Page 1

FEEDER WITH

SOLDER CUTTING FUNCTION

●

Thank you for purchasing the Hakko 374 Self Feeder.

Please read this manual carefully before operating the

Hakko 374. Store the manual in a safe, easily accessible

place for future reference.

●

TABLE OF CONTENTS

SAFETY INSTRUCTIONS / SPECIFICA TIONS............................... 1

P A RT NAMES (FEED CONTROLLER UNIT) .................................. 2

P A RT NAMES (IRON SIDE), ASSEMBLY (IRON SIDE)..................3

ASSEMBL Y (FEED CONTROLLER UNIT) ...................................... 4

OPERATION .................................................................................... 5

MAINTENANCE ............................................................................... 6

OPTIONAL FEEDER PEN ............................................................... 7

OPTIONS AND REPLACEMENT PAR TS ........................................ 8

P AR TS LIST............................................................................... 9, 10

TROUBLESHOOTING ................................................................... 11

Page 2

SAFETY INSTRUCTIONS

■To avoid injury, do not attempt to assemble

while the soldering iron is hot.

■The cutting plate is sharp. Be careful not to cut

your fingers.

■When resin core solder that has been cut is

not used, the properties of the resin (flux) may

deteriorate with time.

■Once the solder has been cut and is inside the

guide pipe, the heat from the soldering iron may

accelerate the deterioration of the resin (flux).

Use solder that is inside the guide pipe as soon

as possible.

■Do not damage the guide pipe by bending or

twisting it.

SPECIFICATIONS

■Do not allow the tube to be bent at a severe

angle. Otherwise, it will become clogged with

solder.

■Keep the cutting blade, driving pulley, and

following pulley clean of solder and flux using

a brush or other suitable cleaning device.

■The switch input is no-voltage input. Do not

apply voltage to the switch jack.

■Periodically remove the nozzle and clean off

any accumulated flux.

■Do not damage the return length adjustment

knob by turning it with excessive force.

Power consumption

Motor rating

Solder diameter

Solder feed time

Solder feed speed

Solder feed quantity

Solder return quantity

Outer dimensions

Weight

*Specifications and design subject to change without notice.

6 W

24V DC, 3.2 W

0.6, 0.8, 1.0, 1.2, 1.6 mm

(0.02, 0.03, 0.04, 0.05, 0.06 in.)

0 to 7 sec.

4.5 to 26 mm/sec.

(0.18 to 1.02 in./sec.)

0 to 182 mm

(0 to 7.17 in.)

0 to 5 mm

(0 to 0.2 in.)

107(W) × 106(H) × 215(D) mm

(4.2(W) × 4.2(H) × 8.5(D) in.)

1.6 kg (3.5 lb.)

(fixed speed)

●●

●Solder diameters

●●

The solder diameters that can be used with the

Hakko 374 are shown in the table below . Certain

parts may need to be changed to accommodate

the desired diameter. See “Changing the solder

diameter” on page 4 for details.

Up to 1-kg bobbins of solder can be used.

●●

●Soldering irons

●●

Soldering iron

Hakko 900M

(used with Hakko 926, 927, and 928)

Hakko 900L

(used with Hakko 926, 927, and 928)

Hakko 902

(used with Hakko 931 and 932)

Hakko 904 (used with Hakko 929)

Hakko Dash

Hakko Mach

Hakko 907 (used with 936 and 937)

Hakko 908 (used with 936 and 937)

I

Comments

Only when footswitch is used.

1

Page 3

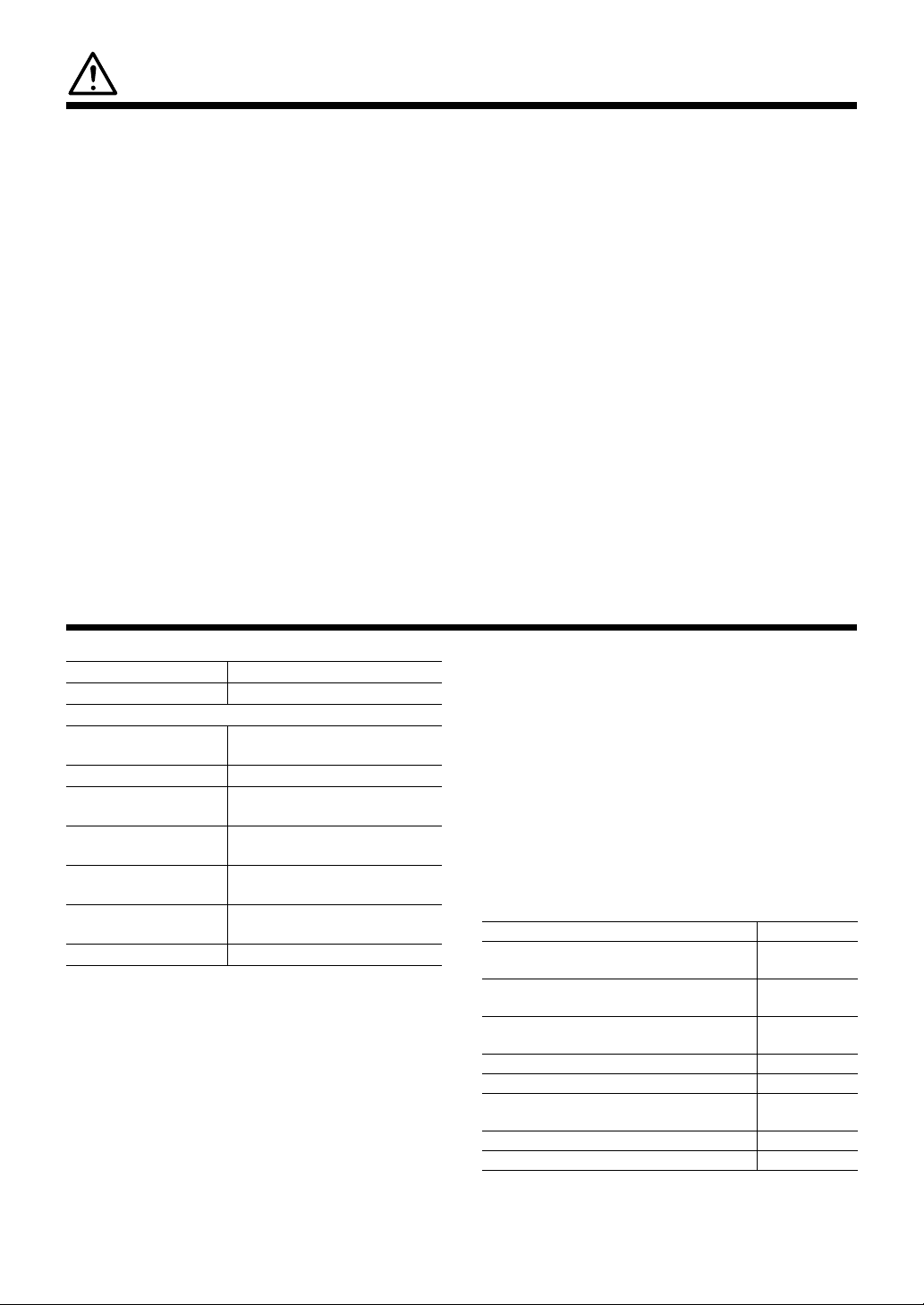

PART NAMES

●●

●Feed controller unit

●●

Switch jack

Mode switch

Feed time control knob

Feed speed control knob

Feed unit cover

Power switch

Following

pulley asse’y

Arm

AA'

Cutting blade

Driving pulley shaftFollowing gear shaft

Following pulley set screw

Driving

pulley asse’y

Feed nozzle

set screw

Feed nozzle

connection hole

Arm mounting screw

Tension adjusting screw

Return length adjusting knob

A'

Driving pulley

Driving pulley set screw

Supply nozzle

Motor mounting

plate

Following pulley

Stopper

A

Arm support shaft

Arm

Solder

bobbin shaft

2

Page 4

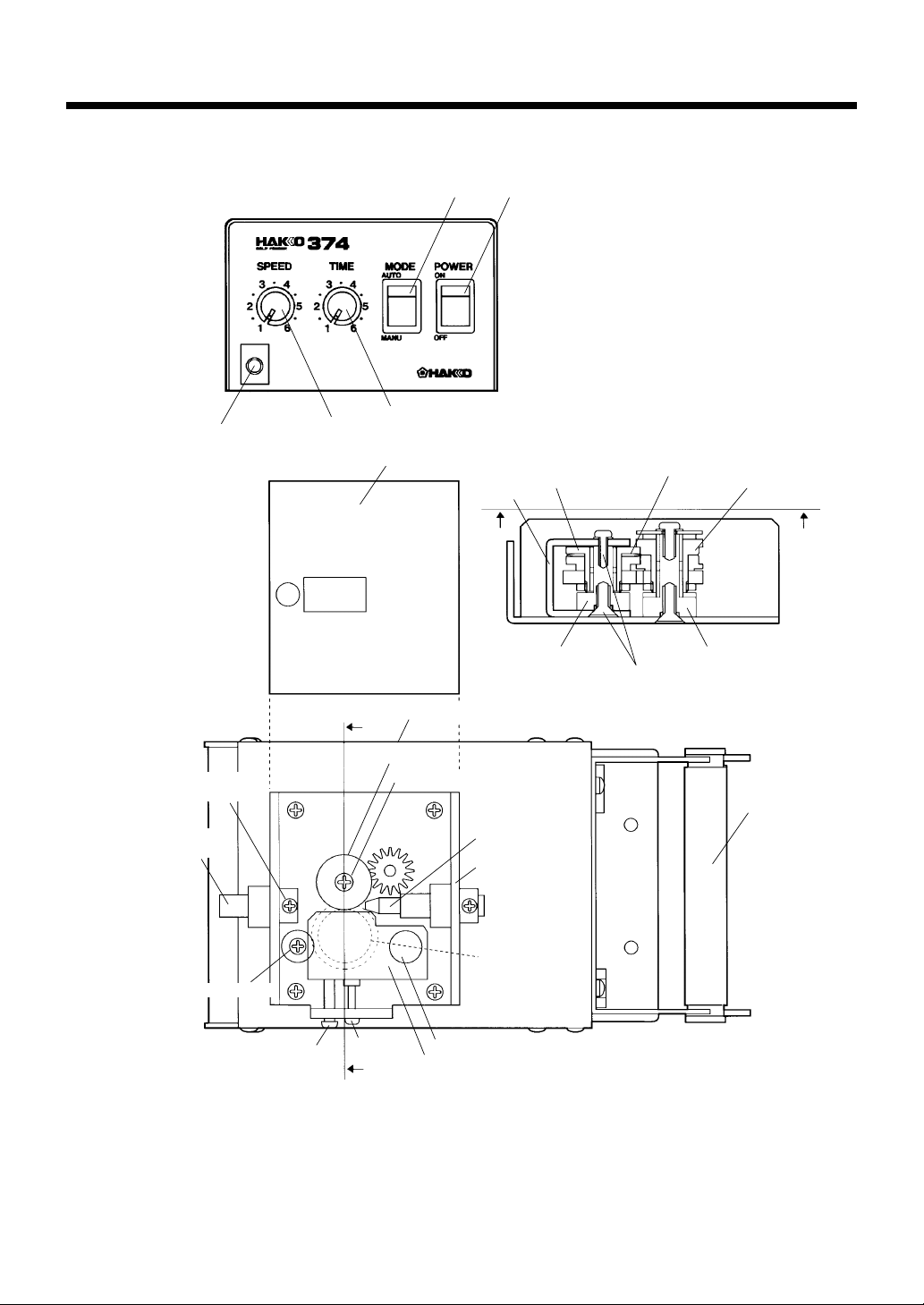

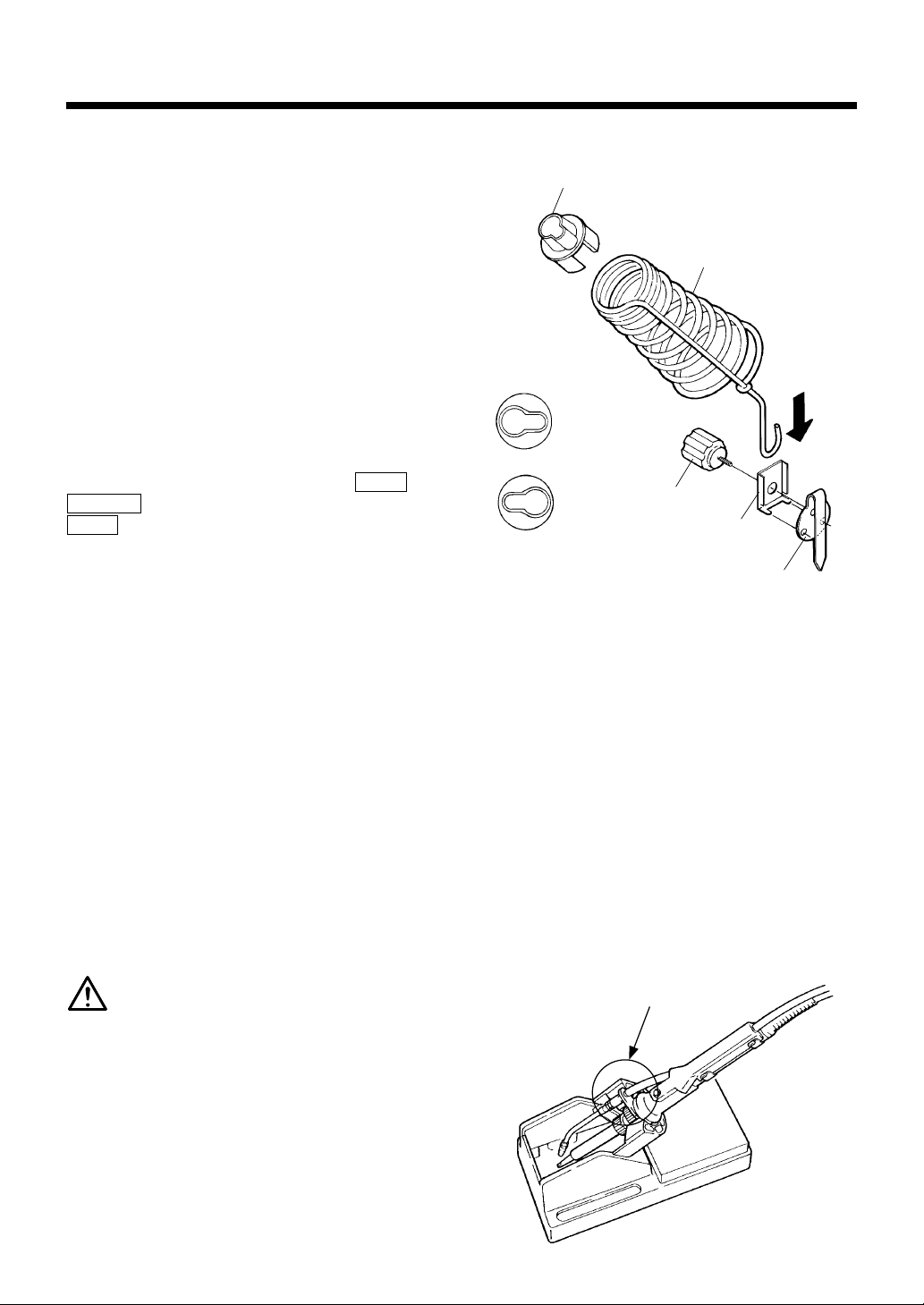

PART NAMES (IRON SIDE)

G

The guide pipe assembly and the tube unit are optional.

Select in accordance with the soldering iron and solder diameter to be used. (See page 8.)

●●

●Guide pipe assembly

●●

Guide pipe locking nut

Nozzle

Guide pipe

Guide pipe

support plate

Joint

●●

●Tube unit

●●

Tube

Feed switch

Feed nozzle

Attachment

Mini plug

ASSEMBLY (IRON SIDE)

Make sure the selected guide pipe assembly or tube unit matches the soldering iron and solder diameter to be used.

(1)Attaching the guide pipe

assembly

The guide pipe assembly is attached between the

nipple (or nut) and the handle. Depending on the type

of soldering iron, a washer may be necessary. See

the figures below.

CAUTION

●To avoid injury, do not attempt to assemble while the

soldering iron is hot.

●Do not damage the guide pipe by bending or twisting it.

●Do not allow the tube to be bent at a severe angle.

Otherwise, it will become clogged with solder.

Hakko 900

Hakko Dash

Hakko 907 and 908

Nut

Nozzle

Guide pipe assembly

Handle

(2)Attaching the tube unit

Guide pipe

Nozzle

uide pipe support plate

(a) Attach the guide pipe assembly to the tube. The

tube is double structure. Insert the inner tube into

the joint and pass the outer tube over the outside

of the joint so that it covers the threaded portion.

Do not bend the tube.

(b) Attach the attachment to the soldering iron

Note) The attachment is not necessary when using the

1. Decide from which side of the attachment you will pass

the tube. Then, position the attachment so that the

tube connects to the guide pipe as straight as possible.

Guide pipe locking nut

Joint

Feed switch

Hakko Mach I.

Rear view of attachment

Attachment

Tube

Secure with clips

Hakko 902 and 904

Nipple

Hakko Mach I

Wave washer (No.B2684)

Stopper

Nut

918 - No.B2685

920

921 No.B2686

(

922

The tube can be passed through either the left or the

right side of the attachment. When changing the tube,

be careful not to damage the internal wiring.

)

2. Secure the attachment with the handle and the

adhesive tape on the rear of the attachment.

Refer to the figure above and be sure to attach the

attachment and the guide pipe at the correct angle.

3

Page 5

ASSEMBLY (FEED CONTROLLER UNIT)

Feed nozzle

set screw

Feed nozzle

connection

hole

Arm mounting

screw

Tension adjusting

screw

Driving pulley set screw

Supply

nozzle

Following pulley

Following

pulley

set screw

Stopper

Arm support shaft

Arm

Solder

bobbin

shaft

(1)Connect the feed nozzle

Insert the feed nozzle into the feed nozzle connection

hole and tighten the set screw. Do not tighten the set

screw excessively or you may crack the tube.

(2)Connect the mini plug

Insert the mini plug into the jack on the front of the

station. When use the Mach-

I, insert the footswitch

plug into the jack on the front of the station.

(3)Setting the solder

If there is any solder in the tube, remove it before

installing the new solder.

(4)Changing the solder

diameter

The following parts may need to be changed in order

to accommodate a change in the solder diameter or

type of soldering iron used.

Driving pulley assembly

Following pulley assembly

Supply nozzle

Guide pipe assembly

Tube unit

Change these parts as necessary according to the

procedure below.

CAUTION

The position of the stopper was set at the factory before

shipping. Do not move the stopper.

(a) Turn the power OFF . Loosen the tension adjusting

screw and the arm mounting screw, open the arm,

and remove any solder remaining in the tube.

(b) Remove the arm support shaft and remove the

arm assembly.

(c) Remove the following pulley set screws (two: top

and bottom) and change the following pulley.

(a) Pass the solder bobbin shaft through the solder

bobbin and attach the shaft to the rear of the

station. As shown below, attach the shaft so that

the solder is fed from the top of the bobbin.

(b) Pass the solder through the supply nozzle.

(c) Turn the power switch ON and set the mode to

MANUAL .

(d) While pressing the feed switch (or footswitch), the

solder is fed through the feed nozzle.

(e) While pressing the feed switch (or footswitch),

insert the tip of the solder between the driving

pulley and the following pulley.

(d) Remove the driving pulley set screw and change

the driving pulley.

NOTE) Install both the top and bottom oil-less washers

so that the black side of each is facing upward.

(See parts list.)

(e) Adjust so that the gears mesh properly and tighten

the tension adjusting screw until the stopper screw

touches the left end of the notch (screw hole) in

the motor mounting plate.

(f) Tighten the arm mounting screw.

(5)Vertical mounting

The Hakko 374 can be mounted vertically.

Mount as shown in the figure.

46 mm

(1.8 in.)

2-ø4.2 mm

(0.08-ø0.17 in.)

4

Page 6

OPERATION

To feed the solder, simply press the feed switch (or foot-switch). Details are explained below.

(1)Mode

AUTO MODE

In AUTO MODE, the solder is fed at the specified

speed for the specified amount of time regardless of

how long the feed switch is pressed.

MANUAL MODE

In MANUAL MODE, while pressing the switch the

solder is fed at the specified speed.

(2)Setting the feed time and

feed speed

Set the feed rate before setting the feed time. The

feed speed setting is effective in both AUTO and

MANUAL modes. The feed time is only effective in

AUTO mode.

(3)Adjusting the return length

A specified length of solder can be retracted after the

solder has been fed. This function is necessary when

the Hakko 374 is used with an automatic soldering

machine.

The return length setting range is 0 to 5 mm (0 to

0.2 in.). However, the solder will be wound back onto

the bobbin if the return length is set to be longer than

the feed length. Keep the return length setting as short

as possible. Also, set the return length so that the tip

of the solder stops short of the tip of the nozzle.

Otherwise, the flux will tend to accumulate in the

nozzle.

There is a hole on the side of unit which leads to the

return length adjusting screw. Insert a screwdriver into

this hole and turn the screw to adjust the return length.

(4)Using the iron holder

Iron receptacle

Spring iron holder

OR

Mounting knob

Iron holder fitting

Cover mounting plate

●●

●Hakko 900, 902, 904

●●

When attaching soldering units other than the Hakko

926 to the Hakko 631, all you have to do is to change

the spring iron holder.

●●

●Hakko Dash and Hakko Mach

●●

Use the Hakko 631 (product number: 631-07).

●●

●Hakko 907 and 908

●●

Use the iron holder made for the Hakko 907 and 908.

Place the handpiece on the holder so that the right

side of the holder and the right side of the guide pipe

support plate are aligned as shown below. To align

with the left side, remove the guide pipe locking nut

and the joint and install the guide pipe support plate

so that it is on the left side.

I

CAUTION

Attach the iron receptacle so that the tip of the

soldering iron and the guide pipe are parallel.

●●

●Hakko 926

●●

Attach the iron holder for the Hakko 926 as shown in

the figure at the top of the next column. (In the case

of the Hakko 926, the holder can only be attached on

the left toward the front of the unit.)

5

Page 7

MAINTENANCE

CAUTION: The cutting blade is sharp. Be very careful when

handling the cutting blade.

Keep the cutting blade, driving pulley, and following pulley clean of solder

and flux using a brush or other suitable cleaning device. If the solder is not

being cut properly or the unit is generating solder balls even though the unit

is well maintained, the cutting blade may be worn. Follow the procedure

below to change the cutting blade.

Replacing the cutting blade

1. Follow steps (a) through (c) under “Changing the

solder diameter” on page 4 and remove the

following pulley assembly.

2. Use a 14-mm wrench and a pair of C-ring pliers

(or other pliers with a tip-size of about 2 mm

0.08 in.) to disassemble the following pulley

assembly.

Pliers

Turn counterclockwise

Following pulley assembly

3. Remove the cutting blade from between the top

and bottom pieces of the following pulley.

If the cutting blade is difficult to remove due to

accumulated flux and solder, push a pin downward

through the four holes on the top piece and pry the

pieces apart.

4. Clean any accumulated flux or solder off each part.

5. Assemble in the reverse order of disassembly.

Following pulley top piece

Cutting blade

Following pulley bottom piece

Wrench

Following gear

Nut

6

Page 8

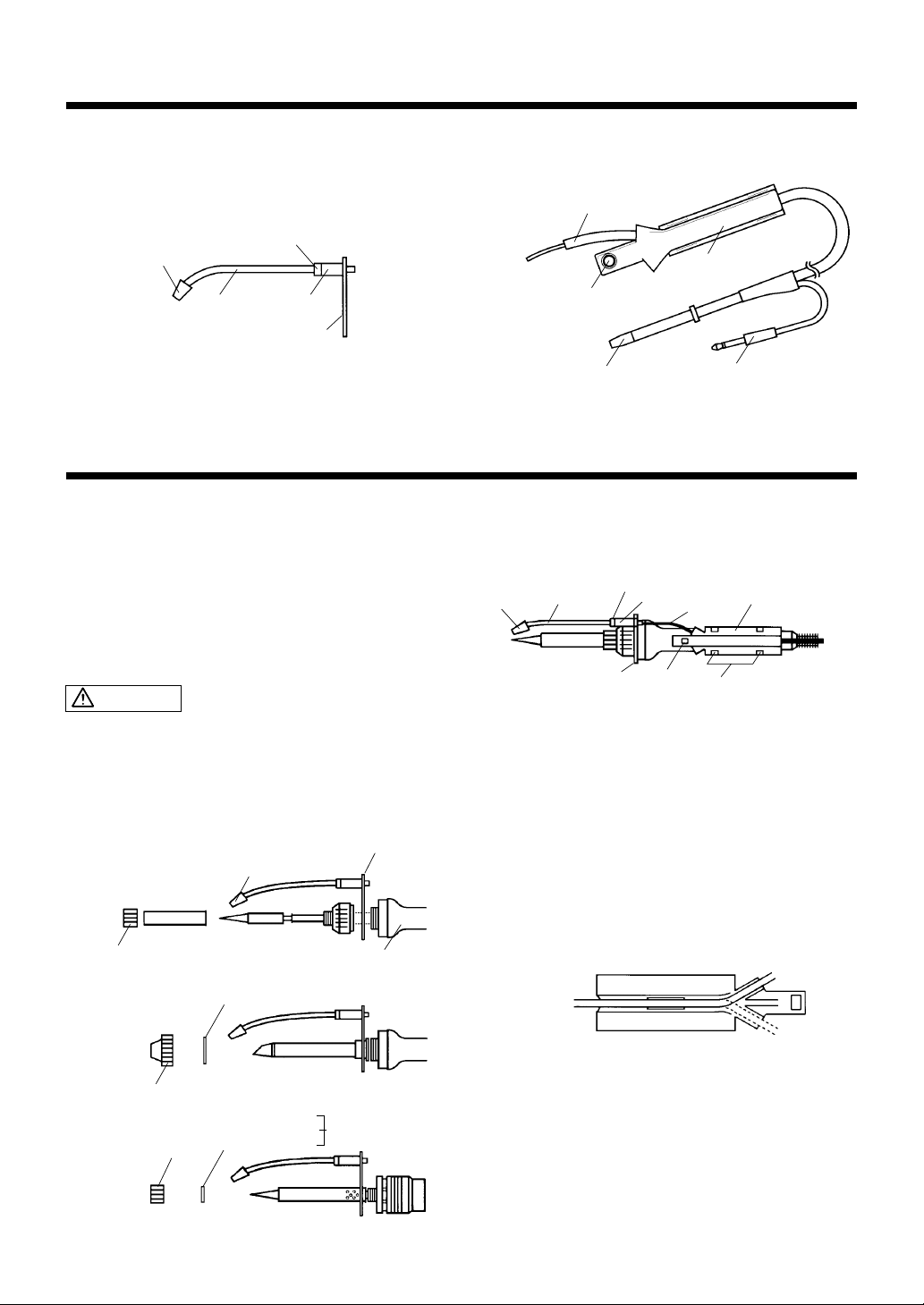

OPTIONAL FEEDER PEN

Thread solder can be fed automatically by connecting the optional feeder

pen to the Hakko 374 feed controller unit. The feeder pen can be used for

the following purposes.

●The feeder pen can be used for conventional

soldering where the soldering iron is held in one

hand and the pen is held in the other to supply the

solder.

●The feeder pen can be fixed in a certain position to

supply solder to a substrate automatically.

Assembly

(1)Connecting to the main unit

Feeder pen

Feed nozzle

set screw

Feed nozzle

Part No.

C1234

C1235

B2124

Part name

Feeder Pen, for solder diameters

from 0.6 to 1.0 mm (0.02 to 0.04 in.)

Feeder Pen, for solder diameters

from 1.2 to 1.6 mm (0.05 to 0.06 in.)

Feeder Switch

(switch designed for the feeder pens)

(2)Mounting the feeder switch

(Part number: B2124)

The feeder switch is a hand-operated switch designed

especially for used with the feeder pens. Solder is fed

when the feed button is pressed.

Feed button Feeder switch

Mount so that the tip

comes to here.

Hakko 374 unit

1. Make sure the feeder pen matches the solder

diameter to be used.

2. Insert the feed nozzle into the feed nozzle

connection hole on the feed controller unit.

3. Tighten the feed nozzle set screw.

7

Feeder pen

Mini plug

Switch jack

1. Attach the feeder switch securely to the handle of

the feeder pen with adhesive tape on the back of

the feeder switch.

2. Insert the mini plug into the switch jack on the

Hakko 374 unit.

* The feeder pen can also be used with a foot-switch

instead of the feeder switch.

Page 9

OPTIONS AND REPLACEMENT PARTS

Part

No.

B1631

B1672

B2125

B1632

B1673

B2126

B1957

B1958

B2127

B2143

B2144

B2145

B1674

B1675

B1676

B1677

B2119

B1679

B1680

B1681

B1682

B2120

B1684

B1685

B1686

B1687

B2121

B1689

B1690

B1691

B1692

B2122

B1694

B1695

B1696

B1697

B2123

B2146

B2147

B2148

B2149

B2156

B2151

B2152

B2153

B2154

B2157

Part Name

Tube unit A

Tube unit B

Tube unit G

Tube unit C

Tube unit D

Tube unit H

Tube unit E

Tube unit F

Tube unit I

Tube unit J

Tube unit K

Tube unit L

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Guide pipe asse’y

Diameter

of solder

0.6~1.0mm

(0.02~0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6~1.0mm

(0.02~0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6~1.0mm

(0.02~0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6~1.0mm

(0.02~0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6mm (0.02 in.)

0.8mm (0.03 in.)

1.0mm (0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6mm (0.02 in.)

0.8mm (0.03 in.)

1.0mm (0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6mm (0.02 in.)

0.8mm (0.03 in.)

1.0mm (0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6mm (0.02 in.)

0.8mm (0.03 in.)

1.0mm (0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6mm (0.02 in.)

0.8mm (0.03 in.)

1.0mm (0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6mm (0.02 in.)

0.8mm (0.03 in.)

1.0mm (0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6mm (0.02 in.)

0.8mm (0.03 in.)

1.0mm (0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

Applicable

Models

900M, 900L

DASH

MACH

902, 904

907, 908

900M, N452

N453

900L, N454

920, 921, 922

918

902, 904

907

908

Part

Part Name

No.

B1699

Nozzle

B1700

Nozzle

B1701

Nozzle

B1702

Nozzle

B1703

Nozzle

B1704

Guide pipe A

B1705

Guide pipe B

B2116

Guide pipe G

B1706

Guide pipe C

B1707

Guide pipe D

B2117

Guide pipe H

B1708

Guide pipe E

B1709

Guide pipe F

B2118

Guide pipe I

B1647

Spring iron holder A

B1648

Spring iron holder B

B1649

Foot switch

B1650

Clip A / 1 pc.

B1956

Clip B / 1 pc.

B2158

Clip C / 1 pc.

631-07

Hakko 631

Iron holder

C1141

Hakko 936/937

Iron holder

C1142

Hakko 936/937

Iron holder

B1863

Mini plug

C1234

Feeder pen

C1235

Feeder pen

B2124

Feeder switch

The 900M and 900L are soldering irons used with the Hakko 926,

Hakko 927, and Hakko 928.

The 902 is a soldering iron used with the Hakko 931 and the

Hakko 932.

The 904 is a soldering iron used with the Hakko 929.

The 907 and 908 are solder irons used with the Hakko 936 and

the Hakko 937.

918, 920, 921, and 922 are product numbers from the Hakko

Mach I series. Parts that support the entire series are indicated

by MACH.

N452, N453, and N454 are product numbers from the Hakko

Dash series. Parts that support the entire series are indicated by

Dash.

The following parts may need to be changed in order to

accommodate a change in the solder diameter or type of

soldering iron used.

Driving pulley assembly

Following pulley assembly

Supply nozzle

Guide pipe assembly

Tube unit

Change these parts as necessary.

Diameter

of solder

0.6mm (0.02 in.)

0.8mm (0.03 in.)

1.0mm (0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6~1.0mm

(0.02~0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6~1.0mm

(0.02~0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

0.6~1.0mm

(0.02~0.04 in.)

1.2mm (0.05 in.)

1.6mm (0.06 in.)

—

—

—

—

—

—

—

—

—

—

0.6~1.0mm

(0.02~0.04 in.)

1.2~1.6mm

(0.05~0.06 in.)

—

Applicable

Models

—

—

—

—

—

900M, 920

921, 922

N452, N453

907

900L, 918,

N454,

908

902, 904

926

927, 928, 929,

931, 932

—

900M, 900L,

DASH

902, 904

907, 908

DASH, MACH

900S

907, 908, 913,

914

—

—

—

—

8

Page 10

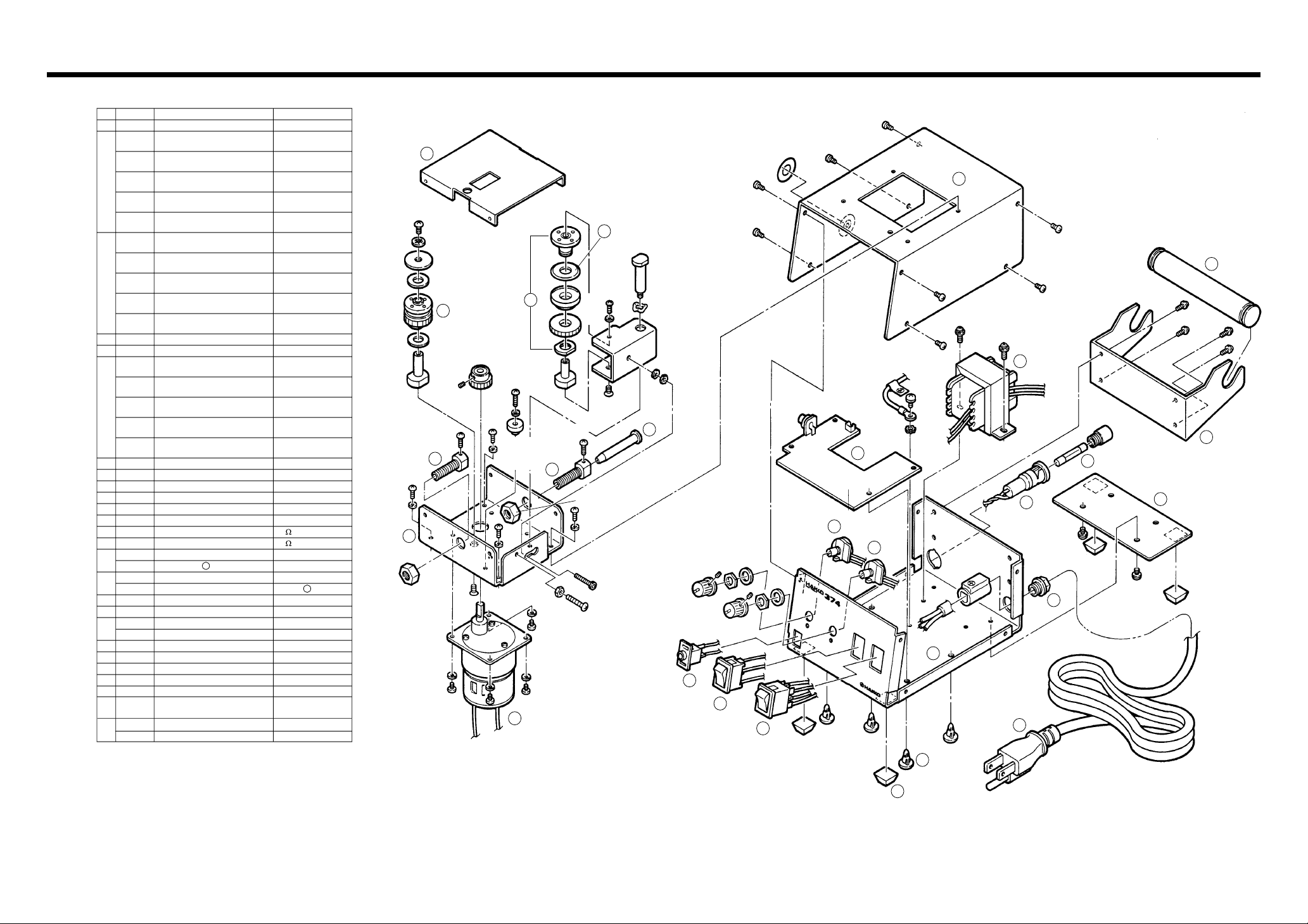

PARTS LIST

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Part No.

B2132

B2104

B2105

B2106

B2107

B2108

B2109

B2110

B2111

B2112

B2113

A1323

B1890

B2133

B2134

B2135

B2136

B2137

B2129

B2142

B2130

B1901

B1902

B1899

B1197

B1905

B1041

B1134

B1907

B1139

B1903

B1906

B1487

B2604

B2131

B1208

B1895

B1037

B1114

B1169

B1900

B1912

Part Name

Cover for feeding unit

Driving pulley asse’y /

for ø0.6mm (0.02 in.) solder

Driving pulley asse’y /

for ø0.8mm (0.03 in.) solder

Driving pulley asse’y /

for ø1.0mm (0.04 in.) solder

Driving pulley asse’y /

for ø1.2mm (0.05 in.) solder

Driving pulley asse’y /

for ø1.6mm (0.06 in.)solder

Following pulley asse’y /

for ø0.6mm (0.02 in.) solder

Following pulley asse’y /

for ø0.8mm (0.03 in.) solder

Following pulley asse’y /

for ø1.0mm (0.04 in.) solder

Following pulley asse’y /

for ø1.2mm (0.05 in.) solder

Following pulley asse’y /

for ø1.6mm (0.06 in.) solder

Cutting blade

Nozzle support

Supply nozzle /

for ø0.6mm (0.02 in.) solder

Supply nozzle /

for ø0.8mm (0.03 in.) solder

Supply nozzle /

for ø1.0mm (0.04 in.) solder

Supply nozzle /

for ø1.2mm (0.05 in.) solder

Supply nozzle /

for ø1.6mm (0.06 in.) solder

Motor fixing plate

Motor

Cover

Solder bobbin shaft

Solder bobbin support

P.W. B.

Potentiometer for feed speed control

Potentiometer for feed time control

Fuse holder

Fuse holder

Fuse

Fuse

Mini jack

Switch

Power switch

Power switch

Chassis

Cord stopper

Chassis support plate

Rubber stopper

Locking spacer

Power cord /

3 core & European plug

Transformer

Transformer

Description

Note: Spare or repair parts do not include mounting screws, if they are

not listed on the description. Screws must be ordered separately.

1

9

Pan head screw

M4×6

With cutting blade

With cutting blade

With cutting blade

With cutting blade

With cutting blade

With wire, connector

With potentiometer

5k

1k

S

Without fuse, 100, 110V

Without fuse, 220, 230V

125V-1A/100, 110V

S

/220, 230V

250V-1A

100 - 120V

220 - 240V

Set of 4

Set of 4

CE

100V

230V

Internal tooth

lock washer

(nominal size 4)

Nut

M8 P0.75

Hexagon

socket

set screw

M3×3

Pan head

screw

M3×6

5

7

Spring

washer

(nominal

size 3) (4)

Pan head screw

M3×4 (4)

2

3

Pan head

screw

M3×10

Spring

washer

(nominal

size 3)

Pan head

screw with washer

M3×5 (with spring

washer) (4)

Flat head screw

M4×8

5

Nut

M4 No.3

Pan head

screw

M3×6

8

4

Pan head

screw

M3×10

Spring

washer

(nominal

size 3)

Flat head screw

M4×8

Nut M8 P0.75

Hexagon socket

head cap screw

M3×15

Pan head screw

M4×16

Wave

washer

(nominal

size 8)

Nut M3

Width

across

flat 5.5

6

17

Nut P0.75 2t (2)

18

19

13

External

tooth washer

(nominal

size 4)

12

14

Pan head screw

with washer

M4×5

(with spring

washer)

20

Pan head screw

with washer

M3×6 (with spring,

plain washer) (2)

26

25

Pan head

screw

M3×4 (8)

15

Pan head screw

with washer

M4×5 (with spring

washer) (2)

21

Pan head screw with washer

M3×5 (with spring washer) (4)

16

10

11

22

23

24

109

Page 11

TROUBLESHOOTING

When the Hakko 374 fails to feed the solder properly, check the following items.

●●

●Do the parts match the solder diameter?

●●

●Is the tension adjusted properly?

●Is the tube bent or twisted?

●Have solder and flux accumulated on the

driving pulley, the following pulley, and the

cutting blade?

●Is the tension adjustment screw tight?

●Is the arm mounting screw tight?

●●

●Is the guide pipe clogged with flux?

●●

●Is the tip of the nozzle clogged with flux?

●Is the mini plug connected properly?

●Is the fuse blown?

●Is the power supply of the correct voltage and

frequency?

●Are the feed speed and the feed time appropriate?

●Is the tip temperature appropriate?

HEAD OFFICE

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

http://www.hakko.com E-mail:sales@hakko.com

OVERSEAS AFFILIATES

U.S.A.: AMERICAN HAKKO PRODUCTS, INC.

TEL: (661) 294-0090 FAX: (661) 294-0096

Toll Free (800)88-HAKKO

4 2 5 5 6

http://www.hakkousa.com

HONG KONG: HAKKO DEVELOPMENT CO., LTD.

TEL: 2811-5588 FAX: 2590-0217

http://www.hakko.com.hk

E-mail:info@hakko.com.hk

SINGAPORE: HAKKO PRODUCTS PTE., LTD.

TEL: 6748-2277 FAX: 6744-0033

http://www.hakko.com.sg

E-mail:sales@hakko.com.sg

Please access to the following address for the other Sales affiliates.

http://www.hakko.com/address

11

MA00519JB030422

Apr.2003

Loading...

Loading...