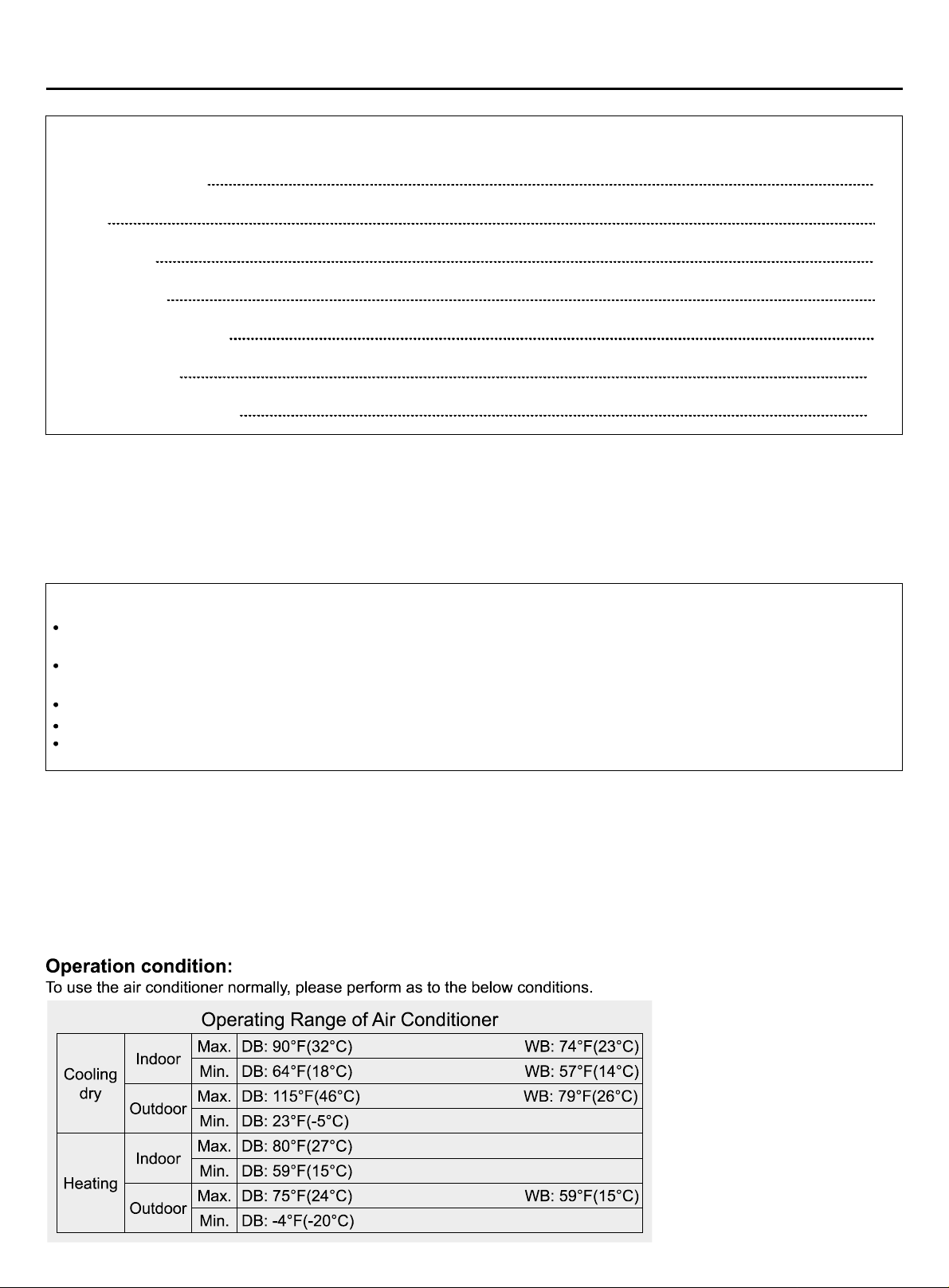

Haier MVAH048MV2AA, MVAH042MV2AA, MVAH036MV2AA, MVAH030MV2AA, MVAH024MV2AA Owner’s Manual

...Page 1

Indoor Unit Operation & Installation Manual

MVAH009MV2AA

MVAH012MV2AA

MVAH018MV2AA

MVAH024MV2AA

MVAH030MV2AA

MVAH036MV2AA

MVAH042MV2AA

MVAH048MV2AA

Please read this manual carefully before using

Keep this operation manual for future reference

Original instructions

Page 2

User Manual

Contents

Parts and Functions

Safety

Maintenance

Fault Checkup

Installation Procedures

Electrical Wiring

Test Run & Fault Code

Your air conditioner may be subject to any change owing to the improvement of Haier products.

MRV series multi zone air conditioning systems can operate multiple indoor units in heating or cooling. When in cooling,

only units set to cool will run. Same logic applies for heating..

Turn power on for 12 hours prior to start-up to allow the crankcase heater adequate time to protect the compressor. All

indoor units on the same refrigeration system should use the unified power switch to

ensure that all indoor units are all powered on during system operation.

13

19

Warning

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons

in order to avoid a hazard.

This equipment should not be used or serviced by personnel who have not been properly trained in its operation and

maintenance.

Children should be supervised to ensure that they do not play with the appliance.

The appliances are not intended to be operated by means of an external timer or separate remote-control system.

Keep the appliance and its cord out of reach of children less than 8 years.

1

2

4

5

6

Product Features

1.Function of central control (optional from our company);

2.Automatic display of fault detection;

3.The air conditioner is provided with the function fo compensation for power supply.During operation,when the power supply

fails emergently and resumes again,the air conditioner returns to the working condition before power failure,if provided

with compensation function.

4.Now this indoor unit only has wired controller function,the indoor unit that has remote controller function need to set in

factory especially.

Page 3

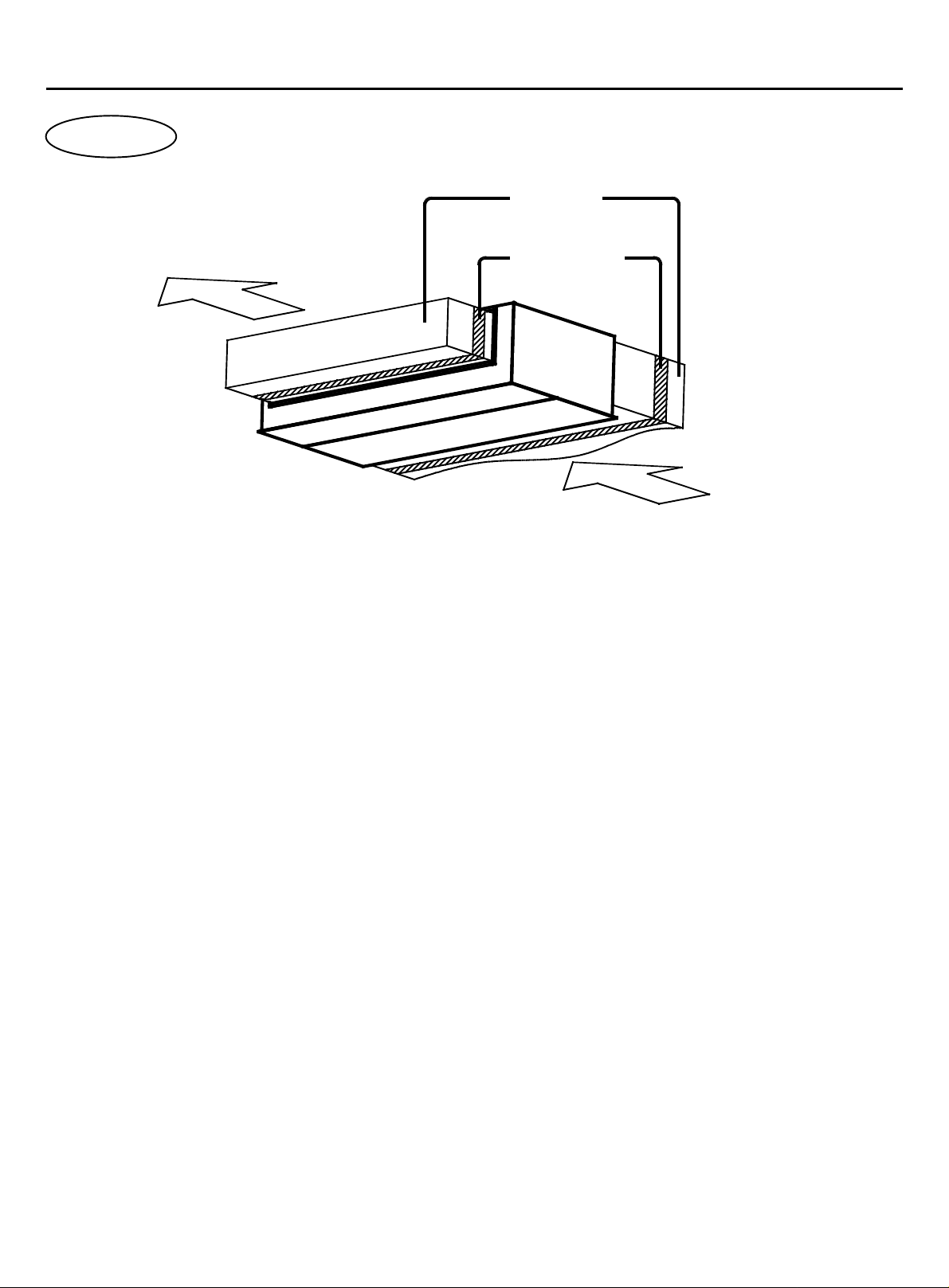

Parts and Functions

indoor unit

air duct

air outlet port

soft connection

air inlet port

1

Page 4

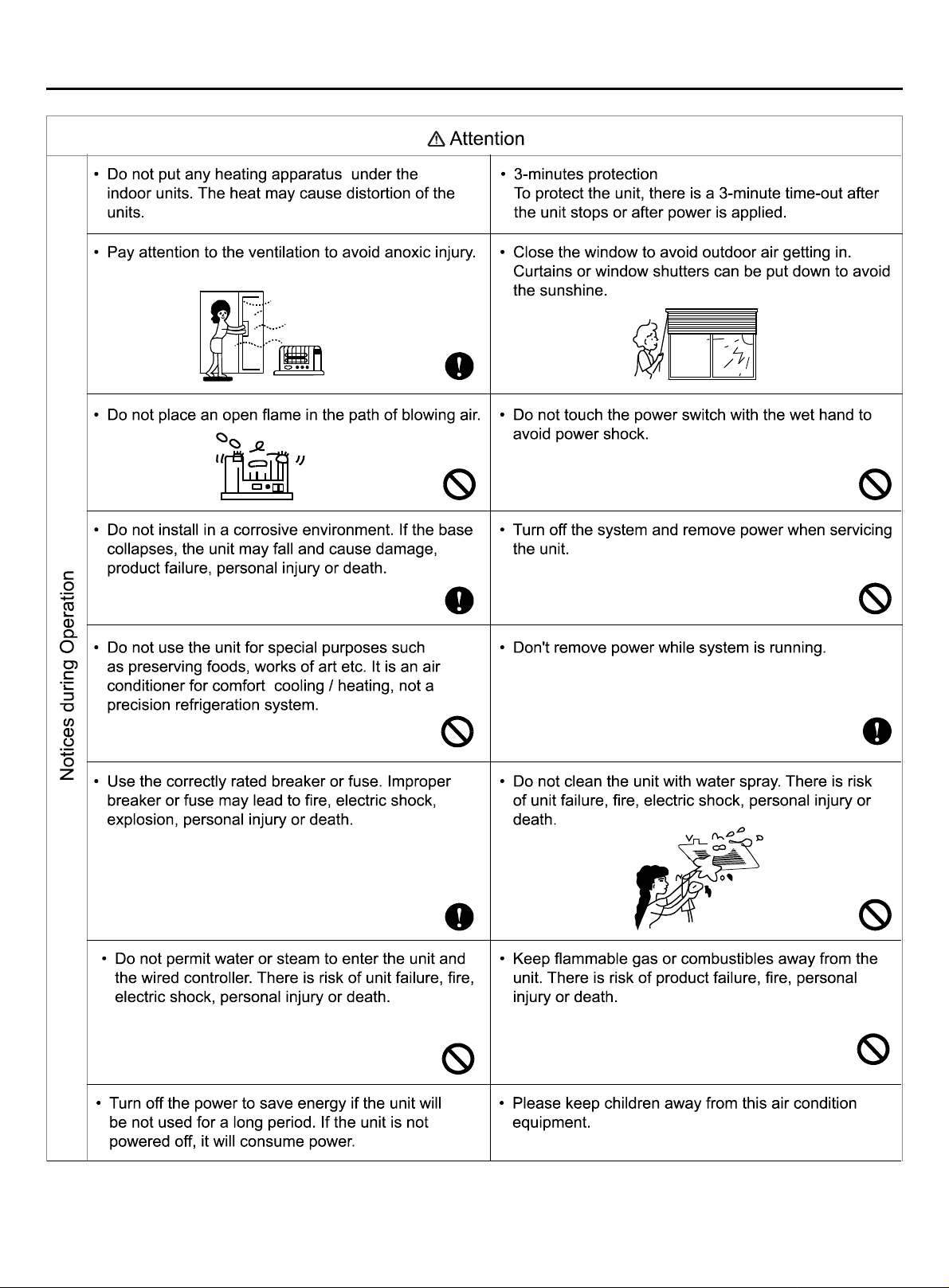

Safety

2

Page 5

Safety

3

Page 6

Maintenance

4

Page 7

Fault Checkup

5

Page 8

Installation Procedures

This manual cannot completely illustrate all the properties of the products you bought. Please contact the local Haier

distribution center if you have any question or request.

1. Before installation [Don’t throw away the attached parts required for the installation]

Determine the route to move the unit to the installation site;

Transport the unit in it's box to prevent damage.

2. Select the installation site

(1) The installation site should be selected according the following

conditions, which should be approved by users.

where an ideal air distribution can be ensured;

where there is no blockage in the air passage;

where the condensed water can be drained out properly;

where the structure can bear the weight of the indoor unit;

where enough space can be ensured for maintenance.

where the lengths of the piping between indoor units and

outdoor units are within the allowable range (refer to Installation

of Outdoor Units)

where the distance of at least 3.28ft (1m) between indoor

units, outdoor units, mains supply, connecting wires and television

or radio should be kept as to avoid the image disturbance and

noises of the above electrical appliances. (Even if 3.28ft (1m) can

be ensured, noise might occur if there is strong electric wave.)

Additionally, equipments, television or other valuables can’t be

put under the unit as to avoid the condensed water of the unit

from dropping into the above articles, causing damaging.

(2) Height of Ceiling:

The ceiling should be located at the place, where the

central position of air outlet port is less than 9.84ft (3m) high

above the ground.

(3) Hoisting studs should be used during installation.

Check if the location can bear the weight of the unit.

Reinforce it before installation if necessary.

(4)The dimension of maintenance

Make sure that it is easy to demount the electrical control

box, fan, montor, filter.

Required Tools for Installation

Brazing torch

15% silver phosphorous copper brazing alloy

Wire stripper

Soap-and-water solution or gas leakage detector

Torque wrench

17mm, 22mm, 26mm

Tubing cutter

Reaming tool

Flaring tool

Razor knife

Measuring tape

Level

Vacuum pump

Micron gauge

Nitrogen

Mini-Split AD-87 Adapter (1/4* to 5/16*)

Non-adhesive Tape

Adhesive Tape

Electrical wiring

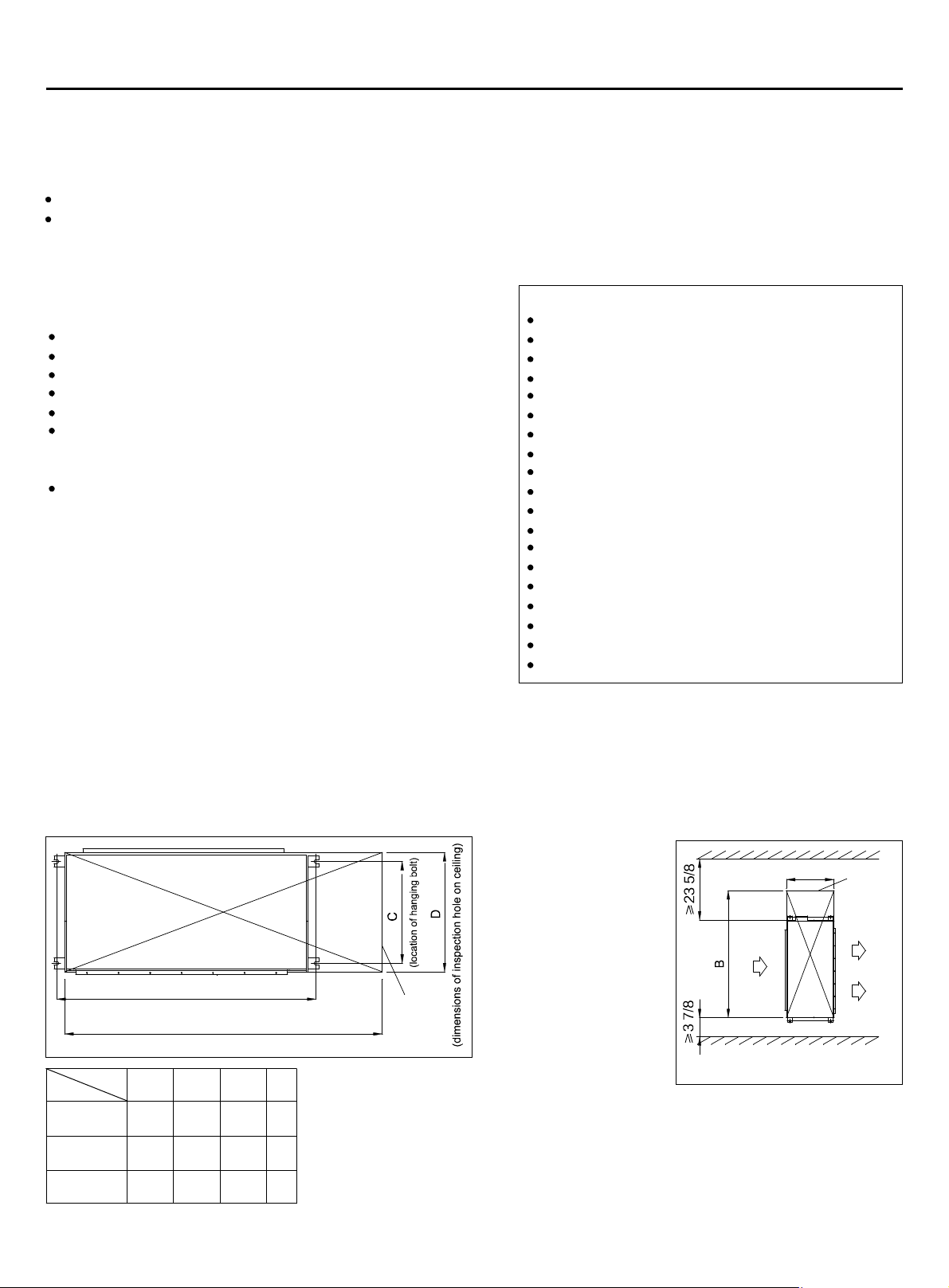

(dimensions of inspection hole on ceiling)

Size

Model

MVAH009-

018MV2AA

MVAH024-

030MV2AA

MVAH036-

048MV2AA

A

(location of hanging bolt)

B

C

B

A

(in)

(in)

31

43 1/4

18 5/8

38 7/8

51 1/8

18 5/82525

55 1/467 3/420 7/829

(in)

(in)

D

checking

port

barrier

D

space needed for installation (unit:in)

checking

port

6

Page 9

Installation Procedures

3. Preparation before Installation

(1) Unit height is 11 inches

H

C

top

E

C

A

Size

Model

MVAH009-

018MV2AA

MVAH024-

030MV2AA

MVAH036-

048MV2AA

(in)

31

18 5/8

38 7/8

18 5/8

55 1/420 7/8

(in)

(in)

29 1/2

29 1/2

53 7/8

(2) If necessary, make a hole for installation and inspection on the ceiling. (used for the situation with a ceiling)

For the size of the inspection hole on the ceiling, please refer to the above drawing.

Before installation, finish all the preparations for all piping connected to indoor units (refrigerant, water drainage) and

wiring (connection line of the line control, connection line between indoor units and outdoor unit) so that they can be

connected with indoor units right after installation.

For the inspection hole, the ceiling might be reinforced to keep the evenness of the ceiling and avoid the vibration of the

ceiling. For details, please consult the construction contractor.

H

(in)

27 3/8

27 3/8

31 3/8

(3) Install the 3/8"(M10) hanging bolts

In order to support the weight of the unit, use barb bolts in the situation with a ceiling.

notch grapping

notch plug

In the situation with the new ceiling, use inlaid bolts, embedded bolts or other parts

provided on site. Before proceeding the installation, adjust the gap between the bolt

and the ceiling.

(4) Installation of Indoor Units

Fix the indoor unit with the hoisting stud.

3/8" nut

hanging bolt

3/8"(M10) shim

3/8"(M10) hanging bolts

If necessary, the machine can be hanged

on the beam with bolts instead of the

main unit

3/8" washer

hoisting stud.

Note:

When the sizes of the main unit don’t match the hole on the ceiling, regulate the slot on the hanging bracket.

Adjusting the level

Adjust the level with a level meter or according to the following ways:

Make the adjustment as shown in the figure.

plug

concrete

Static Pressure Range

unit: IWC

Static Pressure Range

0~0.8

7

Page 10

Installation Procedures

4. Drainpipes

MVAH009-030MV2AA

MVAH036-048MV2AA

drain pipe

gas pipe

1 1/8

20 1/8

18 5/8

liquid pipe

18 3/8

29

unit: in

16 1/4

1 1/8

18 3/8

16

18 3/8

(a) To prevent water flowing back into air conditioner when the unit stops running, drain hose should decline to the drainage

side with an inclination of above 1/100. Drain hose expansion or water accumulation should be prevented, or else it will

cause abnormal noise.

Proper Piping

hanging bolt

heat insultor

39 3/8~78 6/8in

gradient of 1/100 or over

Improper Piping

air outlet port

avoid lobing

avoid curving

don't put pipe

into water

(b) Please use the accessory drain hose to connect indoor unit's water outlet and PVC pipe. Use snap rings to tighten

them as shown in the following figure:

main unit

wash port

wash port

sealing washer [for insulation]

(accessory)

drainage hose

joint (purchased at local shop)

drainage hose

thread clip

(accessory)

sealing washer [for insulation](accessory)

binding

8

hard PVC tube (purchased at local shop)

sealing washer [for insulation](accessory)

Page 11

Installation Procedures

(c) Please use rigid PVC adhesive for connection of other pipes and ensure there

is no leakage.

ensure the biggest height difference

(about 3 7/8in)

(d) Drain hose must be wrapped with insulation sleeve and tightened with a strap to

prevent air leakage from producing condensate.

(e) When connecting the drain hose, do not pull on it to avoid the pipe connections

from getting loose or disconnected. Drain hose should not be pulled out laterally for

gradient of 1/100 or over

more than 8in(200mm) and should be supported every 31-39in(0.8- 1.0m) to avoid bending.

(f) The end of drain hose should be more than 2in(50mm) away from the ground or the bottom of drainage tank. It should

not be put in water. To directly drain condensate into drainage ditch, the drain hose must be U-shaped to avoid smell from

entering through the hose into room.

Testing Drainage System

Before the test, ensure the drain hose is clear and all connections are tightly sealed.

Then perform the drainage test as follows:

1. Add about 0.132gal (500ml) of water into the water pan through water injection hole.

2. Switch on the power and operate the unit in cooling mode. Check that the water outlet drains water normally and that

there are no leakages at the connections. After the drainage test is complete, replace the water injection hole plug.

3. In the condition of new house, test the drainage system before fitting up the ceiling.

4. Even if it is installed in the season needed to heating, the testing should also be performed.

5. Installation of Air Return & Air Exhaust Pipes

For the choice and installation of air return port, air return pipe, air exhaust port and exhaust pipe, please consult service

personnel of Haier company. Calculate the design chart and exterior static pressure, and select the exhaust pipe with

appropriate length and shapes.

main unit of air

conditioner

ceiling

suface

special exhaust

port (purchased at

local shop)

exhaust pipe

(purchased

at local

shop)

access panel

air return

pipe

(purchase

d at local

shop)

special air return

pipe (purchased at

local shop) with air

cleaner

The length difference between pipes should be limited to be less than 2:1;

Make the piping as short as possible;

Keep the min. elbow quantity;

Wind the heat insulating material around the flange between the main unit and the exhaust

pipe for heat insulation and sealing. Install the piping before fitting up the ceiling.

At least 6.6 feet air duct is needed at air inlet and air outlet.

Flexible connection is needed between indoor units and air duct.

ESP should be lower than 0.8 IWC.

6. Cautions in Installation of Air Return Duct & Exhaust Duct

It is recommended to use ducting, which can be

anti-condensation and absorb sound. (purchased at local shops)

Heat insulation should be made for the ducting.

The special exhaust port should be arranged at the place where the air is distributed evenly.

An access panel should be added to the ceiling below the indoor unit for serviceability.

special exhaust port

positioning with bolt

supply

duct

air

air

9

Page 12

Installation Procedures

7.Connection of return air duct (setting back air return opening when leaving factory)

Remarks:

This series of air conditioners can be arranged in two air return modes: 1. Air return from the back (Factory default); 2. Air

return from the bottom (can be adjusted on site. See the following figures.)

Note:

The downward air return mode will increase noise 3-5dB(A). It is recommended to install the air conditioner in downward

return air mode 2 if enough space is available.

F

8. Adding fresh air intake duct

(1) Cut away the circular opening on the side of the return

end

Model

Size

MVAH009~018MV2AA

MVAH024-030MV2AA

MVAH036-048MV2AA 50 3/8 9 2/8

(2) Install round duct collar (obtained locally)

F

(in)

26

29 1/8

below air return openingback air return opening

G

(in)

7 7/8

7 7/8

cut away

cut away

(3) Use foil tape to prevent air leaks

Duct collar

10

Page 13

Installation Procedures

9.Install outlet flange

Install outlet flange basising the needs, the outlet flange is standard component, bolts are laied in accessories box.

ceiling

Note:

You can select not to connect with the flange. Instead of it, you can use the round plastic air outlet (purchased by user)

10. Examples for Bad Installation

The unit is not equipped with the air return pipe and the inner side of the suspending ceiling is used as the blast pipe,

causing the humidity increasing due to irregular air mass, strong wind or sunlight from the outside world.

There might be condensate dropping down at the outer side of the blast pipe. The humidity is high, even if the inner side

of the suspended ceiling isn’t used as a blast pipe in new concrete buildings. At this time, the whole body should use the

thermo wool for heat preservation (the thermo wool can be packed with a steel wire).

It is operated under the conditions beyond the limits, leading to the overload of the compressor.

Affected by the capacity of the exhaust fan, and the strong wind and wind direction in the outer flue, when the blowing

quantity of the air conditioner exceeds the limits, the drained water of the heat exchanger will overflow, causing water

leakage.

exhaust fan

example of bad installation

11. Static Pressure GradeSetting

For MVAH036~048MV2AA units, after installation need to preliminary estimates external static pressure, according to the

external static pressuresetting the unit's static pressure grade by controller.

Note: The detail operation methods for setting the unit's static pressure grade refer to the controller manual.

The static pressure range of each gradeas follows:

Grade Grade/Static Pressure Range (IWC)

1 0~0.1

2 0.1~0.3

3 0.3~0.5

4 0.5~0.7

5 0.7~0.8

11

Page 14

Installation Procedures

12. Refrigerant Tube

Pipe Length & Height Difference

Please refer to the attached manual of outdoor units.

Piping Materials & Heat Insulating Materials

As to prevent condensation, heat insulating treatment

should be performed. The heat insulating treatment

for gas and liquid piping should be done respectively.

Tubing Materials & Specifications

Piping Material

Heat Insulating Material

Hard PVC tube VP 1in (inner bore)

Vesicant polythene thickness: over 1/4in

Model

Tubing Size

Tubing Material

Gas pipe

Liquid pipe

MVAH009~018MV2AA

1/2

1/4

Seamless copper pipe rated for R410A refrigerant

MVAH024~048MV2AA

5/8

3/8

Refrigerant Recharge Amount

Add the refrigerant according to the installation instruction of outdoor unit. The addition of R410A refrigerant must be

performed with a digital scale to ensure the proper charge. Compressor failure can be caused by over or under charging

the system.

Connecting Procedures of Refrigerant Tubing

Proceed the flare tube connecting operation

to connect all the refrigerant tubes.

Dual wrenches must be used in the

connection of indoor unit tubing.

wrench

Mounting torque refers to the

right table

Cutting and Enlarging

Cutting or enlarging pipes should be proceeded by

installation personnel according to the operating criterion

if the tube is too long or flare opening is broken.

Vacuumizing

Vacuumize from the stop valve of outdoor units with vacuum

pump. Refrigerant sealed in indoor machine is not allowed

to use for vacuumization.

Connecting

1. Connecting circular terminals:

The connecting method of circular terminal is shown in the

Fig. Take off the screw, connect it to the terminal tier after

heading it through the ring at the end of the lead and then

tighten it.

2.Connecting straight terminals:

The connection methods for the circular terminals are shown

as follows: loosen the screw before putting the line terminal

into the terminal tier, tighten the screw and confirm it has

been clamped by pulling the line gently.

Connecting

circular terminals:

Open All Valves

Open all the valves of outdoor units. [NB: oil balancing stop

valve must be shut up completely when connected one

main unit.]

3.Pressing connecting line

After connecting line is completed, press the connecting

line with clips which should press on the protective sleeve

of the connecting line.

Checkup for Air Leakage

Check if there is any leakage at the connecting part and

bonnet with hydrophone or soapsuds.

12

correct

pressing

terminal tier

pressing clip

wrong

pressing

Page 15

Electrical Wiring

13

Page 16

Electrical Wiring

14

Page 17

Electrical Wiring

15

Page 18

Electrical Wiring

16

Page 19

Electrical Wiring

17

Page 20

Electrical Wiring

Code setting of wired controller

Function switches

Switch

Code

status

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

Note: ON indicates short circuit; OFF indicates disconnection.

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Function description

Auxiliary wired controller

Master wired controller

Common wired controller

New fan-only has refrigerating,

heating, and air supplying modes

Display ambient temperature

Do not display ambient temperature

26 lock disabled

26 lock enabled

Collect ambient temperature of wired

controler

Collect ambient temperature of PCB

Power failure memory disabled

Power failure memor enabled

Temperature sensor 4k7 enabled

Temperature sensor 4k7 disabled

Temperature sensor 5k1 enabled

Temperature sensor 5k1 disabled

Default setting

OFF

ON

OFF

ON

ON

OFF

ON

OFF

Remarks

Betewwn SW7 and SW8, one and

only one must be ON for any given

period

The difference between master and slave wired controller

Topic Master controller Slave controller

Function ON/OFF, Mode, Fan speed, Temp, Swing function only.All function

18

Page 21

Test Run & Fault Code

19

Page 22

Page 23

Page 24

Qingdao Haier Air Conditioner Electric Co.,Ltd.

Haier Industrial Park,Qianwangang Road,Eco-Tech Development Zone,

Qingdao 266555,Shandong,P.R.C.

Loading...

Loading...