Page 1

SELF FEEDER

Thank you for purchasing the HAKKO 373 Self Feeder.

Please read this manual carefully before operating the

HAKKO 373. Store the manual in a safe, easily

accessible place for future reference.

CAUTION: You must install the Solder Dia. Adjustment Ring before use.

TABLE OF CONTENTS

Precautions.................................................................1

Specifications..............................................................1

Names of Parts ...........................................................2

Setting Up the HAKKO 373 ........................................3

Operation ....................................................................6

Replacement of Parts .................................................8

Options & Replacement Parts ....................................9

Parts List................................................................... 11

Troubleshooting Guide..............................................13

Page 2

Precautions

CAUTION

· Setting up should be done while the soldering iron is cool, or you may get burnt.

·Do not force the guide pipe bend or turn as this may result in damage.

·Do not operate with tube bending or holding in sharp angle. It may cause to clogging.

·Input of switching is no-voltage input. Do not apply voltage to the jack for switch.

·Periodically, remove the guide pipe and clean out clogged flux.

·Do not force the adjustment screw to adjust the amount of solder return. It may cause to damage.

·If the power cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified person in order to avoid personal injury or damage to the unit.

Specifications

·Usable Solder

Usable solders are as follows. Some of the parts should be changed according to the diameter of

solder desired to use.

Dia. of

solder

Maximum quantity of usable solder is 1 kg (2.2 pounds).

(mm)

(inch)

0.6, 0.65, 0.8, 1.0, 1.2, 1.6

0.024, 0.025, 0.031, 0.039, 0.047, 0.063

·Usable Soldering Iron

Soldering Iron

HAKKO 900M (For HAKKO 926, 927, 928)

HAKKO 900L (For HAKKO 926, 927, 928)

HAKKO 902 (For HAKKO 931)

HAKKO 903 (For HAKKO 939)

HAKKO 904 (For HAKKO 929)

HAKKO DASH

HAKKO MACH-I

HAKKO 907 (For HAKKO 936, 937)

HAKKO 908 (For HAKKO 936, 937)

Operationable only with Foot Switch

·Specifications

Power Consumption

Motor Rate

Solder Feed Time

Solder Feed Speed

Solder Feed Quantity

Solder Return Quantity

Outer Dimensions

Weight

6 W

DC 24 V 3.2W

0~7 sec.

4.5~26 mm (0.14~1 in.)/sec.

0~182 mm (0~7.2 in.)

0~5 mm (0~0.2 in.) (Fixed Speed)

107(W) x 110(H) x 215(D)

Approx.1.5 kg/3.3 pounds

Remarks

1

Page 3

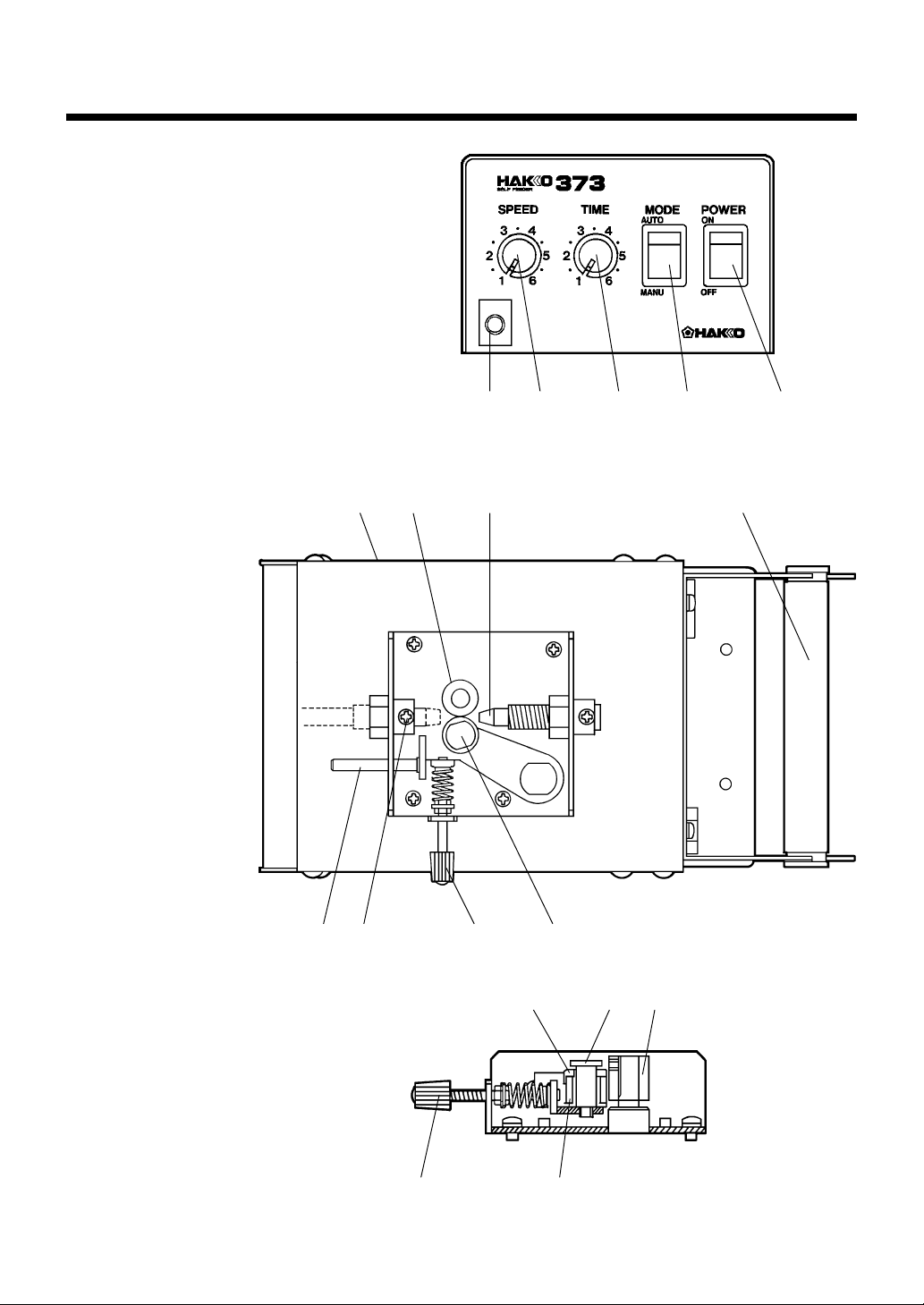

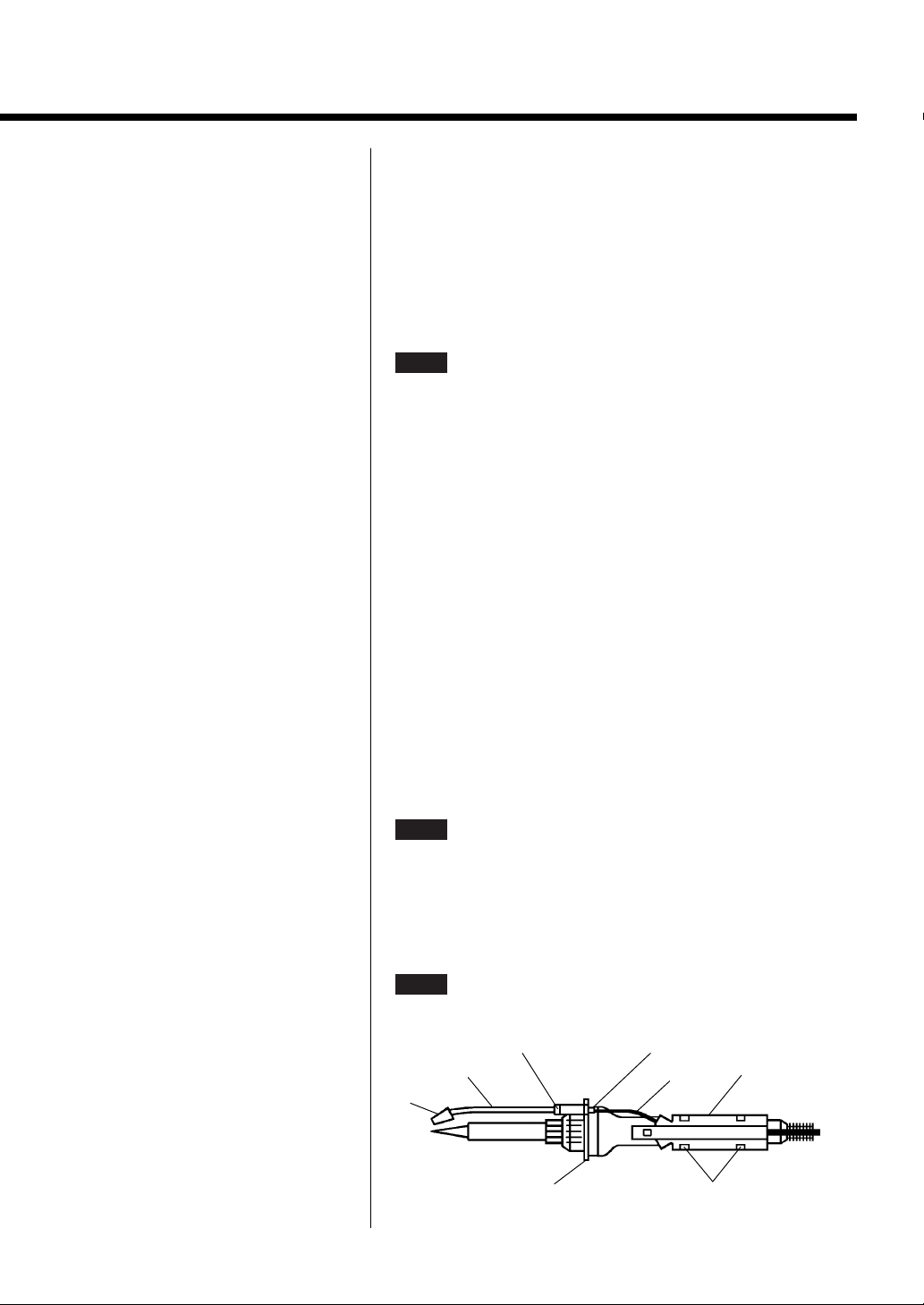

Names of Parts

1.Jack for Switch

2. Feed Speed Control Knob

3.Feed Time Control Knob

4.Mode Switch

5.Power Switch

6.Release Lever

7.Securing Screw

8.Tension Adjustment Knob

9.Tension Gear Guide Shaft

10.Adjustment for the amount of solder return

11.Feed Gear

12.Supply Nozzle

13.Solder Bobbin Shaft

10 1 1 12 13

12 3 4 5

14.Solder Dia. Adjustment Ring

15.T ension Gear

8

976

14 9 11

8

15

2

Page 4

Setting Up the HAKKO 373

·Setting up should be done while the soldering iron is cool, or you may get burnt.

·Do not force the guide pipe bend or turn as this may result in damage.

·Do not operate with tube bending or holding in sharp angle. It may cause to clogging.

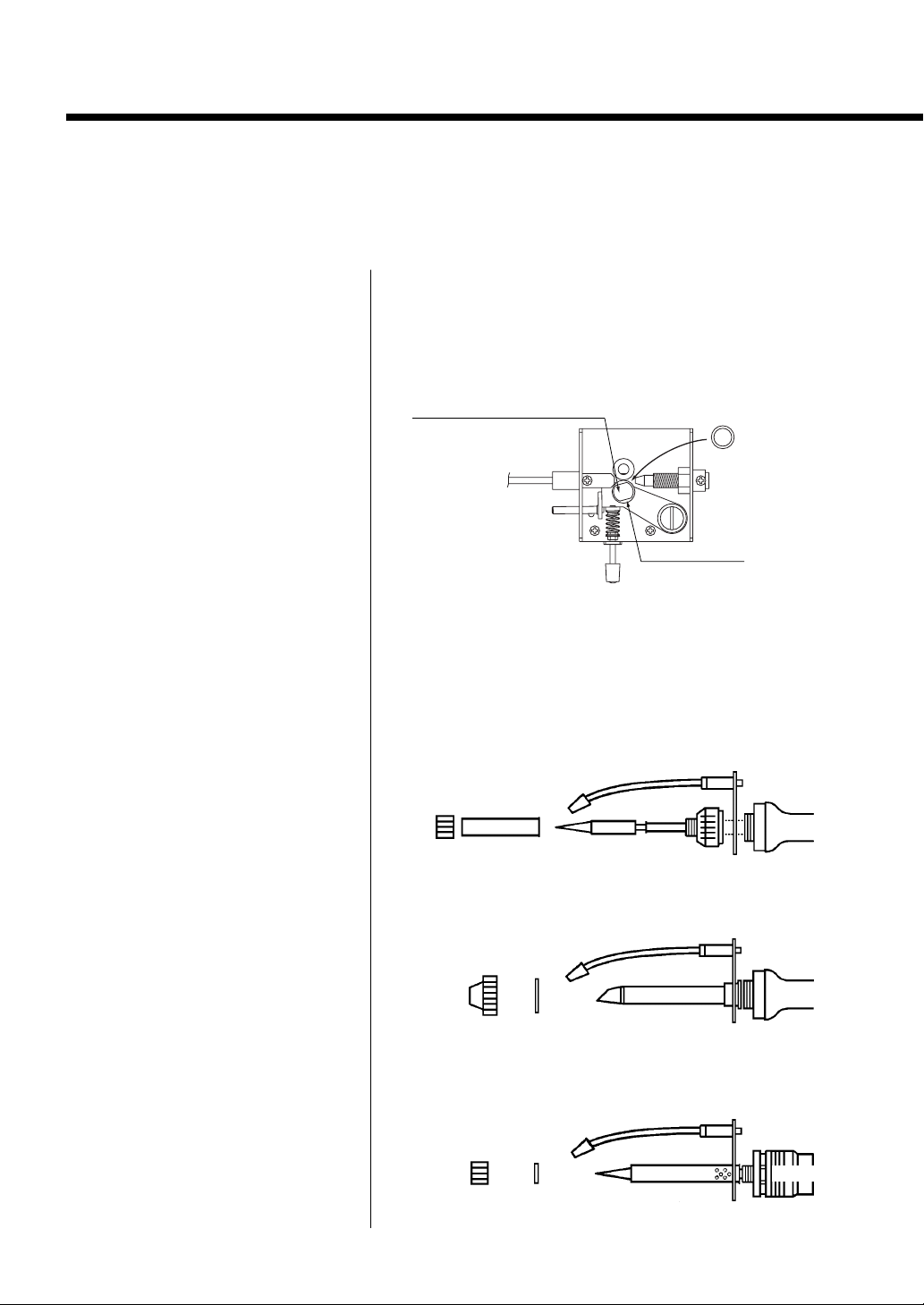

1. Install the Solder Dia.

Adjustment Ring

2. Setting the Guide Pipe

Asse’y

1. Remove the tension gear guide shaft.

2. Attach the solder dia. adjustment ring according to the

diameter of your desired solder and attach the tension

gear guide shaft.

Tension Gear Guide Shaft

Tension Gear

Solder Dia.

Adjustment Ring

Set the guide pipe asse’y between the nipple (or nut) and

handle, and secure it. Washer may need depend on the type

of iron. Please refer to the following figure.

HAKKO 900, HAKKO DASH & 907, 908

Guide Pipe Asse’y

Nut

HAKKO 902, 903, 904

Nipple Wave Washer

HAKKO MACH-I

Ring Washer

Nut

3

Handle

Guide Pipe Asse’y

Handle

Guide Pipe Asse’y

Handle

Page 5

3. Setting the Tube Unit

Setting Up the HAKKO 373

(a)Attach the Tube to Guide

Pipe Asse’y .

(b)Set the Attachment on the

Handle of Soldering Iron.

The tube is double structure. Insert the inside tube into the

hole of the connection, and the outside black tube should

fully cover the screw part of the connection. Be sure that

not to bend the tube.

NOTE

The Att achment is not necessary if you use HAKKO MACHI.

i. Position the attachment on the handle of iron. Decide

which outlet of attachment should use for the tube as the

tube can be pulled out from either way of the attachment.

Find the best position where can connect the tube straight

to the pipe. Be careful not to damage the inner wiring if

replace the tube inside of the attachment.

ii. Secure the attachment. Set the attachment on the handle

securely with clips and adhesive tape on backside of the

attachment. Refer to the following figure on the setting

position of the attachment and the guide pipe. Pay

attention on the setting angle of the guide pipe and the

attachment.

4. Connect the Feeding

Nozzle

Insert the feeding nozzle into the feeding unit on the top of

the station, and secure it with screw.

NOTE

Securing the screw excessively may break the feeding

nozzle.

5. Connect the Mini-plug Insert the mini-plug branching from the tube unit into the

jack of the station.

NOTE

Nozzle

Connect the mini-plug of foot switch to the station if you

use HAKKO MACH-I.

Securing Nut for Guide Pipe Connection

Guide Pipe

Tube

Attachment

ClipsGuide Pipe Holder

4

Page 6

Setting Up the HAKKO 373

6. Setting the Solder Set a new solder after pull the old solder out when the old

one left in tube.

(a)Remove the tension gear guide shaft. And attach the

solder dia. adjustment ring according to the diameter of

your desired solder.

(b)Insert the solder bobbin shaft in the solder bobbin and

mount it on rear of the station. Solder should be fed over

the bobbin as the following figure.

(c) Insert the solder from the supply nozzle.

(d)With pressing release lever, put the inserted solder of

approx. 10 mm/0.4 in. into the feeding nozzle through

between tension gears.

MANUAL

.

7. Changing the Solder

Diameter

(e)Power switch on, and set MODE to

(f) Press the trigger switch, and feed the solder.

Replace the solder dia. adjustment ring, when using the

soldering iron continuously but desire to change the

diameter of solder. The guide pipe asse’y should change

according to the diameter of solder. Refer to the section

“Replacement of Parts”.

(a)Power switch off. Open the release lever and roll back

the left solder to the bobbin.

(b)Remove the tension gear guide shaft, and replace the

solder dia. adjustment ring according to desired solder

dia. Remove the tension gear guide shaft turning with a

spanner or pliers.

(c) Replace the guide pipe asse’y if it’s necessary.

8. Use in Vertical Vertical use is available. Fixing in vertical is as following

figure.

46mm

2-ƒÓ4.2

5

Page 7

Operation

Solder will be fed by pressing the feed switch (or foot switch).

·MODE ·AUTO MODE

If you press the feed switch, solder will be fed with set time

and speed independently of length of pressing time.

·MANUAL MODE

Solder will be fed with set speed during pressing the feed

switch.

·Setting for Feeding

Time and Speed

·Adjustment for the

Amount of Solder

Return

Set the speed before the time. For the setting speed, both

AUTO

for setting time.

After feed solder, specific length of solder can be returned.

This solder return function permits use for simple robots.

Amount of solder return is adjustable within 0~13 mm

(0~0.51 in.). Solder should be rolled back if the amount of

solder return is bigger than the amount of solder feed. Please

set the amount of solder return as small as possible. If the

tip of the returning solder reaches to the guide pipe, flux

will easily accumulate at this point. Be sure that it will not

happen.

Insert a driver into a adjustment hall on the side of the

station. Turn lef t for smaller and turn right for bigger amount.

MANUAL

&

are effective, but only

AUTO

is effective

·Adjustment of Tension When adjust the tension, be sure that not the gear to be

slipped during feed solder, or do not force to feed solder

slipping gear when solder clog.

Set the tension gear loosely for fine solder (ƒÓ0.6mm,

0.8mm/0.024 in., 0.031 in.). Refer to the following chart.

Solder Dia. ø0.6mm

maximum

6

ø1.0mm

14mm

ø1.6mm

10mm

Page 8

Operation

·Usage of Iron Holder

• HAKKO 926

If you use HAKKO 926, refer to the following figure to set

the iron holder. (As for the HAKKO 926, the setting is

available only on it’s left.)

Iron Receptacle

Spring Iron Holder

or

Thumb screw

Holder Mounting Base

Set the iron receptacle in the spring iron holder keeping the

iron tip and the guide pipe horizontally.

• HAKKO 631 Simply replace the iron holder if you use with iron holder

HAKKO 631 for except HAKKO 926.

• HAKKO 907, 908 Place the soldering iron in the iron holder so that the right

side of the guide pipe holder fits to the right side of the iron

receptacle.

When you want to fit it to the left side of the iron receptacle,

remove the securing nut for the guide pipe and the

connection; then reattach them in the opposite side.

7

Page 9

Replacement of Parts

1. When you change the

Solder Diameter

Changing matter

From the range of 0.6~1.0mm to the range of 0.6~1.0mm

From the range of 1.2~1.6mm to the range of 1.2~1.6mm

From the range of 0.6~1.0mm to the range of 1.2~1.6mm

From the range of 1.2~1.6mm to the range of 0.6~1.0mm

2. When you change the

Soldering Iron

Please replace the parts indicated on the following chart when

you change solder diameter.

Please replace the tube unit and guide pipe asse’y, when

you change the soldering iron. It is not necessary to replace

the parts if the items are in the same frame in the following

chart. Foot switch is necessary if you use the HAKKO

MACH-I.

Tube Unit

Guide Pipe Asse’y

900M, 900L, N452, N453, N454 902, 903, 904

N452, N453, 900M N454, 900L 920, 921, 922 918

Solder Dia.

Adjustment Ring

replace

replace

replace

replace

Nozzle

replace

replace

replace

replace

918, 920, 921, 922 907, 908

902, 903, 904

Guide

Pipe

same

same

replace

replace

Tube

Unit

same

same

replace

replace

907 908

8

Page 10

Options & Replacement Parts

Part No.

B1626

B1627

B1628

B1629

B1630

B1631

B1672

B1632

B1673

B1957

B1958

B2143

B2144

B1674

B1675

B1676

B1677

B1678

B1679

B1680

B1681

B1682

B1683

B1684

B1685

B1686

B1687

B1688

B1689

B1690

B1691

B1692

B1693

Part Name

Solder Dia. Adjustment Ring

Solder Dia. Adjustment Ring

Solder Dia. Adjustment Ring

Solder Dia. Adjustment Ring

Solder Dia. Adjustment Ring

Tube Unit A/with Switch

Tube Unit B/with Switch

Tube Unit C

Tube Unit D

Tube Unit E/with Switch

Tube Unit F/with Switch

Tube Unit J/with Switch

Tube Unit K/with Switch

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Dia. of Solder

0.6, 0.65mm

0.8mm

1.0mm

1.2mm

1.6mm

0.6~1.0mm

1.2~1.6mm

0.6~1.0mm

1.2~1.6mm

0.6~1.0mm

1.2~1.6mm

0.6~1.0mm

1.2~1.6mm

0.6, 0.65mm

0.8mm

1.0mm

1.2mm

1.6mm

0.6, 0.65mm

0.8mm

1.0mm

1.2mm

1.6mm

0.6, 0.65mm

0.8mm

1.0mm

1.2mm

1.6mm

0.6, 0.65mm

0.8mm

1.0mm

1.2mm

1.6mm

Soldering Iron

-

-

-

-

900M, 900L, DASH

MACH-I

902, 903, 904

907, 908

900M, N452, N453

900L, N454

920, 921, 922

918

9

Page 11

Options & Replacement Parts

Part No.

B1694

B1695

B1696

B1697

B1698

B2146

B2147

B2148

B2149

B2150

B2151

B2152

B2153

B2154

B2155

B1699

B1700

B1701

B1702

B1703

B1704

B1705

B1706

B1707

B1708

B1709

B1647

B1648

B1649

B1650

B1956

B2158

631-07

·900M, 900L are Iron Parts for HAKKO 926, 927, 928.

·902 is Iron Part for HAKKO 931.

·903 is Iron Part for HAKKO 929 (120V), 939.

·904 is Iron Part for HAKKO 929 (100, 110, 220, 230, 240V).

·918, 920, 921, 922 are Parts No. of HAKKO MACH-I series. MACH-I means applicable for all items of HAKKO MACH-I series.

·N452, N453, N454 are Parts No. of HAKKO DASH series. DASH means applicable for all items of HAKKO DASH series.

·907, 908 are Iron Parts for HAKKO 936, 937.

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Guide Pipe Asse’y

Nozzle

Nozzle

Nozzle

Nozzle

Nozzle

Guide Pipe A

Guide Pipe B

Guide Pipe C

Guide Pipe D

Guide Pipe E

Guide Pipe F

Spring Iron Holder A

Spring Iron Holder B

Foot Switch

Clip A/1 pc

Clip B/1 pc

Clip C/1 pc

HAKKO631 Iron Holder

Part Name

Dia. of Solder

0.6, 0.65mm

0.8mm

1.0mm

1.2mm

1.6mm

0.6, 0.65mm

0.8mm

1.0mm

1.2mm

1.6mm

0.6, 0.65mm

0.8mm

1.0mm

1.2mm

1.6mm

0.6, 0.65mm

0.8mm

1.0mm

1.2mm

1.6mm

0.6~1.0mm

1.2~1.6mm

0.6~1.0mm

1.2~1.6mm

0.6~1.0mm

1.2~1.6mm

-

-

-

-

-

-

-

Soldering Iron

902, 903, 904

907

908

-

-

-

-

900M, 920, 921, 922

N452, N453, 907

900L, 918, N454,

908

902, 903, 904

926

927, 928, 929, 931

900M, 900L, DASH

902, 903, 904

907, 908

DASH, MACH-I

10

Page 12

Parts List

Parts List

Part No.

Item No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Part Name Description

B1897 Cover for Feeding Unit

B1882 Tension Gear Guide Shaft

B1626 Solder Dia. Adjustment Ring for 0.6, 0.65mm

B1627 Solder Dia. Adjustment Ring for 0.8mm

B1628 Solder Dia. Adjustment Ring for 1.0mm

B1629 Solder Dia. Adjustment Ring for 1.2mm

B1630 Solder Dia. Adjustment Ring for 1.6mm

B1885 Tension Gear

B1886 Tension Lever Fixing Shaft

B1908 Washer for Wave Washer

B1894 Tension Lever w/Screw

B1883 Tension Spring

B1881 Feed Gear w/Screw

B1887 Washer for Tension Lever Fixing Guide

B1888 Tension Lever Fixing Guide

B1889 Tension Lever Fixing Washer

B1890 Nozzle Support w/Nut, Screw

B1892 Supply Nozzle

B1891 Motor Fixing Plate

B1893 Release Lever w/Washer

B1884 Tension Adjustment Knob w/Nuts

B1880 Motor

B1898 Cover

B1900 Transformer 100V–24V

B1909 Transformer 110V–24V

B1910 Transformer 120V–24V

B1911 Transformer 220, 230V–24V

B1912 Transformer 240V–24V

B1901 Solder Bobbin Shaft

B1902 Solder Bobbin Support

B1899 P.W.B. w/Potentiometers

B1041 Fuse Holder w/o Fuse

B1134 Fuse Holder (S) w/o Fuse

B1907 Fuse 125V–1A/100,110,120V

B1138 Fuse 250V–1A/220,230,240V

B1139 Fuse 250V–1A S /220,230V

B1895 Chassis Support Plate w/Rubber Stoppers

B1904 Knob

B1903 Mini Jack

B1906 Switch

B1487 Power Switch

B1197 Potentiometer for Feed Speed Control 5K , w/Nut

B1905 Potentiometer for Feed Time Control 1M , w/Nut

B1896 Chassis w/Rubber Stoppers

B1037 Rubber Stopper Set of 4

B1114 Locking Spacer Set of 4

B1208 Cord Stopper

B1163 Power Cord 3 Core & American Plug, 100V

B1007 Power Cord 3 Core But No Plug

B1168 Power Cord 3 Core & American Plug

B1169 Power Cord 3 Core & European Plug

B1214 Power Cord 3 Core & Australian Plug

B1964 Power Cord 3 Core & BS Plug

B2087 Power Cord 3 Wire & BS Plug (CE)

1

Hexagon

Socket Set Screw

M 3 x 3

Pan Head Screw

M 3 x 6

Pan Head Screw

with Washer

M 3 x 5(4)

15

Nut

M 8 P0.75

16

Plain Washer

nominal size 3

Pan Head Screw

with Washer

M 3 x 5(4)

13

9

18

2

3

4

Pan Head Screw

M 3 x 3

Pan Head

Screw

M 3 x 6

10

13

Nut

M 8 P0.75

17

5

6

Wave Washer

nominal size WW–10

7

Push Type

8

Lock Nut

nominal size 3

11

Nut M 3(2)

12

14

Note: Spare or repair parts do not include mounting screws, if they are not listed on the description.

Screws must be ordered separately.

19

Pan Head Screw

M 3 x 4(8)

21

22

Nut

M 7 P0.75 2t (2)

27

27

28

29

30

23

External Tooth

Lock Washer

nominal size 4

31

Pan Head Screw

with Washer M 4 x 5

32

35

34

Pan Head Screw

with Washer (w/Spring, Plain Washer)

M 3 x 6(2)

20

25

24

36

33

37

Pan Head Screw

with Washer

M 3 x 5(4)

26

Pan Head

Screw

with Washer

M 4 x 5(2)

11

12

Page 13

Troubleshooting Guide

If the solder can not be fed smoothly, please check following points.

·Are you using proper parts according to the diameter of solder?

·Did you adjust the tension properly?

·Isn’t the tube bent or transformed?

·Isn’t solder adhered at the feed gear or the tension gear?

·Isn’t the nozzle clogged with flux?

·Is the mini-plug correctly connected?

·Isn’t the fuse blown?

·Is the power cord correctly connected?

13

Page 14

September 1998

Loading...

Loading...