TECHNICAL MANUAL

FOR HALE

SINGLE STAGE BOOSTER PUMPS

BY

HALE PRODUCTS, INC.

A Unit of IDEX Corporation

607 NW 27th Ave, Ocala, FL 34475

(800) 533.3569

(800) 520.3473 (FAX)

www.haleproducts.com

MANUAL P/N FSG–MNL–00184 REV A

COPYRIGHT © 2002 – 2018 BY HALE PRODUCTS, INC. ALL RIGHTS RESERVED

TABLE OF CONTENTS

Section Title Page

1. SAFETY ............................................................................................................................................. 1

1.1. PPE ............................................................................................................................................ 1

1.2. Environmental Protection ........................................................................................................ 1

1.3. Training ..................................................................................................................................... 2

1.4. Safety Summary ....................................................................................................................... 2

2. INTRODUCTION................................................................................................................................ 7

2.1. Overview .................................................................................................................................... 7

2.2. How To Use This Manual .......................................................................................................... 7

2.3. Pump Specifications And Numbering ...................................................................................... 8

2.4. Principles Of Operation ............................................................................................................ 8

2.4.1 Explanation Of Terms ......................................................................................................... 9

2.4.1.1 Atmospheric Pressure (Static Air Pressure) ............................................................... 9

2.4.1.2 Cavitation .................................................................................................................. 10

2.4.1.3 Dead Heading ........................................................................................................... 10

2.4.1.4 Impeller And Clearance Rings ................................................................................. 10

2.4.1.5 Priming Pump ........................................................................................................... 10

2.4.1.6 Relief Valve ............................................................................................................... 10

2.4.1.7 PM Relief Valve Control ............................................................................................ 11

2.4.1.8 Volute ........................................................................................................................ 11

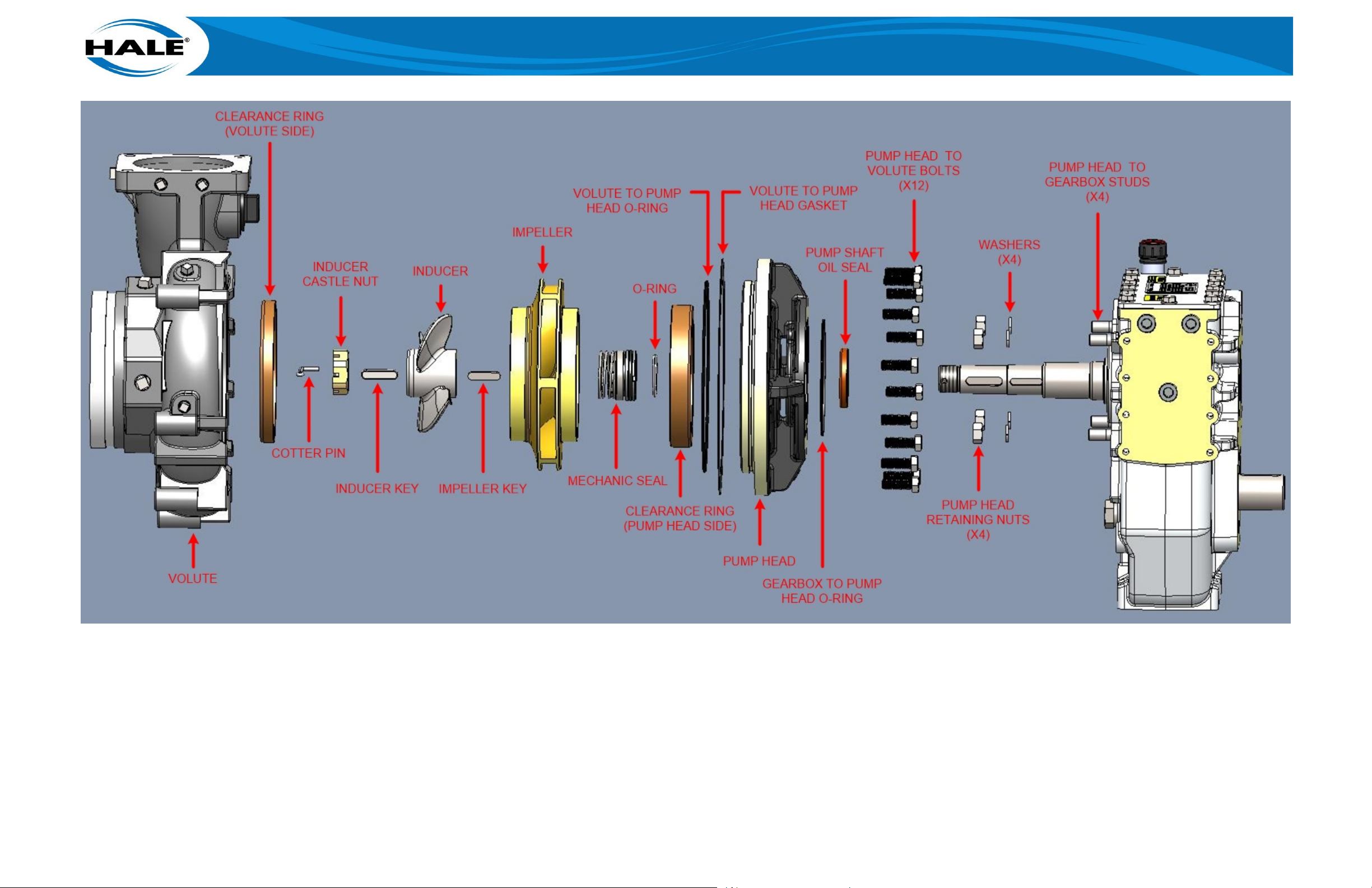

2.4.2 Standard Booster Pump Components ............................................................................ 11

2.4.2.1 Volute

2.4.2.2 Impeller And Shaft Assembly ................................................................................... 12

2.4.2.3 Mechanical Seal ....................................................................................................... 12

2.4.2.4 Gearbox ..................................................................................................................... 13

........................................................................................................................ 12

2.5. Pump Drives ........................................................................................................................... 13

2.6. Optional Pump Components ................................................................................................. 14

2.6.1 Anodes ............................................................................................................................. 14

2.6.2 TRVs ................................................................................................................................. 15

i

TABLE OF CONTENTS – CONTINUED

Section Title Page

3. MAINTENANCE OPERATING PROCEDURES ................................................................................. 17

3.1. Repair Verification Operations .............................................................................................. 18

3.2. Vacuum Test ........................................................................................................................... 20

3.3. Pressure Test ......................................................................................................................... 22

3.4. Pumping From Draft Verification Operations ....................................................................... 23

3.4.1 Draft Limiting Factors ....................................................................................................... 25

3.5. Cavitation (Details) ................................................................................................................. 26

3.5.1 Process Of Cavitation ...................................................................................................... 26

3.5.2 Warning Signs Of Cavitation ........................................................................................... 27

3.5.2.1 Discharge Pressure ................................................................................................... 27

3.5.2.2 Vacuum Compound Gauge....................................................................................... 27

3.5.3 How To Prevent Cavitation .............................................................................................. 27

3.5.3.1 General Considerations ............................................................................................ 28

3.5.3.2 During Operations ..................................................................................................... 29

3.6. Post Operation Procedure ....................................................................................................... 30

4. PREVENTIVE MAINTENANCE ......................................................................................................... 31

4.1. Preventive Maintenance Plan And Schedule ....................................................................... 31

4.2. Maintenance Log ................................................................................................................... 33

4.3. Extreme Conditions Maintenance Guidelines ...................................................................... 34

4.3.1 Freezing Weather ............................................................................................................ 34

4.3.2 Contaminated Water ................................................................................................

4.4. Booster Pump Preventive Maintenance Procedures ........................................................... 35

4.4.1 After Each Use (Flush Pump) .......................................................................................... 35

4.4.2 Leakage Checks .............................................................................................................. 35

4.4.3 Quarterly Maintenance.................................................................................................... 36

....... 35

4.4.3.1 Check Gearbox Oil Level ........................................................................................... 36

4.4.3.2 Perform Vacuum Test ............................................................................................... 37

4.4.4 Annual Pump Maintenance ............................................................................................ 38

4.4.4.1 Performance Testing ................................................................................................. 38

4.4.4.1.1 Testing Overview ................................................................................................. 38

ii

TABLE OF CONTENTS – CONTINUED

Section Title Page

4.4.4.1.2 Testing Equipment And Materials ..................................................................... 38

4.4.4.1.3 Performance Testing Test Procedure ............................................................... 41

4.4.5 Annual Pump Maintenance ............................................................................................ 41

4.4.6 Triennium Pump Maintenance ....................................................................................... 42

4.4.6.1 Gearbox Fluid Change .............................................................................................. 42

5. CORRECTIVE MAINTENANCE (REPAIR) ....................................................................................... 43

5.1. Troubleshooting ..................................................................................................................... 43

5.1.1 PTO Or Pump Engagement Problems ............................................................................ 43

5.1.2 Pump Priming Problems ................................................................................................. 44

5.1.3 Insufficient Pump Capacity ............................................................................................. 45

5.1.4 Engine Speed Problems ................................................................................................. 45

5.1.5 Relief Valve Problems ..................................................................................................... 46

5.1.6 Gearbox Problems........................................................................................................... 46

5.1.7 Discharge Valve Problems .............................................................................................. 46

5.1.8 Cavitation......................................................................................................................... 47

5.2. Maintenance Level 1 ............................................................................................................. 48

5.3. Maintenance Level 2 ............................................................................................................. 48

5.4. Maintenance Level 3 ............................................................................................................. 48

5.5. Maintenance Impeller Renew ............................................................................................... 48

5.6. Miscellaneous Maintenance ................................................................................................. 49

5.7. General Repair Guidelines ................................................................................................

5.7.1 Match Mark Or Note Component Orientation ............................................................... 49

5.7.2 Recommended Lubricants ............................................................................................. 49

5.7.3 Cleaning And Lubrication Required For Mechanical Seal Installation ........................ 50

5.7.4 Replacement Fasteners ................................................................................................. 50

.... 49

5.7.5 Circlip/Snap Ring Installation ........................................................................................ 51

5.7.6 Thread Lock Or Sealant Compound ............................................................................... 51

5.7.7 Cleaning And Inspection Guidelines .............................................................................. 51

5.7.7.1 Recommended Cleaners ......................................................................................... 52

5.7.8 Repair Kits ....................................................................................................................... 52

iii

TABLE OF CONTENTS – CONTINUED

Section Title Page

5.7.9 Impeller Renew Kits ........................................................................................................ 52

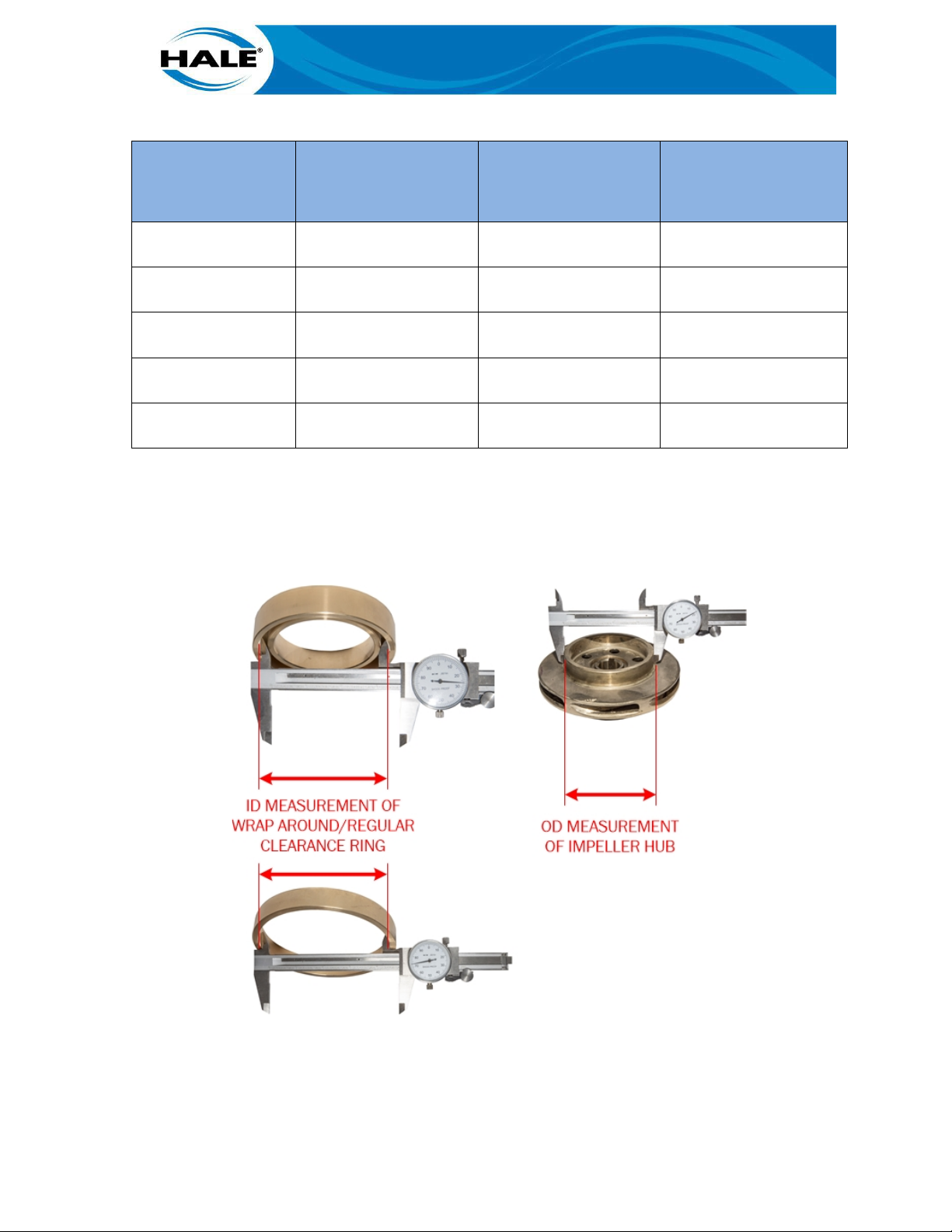

5.7.9.1 Worn Clearance Rings And Impeller Hubs............................................................... 52

5.8. Removal And Replacement Instruction Guidelines ............................................................. 54

5.8.1 Tools Required/Suggested ............................................................................................. 54

5.8.2 General Pump Disassembly For Access Guidelines ...................................................... 55

5.8.2.1 General Pump Removal From The Apparatus ......................................................... 56

5.8.3 General Pump Disassembly Methodology ...................................................................... 58

5.8.4 Level 1 Procedures .......................................................................................................... 67

5.8.4.1 RSD Suction Head R&R ............................................................................................ 67

5.8.4.2 RSD Volute R&R ........................................................................................................ 69

5.8.4.3 AP/MBP Volute R&R ................................................................................................. 72

5.8.4.4 CBP Volute R&R ........................................................................................................ 74

5.8.4.5 MBP/RSD Inducer R&R ............................................................................................ 76

5.8.4.6 MBP/RSD Impeller R&R ........................................................................................... 81

5.8.4.7 AP Impeller R&R ........................................................................................................ 83

5.8.4.8 CBP Impeller R&R ..................................................................................................... 87

5.8.4.9 AP/CBP/MBP Mechanical Seal R&R ....................................................................... 90

5.8.4.10 RSD Mechanical Seal R&R ....................................................................................... 93

5.8.4.11 AP/CBP/MBP Pump Head R&R ............................................................................... 96

5.8.4.12 RSD Pump Head R&R ............................................................................................... 98

5.8.4.13 Pump Head R&R Bench Procedures .................................................................... 102

5.8.4.13.1 Pump Shaft Oil Seal Bench Procedure........................................................... 102

5.8.4.13.2 RSD Mechanical Seal Anti Rotation Pin Bench Procedure ........................... 103

5.8.5 Level 2 Procedures ....................................................................................................... 105

5.8.6 Level 3 Procedures ....................................................................................................... 105

5.8.7 Miscellaneous Procedures ........................................................................................... 106

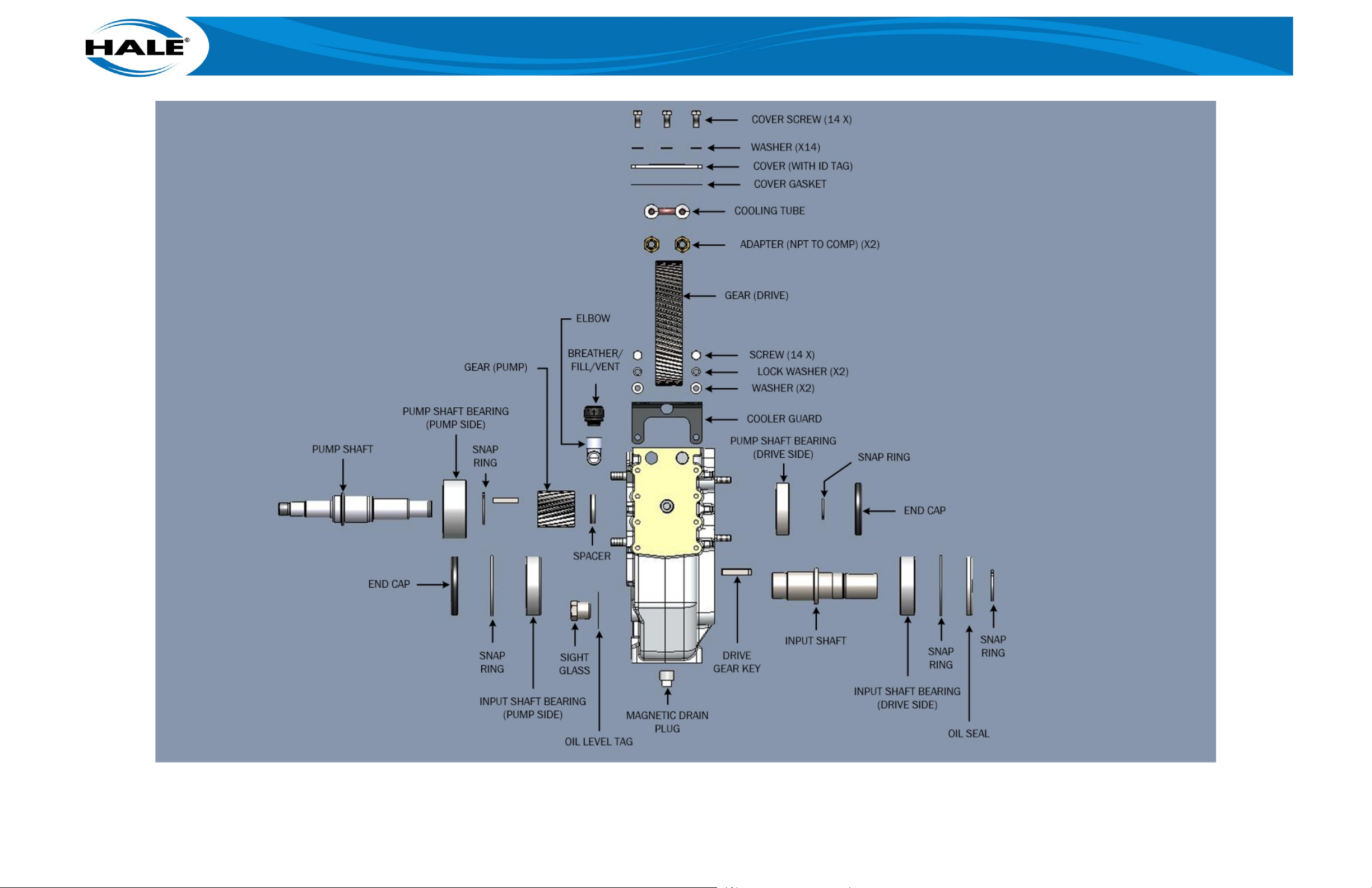

5.8.7.1 Cooling System ....................................................................................................... 106

5.8.7.1.1 Cooling Tube R&R ............................................................................................ 108

5.8.7.2 Pump Clearance Ring R&R .................................................................................... 110

5.8.8 General Install On The Apparatus ............................................................................... 117

iv

TABLE OF CONTENTS – CONTINUED

Section Title Page

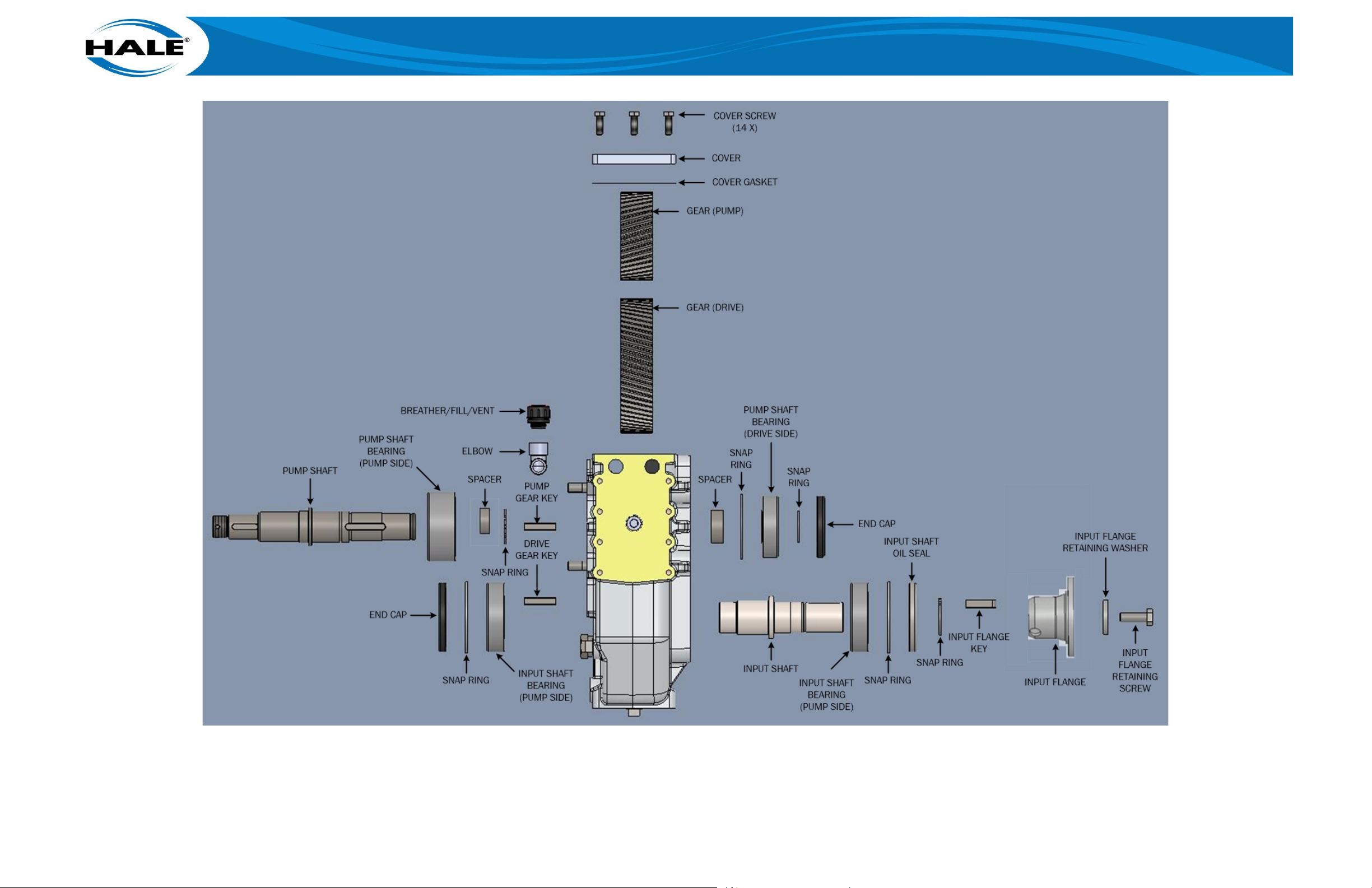

5.9. Gearbox ................................................................................................................................ 118

5.9.1 Gearbox R&R ................................................................................................................. 118

5.9.2 Gearbox Bench Procedures .......................................................................................... 120

5.9.2.1 Input Shaft .............................................................................................................. 121

5.9.2.1.1 Input Shaft Oil Seal (ONLY).............................................................................. 126

5.9.2.1.2 Input Shaft Bearings (ONLY) ........................................................................... 127

5.9.2.1.3 Input Shaft Endcap (ONLY) .............................................................................. 128

5.9.2.1.4 Drive Gear (Input Shaft) ................................................................................... 129

5.9.2.2 Pump Shaft ............................................................................................................. 131

5.9.2.2.1 Pump Shaft Bearings (ONLY) .......................................................................... 139

5.9.2.2.2 Pump Shaft Endcap (ONLY) ............................................................................. 139

5.9.2.2.3 Pump Gear (ONLY) ........................................................................................... 141

APPENDIX A. TIGHTENING (TORQUE) INFORMATION ................................................................ A–1

APPENDIX B. TEST EQUIPMENT AND SPECIAL TOOL INFORMATION ....................................... B–1

B.1. SPECIAL TOOL INFORMATION ............................................................................................. B–1

APPENDIX C. ANCILLARY PUMP EQUIPMENT ............................................................................ C–1

C.1. PRIMING SYSTEMS .............................................................................................................. C–1

C.1.1 Priming Pump ................................................................................................................ C–1

C.1.2 Priming Valves ............................................................................................................... C–2

C.2. TEMPERATURE CONTROL DEVICES .................................................................................... C–4

C.2.1 TRV ................................................................................................................................. C–4

C.2.2 TRV–L Kit ....................................................................................................................... C–4

C.3. ANCILLARY EQUIPMENT PREVENTIVE MAINTENANCE PROCEDURES ............................. C–5

C.3.1 Weekly Maintenance .................................................................................................... C–5

C.3.1.1 Pump Shift Warning Indicator Lights ..................................................................... C–5

C.3.1.2 Check Valves ........................................................................................................... C–5

C.3.1.3 Check And Clean Intake Strainers ......................................................................... C–5

C.3.1.4 Check All Gauges .................................................................................................... C–5

C.3.1.5 Check Pump Controls ............................................................................................. C–5

C.3.1.6 Inspect Water and Foam Tanks ............................................................................. C–5

v

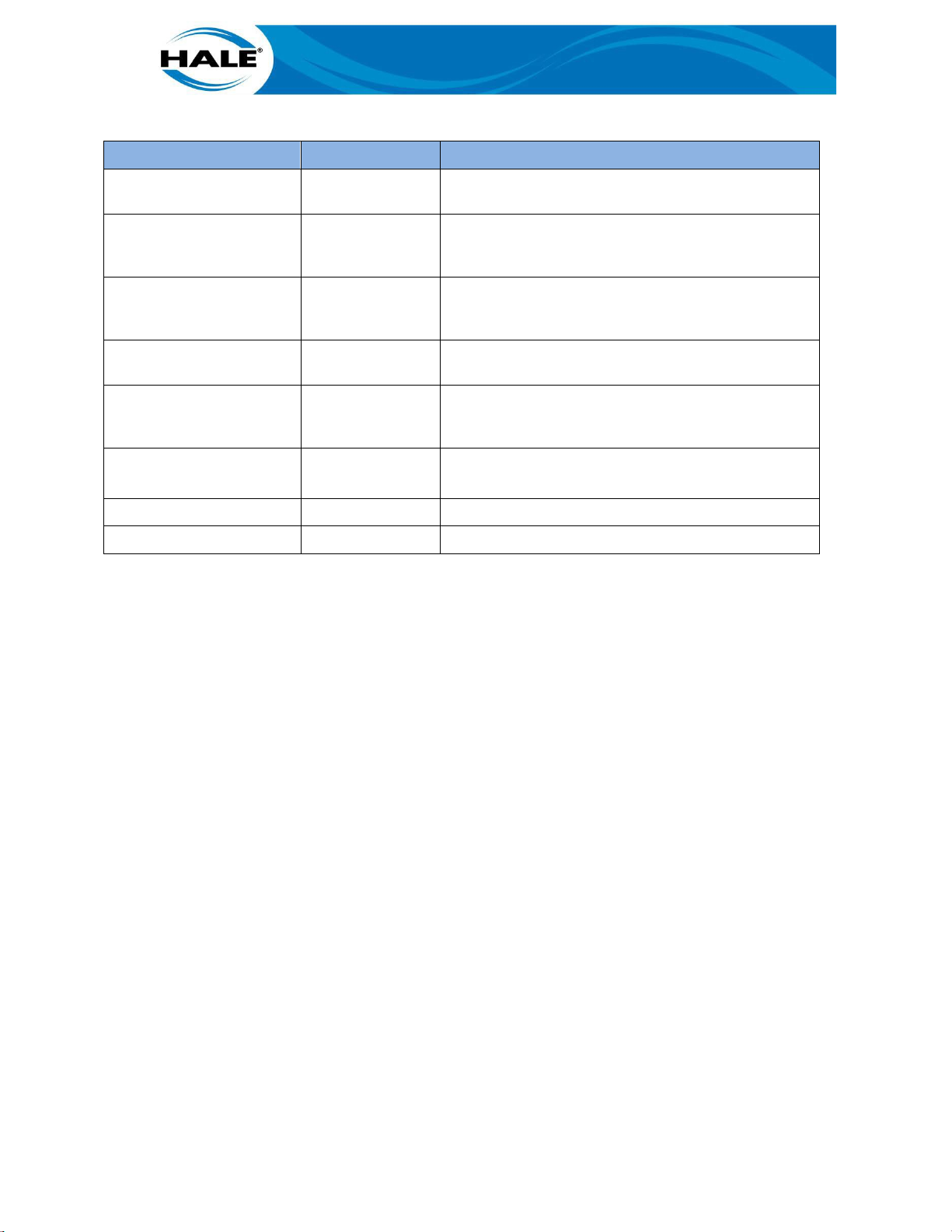

FSG–MNL–00184 REVISION HISTORY

CHANGE

DATE

AFFECTED PAGES

TABLE OF CONTENTS – CONTINUED

Section Title Page

C.3.1.7 Check Roof and Bumper Turrets ........................................................................... C–5

C.3.1.8 Check Auxiliary Fire Suppression Equipment ....................................................... C–6

C.3.2 Monthly Maintenance .................................................................................................. C–6

C.3.2.1 Priming System Test (Dry Vacuum Test) ............................................................... C–6

C.3.2.2 Drive Line And Flange Bolts .................................................................................. C–7

C.3.3 Annual Maintenance .................................................................................................... C–8

C.3.3.1 Check Drain Lines to Multi-Drain .......................................................................... C–8

C.3.3.2 Tank To Pump Flow Rate Test ............................................................................... C–8

C.3.3.3 ESP Primer Maintenance....................................................................................... C–9

APPENDIX D. OPERATOR MAINTENANCE LOG .......................................................................... D–1

APPENDIX E. MANUFACTURER'S INFORMATION ....................................................................... E–1

E.1. Manufacturer's Information ................................................................................................ E–1

E.2. Warranty ............................................................................................................................... E–1

E.3. Returned Goods Procedure ................................................................................................. E–1

Revision A 8 May 2019 All – Initial Release

vi

LIST OF FIGURES

Number Title Page

Figure 1. Centrifugal Force From A Rotating Disk ........................................................................... 8

Figure 2. Single Stage Water Flow ................................................................................................... 9

Figure 3. Clearance Ring Water Flow ............................................................................................ 10

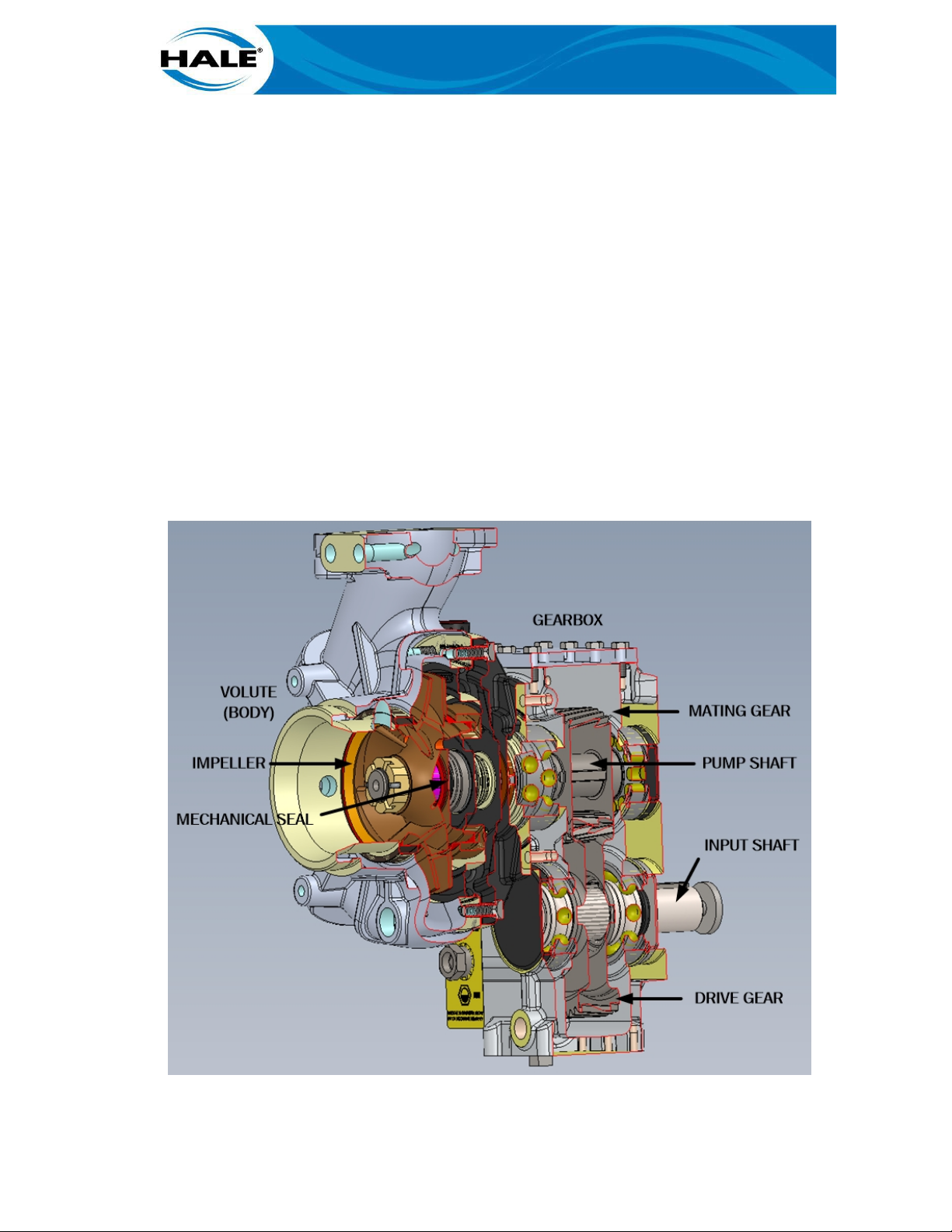

Figure 4. Parts Of The Hale Booster Pump ................................................................................... 11

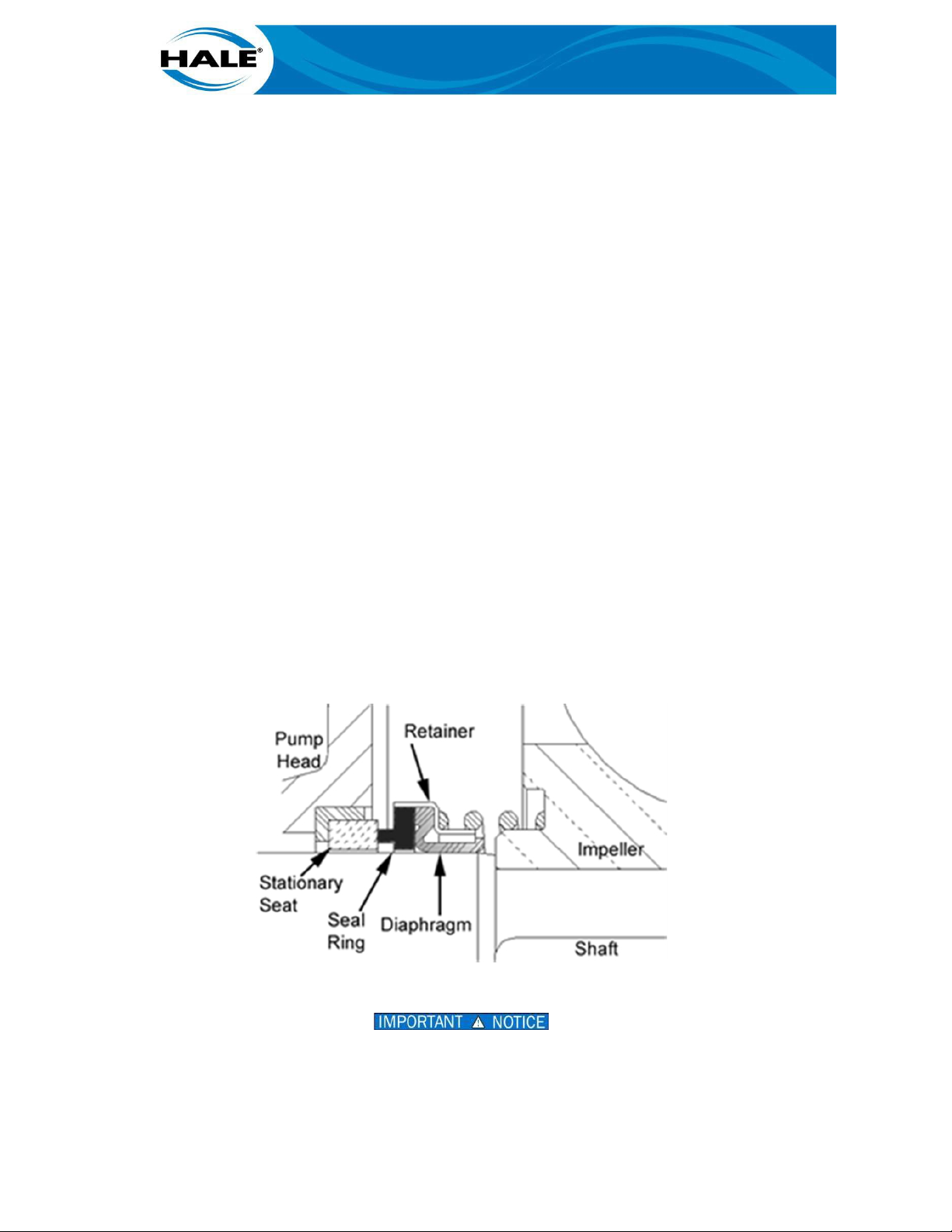

Figure 5. Mechanical Seal ............................................................................................................. 12

Figure 6. Direct Engine Mount ....................................................................................................... 14

Figure 7. Hale Anode ...................................................................................................................... 14

Figure 8. Driver Compartment Indicator Lights ............................................................................ 18

Figure 9. Pump Operator Panel ..................................................................................................... 19

Figure 10. Results Of Cavitation .................................................................................................. 26

Figure 11. Low Pressure Regions ................................................................................................ 27

Figure 12. Typical Gearbox Oil Fill/Level Component Locations ............................................... 36

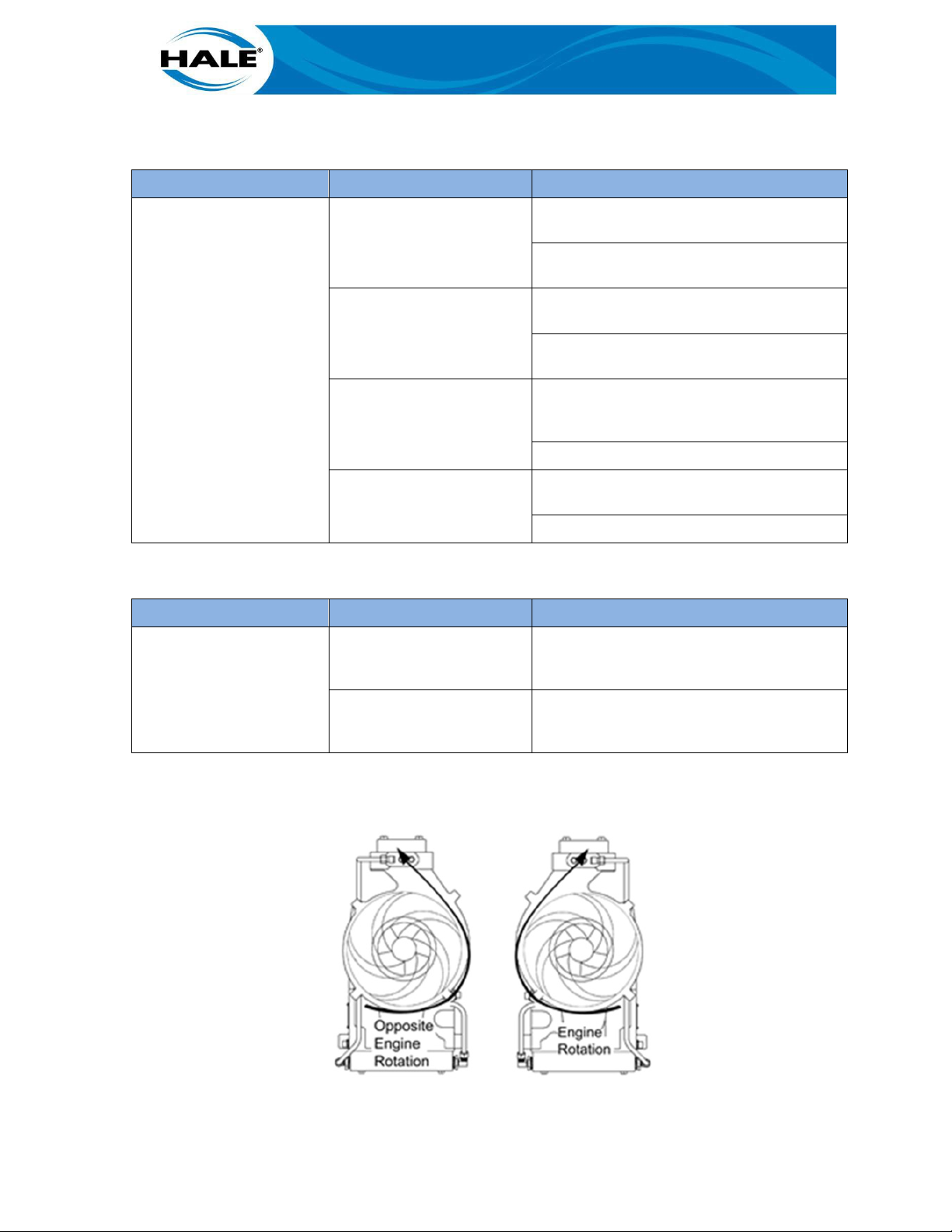

Figure 13. Engine Or Opposite Engine Rotation ......................................................................... 47

Figure 14. Circlips (How To Recognize And Remove Them) ...................................................... 51

Figure 15. Measuring For Worn Clearance Rings And Impeller Hubs ....................................... 53

Figure 16. Seal Removal Tool And Seal Driver Kit ...................................................................... 55

Figure 17. Caliper (Depth Rod Extended) ................................................................................... 55

Figure 18. Pump And Gearbox Assembly R&R ........................................................................... 57

Figure 19. One-Piece Volute (AP, CBP, MBP) .............................................................................. 59

Figure 20. Three-Piece Volute (RSD) ........................................................................................... 59

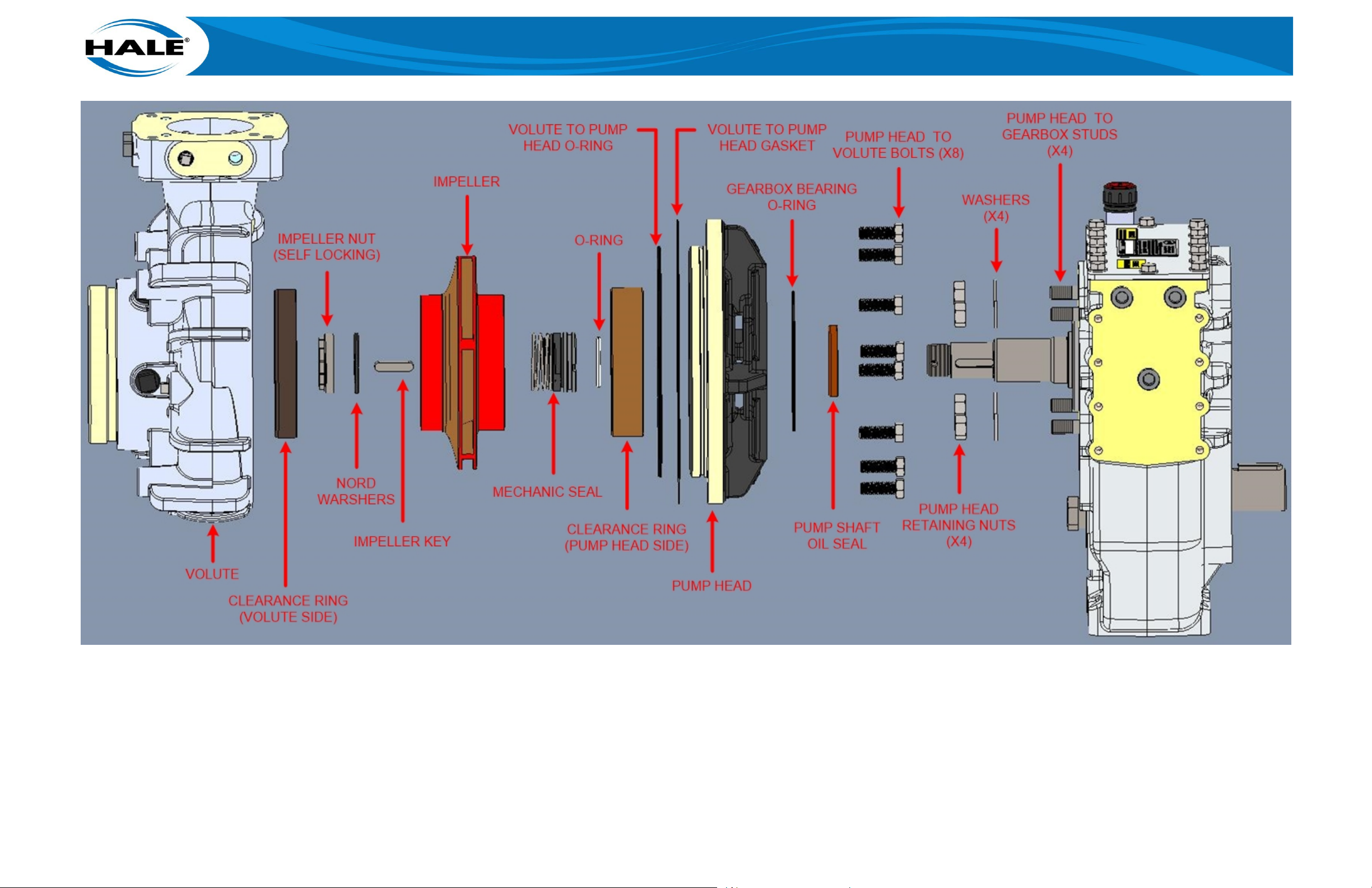

Figure 21. AP Pump Exploded View ............................................................................................. 61

Figure 22. CBP Pump Exploded View .......................................................................................... 62

Figure 23. MBP Pump Exploded View ......................................................................................... 63

Figure 24. RSD Pump Exploded View .......................................................................................... 64

Figure 25. Gearbox Exploded View (All Except 3.74:1 GR) ........................................................ 65

Figure 26. Gearbox Exploded View (3.74:1 GR) ......................................................................... 66

Figure 27. AP/MBP Volute R&R ................................................................................................... 72

Figure 28. MBP Inducer R&R ....................................................................................................... 77

Figure 29. RSD Inducer R&R ....................................................................................................... 77

Figure 30. MBP Impeller R&R ...................................................................................................... 82

Figure 31. AP Impeller R&R ......................................................................................................... 84

Figure 32. CBP Impeller R&R ....................................................................................................... 87

Figure 33. NORD-lock Washers Installation Details ................................................................... 89

Figure 34. Typical Mechanical Seal Detail .................................................................................. 91

Figure 35. RSD Mechanical Seal Notch ...................................................................................... 94

Figure 36. Align Slot On Seal With Pin In Pump Head ................................................................ 95

Figure 37. Pump Head (Pump Side) .......................................................................................... 100

Figure 38. Pump Head (Drive Side) ........................................................................................... 101

Figure 39. Slots Cut In Clearance Ring–Volute......................................................................... 111

Figure 40. Clearance Ring Driven Out–Volute .......................................................................... 111

vii

LIST OF FIGURES – CONTINUED

Number Title Page

Figure 41. Wrap Around Clearance Rings – Pump Heads ....................................................... 113

Figure 42. Clearance Ring Drilled Out (MPB Pump Head) ....................................................... 113

Figure 43. Clearance Ring Bent Inward And Cut Thru ............................................................. 113

Figure 44. Slots Cut In Clearance Ring - Suction Head ........................................................... 115

Figure 45. Clearance Ring Driven Out – Suction Head............................................................ 115

Figure 46. RSD Wrap Around Clearance Rings ........................................................................ 116

Figure 47. RSD Wrap Around Clearance Ring R & R ................................................................ 117

Figure 48. Pump Shaft Assembly .............................................................................................. 133

Figure 49. AP/CBP Pump Shaft ................................................................................................. 135

Figure 50. MBP/RSD Pump Shaft ............................................................................................. 136

Figure 51. Rotary Vane Positive Displacement Type Priming Pump ....................................... C–1

Figure 52. Rotor And Vanes ....................................................................................................... C–2

Figure 53. ESP Priming Pump ................................................................................................... C–2

Figure 54. PVG Priming Valve .................................................................................................... C–3

Figure 55. SPVR Priming Valve .................................................................................................. C–3

Figure 56. TRV ............................................................................................................................ C–4

Figure 57. TRV–L ........................................................................................................................ C–4

Figure 58. Engage Priming Pump .............................................................................................. C–6

Figure 59. Grade 8 Bolt Marking ............................................................................................... C–7

Figure 60. Class 10.9 Bolt Marking .......................................................................................... C–7

Figure 61. ESP Exploded View ................................................................................................... C–9

Figure 62. ESP-PVG Primer Repair Kit (P/N 546-1410-03-0) ............................................... C–10

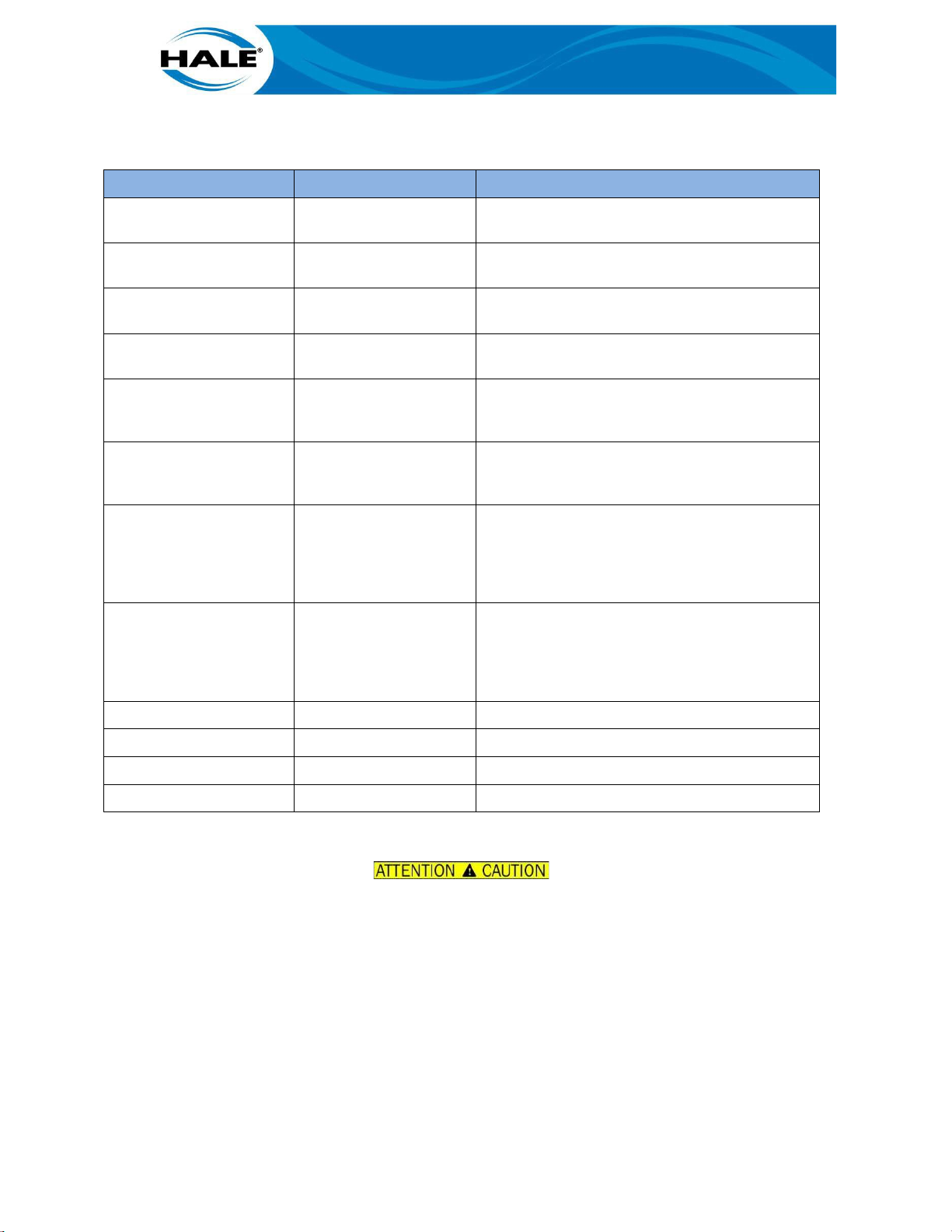

LIST OF TABLES

Number Title Page

Table 1. Vacuum Test Tools And Consumables List .................................................................... 20

Table 2. Pressure Test Tools And Consumables List .................................................................. 22

Table 3. Additional Losses Beyond NFPA Rating Baseline ......................................................... 25

Table 4. Hose Sizes For Pump Rating Capacity ........................................................................... 28

Table 5. Lift Loss From Barometric Pressure .............................................................................. 29

Table 6. Lift Loss From Elevation ................................................................................................. 29

Table 7. Recommended Preventive Maintenance – Pump ........................................................ 31

Table 8. Recommended Preventive Maintenance – Ancillary Equipment ................................. 32

Table 9. Example Performance Test ............................................................................................ 38

Table 10. Pressure And Flow For Various Size Nozzles ................................................................. 39

viii

LIST OF TABLES – CONTINUED

Number Title Page

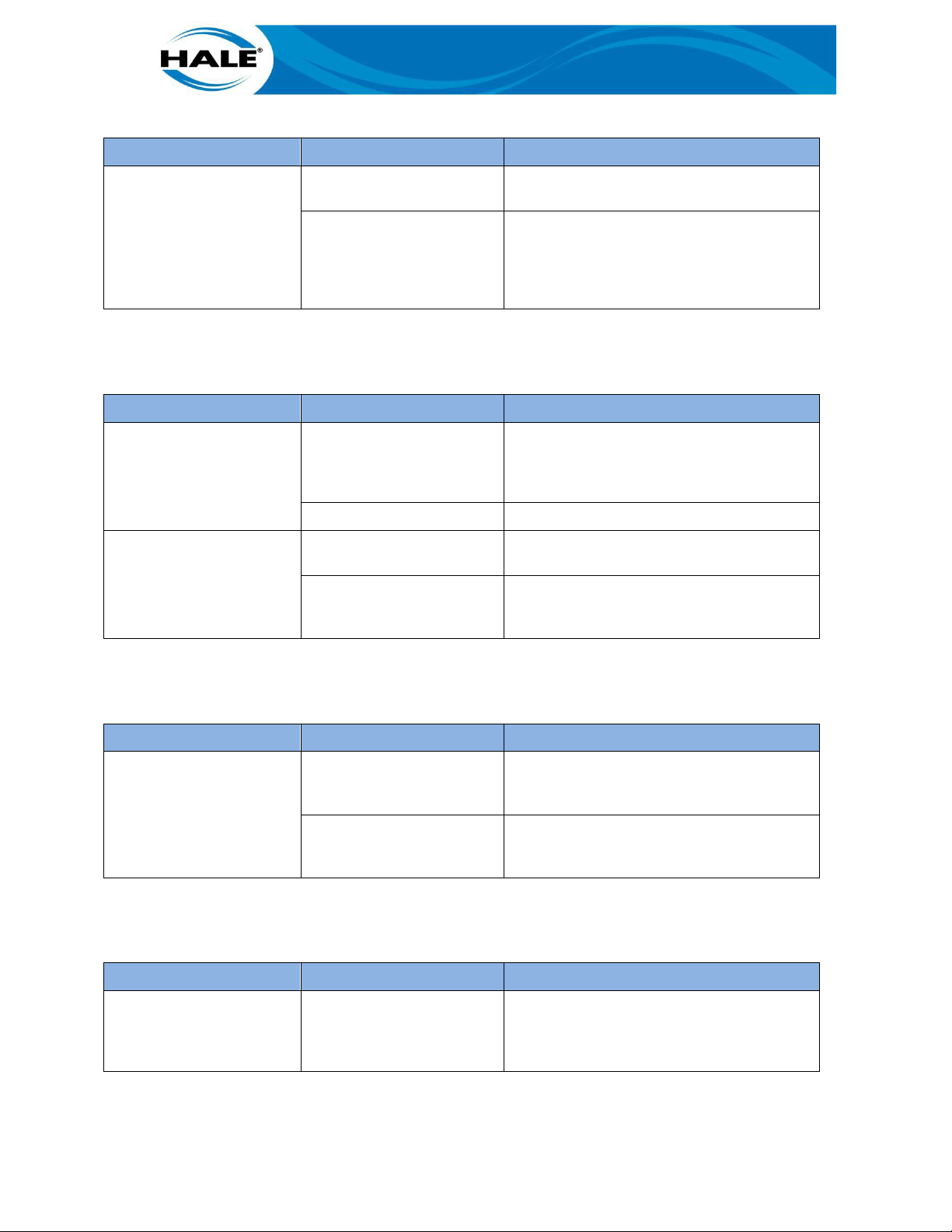

Table 11. Engagement SCR Table .................................................................................................. 43

Table 12. Pump Priming SCR Table ............................................................................................... 44

Table 13. Insufficient Pump Capacity SCR Table .......................................................................... 45

Table 14. Engine Speed SCR Table ................................................................................................ 45

Table 15. Relief Valve SCR Table ................................................................................................... 46

Table 16. Gearbox SCR Table ......................................................................................................... 46

Table 17. Discharge Valve(s) SCR Table ........................................................................................ 46

Table 18. Cavitation SCR Table ...................................................................................................... 47

Table 19. Rotation SCR Table ......................................................................................................... 47

Table 20. Recommended O-ring Lubricant .................................................................................... 49

Table 21. Recommended Mechanical Seal Lubricant .................................................................. 50

Table 22. Maximum Torque Values ............................................................................................... 50

Table 23. Impeller And Clearance Ring Diameters And Clearance Values.................................. 53

Table 24. Pump R&R From The Apparatus Tools And Consumables List .................................... 56

Table 25. RDS Suction Head R&R Tools And Consumables List .................................................. 67

Table 26. RSD Volute R&R Tools And Consumables List.............................................................. 70

Table 27. AP Volute R&R Tools And Consumables List ................................................................ 72

Table 28. CBP Volute R&R Tools And Consumables List .............................................................. 74

Table 29. MBP/RSD Inducer R&R Tools And Consumables List .................................................. 78

Table 30. MBP/RSD Impeller R&R Tools And Consumables List ................................................. 82

Table 31. AP Impeller R&R Tools And Consumables List ............................................................. 84

Table 32. CBP Impeller R&R Tools And Consumables List

Table 33. AP/CBP/MBP Mechanical Seal Bench Procedure Tools And Consumables List........ 90

Table 34. RSD Mechanical Seal Bench Procedure Tools And Consumables List ....................... 93

Table 35. AP/CBP/MBP Pump Head R&R Tools And Consumables List ..................................... 97

Table 36. RSD Pump Head R&R Tools And Consumables List .................................................... 99

Table 37. Pump Shaft Oil Seal Bench Procedure Tools And Consumables List ........................ 102

Table 38. Mechanical Seal Pin Bench Procedure Tools And Consumables List ....................... 104

Table 39. Gearbox Cooling Tube R&R Tools And Consumables List .......................................... 107

Table 40. Pump Clearance Ring R&R Tools And Consumables List .......................................... 110

Table 41. Input Shaft Bench Procedure Tools And Consumables List ...................................... 121

Table 42. Input Shaft Oil Seal Bench Procedure Tools And Consumables List ......................... 126

Table 43. Input Shaft Endcap Bench Procedure Tools And Consumables List ......................... 128

Table 44. Drive Gear Bench Procedure Tools And Consumables List ....................................... 130

Table 45. Pump Shaft Bench Procedure Tools And Consumables List ..................................... 131

Table 46. Pump Shaft Endcap R&R Tools And Consumables List ............................................. 139

Table 47. Pump Gear Bench Procedure Tools And Consumables List ...................................... 142

........................................................... 88

ix

ESP

Environmentally Safe Priming

gpm

Gallons Per Minute

Abbreviations And Acronyms

The abbreviations used in this manual are limited to standard (commonly used and accepted)

scientific units of measure and therefore are NOT defined or listed. The acronyms used in this

manual are defined in this listing (in numerical-alphabetical order) and are NOT defined within

the text.

AKA Also Known As

AP Attack Pump

CBP Centrifugal Booster Pump

CCW Counter Clockwise

CW Clockwise

EVT Emergency Vehicle Technician

FAST Factory Authorized Service Team

GR Gear Ratio

ID Inside Diameter

Lpm Liters Per Minute

N/A Not Applicable

NFPA National Fire Protection Act

NFPA 1901 Standard For Automotive Fire Apparatus

NFPA 1911 Standard For The Inspection, Maintenance, Testing, And Retirement Of In-

Service Automotive Fire Apparatus

NLGI National Lubrication Grease Institute

NPT Normal Pipe Thread

OEM Original Equipment Manufacturer

OD Outside Diameter

PM Panel Mounted

PMD Panel Mounted Display

PPE Personal Protection Equipment

PTO Power Take Off

R&R Removal and Replacement (Installation)

RSD Removable Side Drive

SAE Society of Automotive Engineers

SCR Symptom, Cause, Remedy (Troubleshooting Table)

SPV Semi-automatic Priming Valve

SPVR Suction Pressure Relief Valve

TRV Thermal Relief Valve

x

1. SAFETY

This section provides definitions for DANGERS, WARNINGS, CAUTIONS, NOTICES, and NOTES

contained herein, precautions to be taken for pump repair as well as an alphabetical summary

listing of the DANGERS, WARNINGS, CAUTIONS, and NOTICES used in this manual.

DANGERS, WARNINGS, CAUTIONS, or NOTICES that immediately precede a step apply directly to

that step and all sub steps. DANGERS, WARNINGS, CAUTIONS, or NOTICES that precede an entire procedure apply to the entire procedure. WARNINGS and CAUTIONS consist of two parts: a

heading (that identifies possible result if disregarded) and a statement of the hazard (that provides the minimum precautions). The headings used and their definitions are.

INDICATES A HAZARDOUS SITUATION, WHICH IF NOT AVOIDED WILL RESULT IN SERIOUS INJURY OR DEATH.

INDICATES A HAZARDOUS SITUATION, WHICH IF NOT AVOIDED COULD RESULT IN

SERIOUS INJURY OR DEATH.

INDICATES A POTENTIALLY HAZARDOUS SITUATION, WHICH IF NOT AVOIDED MAY

RESULT IN MINOR OR MODERATE INJURY.

ADDRESSES PRACTICES NOT RELATED TO PERSONAL INJURY.

NOTE

Highlights an essential aspect of an operating or maintenance procedure, condition,

or statement and/or provides pertinent ancillary information.

NOTES may precede or follow the step or procedure, depending upon the information and how it

pertains to the procedure/step. The headings used and their definitions are.

1.1. PPE

The following is the minimum PPE required when performing maintenance.

• Safety Glasses • Work Shoes (Steel Toe)

• Safety Gloves • Ear Protection

• General Protection • Single Use

• Chemical Resistant • Ear Muffs

1.2. Environmental Protection

Used oil from the gearbox must be disposed of in accordance with your local regulations. It is

prohibited to pour oil and other contaminants onto the ground, down sewers, drains, or into water courses. Dispose of lubricants through authorized waste disposal contractors, licensed waste

disposal sites, or to the waste reclamation trade. If in doubt, contact your Local Environmental

Agency for advice regarding disposal policies.

1

1.3. Training

AP, CBP, MBP, and RSD pumps must only be operated and maintained by trained personnel.

Training is available via the Hale Products Inc. website (www.haleproducts.com), Godiva √erified

Training (godiva.co.uk), or through your local dealer or vehicle manufacturer. The Hale website

provides a description of the course content and general information about the training, including an invitation to register with the EVT Certification Commission (www.evtcc.org) to take one

EVT exam at the Hale facility.

NOTE

Be sure to record the contact phone number and contact person’s information before

completing the form.

Complete the SESSIONS, ORGANIZATION CONTACT INFORMATION, STUDENT CONTACT INFORMATION portions of the form. Check the Captcha (provides the proof of human input) and then

click the SUBMIT button at the bottom of the page.

NOTE

Under the FAST buttons select No unless your facility is a FAST center. Do NOT click

Yes unless you know for sure you are a FAST member requiring certification or recertification (a certification is valid for 4 years).

When the Thank you for Registering page appears record the halemarketing email address (Add

this address to your email address book to prevent your response from being routed to the Junk

folder.) and call the contact phone number (recorded earlier) to arrange payment.

NOTE

Due to demand, classes fill far in advance of the scheduled dates. The ONLY way to

hold the selected dates is to pay at the time of enrollment submission.

1.4. Safety Summary

DO’S

• When installing or removing the pump, use ONLY appropriately rated lifting equipment that

has been inspected and is in good condition.

• Use/wear all required PPE when operating the pump (including for maintenance purposes).

See paragraph 1.1, PPE.

DON’TS

• Do NOT remove guards; rotating parts must be guarded against accidental contact.

• Do NOT insert items into the suction tube when pump is running.

• Do NOT disconnect discharge hoses while the unit is running.

• Do NOT loosen/unfasten/remove components while the unit is running.

The following warnings and cautions are used throughout this manual and are provided here as

a safety summary. WARNINGS or CAUTIONS within a procedure (preceding an individual step),

apply directly to that step, however WARNINGS or CAUTIONS that precede the entire procedure,

apply to the ENTIRE procedure.

2

A PRESS PRESENTS A POTENTIAL CRUSH HAZARD (FROM MOVING PARTS) AND/OR

STRIKE HAZARD (FROM EJECTED PARTS). WEAR APPROPRIATE PPE.

A PRESSURE HAZARD MAY EXIST EVEN WHEN THE PUMP IS NOT RUNNING. PRIOR

TO REMOVING HOSES OR CAPS FROM PUMP CONNECTIONS, RELIEVE PRESSURE BY

OPENING DRAINS. BLEEDER VALVES SHOULD ALSO BE USED WHEN CONNECTING

TO AN INTAKE FROM A PRESSURIZED SOURCE.

ALWAYS FOLLOW LOCAL GUIDELINES FROM THE AHJ AND THE APPARATUS MANUFACTURER.

ALWAYS FOLLOW PROPER OPERATING PROCEDURES. THE PUMP OPERATOR MUST

BE FAMILIAR WITH THE PUMP OPERATING INSTRUCTIONS AS WELL AS OTHER OPERATING GUIDELINES FOR THE APPARATUS AND ACCESSORIES.

DO NOT EXCEED OPERATING PRESSURE LIMITS OF PUMP, INSTALLED PLUMBING,

HOSE(S), OR EQUIPMENT IN USE.

DO NOT LEAVE THE CAB OR ATTEMPT TO PUMP UNTIL ALL OK TO PUMP LIGHTS IN

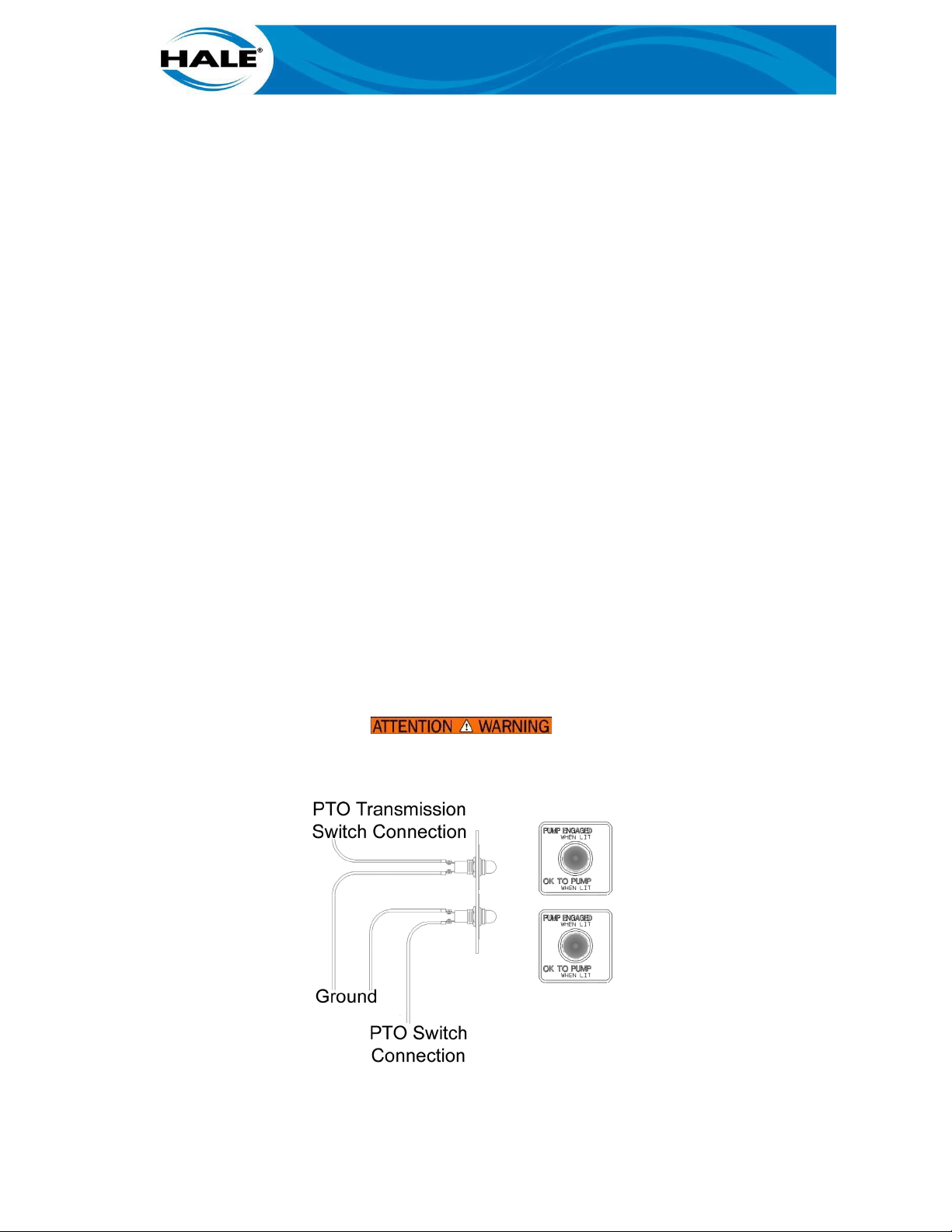

THE CAB ARE ILLUMINATED. SEE FIGURE 7.

OPERATORS, INSTALLERS, AND MAINTENANCE PERSONNEL MUST BE TRAINED AND

QUALIFIED FOR ALL THE ACTIVITIES THEY PERFORM.

ALWAYS USE PROPER PPE. OIL MAY BE TOXIC TO PEOPLE AND/OR THE ENVIRONMENT. CATCH AND DISPOSE OF OIL PROPERLY. IMPROPER OIL HANDLING MAY RESULT IN HEALTH RISKS AND/OR CRIMINAL PUNISHMENTS.

FAILING TO REDUCE SYSTEM PRESSURE BEFORE SYSTEM SHUTDOWN OR FLUSHING COULD RESULT IN WATER HAMMERING.

THE AP PUMP AND GEARBOX ASSEMBLIES WEIGH APPROXIMATELY 140 LBS

(64 KG). USE PROPER LIFTING DEVICE WHEN REMOVING OR INSTALLING THE PUMP

AND GEARBOX ASSEMBLY.

THE CBP PUMP AND GEARBOX ASSEMBLIES WEIGH APPROXIMATELY 100 LBS

(45 KG). USE PROPER LIFTING DEVICE WHEN REMOVING OR INSTALLING THE PUMP

AND GEARBOX ASSEMBLY.

THE MBP PUMP AND GEARBOX ASSEMBLIES WEIGH APPROXIMATELY 170 LBS

(77 KG). USE PROPER LIFTING DEVICE WHEN REMOVING OR INSTALLING THE PUMP

AND GEARBOX ASSEMBLY.

3

THE RSD PUMP AND GEARBOX ASSEMBLIES WEIGH APPROXIMATELY 225 LBS

(102 KG). USE PROPER LIFTING DEVICE WHEN REMOVING OR INSTALLING THE

PUMP AND GEARBOX ASSEMBLY.

USE PPE TO PROTECT HANDS AND FINGERS FROM SHARP EDGES. THE EDGES OF

THE BLADES ON THE INDUCER MAY BE SHARP.

A MECHANICAL SEAL IS A PRECISION ENGINEERED DEVICE. CARE MUST BE TAKEN

NOT TO DAMAGE THE MATING FACES (SEAL FORMING PORTION) OF THE SEAL. ENSURE THE FACES REMAIN ABSOLUTELY CLEAN THROUGHOUT THE ENTIRE INSTALLATION. SEAL FACES MUST BE CLEANED WITH THE ALCOHOL WIPES PROVIDED WITH

THE REPAIR KIT.

ALWAYS INSTALL NEW BEARINGS WHEN INSTALLING THE PUMP GEAR OR PUMP

SHAFT (ESPECIALLY IF METAL WAS FOUND IN THE GEAR OIL). FAILURE TO INSTALL

NEW BEARINGS MAY RESULT IN PREMATURE PUMP FAILURE OR ADDITIONAL

EQUIPMENT DAMAGE.

ALWAYS USE AND ONLY USE PAC-EASE RUBBER LUBRICANT EMULSION (OR EQUIVALENT) WHEN INSTALLING THE MECHANICAL SEAL. USING ANY OTHER LUBRICANT OR

NOT USING THE LUBRICANT MAY DAMAGE THE MECHANICAL SEAL AND SEAT.

DO NOT ALLOW PUMP GEAR TO SLIDE THRU SUPPORTS. DO NOT ALLOW THE NEW

OIL SEAL TO BE CUT ON THE KEYWAY OR PINCHED BETWEEN THE ADJACENT PUMP

SHAFT COMPONENTS OR BE DAMAGED IN ANY OTHER WAY. DAMAGING THE OIL

SEAL WILL RESULT IN AN OIL LEAK AND POSSIBLE EQUIPMENT DAMAGE AND/OR

FAILURE.

DO NOT ALLOW THE PRESSURE ON THE INTAKE GAUGE TO GO BELOW ZERO. PLACING A VACUUM ON THE WATER MAIN MAY RESULT IN SERIOUS DAMAGE TO OR FAILURE OF THE WATER MAIN.

DO NOT APPLY LOCTITE TO A SELF-LOCKING NUT. DO NOT REUSE A SELF-LOCKING

NUT. REUSING A SELF-LOCKING NUT OR ADDING LOCTITE MAY RESULT IN THE ITEM

FAILING TO BE SECURED.

DO NOT CUT THRU THE CLEARANCE RING. CUTTING THRU THE CLEARANCE RING

WILL DAMAGE THE PUMP HEAD/SUCTION HEAD/VOLUTE AND MAY RESULT IN PUMP

FAILURE.

4

DO NOT DRIVE THE CLEARANCE RING INTO THE /SUCTION HEAD/VOLUTE AT AN ANGLE OR UNEVENLY (ALL THE WAY FROM ONE SIDE AT A TIME). BENDING, WARPING,

OR CHIPPING THE CLEARANCE RING MAY RESULT IN POOR PERFORMANCE OR PUMP

FAILURE.

DO NOT INSTALL A USED COTTER PIN. A USED PIN MAY FAIL RESULTING IN DEBRIS

GOING THRU THE PUMP AND/OR LOOSENING OF THE CASTLE NUT THAT SECURES

THE IMPELLER.

DO NOT LOOSEN THE CASTLE NUT TO INSTALL THE COTTER PIN. CONTINUE TO

TIGHTEN THE CASTLE NUT UNTIL THE COTTER PIN CAN BE PUSHED THRU THE HOLE

IN PUMP SHAFT.

DO NOT LUBRICATE VANES OR VANE SLOTS. USING LUBRICANT ON THE VANES OR

VANE SLOTS DURING DISASSEMBLY, CLEANING, OR ASSEMBLY EVENTUALLY CAUSES A GUMMY RESIDUE TO DEVELOP, RENDERING THE SYSTEM INOPERATIVE.

DO NOT OPEN THE THROTTLE UNLESS THE OK TO PUMP (GREEN INDICATOR LIGHT)

IS ON. SEE FIGURE 8. FAILURE TO WAIT FOR THE ILLUMINATED GREEN INDICATOR

MAY RESULT IN EQUIPMENT DAMAGE OR FAILURE.

DO NOT OVER FILL THE GEARBOX. EXCEEDING THE OIL LEVEL MAY RESULT IN

EQUIPMENT DAMAGE.

DO NOT RUN THE PRIMER FOR MORE THAN 45 SECONDS IF PRIME IS NOT

ACHIEVED. IF PRIME IS NOT ACHIEVED IN 45 SECONDS, STOP AND LOOK FOR CAUSES (AIR LEAKS OR BLOCKED SUCTION HOSE). RUNNING THE PRIMER FOR LONGER

PERIODS WITHOUT ACHIEVING PRIME MAY RESULT IN PRIMER AND/OR PUMP DAMAGE OR FAILURE.

DO NOT STRIKE THE IMPELLER. STRIKING THE IMPELLER MAY RESULT IN IRREPARABLE DAMAGE.

DO NOT STRIKE THE INDUCER OR IMPELLER. STRIKING THE INDUCER OR IMPELLER

MAY RESULT IN IRREPARABLE DAMAGE.

DO NOT USE GREASE DURING GEARBOX/PUMP SHAFT ASSEMBLY. IN ALL OTHER

CASES IT IS ACCEPTED PRACTICE TO HOLD COMPONENTS IN PLACE OR LUBRICATE

THEM FOR EASE OF ASSEMBLY USING GREASE, HOWEVER DURING GEARBOX/PUMP

SHAFT ASSEMBLY USE ONLY GEAR OIL. GREASE IS NOT COMPATIBLE WITH THE

SYNTHETIC GEAR OIL AND MAY CAUSE DRAIN HOLES TO CLOG PREVENTING CRITICAL LUBRICATION.

5

IF A PUMP IS OPERATED WITHOUT WATER, OR WITHOUT DISCHARGING WATER, IT

MAY OVERHEAT. FAILURE TO FLOW WATER MAY DAMAGE THE MECHANICAL SEAL OR

THE DRIVE MECHANISM.

IF IN 30 TO 45 SECONDS ONE OF THE FOLLOWING (BULLETS) DOES NOT OCCUR

STOP THE PUMP AND CHECK FOR AIR LEAKS OR A POSSIBLE PUMP TROUBLE.

• THE DISCHARGE GAUGE READING INCREASES

• THE INTAKE GAUGE READING FALLS BELOW ZERO

• THE PRIMING PUMP DISCHARGES WATER TO THE GROUND

CONTINUING TO RUN THE PRIMING PUMP MAY RESULT IN PUMP FAILURE OR DAMAGE.

OIL AND GREASE (INCLUDING SKIN OILS) WILL DAMAGE THE MECHANICAL SEAL

FACE. NEVER TOUCH THE MATING FACES OF THE MECHANICAL SEAL. WEAR PROTECTIVE GLOVES TO PREVENT TOUCHING THE SEAL FACES WITH YOUR BARE HANDS.

(USE RUBBER, ACRYLIC, LATEX, ETC. – DO NOT USE CLOTH OR LEATHER.)

RUNNING THE ENGINE AT SPEEDS HIGHER THAN 1200 RPM DURING PRIMING IS

NOT RECOMMENDED SINCE IT WILL NOT IMPROVE PRIMING OPERATION AND MAY

CAUSE DAMAGE TO THE PUMP.

USE ONLY PAC-EASE RUBBER LUBRICANT EMULSION (OR EQUIVALENT) ON THE

RUBBER MECHANICAL SEAL PARTS TO EASE INSTALLATION. USING ANY OTHER LUBRICANT CAN DAMAGE THE SEAL AND SEAT.

6

2. INTRODUCTION

This section provides an overview of the Flex series pumps, drives, and their options. Additionally, the section provides how to use this manual and principles of operation (including an explanation of terms and standard components).

2.1. Overview

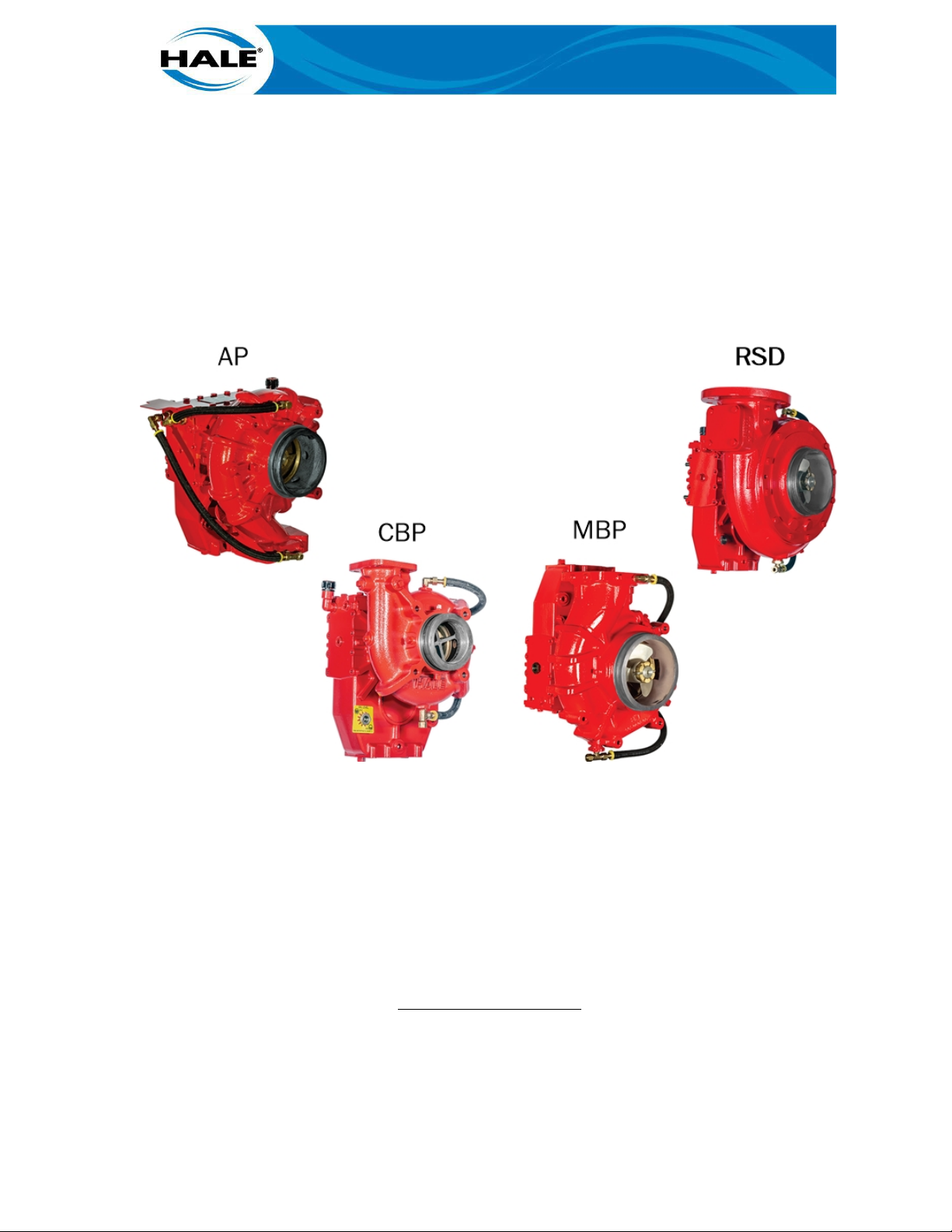

Hale Products currently produces four models of booster pumps:

• AP • MBP

• CBP • RSD

Unless otherwise indicated, these procedures will apply to all models of Hale booster pumps: Any

variations in operation or maintenance for the different models will be addressed within the context of this manual. The AP, CBP, and MBP booster pump maintenance technics are similar and

are therefore grouped in this manual. The RSD booster pump maintenance technics differ significantly and are presented separate from the AP, CBP, and MBP booster pumps.

Hale booster pumps are the favorite of fire fighters throughout the world. Booster pumps can be

used as initial attack pumps or as auxiliary pumps in conjunction with the apparatus main pump.

Covering a range of capacities from 20 gpm (75 Lpm) to 1500 gpm (5,678 Lpm), Hale booster

pumps offer the versatility, dependability, reliability, small size, and ease of operation so necessary for effective firefighting.

Hale booster pumps are of a compact size and lightweight design for easy mounting on the apparatus chassis. The pump coupled with the new aluminum gearbox allows the apparatus builder to

only supply the PTO and connecting shaft or direct engine mount a Flex series single stage

booster pump.

2.2. How To Use This Manual

This manual was developed for the purposes of FAST team and OEM support. This manual provides information and procedures to perform three levels of pump maintenance and impeller

renewal. The manual also provides information to be used to troubleshoot and R&R failed components based on the three levels of repair and impeller renew kits available from Hale Products

Inc. The repair/impeller renew kits support pump maintenance, repair, and rebuild.

This manual requires the use of the both the Hale Assembly drawings and the Parts Manual For

Hale Single Stage Booster Pumps (FSG–MNL–00185) for parts identification. Use the Parts

Manual to determine the drawing sheet (or sheets) required for reference. Then use the drawing(s) to locate the part and the item number associated with that part. The item number also

appears listed (in numerical order) in the parts table along with the part number, description, and

quantity for that item number.

The Introduction section is of interest to management for pump familiarization, visual recognition, pump identification documentation, and risk assessment information.

The Safety section is of interest to both management and maintainers as it provides precautions

for maintenance (including operation for maintenance purposes) and definitions of warnings,

cautions, and notes. This section also provides a summary of both PPE and a DANGER/ WARNING/CAUTION/NOTICE summary. The section provides a single point view of compiled hazards

and PPE in a condensed format. The appropriate DANGER, WARNING, CAUTION, or NOTICE and

PPE list also appears at each point of use throughout the manual.

7

The two Maintenance sections provide all aspects of maintaining the AP, CBP, MBP, and RSD

pumps, including sparing, preventive and corrective maintenance (which includes troubleshooting and remove and replace instructions). Notice that the use of this manual also requires

maintenance personnel to have received Hale training prior to using it. Use Hale Training Academy (Pumping And Maintenance) training (see paragraph 1.3, Training) and the two Maintenance

sections for all aspects of maintaining the pumps.

Within the two Maintenance sections, the troubleshooting provided utilizes SCR tables which

provide the list of known symptoms associated with a pump trouble/problem/failure. To use a

SCR table, locate the indicated SYMPTOM, verify the associated CAUSE (the maintainer must verify ALL the associated causes if multiple causes are listed) and then perform the associated

REMEDY (or remedies). The R&R procedures provide pump removal from the apparatus via two

separate methods: removing a pump as a complete assembly or removing only the pump portion

leaving the gearbox in the apparatus. Once removed the subsequent pump or gearbox repairs

are treated as bench procedures each covering a specific level (1, 2, 3, or renewal) of maintenance. Each level of maintenance requires the associated repair kit be utilized. Utilizing the associated repair kit ensures all the required components are available for replacement. Utilizing

the repair kits as intended prolongs pump performance and supports the manufacturer’s warranty.

Performing a procedure is NOT the ONLY key action in maintaining a pump, documentation of the

pumps Preventive Maintenance, R&R, and SYMPTOM/REMEDY history (including meaningful

tracking of when each issue occurred) is also key to maintaining each pump. A maintenance log

with meaningful entries will provide invaluable insight, time/money savings (in reduced down

time and shorted troubleshooting time), and cost savings over the life cycle of each pump.

2.3. Pump Specifications And Numbering

Hales policy is one of continuous development. Hale therefore reserves the right to amend specifications without notice or obligation. Refer to Section 2.2, Pump Specifications And Numbering,

in the Hale OIM manual (FSG–MNL–00183) for serial number locations, model number definitions, and major pump features. Refer to the Hale Products website (www.haleproducts.com) for

detailed booster pump specifications. NOTE: Using your pumps serial number and the Hale website (or Customer Service) is the best way to ensure you receive/utilize the correct replacement

parts for your pump.

2.4. Principles Of Operation

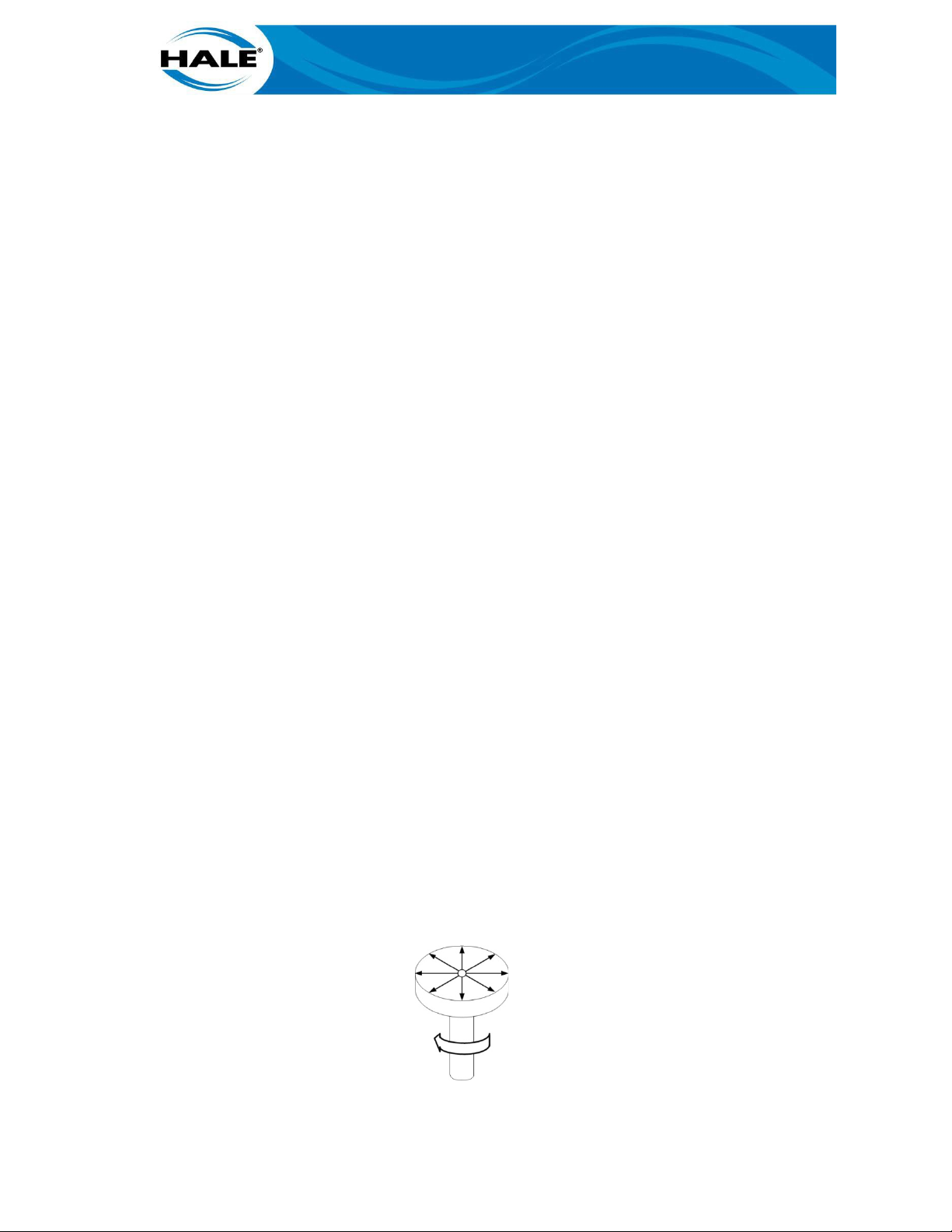

Hale booster pumps are centrifugal pumps that operate on the principle that centrifugal force is

created by a rapidly spinning disk. Figure 1 shows an amount of water has been placed at the

center of a disk. The disk is rotated and the water is thrown outward from the center to the edge

of the disk. The velocity at which the water travels from the center directly relates to the diameter

of the disk and the speed of rotation. When water is confined in a closed container (such as the

volute), the velocity is converted to pressure; pressure is therefore, dependent on the speed of

rotation.

8

Figure 1. Centrifugal Force From A Rotating Disk

There are three interrelated factors that regulate the performance of a centrifugal pump:

Speed (RPM):

If the speed of rotation increases with the flow held constant, the water pressure increases.

Pressure:

Pressure is usually expressed in psi or bar. If pressure changes and speed is constant, the flow

will change inversely (if pressure increases, flow decreases).

Flow:

Flow is usually expressed in gpm or Lpm that a pump can deliver when supplied from draft. If the

pressure is held constant, the flow will increase with an increase in the speed of rotation.

The centrifugal pump is preferred by the fire protection service due to its ability to fully utilize any

positive inlet pressure, reducing the strain on the pump.

For example, if the required discharge pressure is 120 psi (8 bar), and the inlet pressure is

45 psi (3 bar), the pump must only produce the difference in pressure of 75 psi (5 bar). This contributes to low engine and pump speeds which reduces wear on the pump. Another important

benefit is the centrifugal pump has basically only two moving parts; the impeller and the shaft.

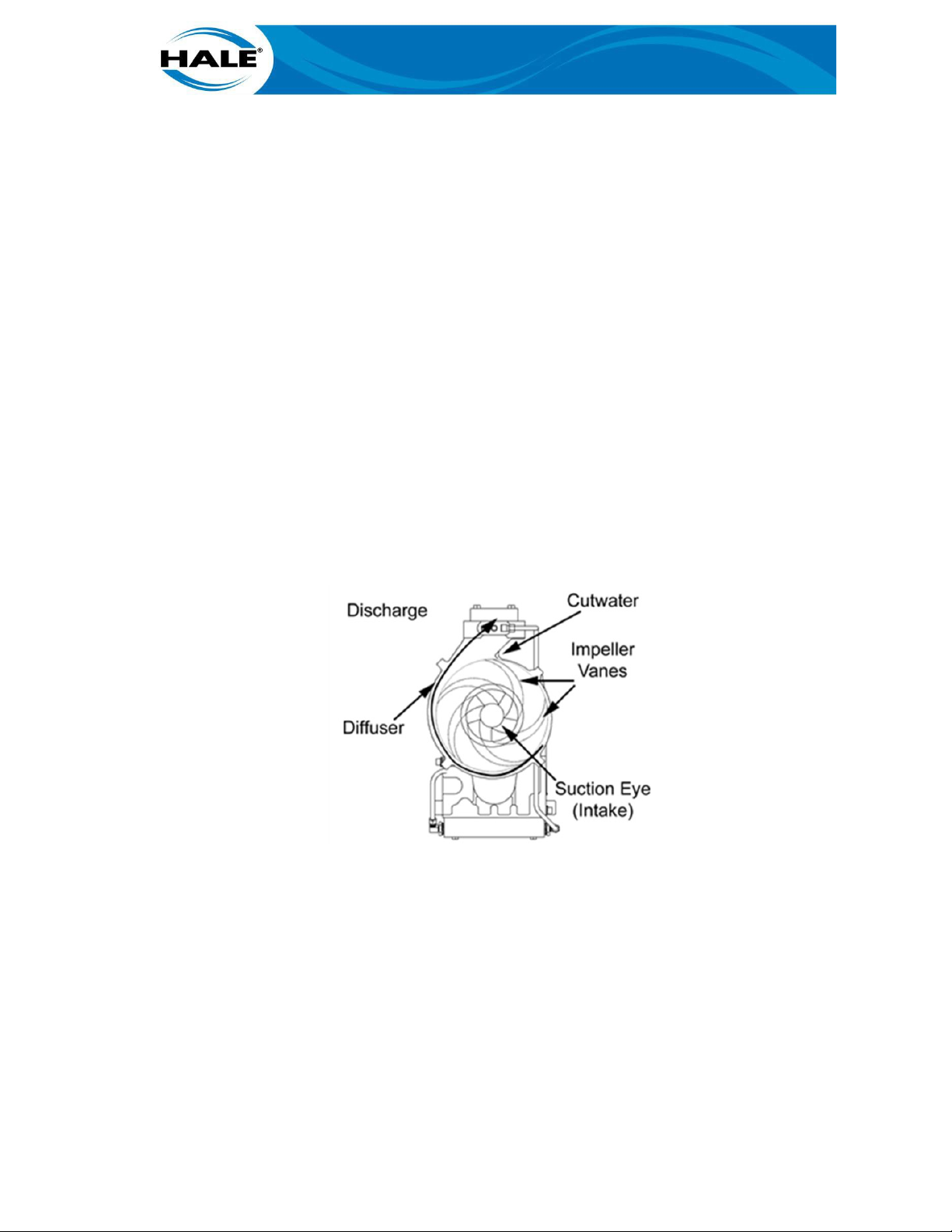

As shown on Figure 2, during operation water enters the suction eye of the impeller (intake). The

rotating impeller vanes develop discharge pressure and direct the water to the discharge opening. The cutwater is a wedge that divides the water between the volute (a single chamber diffuser) and the pump discharge.

Figure 2. Single Stage Water Flow

2.4.1 Explanation Of Terms

The following major terms are explained in sufficient detail to allow a maintainer to communicate

pumping issues or troubles with Hale Customer Service personnel. As a basic understanding of

the terms (and the principles associated with them) will assist operators (for both operations and

maintenance purposes) utilize common terminology and understand accepted principles when

communicating among each other.

2.4.1.1 Atmospheric Pressure (Static Air Pressure)

Air pressure is 14 pounds (AKA psi) at sea level. Pressure increases below sea level and decreases above sea level due to the increased or decreased volume of air pushing down at that

height. In addition to the amount of air, weather also effects air pressure. Air in a high pressure

9

area compresses and warms as it descends. The warming inhibits the formation of clouds,

meaning the sky is normally sunny in high pressure areas. But haze and fog still might form. Just

the opposite occurs within an area of low atmospheric pressure. Atmospheric pressure affects a

pumps ability to pump from draft. Higher pressures will increase a pumps performance, while

lower pressures can cause a noticeable decrease in lift.

2.4.1.2 Cavitation

The definition of cavitation is the formation of empty cavities (low-pressure bubbles) in a liquid

being moved by means of mechanical force (such as the rotation of an impeller) which is then

followed by their immediate and sudden implosion. The resulting forces can be as damaging as

striking the metal with a hammer. Cavitation within a pump may sound as if the pump were filled

with gravel or being struck with a hammer. See Section 3.5, Cavitation (Details), for more details.

2.4.1.3 Dead Heading

Operating a pump without any discharge is known as dead heading. Lack of flow causes temperatures to rise inside the pump.

2.4.1.4 Impeller And Clearance Rings

The impeller is the primary working part of a centrifugal pump. The impeller moves the water. An

impeller consists of two discs surrounding curved vanes. The vanes force water to rotate within

the discs resulting in the water being thrown outward at high velocity. The water from the impeller discharges into the volute, converting the high velocity energy into pressure.

The clearance rings minimizes the amount of water that bypasses the discharge and returns to

the suction side of the impeller reducing pump performance (gpm). The wrap around clearance

ring reduces the bypass even more than the typical style ring (see Figure 3). Clearance rings are

ware items that protect the volute from experiencing the ware generated by the moving water

and especially the debris (sand, salt, etc.) when present.

Figure 3. Clearance Ring Water Flow

2.4.1.5 Priming Pump

An auxiliary pump attached to provide positive displacement of air out of the booster pump creating a vacuum which initially draws water into the pump. The type of priming pump used (by Hale)

for the AP, CBP, MBP, and RSD pumps is an electric motor driven rotary vane pump. Once the

main pump is primed and pumping, the priming pump is turned off.

2.4.1.6 Relief Valve

An automated valve with a control mechanism that maintains the pump pressure within 30 psi

when the pump discharge is gated (reduced) or closed (off). The valve maintains a set pressure

by diverting a portion of the pump discharge flow into the pump suction.

10

2.4.1.7 PM Relief Valve Control

The PM indicates a panel mounted hand-adjustable valve. When set to the desired pressure, the

relief valve will maintain the desired pump discharge pressure and limit a pressure increase to

no more than 30 psi (2 bar).

2.4.1.8 Volute

The increasing discharge path of the pump, its function is to collect the water from the impeller

and depending on its design can either increase pressure and decrease velocity or increase velocity and decrease pressure.

2.4.2 Standard Booster Pump Components

All Hale Flex Series single stage booster pumps (AKA the standard pump) consist of the following:

• Volute • Gearbox

• Impeller • Gears (Drive, Mating/Pump)

• Mechanical Seal • Shaft Assemblies (Input, Pump)

Figure 3 shows these standard parts of a Hale booster pump. These parts are briefly described in

the following paragraphs.

Figure 4. Parts Of The Hale Booster Pump

11

2.4.2.1 Volute

The Hale AP, CBP, and MBP single stage booster volutes (body) are a single-piece casting. Service of the impeller, clearance rings, and mechanical seal is accomplished by removing the volute from the assembled pump head and gearbox. The Hale RSD single stage booster volute is a

three-piece casting, with service of the impeller, clearance rings, and mechanical seal accomplished by removing ONLY the appropriate piece of the volute required to access the component

requiring service.

All volutes are constructed from fine grain cast iron. For areas where salt water is commonly

used, a bronze version of each booster pump is available.

The Hale Flex Series single stage booster pumps support multiple discharge port configurations.

Depending on the model, the pumps provide between 12 and 24 different configurations (including both rotations – ER or OER). Refer to the Parts Manual For Hale Single Stage Booster Pumps

(FSG–MNL–00185), Section 2,

charge Positions paragraphs) for a reference to the appropriate drawing and sheet number(s)

providing the views of the volute positions.

2.4.2.2 Impeller And Shaft Assembly

The impeller provides velocity to the water. The impeller is made of high quality bronze and is

mounted on a stainless steel shaft that is rotated by the gearbox. Water enters the rotating impeller at the intake (or eye). The vanes guide water from the intake to the discharge. Vanes curve

away from the direction of rotation so water moves toward the outer edge (see Figure 2). The

shrouds (discs) form the sides of the impeller and keep the water confined to increase acceleration and pressure. The back of the impeller houses the rotating portion of the mechanical seal.

Hale Booster Pump Illustrated Breakdowns, (Gearbox And Dis-

2.4.2.3 Mechanical Seal

The mechanical seal is common to all Hale booster pumps. Figure 4 shows a stationary seat is in

constant contact with a rotating seal ring to prevent leakage. The seal ring/diaphragm is specifically designed for high-temperature, low friction, self-adjusting, dependable operations.

Figure 5. Mechanical Seal

IF A PUMP IS OPERATED WITHOUT WATER, OR WITHOUT DISCHARGING WATER, IT

MAY OVERHEAT. FAILURE TO FLOW WATER MAY DAMAGE THE MECHANICAL SEAL OR

THE DRIVE MECHANISM.

12

2.4.2.4 Gearbox

The gearbox is cast aluminum and machine finished. The gearbox can be mounted in any one of

six positions. Refer to FSG–MNL–00185 (Parts Manual For Hale Single Stage Booster Pumps),

paragraph 2.1, (Gearbox Illustrated Breakdowns) for a reference to the appropriate drawing and

sheet number providing the views of the gearbox positions available.

Inside the gearbox a gear set transfers engine power from the input shaft, made of heat treated

nickel steel, to the pump shaft to turn the impeller at the appropriated speeds, which are determined by the gear ratio of the gear set selected. Hale offers a variety of pump gear ratios to accommodate a wide range of end-user and apparatus manufacturer requirements based on the

pump's intended use, horsepower and speed rating of the engine, or the torque rating of the

transmission PTO. Refer to FSG–MNL–00185 (Parts Manual For Hale Single Stage Booster

Pumps), paragraph 2.1, (Gearbox Illustrated Breakdowns) for a reference to the appropriate

drawing and sheet number providing the gear ratio listings available.

2.5. Pump Drives

The Hale Flex Series pumps support the common types of booster pump drives used on firefighting apparatus:

• The most common drive is the PTO mounted on the truck transmission or four-wheel drive

transfer case, which allows for pump and roll operation.

• Direct engine mounting via SAE#3 (or #4) flywheel housing.

Hale booster pumps are built to produce the volumes and pressures shown on their respective

performance curves and specifications (see paragraph 2.3, Pump Specifications And Numbering). However, the volumes and pressures safely obtainable are dependent on the torque capacity of the apparatus transmission or transfer case, power takeoff and the pump drive line. In most

cases, the torque rating of the PTO determines maximum pump performance.

The apparatus builder can provide various pump performance spots that will define the torque

limit of the PTO in terms of gpm and psi. When pumping continuously, care should be taken not

to overheat the PTO, transmission or transfer case.

Hale booster pumps are available for either engine rotation or opposite engine rotation PTO operation. Since some PTOs match engine rotation and some turn opposite of the engine rotation,

each pump model can be built to match the rotation of the PTO.

NOTE

Please refer to Hale Bulletin #886 and F–72 (Hale Torque Limit Chart) for further assistance in selecting the correct Flex series booster pump PTO.

Hale booster pumps are also available with an adapter that allows direct engine mount. Figure 5

shows the available flywheel housing (SAE #3 or #4) with the gearbox in the inverted configuration and the volute in the up configuration.

13

Figure 6. Direct Engine Mount

2.6. Optional Pump Components

In addition to the basic parts of Hale booster pumps described above, the following items are

available to enhance pump operation:

• Anodes

• TRVs

2.6.1 Anodes

The Hale anode system (Figure 6) helps prevent pump damage caused by galvanic corrosion.

Figure 7. Hale Anode

Galvanic action pits the pump and pump shaft material. The popularity of non-corrosive water

tanks and piping has increased this type of corrosion in today’s fire pumps. The Hale anode system is a sacrificial metal, which helps prevent corrosion. A Hale makes an anode that will fit on

any Hale truck mounted pump, regardless of age or model. The RSD uses Hale anodes designed

to be easily installed ONLY requiring four bolts and a gasket. Total time to install is just fifteen

minutes or less, yet it will provide years of protection for the pump. The anode kit is designed for

installation in the standard Hale 115 series flange opening located on the side of the RSD volute

(K port). On fabricated manifolds and similar applications, the installer is to provide 1-1/4-in NPT

openings and install anodes directly. It is recommended that one anode be installed on the suction side and one on the discharge side.

14

2.6.2 TRVs

Hale optional offers a thermal relief valve in two temperature ranges and with remote indication.

• TRV–120

• TRV–170

• TRV–L

The TRV is a thermal relief valve that acts as a thermostat and opens when the temperature of

the water in the pump exceeds 120 ℉ (TRV–120) or 170 ℉ (TRV–170) and resets (closes)

when the water cools. The RSD utilizes the standard Hale 115 series flange opening located on

the side of the volute (K port) and a flange adaptor to house the TRV. For all other Flex series

booster pumps the TRV must be installed on a fabricated manifold and similar application and

the installer is to provide 1-1/4-in NPT opening and install the TRV close to the volute discharge

port. The TRV discharge water should be directed to the ground or back to the booster tank, helping to keep the pump cool and avoiding premature wear and damage.

The TRV–L is a TRV (120 ℉ or 170 ℉) with the added feature of a remoted indicator (audible

and visual) panel to show when the TRV is open and flowing water. The indicator panel also has

an integral test switch.

15

3. MAINTENANCE OPERATING PROCEDURES

This section provides information and procedures for the operation of Hale booster pumps for

the purpose of performing maintenance. Maintenance operating procedures differ greatly from

typical operations. Typical operations are based on the pump being installed in a firefighting apparatus and include pumping from: an onboard tank, or a hydrant, or from draft. Operating procedures for maintenance purposes include pump performance verification, repair verification,

and troubleshooting and unless otherwise indicated, these instructions apply to all Hale booster

pumps.

THE PROCEDURES IN THIS SECTION PROVIDE ONLY GENERAL/MINIMAL INSTRUCTION. DO NOT REPLACE LOCAL PROCEDURES OR POLICIES OR RECOMMENDATIONS

AND PROCEDURES PROVIDED IN THE APPARATUS/TRUCK/UNIT MANUAL WITH

THESE PROCEDURES.

ALWAYS FOLLOW LOCAL GUIDELINES FROM THE AHJ AND THE APPARATUS MANUFACTURER.

ALWAYS FOLLOW PROPER OPERATING PROCEDURES. THE PUMP OPERATOR MUST

BE FAMILIAR WITH THE PUMP OPERATING INSTRUCTIONS AS WELL AS OTHER OPERATING GUIDELINES FOR THE APPARATUS AND ACCESSORIES.

A PRESSURE HAZARD MAY EXIST EVEN WHEN THE PUMP IS NOT RUNNING. PRIOR

TO REMOVING HOSES OR CAPS FROM PUMP CONNECTIONS, RELIEVE PRESSURE BY

OPENING DRAINS. BLEEDER VALVES SHOULD ALSO BE USED WHEN CONNECTING

TO AN INTAKE FROM A PRESSURIZED SOURCE.

DO NOT EXCEED OPERATING PRESSURE LIMITS OF PUMP, INSTALLED PLUMBING,

HOSE(S), OR EQUIPMENT IN USE.

OPERATORS, INSTALLERS, AND MAINTENANCE PERSONNEL MUST BE TRAINED AND

QUALIFIED FOR ALL THE ACTIVITIES THEY PERFORM.

FAILING TO REDUCE SYSTEM PRESSURE BEFORE SYSTEM SHUTDOWN OR FLUSHING COULD RESULT IN WATER HAMMERING.

IF IN 30 TO 45 SECONDS ONE OF THE FOLLOWING (BULLETS) DOES NOT OCCUR

STOP THE PUMP AND CHECK FOR AIR LEAKS OR A POSSIBLE PUMP TROUBLE.

• THE DISCHARGE GAUGE READING INCREASES

• THE INTAKE GAUGE READING FALLS BELOW ZERO

• THE PRIMING PUMP DISCHARGES WATER TO THE GROUND

CONTINUING TO RUN THE PRIMING PUMP MAY RESULT IN PUMP FAILURE OR DAMAGE.

Utilize the testing provided herein ONLY for the intended purpose. The Repair Verification Operations procedure (paragraph 3.1) is intended as the initial post repair test for a repaired booster

pump and the paragraphs description explains why. If the pump passes the Repair Verification

Operations procedure proceed with the Pumping From Draft Verification Operations procedure

(paragraph 3.4 on page 23). ALWAYS verify a repaired pumps drafting ability before returning the

pump to service.

17

The Vacuum Test (paragraph 3.2 on page 20) is intended as the initial check to determine if a

pump leaks. This test quickly and safely indicates if a leak exists however it typically ONLY indicates a leak is present and usually does NOT locate the leak (or leaks). If a pump fails the Vacuum Test utilize the Pressure Test (paragraph 3.3 on page 22) to locate the leak (or leaks).

3.1. Repair Verification Operations

Perform the following steps when a repair is completed to verify the pump is functional. This procedure is performed by pumping from a hydrant to ensure a clean, high quality water source and

to eliminate the risk of pump damage that could occur from an extended priming period which

could result from attempting to draft with an unverified pump.

NOTES

Refer to department procedures for setting wheel chocks and laying out suction and

discharge hoses.

All valves, drain cocks, and caps should be closed.

A. Prepare truck to pump.

Position truck for best hydrant hookup and discharge hose layout. 1.

Bring truck to a complete stop and come to an idle. (Never attempt to 2.

shift a moving truck from

Apply truck parking brake. 3.

Shift truck transmission into NEUTRAL. 4.

Engage pump PTO switch. 5.

Shift road transmission into proper gear (usually DRIVE). 6.

Check the indicator lights to see if pump is in gear, check speedometer, 7.

and listen as pump goes in gear.

Momentarily press accelerator to ensure shift is complete. 8.

DO NOT LEAVE THE CAB OR ATTEMPT TO PUMP UNTIL ALL OK TO PUMP INDICATORS

IN THE CAB ARE ILLUMINATED. SEE FIGURE 7.

ROAD to PUMP.)

18

Figure 8. Driver Compartment Indicator Lights

ONLY after completing ALL previous steps, exit driving compartment. 9.

DO NOT OPEN THE THROTTLE UNLESS THE GREEN INDICATOR LIGHT IS ON.

SEE FIGURE 8.

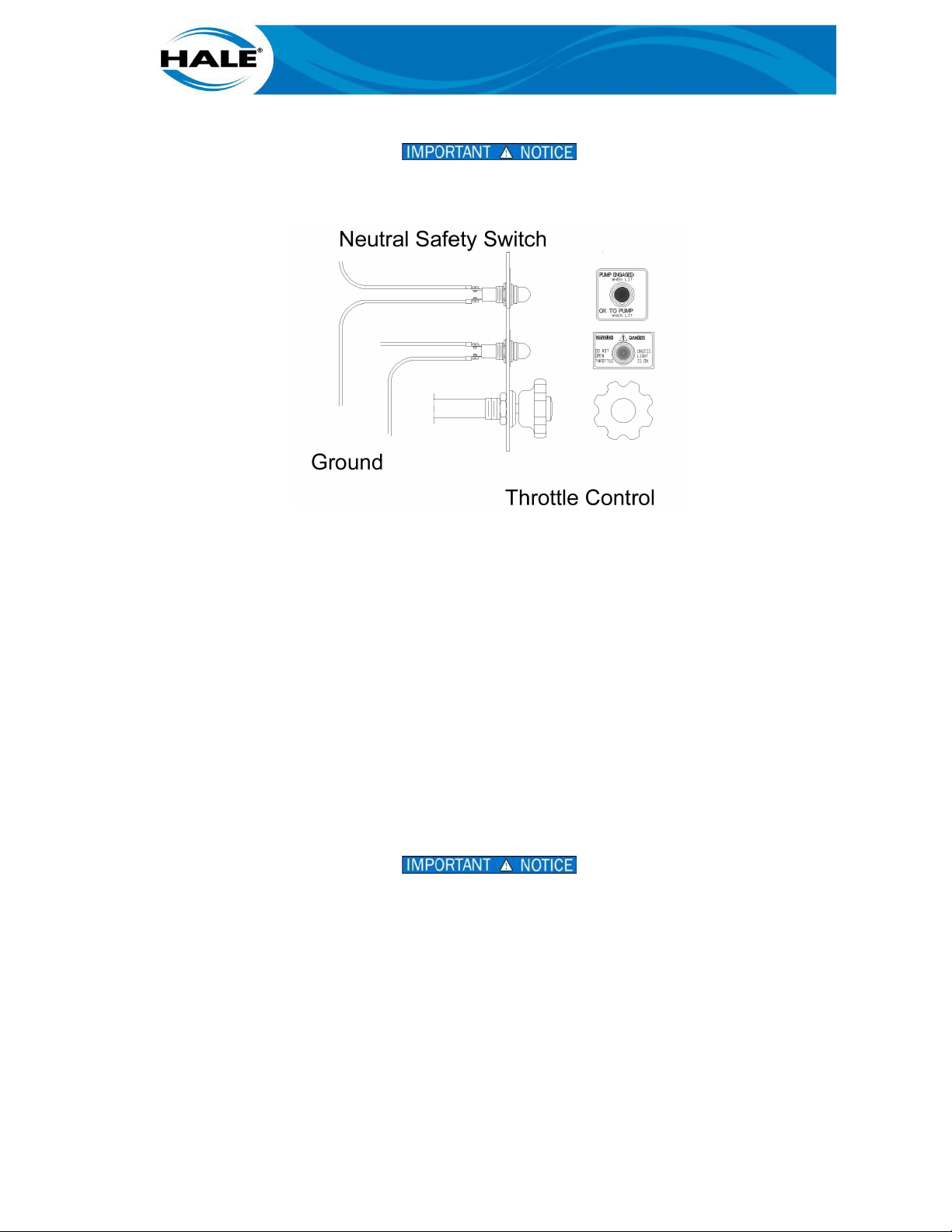

Figure 9. Pump Operator Panel

Verify pump panel shift indicator light is on. 10.

Set wheel chocks. 11.

Complete all hose connections. 12.

B. Prepare pump to pump.

Open hydrant and bleeder valves (to bleed off air in suction hose). 1.

Open suction valve. 2.

If necessary to eliminate air pockets, prime pump. 3.

(For instructions, see paragraph 3.2, Pumping From Draft, on page 20.)

Slowly open appropriate discharge(s). 4.

Advance engine throttle gradually until master discharge gauge indicates 5.

desired pressure.

DO NOT ALLOW THE PRESSURE ON THE INTAKE GAUGE TO GO BELOW ZERO. PLACING A VACUUM ON THE WATER MAIN MAY RESULT IN SERIOUS DAMAGE TO OR FAILURE OF THE WATER MAIN.

NOTES

The master intake gauge reading must be maintained at 5 psi (0.3 bar), minimum. If

the gauge shows a vacuum the pump is attempting to draw more water than the hydrant can supply. When this occurs, reduce the pump flow to increase the pressure.

As the throttle is opened, the pressure gauge reading should increase with the engine speed. If the engine speed increases without an increase in pressure, the pump

is beginning to cavitate. Close the throttle slowly until the pressure begins to drop

and the engine returns to an idle.

19

Standard Tools

Special Tools

Consumables

If pump overheats, perform appropriate following step. 6.

a) If pump is NOT equipped with a Hale TRV valve, open appropriate valve(s) (usually

tank fill or gutter line) to provide a bypass line.

b) If pump is furnished with a Hale TRV valve, open valve to booster tank (both suc-

tion and discharge sides) to circulate water (and/or fill water tank).

C. Verify pump is operating correctly by checking ALL gauge readings.

D. Begin shutdown.

Gradually reduce throttle and pump pressure until engine is at idle speed. 1.

Close discharge(s). 2.

Ensure tank is full of water. 3.

If opened, close bypass line valve(s) or TRV. 4.

Close suction valve. 5.

Place transmission in NEUTRAL. 6.

Disengage PTO. 7.

Close hydrant. 8.

E. Disconnect all hose connections and stow hoses.

F. Make all appropriate Maintenance Log entries.

G. Perform Pumping From Draft Verification Operations procedure (see para-

graph 3.4 on page 23).

3.2. Vacuum Test

Refer to Table 1 for a list of tools and/or consumables required for this procedure.

Table 1. Vacuum Test Tools And Consumables List

PPE

(Eye, Hand, and Ear Protection)

Blanking Cap(s) (As Required)

Tachometer

30 inHg Vacuum Gauge (or Manometer)

(Use ONLY a High Quality Calibrated Gauge/

Manometer)

Shop Rag(s) (As Required)

This test is intended to ONLY test the booster pump for leaks. A known good vacuum pump is

preferred for this test. However, if the apparatus has a primer pump, that primer can be used for

this test to verify both are leak free and the primer does NOT exhibit excessive wear or damage.

If the apparatus associated primer does NOT reach a vacuum of 22 (± 2) inHg (0.745 bar) but

holds a lower vacuum, a fault in the primer is indicated. Perform the following steps to Vacuum

Test a pump.

A. Place blanking cap(s) on pump inlet(s).

B. If no apparatus primer is present, connect a known good primer or vacuum

C. Close discharge valve(s) or place blanking cap(s) on pump outlet(s).

20

pump (along with a vacuum/compound gauge) to highest discharge port.

DO NOT RUN THE PRIMER FOR MORE THAN 45 SECONDS IF PRIME IS NOT

ACHIEVED. IF PRIME IS NOT ACHIEVED IN 45 SECONDS, STOP AND LOOK FOR CAUSES (AIR LEAKS OR BLOCKED SUCTION HOSE). RUNNING THE PRIMER FOR LONGER

PERIODS WITHOUT ACHIEVING PRIME MAY RESULT IN PRIMER AND/OR PUMP DAMAGE OR FAILURE.

NOTE

NFPA 1901 recommends: The time required to prime the pump if the rated capacity

is 1250 gpm or less shall not exceed 30 seconds. If the rated capacity is 1500 gpm

or more, the time to prime the pump shall not exceed 45 seconds.

D. Run primer pump and observe vacuum/compound needle as follows.