Page 1

tm

FoamLogix

Models 3.3 / 5.0 / 6.5 Electronic

Foam Proportioning System

Installation and Operations Manual

Hale Products Inc. ◆ A Unit of IDEX Corporation

700 Spring Mill Avenue

Telephone: 610-825-6300

Web: www.haleproducts.com

◆ Conshohocken, PA 19428 U.S.A.

◆ FAX: 610-825-6440

Manual p/n: 029-0021-68-0

Page 2

APPARATUS INFORMATION

ENGINE ______________________________________________

TRANSMISSION _______________________________________

MAXIMUM CAFS ENGINE RPM ___________________________

CAFS ENGINE SPEED RANGE ___________________________

NOTICE !

Class1 cannot assume responsibility for product failure resulting from improper

maintenance or operation. Class1 is responsible only to the limits stated in the

product warranty. Product specifications contained in this manual are subject to

change without notice.

All Class1 products are quality components -- ruggedly designed, accurately

machined, precision inspected, carefully assembled and thoroughly tested. In

order to maintain the high quality of your unit, and to keep it in a ready condition, it

is important to follow the instructions on care and operation. Proper use and good

preventive maintenance will lengthen the life of your unit.

ALWAYS INCLUDE THE UNIT SERIAL NUMBER

IN YOUR CORRESPONDENCE.

ECO NO REV CHANGE FROM BY DATE APVD

0602 A Initial Release, for Printing LwH 08/10/2007 MAL

Manual p/n: 029-0021-68-0, Rev. -A

Printed in U.S.A.

HALE PRODUCTS, INC.

A Unit of IDEX Corporation

Conshohocken, PA 19428 USA

DRAWN BY LwH ISSUE DATE

© Hale Products, Inc. 2007

NOT TO BE REPRODUC ED OR USED TO

MAKE OTHER DRAWI NGS OR MACHINE RY.CHECKED BY PRW 08/10/2007

All Rights Reserved

COPYRIG HT ©

Page 3

Table of Contents ❑

Contents Page

FoamLogix 3.3 / 5.0 / 6.5 Installation and Operations

How to use this manual ........................................................................................ 11

1 Safety Precautions................................................................................................. 13

1.1 Definitions......................................................................................................................... 13

1.2 Guidelines ......................................................................................................................... 14

1 System Overview................................................................................................... 19

2.1 Rotary Gear Pump............................................................................................................ 19

2.2 Control Unit....................................................................................................................... 19

2.3 Water FLow Sensor.......................................................................................................... 20

2.4 Feed Back Sensor ........................................................................................................... 20

Table 2-1: Maximum Foam Solution Flows..........................................................................20

2.5 Tank Selector Valves ....................................................................................................... 21

Air Dual Tank Selector (ADT) ...........................................................................................................21

Manual Dual Tank Selector (MDT II) ................................................................................................ 21

Manual Single Tank (MST)...............................................................................................................22

2.6 Low Pressure Strainer ..................................................................................................... 22

Hale FS Series Strainers ..................................................................................................................22

2.7 Ordering Information ....................................................................................................... 23

2.8 Hale Foam System Specifications .................................................................................. 24

Figure 2-2: Foam Pump Installation Envelope Dimensions.................................................25

Figure 2-3: Foam Pump Installation Envelope Dimensions, ADT Option Only....................26

2.9 System Configuration ...................................................................................................... 27

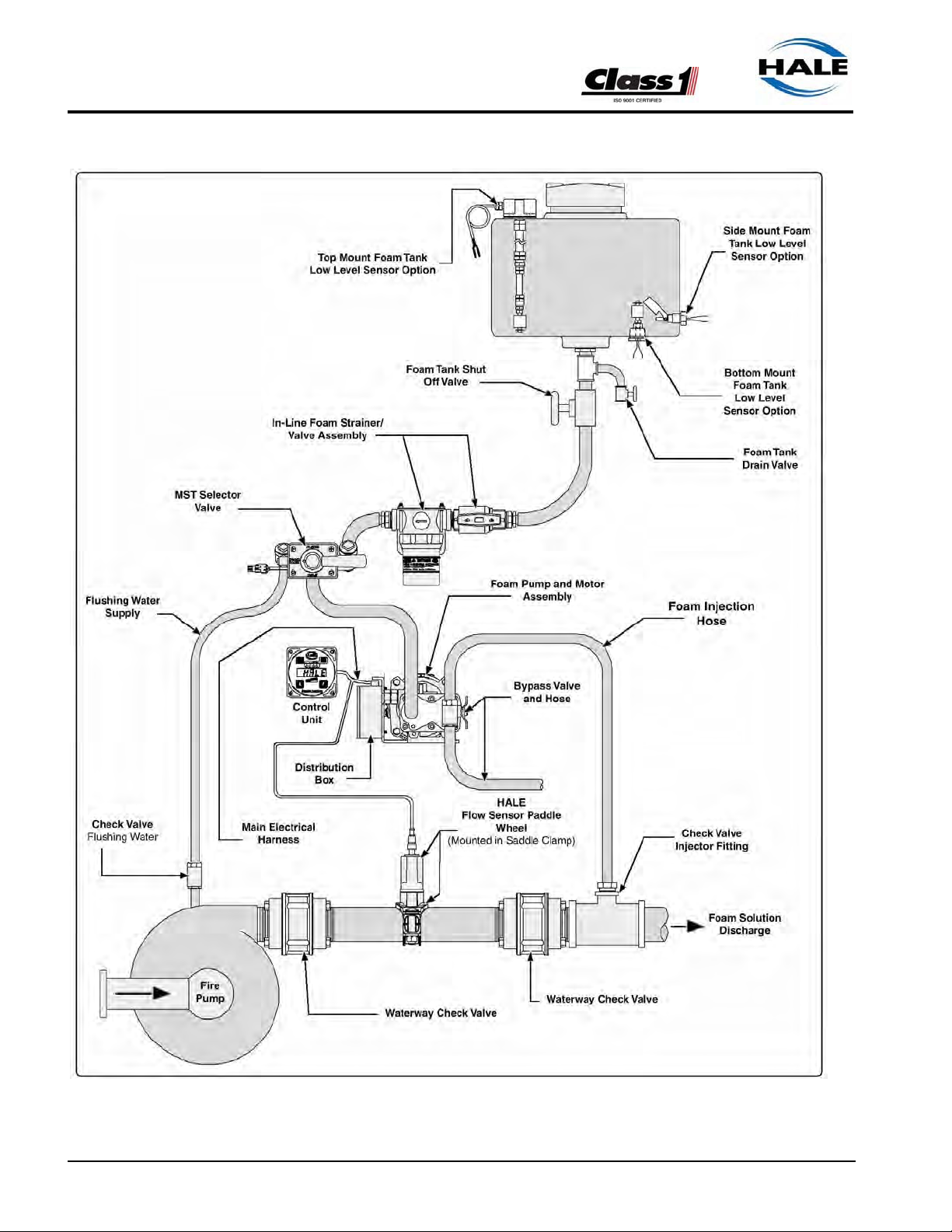

Hale Foam Proportioner System, Models 3.3, 5.0 or 6.5..................................................................27

Figure 2-4: FoamLogix Available Models ............................................................................ 27

Figure 2-5: Hale Foam Proportioner Systems, Models 3.3, 5.0 and 6.5.............................. 27

2.10 Cable Harness .................................................................................................................. 28

Figure 2-6: Power Connection Wire Harness ..................................................................... 28

2.11 Dual Foam Concentrate Tank System Options ............................................................ 29

Figure 2-7: Dual Tank Foam Concentrate Tank System Options........................................29

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

3

Page 4

❑ Table of Contents

Contents - continued Page

2.12 Dual Foam Concentrate Tank Options........................................................................... 30

2.13 Single Foam Concentrate Tank Options ....................................................................... 31

2.14 Strainer Options .............................................................................................................. 32

2.15 Low Tank Level Sensor Options ................................................................................... 33

2.16 Flow Sensors.................................................................................................................... 34

2.17 Check Valve Manifolds .................................................................................................... 35

2.18 Remote Activation Switch Option ................................................................................. 36

2.19 Check Valves, Flanges, Gaskets ................................................................................... 37

2.20 Elbows and Mini Manifolds ............................................................................................ 38

2.21 Hale Foam System Layout Drawings ............................................................................ 39

Figure 2-10: Typical Single Foam Concentrate Tank ..........................................................39

Figure 2-11: Single Foam Tank with MST and In-Line Strainer/Valve Assembly ................ 40

Figure 2-12: Single Foam Tank with MST and FS Series Strainers .................................... 41

Figure 2-13: Dual Foam Concentrate Tanks, with MDT II and In-Line

Strainer/Valve Assembly.................................................................................................42

Figure 2-14: Dual Foam Concentrate with MDT II and FS Series Strainer Assembly ......... 43

Figure 2-15: Dual Foam Concentrate Tanks, with ADT and In-Line

Strainer/Valve Assemblies..............................................................................................44

Figure 2-16: Dual Foam Concentrate Tanks with ADT and FS

Series Strainer Assemblies............................................................................................. 45

3 Installation ............................................................................................................. 47

3.1 Foam Pump and Motor Assembly .................................................................................. 48

3.2 Foam Concentrate Strainer............................................................................................. 48

3.3 Control Unit / Instruction Placard................................................................................... 49

3.4 Installer Supplied Components ...................................................................................... 50

Foam Concentrate Suction Hose ..................................................................................................... 50

Recommended Components .................................................................................................... 50

Recommended Components .................................................................................................... 51

Foam Concentrate Discharge Hose .................................................................................................51

Recommended Components .................................................................................................... 51

Foam Concentrate Bypass Hose...................................................................................................... 52

Recommended Components .................................................................................................... 52

Check Valves....................................................................................................................................52

4

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 5

Table of Contents ❑

Contents - continued Page

3.4 Installer Supplied Components - continued

Flushing Water Hose ........................................................................................................................ 5 3

Foam Discharge Drains.................................................................................................................... 54

Electrical Requirements.................................................................................................................... 54

Figure 3-1: Recommended Relay Wiring Schematic ...........................................................55

Table 3-2: Primary Power Cable Sizes................................................................................ 55

FoamLogix Display ........................................................................................................................... 56

Foam Concentrate Tanks(s)............................................................................................................. 56

Table 3-3: Recommended Foam Tank Capacity .................................................................57

Foam Pump Mounting .....................................................................................................................57

Figure 3-4: FoamLogix Pump Installation ............................................................................ 57

Figure 3-5: Base Plate Mounting Hole Locations ................................................................ 58

Plumbing Installation......................................................................................................................... 59

Water and Foam Solution Plumbing .................................................................................................59

Figure 3-6: Typical Check Valve Manifold Installation ........................................................59

Optional Hale Piping Components....................................................................................................60

Figure 3-7: Typical Midship Pump Installation ....................................................................61

Figure 3-8: 4” (102mm) Check Valve Installation.................................................................61

“Waterway” Check Valves ................................................................................................................62

Flow Sensor ..............................................................................................................................62

Figure 3-9: Flow Sensor Tee Position Range ......................................................................62

Table 3-10: Pipe Size vs. Minimum Straight Run ................................................................63

Figure 3-11: Typical Reduced Size Sensor Piping Arrangement.........................................63

Figure 3-12: Flow Sensor Placement ..................................................................................64

Saddle Clamp Installation ..........................................................................................................64

Figure 3-13: Flow Sensor/Saddle Clamp Installation...........................................................65

Foam Pump Flush System ...............................................................................................................65

Dual Tank System .....................................................................................................................65

Single Tank System ..................................................................................................................65

No Tank Option .........................................................................................................................65

Foam Concentrate Plumbing............................................................................................................66

Foam Strainer Connection (In-Line Strainer/Valve).......................................................................... 66

Figure 3-14: In-Line Strainer/Valve Installation....................................................................67

To Install the In-Line Strainer/Valve Assembly ..........................................................................67

Figure 3-15: In-Line Strainer Mounting Bracket Layout ....................................................... 68

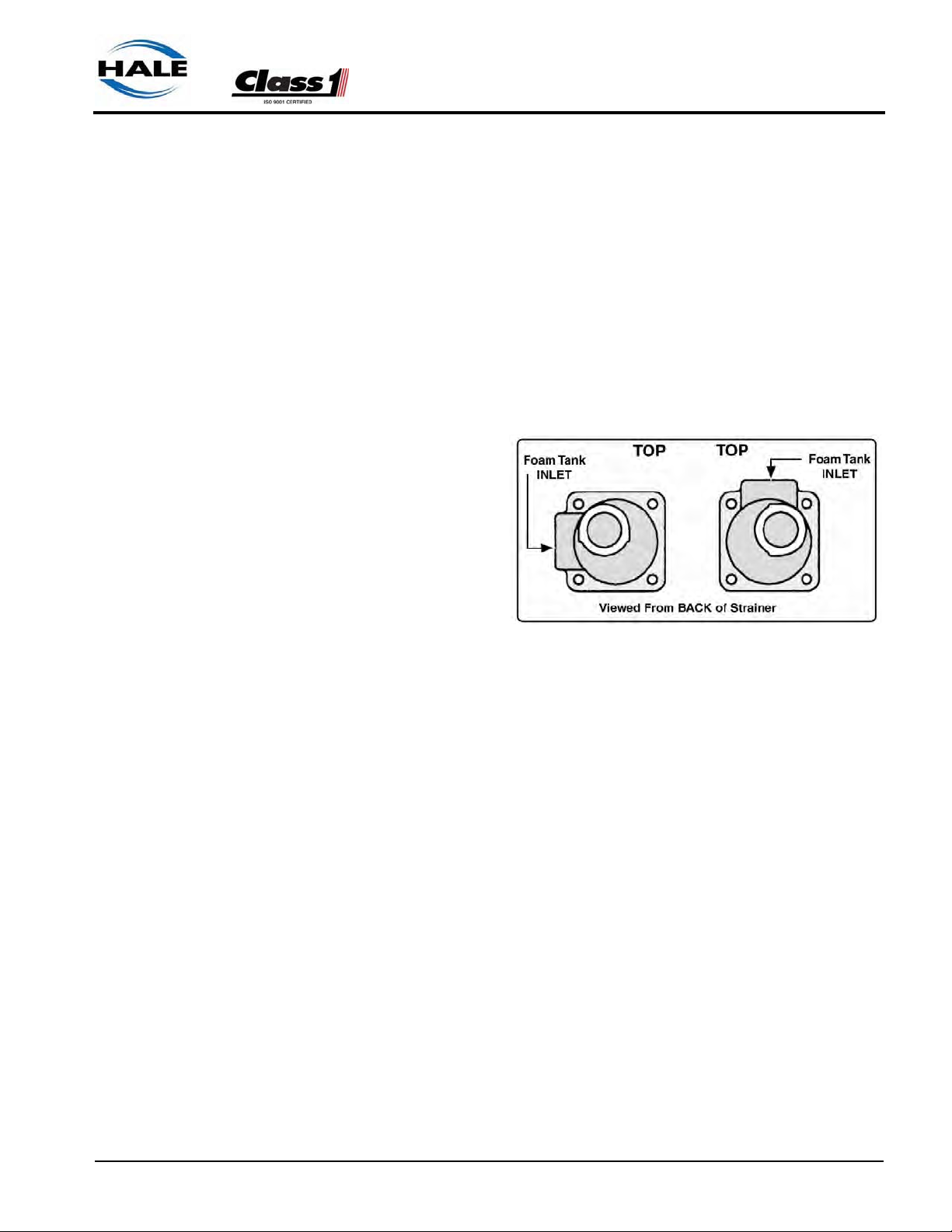

FS Series Strainer ............................................................................................................................69

To Install FS Series Strainers ....................................................................................................69

Figure 3-16: FS Strainer Orientation....................................................................................69

Figure 3-17: FS Strainer Mounting Dimensions...................................................................70

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

5

Page 6

❑ Table of Contents

Contents - continued Page

3.4 Installer Supplied Components - continued

Check Valve / Injector Fitting ....................................................................................................71

Figure 3-18: Check Valve/Injector Fitting Orientation.......................................................... 71

Figure 3-19: Check Valve / Injector Fitting Installation ........................................................71

Foam Concentrate Injection Hose.................................................................................................... 72

Figure 3-20: Injection and Bypass Hose Connections ......................................................... 72

Bypass Hose Connection .................................................................................................................72

Figure 3-21: Bypass Valve Assembly ..................................................................................73

ADT Option Air Connections ............................................................................................................ 73

Figure 3-22: ADT Option Panel Placard Layout Dimensions...............................................74

Figure 3-23: ADT Air Hose Connections, Part 1..................................................................74

Figure 3-24: ADT Option Air Hose Connections, Part 2 ...................................................... 75

3.5 System Plumbing Diagrams ........................................................................................... 77

Figure 3-25: Typical Single Foam Concentrate Tank ..........................................................78

Figure 3-26: Typical Single Foam Tank with MST and In-Line

Strainer/Valve Assembly................................................................................................. 79

Figure 3-27: Typical Single Foam Tank, with MST and FS Series Strainers....................... 80

Figure 3-28: Single Foam Tank with MST II and In-Line Strainer/Valve Assembly ............. 81

Figure 3-29: Typical Single Foam Tank with MST II and FS Series Strainers.....................82

Figure 3-30: Typical Single Foam Tank with ADT and In-Line

Strainer/Valve Assemblies.............................................................................................. 83

Figure 3-31: Typical Dual Foam Tanks, with ADT and FS Series Strainer Assemblies ...... 84

3.6 Electrical ........................................................................................................................... 85

Single and Dual Tank Electrical Harness Overview ........................................................................ 87

Figure 3-32: Single Tank Electrical Harness Overview .......................................................87

Figure 3-33: Dual Tank Electrical Harness Overview ..........................................................88

Control / Display Unit........................................................................................................................ 88

Figure 3-34: Control/Display Unit Mounting Dimensions ..................................................... 89

Figure 3-35: Distribution Box Connections .......................................................................... 90

Distribution Box Ground / Primary Power .........................................................................................90

RFI / EMI ..........................................................................................................................................91

Figure 3-36: Extra Cable Storage........................................................................................ 92

Flow Sensor Connections................................................................................................................. 92

“Low Level Sensor” Installation (Foam Tank)...................................................................................92

Figure 3-37: Low Level Sensor Mounting Options............................................................... 93

Figure 3-38: Side Mount Sensor Location Dimensions .......................................................93

Figure 3-39: Top Mount Sensor Dimensions ....................................................................... 95

Figure 3-40: Top Mount Low Level Sensor Assembly ......................................................... 97

6

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 7

Table of Contents ❑

Contents - continued Page

3.6 Electrical - continued

Low Level Sensor Wiring.................................................................................................................. 97

Remote Activation Switch Option .....................................................................................................99

Figure 3-41: Remote Activation Switch Installation Dimensions........................................100

3.7 Start Up Check List ........................................................................................................ 101

Electrical .........................................................................................................................................101

Liquid ..............................................................................................................................................102

Foam Pump .................................................................................................................................... 103

Optional ADT ..................................................................................................................................103

3.8 Installation and Delivery Check List............................................................................. 104

3.9 System Installer Start-UP .............................................................................................. 105

Initial System Power Check............................................................................................................105

Figure 3-43: Initial Start-Up, System Ready Displays........................................................105

System Operation Check................................................................................................................106

Figure 3-44: Simulated Flow Mode Display ....................................................................... 107

4 User Setup and Calibration ............................................................................... 109

4.1 Initial End User Setup .................................................................................................... 109

Figure 4-1: Initial Start-Up, System Ready Displays..........................................................109

System Power Check ..................................................................................................................... 109

Priming the Foam Pump.................................................................................................................110

Figure 4-2: Simulated Flow Mode Display .........................................................................110

4.2 User Calibration.............................................................................................................. 111

Entering Passwords........................................................................................................................112

Figure 4-3: Password Sequence ....................................................................................... 112

Restoring Factory Defaults ............................................................................................................. 113

Figure 4-4: Password and Calibration Modes - Display..................................................... 113

Calibration....................................................................................................................................... 113

Flow Sensor Calibration.................................................................................................................. 114

Figure 4-5: Flow Sensor Calibration - Display ...................................................................114

Record Calibration Factors ............................................................................................................. 115

Figure 4-6: Flow Sensor Calibration Factor.......................................................................115

Simulated Flow ...............................................................................................................................115

Figure 4-7: Simulated Flow Calibration..............................................................................115

Foam Concentrate Injection Rate...................................................................................................116

Figure 4-8: Foam Concentrate Injection Rate Default Value, Tank “A” Shown ................. 116

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

7

Page 8

❑ Table of Contents

Contents - continued Page

4.2 User Calibration - continued

Foam Pump Feedback Calibration ................................................................................................. 116

Figure 4-9: Foam Pump Feedback Calibration, Tank “A” Shown ...................................... 117

Figure 4-10: Foam Concentrate Collection........................................................................117

Figure 4-11: Feedback Calibration Factor, Tank “A” Shown .............................................118

Exit and Save Calibration ............................................................................................................... 118

Figure 4-12: Exit and Save Calibration .............................................................................. 119

Relief Valve ....................................................................................................................................119

Figure 4-13: Relief Valve ...................................................................................................119

English to Metric Units....................................................................................................................120

5 Operation ............................................................................................................. 121

5.1 Description ..................................................................................................................... 121

Figure 5-1: Control Unit Identification ................................................................................ 121

5.2 Control Display Unit ...................................................................................................... 122

Control Unit Functions ....................................................................................................................122

Figure 5-2: Function Modes............................................................................................... 123

5.3 Reset Functions ............................................................................................................. 124

5.4 Foam Concentrate Injection Rate................................................................................. 124

5.5 Flush ............................................................................................................................... 125

Figure 5-3: Flush................................................................................................................ 125

5.6 Warning Messages ........................................................................................................ 125

Low Foam Tank Level Message.....................................................................................................126

Figure 5-4: Low Foam Tank Message, Tank “A” Shown ................................................... 126

Priming Message............................................................................................................................126

High Ambient Temperature Message............................................................................................. 127

Figure 5-5: Priming, HIGH Temperature and LOW Battery Messages.............................. 127

5.7 Priming the Foam Pump................................................................................................ 128

5.8 Normal Operation Summary ........................................................................................ 129

Energize System....................................................................................................... 129

Select Foam Tank..................................................................................................... 129

Figure 5-6: Normal Operation Summary Chart..................................................................129

Begin Foam Injection. ............................................................................................... 130

Change Injection Rate. ............................................................................................. 130

Read Injection Rate. ................................................................................................. 130

8

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 9

Table of Contents ❑

Contents - continued Page

5.8 Normal Operation Summary - continued

Read Total Water or Foam Solution. ...................................................................... 130

Read Total Foam Concentrate .................................................................................. 131

Reset Totalized Values ............................................................................................. 131

End Foam Injection ................................................................................................... 131

5.9 Simulated Flow Mode Operation................................................................................... 131

Simulated Flow Sequence ............................................................................................................. 132

Figure 5-7: Simulated Flow Display Sequence ..................................................................132

5.10 Dual Tank System Selection ......................................................................................... 133

Figure 5-8: Dual Tank Selector Operating Positions .........................................................134

5.11 Flushing Hale FoamLogix.............................................................................................. 135

Figure 5-9: Hale MST Selector Operation .........................................................................136

5.12 Remote On/Off Switch Option....................................................................................... 137

To operate: .....................................................................................................................................137

Figure 5-10: Remote Activation Switch..............................................................................137

6 Maintenance ........................................................................................................ 139

6.1 Maintenance Procedures............................................................................................... 139

After each use.................................................................................................................................139

Monthly ...........................................................................................................................................139

Every Two (2) Months..................................................................................................................... 139

Annually .......................................................................................................................................... 139

7 Troubleshooting .................................................................................................. 141

7.1 User Diagnostics ............................................................................................................ 141

Figure 7-1: Distribution Box Overview ...............................................................................141

7.2 System Overview............................................................................................................ 142

Figure 7-2: FoamLogix, Closed Loop Flow Diagram ......................................................... 142

Distribution Box...............................................................................................................................143

Pump / Motor ..................................................................................................................................143

Bar Graph .......................................................................................................................................143

Summary ........................................................................................................................................ 144

7.3 Problem Isolation ........................................................................................................... 144

7.4 Flow Charts..................................................................................................................... 146

Chart 7-3: Hale FoamLogix System Troubleshooting Flow Chart...................................... 146

Chart 7-4: Power System Troubleshooting........................................................................ 147

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

9

Page 10

❑ Table of Contents

Contents - continued Page

Appendix A: Foam Concentrate Compatibility ............................................... 149

Chart A-1: Hale Class “A” Foam Concentrate Compatibility.............................................. 149

Chart A-2: Hale Class “B” Foam Concentrate Compatibility.............................................. 150

Reference ....................................................................................................................................... 151

Express Warranty................................................................................................153

8 Illustrated Parts Breakdown..............................................................................157

General............................................................................................................................ 157

Abbreviations ................................................................................................................. 157

8.1 Air Dual Tank Valve (ADT) Option ................................................................................ 158

8.2 Harness Components.................................................................................................... 160

8.3 Dual Foam Concentrate Tank Options......................................................................... 161

8.4 Single Foam Concentrate Tank Options ..................................................................... 162

8.5 Low Tank Level Sensor Options ................................................................................. 163

8.6 Flow Sensors.................................................................................................................. 164

8.7 Main Cable Harness, Single and Dual Tank ................................................................ 165

8.8 Check Valve Manifolds .................................................................................................. 166

8.9 Remote Activation Switch Option ............................................................................... 167

8.10 Check Valves, Flanges, Gaskets ................................................................................. 168

8.11 Elbows and Mini Manifolds .......................................................................................... 169

9 Plate Drawings..................................................................................................... 170

10

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 11

How to use this manual

This manual is divided into eight (8) sections for clarity and ease of use. Each of

the following sections can be stand alone or used in conjunction with each other.

1SAFETY

This section must be carefully read, understood and adhered to strictly by

all installer/builders, operators and service personnel using the Hale FoamLogix, Models 3.3, 5.0 and 6.5, Electronic Foam Proportioning System. Do

not use or install the system until you have thoroughly read this section.

Failure to comply could cause serious injury to yourself and others, or damage to the system.

How To Use This Manual ❑

2 INTRODUCTION

System overview provides an introduction to the Hale FoamLogix Proportioning System along with guidelines for designing and ordering a complete

system.

3 INSTALLATION

This section offers installer/builder installation procedures, plumbing overview diagrams, electrical installation and startup and delivery check lists, to

assist the OEM with installation and initial setup of Hale FoamLogix Proportioning System on an apparatus.

4 USER CALIBRATION

User calibration is used by the installer and the end user for start-up and

calibration of the Hale FoamLogix Proportioning System to produce the

proper foam flow.

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

11

Page 12

❑ How To Use This Manual

5 OPERATION

The Operation section primarily used by the apparatus user for proper operation and maintenance of the Hale FoamLogix Proportioning System. It is a

guide to the operation of the system and includes operating procedures for

the most commonly used options.

6 GENERAL MAINTENANCE

This section describes the routine inspection and maintenance requirements for the Hale FoamLogix System.

7 TROUBLESHOOTING

If a problem develops, see this section for troubleshooting procedures.

8 PARTS IDENTIFICATION

Section 8 includes a parts breakdown of the most commonly used parts of

the FoamLogix 3.3, 5.0 and 6.5 Systems. Also see Section 8, Parts Identification and Drawing Package, heading “Illustrated Parts Breakdown” on

page 157.

9 PLATE DRAWINGS

Section 9 includes a listing of required installation and parts identification

drawings for the FoamLogix 3.3, 5.0 and 6.5 Systems. Also see Section

Parts Identification and Drawing Package, heading “9 Plate Drawings” on

page 170.

12

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 13

1 Safety Precautions

THE HALE “FOAMLOGIX™” MODELS 3.3, 5.0 and 6.5 ELECTRONIC FOAM

PROPORTIONING SYSTEMS ARE DESIGNED FOR OPTIMUM SAFETY OF ITS

OPERATORS AND TO PROVIDE RELIABLE AND SAFE FOAM CONCENTRATE

INJECTION. FOR ADDED PROTECTION AND BEFORE ATTEMPTING INSTAL LATION OR OPERATION PLEASE FOLLOW THE SAFETY GUIDELINES LISTED

IN THIS SECTION. ADHERE TO ALL WARNING, DANGER, CAUTION AND

IMPORTANT NOTES FOUND WITHIN THIS GUIDE.

THIS SECTION ON SAFETY MUST BE CAREFULLY READ, UNDERSTOOD

AND ADHERED TO STRICTLY BY ALL INSTALLERS AND SYSTEM OPERATORS BEFORE ATTEMPTING TO INSTALL OR OPERATE THE FOAMLOGIX

FOAM PROPORTIONING SYSTEM.

WHEN DEVELOPING DEPAR TMENTAL APPARATUS OPERATING PROCEDURES, INCORPORATE THE WARNINGS AND CAUTIONS AS WRITTEN.

Safety Precautions ❑

IMPORTANT !

FoamLogix is a trademark of Hale Products, Incorporated. All other brand and

product names are the trademarks of their respective holders.

1.1 DEFINITIONS

DANGER – Immediate hazard which WILL result in severe personal injury

or death if the warning is ignored.

WARNING – Hazards or unsafe practices which COULD result in severe

personal injury or death if the warning is ignored.

DAN GER !

WARNING !

CAUTION – Hazards or unsafe practices which COULD result in minor or

moderate personal injury if the warning is ignored.

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

CAUTION !

13

Page 14

❑ Safety Precautions

NOTICE – Practices which could result in damage to the apparatus or other

property.

1.2 GUIDELINES

READ ALL INSTRUCTIONS THOROUGHLY BE FORE

BEGINNING ANY INSTAL LATION OR OPERATION PROCESS.

❑ Installation should be performed by a trained and qualified installer, or

your authorized Hale Products Service Representative.

❑ Be sure the installer has sufficient knowledge, experience and the proper

tools before attempting any installation.

❑ Make sure proper personal protective equipment is used when operating

or servicing the apparatus.

NOTICE !

❑ A foam tank low level sensor must be utilized to protect the Hale foam

proportioner from dry running. Failure to use a low level sensor with the

Hale Foam System voids warranty.

❑ DO NOT permanently remove or alter any guard or insulating devices, or

attempt to operate the system when these guards are removed.

Make sure all access/service panels and covers are installed, closed and

latched tight, where applicable.

❑ DO NOT remove or alter any hydraulic or pneumatic connections, electri-

cal devices, etc. DO NOT tamper with or disconnect safety features or

modify protective guards (such as covers or doors). DO NOT add or

remove structural parts. Doing so voids the warranty.

Any of the above could affect system capacity and/or safe operation of

the system and is a serious safety violation which could cause personal

injury, could weaken the construction of the system or could affect safe

operation of the FoamLogix Proportioning System.

WARNING !

NO MODIFICATIONS OR ADDITIONS MAY BE MADE TO THE FOAMLOGIX

PROPORTIONING SYSTEM WITHOUT PRIOR WRITTEN PERMISSION FROM:

14

Hale Products, Incorporated

Fire Suppression Division

700 Spring Mill Avenue

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 15

Safety Precautions ❑

Conshohocken, PA 19428

Telephone: .........610-825-6300

Fax: ....................610-825-6440

❑ To prevent electrical shock always disconnect the primary power source

before attempting to service any part of the Hale FoamLogix System.

❑ All electrical systems have the potential to cause sparks during service.

Take care to eliminate explosive or hazardous environments during service and/or repair.

❑ To prevent system damage or electrical shock the main power supply

wire is the last connection made to the Hale Foam Propor tioner Distribution Box.

❑ Release all pressure then drain all concentrate and water from the sys-

tem before servicing any of its component parts.

❑ Do not operate the system at pressures higher than the maximum rated

pressure.

❑ Use only pipe, hose, and fittings from the foam pump outlet to the injector

fitting, which are rated at or above the maximum pressure rating at which

the water pump system operates.

❑ Hale Foam proportioning systems are designed for use on negative

ground direct current electrical systems only.

❑ Do not mount radio transmitters or transmitter cables in direct or close

contact with the FoamLogix Control Unit.

❑ Before connecting the cord sets and wiring harnesses, inspect the seal

washer in the female connector.

If the seal washer is missing or damaged, water can enter the connector

causing corrosion. This could resulting in possible system failure.

❑ Always disconnect the power cable, ground straps, electrical wires and

control cables from the control unit or other Hale Foam system equipment before electric arc welding at any point on the apparatus

Failure to do so could result in a power surge through the unit that could

cause irreparable damage.

❑ DO NOT connect the main power lead to small leads that are supplying

some other device, such as a light bar or siren.

The Hale FoamLogix, Models 3.3, 5.0 and 6.5, require 60 AMP minimum current.

❑ When operating the Hale FoamLogix in Simulated Flow Mode, an outlet

for the foam concentrate must be provided to prevent excessive pressure

buildup in the discharge piping or hoses.

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

15

Page 16

❑ Safety Precautions

❑ Unless engaged in Class “B” foam operations, the air dual tank (ADT)

toggle switch, or the manual dual tank (MDT) II selector handle must be

in the TANK “A” or FLUSH position. If either is in the FLUSH position

when the foam system is started, the foam pump runs for approximately

twenty (20) seconds, then SHUTS DOWN.

❑ Make sure the foam tank and foam concentrate suction hoses are clean

before making final connections to the foam pump. If necessary flush the

tank and hoses prior to making connection.

❑ Check all hoses for weak or worn conditions after each use. Ensure that

all connections and fittings are tight and secure.

❑ Ensure that the electrical source of power for the unit is a negative (–)

ground DC system, of correct input voltage, with a reserve minimum current available to drive the system.

❑ The in-line strainer/valve assembly is a low pressure device and CAN-

NOT withstand flushing water pressure in excess of 45 PSI (3 BAR).

When installing the in-line strainer in systems equipped with the Hale

MDT II or MST, make sure the in-line strainer/valve assembly is installed

on the “inlet” side of the valve.

If the strainer is subjected to flushing water, install Hale FS Series

strainers.

❑ When determining the location of the Hale FoamLogix System compo-

nents keep in mind piping runs, cable routing and other interferences that

could hinder or interfere with proper system performance.

❑ Always position the check valve/injector fitting at a horizontal or higher

angle to allow water to drain away from the fitting. This avoids the possibility of sediment deposits or the formation of an ice plug.

❑ The cord sets provided with each Hale Foam system are 100% electri-

cally shielded assemblies.

NEVER attempt to shorten or lengthen the molded cables. If necessary,

order longer or shorter cord sets to suit your application needs.

❑ Each cord sets provided is indexed to ensure correct receptacle installa-

tion (they inser t one way only).

When making cord set connections DO NOT force mismatched connections as damage can result in improper system operation.

❑ Make sure all connections are sound, and that each connection is

correct.

❑ The cables shipped with each Hale Foam system are 100% tested at the

factory with the unit. Improper handling and forcing connections can

damage these cables which could result in other system damage.

16

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 17

Safety Precautions ❑

❑ There are no user serviceable parts inside Hale Foam system electrical/

electronic components.

Opening the distribution box, control unit, foam multiplexing display unit, etc., voids the warranty.

❑ Use mounting hardware that is compatible with all foam concentrates to

be used in the system. Use washers, lock washers and cap screws

made of brass or 300 series stainless steel.

❑ When making wire splice connections, make sure they are properly insu-

lated and sealed using an adhesive filled heat shrink tubing.

❑ ALWAYS connect the primary positive power lead from the terminal block

to the master switch terminal or the positive (+) battery terminal.

Use a minimum 4 AWG type SGX (SAE J1127) chemical resistant battery cable and protect with wire loom.

❑ Prevent corrosion of power and ground connections by sealing these

connections with the silicone sealant provided.

❑ Prevent possible short circuit by using the rubber boot provided to insu-

late the primary power connection at the Hale FoamLogix Distribution

Box.

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

17

Page 18

❑ Safety Precautions

Notes

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

18

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 19

1 System Overview

The Hale FoamLogix Models 3.3, 5.0 and 6.5 Foam Proportioning Systems are

completely engineered, factory matched foam proportioning systems that provide

reliable, consistent foam concentrate injection for Class “A” and Class “B” foam

operations.

Hale FoamLogix Foam Systems accurately deliver from 0.1% to 10.0% foam concentrate through a check valve/injector fitting, directly into the water discharge

stream. It is then fed as foam solution into a standard fog nozzle, an air aspirated

nozzle, or CAFS equipment, through the apparatus discharge piping. A properly

configured and installed foam system with Hale recommended components virtually eliminates contamination of the booster tank, fire pump and relief valve with

foam concentrate.

Introduction ❑

2.1 ROTARY GEAR PUMP

The hear t of the Hale FoamLogix 3.3, 5.0 and 6.5 systems is an electric

motor driven rotary gear pump. The pump is constructed of bronze and

stainless steel and is compatible with almost all foam concentrates. The

pump is close coupled to the electric motor thereby eliminating maintenance

of an oil-filled gearbox. A relief valve mounted on the foam pump and constructed of stainless steel, protects the foam pump and foam concentrate

discharge hoses from over pressurization and damage.

2.2 CONTROL UNIT

The control unit, mounted on the operator panel, is the single control point

for the FoamLogix system. Pressing the ON button starts foam concentrate

injection. A super bright digital LED display shows the:

❑ Water flow rate

❑ Total water flow

❑ Foam concentrate injection percentage

❑ Total foam concentrate used, depending on the display mode selected

A bar graph indicates the approximate system capacity being used. Adjustment of the foam concentrate injection rate is accomplished by pressing the

appropriate button while the system is operating.

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

19

Page 20

❑ Introduction

The control unit display also warns the operator if errors or abnormal operations occur in the system, such as low foam level.

2.3 WATER FLOW SENSOR

The foam concentrate injection rate is controlled by a computer chip in the

control unit for accurate, repeatable, reliable foam concentrate injection. A

water flow sensor constantly monitors water flow through the discharge piping. The information from the flow sensor is provided to the control unit by a

shielded cable. When the FoamLogix system is activated at the control unit

a signal is sent through the control cable to the distribution box to begin

foam concentrate injection. The distribution box then provides power to the

electric motor. As the motor rotates the pump, foam concentrate flows

through the foam pump discharge to the one piece check valve/injector fitting into the water discharge stream.

Note: All Hale FoamLogix Foam systems require a flow sensor for operation.

2.4 FEED BACK SENSOR

Injection

Rate

(Percent

%)

0.1 3,300 12,492 5,000 18,927

0.2 Not 6,245 2,500 9,464

0.3 1,100 4,164 1,667 6,310

0.5 660 2,498 1,000 3,785 1,300 4,921

1.0 330 1,249 500 1,893 650 2,461

3.0 110 416 167 632 216 818

6.0 55 208 83 314 108 409

GPM LPM GPM LPM GPM LPM

Table 2-1: Maximum Foam Solution Flows

A feedback sensor in the foam pump discharge measures foam concentrate

flow. The water flow rate and foam concentrate flow rate are constantly

compared by the computer chip in the control unit.

Maximum Foam Solution Flows

Model 3.3 Model 5.0 Model 6.5

Not

Applicable

20

The motor speed is constantly adjusted to maintain the operator selected

foam concentrate injection rate. Since the system is flow based, injection

rate remains constant regardless of changes in system pressure or the

number of discharges that are open (within the limits of the system).

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 21

There are three models of Hale Foam systems covered by this manual. The

Hale FoamLogix Model 3.3 (3.3GPM / 12.5LPM), Model 5.0 (5.0GPM /

19LPM) and Model 6.5 (6.5GPM / 24.6LPM).

The maximum rated foam concentrate flow in gallons per minute is denoted

by the model number. Table 2-1: “Maximum Foam Solution Flows” on page

20 shows the system capacities at various foam concentrate injection rates

for each Hale FoamLogix Model.

The Hale FoamLogix 3.3, 5.0 and 6.5 system configuration is shown in Figure 2-2: “Foam Pump Installation Envelope Dimensions“ on page 25. Also

see Figure 2-3: “Foam Pump Installation Envelope Dimensions, ADT Option

Only” on page 26.

2.5 TANK SELECTOR VALVES

Selection of the desired foam concentrate tank with the ADT panel mounted

toggle switch or MDT II selector automatically changes the foam concentrate injection rate to the preset default rate for the selected foam tank. No

further operator intervention is required.

Introduction ❑

The ADT, MDT II and MST include the check valves and connection points

to provide foam pump flushing capabilities.

Air Dual Tank Selector (ADT)

The Air Dual Tank (ADT) valve is an air operated foam tank selector valve

that enables selection of foam concentrate dependent on fire ground operational demands.

The ADT is an integral par t of the foam pump and provides an electrical

interlock for the low tank level sensors and concentrate injection rate. A

panel mounted selector toggle switch with indicator lights controls foam concentrate tank selection and shows which foam concentrate tank is in use.

Manual Dual Tank Selector (MDT II)

The Manual Dual Tank (MDT II) selector valve is available for the Hale Foam

systems with dual tanks. The MDT II is a panel mounted, manually operated selector that provides selection of foam concentrate dependent on fire

ground operational demands.

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

21

Page 22

❑ Introduction

The MDT II also provides an electrical interlock for the low tank level sensors and concentrate injection rate. The MDT II is not suitable for top mount

operator panel installations and some side operator panels due to gravity

feed requirements of foam concentrate to the foam pump.

Manual Single Tank (MST)

Single tank foam systems can be configured with a Manual Single Tank

(MST) selector, which provides a flush function connection to the foam system electronic controls.

2.6 LOW PRESSURE STRAINER

A low pressure foam concentrate strainer is mounted at the inlet of the foam

pump. The strainer protects the pump from debris that might accumulate in

the foam concentrate tank. The strainer and valve assembly has a composite nonmetallic housing with stainless steel mesh strainer element and

includes a service shut-off valve and mounting bracket.

The assembly uses a 1-1/4” (32mm) NPT thread and is supplied with fittings

for connection of either 1-1/4” (32mm) ID, 1” (25mm) ID or 3/4” (19mm) ID

foam concentrate suction hose. The in-line strainer and valve assembly is

suitable for use with both Class “A” and Class “B” foam concentrates and is

designed for installations where the strainer is mounted in the foam pump

suction line.

The strainer and valve are low pressure devices and are designed for installations where the strainer IS NOT subject to HIGH pressure flushing water.

Hale FS Series Strainers

Hale FS series strainers (FS15 and FS25) are panel mounted with a 500

PSIG (34 BAR) pressure rating, suitable for use where flushing water pressure must pass through the strainer.

The FS15 strainer uses 3/4” (19mm) NPT connection ports and a 1-1/2”

NST cap. It is suitable for use with Class “A” and low viscosity Class “B”

foam concentrates.

The FS25 strainer uses 1” (25mm) NPT connection ports and a 2-1/2” NST

cap. It is suitable for use with both Class “A” and Class “B” foam

concentrates.

22

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 23

Introduction ❑

2.7 ORDERING INFORMATION

Use the current Hale FoamLogix Foam System Price List and Order Form to

help ensure a complete matched system is provided to the end user.

Use the following procedure when ordering a Hale FoamLogix Foam System. Follow all steps to ensure that a complete system is ordered:

1. Check Hale Foam system product information update (Bulletin #961) for

the latest information and advice for foam system selection. A copy of

Bulletin #961 is located at the back of this manual.

2. Determine the type of foam concentrate being used in the system and

ensure system compatibility by referring to the Hale Foam Concentrate

Compatibility Char t. Also see Heading “Appendix A: Foam Concentrate

Compatibility” on page 149.

3. Determine the Hale Foam system needed.

❑ Model 6.5 (24VDC motor only)

❑ Model 5.0

❑ Model 3.3

❑ 12 VDC

❑ 24 VDC motor

4. Determine tank selector needed based on the number of foam concentrate tanks installed.

❑ ADT........... for dual tank systems

❑ MDT II ....... for dual tank systems (not available for model 6.5)

❑ MST .......... for single tank systems

❑ No Select .. for single tank systems –

System installer/builder must provide flushing water connection to the

foa m pump.

5. Determine strainers needed.

❑ In-line Strainer and Valve Assembly

❑ FS 15 Strainer

❑ FS 25 Strainer

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

23

Page 24

❑ Introduction

6. Determine the low tank level sensors needed.

❑ Side Mount

❑ Bottom Mount

❑ Top Mount Assembly

7. Select the flow sensor, then the mounting weld fitting or saddle clamp

based on discharge pipe size.

8. Select harness length.

❑ 10 feet flow sensor x 15 feet controller

❑ 15 feet flow sensor x 20 feet controller

9. Additional Hale components available to enhance system operation and

ease installation include:

❑ Waterway Check Valves

❑ Manifolds

❑ Flanges

❑ Foam Tanks, etc.

10. Components shown in bold type represent the best value performance

system. All components listed have been engineered and tested with

Hale foam systems to provide optimum system performance. Using the

information provided and the detailed ordering procedures on the option

order form ensures a complete Hale foam system is ordered, thus eliminating delays caused by missing components.

11. System components are shown in the following heading “Hale Foam

System Specifications.”

2.8 HALE FOAM SYSTEM SPECIFICATIONS

(See Figure 2-2: “Foam Pump Installation Envelope Dimensions,” on page

25.) Also see Figure 2-3: “Foam Pump Installation Envelope Dimensions,

ADT Option Only” on page 26.

24

Foam Pump ....................................... Rotary Gear Positive Displacement

Rated Foam Concentrate Output

Model 3.3 ......................................................................3.3 GPM (13 LPM)

Model 5.0 ......................................................................5.0 GPM (19 LPM)

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 25

Introduction ❑

Rated Foam Concentrate Output - continued

Model 6.5 ...................................................................... 6.5 GPM (25 LPM)

Maximum System Operating Pressure

Model 3.3 ....................................................................... 350 PSI (24 BAR)

Model 5.0 ....................................................................... 200 PSI (14 BAR)

Model 6.5 ....................................................................... 200 PSI (14 BAR)

Maximum Operating Temperature.................................... 160° F (71° C)

Pump Motor

Standard - Models 3.3 and 5.0 ........................... 3/4 HP (0.6 kW), 12 VDC

Standard - Model 6.5 .......................................1-1/4 HP (0.9 kW), 24 VDC

Optional .............................................................. 3/4 HP (0.6 kW), 24 VDC

Operating Ampere Draw...... 30 AMPS at 12 VDC (15 AMPS at 24 VDC)

Maximum Ampere Draw ...... 60 AMPS at 12 VDC (30 AMPS at 24 VDC)

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Figure 2-2: Foam Pump Installation Envelope Dimensions

(Configured for use with MDT II, MST or No Tank Selection Options.)

25

Page 26

❑ Introduction

26

Figure 2-3: Foam Pump Installation Envelope Dimensions, ADT Option Only

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 27

2.9 SYSTEM CONFIGURATION

Hale Foam Proportioner System, Models 3.3, 5.0 or 6.5

All Hale Foam systems include a: Foam Pump/Motor Assembly, Control

Unit, Main Harness and Check Valve/Injector Fitting. Also see Section 8

“Illustrated Parts Breakdown” on page 157.

Introduction ❑

Foam Pump/Motor Assembly

(Shown with Bypass Valve when configured

for MDT II, MST or No Tank Selector Option)

Check Valve/Injector Fitting

p/n: 038-1790-00-0

Control Unit

p/n: 111530

FoamLogix Model Part Number

Model 6.5, with 24VDC Motor 501-4480-04-0

Model 5.0, with 12VDC Motor 501-3130-04-0

Model 5.0 with 24VDC Motor 501-3130-03-0

Model 3.3 with 12VDC Motor 501-3120-03-0

Model 3.3 with 24VDC Motor 501-3120-04-0

Figure 2-4: FoamLogix Available Models

Figure 2-5: Hale Foam Proportioner Systems, Models 3.3, 5.0 and 6.5

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

27

Page 28

❑ Introduction

2.10 CABLE HARNESS

For cable harness overviews, see Section “ 9 Plate Drawings,” beginning on

page 170. Also see Figure 2-6: “Power Connection Wire Harness” on page

28.

p/n: 113436 ...Control Head Harness, 10’ x 4’ (3.1 x 1.2 m)

10’ - Flow Sensor x 4’ - Motor Control

p/n: 113438 ...Control Head Harness, 10’ x 14’ (3.1 x 4.3 m)

10’ - Flow Sensor x 14’ - Motor Control

p/n: 113439 ...Control Head Harness, 15’ x 19’ (4.6 x 5.8 m)

15’ - Flow Sensor x 19’ - Motor Control

p/n: 113437 ...Control Head Harness, 32” x 5.5’ (0.81 x 1.7 m)

32” - Flow Sensor x 5.5’ - Motor Control

p/n: 113434 ...Single Tank Moto Control

p/n: 113435 ...Dual Tank Motor Control

p/n: 113437 ...Control Head Harness, 32” x 5.5’ (0.81 x 1.7 m)

32” - Flow Sensor x 5.5’ - Motor Control

p/n: 113437 ...Control Head Harness, 32” x 5.5’ (0.81 x 1.7 m)

32” - Flow Sensor x 5.5’ - Motor Control

Figure 2-6: Power Connection Wire Harness

28

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 29

Introduction ❑

2.11 DUAL FOAM CONCENTRATE TANK SYSTEM OPTIONS

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Figure 2-7: Dual Tank Foam Concentrate Tank System Options

29

Page 30

❑ Introduction

2.12 DUAL FOAM CONCENTRATE TANK OPTIONS

30

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 31

2.13 SINGLE FOAM CONCENTRATE TANK OPTIONS

Introduction ❑

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

31

Page 32

❑ Introduction

2.14 STRAINER OPTIONS

Note: For Hale FS Series Strainers,

use when Strainer is subjected to

flushing water pressure.

Also see Figure

3-14: “In-Line

Strainer/Valve

Installation” on

page 67.

32

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 33

Introduction ❑

2.15 LOW TANK LEVEL SENSOR OPTIONS

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

33

Page 34

❑ Introduction

2.16 FLOW SENSORS

Each Hale foam system requires a flow sensor to operate. Pipe size must

be selected based on the minimum and maximum water flow in the foam

capable discharge. Following is a list of pipe size and rated flow ranges

along with flow sensor saddle clamp part numbers. In all instances a weld

fitting may be substituted for the saddle clamp.

Pipe Size

1½” (38mm) 10 - 330 38 - 1,249

2” (50mm) 20 - 550 76 - 2,082

2½” (64mm) 30 - 800 114 - 3,028

3” (76mm) 50 - 1,250 189 - 4,732

4” (102mm) 75 - 1,800 284 - 6,814

SCV or DCV 30 - 750 114 - 2,839

Flow Range

GPM LPM

34

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 35

2.17 CHECK VALVE MANIFOLDS

The check valve manifolds include flow sensors, check valve/injector fittings

and single or dual waterway check valve flappers. End connections for the

manifolds are 3” (76mm) Vitaulic.

Introduction ❑

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

35

Page 36

❑ Introduction

2.18 REMOTE ACTIVATION SWITCH OPTION

36

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 37

Introduction ❑

2.19 CHECK VALVES, FLANGES, GASKETS

Threads Part Number

3” (76mm) 115-0080-00-0

2-1/2” (64mm) 115-0070-00-0

2” (51mm) 115-0060-00-0

Blank 115-0050-00-0

Threads Part Number

4” (102mm) 115-0040-00-0

3” (76mm) 115-0030-00-0

2-1/2” (64mm) 115-0020-00-0

Blank 115-0010-00-0

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

37

Page 38

❑ Introduction

2.20 ELBOWS AND MINI MANIFOLDS

38

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 39

System Layout ❑

2.21 HALE FOAM SYSTEM LAYOUT DRAWINGS

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Figure 2-10: Typical Single Foam Concentrate Tank

39

Page 40

❑ System Layout

40

Figure 2-11: Single Foam Tank with MST and In-Line Strainer/Valve Assembly

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 41

System Layout ❑

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Figure 2-12: Single Foam Tank with MST and FS Series Strainers

41

Page 42

❑ System Layout

Figure 2-13: Dual Foam Concentrate Tanks, with MDT II and In-Line Strainer/Valve Assembly

42

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 43

System Layout ❑

Figure 2-14: Dual Foam Concentrate with MDT II and FS Series Strainer Assembly

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

43

Page 44

❑ System Layout

Figure 2-15: Dual Foam Concentrate Tanks, with ADT and In-Line Strainer/Valve Assemblies

44

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 45

System Layout ❑

Figure 2-16: Dual Foam Concentrate Tanks with ADT and FS Series Strainer Assemblies

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

45

Page 46

❑ System Layout

Notes

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

46

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 47

3 Installation

Carefully review the procedures that follow to ensure the system is properly

designed. This section lists components that have been tested with Hale FoamLogix and provide the best system performance. Using the recommended materials and specified parts ensures a virtually maintenance free installation.

Differences in apparatus plumbing and foam system configuration make it impractical to show exactly how the Hale FoamLogix 3.3, 5.0 or 6.5 system is installed on a

particular apparatus. The information contained in this section applies to most situations and should be used when designing and installing a Hale FoamLogix 3.3,

5.0 or 6.5 system. System plumbing and electrical diagrams are provided to assist

with installation.

Before proceeding with system installation, carefully review the procedures that follow to ensure the system is properly designed.

Installer Installation ❑

The Hale FoamLogix system is supplied with six major components that must be

located on the apparatus.

❑ Foam pump and motor assembly

❑ Control unit

❑ In-Line foam strainer/valve assembly

❑ Instruction/system diagram placard

❑ Flow Sensor

❑ Check valve injector fitting

Notes: The flow sensor and check valve injector fitting may be pre-mounted, if a

manifold or pre-configured package is ordered.

Optional components that require mounting on the apparatus include:

❑ ADT operating switch and indicator lights

❑ Flanged elbows

❑ Foam tank(s)

❑ FS-15 or FS-25 panel mounted foam strainers

❑ Manual “dual” tank (MDT II) selector valve

❑ Manual “single” tank (MST) selector valve

❑ Mini Manifold

❑ Remote activation switch

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

47

Page 48

❑ Installer Installation

IMPORTANT !

WHEN DETERMINING THE LOCATION OF THE HALE FOAMLOGIX COMPONENTS BEING INSTALLED KEEP IN MIND PIPING RUNS, CABLE ROUTING

AND OTHER INTERFERENCES THAT COULD HINDER OR INTERFERE WITH

PROPER SYSTEM PERFORMANCE.

3.1 FOAM PUMP AND MOTOR ASSEMBLY

Ideally, the foam pump and motor assembly should be located in an area

that is protected from road debris and excessive heat buildup. The back of

a compartment or a compartment shelf is often an ideal location. The foam

system master power switch and bypass valve are located on the foam

pump and motor assembly. Access to these components must be

provided.

The foam pump and motor assembly must be mounted below the discharge

of the foam tank(s) to provide for gravity feed to the foam pump. The foam

tank(s) must be located where refilling can be easily accomplished with 5

gallon (19 liter) pails and other methods suitable to the end user. Most

water tank manufacturers build the foam tank into the booster tank.

When specifying a foam tank(s), make sure provisions are made for:

❑ Installation of the low tank level sensor

❑ Foam suction connections

❑ Tank drainage

❑ Proper fill openings, per NFPA requirements

In addition, a foam tank refill system may be required. See Hale EZFill

Foam Tank Refill System for these installation requirements.

3.2 FOAM CONCENTRATE STRAINER

Determine a location on the apparatus to mount the foam strainer.

CAUTION !

THE IN-LINE STRAINER/VALVE ASSEMBLY IS A LOW PRESSURE DEVICE

THAT WILL NOT WITHSTAND FLUSHING WATER PRESSURE. WHEN

INSTALLING THE IN-LINE STRAINER IN SYSTEMS EQUIPPED WITH HALE

“MDT II” OR HALE “MST,” MAKE SURE THE IN-LINE STRAINER/VALVE

ASSEMBLY IS IN THE HOSE ON THE INLET SIDE OF THE VALVE.

48

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Page 49

Installer Installation ❑

CAUTION ! - continued

IF THE STRAINER IS SUBJECT TO FLUSHING WATER PRESSURE, USE

HALE “FS” SERIES STRAINERS.

Mount the in-line foam strainer/valve assembly in the foam concentrate

hose from the foam tank to the foam pump suction connection, ADT, MDT II

or MST.

If panel mounted FS series strainers are installed, mount the strainer in the

foam concentrate hose that supplies concentrate to the ADT, MDT II or

MST. The FS series strainer may also be mounted in the outlet hose of the

MDT II or MST.

IMPORTANT !

WHEN DETERMINING THE STRAINER LOCATION KEEP IN MIND THE

REQUIREMENT FOR GRAVITY FEED OF FOAM CONCENTRATE TO THE

FOAM PUMP THROUGH THE STRAINER AND AVOID AIR TRAPS IN THE

HOSES. ALSO, CLEARANCE MUST BE PROVIDED TO ALLOW REMOVAL OF

THE BOWL ASSEMBLY TO CLEAN THE STAINLESS STEEL MESH, TO MAKE

HOSE CONNECTIONS TO THE STRAINER AND FOR OPERATION OF THE

SERVICE VALVE.