Haier HWD1000, HWD1500, HWD1600 User Manual

HWD1000

HWD1500

HWD1600

F

RONT LOAD WASHER

& D

RYER COMBO

Index

• Installation Guidelines

• Maintenance Guidelines

• Common Operation Issues

• Component Test Information

• HWD1000 Error Code List

• HWD 15/1600 Error code list

• HWD 15/1600 Self Check Mode

• Poor Drying Performance Troubleshooting

• HWD1000 Common Parts List

• HWD1500 Common Parts List

• HWD1600 Common Parts List

2

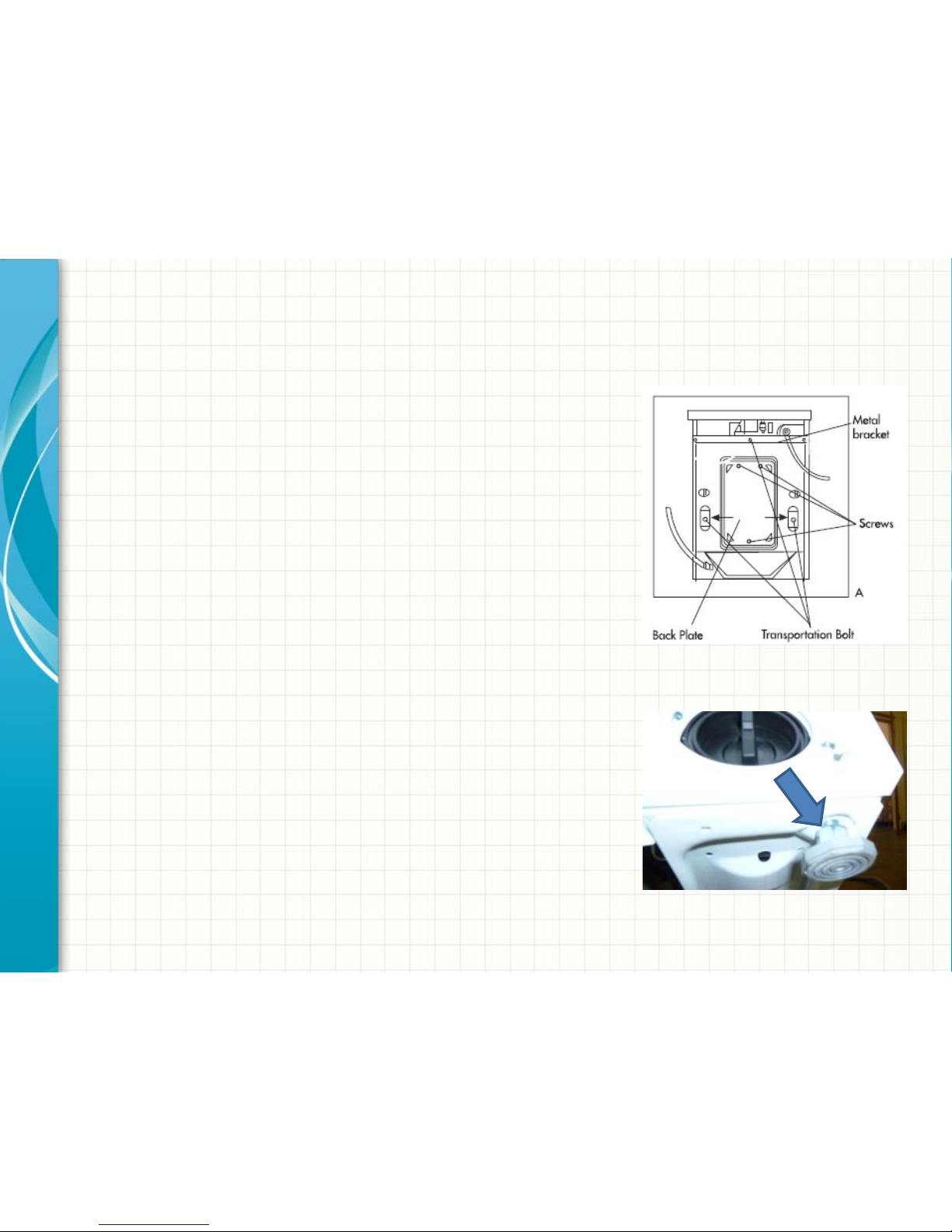

Installation Guidelines Part 1

• Do not remove the shipping

bolts until the unit is at the

installation space

– Remove the shipping bolts just

before the unit is to be moved

into the final location

• Make sure the unit is level

– Level can be verified by pressing

on all 4 corners, if any of the

corners move additional

adjustment is required

– BE SURE TO LOCK THE LEVELING

LEGS

3

Installation Guidelines Part 2

• Make sure the Hot and cold supply lines are

connected properly, unobstructed and fully open

– Do not reuse old water supply hoses

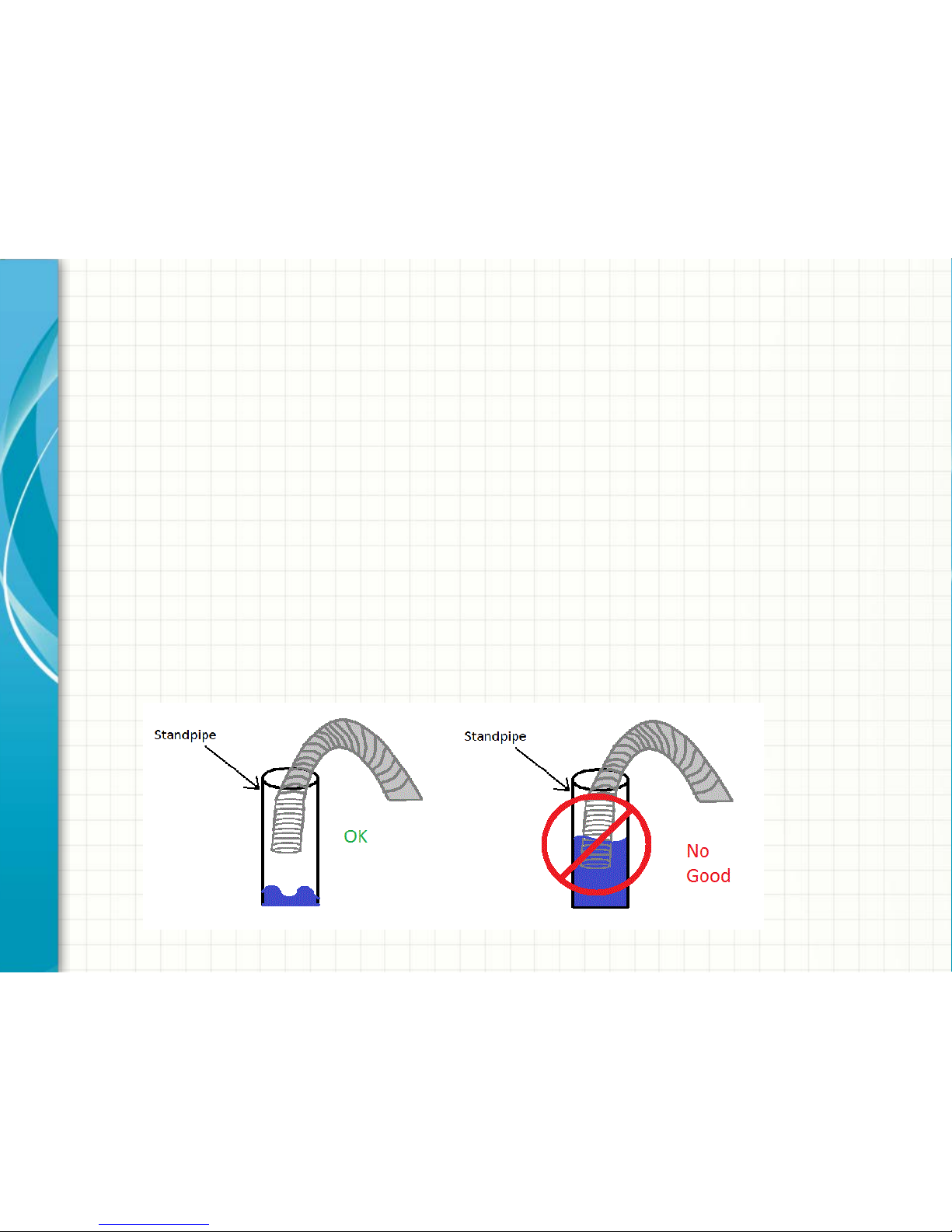

• Make sure the drain hose is installed into the

standpipe properly and secured

– The drain hose end should not be submerged

4

Maintenance Guidelines

• Use High Efficiency (HE)

detergent only

– The wrong type of soap can lead to

poor wash performance and

possibly damage the washer

• Clean the Drain Filter every two

weeks

• Inspect the door boot gasket for

tears or foreign matter with

each new cycle

• Clean the door boot with bleach

monthly to prevent mold

5

Common Operation Issues

• Clothes do not dry within 120 Minutes

• The washer will wash ~ 12 pounds of clothes at once but

the unit only designed to dry 6.6 lbs. of clothes within 2

hours

• 6.6 Lbs. is approximately 2 full outfits

• This unit uses energy saving vent less condensation drying,

different from traditional vented drying

• Condensation drying operates like a cold drink on a hot day

where the cold surface of the glass attracts moisture to the

outside of the glass.

• The condensation dryer circulates air through the drum, but

instead of being vented back out, it is passed through a heat

exchanger. This heat exchanger is essentially a cooling

surface, attracting moisture. The moisture drips into a

drainpipe. After passing through the heat exchanger the air

is reheated and blown back into the drum. This process is

repeated throughout the dry cycle.

6

Common Operation Issues

• Cannot open the door

– This unit uses a safety interlock that locks the door

for three minutes after the cycle ends or the stop

button is pressed

• This is done to protect the user from flood damage and

excessive heat

• Clothes come out dry but wrinkled

– The smaller drum size may not allow garments to

“fluff”, try reducing the number of garments being

dried at one time.

7

Loading...

Loading...