Page 1

SERVICE MANUAL

LED TV

Model No. LE55B1381a

MST 318

Chassis

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair

the product or products dealt with in this service information by anyone else could result in serious injury or death.

©2011 Qingdao Haier Electronics Co., Ltd.

All rights reserved. Unauthorized copying and distribution is a violation of law.

Haier Group

Page 2

Service Manual

Model No.:

Chapter 1: General Information

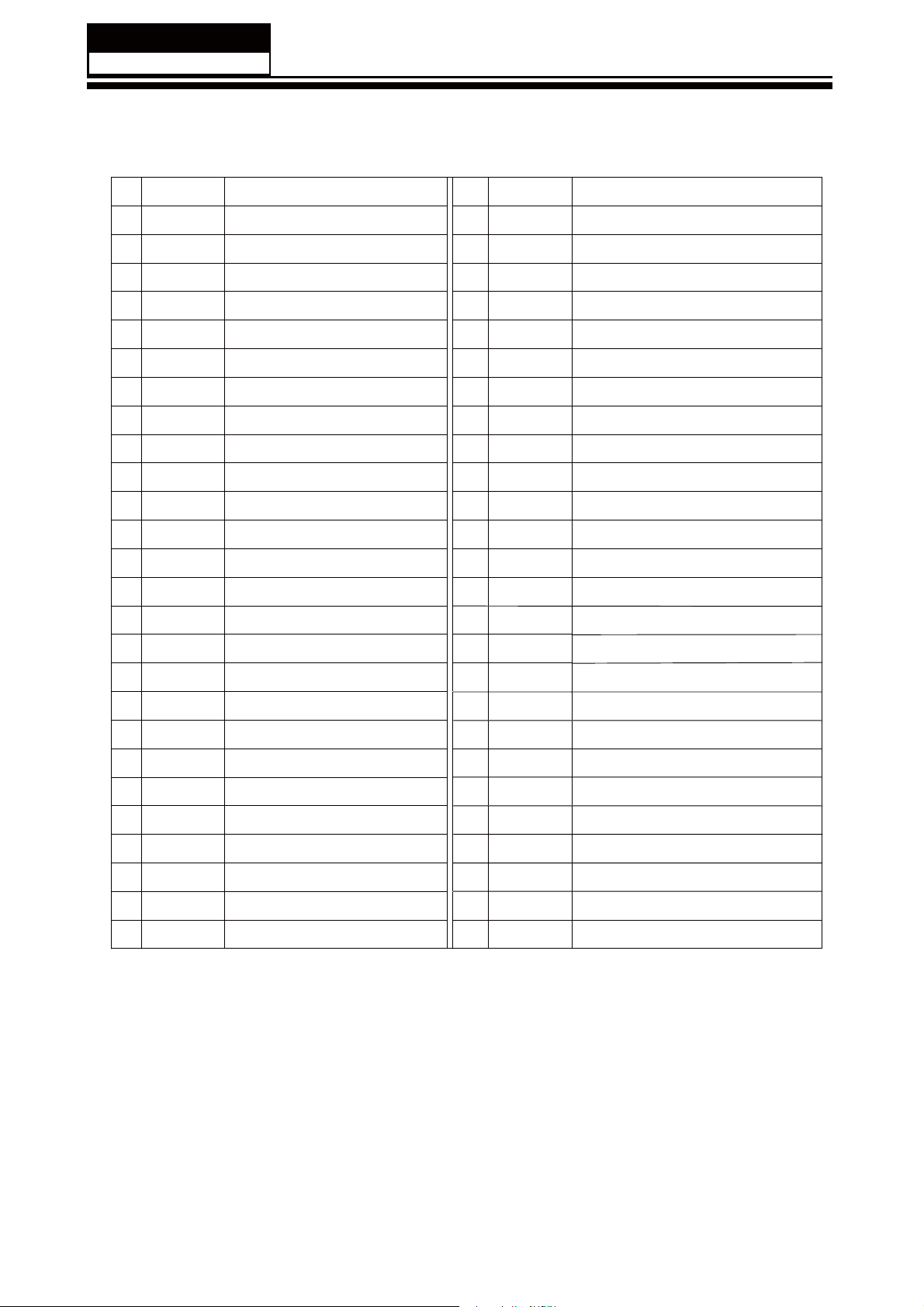

1-1. Table of Contents

1. General Information...........................................................................

1-1. Table of Contents

1-2. General Guidelines

1-3. Important Notice

1-4. How to Read this Service Manual

....................................................................................

3. Location of Controls and Components...........................................

3-1. Board Location

3-2. Main Board

3-3. Power Board

3-4. LCD Panel

4. Disassemble and Assemble..........................................................

5. Installation Instructions..…....………………...........………….........

1

4

4

4

7

7

88

8

8

11

12

15

20

21

12snoitcennoCtnempiuqElanretxE1-5

42snoitcennoCIMDH2-5

6. Operation Instructions....…....………………...........………….........

6-1 Front Panel Controls

6-2 Back Panel Controls

6-3 Universal Remote Control

7. Electrical Parts…....………………...........………….........................

7-1. Block Diagram

7-2. Circuit Diagram

8. TV OPERATION........………….........................................................

8-1 TV OSD Menu

8-2 Upgrade software

8-3 Factory menu

27

27

27

28

29

29

30

39

39

45

46

- 01 -

Page 3

Service Manual

Model No.:

9. Trouble-shooting…………..............................................................

9-2. Main Board Failure Check

9-3. Panel Failure

51

15kcehCelpmiS.1-9

52

55

- 02 -

Page 4

Service Manual

Model No.:

1-2. General Guidelines

When servicing, observe the original lead dress. If a short circuit is found, replace all parts

which have been overheated or damaged by the short circuit.

After servicing, see to it that all the protective devices such as insulation barriers, insulation

papers shields are properly installed.

After servicing, make the following leakage current checks to prevent the customer from

being exposed to shock hazards.

1) Leakage Current Cold Check

2) Leakage Current Hot Check

3) Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive

1-3. Important Notice

1-3-1. Follow the regulations and warnings

Most important thing is to list up the potential hazard or risk for the service personnel to

open the units and disassemble the units. For example, we need to describe properly

how to avoid the possibility to get electrical shock from the live power supply or charged

electrical parts (even the power is off).

This symbol indicates that high voltage is present inside.It is dangerous to

make any king of contact with any inside part of this product.

This symbol indicates that there are important operating and maintenance

instructions in the literture accompanying the appliance.

1-3-2. Be careful to the electrical shock

7RSUHYHQW GDPDJHZKLFKPLJKWUHVXOWLQHOHFWULFVKRFN RU¿UH GRQRWH[SRVHWKLV79 VHW

to rain or excessive moisture. This TV must not be exposed to dripping or splashing water,

DQGREMHFWV¿OOHGZLWKOLTXLGVXFKDVYDVHVPXVWQRWEHSODFHGRQWRSRIRUDERYHWKH79

1-3-3. Electro static discharge (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

components commonly are called Electrostatically Sensitive (ES) Devices. The following

techniques should be used to help reduce the incidence of component damage caused by

electros static discharge (ESD).

1-3-4. About lead free solder (PbF)

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder

must be used in the servicing and repairing of this product.

8VHWKHJHQHZLQJSDUWVVSHFL¿HGSDUWV

Special parts which have purposes of fire retardant (resistors), high-quality sound

(capacitors), low noise (resistors), etc. are used.

When replacing any of components, be sure to use only manufacture's specified parts

shown in the parts list.

Safety Component

Ɣ&RPSRQHQWVLGHQWL¿HGE\PDUNKDYHVSHFLDOFKDUDFWHULVWLFVLPSRUWDQWIRUVDIHW\

- 03 -

Page 5

Service Manual

Model No.:

1-3-6 Safety Check after Repairment

&RQ¿UPWKDWWKH VFUHZVSDUWVDQGZLULQJZKLFKZHUHUHPRYHGLQ RUGHUWRVHUYLFHDUHSXW

in the original positions, or whether there are the positions which are deteriorated around

the serviced places serviced or not. Check the insulation between the antenna terminal or

external metal and the AC cord plug blades. And be sure the safety of that.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power source before;

a. Removing or reinstalling any component, circuit board module or any other receiver

assembly.

b. Disconnecting or reconnecting any receiver electrical plug or other electrical

connection.

c. Connecting a test substitute in parallel with an electrolytic capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity installation of electrolytic

capacitors may result in an explosion hazard.

2. Test high voltage only by measuring it with an appropriate high voltage meter or other

voltage measuring device (DVM, FETVOM, etc) equipped with a suitable high voltage

probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its assemblies.

4. Unless specified otherwise in this service manual, clean electrical contacts only by

applying the following mixture to the contacts with a pipe cleaner, cotton-tipped stick or

comparable non-abrasive applicator; 10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength).

CAUTION:7KLVLVDÀDPPDEOHPL[WXUH

8QOHVVVSHFL¿HGRWKHUZLVHLQWKLVVHUYLFHPDQXDOOXEULFDWLRQRIFRQWDFWVLVQRWUHTXLUHG

Capacitors may result in an explosion hazard.

5. Do not defeat any plug/socket B+ voltage interlocks with which receivers covered by this

service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its electrical assemblies unless

all solid-state device heat sinks are correctly installed.

7. Always connect the test receiver ground lead to the receiver chassis ground before

connecting the test receiver positive lead.

Always remove the test receiver ground lead last. Capacitors may result in an explosion

hazard.

8VHZLWKWKLVUHFHLYHURQO\WKHWHVW¿[WXUHVVSHFL¿HGLQWKLVVHUYLFHPDQXDO

CAUTION: 'RQRWFRQQHFWWKHWHVW¿[WXUHJURXQGVWUDSWRDQ\KHDWVLQNLQWKLVUHFeiver.

9. Remove the antenna terminal on TV and turn on the TV.

10. Insulation resistance between the cord plug terminals and the eternal exposure metal

should be more than Mohm by using the 500V insulation resistance meter.

11. If the insulation resistance is less than M ohm, the inspection repair should be required.

If you have not the 500V insulation resistance meter, use a Tester. External exposure

metal: Antenna terminal Headphone jack

- 04 -

Page 6

Service Manual

Model No.:

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive (ES) Devices.

Examples of typical ES devices are integrated circuits and some field-effect transistors

and semiconductor "chip" components. The following techniques should be used to help

reduce the ncidence of component damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or semiconductorequipped assembly, drain off any electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist

strap device, which should be removed to prevent potential shock reasons prior to applying

power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly

on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static type solder removal device. Some solder removal devices not

FODVVL¿HGDVDQWLVWDWLFFDQJHQHUDWHHOHFWULFDOFKDUJHVVXI¿FLHQWWRGDPDJH(6GHYLFHV

'RQRWXVHIUHRQSURSHOOHGFKHPLFDOV7KHVHFDQJHQHUDWHHOHFWULFDOFKDUJHVVXI¿FLHQW

to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately

before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement

ES device, touch the protective material to the chassis or circuit assembly into which the

device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other

safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices.

(Otherwise harmless motion such as the brushing together of your clothes fabric or the

OLIWLQJRI\RXUIRRWIURPDFDUSHWHGÀRRUFDQJHQHUDWHVWDWLFHOHFWULFLW\VXI¿FLHQWWRGDPDJH

an ES device.)

1-3-7. Ordering Spare Parts

Please include the following informations when you order parts. (Particularly the Version

letter)

1. Model number, Serial number and Software Version

The model number and Serial number can be found on the back of each product and the

Software Version can be found at the Spare Parts List.

2. Spare Part No. and Description

<RXFDQ¿QGWKHPLQWKH6SDUH3DUWV/LVW

- 05 -

Page 7

1-3-8. Photo used in this manual

The illustration and photos used in this Manual may not base on the final design of

products, which may differ from your products in some way.

1-4. How to Read this Service Manual

Using Icons:

,FRQVDUHXVHGWRDWWUDFWWKHDWWHQWLRQRIWKHUHDGHUWRVSHFL¿FLQIRUPDWLRQ7KHPHDQLQJRI

each icon is described in the table below:

Note:

A “note” provides information that is not indispensable, but may nevertheless be valuable

to the reader, such as tips and tricks.

Service Manual

Model No.:

Caution:

A “caution” is used when there is danger that the reader, through incorrect manipulation,

may damage equipment, loose data, get an unexpected result or has to restart(part of) a

procedure.

Warning:

A “warning” is used when there is danger of personal injury.

Reference:

A “reference” guides the reader to other places in this binder or in this manual, where he/

VKHZLOO¿QGDGGLWLRQDOLQIRUPDWLRQRQDVSHFL¿FWRSLF

- 06 -

Page 8

Service Manual

Model No.:

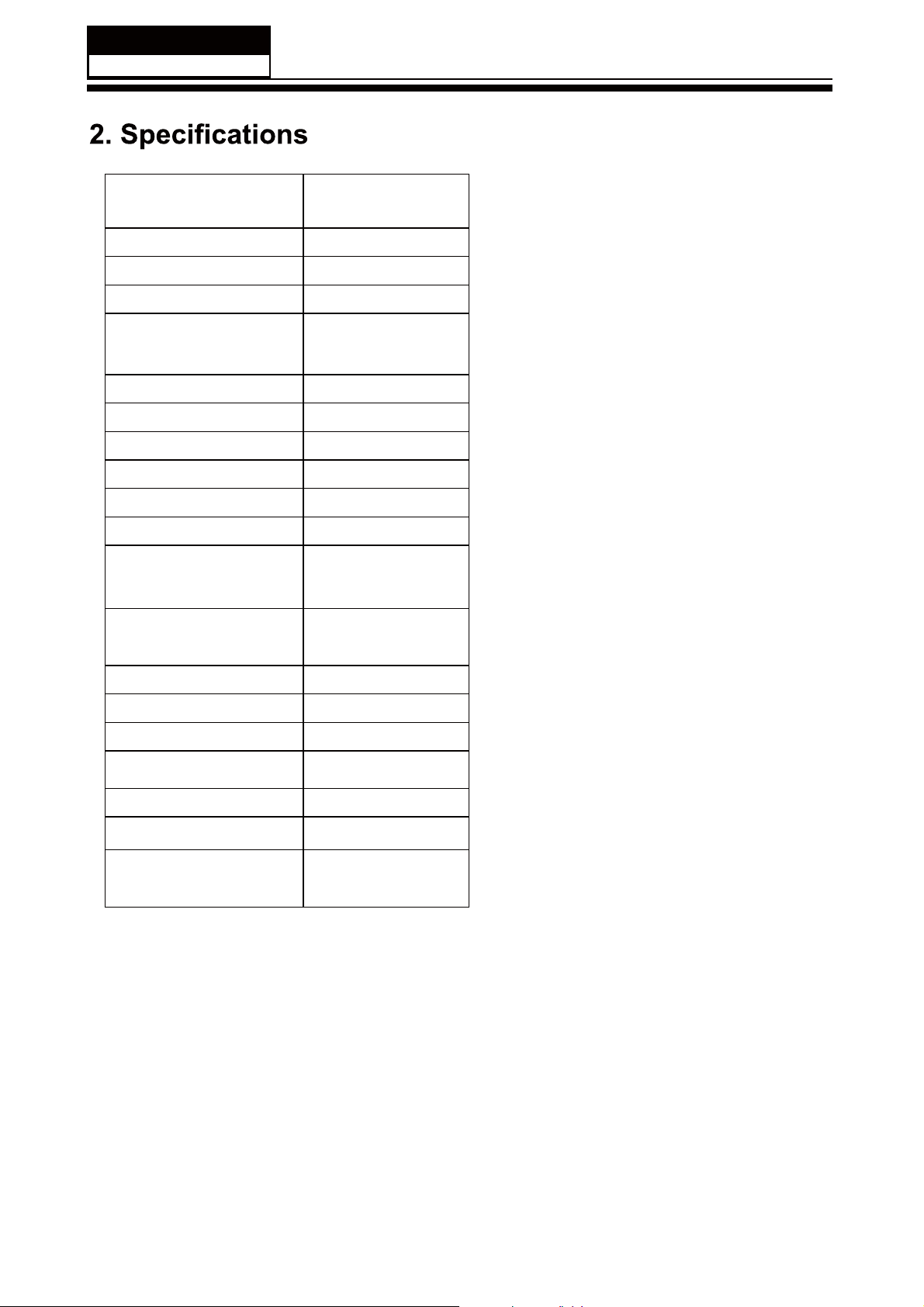

Model

Screen Size 54.6inch

Aspect Ratio 16:9

Resolution 1920x1080

Response Time (ms)

Angel ofView 176

Color Display16777216

No. of Preset Channels 203

OSD LanguageEnglish/France/Spaish

Color System NTSC

Audio System M/N

Audio Output Power

(Built-in) (W)

Audio Output Power

(outer) (W)

LE55B1381a

6 (GRAYTO

GRAY)

o

10W×2

No

Tot al Power Input (W) 160W

Voltage Range (V) AC100V-240V

Power Frequency (Hz) 50~60Hz

Net Weight (KG) 29

Gross Weight (KG) 34.2

Net Dim

Packaged Dimension

(MM)

ension (MM)

1302*325*855

1400*160*890

- 07 -

Page 9

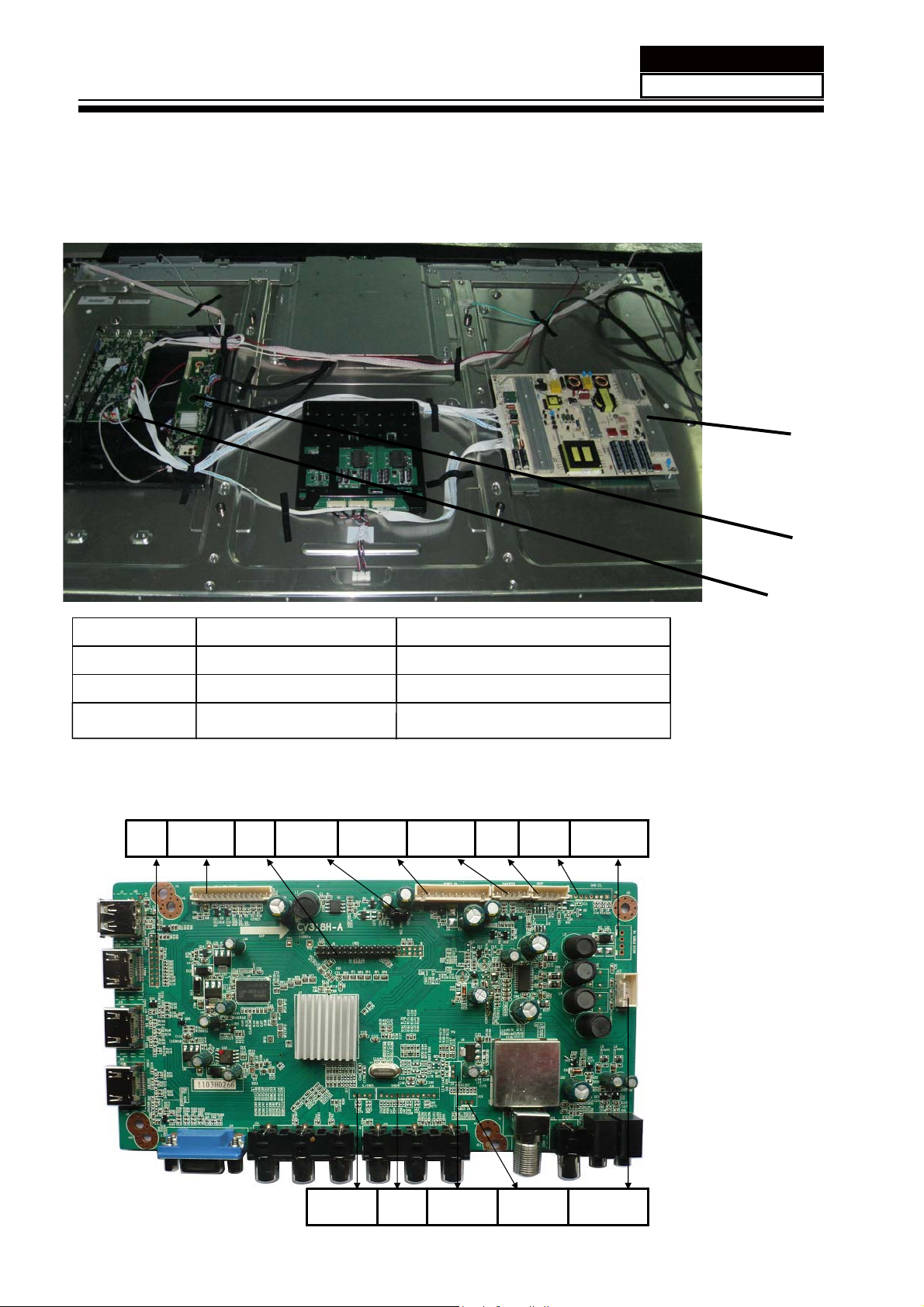

3. Location of Controls and Components

3-1 Board Location

Service Manual

Model No.:

%%RDUG

No. Part Number Description

A Board

B Board

C Board

0113070686

0113050420

0113060163

Main board

Power board

120HZ control board

3-2 Main Board

J10:

HDMI

J4:IR&KEY

BOARD

J9:

LVDS

J6:PANEL

POWER

J5:POWER

IN

J1:

INVERTER

J2:

HDCP

J3:DVD

CTL

&%RDUG

$%RDUG

J8:AUDIO

POWER IN

J17:

S_VIDEO

J18:

YPBPR

J14:AUDIO

OUT

- 08 -

J19:AUDIO

IN

J12:

SPEAKER

Page 10

Service Manual

Model No.:

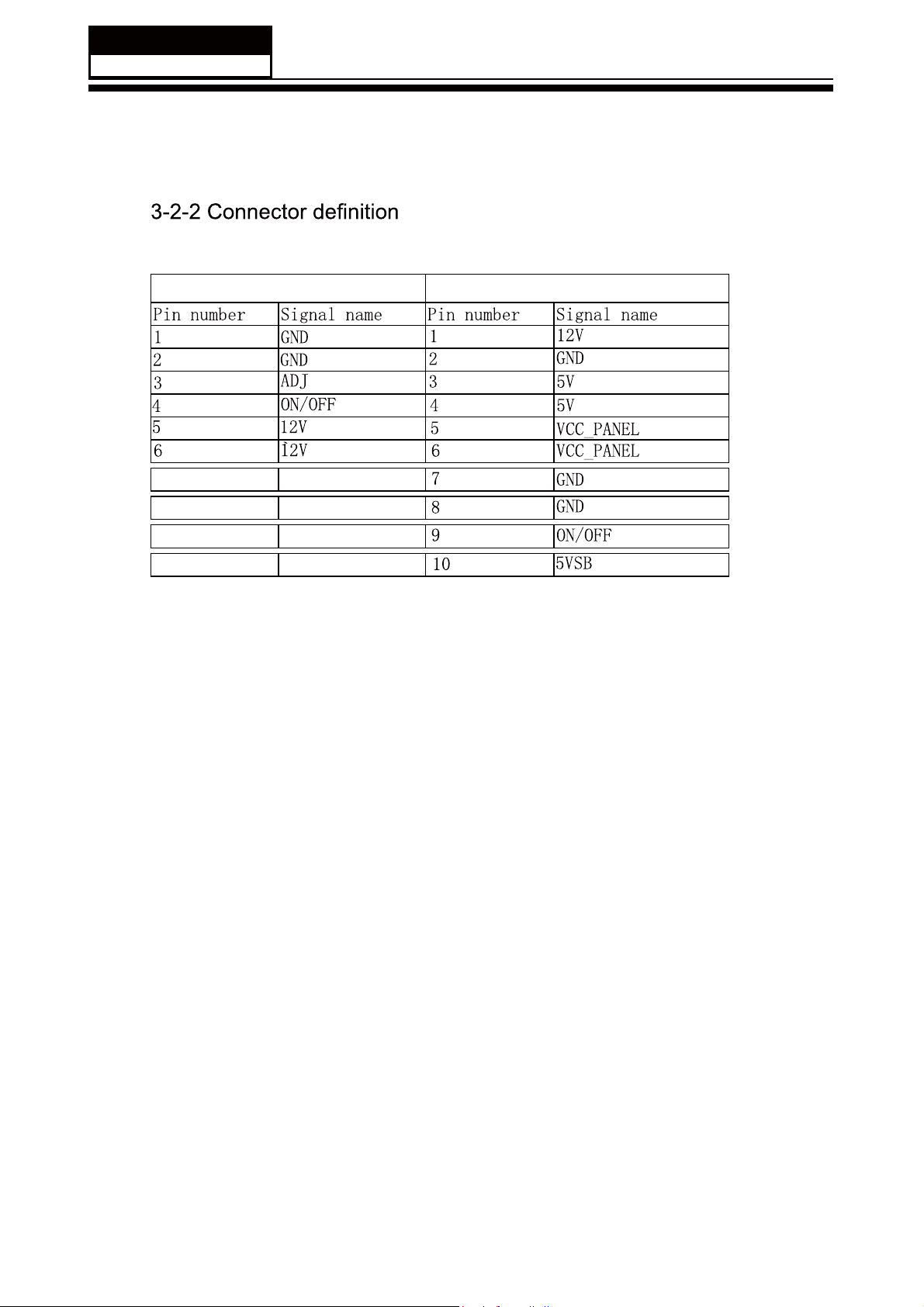

3-2-1 Function Description:

Main Board

Process signal which incept from exterior equipment then translate into signalthatpanel

can display.

Main board connector

Power connectors (J1, J5)

J1

Notes:

J1-Pin 4: Backlight on/off:

The system can turn on or turn off the backlight of TFT LED Panel throughthepower

supply unit path.

J5-Pin 9: System power on / standby

System board will use this pin to control system power.

J1-Pin 3: Control the luminance of backlight

The system can generate the PWN signal to control the strength of TFT LED Panel’s

backlight through this connector

J5

- 09 -

Page 11

Keypad and remote connector (J4)

Service Manual

Model No.:

Pin number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Signal name

GND

K7

K6

K5

K4

K3

K2

K1

K0

GND

IR

LED_G

LED_R

GND

Description

Ground

Power key

NC

CH- key

CH+ key

Vol- key

Vol+ key

Meny key

TV/AV key

Ground

IR Receive

Green Indicator

Red Indicator

+5V DC Power Supply

- 10 -

Page 12

Service Manual

Model No.:

Speaker connector J12

Pin number Signal nam e Description

1

2

3

4

R+

R-

L-

L+

Audio Right+channel Output

Audio Right- channel Output

Audio Left- channel Output

Audio Left+channel Output

3-3. Power Board

Pin-CON1 Connection And Function

NO. Pin Connection Function

1 AC-N AC INPUT NUTURE

2 AC-L AC INPUT LINE

Pin-CON2 Connection And Function TYPE:2.54MM*13PIN

NO. Pin Connection Function

1 12V 12V DC OUTPUT

2 12V 12V DC OUTPUT

3 GND 12V DC RETURN

4 GND 5V DC RETURN

5 GND 5V DC RETURN

65V 5VDCOUTPUT

75V 5VDCOUTPUT

85VSB 5VDCOUTPUT

9 PS-ON SMPS ON/OFF CONTROL(ON=HIGH)

10 5V 5V DC OUTPUT

11 5V 5V DC OUTPUT

12 GND 5V DC RETURN

13 GND 5V DC RETURN

Pin-CON3 Connection And Function TYPE:2.54MM*4PIN

NO. Pin Connection Function

1 GND 24V DC RETURN

2 GND 24V DC RETURN

3 24V 24V DC OUTPUT

4 24V 24V DC OUTPUT

Pin-CON4 Connection And Function TYPE:2.54MM*8PIN

NO. Pin Connection Function

1 GND 24V DC RETURN

2 GND 24V DC RETURN

3 GND 24V DC RETURN

4 GND 24V DC RETURN

5 24V 24V DC OUTPUT

6 24V 24V DC OUTPUT

7 24V 24V DC OUTPUT

8 24V 24V DC OUTPUT

- 11 -

Page 13

3-4. LED Panel

Service Manual

Model No.:

V546H1-LE5

- 12 -

Page 14

Service Manual

Model No.:

3-5 Interface Connec tions

CNF2 Connector Pin Assignment(187059-51221(P-two) or equivalent)

-

Symbol

No

GND

1

2

NC

NC

3

NC

4

NC

5

NC

6

SELLVDS

7

NC

8

NC

9

NC

10

GND

11

CH1[0]-

12

CH1[0]+

13

CH1[1]-

14

CH1[1]+

15

CH1[2]-

16

CH1[2]+

17

GND

18

CH1CLK-

19

CH1CLK+

20

GND

21

CH1[3]-

22

CH1[3]+

23

CH1[4]-

24

CH1[4]+

25

NC

26

Description

Ground

1

1

1

1

1

LVDS Data Format Selection 2

1

1

1

Ground

First pixel Odd LVDS Signal-

First pixel Odd LVDS Signal+

First pixel Odd LVDS Signal-

First pixel Odd LVDS Signal+

First pixel Odd LVDS Signal-

First pixel Odd LVDS Signal+

Ground

First pixel Odd LVDS Clock-

First pixel Odd LVDS Clock+

Ground

First pixel Odd LVDS Signal-

First pixel Odd LVDS Signal+

First pixel Odd LVDS Signal-

First pixel Odd LVDS Sig

nal+

1

No

Symbol

NC

27

CH2[0]-

28

29

CH2[0]+

CH2[1]-

30

31

CH2[1]+

CH2[2]-

32

CH2[2]+

33

GND

34

CH2CLK-

35

36

CH2CLK+

37

GND

38

CH2[3]-

39

CH2[3]+

CH2[4]-

40

41

CH2[4]+

42

NC

NC

43

GND

44

GND

45

GND

46

NC

47

48

59

50

51

-

-

VCC

VCC

VCC

VCC

Descrip tion

Second pixel Odd LVDS Signal-

Second pixel Odd LVDS Signal+

Second pixel Odd LVDS Signal-

Second pixel Odd LVDS Signal+

Second pixel Odd LVDS Signal-

Second pixel Odd LVDS Signal+

Ground

Second pixel Odd LV

Second pixel Odd LVDS Clock+

Ground

Second pixel Odd LVDS Signal-

Second pixel Odd LVDS Signal+

Second pixel Odd LVDS Signal-

Second pixel Odd LVDS Signal+

DC power supply

DC power supply

DC power supply

DC power supply

DS Clock-

N o t e :1)Reserved for internal use.Please leave it open

N o t e : 2)High=connect to +3.3V:JEIDA Format;Low=connect to GND or Open:VESA

Format

1

1

1

1

- 13 -

Page 15

Service Manual

Model No.:

CNF3 Connector Pin Assignment(187059-51221(P-two) or equivalent)

-

Symbol

No

GND

1

2

NC

NC

3

NC

4

NC

5

NC

6

NC

7

NC

8

GND

9

CH3[0]-

10

CH3[0]+

11

CH3[1]-

12

CH3[1]+

13

CH3[2]-

14

CH3[2]+

15

GND

16

CH3CLK-

17

CH3CLK+

18

GND

19

CH3[3]-

20

CH3[3]+

21

Description

Ground

1

1

1

1

1

1

1

Ground

Third pixel Odd LVDS Signal-

Third pixel Odd LVDS Signal+

Third pixel Odd LVDS Signal-

Third pixel Odd LVDS Signal+

Third pixel Odd LVDS Signal-

Third pixel Odd LVDS Signal+

Ground

Third pixel Odd LVDS Clock-

Third pixel Odd LVDS Clock+

Ground

Third pixel Odd LVDS Signal-

Third pixel Odd LVDS Signal+

No

Symbol

CH3[4]-

22

23

CH3[4]+

24

25

CH4[0]-

26

27

CH4[0]+

CH4[1]-

28

29

CH4[1]+

30

CH4[2]-

31

CH4[2]+

32

CH4CLK-

33

34

CH4CLK+

35

36

37

CH4[4]-

38

39

CH4[4]+

NC

40

41

NC

42

NC

NC

GND

GND

CH4[3]-

CH4[3]+

Descrip tion

Third pixel Odd LVDS Signal-

Third pixel Odd LVDS Signal+

1

1

Four pixel Odd LVDS Signal-

Four pixel Odd LVDS Signal+

Four pixel Odd LVDS Signal-

Four pixel Odd LVDS Signal+

Four pixel Odd LVDS Signal-

Four pixel Odd LVDS Signal+

Ground

Four pixel Odd LVDS Clock-

Four pixel Odd LVDS Clock+

Ground

Four pixel Odd LVDS Signal-

Four pixel Odd LVDS Signal+

Four pixel Odd LVDS Signal-

Four pixel Odd LV

DS Signal+

1

1

1

N o t e :1)Reserved for internal use.Please leave it open

- 14 -

Page 16

CN1(Header):CI0114M1HR0-LA(CviLux)

3LQ Ĉ 6 \P ERO )HDWXUH

1

2

Service Manual

Model No.:

3

4

5

6

7

8

9

10

11

12

13

14

VBL +24V

GND GND

Status

E_PWM

I_PWM

BLON BL ON/OFF

Normal (3.3V)

Abnormal(0V)

Extemal PWM

Control

Ixtemal PWM

Control

Note(1)Pin12:Extemal PWM control (use pin 12):Pin 13 must open.

Note(2)Pin13:Intemal PWM control (use pin 13):Pin12 must open.

Note(3)Pin12 and Pin13 can’t open in the same period.

3-6 120HZ Control Board

CON1 CON2

CON 3 CON4

Pin NO.

CON1 ISP debug interface

CON3 CON4

LVDS C and D team OUTPUT

J1 INVERTER Input from mainboard J2 Power output to mainboard

J3 POWER Input

Description

Pin NO.

CON2

J2 J1 J3

Description

LVDS A and B team INPUT

LVDS A and B team OUTPUT

- 14 -

Page 17

Service Manual

Model No.:

4. Disassemble and assemble

Front

Back

4-1, Remove the10 screws as below picture

- 15 -

Page 18

Service Manual

Model No.:

4-2, Remove the 21 screws on the back cabinet

4-3, Remove the 4 screwsof the fixing board on the back cabinet.

4-4, Remove the 2 screws as below picture

- 16 -

Page 19

Service Manual

Model No.:

4-5, Remove the 7 screws on the fixing board

4-6,Remove the 4 screws as below picture

- 17 -

Page 20

Service Manual

Model No.:

-7, Remove the 4 screws fixing the power board.

4-8,Remove the 2 screws as below picture

- 18-

Page 21

Service Manual

Model No.:

4-9,Remove the 1 screws as below picture

4-10, Remove the 6 screws fixing the side iron stick.

- 19 -

Page 22

Service Manual

Model No.:

4-11

- 20 -

Page 23

5. Installation Instructions

5-1 External Equipment Connections

Accessories

Service Manual

Model No.:

CCD

GUIDE

CH+

ENTER

CH

MTS/SAP

5

0

STOP

PREV

FAVORITE

VOL+

AUDIO

SLEEP

3

6

RECALL

REPEAT

NEXT

CH.LIST

User GUIDE

Battery

PICTURE

ARC

12

4

789

INPUT

MENU MUTE

VOL

EXIT

PLAY/PAUSE

USB

REV FWD

DISPLAY

Remote Control

Antenna Connection

Connect one end of a coaxial cable (not included) to the ANT IN jack on the back of

your TV/DVD combo, then connect the other end of the cable into the antenna or cable

TV wall outlet.

To improve picture quality from an antenna in a poor signal area, install a signal

If you need to split the antenna signal to connect two TVs, install a two-way splitter.

- 21 -

Page 24

Service Manual

Model No.:

AV Input Connection

Note: All cables shown are not included with the TV.

RCAVideo Cable RCAAudio Cable

DVD or VCR

- Connect the VIDEO and AUDIO output jacks on the DVD or VCR to the AV IN jacks on the TV

set with a RCA cable.

- Match the jacks colors: Video=yellow, Audio left=White, Audio right=red.

- Turn on the DVD/VCR, and select “AV” in the input source menu.

YPbPr Connection

Note: All cables shown are not included with the TV.

Audio Cable

YPbPr Cable

Y Pb Pr

DVD or VCR

- Connect the YPbPr output jacks on the DVD or VCR to the YPbPr input jacks on the TV set

with a YPbPr cable. The picture quality is improved compared to a regular VCR to the video

input.

- Match the jacks colors: Y=Green, Pb=Blue, Pr=red.

- Connect the audio output jacks on the DVD or VCR to the audio input jacks on the set with an

audio cable.

- Turn on the DVD/VCR, and select “YPbPr” in the input source menu.

It can be connected to the following appliances: VCR, multi disc player, DVD, camcorder, video game

or stereo system, etc.....

YPbPr can support these video fomats: 480i, 576i, 480p, 576p, 720p, 1080i, 1080p.

Note: 1.AV share the audio input channel.

2.When HDMI 1 port get DVIsignal, the PC Audio channel is changed to receive

3.Som etimes it will not support in different device

the audio for HDMI1 port.

- 22-

Page 25

PC Connection

Note: All cables shown are not included with the TV.

PC audio

cable

VGA cable

- If using a sound card, adjust the

PC sound as required.

- Set the video resolution of your

PC to 1024x768, 60Hz on its

original monitor.

Make the connections between

the T

V monitor and your PC,

switch on the monitor before

booting the PC.

You can now set your preferred

resolution from the choice

supported.

See the table of supported

resolutions on the right.

Service Manual

Model No.:

- Connect the RGB jack on the PC to the VGA jack on the TV set with a VGA cable.

- Connect the audio output jack on the PC to the PC IN jack on the TV set with a stereo audio

cable.

- Turn on the PC, and select “VGA” in the input source menu.

PRESET MODE

Resolution Refresh Rate

1920*1080

1680*1050

1440*900

1280*1024 60HZ 63.5KHZ

1024*768

800*600

640*480

720*400 70HZ 31.5KHZ

60H 74KHZ

60HZ 74.6KHZ

60HZ 64.7KHZ

60HZ 65.3KHZ

60HZ 55.5KHZ

60HZ 59.9KHZ

60HZ 48.4KHZ

70HZ 56.5KHZ

75HZ 60.0KHZ

60HZ 37.9KHZ

70HZ 47.2KHZ

75HZ 46.9KHZ

60HZ 31.5KHZ

70HZ 37.9KHZ

75HZ 37.5KHZ

- 23 -

Page 26

Service Manual

Model No.:

5-2 HDMI Connections

When the source device(DVD player or Set Top Box) supports HDM

How To Connect

1. Connect the source device to HDMI port of this TV with an HDMI cable(not supplied

with this product).

2. No separated audio connection is necessary.

How To Use

If the source device supports Auto HDMI function, the output resolution of the source

device will be automatically

set to 1280x720p.

If the source device does not support Auto HDMI, you need to set the output resolution

appropriately.

To get the best picture quality, adjust the output resolution of the source device to

1280x720p.

Select HDMI input source in input source option of Select Main source menu.

When the source device(DVD player or Set Top Box) supports DVI

How To Connect

1. Connect the source device to HDMI port of this TV with a HDMI-to-DVI cable(not

supplied with this product).

2. A separated audio connection is necessary.

3. If the source device has an analog audio output connector, connect the source device

audio output to DVI Audio In port located on the PC port.

How To Use

If the source device supports Auto DVI function, the output resolution of the source device

will be automatically

set to 1280x720p.

If the source device does not support Auto DVI, you need to set the output resolution

appropriately.

To get the best picture quality, adjust the output resolution

1280x720p.

Press the INPUT button to select HDMI input source in input source option of Select Main

source menu.

Installation

of the source device to

- 24 -

Page 27

Cable sample

Service Manual

Model No.:

HDMI Cable

(not supplied with the product)

HDMI to DVI Cable

( not supplied with the product)

Analog Audio Cable

(Stereo to RCA type)

(not supplied with the product)

- 25 -

Page 28

Service Manual

Model No.:

Power source

TO USE AC POWER SOURCE

Use the AC polarized line cord provided for operation on AC.

Insert the AC cord plug into a standard polarized AC outlet.

NOTES:

Use the attached power cord only.

electrician replace the obsolete outlet.

simply unplug the unit from the AC outlet and plug it back in. The unit should return to

normal operation.

- 26 -

Page 29

6. Operation Instructions

Basal information

6-1 Front panel controls

VOLINPUT MENU

CH

2). The functions of the buttons:

INPUT: Press to display the input source menu.

MENU: Press to display the OSD menu,

press again to exit the menu.

VOL+/-: Press to adjust the volume.

CH / : Press to scan through channels.

Service Manual

Model No.:

STANDBY: Turn on/standby the TV set.

6.2 Back panel controls

USB HDMI1 HDMI2 HDMI3

USB: For service(software update) and media.

HDMI1/2/3 : Connect it to the HDMI output of the external devices.

VGA: For PC display.Connect it to the D-Sub 15 pins analog output connector of the PC.

PC audio: Connect it to the audio output terminal of PC.

Component

YPbPr: Connect them to the YPbPr video output terminal of the external devices.

R/L in: Connect them to the audio output terminal of the external devices.

AV IN

VIDEO: Connect it to video output terminal of the external devices

VIDEO

COAX

AV IN

AUDIO OUT

RF IN

AC POWER IN

R/L in: Connect them to the audio output terminal of the external devices.

AUDIO OUT R/L: Connect them to the audio input terminal of the external devices.

Coax: Digital audio output.

Connect antenna or cable 75 Ohm coaxial to receive TV signal.

RF:

Headphone: Connect it to your headphone or other audio equipments.

AC POWER IN : Connect to the AC POWER with the mains cable.

- 27-

Page 30

Service Manual

Model No.:

6-3 Setting Up Your Remote Control

MTS/SAP

VOL+

STOP

PREV

FAVOR IT E

AUDIO

SLEEP

3

6

RECALL

REPEAT

NEXT

CH.LIST

2

9

13

11

17

16

14

15

3

1

3

4

12

5

7

8

6

PICTURE

CCD

ARC

12

4

789

INPUT

MENU MUTE

VOL

EXIT

USB

REV FWD

DISPLAY

5

0

CH+

ENTER

CH

PLAY/PAUSE

GUIDE

Insert Batteries Into the Remote Control

12

1. Remove the battery cover.

2. Inserting the 2 AAA 1.5V batteries making sure the

polarity (+ or -) of the batteries matches the polarity

marks inside the unit.

3. Mount the battery cover.

Replace with new batteries when the TV set begins

to show the following symptoms:

Operation is unsteady or erratic. Sometimes the TV

set does not function with Remote Control Unit.

Remark:

1) Alkaline Battery Recommended.

2) Remove batteries when they are exhausted or if the

remote control is not to be used for long time.

1: POWER

TO set the TV to standby or power on.

2:PICTURE

ress repeatedly to cycle through the available.

3:CCD

Press to display the closed caption.

4:ARC

Adjust picture size.

5:NUMBER KEY

For direct access to channels.

6:INPUT

Press to display the input source menu.

7:MENU

To display the menu.

8:VOL+/To adjust the sound level.

9:EXIT

Exit from the current menu.

10:USB

Switch to the USB source directly.

11:REV

Fast backward key.

12:FWD

Fast forward key.

13:Be used in programme edit:

Display:Display the information of current mode.

Guide:Press to enter the EPG menu directly.

Yellow:Press to add or remove favorite channel.

Blue:Display the prog

ram list.

14:AUDIO

Press to cycle through the different sound settings.

15:MTS

Press to select the audio channels.

16:SLEEP

Setthe time to turn off the TV.

17:MUTE

To disable or enable the sound.

18:CH+/CHTo access the next or previous TV Program.

19:RECALL

To access the previously viewed programme.

20:PLAY/PAUSE

Play/Pause key.

21:STOP

Stop key.

22.PREV

Previous key.

23.NEXT

Next key.

- 28 -

Page 31

Service Manual

Model No.:

7. Electrical parts

7-1. Block diagram

Schematics BlockDiagram

LED PANNEL

D D

5

4

flash

4M

3

BACKLIGHT

2

1

Antenna in

C C

B B

A A

5

TDA18273

POWER

lvds

MST318

DDR2 512M

Design:

Checked:

Apprd:

4

3

TPA3124

COAX

Earphone

HDMI

VGA

YPbPr

AV

SCART

USB

MODEL:MST318

PART NO.:

SPEAKER

TITLE: Cover page

DWG NO.:

VER:SHEET: 0 pages 8

2

1

- 29 -

Page 32

Service Manual

Model No.:

7-2. Circuit Diagram

D D

J5

10

8

7

9

8

7

9

10

6

NC/SS14D4NC/SS14

C3

R47

R47

12

D4

12

1K

SW_POWER

12

+5Vstb

R291KR29

3.3n

3.3n

PANEL_+5V

1

5

4

+5Vstb

3

+5Vstb

12

+5V_SW

1.32V DC-DC 1150mA

1 2

1 2

C2100n C2100n

C14

C14

R347K R347K

12

A A

2 1

D29M7D29M7

12

100uF/16V

100uF/16V

C168

5

4

3

DVD_STB3

DVD_AUTO3

DVD_EN3

DVD_EN

DVD_STB

DVD_AUTO

C168

BM1117-ADJ

BM1117-ADJ

ADJ/GND

ADJ/GND

R104 91R/1%R104 91R/1%

2 3

10u

10u

100n

100n

1

2

DVD_PW_ON3

DVD_PW_ON

1

2

1

Q13

Q13

NC/3904

NC/3904

C98

C98

C68

C68

4

OUT

OUT

200R/1%

200R/1%

100uF/16V

100uF/16V

R76 1kR76 1k

1

M7

12

12

U6

U6

IN

IN

321

R103

R103

C101

C101

+3.3V_SW

+2.5V

TP7

+2.5V

TP7

+2.5V

2 1

D13M7D13

12

12

1

NC/10k

NC/10k

R77

R77

12

B B

+2.5V

+5VA

21

D12M7D12

M7

+1.8V

1.8VA

1.8VA

1.8VA

TP5

TP5

+5Vstb

BM1117-ADJ

BM1117-ADJ

R71820R_1%R71820R_1%

10u

10u

100n

100n

BM1117-ADJ

BM1117-ADJ

ADJ/GND

ADJ/GND

1

R162820R_1%R162820R_1%

1 2

+5V_SW

10u

10u

100n

100n

ADJ/GND

ADJ/GND

1

1 2

12

C119

C119

12

C123

C123

4

OUT

OUT

2

R163

510R_1%

R163

510R_1%

100uF/16V

100uF/16V

12

C42

C42

12

C61

C61

4

OUT

OUT

2

510R_1%

510R_1%

100uF/16V

100uF/16V

IN

IN

3

C139

C139

C

+5VA

XH-10AJ5XH-10A

445

11223

6

5

22p

22p

C22

C22

C44

100n

C44

100n

C20

22p

C20

22p

C28

100n

C28

100n

C19

C19

100n

100n

C32

22p

C32

22p

220u/16V

220u/16V

CA1

CA1

C31

470u/16V

C31

470u/16V

PW_ON/OFF

PW_ON/OFF

1 2

1

2 3

Q1

3904Q13904

12

12

R4

4.7kR44.7k

R46 4.7kR46 4.7k

1

2

1

2 3

3904Q63904

3

+12V_SW

2 1

+5V_SW

Q6

2.2K

2.2K

220u/16VC3220u/16V

4.7K

4.7K

R42 NC/0RR42 NC/0R

1

2

SW_POWER

R12

R12

U3

U3

IN

IN

3

12

R70

R70

+3.3V_SW

12

C36

C36

TP3

+3.3V_SW

TP3

+3.3V_SW

1

+5Vstb

U9

U9

12

+3.3Vstb

12

TP8

+3.3Vstb

TP8

+3.3Vstb

1

2

1

D

D

D

a

a

a

A3

A3

A3

Wednesday, April 20, 2011

Wednesday, April 20, 2011

Wednesday, April 20, 2011

tnemucoDeziS

tnemucoDeziS

tnemucoDeziS

N

N

N

u

u

u

m

m

m

02.POWER

02.POWER

02.POWER

teehS:et

teehS:et

teehS:et

2 10

2 10

2 10

of

of

of

20

20

20

veRreb

veRreb

veRreb

C8 NC/100nC8 NC/100n

C9 NC/100nC9 NC/100n

C7 NC/100nC7 NC/100n

1 2

1 2

1 2

Title

Title

Title

CV318H-A-20

CV318H-A-20

CV318H-A-20

1

R34

R34

Q5

NC/3904Q5NC/3904

R18 NC/100RR18 NC/100R

2 3

8

DIR

DAT

STB

112233445566778

J3

NC/PH-8AJ3NC/PH-8A

1 2

1 2

1 2

R20 NC/100RR20 NC/100R

R19 NC/100RR19 NC/100R

DAT

STB

DIR

NC/47k

NC/47k

NC/2.2k

NC/2.2k

+12V_SW+5.1V_DVD

R41

R41

12

12

12

C15

NC/1u

C15

NC/1u

2

Q2 NC/AO3401Q2 NC/AO3401

1

3

12

C11

NC/100n

C11

NC/100n

+5.1V_DVD

L:OFF

H:ON

2 3

3904

3904

PW_ON/OFF

1

R146 10kR146 10k

2

1

Q20

Q20

2.2k

12

C

+5Vstb

12

12

C381uC38

1u

2

Q14 AO3401Q14 AO3401

1

100n

100n

3

+5VA

12

C35

C35

1

TP4

TP4

+5VA

+5VA

1 2

10K_1%

10K_1%

R75

47k

R75

47k

R140

2.2k

R140

5

SYNC8EN7COMP6FB

MP1482U1MP1482

VSW

GND

U1

PAD

VIN

BS

3

2

9

1

4

12

100n

100n

4.3K/1%

4.3K/1%

R24

R24

12

C24

100n

C24

100n

12

C25

470uF/16V

C25

470uF/16V

+5V_SW

C10

C10

1 2

R10R R10R

1 2

C1

10nC110n

L1 33uH/2.5AL1 33uH/2.5A

12

12

R33

R33

+1.32V_DC

+1.32V_DC

1

+1.32V_DC

2

1

TP1

TP1

- 30 -

Page 33

Service Manual

Model No.:

HDMI2-RX2N6

HDMI2-HPDIN6

HDMI2-SDA6HDMI2-CLKP6

HDMI2-CLKN6

HDMI2-CLKN

HDMI2-HPDIN

HDMI2-SDA

HDMI2-SCL

HDMI2-RX2N

HDMI2-CLKP

5

12

10uF/25V

10uF/25V

C111

C111

R142 10KR142 10K

1 2

47K

47K

R153

R153

12

2

R152 100RR152 100R

Q21

3906

Q21

3906

1

12

System-RST

C1161nC116

1n

4

MSD318QT

MSD318QT

SPI_CSN_1

SPI_SDO

2

22RX4

22RX4

1

SPI-CS0N

SPI-SDO

3

1 2

DO not use Microchip EEPROM for U9

R48

4.7K

R48

4.7K

4

NC/24C04U2NC/24C04

U2

A01A12A23GND

I2C address

at A4

VCC

SDA

SCL

WP

7

8

6

5

R40 22RR40 22R

R25 22RR25 22R

12

100n

100n

C54

C54

I2C-SCL

I2C-SDA

I2C-SDA

I2C-SCL

I2C-SDA

I2C-SCL

2

R32 100RR32 100R

R26 100RR26 100R

SDA

SCL

SCL

SDA

+5V_SW

+12V_SW

6

J2

PH-6AJ2PH-6A

11223344556

6

HDMI2-RX1P6

HDMI2-RX2P6HDMI2-SCL6

HDMI2-RX0N

HDMI2-RX1N6

HDMI2-RX0P6

HDMI2-RX1P

HDMI2-RX1N

HDMI2-RX2P

HDMI2-RX0N

100K

100K

D20

BAV99

D20

BAV99

213

12

C115

100n

C115

100n

GPIO

GPIO

GPIO1(UART_RX1)

GPIO0(UART_TX1)

GPIO2

K5

H4

H6

SPI_SCK

SPI_SDI

8642

8642

RP19

RP19

7531

7531

78

5634

SPI-SCK

SPI-SDI

+3.3V_SW

HDCP KEY

+3.3V_SW

D

A

HDMI1-SCL

HDMI1-SDA

HDMI1-SDA

HDMI1-SCL

HDMI2-RX0P

R141

R141

12

+3.3Vstb

321

Debug Port

Debug Port

PWM

PWM

DDCA_DAN6DDCA_CK

PWM1

PWM2

PWM3

AA15

V13

M6

Panel_ON

PBACK_ADJ

UART-TXD

UART-RXD

220P

220P

100K

100K

HDMI1-CLKN

HDMI1-HPDIN

HDMI1-HPDIN

HDMI1-CLKN

PF_OND_A14

PWM0

Y15

W15

PWM0

PWM1

I2S_OUT_BCK

I2S_OUT_MCK

I2S_OUT_SD

1K

1 2

1K

PWM0

PWM1

SPI_SDI

SI5SCK6HOLD#7VDD

VSS

4

12

C159

100n

C159

100n

R204

R204

10K

10K

C117

C117

12

R156

R156

HDMI1-RX2N

HDMI1-CLKP

HDMI1-RX2N

HDMI1-CLKP

PF_OND_A13

PF_OND_A12

T15

L17

U15

1K

1K

NC/1K

NC/1K

1K

WP#

3

FLASH_WPN1

12

1

2

FLASH_WPNSPI_SCK

C133100nC133100n

AUOUTR2 audio_Out_r

2

1

12

HDMI1-RX1N

HDMI1-RX2P

HDMI1-RX1N

HDMI1-RX2P

PF_OND_A10

PF_OND_A11

P17

SO

2

SPI_SDO

R200 4.7KR200 4.7K

4.7K

4.7K

12

R155 0RR155 0R

HDMI1-RX1P

HDMI1-RX0N

HDMI1-RX1P

HDMI1-RX0N

Reset

PF_OND_A8

PF_OND_A9

P16

M16

N17

12

R2021KR202

12

R1671KR167

12

R166

R166

12

R2231KR223

12

R1291KR129

R1361KR136

8

CE#

1

SPI_CSN_1

12

HDMI1-RX0P

HDMI1-RX0P

PF_OND_A7

R175

R175

220P

220P

100K

100K

with width trace

PF_OND_A6

R17

N16

+3.3V_SW +3.3Vstb

+3.3Vstb

U10 EN25Q32U10EN25Q32

HDMI Block

MIUA_DQ[15:0]

MIUA_A[13:0]

HDMI0-RX1P

HDMI0-SDA

HDMI0-CLKP

HDMI0-CLKN

HDMI0-RX0N

HDMI0-RX1N

HDMI0-RX2P

HDMI0-SCL

HDMI0-RX2N

HDMI-CEC

HDMI0-RX0P

HDMI0-HPDIN

MIUA_DQ[15:0]

MIUA_A[13:0]

HDMI0-RX2N

HDMI0-SDA

HDMI0-RX0N

HDMI0-CLKP

HDMI0-HPDIN

HDMI0-SCL

HDMI-CEC

HDMI0-CLKN

HDMI0-RX1P

HDMI0-RX1N

HDMI0-RX2P

HDMI0-RX0P

C1181uC118

1u

Close to IC

C1221uC122

1u

PF_OND_A0

PF_OND_A1

PF_OND_A2

PF_OND_A3

PF_OND_A4

PF_OND_A5

V15

V17

R16

R18

V16

V18

Parallel Flash

Parallel Flash

PF_OND_D15

N18

AUVRP

AUVAG

PF_OND_D14

PF_OND_D13

K18

R19

AUVRM

PF_OND_D10

PF_OND_D11

PF_OND_D12

M18

M17

PF_OND_D8

PF_OND_D9

K16

K17

XTALI

12

C141

27p

C141

27p

3

12

12

XTALO

C142

27p

C142

27p

NAND_IO_4

NAND_IO_5

NAND_IO_6

NAND_IO_7

L16

L19

M20

M21

M19

IC Configuration Selection

Front End

Front End

TGPIO3/ I2C_SDA

TGPIO2/ I2C_CLK

TGPIO1/DNGAIN

TGPIO0/UPGAIN

RF_TAGC

MSD318QT

MSD318QT

IFAGC

Y7

AA7

V7

W6

Y6

AA6

DEMOD_IF_AGC

SCLK

SDAT

D_RF_AGC

K10

J15

J16

J14

K7

VSS40

VSS44

VSS43

VSS41

VSS42

MSD318QT

MSD318QT

AUOUTL2 audio_Out_l

R157 0RR157 0R

C120

C120

12

12

12

R158

R158

MSD318QT

MSD318QT

GPIO

GPIO

TESTPIN

LHSYNC

LDE

LCK

U12

U13

T13

R10

TESTPIN

MIUA_DQM1

NAND_IO_3

L20

SSIF/SIFM

W9

J13

VSS39

LVSYNC

T12

MIUA_DQM0

MIUA_DQM1

24MHZY124MHZ

NAND_IO_2

SSIF/SIFP

VSS38

DVD_STB

B

MIUA_DQM0

K19

AA9

J12

MIUA_DQSB1

MIUA_DQS1

MIUA_DQS1

Y1

NAND_IO_0

NAND_IO_1

K20

VIFM

VIFP

Y9

J11

VSS37

VSS36

MIUA_DQSB1

R194 1MR194 1M

1 2

K21

W8

J10

MIUA_DQS0

MIUA_DQS0

IM

Y8

DTV-IFN

J9

VSS35

B_ODD1/LA4P/LLV8P

W16

B0_RXE4+

MIUA_DQSB0

MIUA_DQSB0

NAND_WPZ/PF_OND_A15

R21

IP

W7

DTV-IFP

B_ODD0/LA4N/LLV8N

AA16

B1_RXE4-

C

MIUA_ODT

MIUA_CASZ

MIUA_RASZ

MIUA_BA2

MIUA_MCKE

MIUA_WEZ

MIUA_BA0

MIUA_BA1

MIUA_MCKE

MIUA_BA1

MIUA_BA2

MIUA_WEZ

MIUA_CASZ

MIUA_BA0

MIUA_RASZ

MIUA_ODT

USB0_DP

USB0_DM

System XTAL

USB0_DP

USB0_DM

PF_CE0Z

PF_CE1Z

PF_WEZ

PF_OEZ

PF_RBZ

PF_ALE

P19

N21

N19

P20

R20

N20

SPDIF

SPDIF

SPDIF OUT

SPDIF IN

C6

M5

SPDIF_OUT

H13

H12

H11

H15

H10

H14

H9

VSS31

VSS30

VSS29

VSS28

VSS34

VSS33

VSS32

B_ODD4/LACKN/LLV6N

B_ODD5/LACKP/LLV6P

G_ODD0/LA1N/LLV4N

G_ODD1/LA1P/LLV4P

B_ODD6/LA2N/LLV5N

B_ODD2/LA3N/LLV7N

B_ODD3/LA3P/LLV7P

B_ODD7/LA2P/LLV5P

AA18

AA19

W19

Y18

W18

W17

Y16

Y17

B6_RXE2-

G1_RXE1+

B3_RXE3+

B2_RXE3-

B5_RXEC+

B4_RXEC-

B7_RXE2+

G0_RXE1-

MIUA_MCLK

MIUA_MCLKZ

MIUA_MCLK

MIUA_MCLKZ

USB Block

DM_P1

DP_P1

Y14

I2S_OUT_SD1L5I2S_OUT_SD2

I2S_OUT_SD3

I2S_OUT_SD

L6

D4

DVD_EN

G12

G13

G14

VSS27

VSS26

VSS24

VSS25

LVDS

LVDS

G_ODD4/LB4N/LLV2N

G_ODD2/LA0N/LLV3N

G_ODD5/LB4P/LLV2P

G_ODD3/LA0P/LLV3P

AA20

Y20

Y19

G4_RXO4+

G3_RXE0+

G2_RXE0-

DDR2-SDRAM

Block

D_RF_AGC

DEMOD_IF_AGC

IF+

IF-

C112 10nC112 10n

C113 10nC113 10n

R145 220RR145 220R

R148 220RR148 220R

D_RF_AGC

DEMOD_IF_AGC

DTV-IFN

DTV-IFP

USB Hostx2

USB Hostx2

HOTPLUGC

DM_P0

DP_P0

CEC

AA10

C5

W14

K4

B5

HDMI2-HPDIN

HDMI-CEC

USB0_DP

USB0_DM

I2S IN/OUT

I2S IN/OUT

I2S_OUT_MCK

I2S_OUT_BCK

I2S_OUT_WS

I2S_IN_BCK

I2S_IN_WS

I2S_IN_SD

H5

F5

G6

F6

L4

P5

P4

I2S_OUT_BCK

I2S_OUT_MCK

I2S_OUT_SD

DVD_AUTO

G10

G11

F14

F13

G9

VSS21

VSS22

VSS20

VSS23

R_ODD0/LBCKN/LLV0N

R_ODD1/LBCKP/LLV0P

R_ODD2/LB2N/RLV8N

R_ODD3/LB2P/RLV8P

G_ODD6/LB3N/LLV1N

G_ODD7/LB3P/LLV1P

W21

V21

V19

V20

Y21

W20

U19

R1_RXOC+

R3_RXO2+

R0_RXOC-

G5_RXO4-

G7_RXO3+

G6_RXO3-

R2_RXO2-

AMP_RIN

SPDIF_OUT

AMP_LIN

AMP_LIN

AMP_RIN

SPDIF_OUT

DIF BLOCK

DDCDC_DA

DDCDC_CK

C_RXCP

W10

Y10

W11

HDMI2-CLKP

HDMI2-SCL

HDMI2-SDA

F12

F10

F11

VSS18

VSS19

VSS92N9VSS93

P9

R_ODD4/LB1N/RLV7N

R_ODD7/LB0P/RLV6P

R_ODD5/LB1P/RLV7P

T20

U20

T19

R4_RXO1-

R5_RXO1+

R7_RXO0+

audio_Out_r

audio_Out_l

audio_Out_l

audio_Out_r

C_RXCN

C_RX2P

W13

Y11

HDMI2-CLKN

HDMI2-RX2P

VRM

U8

AUVRM

E14

VSS15

VSS16F9VSS17

AA4

R_ODD6/LB0N/RLV6N

T21

R6_RXO0-

AUOUTL1

AUOUTR1

AUOUTR1

B1_RXE4-

B0_RXE4+

B0_RXE4+

C_RX2N

C_RX1P

Y13

HDMI2-RX2N

VAG

VRP

U7

AUVAG

E13

VSS14

VSS13

VSS88U4VSS89V3VSS90Y4VSS91

AUOUTL1

B3_RXE3+

B2_RXE3-

B7_RXE2+

B3_RXE3+

B2_RXE3-

B1_RXE4-

C_RX0N

C_RX1N

C_RX0P

AA12

AA13

W12

HDMI2-RX1P

HDMI2-RX0P

HDMI2-RX1N

EARPHONE_OUTR

EARPHONE_OUTL

T7

T6

AUVRP

AUOUTR2

E10

E11

E12

VSS11

VSS10

VSS12

VSS87

H16

U7B

U7B

MSD318QT

MSD318QT

LINE OUT

G0_RXE1-

G1_RXE1+

B6_RXE2-

B6_RXE2-

G1_RXE1+

B7_RXE2+

HOTPLUGB

DDCDB_DA

DDCDB_CK

D6

D5

Y12

A2

HDMI2-RX0N

HDMI1-HPDIN

HDMI1-SDA

LINE_OUT_0R

LINE_OUT_1R

LINE_OUT_1L

W5

V6

U6

U5

AUOUTL2

AUOUTL1

AUOUTR1

D13

D14

D12

E9

VSS7

VSS8

VSS9

PWR/GND

PWR/GND

VSS85V1VSS86

VSS84

V2

P8

M7

MVREF

J17

C

AV2_RIN

AV2_LIN

AV2_LIN

B4_RXEC-

B5_RXEC+

G2_RXE0-

G3_RXE0+

B4_RXEC-

G3_RXE0+

G0_RXE1-

G2_RXE0-

B5_RXEC+

HDMI Inx3

HDMI Inx3

B_RXCN

B_RXCP

B_RX2N

B_RX1P

B_RX2P

D2

D3

D1

B1

B2

HDMI1-CLKN

HDMI1-RX2N

HDMI1-RX2P

HDMI1-CLKP

HDMI1-SCL

Audio In/Out

Audio In/Out

LINE_OUT_0L

LINE_IN_4R

LINE_IN_3R

LINE_IN_4L

W4

V4

Y1

V5

AUOUTL0

AUOUTR0

AV2_RIN

AV2_LIN

10R/500mA

10R/500mA

D10

D11

J7

J8

VSS5

VSS6

VSS4

VSS78T5VSS79

VSS81

VSS80

VSS82N7VSS83

P7

R7

R6

PAD_IO[10](A-CLK-)

PAD_IO[36](A-WEZ)

PAD_IO[11](A-ODT)

C21

B10

C11

B_MDDR_VREF

MIUA_WEZ

MIUA_ODT

YPBPR2-Rin

YPBPR2-Lin

YPBPR2-Lin

AV2_RIN

G7_RXO3+

G5_RXO4-

G4_RXO4+

G4_RXO4+

G5_RXO4-

B_RX0N

B_RX1N

B_RX0P

C3

C2

HDMI1-RX1P

HDMI1-RX0P

HDMI1-RX1N

LINE_IN_2R

LINE_IN_2L

LINE_IN_3L

Y2

W3

YPBPR2-RinYPBPR2-Rin

1 2

L10

L10

AVSS_PGA

AVSS_PGAM9DVDD8

VSS1H7VSS2H8VSS3

VSS77

VSS76

VSS75

C17

C12

PAD_IO[12](A-CLK+)

PAD_IO[37](A-CKE)

PAD_IO[9](A-RAS)

D19

B11

MIUA_MCLK

MIUA_MCLKZ

MIUA_MCKE

B

LINE_IN_0R

LINE_IN_1L

LINE_IN_1R

LINE_IN_1R

LINE_IN_1L

R3_RXO2+

G6_RXO3-

G7_RXO3+

G6_RXO3-

HOTPLUGA

DDCDA_DA

B3

J5

G4

HDMI1-RX0N

HDMI0-HPDIN

LINE_IN_1R

LINE_IN_1L

W1

W2

AA2

YPBPR2-Lin

LINE_IN_1R

C81 1uC81 1u

1

2

G15

DVDD_NODIE

VSS73

VSS74

B15

C20

P15

PAD_IO[40](A-BA2)

PAD_IO[7](A-CAS)

A10

C10

E19

MIUA_CASZ

MIUA_RASZ

LINE IN

LINE_IN_0L

LINE_IN_0R

R2_RXO2-

R5_RXO1+

R3_RXO2+

R5_RXO1+

R2_RXO2-

DDCDA_CK

A_RXCP

E2

K6

HDMI0-CLKP

HDMI0-SDA

HDMI0-SCLLINE_IN_0L

LINE_IN_0R

LINE_IN_0L

Y3

AA3

LINE_IN_1L

LINE_IN_0R

LINE_IN_0L

DVDD_NODIE

E18

F15

AVDD1P2_ADC

VSS71

VSS72

P13

P14

PAD_IO[39](A-BA0)

PAD_IO[38](A-BA1)

D21

D20

MIUA_BA2

MIUA_BA0

MIUA_BA1

Audio Block

R1_RXOC+

R4_RXO1-

R0_RXOC-

R6_RXO0-

R7_RXO0+

R0_RXOC-

R1_RXOC+

R6_RXO0-

R4_RXO1-

R7_RXO0+

A_RXCN

A_RX1N

A_RX2N

A_RX0P

A_RX1P

A_RX2P

G2

G3

G1

E1

F3

HDMI0-RX1P

HDMI0-RX2N

HDMI0-RX1N

HDMI0-RX2P

HDMI0-CLKN

CVBS_OUT1

CVBS4PT1CVBS5P

R5

T2

D18

D17

E16

E17

E15

VDD6

VDD7

VDD5

VDD4

VDD3

VDD2

VSS68

VSS70

VSS66

VSS67

VSS69

P10

P12

N15

P11

PAD_IO[42](A-AD10)

PAD_IO[35](A-AD12)

PAD_IO[0](A-AD13)

PAD_IO[2](A-AD11)

PAD_IO[46](A-AD9)

PAD_IO[4](A-AD8)

G20

A7

B7

G19

F19

MIUA_A12

MIUA_A13

MIUA_A9

MIUA_A10

MIUA_A11

SV-Yin

SV-Cin

VCOM0

SV-Yin

SV-Cin

VCOM0

LVDS Block

PW_ON/OFF

PW_ON/OFF

R150 10KR150 10K

1 2

XTAL

XTAL

XTAL_OUT

XTAL_IN

A_RX0N

Y5

F2

E3

HDMI0-RX0P

HDMI0-RX0N

XTALI

CVBS Inx6

CVBS Inx6

CVBS0PU3CVBS1PU2CVBS2PT3CVBS3P

T4

SV-Yin

SV-Cin

+3.3Vstb

+1.32V_DC

D16

D15

F8

AVDD_EAR33

VDD1

VSS62

VSS64

VSS63

VSS65

N13

N14

N12

N11

PAD_IO[43](A-AD5)

PAD_IO[45](A-AD7)

PAD_IO[3](A-AD4)

PAD_IO[6](A-AD6)

C8

B8

F20

G21

MIUA_A7

MIUA_A8

MIUA_A6

MIUA_A5

CVBS Block

AV_VIN

AV_VIN

2

MUTE_DET9

MUTE_AMP

DVD_PW_ON

MUTE_AMP

DVD_PW_ON

MUTE_DET

R83 10KR83 10K

R80 4.7KR80 4.7K

1 2

1 2

+5Vstb

I2C-Master

I2C-Master

DDCR_DA

DDCR_CK

RESET

T14

AA5

C7

U14

SCL

XTALO

System-RST

SDA

SOGIN2

VCOM0

BIN2M

BIN2P

P3

P2

U1

P1

DVD_YPbPr_SOG

DVD_YPbPr_BIN+

DVD_YPbPr_BIN-

VCOM0

AV_VIN

+3.3Vstb

+3.3Vstb

+3.3Vstb

+3.3Vstb

G7

D8

F7

AVDD3.3V_DVI3

AVDD3.3V_ADCD7AVDD3.3V_DVI1

AVDD3.3V_DMPLLE7AVDD3.3V_DVI2E8AVDD_AU331

VSS60

VSS61

VSS59

M15

M14

N10

M13

DDR2 16bit

DDR2 16bit

PAD_IO[26](A-LDQM)

PAD_IO[41](A-AD1)

PAD_IO[44](A-AD3)

PAD_IO[8](A-AD0)A9PAD_IO[5](A-AD2)

B17

C9

B9

F21

E20

MIUA_A2

MIUA_A3

MIUA_A1

MIUA_DQM0

MIUA_A4

MIUA_A0

DVD_YPbPr_RIN-

DVD_YPbPr_RIN+

DVD_YPbPr_BIN-

DVD_YPbPr_RIN-

DVD_YPbPr_RIN+

UART-RX

DVD_STB

UART-TX

UART-RX

UART-TX

SAR2E5SAR3

IRIN

J6

A6

IR_SYNC

IR_SYNC

GIN2M

RIN2M

GIN2P

RIN2P

N3

R3

N1

DVD_YPbPr_GIN-

DVD_YPbPr_GIN+

DVD_YPbPr_RIN+

M8

N8

AVDD2.5V_MOD1

AVDD2.5V_MOD2

VSS58

VSS56L7VSS57

M12

M11

PAD_IO[22](A-UDQSM)

PAD_IO[24](A-LDQSM)

PAD_IO[23](A-LDQSP)

PAD_IO[25](A-UDQM)

B16

C18

A16

MIUA_DQS0

MIUA_DQM1

MIUA_DQSB0

DVD_YPbPr_GIN+

DVD_YPbPr_BIN+

DVD_YPbPr_GIN-

DVD_YPbPr_BIN+

DVD_YPbPr_BIN-

DVD_YPbPr_GIN-

DVD_EN

DVD_EN

DVD_STB

R59 4.7KR59 4.7K

R151 4.7KR151 4.7K

1

1

2

2

SAR0E4SAR1

B6

KEY_1

KEY_0

KEY_0

KEY_1

HSYNC1

VSYNC1

SOGIN1

R4

R2

P6

DVD_YPbPr_RIN-

K9

L8

AVDD2.5V_ADCB1K8AVDD2.5V_ADCB2

AVDD2.5V_AUL9AVDD2.5V_REF_Demod

PAD_IO[21](A-UDQSP)

PAD_IO[20](A-DQ15)

PAD_IO[27](A-DQ14)

A15

C16

C15

MIUA_DQS1

MIUA_DQSB1

MIUA_DQ15

YPbPr_SOG

DVD_YPbPr_SOG

DVD_YPbPr_GIN+

DVD_YPbPr_SOG

YPbPr_SOG

Panel_ON

DVD_AUTO

SCL

DVD_AUTO

Panel_ON

R11 4.7KR11 4.7K

R147 4.7KR147 4.7K

R62 4.7KR62 4.7K

1 2

1 2

1 2

GPIO_PM5

GPIO_PM6

U10

V10

FLASH_WPN

MUTE_AMP

MUTE_DET

RGB Inx3

RGB Inx3

GIN1M

BIN1M

GIN1P

BIN1P

M2

L2

L1

K3

L3

YPbPr_BIN-

YPbPr_SOG

YPbPr_GIN-

YPbPr_BIN+

YPbPr_GIN+

VDDP

2.5V_MAINCHIP

AVDD2P5_PGA

M10

G17

H17

F17

VDDP3.3V1

VDDP3.3V2

VDDP3.3V3

AVDD2.5V_PGA

VSS52

VSS53

VSS54

VSS55

L12

L14

L13

L15

PAD_IO[19](A-DQ10)

PAD_IO[16](A-DQ13)

PAD_IO[30](A-DQ11)

PAD_IO[28](A-DQ12)

C14

B13

B18

A19

C19

MIUA_DQ13

MIUA_DQ10

MIUA_DQ12

MIUA_DQ14

MIUA_DQ11

D

YPbPr_RIN+

YPbPr_GIN-

YPbPr_GIN+

YPbPr_BIN-

YPbPr_BIN+

YPbPr_RIN-

YPbPr_GIN+

YPbPr_RIN+

YPbPr_BIN+

YPbPr_RIN-

YPbPr_BIN-

YPbPr_GIN-

SCLK

SDAT

SDAT

SDA

R13 4.7KR13 4.7K

R1604.7KR1604.7K

1

1

2

2

+3.3V_SW

PM Domain

PM Domain

GPIO_PM2

GPIO_PM4G5GPIO_PM7T8GPIO_PM1

GPIO_PM0

GPIO_PM3

T10

V9

U9

T9

PW_ON/OFF

LED MIUA_DQ6

ON_PBACK

DVD_PW_ON

LED

HSYNC0

VSYNC0

SOGIN0

RIN1M

RIN1P

BIN0P

N4

M3

N2

H3

N5

YPbPr_RIN+

YPbPr_RIN-

VGA_VSYNC0

VGA_HSYNC0

AVDD_MEMPLL

G18

G16

F16

F18

AVDD3.3V_MEMPLL1

AVDD_DDR8

AVDD3.3V_MEMPLL2

AVDD_DDR9

AVDD_DDR10

VSS50

VSS47

VSS48

VSS51

VSS49

L10

K14

L11

K15

PAD_IO[13](A-DQ5)

PAD_IO[17](A-DQ7)

PAD_IO[18](A-DQ8)

PAD_IO[29](A-DQ9)

PAD_IO[34](A-DQ4)

PAD_IO[31](A-DQ6)

B12

A18

A13

B14

B19

MIUA_DQ8

MIUA_DQ7

MIUA_DQ9

MIUA_DQ5

SCLK

R159 4.7KR159 4.7K

1 2

BIN0M

H1

BIN+

J21

AVDD_DDR7

VSS46

K13

PAD_IO[33](A-DQ3)

B21

MIUA_DQ4

VGA_VSYNC0

SPI_CK

GIN0P

H2

BIN-

J20

AVDD_DDR6

VSS45

K12

PAD_IO[15](A-DQ2)

B20

MIUA_DQ3

VGA_VSYNC0

TUNER_3.3

SPI_DI

B4

SPI-SCK

GIN0M

J2

GIN+

J19

AVDD_DDR5

K11

PAD_IO[32](A-DQ1)

A12

MIUA_DQ2

VGA_HSYNC0

VGA_HSYNC0

A4

SPI-SDI

J3

GIN-

J18

A20

MIUA_DQ1

A

BIN-

BIN+

BIN+

SPI_CSZ

SPI_DO

C4

SPI-SDO

RIN0M

RIN0P

K2

RIN+

H21

AVDD_DDR3

AVDD_DDR4

PAD_IO[14](A-DQ0)

C13

MIUA_DQ0

GIN+

BIN-

ON_PBACK

PBACK_ADJ

ON_PBACK

R50 10KR50 10K

1 2

A3

SPI-CS0N

K1

RIN-

H20

AVDD_DDR2

GND_EFUSE

RGB Block

RIN-

RIN+

GIN-

GIN+

RIN+

RIN-

GIN-

GPIO PULL-UP

PBACK_ADJ

R51 4.7KR51 4.7K

1

2

+5V_SW

U7C

U7C

U7D

U7D

1.8VA

H19

H18

AVDD_DDR1

U7E

U7E

D9

U7A

U7A

v10v10v

10

5

4

3

2

Custom

Custom

Custom

mucoDeziS

mucoDeziS

mucoDeziS

e

e

e

tn

tn

tn

N

N

N

1

rebmu

rebmu

rebmu

03.MSD318QT

03.MSD318QT

03.MSD318QT

teehS:etaD

teehS:etaD

teehS:etaD

39Wednesday, April 20, 2011

39Wednesday, April 20, 2011

39Wednesday, April 20, 2011

of

of

of

R

R

R

e

e

e

v

v

v

Title

Title

Title

CV318H-A-20

CV318H-A-20

CV318H-A-20

UART-TX

R283 100RR283 100R

1

2

UART-TXD

1 2

UART-RX

R286 100RR286 100R

UART-RXD

4.7K

4.7K

1 2

1 2

4.7K

4.7K

R287

R287

R291

R291

DEBUG PORT

+3.3Vstb

AUOUTR0

R1700RR1700R

C126

220P

C126

220P

12

12

R171

R171

100K

100K

12

AMP_RIN

AUDIO_OUT

AUOUTL0

R184 0RR184 0R

2

220P

220P

C129

C129

1

12

12

100K

100K

R182

R182

AMP_LIN

+3.3Vstb

1

12

C114

100n

C114

100n

12

2

100n

100n

C134

C134

12

100n

100n

C167

C167

12

100n

100n

C166

C166

+2.5V

1

L15

10R/500mA

L15

10R/500mA

L12

10R/500mA

L12

10R/500mA

2

AVSS_PGA

AVDD2P5_PGA

2.5V_MAINCHIP

12

C158

100n

C158

100n

MSTIC_POWER_MAIN

+3.3V_SW

1

L4 10R/500mAL4 10R/500mA

2

C601uC60

1u

VDDP

12

C70

100n

C70

100n

AVDD_MEMPLL

12

C67

100n

C67

100n

1 2

10u

10u

100n

100n

100n

100n

C46

C46

12

C65

C65

12

C71

C71

VDDC 1.2V_MAIN

+1.32V_DC

1 2

10K_1%

10K_1%

100n

100n

12

R114

R114

1 2

R112

10K_1%

R112

10K_1%

B_MDDR_VREF

C85

C85

1.8VA

12

C82

C82

100n

100n

12

C84

100n

C84

100n

DDR2 Power

1.8VA

1

- 31 -

Page 34

Service Manual

Model No.:

MIUA_MCLK

MIUA_MCLKZ

1.8VA

100R

100R

R134

R134

MIUA_A13

MA_MCLKZ

MA_MCLK

5

C110

10n

C110

10n

MA_RASZ

MA_CASZ

R135

R135

MA_WEZ

75R

75R

MA_ODT

4

3

MIUA_ODT

100R

100R

K7

L7

K3

L8

K9

J7

B8

B2

D2

D8

E7

F2

F8

H8

H2

A7

J3

N1

P9

E3

A3

EDE5116AJBG-8E

EDE5116AJBG-8E

R133

R133

12

12

A13

RAS

CAS

WE

CS

ODT

VSSDL

VSSQ10

VSSQ9

VSSQ8

VSSQ7

VSSQ6

VSSQ5

VSSQ4

VSSQ3

VSSQ2

VSSQ1

VSS4

VSS3

VSS2

VSS1

VSS

UDQS

UDM

B3

R164 75RR164 75R

1 2

MA_CKE

R8

K2

K8

CK

CKE

UDQS

DQ15

B9

A8

B7

J8

BA2/RFU2

CK

DQ13

DQ14

B1

MA_A12

MA_A11

MA_BA2

L1

D9

DQ12

MA_BA1

L3

D1

MA_BA0

A12R2BA0L2BA1

DQ11

DQ10

D3

MA_A10

MA_A9

M2

P7

P3

A9

A11

A10

D7

C2

R115

10K_1%

R115

10K_1%

C77

C77

10n

10n

MA_A7

MA_A6

MA_A4

MA_A2

MA_A5

MA_A8

P8

MA_A3

N8

N7

N3

N2

A4

A6

A7P2A8

A5

A1M3A2M7A3

DQ0G8DQ1G2DQ2H7DQ3H3DQ4H1DQ5H9DQ6F1DQ7F9DQ8C8DQ9

A_MVERF

MA_A1

A0

LDM

10K_1%

10K_1%

MA_A0

M8

NC4

NC3

VDD1

VDD2

VDD3

VDD4

VDD5

VDDQ1

VDDQ2

VDDQ3

VDDQ4

VDDQ5

VDDQ6

VDDQ7

VDDQ8

VDDQ9

VDDQ10

VDDL

VREF

NC1

NC2

LDQSF7LDQS

E8

F3

R107

R107

U5

U5

R3

R7

J9

M9

R1

E1

A1

C1

A9

C3

C7

C9

G1

G3

G7

G9

E9

J1

A_MVERF

J2

A2

E2

MA_DQSB1

22RX4

22RX4

7

1 2

5

7531

7531

RP16

RP16

8642

8642

8

634

MA_MCLKZ

MA_MCLK

1.8VA

MA_DQS1

MIUA_BA1

MIUA_WEZ

MIUA_BA0

MIUA_MCKE

1 2

1u

100n

100n

100n

100n

100n

100n

100n

100n

100n

100n

100n

100n

MIUA_DQSB0

3 4

MA_DQSB0

C911uC91

C58

C58

C105

C105

C106

C106

C108

C108

C107

C107

C62

C62

MIUA_DQS0

22RX4

22RX4

5 6

7 8

7531

7531

8642

8642

5

RP12

RP12

MA_DQS0

1.8VA

4

3

aD

aD

aD

ziS

ziS

ziS

Custom

Custom

Custom

t

t

t

e

e

e

2

ucoD

ucoD

ucoD

m

m

m

Wednesday, April 20, 2011

Wednesday, April 20, 2011

Wednesday, April 20, 2011

04.MEMORY

04.MEMORY

04.MEMORY

hS:e

hS:e

hS:e

e

e

e

te

te

te

410

410

410

1

of

of

of

MIUA_RASZ

MIUA_A0

MIUA_CASZ

785

3 4

Title

Title

Title

CV318H-A-20

CV318H-A-20

CV318H-A-20

7531

7531

8642

8642

6

MA_RASZ

MA_A0

MA_CASZ

MIUA_A2

1 2

RP1775RX4

RP1775RX4

MA_A2

22RX4

MA_DQ1

MA_DQSB0

MA_DQSB1

MA_DQM1

MA_DQS1

MA_DQ15

MA_DQ14

MA_DQ13

MA_DQ12

MA_DQ11

MA_DQ10

MA_DQ8

MA_DQ9

MA_DQ6

MA_DQ4

MA_DQ7

MA_DQ5

MA_DQ3

MA_DQ2

MA_DQM0

MA_DQ0

MA_DQS0

R119 22RR119 22R

R118 22RR118 22R

MA_DQ3

MA_DQ4

785634

MIUA_DQ4

MIUA_DQ3

MIUA_DQM0

MA_DQ1

MA_DQ6

8642

8642

7531

7531

12

MIUA_DQ6

MIUA_DQ1

MA_DQ14

RP10

RP10

MIUA_DQ14

MA_DQ12

MA_DQ9

563412

MIUA_DQ12

MIUA_DQ9

MA_DQ11

8642

8642

7531

7531

78

RP1122RX4

RP1122RX4

MIUA_A[13:0]

MIUA_DQ11

MIUA_DQM1

MIUA_A1

MIUA_A9

MIUA_A3

MIUA_A5

MIUA_A4

MIUA_A6

MIUA_A8

3 4

1

7531

7531

8642

8642

2

MA_A11MIUA_A11

MA_A6

MA_A8

75RX4

75RX4

785 6

RP18

RP18

MA_A4

MIUA_A10

MIUA_BA2

75RX4

75RX4

1

7 8

5 6

3 4

7531

7531

8642

8642

RP8

RP8

2

78

MA_A1

MA_A5

MA_BA2

MA_A10

MA_A3

MIUA_A7

2

8642

8642

7531

7531

34

56

1

MA_A9

MA_A7

MIUA_A12

75RX4

75RX4

RP7

RP7

MA_A12

MA_DQ5

12

MIUA_DQ5

MA_DQ2

MIUA_DQ2

MA_DQ0

MA_DQ7

8642

8642

7531

7531

5634

78

RP1522RX4

RP1522RX4

MIUA_DQ0

MIUA_DQ7

MA_DQ10

MA_DQ13

MIUA_DQ13

MIUA_DQ10

MA_DQ15

MA_DQ8

RP14 22RX4

RP14 22RX4

8642

8642

22RX4

22RX4

7531

7531

78

563412

MIUA_DQ15

MIUA_DQ8

2

34

1

MIUA_DQSB1

MIUA_DQM1

MIUA_A[13:0]

MIUA_DQ[15:0]

MIUA_DQ[15:0]

MIUA_DQM1

22RX4

6

8642

8642

7531

7531

5

78

RP13

RP13

MIUA_DQS1

MIUA_DQM0

MIUA_DQS1

MIUA_DQM0

MIUA_DQS1

MIUA_DQSB1

MA_WEZ

MIUA_DQSB1

MIUA_DQS0

341 2

MA_CKE

MIUA_DQS0

MIUA_DQSB0

5 6

7531

7531

8642

8642

MA_BA1

MIUA_DQSB0

MIUA_ODT

7 8

RP975RX4

RP975RX4

MA_BA0

MIUA_ODT

MIUA_BA2

MIUA_BA2

C57

100n

C57

100n

C103

C103

100n

100n

100n

100n

C75

C75

2

MIUA_WEZ

MIUA_MCLKZ

MIUA_MCKE

MIUA_CASZ

MIUA_BA0

MIUA_RASZ

MIUA_BA1

MIUA_RASZ

MIUA_BA0

MIUA_BA1

MIUA_CASZ

MIUA_WEZ

MIUA_MCKE

MIUA_MCLK

MIUA_MCLK

MIUA_MCLKZ

1

RrebmuNtne

RrebmuNtne

RrebmuNtne

e

e

e

20

20

20

v

v

v

A

B

C

D

- 32 -

Page 35

Service Manual

Model No.:

C175

C175

10

GNDDIG2

XTOUT1

21

3.3V_Tun

9

FREEZE

XTOUT2

22

C C

IF-06

IF-06

J20

J20

4

RF

4

3

223

1

330nH 140mA 5%

330nH 140mA 5%

L19

L19

1 2

220nH 120mA 5%

220nH 120mA 5%

L18

L18

1

2

6

7

8

MasterSync

Test2

23

GNDDIG1

IFn

24

C135 100nC135 100n

12

R177 0RR177 0R

1 2

5

STO4NC1

AS_MSSel

TDA18273

TDA18273

GNDIF

VCCIF

IFP

25

26

1 2

C138

C138

6.8n

6.8n

C136 100nC136 100n

NC

2

1

R176 0RR176 0R

1

RF in

2

12

120P

120P

C209

C209

1

120P

120P

C208

C208

12

1 2

C207

C207

150P

150P

3

DD1

DD1

BAV99

BAV99

27

3.3V_Tun

R188NCR188

C204

82P

C204

82P

12

0R

R2380RR238

1

2

3

VCCRF

RFin

LTO

CapRFAGC

UHFSupply

VCCRF Filter

VHFSens

V_IF_AGC

V_Sync

VHFSupply

IRQ

29

30

28

12

R1781KR1781K

1 2

IFAGC

3.3V_Tun

U11

U11

41

gnd

40

39

NC2

2.2nH 1000mA +/- 0.2nH

2.2nH 1000mA +/- 0.2nH

38

UHFH

37

36

UHFL

2.4nH_220mA_+/-0.05nH

2.4nH_220mA_+/-0.05nH

35

8.2nH_110mA_+/-0.1nH

8.2nH_110mA_+/-0.1nH

34

VHFH

33

32

VHFL

L11100nH_150mA_+/-5%L11100nH_150mA_+/-5%

31

D D

C193

C193

220n

220n

L17

L17

L16

L16

1 2

12

100n

100n

C160

C160

5

4

12

3.3V_Tun

L14

L14

3

2

IF+

IF-

2

1 2

33p

33p

1 2

33p

33p

B B

Each of these Vcc pins of TDA18272 is decoupled by a

single capacitor (pin 1, 35, 27, 16)

3.3V_Tun

1 2

C169

C169

47n

47n

1 2

10u

18p

18p

3.3V_Tun

C161

C161

C147

C147

C140

C140

C128

C128

C180

C180

10u

11

SCL

12

SDA

13

Test1

14

Xtal

15

C176

C176

Xtalnot

16

VCCSYN

17

CAPREGVCO

18

GNDSYNT

12

19

VTUN

20

CP

1

R193

R193

2

430R

430R

C197

C197

C198

C198

T_SCL

R239 47RR239 47R

SCLK

SCLK 3

1 2

47n

47n

1 2

47n

47n

1 2

47n

47n

T_SDA

R240 47RR240 47R

SDAT

SDAT3

C196

C196

3.3V_Tun3.3V_Tun

C137

C137

3.3V_Tun

C146

C146

1 2

18p

18p

Y2

16MHZY216MHZ

3

1 2

12

1 2

100n

100n

6.8n

6.8n

1 2

2.7n

2.7n

1 2

220n

220n

A A

IFAGC

C127

C127

100n

100n

R189

R189

100R

5

4

3

2

100R

22n

22n

C131

C131

R1870RR187

0R

TUNER_3.3

100n

100n

C132

BM1117-ADJ

BM1117-ADJ

22n

22n

C132

10K

10K

D_RF_AGC

100n

100n

ADJ/GND

ADJ/GND

R192 820R/1%R192 820R/1%

1

1

2

R186

R186

10u

10u

C30

C30

100n

100n

C121

C121

100n

100n

C172

C172

OUT

OUT

4

2

9.1K

9.1K

R185

R185

12

IN

IN

3

R180

R180

510R/1%

510R/1%

100uF/16V

100uF/16V

C162

C162

C144

C144

12

C125

C125

R172

100R

R172

100R