Page 1

®

SMD Rework Station

●

Thank you for purchasing the Hakko 850B SMD Rework

Station.

The Hakko 850B is designed to solder and desolder surface

mounted devices with hot air.

Please read this manual before operating the Hakko 850B.

Keep this manual readily accessible for reference.

●

TABLE OF CONTENTS

PACKING LIST / SPECIFICATIONS....................................................... 1

SAFETY INSTRUCTIONS...................................................................... 2

PART NAMES......................................................................................... 3

PREPARATION: ASSEMBLY AND ELECTRICAL CONNECTION......... 4

OPERATION........................................................................................... 5

MAINTENANCE / INSPECTION ............................................................ 7

TEMPERATURE DISTRIBUTION CHART ............................................. 8

OPTIONAL NOZZLES.......................................................................... 11

PARTS LIST / HANDPIECE................................................................. 12

STATION ....................................................................... 13

WIRING DIAGRAM .............................................................................. 15

Page 2

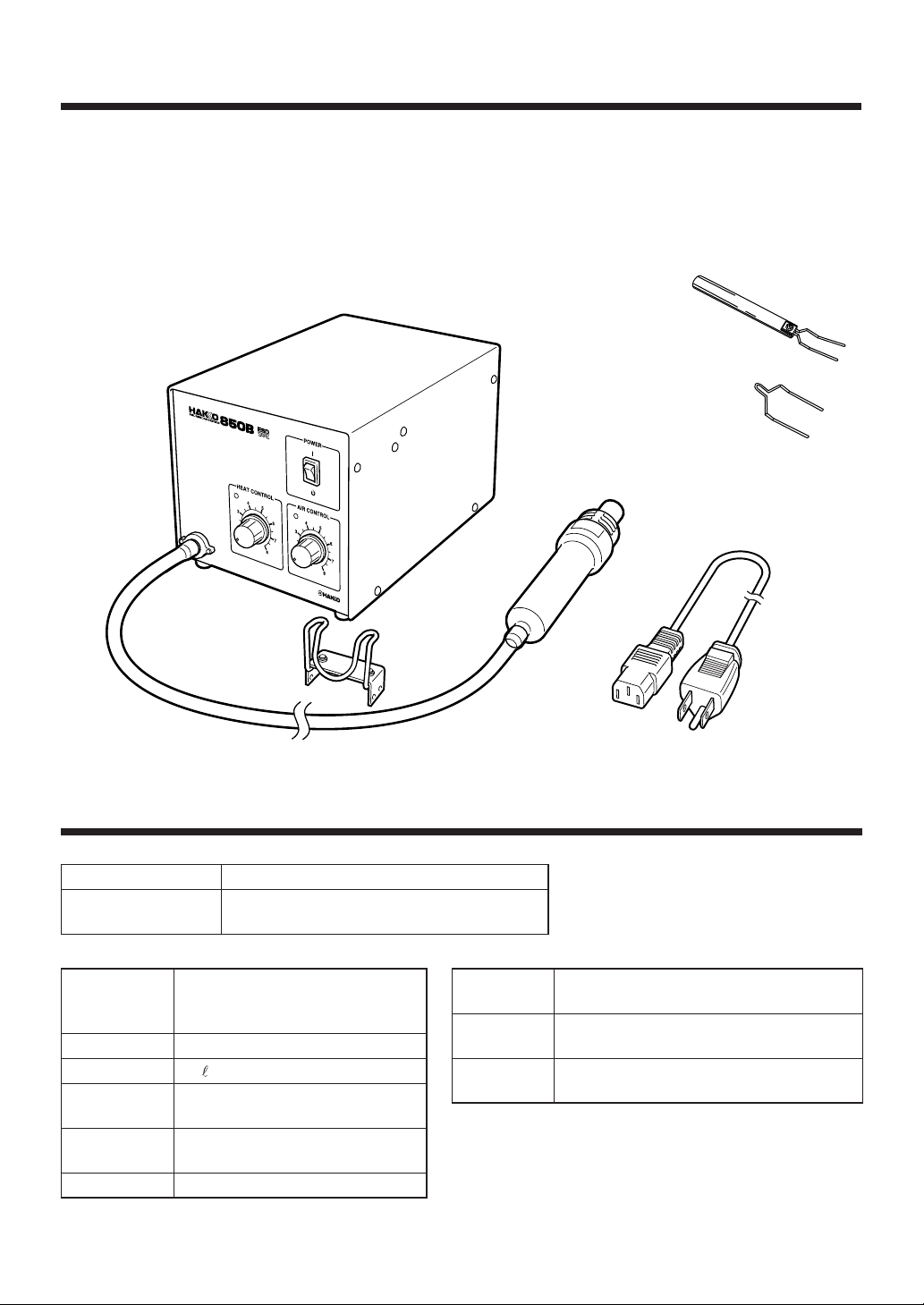

PACKING LIST

Check the contents of the Hakko 850B package and

confirm that all the items listed below are included:

Hakko 850B station ............................................. 1

Po wer cord .......................................................... 1

Handpiece holder ................................................ 1

FP pick-up ........................................................... 1

FP pick-up wire.................................................... 1

Instruction manual ............................................... 1

Hakko 850B station

Handpiece holder

* This product does not include a nozzle. A large

selection of nozzles is available for the Hakko

850B. Select the nozzle or nozzles suitab le for the

work to be performed.

FP pick-up

with (S) wire

FP pick-up wire (L)

Handpiece

Power cord

SPECIFICATIONS

Name

Power consumption

● Station

Power

Consumption

Pump

Capacity

Control

temperature

External

dimensions

Weight

1

Hakko 850B

100V – 280W 110V – 270W 120V – 300W

220V – 300W 230V – 310W 240V – 310W

30 W

(Stand-by power consumption

100 – 120V 2W, 220 – 240V 4W)

Diaphragm pump

/min (max)

23

100˚– 420˚C (212˚– 788˚F)

(Use A1126B)

225(l) × 160(w) × 145(h) mm.

8.9(l) × 6.3(w) × 5.7(h) in.

4 kg. (8.82 lb.)

● Handpiece

Power

consumption

Total length

(w/o cord)

Weight

(w/o cord)

* This product is ESD-protected.

* Specifications and design subject to change without notice.

100V – 250W 110V – 240W 120V – 270W

220V – 270W 230V – 280W 240V – 280W

196(l) mm / 7.72(l) in.

120 g / 0.26 lb.

Page 3

SAFETY INSTRUCTIONS

W ARNING

Warnings and cautions are placed at critical points in this manual to direct the operator's attention

to significant items. They are defined as follows:

W ARNING: Failure to comply with a WARNING may result in serious injury or death.

CAUTION: Failure to comply with a CA UTION ma y result in injury to the operator , or

damage to the items involved. Two examples are giv en below.

●●

● Be sure to comply with following WARNINGS and CAUTIONS for your safety.

●●

W ARNING

● Be sure not to operate the unit with any combination of temperature and air flow settings that

makes the thermal protector trip (the heater lamp turns off during use). This could damage the

unit.

● After use, do not disconnect the plug during the automatic cool-down process.

CAUTION

When the power is ON, the temperature of the hot air and the nozzle ranges from 100° to

450°C. (212° to 842°F.). To avoid injury to personnel or damage to items in the work area,

observe the following:

● Do not direct the hot air toward personnel or touch the metal parts near the nozzle.

● Do not use the product near combustible gases or flammab le materials.

● Advise those in the work area that the unit can reach very high temperatures and should be

considered potentially dangerous.

● Turn the power OFF when no longer using the Hakko 850B or when leaving it unattended.

● Before replacing parts or storing the unit, allow the unit to cool and then turn the power OFF.

●●

● To prevent accidents and failures, be sure to take the following precautions:

●●

● Do not strike the handpiece against hard surfaces or otherwise subject it to physical shoc k. This

will damage the quartz glass shield around the heating element, and could damage the heater

as well.

● Be sure the unit is grounded. Alw ays connect power to a grounded receptacle.

● Do not disassemble the pump.

● Do not modify the unit.

● Use only genuine Hakko replacement parts.

● Do not wet the unit or use the unit with wet hands.

● Remove po wer cord by holding the plug - not the wires.

● Make sure the work area is well ventilated.

● The Hakko 850B is not intended for use by children or infirm persons without supervision.

● Children should be supervised to ensure that they do not play with the Hakko 850B.

2

Page 4

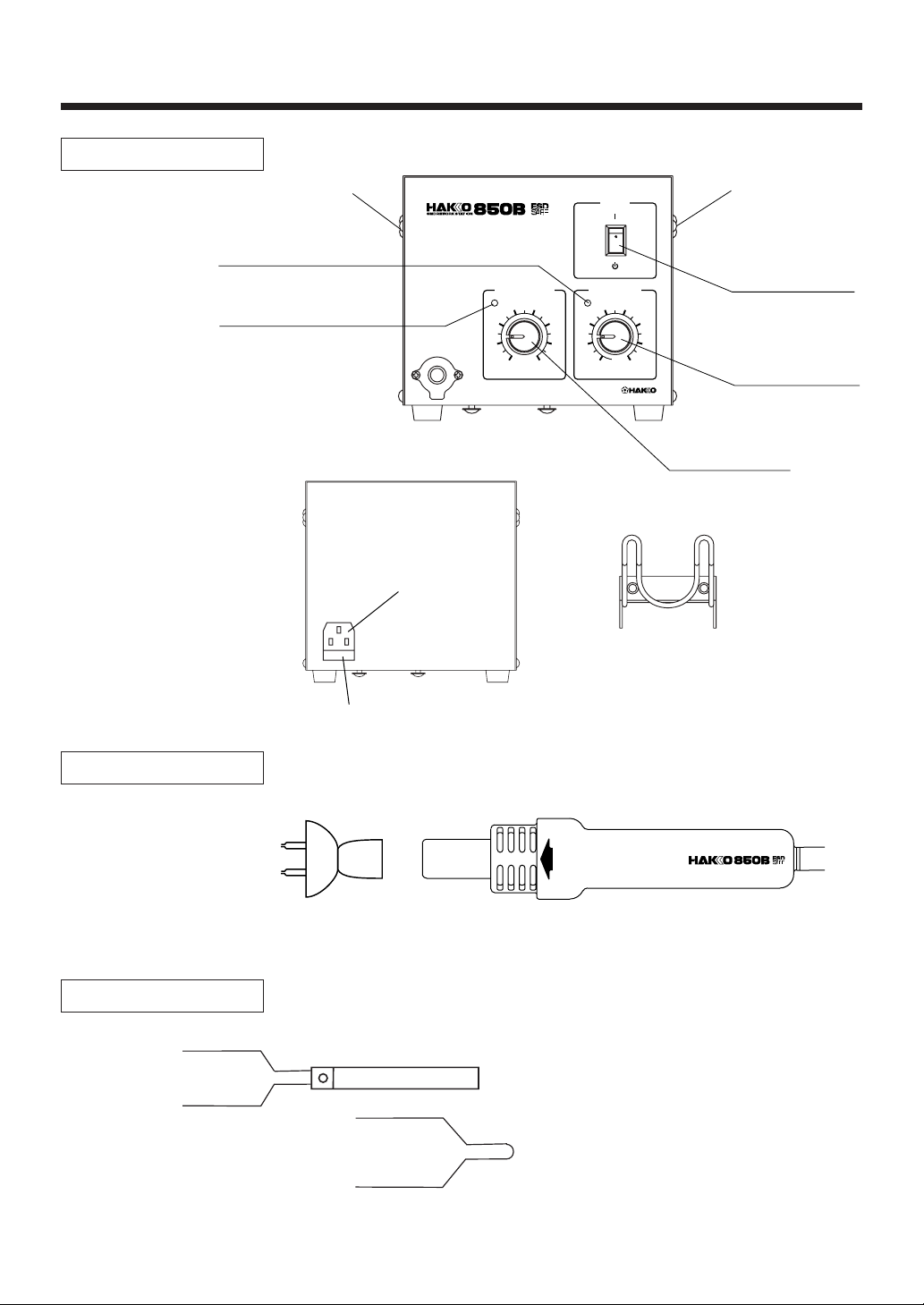

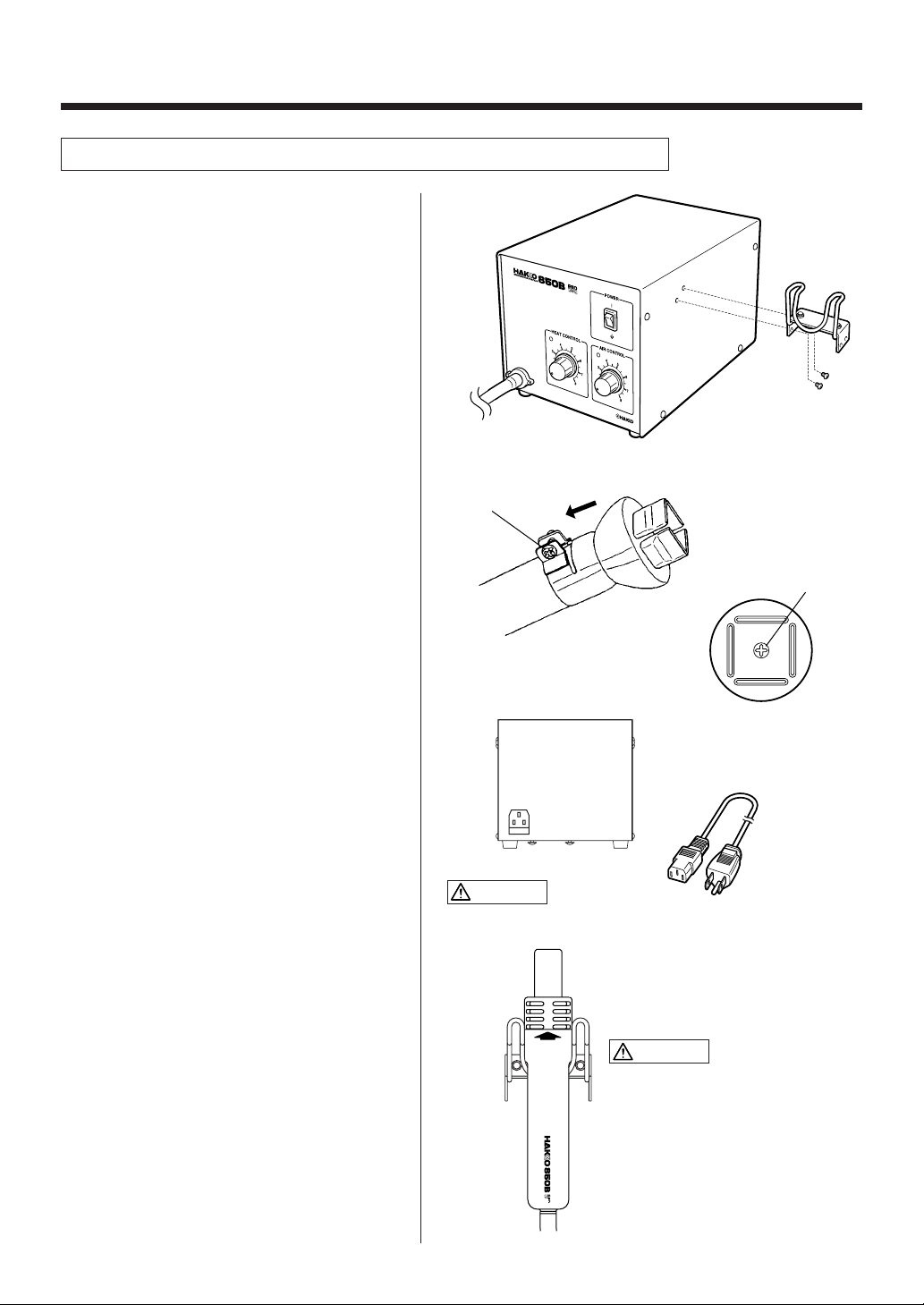

PART NAMES

Station

Handpiece holder

mounting screw

Air flow lamp

Heater lamp

Power

receptacle

HEAT CONTROL

4

3

2

1

POWER

AIR CONTROL

4

5

6

7

8

5

3

2

6

7

1

8

Handpiece holder

mounting screw

Power switch

Air flow

control knob

Temperature

control knob

Handpiece holder

Handpiece

Accessories

Fuse

Nozzle (not included)

FP pick-up with (S) wire

(Width of wire 14mm (0.55in.))

FP pick-up wire (L)

(Width of wire 30mm (1.18in.))

HOT

CAUTION

3

3

Page 5

PREPARATION: ASSEMBLY AND ELECTRICAL CONNECTION

Preparation: Assembly and Electrical Connection

A. Station Assembly

●●

● Attach the handpiece holder.

●●

Remove the handpiece holder mounting

screw from the side of the station. Attach the

handpiece holder to the station. (Figure 1)

(The handpiece holder can be installed on

either the left or right side.)

(Figure 1)

B. Handpiece Assembly

●●

● Attach the nozzle.

●●

Loosen the nozzle mounting screw. Attach

the nozzle as shown in the drawing.

(Figure 2)

C. Electrical Connection and

Power ON

1. Connect the power cord to the power

receptacle on the back panel of the

station. (Figure 4)

2. Place the handpiece on the holder.

(Figure 5)

3. Plug the power cord into a grounded wall

socket. After connection, the automatic

blowing function will start sending air

through the pipe, but the heating element

remains cool.

4. T urn the pow er switch ON.

NOTE: The power switch may be turned on at

any time while the automatic blowing

function is operating. Once the power

switch is turned on, the heating element

will begin to warm up.

Tighten the nozzle

mounting screw.

Inside screw

(Figure 2)

(Figure 3)

When installing an optional

nozzle to the Hakko 850B, do

not remove this inside screw.

(Figure 4)

CAUTION

This product is ESD-protected. Be sure to use a g rounded wall

socket.

HOT

CAUTION

CAUTION

When not in use, place the handpiece

on the holder.

T op View

(Figure 5)

4

Page 6

OPERATION

●●

● QFP Desoldering

●●

1. Adjust the air flow and temperature

control knobs.

Refer to the temperature distribution chart

(page 8) to adjust the air flow and temperature control knobs. Wait for the temperature to stabilize for a short period of time.

HEAT CONTROL

4

3

2

1

POWER

AIR CONTROL

4

5

6

7

8

5

3

6

2

7

1

8

Air flow control knob

WARNING

If the thermal protector is tripped (the heater

lamp turns off during use), reduce the temperature setting or increase the air flow . Be sure

not to operate the unit with temperature and air

flow settings that makes the thermal protector

trip. This could damage the unit.

2. Place the FP pick-up under the IC lead.

Slip the FP pick-up wire under the IC lead.

(Refer to the photo shown.)

If the width of the IC does not match the

size of the FP pick-up , adjust the width of

the pick-up by squeezing the wire. In case

of PLCC or small components such as

chip resistors, desolder by using

tweezers, etc.

3. Heating

Hold the handpiece so that the nozzle is

located directly over , but not touching the

IC, and allow the hot air to melt the solder .

Be careful not to touch the leads of the IC

with the nozzle.

Temperature control knob

4. Remove the IC.

Once the solder has melted, remove the

IC by lifting the FP pick-up.

5. Remove any remaining solder.

After removing the IC, remov e remaining

solder with a soldering iron and wick or

desoldering tool.

5

Page 7

OPERATION

●●

● QFP Soldering

●●

1. Apply the solder paste.

Apply the proper quality of solder paste

and install the SMD on the PWB.

2. Preheat the SMD.

Refer to the photo to preheat SMD.

3. Soldering

Heat the lead frame ev enly.

4. Cleaning

When soldering is completed, clean the

residual flux from the board with an

appropriate cleaner.

NOTE:

Soldering with hot air has many advantages,

such as the inherent ability to pre-heat the

component being replaced. As with any

soldering process, however, there is always the

possibility of forming solder balls, bridges

between leads, and inadequate solder joints.

Always inspect the finished solder joints for

structural and electrical integrity.

●●

● Turn the power switch off.

●●

After the power switch is turned off, an

automatic blowing function begins sending

cool air through the pipe in order to cool the

handpiece. Do not disconnect the plug

during this cooling process.

CAUTION

During the cooling process, the amount of air is

controlled by the setting of the air flow adjustment

knbob. Hakko recommends setting the knob at 8

when cooling for greatest efficiency.

6

Page 8

MAINTENANCE / INSPECTION

●●

● Broken heating element

●●

A. Open the handpiece

1. Remove the three screws holding the

handpiece together. (Figure 1)

2. Move the tube away from the handpiece,

as shown.

3. Open the handpiece. Disconnect the

grounding wire sleeve (1) and pipe from

the protruding portion of the handle.

Remove the pipe.

CAUTION

Quartz glass and heat insulation are inside the

pipe. Be careful not to drop or lose these items.

(Figure 1)

Connector (2)

4. Disconnect the connector (2) and remove

the heating element.

B. Measure the resistance

value

Connect an ohmmeter across the connector

terminals (a). The correct values are approximately:

26-40Ω (100-120V), 70-100Ω (220-240V).

If the resistance value is incorrect, replace

the part.

(Refer to the instructions included with the

replacement part.)

CAUTION

Handle the heating element with care.

the heating element wire!

Insert the handle's projection into the hole in the

pipe.

●●

● Replacing the fuse

●●

Never rub

Grounding wire

sleeve (1)

(a)

1. Unplug the power cord from the power

receptacle.

2. Remove the fuse holder.

3. Replace the fuse.

5A (100-120V), 3.15A (220-240V)

4. Put the fuse holder back in place.

7

Page 9

TEMPERATURE DISTRIBUTION CHART

CAUTION These charts are for reference. If the thermal protector trips, reduce the temperature setting

or increase the air flow.

Test criteria: Measured at a point 3mm (0.12 in.) from the nozzle by recorder.

A1124B

Single Ø2.5 (0.09)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1127B

Air Temperature

˚C

QFP 17.5×17.5 (0.68×0.68)

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1125B

QFP 10×10 (0.39×0.39)

Air flow

68

4

2

1

Air flow

4

2

6

8

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

A1128B

Air Temperature

˚C

QFP 14×20 (0.55×0.78)

500

(932˚F)

300

(572˚F)

100

(212˚F)

Air flow

2

46

15842736

Temperature Control Knob

Air flow

15842736

Temperature Control Knob

4

2

8

6

8

A1126B

QFP 14×14 (0.55×0.55)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1129B

Air Temperature

˚C

QFP 28×28 (1.1×1.1)

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

Air flow

2

Air flow

2

4

6

8

4

6

8

A1130

Air Temperature

˚C

Air Temperature

˚C

Single Ø4.4 (0.17)

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1133

SOP 7.5×15 (0.3×0.59)

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

1

Air flow

2

Air flow

4

6

4

2

A1131

SOP 4.4×10 (0.17×0.39)

8

6

8

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

Air flow

2

4

15842736

Temperature Control Knob

A1134

SOP 7.5×18 (0.3×0.7)

Air flow

15842736

Temperature Control Knob

4

2

6

8

6

8

A1132

SOP 5.6×13 (0.22×0.51)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1135B

PLCC 17.5×17.5 (0.68×0.68)

(44 Pins)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

Air flow

2

2

46

Air flow

8

4

6

8

8

Page 10

TEMPERATURE DISTRIBUTION CHART

A1136B

PLCC 20×20 (0.78×0.78)

(52 Pins)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1139B

PLCC 12.5×7.3 (0.49×0.29)

500

(932˚F)

300

(572˚F)

100

(212˚F)

(18 Pins)

15842736

Temperature Control Knob

Air Temperature

˚C

Air flow

2

Air flow

2

A1137B

PLCC 25×25 (0.98×0.98)

4

6

8

4

6

8

Air Temperature

˚C

Air Temperature

˚C

(68 Pins)

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1140B

PLCC 11.5×11.5 (0.45×0.45)

(28 Pins)

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

Air flow

2

2

4

Air flow

6

8

4

6

8

A1138B

PLCC 30×30 (1.18×1.18)

(84 Pins)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1141B

PLCC 11.5×14 (0.45×0.55)

(32 Pins)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

Air flow

2

Air flow

2

4

6

8

4

6

8

A1142B

Bent Single 1.5×3 (0.06×0.12)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

1

15842736

Temperature Control Knob

A1257B

SOP 11×21 (0.43×0.83)

15842736

Temperature Control Knob

2

Air flow

A1182B

Air flow

8

4

6

4

2

6

8

Air Temperature

˚C

Air Temperature

˚C

(932˚F)

(572˚F)

(212˚F)

BQFP 24×24 (0.94×0.94)

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1258B

SOP 7.6×12.7 (0.3×0.5)

500

300

100

15842736

Temperature Control Knob

Air flow

2

24

Air flow

6

4

6

8

8

A1187B

TSOL 18.5×8 (0.73×0.31)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1259B

SOP 13×28 (0.51×1.1)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

Air flow

24

Air flow

2

6

8

4

6

8

9

Page 11

A1260B

SOP 8.6×18 (0.34×0.71)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

Air flow

24

A1261B

QFP 20×20 (0.78×0.78)

6

8

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

2

Air flow

4

6

8

Air Temperature

˚C

A1262B

QFP 12×12 (0.47×0.47)

500

(932˚F)

300

(572˚F)

Air flow

2

4

6

8

100

(212˚F)

15842736

Temperature Control Knob

A1263B

Air Temperature

˚C

Air Temperature

˚C

QFP 28×40 (1.1×1.57)

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1325

Dual Single Ø1.5×5-10

(0.06×0.2-0.39)

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

A1264B

Air flow

4

Air flow

6

8

6

8

2

4

2

Air Temperature

˚C

QFP 40×40 (1.57×1.57)

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

2

Air flow

4

6

8

100

(212˚F)

15842736

Temperature Control Knob

A1265B

QFP 32×32 (1.26×1.26)

Air Temperature

˚C

500

(932˚F)

300

(572˚F)

100

(212˚F)

15842736

Temperature Control Knob

2

Air flow

4

6

8

100

(212˚F)

15842736

Temperature Control Knob

10

Page 12

OPTIONAL NOZZLES

NOTE:

The size in Name/

Specification

indicates the size

of IC package.

A1124B Single Ø2.5

(0.09)

Ø2.5 (I.D.)

(0.09)

A1129B QFP 28×28

(1.1×1.1)

A:29.7 (1.17)

6.9

(0.27)

B:29.7 (1.17)

A: 9 (0.35)

B:14 (0.55)

29 (1.14)

A1134 SOP 7.5×18

(0.3×0.7)

7.2 (0.28)

A1139B PLCC 12.5×7.3

(0.49×0.29)

(18 Pins)

A1187B TSOL 18.5×8

(0.73×0.31)

QFP SOP

A1125B QFP 10×10

(0.39×0.39)

A1130 Single Ø4.4

(0.17)

29

(1.14)

Ø4.4 (I.D.)

(0.17)

A1135B PLCC 17.5×17.5

(0.68×0.68)

(44 Pins)

19

(0.75)

15 (0.59)

A1140B PLCC 11.5×11.5

(0.45×0.45)

(28 Pins)

6.9

(0.27)

10 (0.39)

A1257B SOP 11×21

(0.43×0.83)

PLCC SOJ

A:10.2 (0.4)

B:10.2 (0.4)

10

(0.39)

A:18.5 (0.73)

B:18.5 (0.73)

10

(0.39)

15

(0.59)

10

A:13 (0.51)

B:13 (0.51)

A

B

A1126B QFP 14×14

(0.55×0.55)

A:15.2 (0.6)

B:15.2 (0.6)

15

(0.59)

A1131 SOP 4.4×10

(0.17×0.39)

4.8

(0.19)

A1136B PLCC 20×20

(0.78×0.78)

(52 Pins)

19 (0.75)

A1141B PLCC 11.5×14

(0.45×0.55)

(32 Pins)

(0.39)

A:15 (0.59)

B:13 (0.51)

10 (0.39)

A1258B SOP 7.6×12.7

(0.3×0.5)

Air nozzle

15

(0.59)

10

(0.39)

A:21 (0.83)

B:21 (0.83)

0.8

(0.03)

1.8

(0.07)

A1127B QFP 17.5×17.5

(0.68×0.68)

19

A1132 SOP 5.6×13

(0.22×0.51)

A1137B PLCC 25×25

(0.98×0.98)

(68 Pins)

19

(0.75)

A1142B Bent Single 1.5×3

(0.06×0.12)

15

(0.59)

A1259B SOP 13×28

(0.51×1.1)

(0.75)

5.7

(0.22)

24 (0.94)

45˚

19

(0.75)

A:19.2 (0.76)

B:19.2 (0.76)

15

(0.59)

24

A:26 (1.02)

B:26 (1.02)

1.5

(0.06) (I.D.)

3 (0.12) (I.D.)

mm (inch)

A1128B QFP 14×20

(0.55×0.78)

A:15.2 (0.6)

B:21.2 (0.83)

21

(0.83)

A1133 SOP 7.5×15

(0.3×0.59)

7.2

(0.28)

A1138B PLCC 30×30

(1.18×1.18)

(84 Pins)

(0.94)

A:31 (1.22)

29 (1.14)

A1182B BQFP 24×24

(0.94×0.94)

21 (0.83)

A1260B SOP 8.6×18

(0.34×0.71)

B:31 (1.22)

A:24.2 (0.95)

B:24.2 (0.95)

15

16

21

(0.59)

(0.63)

(0.83)

29

(1.14)

18.5 (0.73)

A1261B QFP 20×20

(0.78×0.78)

21 (0.83)

A1325 Dual Single

ø1.5×5-10

(0.06×0.2-0.39)

Adjustable Pitch

11

10

21

A:20.2 (0.8)

B:20.2 (0.8)

5 (0.2)

(0.39)

11.7 (0.46)

A1262B QFP 12×12

(0.47×0.47)

(0.83)

12 (0.47)

The pitch

between the

two nozzles

is adjustable.

10 (0.39)

21

(0.83)

12

(0.47)

A:12.2 (0.48)

B:12.2 (0.48)

5 (0.2)

8.2 (0.32)

A1263B QFP 28×40

(1.1×1.57)

A:27.7 (1.09)

B:39.7 (1.56)

10 (0.39)

ø1.5 (I.D.)

(0.06)

39 (1.54)

Screw

11.7

(0.46)

13.5 (0.53)

A1264B QFP 40×40

(1.57×1.57)

29

(1.14)

39 (1.54)

29

(1.14)

39

(1.54)

A:40.2 (1.58)

B:40.2 (1.58)

8.7 (0.34)

A1265B QFP 32×32

(1.26×1.26)

31

(1.22)

19

(0.75)

31

(1.22)

A:32.2 (1.27)

B:32.2 (1.27)

Page 13

PARTS LIST / HANDPIECE

NOTE:

Spare or repair parts do not include mounting

screws, if they are not listed on the description.

Screws must be ordered separately.

1

Self tapping screw

Nominal size

2.6×10 (2)

3

6

Self tapping screw

Nominal size

3×12 (3)

5

2

7

4

8

7

Item No.

1

2

3

4

5

6

7

8

Part No.

B2544

A1143

A1144

A1145

A1146

B1188

B1441

B2556

B1354

B2634

B2635

Part Name

Handle

Heating element

Heating element

Heating element

Heating element

Silicone hose

Pipe assembly

Cord assembly

Cord stopper

Protective spring

Clamp

Description

With screws

100V

110V

120V

220-240V

With screws

(120V only) With nylon strap

(120V only)

12

Page 14

PARTS LIST / STATION

NOTE:

Spare or repair parts do not include mounting

screws, if they are not listed on the description.

Screws must be ordered separately.

Item

No.

10

11

12

13

14

15

16

17

Part

No.

1

B2539

2

B2477

3

B2472

4

B2471

B2480

B2481

5

B2473

6

B2468

B1258

7

B2384

8

B2540

9

B2463

B2542

B2545

B2546

B2547

B2541

B2537

B1028

B1204

–

B2543

B2419

B2421

B2422

B2423

B2424

B2425

B2426

B2436

Part Name

Cover

Handpiece holder

Sound-proof tank

Air pump

Air pump

Air pump

Silicone tube

Fuse

Fuse

Power receptacle

Chassis

Radiation sheet

P.W.B .

P.W.B .

P.W.B .

P.W.B .

Switch

Air nozzle

Knob

Rubber foot

Exhaust nozzle

Tube connector

Power cord, 3 core &

American plug

Power cord, 3 core ,

no plug

Power cord, 3 core ,

BS plug

Power cord, 3 core

European plug

Power cord, 3 core

European plug

Power cord, 3 core ,

BS plug

Power cord, 3 core ,

Australian plug

Power cord, 3 core ,

Chinese plug

Description

assembly

100V, with high nut,

nylon tape, double-side tape

110-120V, with high nut,

nylon band, double-side tape

220-240V, with high nut,

nylon band, double-side tape

8×5×130l (mm.)

0.3×0.2×5.1l (in.)

125V-5A

250V -3.15A

100V,

with potentiometer, triac

110-120V,

with potentiometer, triac

220-230V,

with potentiometer, triac

240V,

with potentiometer, triac

With cord stopper

With screw

Set of 4

If you need exhaust nozzle,

contact your Hakko

representative.

With silicone tube

India

Korea

Eur.

U.K.

Pan head screw

with washer

(w/ spring washer)

M3×6 (4)

10

Pan head screw

(Zn black) M3×10 (2)

Truss screw

(Zn black) M4×5 (12)

11

12

13

1

Pan head screw

with washer

(w/ spring,

plain washer) M3×8

9

14

3

4

2

Pan head screw

with washer

(w/ spring washer)

M4×10 (4)

8

Pan head screw

with washer

(w/ spring washer)

M4×6 (2)

External tooth

lock washer

(nominal size 4)

(2)

6

7

5

16

15

17

Plain washer

polycarbonate

(nominal size 5) (4)

Truss screw

(M4×16) (4)

13

14

Page 15

WIRING DIAGRAM

Pump

Power switch

Power

receptacle

Heating element

P.W. B . /

Heat control

®

OVERSEAS AFFILIATES

U.S.A.

AMERICAN HAKKO PRODUCTS, INC.

25072 ANZA DR. SANTA CLARITA, CA 91355, U.S.A.

TEL: (661) 294-0090 FAX: (661) 294-0096

Toll Free (800)88-HAKKO

4 2 5 5 6

http://www.hakkousa.com

HONG KONG

HAKKO DEVELOPMENT CO., LTD.

ROOM 1504, EASTERN HARBOUR CENTRE,

28 HOI CHAK STREET, QUARRY BAY, HONG KONG.

TEL: 2811-5588 FAX: 2590-0217

http://www.hakko.com.hk/

CHINA

HAKKO DEVELOPMENT CO., LTD.

ROOM 1112-1115, 11 FLOOR, INTERNATIONAL BANK

TOWER 191 DONGFENG ROAD WEST, GUANGZHOU

510180, CHINA.

TEL: (020)8135-0112, 8135-0113 FAX: (020)8135-0181

TAIWAN

HAKKO DEVELOPMENT CO., LTD.

5F, NO.111-1, HSING TE RD.,SANCHUNG, TAIPEI

HSIEN, TAIWAN.

TEL: (02)8512-4588 FAX: (02)8512-4258

15

Triac

HEAD OFFICE

4-5, SHIOKUSA 2-CHOME, NANIWA-KU, OSAKA, 556-0024 JAPAN

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

http://www.hakko.com

SINGAPORE

HAKKO PRODUCTS PTE., LTD.

1, GENTING LINK #02-04, PERFECT INDUSTRIAL

BUILDING, SINGAPORE 349518

TEL: 748-2277 FAX: 744-0033

MALAYSIA

HAKKO PRODUCTS SDN BHD

MALAYSIA HEAD OFFICE

NO.22,JALAN PEMBERITA U1/49,SEKSYEN U1,

TEMASYA INDUSTRIAL PARK,40150 GLENMARIE,

SHAH ALAM,SELANGOR DARUL EHSAN,WEST MALAYSIA.

TEL: (03)519-5223 FAX: (03)519-5221

PENANG BRANCH

19,LORONG IKS JURU 3,

TAMAN PERINDUSTRIAN RINGAN JURU,

14100 SEBERANG PERAI TENGAH,

PENANG,MALAYSIA.

TEL: (04)507-0888 FAX: (04)507-0999

JOHORE BAHRU BRANCH

45A,JALAN SRI BAHAGIA 5,TAMAN SRI BAHAGIA,

81200 JALAN TAMPOI,JOHOR BAHRU,MALAYSIA.

TEL: (07)236-7766 FAX: (07)237-4655

PHILIPPINES

HAKKO PHILS TRADING CO., INC.

NO. 415 WINDSOR TOWER CONDOMINIUM,

163 LEGASPI ST., LEGASPI VILLAGE MAKATI,

METRO MANILA, PHILIPPINES

TEL: (02)817-0712, 815-4993 FAX: (02)810-7649

INDONESIA

P.T. HAKKO PRODUCTSTAMA INDONESIA

COMP BUMI INDAH BLOK IV NO. 40 NAGOYA BATAM, INDONESIA.

TEL: (778)457-459 FAX: (778)452-772

P.T. HAKKO PRODUCTSTAMA INDONESIA

KEBON JERUK PLAZA, BLOK D NO. 6, JALAN RAYA PERJUANGAN,

JAKARTA BARAT, JAKARTA 11530, INDONESIA.

TEL: (21)532-4083 FAX: (21)532-4082

MA00068JB000807

Aug. 2000

Loading...

Loading...