Page 1

SERVICE MANUAL

LED TV

Model No.

MSD6586

LE49K6500U

Chassis

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

Page 2

Service Manual

Model No.:

Chapter 1: General Information

1-1. Table of Contents

1. General Information...........................................................................

1-1. Table of Contents

1-2. General Guidelines

1-3. Important Notice

1-4. How to Read this Service Manual

6SHFL¿FDWLRQV....................................................................................

3. Location of Controls and Components...........................................

3-1. Board Location

3-2. Main Board & AV Board

3-3. Power board

3-4. LCD Panel 13

4. Disassemble and Assemble..........................................................

4-1 Remove the Pedestal

4-2 Remove the Back Cover 14

4-3 Remove the Adhesive

4-4 Remove the Main Board 15

Tape 14

1

1

3

3

6

6

88

8

8

11

14

14

4-5 Remove the Speaker 15

4-6 Remove the Remote Control Board 16

4-6 Remove the Power board 16

5. Installation Instructions..…....………………...........………….........

5-1 External Equipment Connections

5-2 HDMI Connections 21

6. Operation Instructions....…....………………...........………….........

6-1 Front Panel Controls

6-2 Back Panel Controls

6-3 Universal Remote Control

7. Electrical Parts…....………………...........………….........................

7-1. Block Diagram

7-2. Circuit Diagram

7-3. Wiring Connection Diagram

17

17

24

24

24

25

26

26

27

36

- 01 -

Page 3

Service Manual

Model No.:

8. Measurements and Adjustments

8-1. How to enter into the factory model

8-2. How to update software

8-3. How to enter into the Hotel Model

........…………............................

9. Trouble-shooting…………..............................................................

9-1. Simple Check 51

9-2. Main Board Failure Check

9-3. Panel Failure

37

48

49

50

51

52

58

- 02 -

Page 4

Service Manual

Model No.:

1-2. General Guidelines

When servicing, observe the original lead dress. If a short circuit is found, replace all parts

which have been overheated or damaged by the short circuit.

After servicing, see to it that all the protective devices such as insulation barriers, insulation

papers shields are properly installed.

After servicing, make the following leakage current checks to prevent the customer from

being exposed to shock hazards.

1) Leakage Current Cold Check

2) Leakage Current Hot Check

3) Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive

1-3. Important Notice

1-3-1. Follow the regulations and warnings

Most important thing is to list up the potential hazard or risk for the service personnel to

open the units and disassemble the units. For example, we need to describe properly

how to avoid the possibility to get electrical shock from the live power supply or charged

electrical parts (even the power is off).

This symbol indicates that high voltage is present inside.It is dangerous to

make any king of contact with any inside part of this product.

This symbol indicates that there are important operating and maintenance

instructions in the literture accompanying the appliance.

1-3-2. Be careful to the electrical shock

7R SUHYHQW

to rain or excessive moisture. This TV must not be exposed to dripping or splashing water,

DQG REMHFWV ¿OOHG ZLWK OLTXLG VXFK DV YDVHV PXVW QRW EH SODFHG RQ WRS RI RU DERYH WKH 79

GDPDJH ZKLFK PLJKW UHVXOW LQ HOHFWULF VKRFN RU ¿UH GR QRW H[SRVH WKLV 79 VHW

1-3-3. Electro static discharge (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

components commonly are called Electrostatically Sensitive (ES) Devices. The following

techniques should be used to help reduce the incidence of component damage caused by

electros static discharge (ESD).

1-3-4. About lead free solder (PbF)

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder

must be used in the servicing and repairing of this product.

8VH WKH JHQHZLQJ SDUWV VSHFL¿HG SDUWV

Special parts which have purposes of fire retardant (resistors), high-quality sound

(capacitors), low noise (resistors), etc. are used.

When replacing any of components, be sure to use only manufacture's specified parts

shown in the parts list.

Safety Component

Ɣ &RPSRQHQWV LGHQWL¿HG E\ PDUN KDYH VSHFLDO FKDUDFWHULVWLFV LPSRUWDQW IRU VDIHW\

- 03 -

Page 5

1-3-6 Safety Check after Repairment

Service Manual

Model No.:

&RQ¿UP WKDW WKH

in the original positions, or whether there are the positions which are deteriorated around

the serviced places serviced or not. Check the insulation between the antenna terminal or

external metal and the AC cord plug blades. And be sure the safety of that.

VFUHZV SDUWV DQG ZLULQJ ZKLFK ZHUH UHPRYHG LQ RUGHU WR VHUYLFH DUH SXW

General Servicing Precautions

1.

Always unplug the receiver

a. Removing or reinstalling any component, circuit board module or any other receiver

assembly.

b. Disconnecting or reconnecting any receiver electrical plug or other electrical

connection.

c. Connecting a test substitute in parallel with an electrolytic capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity installation of electrolytic

capacitors may result in an explosion hazard.

2. Test high voltage only by measuring it with an appropriate high voltage meter or other

voltage measuring device (DVM, FETVOM, etc) equipped with a suitable high voltage

probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its assemblies.

AC power cord from the

AC power source before;

4. Unless specified otherwise in this service manual, clean electrical contacts only by

applying the following mixture to the contacts with a pipe cleaner, cotton-tipped stick or

comparable non-abrasive applicator; 10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength).

CAUTION: 7KLV LV D ÀDPPDEOH PL[WXUH

8QOHVV VSHFL¿HG RWKHUZLVH LQ WKLV VHUYLFH PDQXDO OXEULFDWLRQ RI FRQWDFWV LV QRW UHTXLUHG

Capacitors may result in an explosion hazard.

5. Do not defeat any plug/socket B+ voltage interlocks with which receivers covered by this

service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its electrical assemblies unless

all solid-state device heat sinks are correctly installed.

7. Always connect the test receiver ground lead to the receiver chassis ground before

connecting the test receiver positive lead.

Always remove the test receiver ground lead last. Capacitors may result in an explosion

hazard.

8VH ZLWK WKLV UHFHLYHU RQO\ WKH WHVW ¿[WXUHV VSHFL¿HG LQ WKLV VHUYLFH PDQXDO

CAUTION: 'R QRW FRQQHFW WKH WHVW ¿[WXUH JURXQG VWUDS WR DQ\ KHDW VLQN LQ WKLV UHFeiver.

9. Remove the antenna terminal on TV and turn on the TV.

10. Insulation resistance between the cord plug terminals and the eternal exposure metal

should be more than Mohm by using the 500V insulation resistance meter.

11. If the insulation resistance is less than M ohm, the inspection repair should be required.

If you have not the 500V insulation resistance meter, use a Tester. External exposure

metal: Antenna terminal Headphone jack

- 04 -

Page 6

Service Manual

Model No.:

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive (ES) Devices.

Examples of typical ES devices are integrated circuits and some field-effect transistors

and semiconductor "chip" components. The following techniques should be used to help

reduce the ncidence of component damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or semiconductorequipped assembly, drain off any electrostatic charge on your body by touching a known

earth ground.

strap device, which should be removed to prevent potential shock reasons prior to applying

power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly

on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

Alternatively, obtain and wear a commercially available discharging wrist

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static type solder removal device. Some solder removal devices not

FODVVL¿HG DV DQWLVWDWLF FDQ JHQHUDWH HOHFWULFDO FKDUJHV VXI¿FLHQW WR GDPDJH (6 GHYLFHV

'R QRW XVH IUHRQSURSHOOHG FKHPLFDOV 7KHVH FDQ JHQHUDWH HOHFWULFDO FKDUJHV VXI¿FLHQW

to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately

before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement

ES device, touch the protective material to the chassis or circuit assembly into which the

device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other

safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices.

(Otherwise harmless motion such as the brushing together of your clothes fabric or the

OLIWLQJ RI \RXU IRRW IURP D FDUSHWHG ÀRRU FDQ JHQHUDWH VWDWLF HOHFWULFLW\ VXI¿FLHQW WR GDPDJH

an ES device.)

1-3-7. Ordering Spare Parts

Please include the following informations when you order parts. (Particularly the Version

letter)

1. Model number, Serial number and Software Version

The model number and Serial number can be found on the back of each product and the

Software Version can be found at the Spare Parts List.

2. Spare Part No. and Description

<RX FDQ ¿QG WKHP LQ WKH 6SDUH 3DUWV /LVW

- 05 -

Page 7

1-3-8. Photo used in this manual

The illustration and photos used in this Manual may not base on the final design of

products, which may differ from your products in some way

1-4. How to Read this Service Manual

Using Icons:

,FRQV DUH XVHG

each icon is described in the table below:

Note:

A “note” provides information that is not indispensable, but may nevertheless be valuable

to the reader, such as tips and tricks.

WR DWWUDFW WKH DWWHQWLRQ RI WKH UHDGHU WR VSHFL¿F LQIRUPDWLRQ 7KH PHDQLQJ RI

Service Manual

Model No.:

.

Caution:

A “caution” is used when there is danger that the reader, through incorrect manipulation,

may damage equipment, loose data, get an unexpected result or has to restart(part of) a

procedure.

Warning:

A “warning” is used when there is danger of personal injury.

Reference:

A “reference” guides the reader to other places in this binder or in this manual, where he/

VKH ZLOO ¿QG DGGLWLRQDO LQIRUPDWLRQ RQ D VSHFL¿F WRSLF

- 06 -

Page 8

Service Manual

Model No.:

6SHFL¿FDWLRQV

- 07 -

Page 9

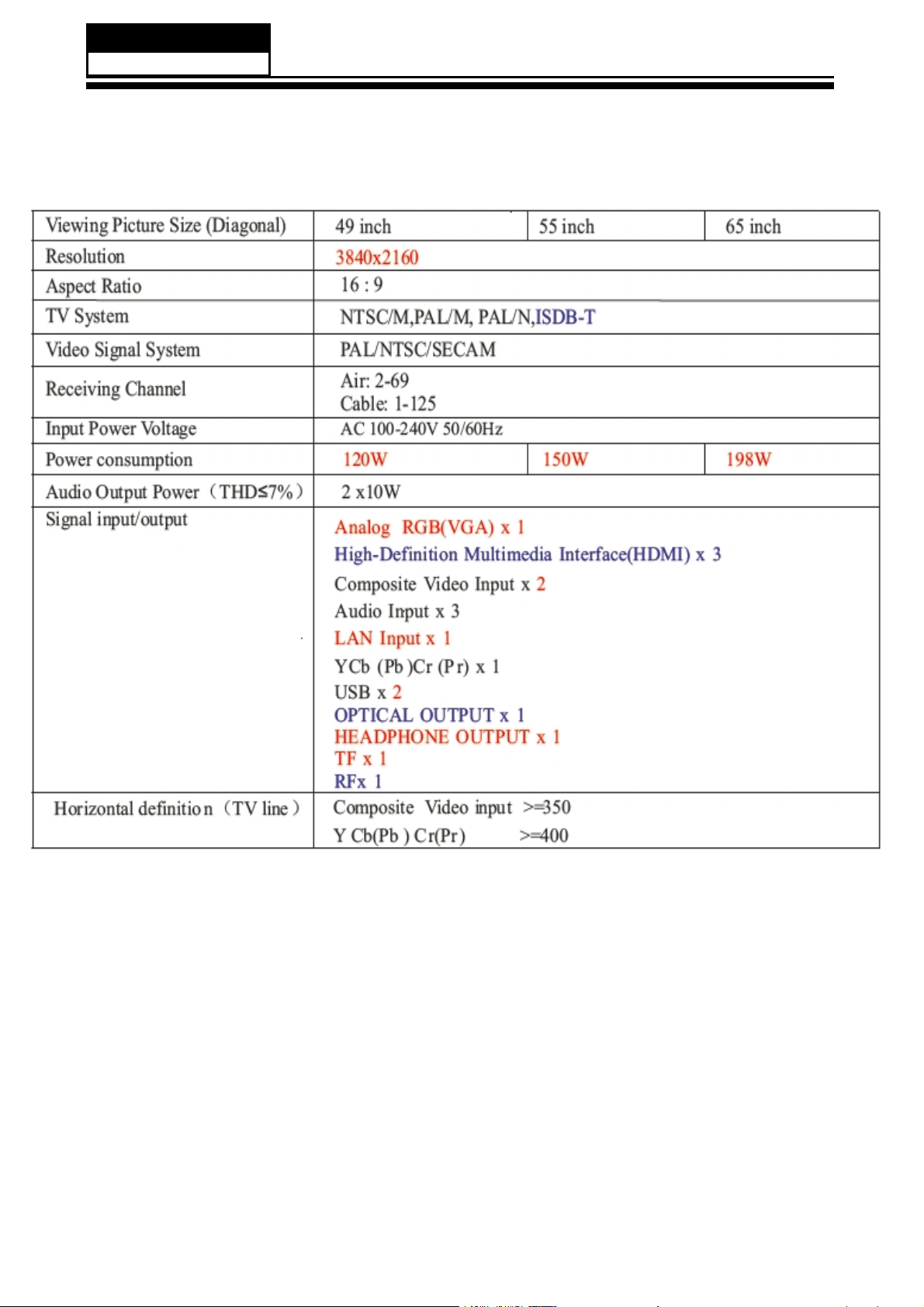

3. Location of Controls and Components

3-1 Board Location

Service Manual

Model No.:

A Board

B Board

3-2 Main Board

No. Description

A Board Mainboard

B

Board

Power Supply

- 08 -

Page 10

Service Manual

Model No.:

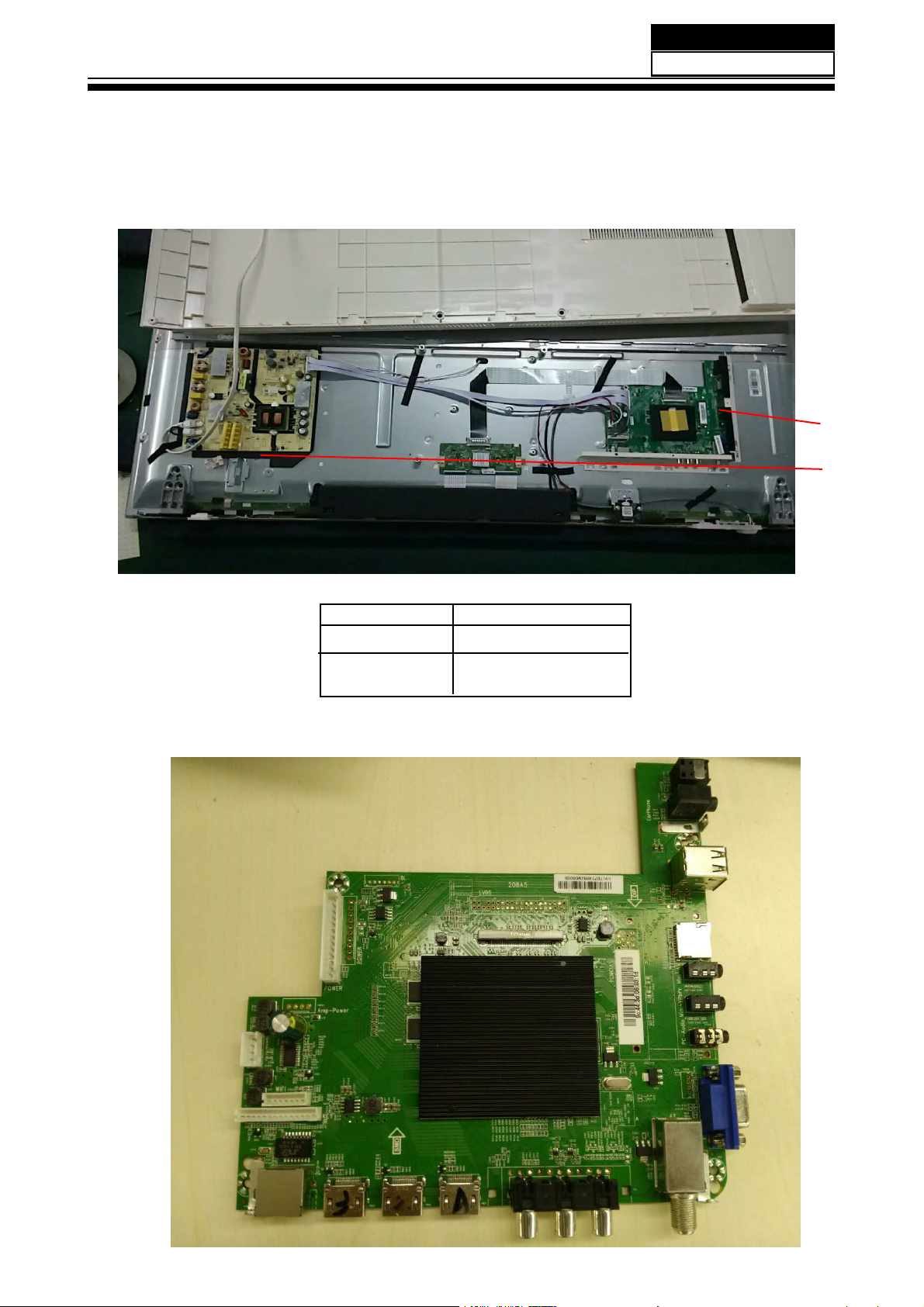

3-2-1 Function Description:

Main Board

Pr

ocess signal which incept from exterior equipment then translate into signal that panel

can display.

3-2-2 Connector denition

Main board connector

Power connectors ( J 20 )

Notes:

J 20-Pin 3: Backlight on/off:

he system can turn on or turn off the backlight of TFT LCD Panel through the power

T

supply unit path.

J 20-Pin 5: System power on / standby

System board will use this pin to control system power.

J 20-Pin 3: Control the luminance of backlight

The system can generate the PWN signal to control the strength of TFT LCD Panel’s

backlight through this connector

Speaker connector (CN604)

Pin number Signal name Description

1 RSPK+ RSPK+

2 RSPK- RSPK3 LSPK- LSPK4 LSPK+ LSPK+

- 09 -

Page 11

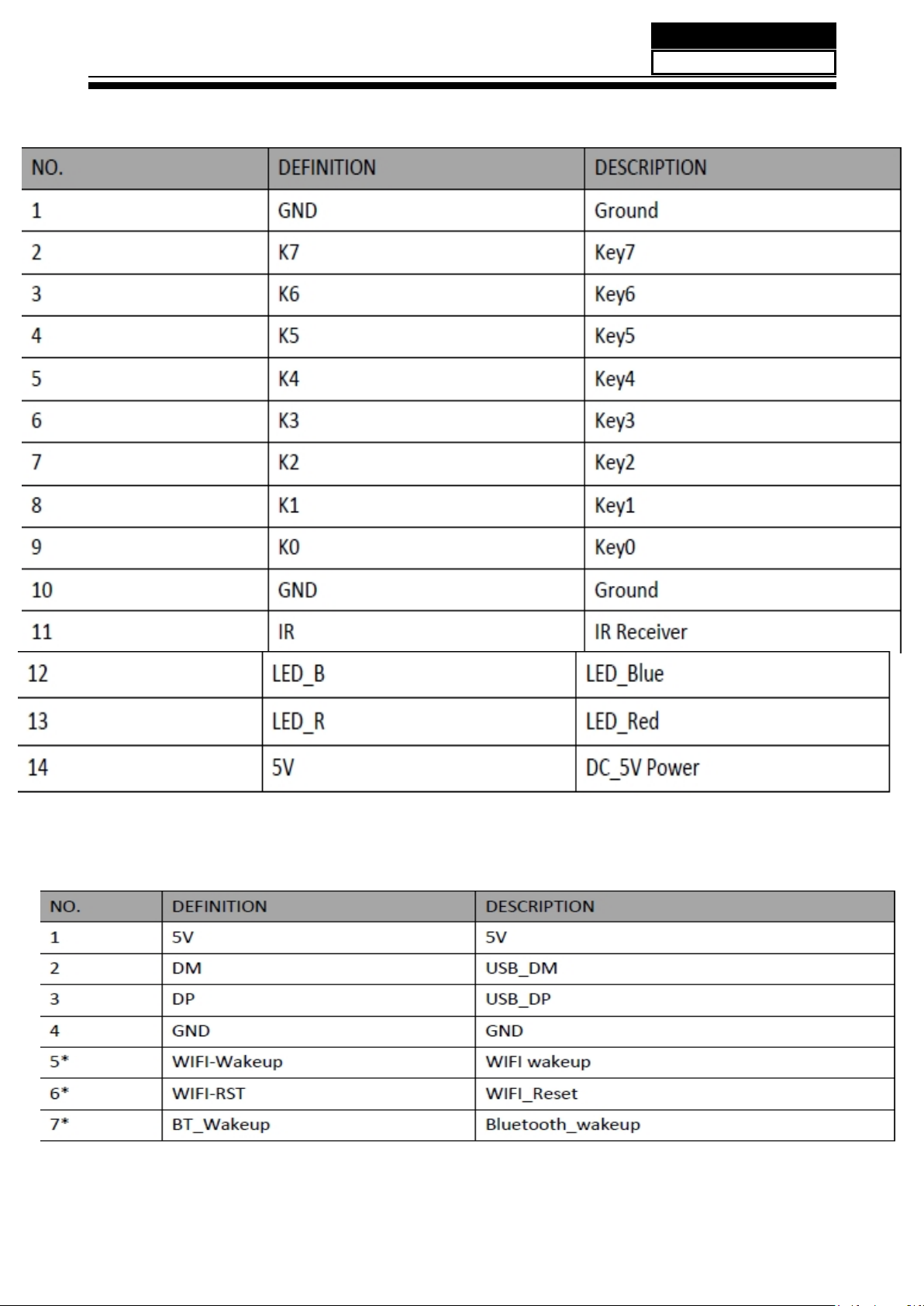

Keypad and remote connector ( 2)Keypad and remote connector ( 2)Keypad and remote connector (J 2)

Service Manual

Model No.:

WIFI J ACK J 25

- 10 -

Page 12

Service Manual

Model No.:

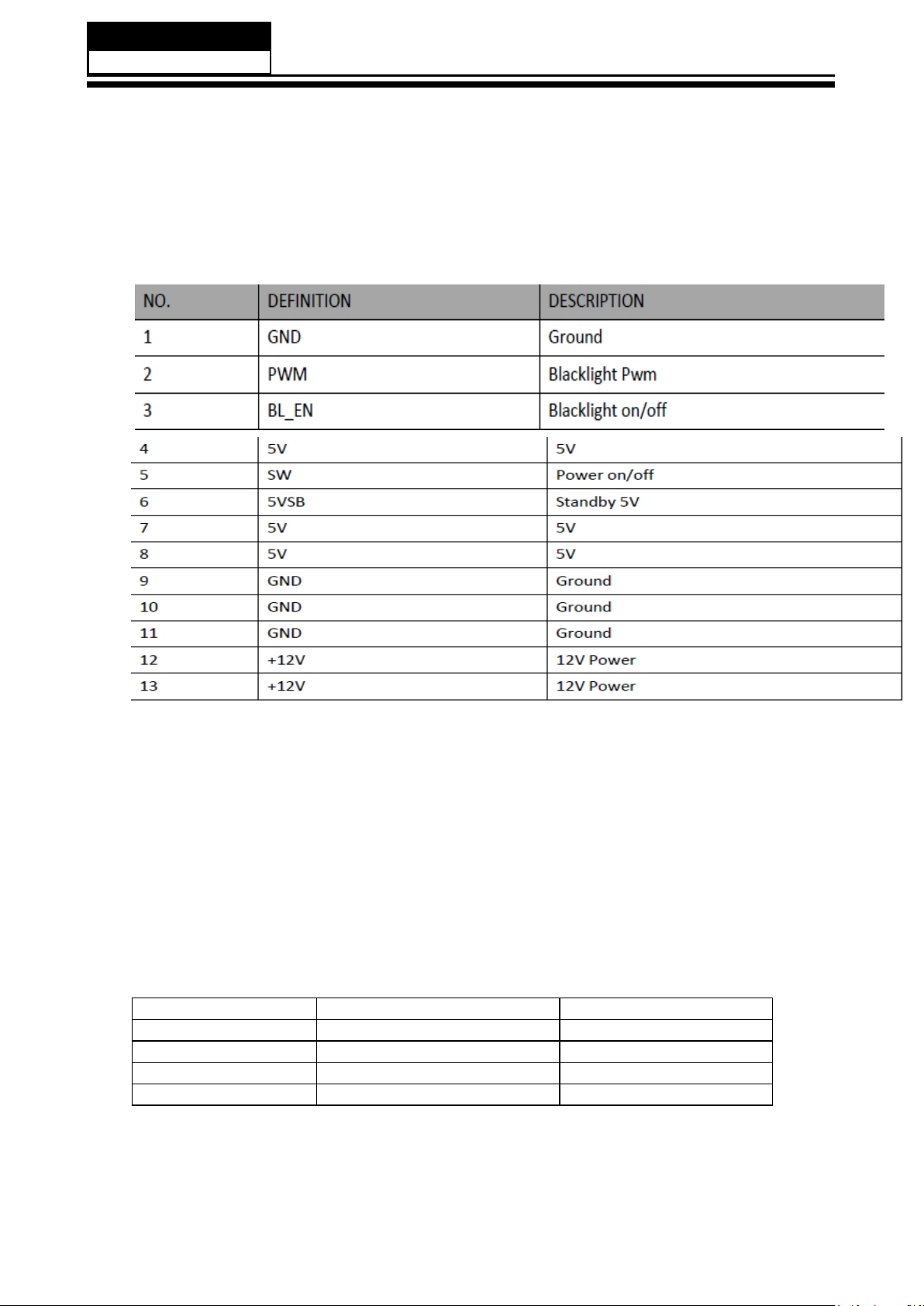

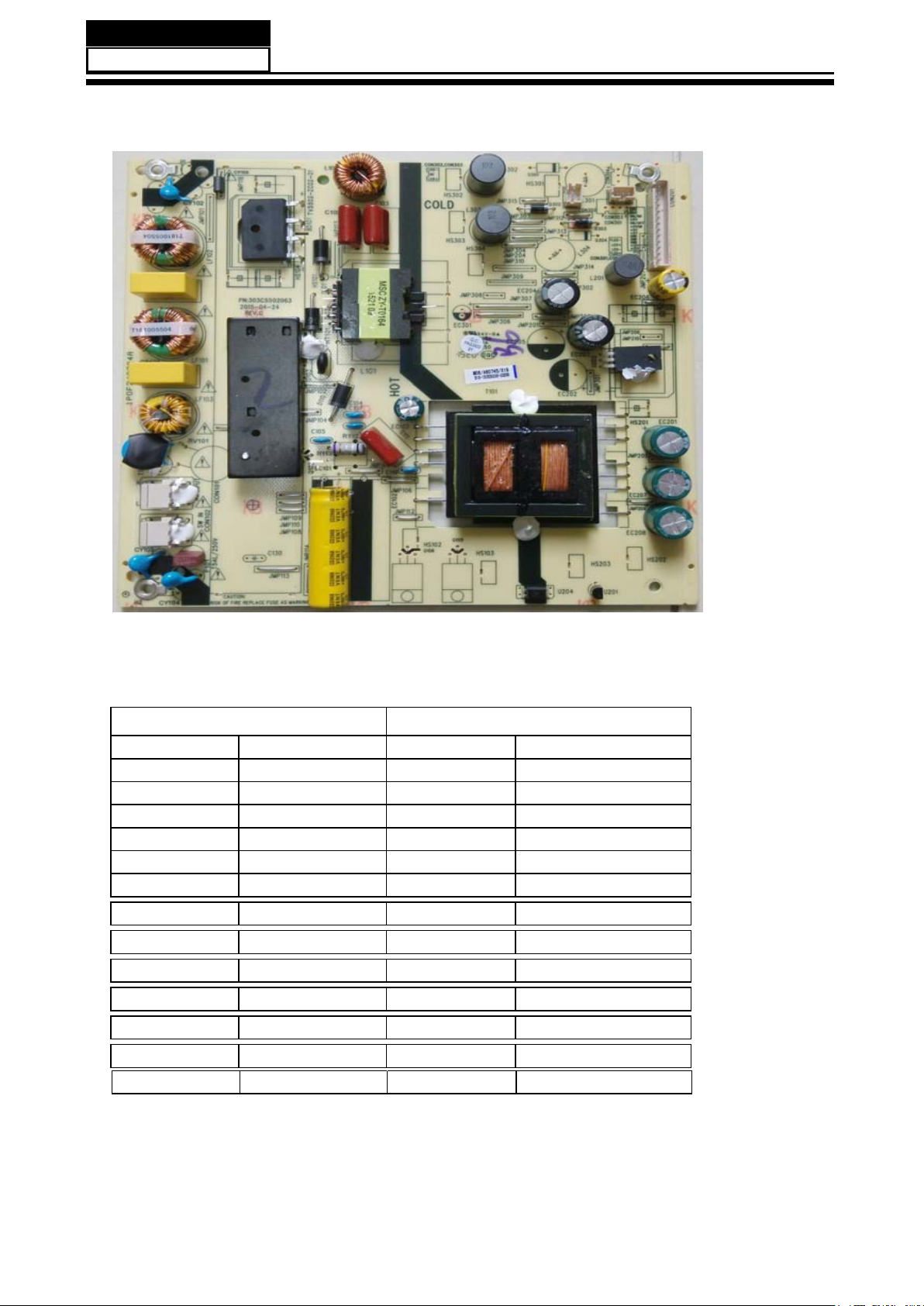

3-3. Power Board

3-3-1 Function Description:

Supply power for Main board, Panel.

3-3-2Connectordefinition

CON201

Pin number Signal name

1

2

3

4

5

6

7 +5V

8

9

10

11

12

13

SGND

AD

ON/BK

+5V

ON/OFF

+5VSTB

+5V

GND

GND

GND

+12V

+12V

- 11 -

Page 13

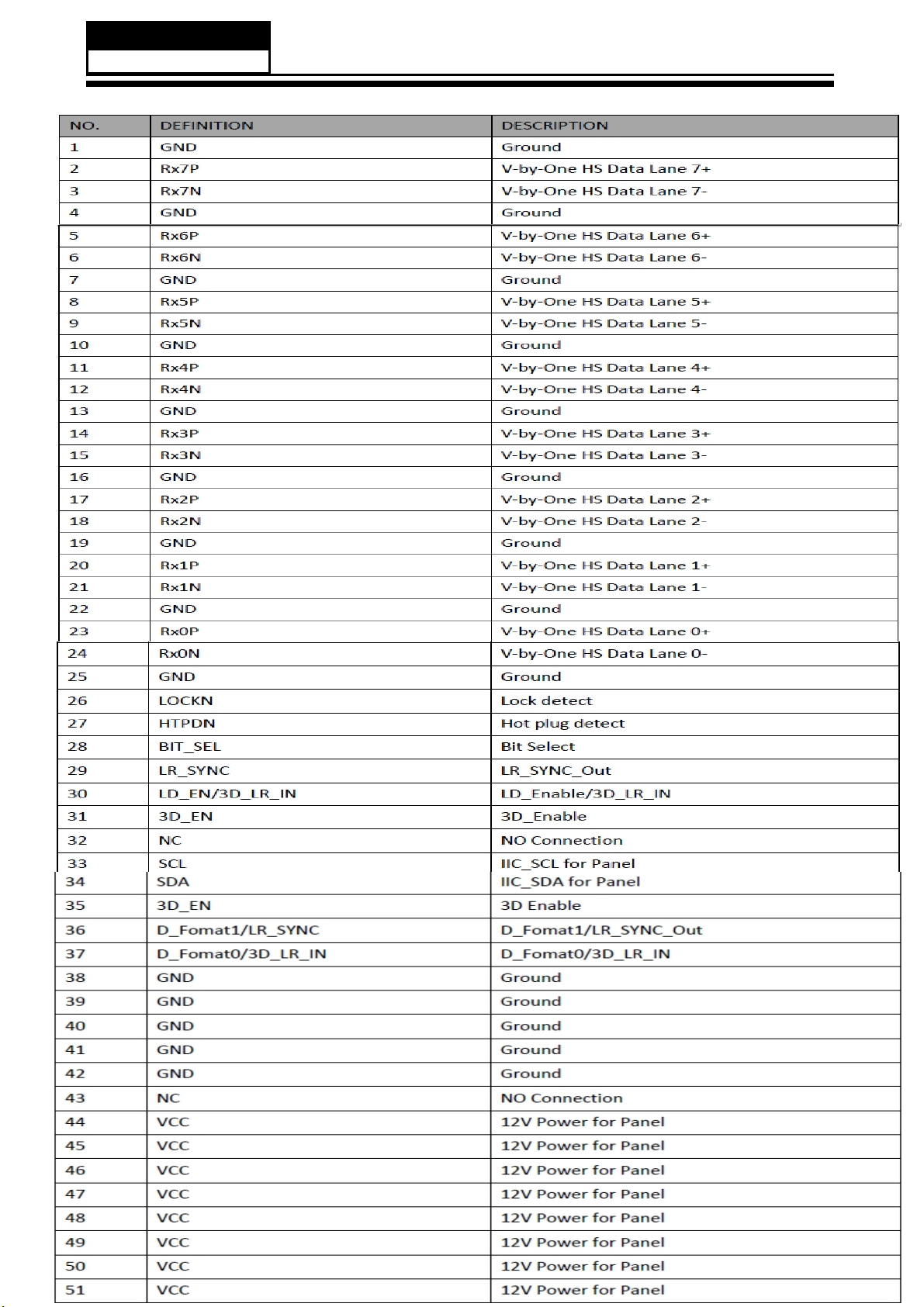

3-4. LED Panel

Service Manual

Model No.:

LSC490FN02-W/

- 12 -

Page 14

Service Manual

Model No.:

3-4-1.Connector de finition

Page 15

Service Manual

Model No.:

4. Disassemble and assemble

4-1 Remove the Pedestal

4-2Remove the Back Cover

/D\ GRZQ WKH XQLW VR WKDW UHDU FRYHU

faces upward

5HPRYH WKH WKUHH VFUHZ IURP WKH

UHDU FRYHU LQGLFDWHG ZLWK ż

7KHQ UHPRYH WKH SHGHVWDO

4-3. Remove the adhesive tape

5HPRYH WKH

¿JXUH DERYH E\ ż

7KHQ UHPRYH WKH EDFN FRYHU IURP WKH

unit.

Remove the adhesive tape indicated on the

WKHVH VFUHZ LQGLFDWHG RQ

- 14 -

¿JXUH DERYH

Page 16

LE49U6500DUA

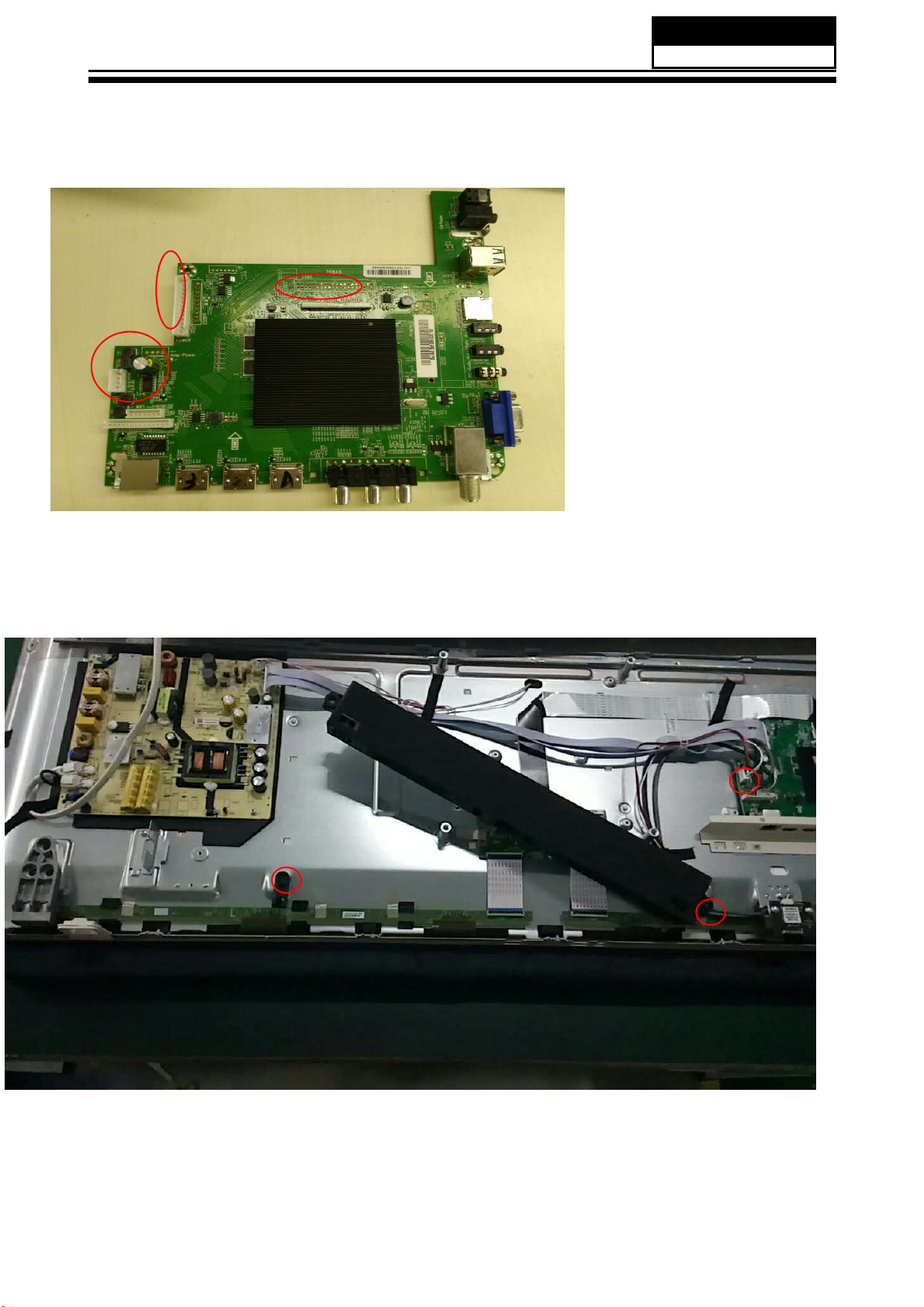

4-4 Remove the Main board

Service Manual

Model No.:

4-5 Remove the speaker

'LVFRQQHFWHG WKH

J2 J25 J20 P501

5HPRYH WKH 0DLQ ERDUG

FRXSOHU

Take out the speaker

- 15 -

Page 17

Service Manual

Model No.:

4-6 Remove the remote control

take out the Remote Control and Keypad Assembly

4-7 Remove the Power Supply

- 16 -

Page 18

5. Installation Instructions

5-1 External Equipment Connections

A

Service Manual

Model No.:

Battery

Remote Control

Antenna Connection

Connect one end of a coaxial cable (not included) to the ANT IN jack on the back of

your TV/DVD combo, then connect the other end of the cable into the antenna or cable

TV wall outlet.

Remote Control

To improve picture quality from an antenna in a poor signal area, install a signal

DPSOL¿HU

If you need to split the antenna signal to connect two TVs, install a two-way splitter.

- 17 -

Page 19

ANTENNA

PC

INSTALLATION

- 18 -

Page 20

* Subject to material object.

SUPPORTED MODE (PC)

1

RESOLUTION

640*480

V.Freq.(Hz) H.Freq.(KHz)

60

31.47

INSTALLATION

2

3

4

5

6

800*600

1024*768

1366*768

1280*1024

1920*1080

(Only for 40")

NOTE: PC V.Freq.(Hz) not more than 60Hz.

PRESET MODE (HDMI)

1

2

3

4

5

RESOLUTION

800*600

1024*768

1366*768

1280*768

1920*1080

60

60

60

60

60

V.Freq.(Hz) H.Freq.(KHz)

60

60

60

60

60

37.88

48.36

47.71

63.98

67.5

37.88

48.36

47.71

47.3

67.5

- 19 -

Page 21

AV EQUIPMENT

This TV provides one group of AV, one group of YPbPr for convenient connection to VCR, DVDor other

video equipment. Please refer to the owner's manual of the equipment to be connected as well.

You can use the input terminals on TV set rear as follows.

- 20 -

Page 22

Service Manual

Model No.:

5-2 HDMI Connections

When the source device(DVD player or Set Top Box) supports HDM

How T

1. Connect the source device to HDMI port of this TV with an HDMI cable(not supplied

with this product).

2. No separated audio connection is necessary.

How To Use

If the source device supports Auto HDMI function, the output resolution of the source

device will be automatically

set to 1280x720p.

If the source device does not support Auto HDMI, you need to set the output resolution

appropriately.

To get the best picture quality, adjust the output resolution of the source device to

1280x720p.

Select HDMI input source in input source option of Select Main source menu.

o Connect

When the source device(DVD player or Set Top Box) supports DVI

How To Connect

1. Connect the source device to HDMI port of this TV with a HDMI-to-DVI cable(not

supplied with this product).

2. A separated audio connection is necessary.

3. If the source device has an analog audio output connector, connect the source device

audio output to DVI Audio In port located on the PC port.

How To Use

If the source device supports Auto DVI function, the output resolution of the source device

will be automatically

set to 1280x720p.

If the source device does not support Auto DVI, you need to set the output resolution

appropriately.

To get the best picture quality, adjust the output resolution of the source device to

1280x720p.

Press the INPUT button to select HDMI input source in input source option of Select Main

source menu.

Installation

- 21 -

Page 23

Cable sample

Service Manual

Model No.:

HDMI Cable

(not supplied with the product)

HDMI to DVI Cable

( not supplied with the product)

Analog Audio Cable

(Stereo to RCA

(not supplied with the product)

type)

- 22 -

Page 24

Service Manual

Model No.:

Power source

TO USE AC POWER SOURCE

Use the AC polarized line cord provided for operation on AC.

Insert the

NOTES:

Ŷ 1HYHU FRQQHFW WKH $& OLQH FRUG SOXJ WR RWKHU WKDQ WKH VSHFL¿HG YROWDJH

Use the attached power cord only.

Ŷ ,I WKH SRODUL]HG $& FRUG GRHV QRW ¿W LQWR D QRQSRODUL]HG $& RXWOHW

GR QRW DWWHPSW WR ¿OH RU FXW WKH EODGH ,W LV WKH XVHUCV UHVSRQVLELOLW\ WR KDYH DQ

electrician replace the obsolete outlet.

Ŷ ,I \RX FDXVH D VWDWLF GLVFKDUJH ZKHQ WRXFKLQJ WKH XQLW DQG WKH XQLW IDLOV WR IXQFWLRQ

simply unplug the unit from the AC outlet and plug it back in. The unit should return to

normal operation.

AC cord plug into a standard polarized AC outlet.

- 23 -

Page 25

6. Operation Instructions

6-1 Front panel controls

Service Manual

Model No.:

Front panel

KEYBOARD

Rear/Side Sockets

- 24 -

Page 26

TELETEXT

Teletext is an information system broadcast by certain channels which can be consulted like

a newspaper. It also offers access to subtitles for viewers with hearing problems or who are

not familiar with the transmission language(cable networks, satellite channels, etc.)

Remote Control

Press:

TEXT

SELECTING A PAGE

DIRECT ACCESS

TO THE ITEMS

INDEX

SUB PAGE

HOLD

You will obtain :

This is used to call or exit teletext modes. The summary appears with a list

of items that can be accessed. Each item has a corresponding 3 digit page

number. If the channel selected does not broadcast teletext, the indication

100 will be displayed and the screen will remain blank (in this case, exit

teletext and select another channel).

Enter the number of the page required using the 0 to 9 up/down. Example:

page 120, enter 120. The number is displayed top left, the counter turns and

then the page is displayed. Repeat this operation to view another page. If

the counter continues to search, this means that the page is not

transmitted. Select another number.

Coloured are as are displayed at the bottom of the screen. The 4 coloured

keys are used to access the items or corresponding pages. The coloured

areas flash when the item or the page is not yet available.

This returns to the contents page (usually page 100).

Certain pages contain sub-pages which are automatically displayed

successively. This key is used to stop or resume sub-page acquisition.

The indication appears top left.

To freeze the page.

REVEAL

MIX

EXIT

SIZE

To display or hide the concealed information (games solutions).

Teletext,program,image are displayed together.

Exit the te le t ex t.

Swi tch t he ima ge to top, botto m,ful l.

EN-18

Page 27

5

D D

3

2

1

5V_Standby_0.85A 5V_Normal_2.06A

5V_Standby 5V_Normal 12V_Normal

5V_Standby_0.85A

5V_Normal_2.06A

12V_Normal_3.5A

12V_Normal_3.5A

MOS

GV3401

V_Panel_1.5A12V_Normal_1.5A

ON/OFF

12V_Normal_2A AMP

C C

5V_Normal_0.5A

MOS

GV3401

Cl_0.5A

AD82587

DC

MSH6110

DC

RT7240

2*8W12V_Normal_1.5A

VDDC_CPU_1.05V_1.6A12V_NORMAL_0.16A

VDDC 0.96V 3.8A12V NORMAL 0.38A

ON/OFF

5V_Normal_0.3A TUNER_0.3A

B B

LDO

1117-3.3

FUSE5V_Normal_1A 5V_USB_1A

1.5A

MSD6586

5V_Normal_0.26A

1117-3.3

3.3V_Normal_0.26ALDO

5V Standy 0.15A

DC

RT8097C

1117-3.3

1.5V_1.5A5V_Standy_0.5A

3.3V Standby 0.15ALDO

WIFI5V_Standby_0.2A

A A

Title

Title

Title

01. Power_Tree

01. Power_Tree

01. Power_Tree

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> <RevCode>

A3

<Doc> <RevCode>

A3

<Doc> <RevCode>

A3

Date Sheet of

Date Sheet of

5

3

2

Date Sheet of

1 13Thursday, March 30, 2017

1 13Thursday, March 30, 2017

1 13Thursday, March 30, 2017

1

Page 28

5

+12V_Normal

J26

1

2

3

4

5

6

D D

7

8

9

10

1*10P*2.54mm/180

J27

1

2

3

4

5

6

1*6P*2.0mm/180

STANDBY

BL-ADJUST

BL-ON/OFF

+5V_Normal

Vcc_Panel

+5V_Standby

+12V_Normal

VDDC_CPU Power

+12V_Normal

R120

100K

C125

C124

靠近

DCDC

10uF/16V/X5R

R123 10K

C126

0.1uF/16V/X5R

0.1uF/16V/X5R

C127

0.1uF/16V/X5R

4

U104

MSH6110A

Addr 0x80

8

PVDD

1

EN

3

5V

4

SDA

I2C-SDA 3,7,13

LX

BST

FB

SCL

PowerPAD

9

D101

L102

2.2uH/6A/不涂胶

NC/SS34

6

C118

7

0.1uF/16V/X5R

2

R2=50K

5

Vout=0.828V*(1+R1/50K)

有

DVFS

R1

I2C-SCL 3,7,13

功能,此

12

DCDC

R122

C119

NC

330pF

R124 15K/1%

不能更改

R124:

538

和

Note

:能提供最大平均电流5A。

远端反馈,即 从

IC

3

6586

统一为

+1.05_VDDC_CPU

底部引线

C120

2

15K

22uF/6.3V/X5R

C121

+1.05_VDDC_CPU

C123

C122

靠近

DC-DC

22uF/6.3V/X5R

0.1uF/16V/X5R

NC/22uF/6.3V/X5R

1

Control

BL-ADJUST

BL-ON/OFF

C C

STANDBY

C117

R119

10K

R126 100R

R117 1K

R118 1K

R121

10K

2.2uF/6.3V/X5R/NC

+5V_Standby

H :Power on

R125

L :Power off

4.7K

PWR-ON/OFF 3

BRI_ADJ 3

VBL_CTRL 3

VDDC Power

R6856 100K

C2245

C2247

C2248

R6944

NC

10uF/16V/X5R

10uF/16V/X5R

0.1uF/16V/X5R

C2178

U11

RT7240

VCC8SW

1

EN

3

VREG5

C29

C30

3900pF

1uF/10V/X5R

0.1uF/16V/X5R

BST

4

SS

5

FB

GND

9

GND

6

7

2

L17

1 2

C31

0.1uF/16V/X5R

C217910pF/NC

R1

RW225.6K/1%

RW2521K/1%

R2

2.2uH/6A/不涂胶

C2261 220uF/10V/X5R/LowESR

470R/1%

R106

远端反馈,即 从

0.96V

C105

+1.10V_VDDC

C106

IC

+1.10V_VDDC+12V_Normal

C107

底部引线

C108

22uF/6.3V/X5R

22uF/6.3V/X5R

22uF/6.3V/X5R/NC

0.1uF/16V/X5R

靠近

DC-DC

Vout=0.765V*(1+R1/R2)=0.979V

Connector

1*13P*2.54mm/180/NC

+12V_Normal

13

12

11

10

9

8

7

6

5

STANDBY

4

3

BL-ON/OFF

2

BL-ADJUST

1

J20

+5V_Normal

+5V_Standby

H :Power on

L :Power off

+5V_Normal

LDO

2

U103

ADJ

+5V_Normal

0.1uF/16V/X5R

4

OUT

IN

321

+3.3V_Normal

C116

C115

C114

10uF/6.3V/X5R

0.1uF/16V/X5R

Title

Title

Title

02. System power

02. System power

02. System power

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> <RevCode>

Custom

<Doc> <RevCode>

Custom

<Doc> <RevCode>

Custom

Date: Sheet of

Date: Sheet of

Date: Sheet of

+5V_Normal

4

U1111117-1.8V

ADJ

OUT

IN

321

+1.8V_Normal

C2260

C162

C163

10uF/6.3V/X5R

0.1uF/16V/X5R

40mA

1

0.1uF/16V/X5R

2 13Thursday, March 30, 2017

2 13Thursday, March 30, 2017

2 13Thursday, March 30, 2017

L103

2.2uH/2.2A

R6953 10K

C131 22pF/NC

R129 15K/1%

R130 5.1K/1%

R2

R69434.7K/1%

12

SW3VIN

POK

FB

GND

JW5212SOTB

5

R1

6

Vout=0.6V*(1+R1/R2)=1.518V

H3

1

2

金属支架

4

Note

:能提供最大平均电流2A。

C132

22uF/6.3V/X5R

+12V_Normal

R6954

R6955

0R/NC

0R/NC

C133

靠近

22uF/6.3V/X5R/NC

+1.5V_DDR

DCDC

R6956

0R/NC

C134

0.1uF/16V/X5R

3

H115

NC

+5V_Standby

C135

C2240

靠近

10uF/10V/X5R

10uF/10V/X5R

RT8097C 2A

1

输入耐压值

C136

DCDC

B B

TP & MARK

1

H104

NC

H108

NC

H113

NC

1

H105

H106

NC

NC

1

1

H110

H109

NC

NC

H1

NC

1

1

5

1

1

H101

NC

1

1

H107

NC

H117

NC

A A

H120

NC

1

1

U106

5.5V

4

1

EN

H118

金属支架

1

2

2

H2

金属支架

0.1uF/16V/X5R

1

2

1117-3.3V

+5V_Standby

U102

ADJ

0.1uF/16V/X5R

4

OUT

IN

321

+3.3V_Standby

C110

C111

C112

10uF/6.3V/X5R

0.1uF/16V/X5R

1117-3.3V

Page 29

HDMI/Audio Block GPIO Pull up

5

Note : Port A needs shielding ground all signal pair

HDMI1-RX0N9

HDMI1-RX0P9

HDMI1-RX1N9

HDMI1-RX1P9

HDMI1-RX2N9

HDMI1-RX2P9

HDMI1-CLKN9

HDMI1-CLKP9

HDMI1-SCL9

HDMI1-SDA9

HDMI1-HPD9

HDMI-CEC9

HDMI1-Detect9

D D

HDMI2-RX0N9

HDMI2-RX0P9

HDMI2-RX1N9

HDMI2-RX1P9

HDMI2-RX2N9

HDMI2-RX2P9

HDMI2-CLKN9

HDMI2-CLKP9

HDMI2-SCL9

HDMI2-SDA9

HDMI2-HPD9

HDMI2-Detect9

HDMI3-RX0N9

HDMI3-RX0P9

HDMI3-RX1N9

HDMI3-RX1P9

HDMI3-RX2N9

HDMI3-RX2P9

HDMI3-CLKN9

HDMI3-CLKP9

HDMI3-SCL9

HDMI3-SDA9

HDMI3-HPD9

HDMI3-Detect9

C C

RGB/CVBS/PHY/USB Block

VGA_HSYNC8

VGA_VSYNC8

SCART_RIN+8

SCART_GIN+8

SCART_BIN+8

YPBPR_PR8

YPBPR_PB8

B B

Crystal

XTALO

XTALI

NOTE:

Config

+3.3V_Standby

A A

R240 4.7K

R245 4.7K

R247 4.7K

R250 4.7K

CHIP_CONFIG[3:0]

{PAD_PM_LED1,PAD_PM_SPI_DI,PAD_PM_LED0,PAD_PWM_PM}

Value Description

4'b1010 1 ARM boot from ROM; outer storage is eMMC

4'b1011 ARM boot from ROM; outer storage is NAND

VGA_RIN+8

VGA_GIN+8

VGA_BIN+8

YPBPR_Y8

SC-FS8

SC-FB8

AV_IN8

SC_AV8

晶体频偏需要小于

C1=C2=2*CL-5

U201C

N3

RXA0N

N2

RXA0P

P3

RXA1N

P2

RXA1P

P1

RXA2N

R3

RXA2P

M1

RXACKN

M2

RXACKP

R2

DDCDA_CK

T3

DDCDA_DA

T2

HOTPLUGA

P5

CEC

U3

HOTPLUGA_HDMI20_5V

J2

RXB0N

K3

RXB0P

K2

RXB1N

L3

RXB1P

L2

RXB2N

L1

RXB2P

J3

RXBCKN

J1

RXBCKP

N5

DDCDB_CK

N6

DDCDB_DA

R4

HOTPLUGB

P4

HOTPLUGB_HDMI20_5V

B1

RXC0N

C1

RXC0P

C2

RXC1N

D3

RXC1P

D2

RXC2N

E3

RXC2P

A2

RXCCKN

B2

RXCCKP

M5

DDCDC_CK

L6

DDCDC_DA

J4

HOTPLUGC

H4

HOTPLUGC_HDMI20_5V

F1

RXD0N

F2

RXD0P

G3

RXD1N

G2

RXD1P

H3

RXD2N

H2

RXD2P

E1

RXDCKN

F3

RXDCKP

K5

DDCDD_CK

L5

DDCDD_DA

M6

HOTPLUGD

L4

HOTPLUGD_HDMI20_5V

MSD6A538

R222 33R

R223 68R

R224 33R

R225 33R

VGA_HSYNC

VGA_VSYNC

R226 33R/NC

R227 68R/NC

R228 33R/NC

R229 33R/NC

R230 33R

R231 68R

R232 33R

R233 33R

R234 68R

R1761 33R

R235 33R

AV_OUT8

C237 33pF

12

C1

Y201

24MHz/20pF

C2

C238 33pF

30PPM

PM_LED1

SPI-SDI

PM_LED0

PM_PWM

Y3

C201 2.2uF/6.3V/X5R

LINE_IN_0L

Y2

C206 2.2uF/6.3V/X5R

LINE_IN_0R

Y1

C207 2.2uF/6.3V/X5R

LINE_IN_2L

AA3

C208 2.2uF/6.3V/X5R

LINE_IN_2R

AB5

LINE_OUT_0L

AB6

AV_OUT

C222

C223

C224

C225

C226

C227

C228

C229

C230

C231

C232

C233

C234

C1333

C235

HDMI

0.047uF/16V/X7R

0.047uF/16V/X7R

0.047uF/16V/X7R

0.047uF/16V/X7R

0.047uF/16V/X7R/NC

0.047uF/16V/X7R/NC

0.047uF/16V/X7R/NC

0.047uF/16V/X7R/NC

0.047uF/16V/X7R

0.047uF/16V/X7R

0.047uF/16V/X7R

0.047uF/16V/X7R

0.047uF/16V/X7R

0.047uF/16V/X7R

0.047uF/16V/X7R

C236

NC/120pF

VCOM

CVBS0

CVBS1

RIN0

GIN0N

GIN0

BIN0

RIN1

GIN1N

GIN1

BIN1

RIN2

GIN2N

GIN2

BIN2

Analog

Audio

I2S

SPDIF

V1

V3

U1

U2

P6

R5

U6

V6

V4

V5

Y6

Y5

W6

W5

T6

R6

V2

T5

U4

U5

EARPHONE_OUT_L

EARPHONE_OUT_R

I2S_OUT_BCK

I2S_OUT_MCK

I2S_OUT_SD1

I2S_OUT_SD2

U201E

RIN0P

GIN0M

GIN0P

BIN0P

HSYNC0

VSYNC0

RIN1P

GIN1M

GIN1P

BIN1P

RIN2P

GIN2M

GIN2P

BIN2P

HSYNC1

VSYNC1

VCOM

CVBS0

CVBS1

CVBSOUT1

MSD6A538

LINE_OUT_0R

LINE_OUT_2L

LINE_OUT_2R

I2S_OUT_WS

AUVAG

AUVRM

I2S_OUT_SD

SPDIF_IN

SPDIF_OUT

RGB

CVBS

AV_LOUT

AC5

AV_ROUT

AC6

HP_Audio-L

AD5

HP_Audio-R

AD6

M4

ARC0

AA2

AUVAG

AA1

AUVRM

T21

NC

R20

NC

R21

NC

AUBCK_OUT

E6

AUMCK_OUT

E5

AUWS_OUT

F4

AUSD_OUT

F6

F5

G5

3D_FLAG

K6

SPDIF_OUT

J5

PHY

GPIO19/LED[0]

GPIO20/LED[1]

USB

USB_DM_PSS

USB3.0

USB_DP_PSS

IR&KEY

+3.3V_Standby+5V_Standby

R212

R213

47K

4.7K

C215

100pF

J2

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1*14P*2.0mm/180

CON14

IR-IN_1

+5V_Standby

LED_RED#

LED_GRE#

MENU

SOURCE

PP+

VV+

KEY7

POWER

IR-in

R215 100R

C212

33pF

KEY0-in KEY0

R218 1K

+5V_Standby

C2259

0.1uF/16V/X5R

5

YPBPR_AUL 8

YPBPR_AUR 8

SC_PC_AUL 8

SC_PC_AUR 8

HDMI-ARC 9

1

TP212

SPDIF_OUT 8

B3

TN

A3

TP

B4

RN

C4

RP

R27

R26

L27

HWRESET

AG1

XIN

AF1

XOUT

AE5

IRIN

B7

USB0_DM

C7

USB0_DP

B6

USB1_DM

A6

USB1_DP

C6

USB2_DM

A5

USB2_DP

AF7

NC

AG7

NC

AG8

AH8

AH9

NC

AG9

NC

538/6586

预留的线路可以删除

LED_RED#

LED_GRE#

IR-IN_1

4

Audio Block

AV_LOUT

AV_ROUT

HP_Audio-L

HP_Audio-R

Close to MST IC

with width trace

MDI_TN

MDI_TP

MDI_RN

MDI_RP

System-RST

XTALI

XTALO

IR-in

都不支持

+5V_Normal

R639

Q601

32

1

SOT-23

KEY0

4

AUVAG

AUVRM

R642

R641

4.7K

1K

3904

20K

靠近

mstar IC

C204

C209

MDI_TN 8

MDI_TP 8

MDI_RN 8

MDI_RP 8

USB2_D- 11

USB2_D+ 11

USB1_D- 11

USB1_D+ 11

USB3_D- 11

USB3_D+ 11

USB3.0

R21

R22

R25

R26

R28 82K/1%

R31 47K/1%

R34

R35

AV_LOUT 8

AV_ROUT 8

C205

1000pF

1000pF

EARPHONE_OUTL 13

EARPHONE_OUTR 13

C210

10uF/6.3V/X5R

0.1uF/16V/X5R

L201

1000R/FBI

!

LED_R

POWER

MENU

SOURCE

V+

V-

P+

P-

KEY7

PCMCIA/TS/NAND/FE

PCM_D[7:0]12

PCM_D0

PCM_D1

PCM_D2

PCM_D3

PCM_D4

PCM_D5

PCM_D6

PCM_D7

PCM_A[14:0]12

PCM_A0

PCM_A1

PCM_A2

PCM_A3

PCM_A4

PCM_A5

PCM_A6

PCM_A7

PCM_A8

PCM_A9

PCM_A10

PCM_A11

PCM_A12

PCM_A13

PCM_A14

SD_CLK

SD_CLK

SD_CMD

SD_CMD

PCM_IRQA_N

PCM_IRQA_N12

PCM_OE_N

PCM_OE_N12

PCM_IORD_N

PCM_IORD_N12

PCM_CE_N

PCM_CE_N12

PCM_WE_N

PCM_WE_N12

PCM_CD_N

PCM_CD_N12

PCM_RESET

PCM_RESET12

PCM_REG_N

PCM_REG_N12

PCM_IOWR_N

PCM_IOWR_N12

PCM_WAIT_N

PCM_WAIT_N12

NAND-CEZ

NAND-CEZ6

NAND-REZ

NAND-REZ6

NAND-RBZ

NAND-RBZ6

NAND-DQS

NAND-DQS6

NAND-AD[7:0]6

NAND-AD0

NAND-AD1

NAND-AD2

NAND-AD3

NAND-AD4

NAND-AD5

NAND-AD6

NAND-AD7

LVDS/GPIO

BRI_ADJ

BRI_ADJ2

LR_SYNC

LR_SYNC7

KEY0-in

PANEL_ON/OFF

PANEL_ON/OFF7

WIFI-reset11

POWER_DETECT

SPI-SDI

UART-RX

R236 100R

UART-RX8

UART-TX

R237 100R

UART-TX8

HP_DET

HP_DET13

AMP_RST

R1823 0R

AMP_RST13

I2C-SCL

I2C-SDA

WOW_WOL11

R1819 100R

R238 100R

R239 100R

0R

7.5K/1%

16.9K/1%

150K/1%

30K/1%

0R

SC_PC_SW8

3

U201B

AC25

PCMDATA[0]/CI_DATA[0]

AG23

PCMDATA[1]/CI_DATA[1]

AB25

PCMDATA[2]/CI_DATA[2]

AD25

PCMDATA[3]/CI_DATA[3]

AC24

PCMDATA[4]/CI_DATA[4]

AC23

PCMDATA[5]/CI_DATA[5]

AD24

PCMDATA[6]/CI_DATA[6]

AD23

PCMDATA[7]/CI_DATA[7]

AE24

PCMADR[0]/CI_A[0]

AE23

PCMADR[1]/CI_A[1]

AC22

PCMADR[2]/CI_A[2]

AD22

PCMADR[3]/CI_A[3]

AC21

PCMADR[4]/CI_A[4]

AG22

PCMADR[5]/CI_A[5]

AD21

PCMADR[6]/CI_A[6]

AC20

PCMADR[7]/CI_A[7]

AC19

PCMADR[8]/CI_A[8]/SDIO_D0

AF21

PCMADR[9]/CI_A[9]/SDIO_D1

AD20

PCMADR[10]/CI_A[10]/SDIO_D2

AD19

PCMADR[11]/CI_A[11]/SDIO_D3

AD18

PCMADR[12]/CI_A[12]

AE18

PCMADR[13]/CI_A[13]

AE20

PCMADR[14]/CI_A[14]

AB24

PCM2_CE_N/SDIO_CLK

AB23

PCM2_IRQA_N/SDIO_CMD

AE17

PCMIRQA/CI_INT

AE21

PCMOEN

AG21

PCMIORD/CI_RD

AC18

PCMCEN/CI_CS

AD17

PCMWEN

AH21

PCMCD/CI_CD

AC16

PCMRST/CI_RST

AF22

PCMREG/CI_CLK

AC17

PCMIOWR/CI_WR

AD16

PCMWAIT/CIWACK

AC13

NAND_ALE/EMMC_IO15

AD12

NAND_WPZ/EMMC_IO17

AG11

NAND_CEZ/EMMC_IO9/EMMC_CMD

AC12

NAND_CLE/EMMC_IO14

AF11

NAND_REZ/EMMC_IO10/EMMC_CLK

AD13

NAND_WEZ/EMMCIO16

AG10

NAND_RBZ/EMMC_IO11/EMMC_RSTn

AE12

NAND_CEZ1/EMMC_IO12

AD14

NAND_DQS/EMMC_IO8

AG15

NAND_AD0/EMMC_IO6/EMMC_D[6]

AH15

NAND_AD1/EMMC_IO7/EMMC_D[7]

AH14

NAND_AD2/EMMC_IO2/EMMC_D[2]

AG14

NAND_AD3/EMMC_IO1/EMMC_D[1]

AG13

NAND_AD4/EMMC_IO0/EMMC_D[0]

AF13

NAND_AD5/EMMC_IO3/EMMC_D[3]

AH12

NAND_AD6/EMMC_IO4/EMMC_D[4]

AF12

NAND_AD7/EMMC_IO5/EMMC_D[5]

MSD6A538

P27

R28

N28

PM_PWMLED_R

AF6

AD10

AC10

N27

M26

M27

M28

AC15

AD15

AF16

AG16

AC11

3D_EN

AD11

P26

N26

VID_0

AB2

VID_1

AB3

AA4

PM_LED0

AD4

PM_LED1

AC4

AE11

3

U201D

PWM0

PWM1

PWM2

T22

NC

PWM_PM

D4

SAR0

D5

SAR1

C5

SAR2

B5

SAR3

E4

SAR5/PW_det

G6

SPI_CK

H6

SPI_DI

H5

SPI_DO

J6

SPI_CZ1/GPIO_PM6

DDCA_CK/UART0_RX

DDCA_DA/UART0_TX

GPIO2/EJ_TCK

GPIO3/EJ_TMS

GPIO4/EJ_TDI

GPIO5/EJ_TDO

GPIO9/TX2

GPIO10/RX2

GPIO11/TX3

GPIO12/RX3

GPIO30/SCK4

GPIO31/SDA4

DDCR_CK

DDCR_DA

VID0

VID1

VID2

Y4

VID3

LED0

LED1

WOL

MSD6A538

CI

PCMCIA

PWM

SAR

SPI

GPIO

/UART

I2C

NAND

EMMC

PM_UART

TS2

(In)

TS0

(In)

TS1

(In/Out)

Front

End

LVDS

60Hz

PM

TS2DATA [0]

TS2CLK

TS2VALID

TS2SYNC

TS0DATA_[0]

TS0DATA_[1]

TS0DATA_[2]

TS0DATA_[3]

TS0DATA_[4]

TS0DATA_[5]

TS0DATA_[6]

TS0DATA_[7]

TS0CLK

TS0VALID

TS0SYNC

TS1DATA_[0]

TS1DATA_[1]

TS1DATA_[2]

TS1DATA_[3]

TS1DATA_[4]

TS1DATA_[5]

TS1DATA_[6]

TS1DATA_[7]

TS1CLK

TS1VALID

TS1SYNC

IFAGC_T

TGPIO0

TGPIO1

TGPIO2

TGPIO3

IFAGC_S

GPIO15/DiSEqC_out

GPIO18/DiSEqC_in

B0M (R_ODD[7])

B0P (R_ODD[6])

B1M (R_ODD[5])

B1P (R_ODD[4])

B2M (R_ODD[3])

B2P (R_ODD[2])

BCKM (R_ODD[1])

BCKP (R_ODD[0])

B3M (G_ODD[7])

B3P (G_ODD[6])

B4M (G_ODD[5])

B4P (G_ODD[4])

A0M (G_ODD[3])

A0P (G_ODD[2])

A1M (G_ODD[1])

A1P (G_ODD[0])

A2M (B_ODD[7])

A2P (B_ODD[6])

ACKM (B_ODD[5])

ACKP (B_ODD[4])

A3M (B_ODD[3])

A3P (B_ODD[2])

A4M (B_ODD[1])

A4P (B_ODD[0])

GPIO_PM4/PW_ctrl

GPIO_PM1/PM_TX1

GPIO_PM5/PM_RX1

IP_T

IM_T

SIFP

SIFM

IP_S

IM_S

QP_S

QM_S

LVSYNC

LHSYNC

GPIO_PM0

GPIO_PM3

GPIO_PM7

GPIO_PM8

2

M24

N24

N25

P25

TS_MDO[7:0] 12

TS_MDO0

AH20

TS_MDO1

AG20

TS_MDO2

AF17

TS_MDO3

AH18

TS_MDO4

AG17

TS_MDO5

AF20

TS_MDO6

AG18

TS_MDO7

AF18

TS_MOCLK

AF19

AH17

AG19

U23

T25

N23

P23

U24

T23

R25

R24

R23

P24

T24

AC2

AC3

AD1

AD2

AC1

AD3

AE2

AF3

AE4

AH2

AH3

AF4

AG3

AG4

AG5

AF5

TS_MOVLD

TS_MOSYNC

TS_D0

TS_D1

TS_D2

TS_D3

TS_D4

TS_D5

TS_D6

TS_D7

TS_CLK

TS_VLD

TS_SYNC

C216

C217

IFAGC

T_SCL

T_SDA

0.1uF/16V/X5R

DIFP

DIFM

0.1uF/16V/X5R

TS_MOCLK 12

TS_MOVLD 12

TS_MOSYNC 12

TS_D[7:0] 12

TS_CLK 12

TS_VLD 12

TS_SYNC 12

IFAGC

R217 0R

DIFP 10

DIFM 10

T_SCL 3,10

T_SDA 3,10

R216 10K

+3.3V_TU

IF_AGC 10

C213

0.022uF/16V/X7R

AMP-MUTE13

I2S out

AUBCK_OUT13

AUMCK_OUT13

AUSD_OUT13

AUWS_OUT13

3D_LR_in

3D_LR_in 7

3D_EN

3D_EN 3,7

I2C-SCL

I2C-SCL 2,7,13

I2C-SDA

I2C-SDA 2,7,13

Heat Sink

S201

Heat-sink-62X70X2.3

R6957

0R/NC

1

VID_0

VID_1

I2C-SCL

I2C-SDA

3D_EN

3D_EN3,7

T_SCL

T_SCL3,10

T_SDA

T_SDA3,10

AUBCK_OUT

AUMCK_OUT

AUSD_OUT

AUWS_OUT

1

2

+3.3V_Standby

R202 4.7K

R204 4.7K

R205 4.7K

+3.3V_Normal

R206 4.7K

R207 4.7K

R208 4.7K

+3.3V_TU

R209 4.7K

R210 4.7K

I2C-SDA2,3,7

I2C-SCL2,3,7

C2262

C2263

100pF/NC

R6958

0R/NC

100pF/NC

RESET

T27

U27

LCK

U26

LDE

T28

V27

B0M

V28

B0P

W28

B1M

W27

B1P

Y27

B2M

AA26

B2P

AA28

BCKM

AB26

BCKP

AB27

B3M

AC26

B3P

AD26

B4M

AD27

B4P

AE26

A0M

AE28

A0P

AF26

A1M

AF27

A1P

AG27

A2M

AG28

A2P

AH27

ACKM

AH26

ACKP

AF25

A3M

AG25

A3P

AG24

A4M

AH24

A4P

AE6

W2

W3

AA5

AA6

PM_TX

AH6

PM_RX

AH5

P21

TEST

2

AMP-MUTE

SD_WP

3D_LR_IN 7

B0M 7

B0P 7

B1M 7

B1P 7

B2M 7

B2P 7

BCKM 7

BCKP 7

B3M 7

B3P 7

B4M 7

B4P 7

A0M 7

A0P 7

A1M 7

A1P 7

A2M 7

A2P 7

ACKM 7

ACKP 7

A3M 7

A3P 7

A4M 7

A4P 7

VBL_CTRL 2

BT_WAKE 2

PWR-ON/OFF 2

SD_CDZ

+5V_Standby

C239

4.7uF/10V/X5R

System-RST

3

D201

R251

BAT54C

100K

1

2

UART

CN206

1*4P*2.0mm/180/NC

1

2

UART-RX

3

UART-TX

4

+12V_Normal

R244

1K

R252

10K

POWER_DETECT

R257

1K

Title

Title

Title

03. MSD6A538/6586

03. MSD6A538/6586

03. MSD6A538/6586

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> <RevCode>

Custom

<Doc> <RevCode>

Custom

<Doc> <RevCode>

Custom

Date: Sheet of

Date: Sheet of

Date: Sheet of

R243 4.7K

R246 4.7K

1

+5V_Standby

3 13Thursday, March 30, 2017

3 13Thursday, March 30, 2017

3 13Thursday, March 30, 2017

Page 30

5

U201F

VDDP33

AVDD_PLL

MSD6A538

G7

VDDC

G8

VDDC

H7

VDDC

H8

VDDC

J7

VDDC

J8

VDDC

J9

VDDC

K7

VDDC

K8

VDDC

K9

VDDC

L7

VDDC

L8

VDDC

L9

VDDC

M9

VDDC

M8

VDDC

M7

VDDC

V18

VDDC_CPU

V19

VDDC_CPU

V20

VDDC_CPU

W18

VDDC_CPU

W19

VDDC_CPU

W20

VDDC_CPU

W21

VDDC_CPU

Y19

VDDC_CPU

Y20

VDDC_CPU

Y21

VDDC_CPU

Y22

VDDC_CPU

AA19

VDDC_CPU

AA20

VDDC_CPU

AA21

VDDC_CPU

AA22

VDDC_CPU

Y12

DVDD_NODIE

Y7

AVDD_NODIE

M10

DVDD_DDR

N9

DVDD_DDR

N10

DVDD_DDR

M14

AVDD_DDR_A

N14

AVDD_DDR_A

P14

AVDD_DDR_A

N15

AVDD_DDR_A

M15

AVDD_DDR_A

Y15

NC

AA15

NC

K12

AVDD_DDR_B

K13

AVDD_DDR_B

K14

AVDD_DDR_B

J12

AVDD_DDR_B

J13

AVDD_DDR_B

K21

AVDD_DDR_DRAM

K26

AVDD_DDR_DRAM

J27

AVDD_DDR_VBP_A

M13

AVDD_DDR_VBP_A_DM

K28

AVDD_DDR_VBN_A

N13

AVDD_DDR_VBN_A_DM

H27

NC

L13

NC

G28

NC

L12

NC

J14

AVDD_DDR_LDO_B

R10

AVDDL_MOD

T13

AVDDL_MOD

AH23

AVDDL_MOD

W15

AVDDL_MOD_CAP

J18

NC

K15

AVDD15_MOD

K16

AVDD15_MOD

AA14

AVDD_MOD

N7

AVDDL_MHL3

N8

AVDDL_MHL3

W10

AVDDL_MHL3_CAP

AA12

AVDD3P3_MHL3

AB12

AVDD3P3_MHL3

AA10

VDDP_3318_A

AB11

VDDP_3318_C

AE15

PADA_EMMC_CTRL

W7

AVDD3P3_DADC

AA9

AVDD3P3_DMPLL

W8

AVDD3P3_ETH

U7

AVDD3P3_USB

T7

AVDD3P3_USB

T8

AVDD3P3_USB3

V7

AVDD3P3_ADC

V8

AVDD3P3_ADC

U8

AVDD_AU33

U9

AVDD_EAR33

AB14

VDDP

AB15

VDDP

AA13

AVDD_LPLL

AB13

AVDD_LPLL

Y13

AVDD_PLL_A

Y14

AVDD_PLL_B

P22

GND_EFUSE

VDDC

D D

VDDC_CPU

DVDD_NODIE

C324

AVDD_NODIE

1uF/10V/X5R

DVDD_DDR

AVDD_DDR3_1V5

C C

B B

A A

NC/100nF

C345

NC/0.1uF

C342

C341

NC/100nF

C347

NC/0.1uF

C346

NC/0.1uF

AVDD_DDR3_1V5

AVDD_DDR3_1V5

AVDD_DDR_VBP_A_DM

AVDD_DDR_VBN_A_DM

AVDD_DDR_VBP_B_DM

AVDD_DDR_VBN_B_DM

AVDD_DDR_LDO_B

C357

AVDD3P3_MHL3

NC

AVDD_DDR

AVDDL_MOD

AVDD15_MOD

AVDD_MOD

AVDDL_MHL3

VDDP_NAND_A

VDDP_NAND_C

AVDD_DADC

AVDD_DMPLL

AVDD33_LAN

AVDD_USB

AVDD_USB3

AVDD33_ADC

AVDD_AU33

AVDD_LPLL

4

U201G

M16

A1

A8

A15

A17

A24

A26

A28

B9

B14

B16

B18

B23

B25

B27

C3

C8

C11

C12

C13

C20

C21

C22

D6

D7

D8

D9

D10

D12

D14

D16

D18

D20

D22

D24

D26

D28

E2

E7

E8

E9

E10

E11

E13

E15

E17

E19

E21

E23

E25

E27

F7

F8

F9

F10

G9

G10

G11

G12

G13

G14

G15

G16

G17

G18

G19

G20

G21

G22

G23

G24

G25

G27

H1

H9

H10

H11

H12

H13

H14

H15

H16

H17

H18

H19

H20

H21

H22

H23

H24

H25

J10

J11

J15

J16

J17

J19

J21

J22

J23

J25

J26

K10

K11

K17

K18

K19

K20

K22

K23

K24

K25

L10

L11

L14

L15

L16

L17

L18

L19

L20

L23

L24

MSD6A538

M22

M3

M12

M17

M18

M19

M20

M11

M21

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

N21

N22

N16

N12

N17

N18

N19

N20

M23

N11

GND

GND

GND

GND

GND

P10

P8

GND

GND

GNDP7GND

GND

GND

GND

GND

GNDP9GND

GND

3

CORE Power

P13

P15

P12

P16

P18

P19

P20

P11

GND

GND

GND

GND

GND

GND

GND

R1

GND

R7

GND

R8

GND

R9

GND

R11

GND

R12

GND

R13

GND

R14

GND

R15

GND

R17

GND

R18

GND

R19

GND

T9

GND

T10

GND

T11

GND

T12

GND

T17

GND

T18

GND

T19

GND

T20

GND

T26

GND

U10

GND

U11

GND

U12

GND

U13

GND

U17

GND

U18

GND

U19

GND

U20

GND

U21

GND

U22

GND

V9

GND

V10

GND

V11

GND

V12

GND

V13

GND

V14

GND

V15

GND

V16

GND

V17

GND

V21

GND

V22

GND

V23

GND

V24

GND

V25

GND

V26

GND

W9

GND

W11

GND

W12

GND

W13

GND

W14

GND

W16

GND

W17

GND

W22

GND

W23

GND

W24

GND

W25

GND

W26

GND

Y8

GND

Y9

GND

Y10

GND

Y11

GND

Y16

GND

Y17

GND

Y18

GND

Y23

GND

Y24

GND

Y26

GND

AA7

GND

AA8

GND

AA11

GND

AA16

GND

AA17

GND

AA18

GND

AA23

GND

AA24

GND

AA25

GND

AA27

GND

AB7

GND

AB8

GND

AB9

GND

AB16

GND

AB17

GND

AB18

GND

AB19

GND

AB20

GND

AB21

GND

AB22

GND

AB28

GND

AC7

GND

AC8

GND

AC9

GND

AC14

GND

AC27

GND

AD7

GND

AD8

GND

AD9

GND

AD28

GND

AE3

GND

AE8

GND

AE9

GND

AE14

GND

AE27

GND

AF2

GND

AF8

GND

AF9

GND

AF10

GND

AF14

GND

AF15

GND

AF23

GND

AF24

GND

AG2

GND

AG6

GND

AG12

GND

AG26

GND

AH1

GND

AH11

GND

AH28

GND

+1.10V_VDDC

C309

C301

C0805

C0805

22uF/6.3V/X5R

22uF/6.3V/X5R/NC

+1.10V_VDDC VDDC

4200mA,100mil

180mA,25mil

+1.10V_VDDC AVDDL_MHL3

80mA,25mil

CPU Power

+1.05_VDDC_CPU

C329

C0805

22uF/6.3V/X5R

NC/22uF/6.3V/X5R

+1.05_VDDC_CPU VDDC_CPU

2300mA,100mil

DDR3

+1.5V_DDR

C349

C348

C0603

C0603

10uF/6.3V/X5R

NC/10uF/6.3V/X5R

+1.5V_DDR

20mA,15mil

+1.5V_DDR

60mA,15mil

+1.5V_DDR

C310

C0603

10uF/6.3V/X5R

10uF/6.3V/X5R

C330

C331

C0603

C0805

10uF/6.3V/X5R

NC/10uF/6.3V/X5R

C350

C0402

2.2uF/6.3V/X5R

NC/2.2uF/6.3V/X5R

AVDD15_MOD

AVDD_DDR_LDO_B

R307 0R

C311

C0603

0.1uF/16V/X5R

2.2uF/6.3V/X5R

DVDD_DDR+1.10V_VDDC

C332

C0603

C351

C0402

C312

C0402

2.2uF/6.3V/X5R

NC/2.2uF/6.3V/X5R

C333

C0402

2.2uF/6.3V/X5R

0.1uF/16V/X5R

C352

0.1uF/16V/X5R

0.1uF/16V/X5R

AVDD_DDR3_1V5

C362

2

C314

C313

C0402

0.1uF/16V/X5R

0.1uF/16V/X5R

+1.10V_VDDC AVDDL_MOD

2300mA,100mil

C334

C335

0.1uF/16V/X5R

0.1uF/16V/X5R

AVDD_DDR

C354

C355

C353

0.1uF/16V/X5R

0.1uF/16V/X5R

AVDD_DDR3_1V5

AVDD_DDR

C363

C315

C316

0.1uF/16V/X5R

0.1uF/16V/X5R

20mA,25mil

L301 120R/FBI

C337

C336

0.1uF/16V/X5R

0.1uF/16V/X5R

C369 0.47uF/6.3V/X5R

C370 0.47uF/6.3V/X5R

C367 NC/0.47uF

C368 NC/0.47uF

C317

C338

0.1uF/16V/X5R

0.1uF/16V/X5R

AVDD_DDR_VBP_A_DM

AVDD_DDR_VBN_A_DM

AVDD_DDR_VBP_B_DM

AVDD_DDR_VBN_B_DM

C318

0.1uF/16V/X5R

0.1uF/16V/X5R

0.1uF/16V/X5R

C321

0.1uF/16V/X5R

C339

1

Standby Power 3.3V

+3.3V_Standby

C302

C304

C303

C0402

C319

C320

C0402

2.2uF/6.3V/X5R

NC/2.2uF/6.3V/X5R

+3.3V_Standby

+3.3V_Standby

+3.3V_Standby

0.1uF/16V/X5R

AVDD_USB+3.3V_Standby

20mA,15mil

AVDD33_LAN+3.3V_Standby

40mA,15mil

40mA,15mil

20mA,15mil

L302 120R/FBI

10mA,15mil

L303 120R/FBI

AVDD_DADC

AVDD_AU33 AVDD_EAR33

C306

C305

C307

0.1uF/16V/X5R

0.1uF/16V/X5R

+3.3V_Standby

10mA,15mil

+3.3V_Standby

60mA,15mil

+3.3V_Standby AVDD_USB3

30mA,15mil

C322

0.1uF/16V/X5R

AVDD_DMPLL

C323

0.1uF/16V/X5R

VCC3.3VA

C308

0.1uF/16V/X5R

0.1uF/16V/X5R

AVDD_NODIE

AVDD33_ADC

Normal Power 3.3V

VCC3.3V+3.3V_Normal

C326

C325

C327

C328

C0402

VDDP33

AVDD3P3_MHL3

AVDD_MOD

0.1uF/16V/X5R

0.1uF/16V/X5R

+3.3V_Normal

+3.3V_Normal

50mA,15mil

50mA,15mil

L304 120R/FBI

AVDD_LPLL

AVDD_PLL

C343

1uF/10V/X5R

C0402

C0402

C340

2.2uF/6.3V/X5R

NC/2.2uF/6.3V/X5R

+3.3V_Normal

+3.3V_Normal

+3.3V_Normal

50mA,15mil

40mA,15mil

50mA,15mil

eMMC/Nand Power

20mA,15mil

20mA,15mil

VDDP_NAND_A

C344

0.1uF/16V/X5R

VDDP_NAND_C+3.3V_Normal

C356

0.1uF/16V/X5R

+1.8V_Normal

Internel LDO

VDDP_NAND_A

C366

2.2uF/6.3V/X5R

Title

Title

Title

04. MSD6A538/6586 Power

04. MSD6A538/6586 Power

04. MSD6A538/6586 Power

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> <RevCode>

Custom

<Doc> <RevCode>

Custom

<Doc> <RevCode>

Custom

Date: Sheet of

Date: Sheet of

5

4

3

2

Date: Sheet of

1

4 13Thursday, March 30, 2017

4 13Thursday, March 30, 2017

4 13Thursday, March 30, 2017

Page 31

5

RP 033RX

E E

D D

AVDD_DDR1_S

RM 01

2K

C 25

NC/10nF

RM 02

C C

AVDD_DDR1_S

B B

2K

MR 07

MR 08

1K/1%

1K/1%

0.1uF/16V/X5R

1000pF

MR 09

2 0R/1%

MR 10

2 0R/1%

DDR3 : MR410 240R/1%

LPDDR3 : MR410 0.1uF

BA2,CSB1,CSB2 need GND shielding

U201A

MIU1

H26

A-RST

G26

A-CKE

L26

DRAM_VREF

C 21

C 20

K27

ZQ

M25

ZQ1

MSD6A538

B-A10

B-A11

B-A12

B-A13

B-A1

B-A15

B-BA0

B-BA1

B-BA2

B-RASZ

B-CASZ

B-WEZ

B-ODT

B-CKE

B-RST

B-MCLK

B-MCLKZ

B-CSB1

B-CSB2

B-DQ[0]

B-DQ[1]

B-DQ[2]

B-DQ[3]

B-DQ[ ]

B-DQ[5]

B-DQ[6]

B-DQ[7]

B-DQM[0]

B-DQS[0]

B-DQSB[0]

B-DQ[8]/DQU0

B-DQ[9]/DQU1

B-DQ[10]/DQU2

B-DQ[11]/DQU3

B-DQ[12]/DQU

B-DQ[13]/DQU5

B-DQ[1 ]/DQU6

B-DQ[15]/DQU7

B-DQM[1]

B-DQS[1]

B-DQSB[1]

B-DQ[16]/DQL0

B-DQ[17]/DQL1

B-DQ[18]/DQL2

B-DQ[19]/DQL3

B-DQ[20]/DQL

B-DQ[21]/DQL5

B-DQ[22]/DQL6

B-DQ[23]/DQL7

B-DQM[2]

B-DQS[2]

B-DQSB[2]

B-DQ[2 ]/DQU0

B-DQ[25]/DQU1

B-DQ[26]/DQU2

B-DQ[27]/DQU3

B-DQ[28]/DQU

B-DQ[29]/DQU5

B-DQ[30]/DQU6

B-DQ[31]/DQU7

B-DQM[3]

B-DQS[3]

B-DQSB[3]

D_DDR3_A0

E1

B-A0

D_DDR3_A

B11

B-A1

D_DDR3_A2

D15

B-A2

D_DDR3_A3

D13

B-A3

D_DDR3_A

B12

B-A

D_DDR3_A5

E12

B-A5

D_DDR3_A6

A12

B-A6

D_DDR3_A7

F1

B-A7

D_DDR3_A8

E16

B-A8

D_DDR3_A9

C9

B-A9

D_DDR3_A10

B13

D_DDR3_A11

D17

D_DDR3_A 2

F18

D_DDR3_A13

A9

D_DDR3_A1

A11

D_DDR3_A15

F17

D_DDR3_BA0

F13

D_DDR3_BA1

F19

D_DDR3_BA2

F12

D_DDR3_RASZ

F16

D_DDR3_CASZ

B10

D_DDR3_WEZ

C10

D_DDR3_ODT

F11

D_DDR3_CKE

C1

D_DDR3_RESET

F15

D_DDR3_MCLK

C15

D_DDR3_MCLKZ

A1

D_DDR3_CSB1

B8

D_DDR3_CSB2

D11

D_DDR3_DQ0

D23

D_DDR3_DQ1

D19

D_DDR3_DQ2

E22

D_DDR3_DQ3

E18

D_DDR3_DQ

B21

D_DDR3_DQ5

B15

D_DDR3_DQ6

A21

D_DDR3_DQ7

C16

D_DDR3_DM0

C17

D_DDR3_DQS0

B19

D_DDR3_DQS0B

C19

D_DDR3_DQ8

B17

D_DDR3_DQ9

E20

D_DDR3_DQ10

F20

D_DDR3_DQ

B20

D_DDR3_DQ12

D21

D_DDR3_DQ13

F23

D_DDR3_DQ1

F21

D_DDR3_DQ15

F22

D_DDR3_DM1

A20

D_DDR3_DQS1

A18

D_DDR3_DQS B

C18

D_DDR3_DQ16

B28

D_DDR3_DQ17

F2

D_DDR3_DQ18

C28

D_DDR3_DQ19

F25

D_DDR3_DQ20

F28

D_DDR3_DQ21

B22

D_DDR3_DQ22

E28

D_DDR3_DQ23

C23

D_DDR3_DM2

A23

D_DDR3_DQS2

B26

D_DDR3_DQS2B

C26

D_DDR3_DQ2

C2

D_DDR3_DQ25

F27

D_DDR3_DQ26

D25

D_DDR3_DQ27

C27

D_DDR3_DQ28

F26

D_DDR3_DQ29

E26

D_DDR3_DQ30

E2

D_DDR3_DQ31

D27

D_DDR3_DM3

A27

D_DDR3_DQS3

C25

D_DDR3_DQS3B

B2

D-DDR3-ODT-T1

D-CSB1

D-DDR3-BA2-T1

D-DDR3-BA0-T1

D-DDR3-A7-T1 D-DDR3-A7-T2

D-DDR3-RESET-T1 D-DDR3-RESET-T2

D-DDR3-A9-T1

D-DDR3-A13-T1

D-DDR3-A2-T1 D-DDR3-A2-T2

D-DDR3-A0-T1

D-DDR3-WEZ-T1

D-DDR3-CASZ-T1

D-DDR3-A15-T1

D-DDR3-A1-T1

D-DDR3-A1 -T1 D-DDR3-A1 -T2

D-DDR3-A11-T1

D-DDR3-A6-T1

D-DDR3-A -T1

D-DDR3-A12-T1

D-DDR3-BA1-T1

D-DDR3-A10-T1

D-DDR3-CKE-T1 D-DDR3-CKE-T2

D_DDR3_DQ0

D_DDR3_DQ13

D_DDR3_DQ15

D_DDR3_DQ9

D_DDR3_DQ12

D_DDR3_DQ1

D_DDR3_DQ10

D_DDR3_DQ3

D_DDR3_DQ1

D_DDR3_DQ

D_DDR3_DQ6

D_DDR3_DM1

D_DDR3_DQ11

D_DDR3_DQ8

D_DDR3_DM0

D_DDR3_DQ7

D_DDR3_DQ5

D_DDR3_DQS1

D_DDR3_DQS1B

D_DDR3_DQS0

D_DDR3_DQS0B

D_DDR3_ODT

D_DDR3_CSB1

642

53

RP 0682RX

D_DDR3_BA2

D_DDR3_BA0

7531

8642

D_DDR3_A3

D_DDR3_A5

RP 0782RX

D_DDR3_A7

D_DDR3_RESE

731

842

D_DDR3_A9

D_DDR3_A13

RP 1082RX

D_DDR3_A2

D_DDR3_A0

7531

8642

D_DDR3_WEZ

D_DDR3_CASZ

RP 182RX

D_DDR3_RASZ

D_DDR3_A15

75

862

D_DDR3_A

D_DDR3_A1

RP 1382RX

D_DDR3_A11

7531

8642

D_DDR3_A6

D_DDR3_A

RP 1582RX

D_DDR3_A12

D_DDR3_BA1

7531

8642

D_DDR3_A10

D_DDR3_CKE

D-DDR3-DQ2

D-DDR3-DQ0

D-DDR3-DQ13

D-DDR3-DQ15

D-DDR3-DQ9

D-DDR3-DQ12

D-DDR3-DQ1

D-DDR3-DQ10

D-DDR3-DQ3

D-DDR3-DQ1

D-DDR3-DQ

D-DDR3-DQ6

D-DDR3-DM1

D-DDR3-DQ11

D-DDR3-DQ8

D-DDR3-DM0

D-DDR3-DQ7

D-DDR3-DQ5

D-DDR3-DQS1

D-DDR3-DQS1B

D-DDR3-DQS0

D-DDR3-DQS0B

3

D_DDR3_ODT

D_DDR3_CSB2

D_DDR3_BA2

D_DDR3_BA0

D_DDR3_A3

D_DDR3_A5

D_DDR3_A7

D_DDR3_RESE

D_DDR3_A9

D_DDR3_A13

D_DDR3_A2

D_DDR3_A0

D_DDR3_WEZ

D_DDR3_CASZ

D_DDR3_RASZ

D_DDR3_A15

D_DDR3_A

D_DDR3_A1

D_DDR3_A11

D_DDR3_A8D_DDR3_A8

D_DDR3_A6

D_DDR3_A

D_DDR3_A12

D_DDR3_BA1

D_DDR3_A10

D_DDR3_CKE

D_DDR3_DQ25D_DDR3_DQ2

D_DDR3_DQ28

D_DDR3_DQ30

D_DDR3_DQ26

D_DDR3_DM2

D_DDR3_DQ2

D_DDR3_DQ19

D_DDR3_DQ17

D_DDR3_DQ20

D_DDR3_DQ22

D_DDR3_DQ18

D_DDR3_DQ16

D_DDR3_DM3

D_DDR3_DQ27

D_DDR3_DQ31

D_DDR3_DQ29

D_DDR3_DQ23

D_DDR3_DQ21

D_DDR3_DQS3B

D_DDR3_DQS3

D_DDR3_DQS2B

D_DDR3_DQS2

D_DDR3-MCLKD_DDR3_MCLK D-DDR3_MCLK

D_DDR3-MCLKZD_DDR3_MCLKZ D-DDR3_MCLKZ

2

AVDD_DDR1_S

MU 01

NT5CB256M16DP-EK

RP 0533RX

D-DDR3-ODT-T2

D-CSB2

642

53

RP 0082RX

D-DDR3-BA2-T2

D-DDR3-BA0-T2

7531

8642

D-DDR3-A3-T2D-DDR3-A3-T1

D-DDR3-A5-T2D-DDR3-A5-T1

RP 0982RX

731

842

D-DDR3-A9-T2

D-DDR3-A13-T2

RP 0882RX

D-DDR3-A0-T2

7531

8642

D-DDR3-WEZ-T2

D-DDR3-CASZ-T2

RP 1282RX

D-DDR3-RASZ-T2D-DDR3-RASZ-T1

D-DDR3-A15-T2

75

862

D-DDR3-A1-T2

RP 182RX

D-DDR3-A11-T2

D-DDR3-A8-T2D-DDR3-A8-T1

7531

8642

D-DDR3-A6-T2

D-DDR3-A -T2

RP 1682RX

D-DDR3-A12-T2

D-DDR3-BA1-T2

7531

8642

D-DDR3-A10-T2

D-DDR3-DQ25

D-DDR3-DQ28

D-DDR3-DQ30

D-DDR3-DQ26

D-DDR3-DM2

D-DDR3-DQ2

D-DDR3-DQ19

D-DDR3-DQ17

D-DDR3-DQ20

D-DDR3-DQ22

D-DDR3-DQ18

D-DDR3-DQ16

D-DDR3-DM3

D-DDR3-DQ27

D-DDR3-DQ31

D-DDR3-DQ29

D-DDR3-DQ23

D-DDR3-DQ21

D-DDR3-DQS3B

D-DDR3-DQS3

D-DDR3-DQS2B

D-DDR3-DQS2

DDR3 4G bit 1866MHz

D CSB1

D DDR3-A15-T1

D DDR3-A0-T2

D DDR3-A1-T2

D DDR3-A2-T2

D DDR3-A3-T2

D DDR3-A -T2

D DDR3-A5-T2

D DDR3-A6-T2

D DDR3-A7-T2

D DDR3-A8-T2

D DDR3-A9-T2

D DDR3-A10-T2

D DDR3-A11-T2

D DDR3-A12-T2

D DDR3-BA0-T2

D DDR3-BA1-T2

D DDR3-BA2-T2

D-CSB2

D DDR3-RASZ-T2

D DDR3-CASZ-T2

D DDR3-WEZ-T2

D DDR3-ODT-T2

D MVREFCA-T2

D-DDR3-A15-T2

D DDR3-A13-T2

D DDR3-A1 -T2

D-DDR3-A0-T1

D-DDR3-A1-T1

D-DDR3-A2-T1

D-DDR3-A3-T1

D-DDR3-A -T1

D-DDR3-A5-T1

D-DDR3-A6-T1

D-DDR3-A7-T1

D-DDR3-A8-T1

D-DDR3-A9-T1

D-DDR3-A10-T1

D-DDR3-A11-T1

D-DDR3-A12-T1

D-DDR3-BA0-T1

D-DDR3-BA1-T1

D-DDR3-BA2-T1

D-DDR3-RASZ-T1

D-DDR3-CASZ-T1

D-DDR3-WEZ-T1

D-DDR3-ODT-T1

D-MVREFCA-T1

D-DDR3-A13-T1

D-DDR3-A1 -T1

MU 00

NT5CB256M16DP-EK

MR 06

2 0R 1%

R9

N3

A0

P7

A1

P3

A2

N2

A3

P8

A

P2

A5

R8

A6

R2

A7

T8

A8

R3

A9

L7

A10

R7

A11

N7

A12

M2

BA0

N8

BA1

M3

BA2

L2

/CS

J3

/RAS

K3

/CAS

L3

/WE

K1

ODT

M8

VREFCA

J1

NC1

J9

NC2

L1

NC3

L9

NC

M7

NC5

T3

A13

T7

NC7

ZQ

L8

T9

MR 05

2 0R/1%

R9

N3

A0

P7

A1

P3

A2

N2

A3

P8

A

P2

A5

R8

A6

R2

A7

T8

A8

R3

A9

L7

A10

R7

A11

N7

A12

M2

BA0

N8

BA1

M3

BA2

L2

/CS

J3

/RAS

K3

/CAS

L3

/WE

K1

ODT

M8

VREFCA

J1

NC1

J9

NC2

L1

NC3

L9

NC

M7

NC5

T3

A13

T7

NC7

ZQ

L8

T9

AVDD_DDR1_S

H9

VDDB2VDDD9VDDG7VDDK2VDDK8VDDN1VDDN9VDDR1VDD

VSSA9VSSE1VSSG8VSSJ2VSSJ8VSSM1VSSM9VSSP1VSSP9VSST1VSS

VSS

B3

H9

VDDB2VDDD9VDDG7VDDK2VDDK8VDDN1VDDN9VDDR1VDD

VSSA9VSSE1VSSG8VSSJ2VSSJ8VSSM1VSSM9VSSP1VSSP9VSST1VSS

VSS

B3

G9

VDDQA1VDDQA8VDDQC1VDDQC9VDDQD2VDDQE9VDDQF1VDDQH2VDDQ

DMU

DQSU

DQSU

DQU0

DQU1

DQU2

DQU3

DQU

DQU5

DQU6

DQU7

DML

DQSL

/DQSL

DQL0

DQL1

DQL2

DQL3

DQL

DQL5

DQL6

DQL7

VREFDQ

CK

/CK

CKE

/RESET

VSSQB9VSSQB1VSSQD1VSSQD8VSSQE2VSSQE8VSSQF9VSSQG1VSSQ

G9

VDDQA1VDDQA8VDDQC1VDDQC9VDDQD2VDDQE9VDDQF1VDDQH2VDDQ

DQSU

/DQSU

DQU0

DQU1

DQU2

DQU3

DQU

DQU5

DQU6

DQU7

DQSL

/DQSL

VREFDQ

/RESET

D3

C7

B7

D7

C3

C8

C2

A7

A2

B8

A3

E7

F3

G3

E3

F7

F2

F8

H3

H8

G2

H7

H1

J7

K7

K9

T2

DQL0

DQL1

DQL2

DQL3

DQL

DQL5

DQL6

DQL7

DMU

DML

CK

/CK

CKE

VSSQB9VSSQB1VSSQD1VSSQD8VSSQE2VSSQE8VSSQF9VSSQG1VSSQ

1

D3

D-DDR3-DM1

C7

D-DDR3-DQS1

B7

D-DDR3-DQS1B

D7

D-DDR3-DQ8

C3

D-DDR3-DQ9

C8

D-DDR3-DQ10

C2

D-DDR3-DQ11

A7

D-DDR3-DQ12

A2

D-DDR3-DQ13

B8

D-DDR3-DQ1

A3

D-DDR3-DQ15

E7

D-DDR3-DM0

F3

D-DDR3-DQS0

G3

D-DDR3-DQS0B

E3

D-DDR3-DQ0

F7

D-DDR3-DQ1

F2

D-DDR3-DQ2

F8

D-DDR3-DQ3

H3

D-DDR3-DQ

H8

D-DDR3-DQ5

G2

D-DDR3-DQ6

H7

D-DDR3-DQ7

H1

D-MVREFDQ-T1

D_DDR3-MCLK

J7

D_DDR3-MCLKZ

K7

K9

D-DDR3-CKE-T1

T2

D-DDR3-RESET-T1

D-DDR3-DM3

D-DDR3-DQS3

D-DDR3-DQS3B

D-DDR3-DQ2

D-DDR3-DQ25

D-DDR3-DQ26

D-DDR3-DQ27

D-DDR3-DQ28

D-DDR3-DQ29

D-DDR3-DQ30

D-DDR3-DQ31

D-DDR3-DM2

D-DDR3-DQS2

D-DDR3-DQS2B

D-DDR3-DQ16

D-DDR3-DQ17

D-DDR3-DQ18

D-DDR3-DQ19

D-DDR3-DQ20

D-DDR3-DQ21

D-DDR3-DQ22

D-DDR3-DQ23

D-MVREFDQ-T2

D-DDR3_MCLK

D DDR3_MCLKZ

D-DDR3-CKE-T2

D-DDR3-RESET-T2

MR 01 56R

MR 02 56R

CB 01

0.01uF/50V/X7R

MR 03 56R

MR 0 56R

1.5V_DDR AVDD_DDR1_S

CB 06

CB 18

CB 29

CB 07

0.1uF/16V/X5R

0.1uF/16V/X5R

CB 19

0.1uF/16V/X5R

0.1uF/16V/X5R

CB 30

0.1uF/16V/X5R

0.1uF/16V/X5R

5

CB 08

CB 20

CB 31

CB 05

10uF/6 3V/X5R

10uF/6 3V/X5R

1.5V_DDR

CB 17

A A

1.5V_DDR

0.1uF/16V/X5R

0.1uF/16V/X5R

CB 28

0.1uF/16V/X5R

0.1uF/16V/X5R

CB 09

CB 10

0.1uF/16V/X5R

0.1uF/16V/X5R

CB 21

CB 22

0.1uF/16V/X5R

0.1uF/16V/X5R

CB 32

CB 33

0.1uF/16V/X5R

0.1uF/16V/X5R

C ose to DDR POWER PIN

CB 13

CB 11

CB 12

0.1uF/16V/X5R

0.1uF 16V/X5R

0.1uF/16V/X5R

0.1uF 16V/X5R

CB 2

CB 23

CB 00

0.1uF/16V/X5R

0.1uF 16V/X5R

0.1uF/16V/X5R

0.1uF 16V/X5R

CB 3

CB 35

CB 36

0.1uF 16V/X5R

0.1uF/16V/X5R

0.1uF/16V/X5R

0.1uF 16V/X5R

CB 1

CB 25

CB 37

CB 15

CB 26

CB 38

CB 16

10uF 6.3V X5R

0.1uF/16V X5R

0.1uF/16V X5R

CB 27

0.1uF/16V X5R

0.1uF/16V X5R

CB 39

0.1uF/16V X5R

0.1uF/16V X5R

CB500

AVDD_DDR1_S

AVDD_DDR1_S

MR 11

1K/1%

MR 17

1K/1%

D-MVREFDQ-T1

MR 13

1K/1%

D-MVREFCA-T1

MR 19

1K/1%

C 22

C 00

AVDD_DDR1_S

C 23

1000pF

0.1uF/16V X5R

AVDD_DDR1_S

C 02

1000pF

0.1uF/16V X5R

MR 12

1K/1%

MR 18

1K/1%

C 2

MR 1

1K/1%

D-MVREFCA-T2

MR 00

C 03

1K/1%

D-MVREFDQ-T2

C 01

1000pF

0.1uF/16V/X5R

C 0

1000pF

0.1uF/16V/X5R

AVDD_DDR1_S AVDD_DDR1_S

RM 03

2K

D-DDR3-CKE-T1 D-DDR3-CKE-T2

RM 00

2K

3

CB 03

0 01uF/50V/X7R

D-DDR3-RESET-T2D-DDR3-RESET-T1

RM 05

2K

RM 0

2K

CB 0

0.01uF/50V/X7R

CSB terminator

D-CSB1

MR 15 70R

D-CSB2

MR 16 70R

2

1.5V_DDR

C 05

0.1uF/16V/X5R

tle

tle

tle

05. DRAM

05. DRAM

05. DRAM

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> RevCode>

Cust m

<Doc> RevCode>

Cust m

<Doc> RevCode>

Cust m

Date: Sheet of

Date: Sheet of

Date: Sheet of

CB 02

0.01uF/50V X7R

5 13Thursday, March 30, 2017

5 13Thursday, March 30, 2017

5 13Thursday, March 30, 2017

1

Page 32

5

ode>

ode>

ode>

4

3

2

1

+3 3V_EMMC

eMMC

D D

C C

EMMC_CLK

EMMC_CMD

EMMC_D0

EMMC_D1

EMMC_D2

EMMC_D3

ONLY SAMSUNG ADD

R1126

10K/NC

W6

W5

W4

AA3

AA5

AA4

AA6

U501

eMMC

CLK

CMD

H3

D0

H4

D1

H5

D2

J2

D3

K6

VDD_IF

VDD_IF

Y4

VDD_IF

VDD_IF

VDD_IF

K4

VSS

Y2

VSS

Y5

VSS

VSS

VSS

公板装

DS

RESET

VDD

VDD

VDD

VDD

VSS

VSS

VSS

VSS

VSS

VSS

CREG/VDDi

8G

D4

D5

D6

D7

J3

J4

J5

J6

R5

U5

M6

N5

T10

U9

H6

M7

P5

R10

U8

T5

K2

EMMC_D4

EMMC_D5

EMMC_D6

EMMC_D7

EMMC_DS

EMMC_RST

+3.3V_EMMCEMMC_VIO

C509

2.2uF/6.3V/X5R

C0402

NET

C516

NC/33pF

NAND-AD[7:0] 3

NAND-CEZ 3

NAND-REZ 3

NAND-RBZ 3

NAND-DQS 3

NAND-REZ

PCM_A11

PCM_A9

PCM_A8

EMMC_D6

EMMC_D7

EMMC_D2

EMMC_D1

EMMC_D0

EMMC_D3

B B

A A

5