWN

FOR ILLUSTRATIVE

PURPOSES ONLY

2

1

4

5

ITEM PART DESCRIPTION QTY

1 047-0210-00-0 FRAME, BACK BACK 1

2 242-0160-00-0 CLAMP, 1" ID 2

3 242-0160-01-0 CLAMP, 3/4" ID 2

4 097-0020-02-0 WASHER, FLAT 1/4" 8

5 110-1206-02-0 NUT, NYLOCK, 1/4-20 4

6 018-1210-02-0 SCREW, HEX HEAD 1/4-20 X 1" 4

3

3

2

34

Fyr Pak

Operation and Maintenance Manual

545-0430-01-0

ENGINE ASSEMBLY, FYR-PAK/PORT

8

9

4

10

1

7

5

3

2

12

6

11

ITEM PART DESCRIPTION QTY UNIT

1 045-0430-01-0 ENGINE, FYR PAK 1 EA

2 044-1050-00-0 SWITCH GUARD 1 EA

3 044-5260-00-0 SHIELD, SPARK PLUG, FYR-PAK 1 EA

4 160214-0 TERM 16-14 GA 5/32" DIA, MALE PIN 1 EA

5 340-0480-00-0 LOOM, 5/32" ID 1 4"

6 101-0620-00-0 DECAL, ON/OFF 1 EA

7 101-0710-00-0 DECAL, WARNING 1 EA

8 101-0680-00-0 DECAL, FYR PAK 1 EA

9 101-1530-13-0 LABEL, WARNING HOT SURFACE 1 EA

10 018-8180-00-0 STUD, 5/16-18 2 EA

11 064-7100-00-0 RIVET, 1/8" DIA 4 EA

12 018-1210-02-0 SCREW, HEX HEAD 1/4-20 X 1" 1 EA

1

1 SUPPLIED WITH ENGINE

35

Fyr Pak

Operation and Maintenance Manual

547-0191-40-0

BASE MOUNT ASSEMBLY, FYR-PAK/PORT

*

1

20

21

6

5

18

7

5

3

4

2

*

21

6

* ITEMS SHOWN FOR

ILLUSTRATIVE PURPOSES ONLY

36

Fyr Pak

Operation and Maintenance Manual

547-0191-40-0

BASE MOUNT ASSEMBLY, FYR-PAK/PORT

11

9

24

13

14

15

16

22

26 27

10

17

22

FOR RIVET INSTALLATION SEE

23

ASSEMBLY 178-55XX-XX-X

19

ITEM PART DESCRIPTION QTY UNIT

1 048-0830-00-0 SHOCK MOUNT 2 EA

2 005-0960-00-0 PLATE, ISOLATING 1 EA

3 048-0830-01-0 SHOCK MOUNT 1 EA

4 2678782 SPACER 1 EA

5 097-0210-01-0 WASHER 3 EA

6 110-1606-02-0 NUT, LOCK STOVER 3/8-16 2 EA

7 097-1110-00-0 WASHER, TEFLON 1 EA

8 DNF18-250FIB-3K TERMINAL, BLADE 1 EA

9 013-1610-26-0 TERMINAL, 5/32" RECEPTACLE 1 EA

10 340-0480-00-0 LOOM, 5/32" ID 1 18"

11 101-0500-00-0 NAMEPLATE SERIAL NUMBER 1 EA

12 101-0640-00-0 DECAL, FUEL MIXTURE (NOT SHOWN) 1 EA

13 101-1530-14-0 LABEL, WARNING CARBON MONOXIDE 1 EA

14 101-1530-10-0 LABEL, WARNING GASOLINE 1 EA

15 101-1530-18-0 LABEL, WARNING SHOCK HAZARD 1 EA

16 101-1530-13-0 LABEL, WARNING HOT SURFACE 1 EA

17 101-1530-15-0 LABEL, WARNING HEARING PROTECTION 1 EA

18 018-1205-02-0 SCREW, HEX HEAD 1/4-20 X 5/8" 2 EA

19 101-0301-00-0 DECAL, NOISE WARNING 1 EA

20 097-0020-01-0 WASHER, FLAT 1/4" 4 EA

21 110-1406-02-0 NUT, NYLOCK 5/16-18 4 EA

22 064-7100-00-0 RIVET, 1/8" DIA 7 EA

23 047-0200-00-0 PUMP MOUNTING BASE 1 EA

24 242-0540-00-0 CLAMP, WIRE 3 EA

25 2120006 RIVET, 3/16" DIA 1 EA

26 242-0530-00-0 CLAMP, PRIMING PUMP 2 EA

27 064-7110-00-0 RIVET, 5/32" DIA 2 EA

12

8

25

37

Fyr Pak

RECOMMENDED SPARES

Operation and Maintenance Manual

HALE 20FP-C8 FYR-PAK PUMPING UNIT

PART NUMBER: 546-1550-50-0

FYR-PAK Engine Spares Kit

PART NUMBER QTY. DESCRIPTION

USM-K264063 1 Starter Kit

USM-K10009 2 Carburetor Gasket Kit

USM-K10013 2 Carburetor Repair Kit

USM-A175061-3 1 Carburetor

USM-010530 1 Strainer Screen

USM-010527 1 Strainer Cover

USM-560475-2 1 Ignition Coil

USM-G819-2 2 Industrial Cylinder Gasket Set

USM-A175013 1 Piston Assembly

USM-A175228 1 Needle Bearing

USM-250449 1 Ignition Switch

USM-C249227 3 Spark Plug

PART NUMBER: 546-1550-55-0

FYR-PAK Pump Spares Kit

PART NUMBER QTY. DESCRIPTION

040-0180-00-0 1 O-Ring, Shaft Sleeve

040-1590-00-0 1 O-Ring, Pump Housing

040-2320-00-0 1 O-Ring, Clearance Ring

064-0309-12-0 2 Clearance Ring Pins

064-1024-01-0 1 Suction Pin

097-0810-00-0 4 Brass Washer

296-5240-00-0 1 Mechanical Seal

029-0600-00-0 2 Alcohol Wipes

029-0610-00-0 1 PAC-EASE 2cc Tube

012-0160-03-0 1 T-Knob Handle

200-0722-01-0 1 Overspeed Switch Assembly

340-0380-01-0 7 inches Clear Hose

010-0340-00-0 3 Fuel Filter

010-0390-00-0 1 Hose Fuel Filter

003-0080-00-0 1 Priming Bulb

242-0620-01-0 4 Hose Clamp

010-0320-02-0 1 Air Filter

003-1050-00-0 1 Priming Pump

340-0490-00-0 10 inches Priming Pump Hose

38

Loading...

Loading...