Page 1

COLOUR TELEVISION

Service Manual

HT-2180

Features

218 programs stored

Auto-correcting black balance

Audio/video input, S-Video input

Haier Group

NO:M-EE-CY-HT-2180-1238 Edition:2003.1.20

Page 2

Contents

1 Contents------------------------------------------------------------------------------------

2

Product Code illumination and Series Introduction------------------------2

1

3 Features------------------------------------------------------------------------------------3

4 Safety Precautions---------------------------------------------------------------------4

5 Warning and Cautions----------------------------------------------------------------5

6 Net dimension---------------------------------------------------------------------------11

7 Parts and Functions-------------------------------------------------------------------12

8 Remote Controller Functions------------------------------------------------------14

9 Program Diagram----------------------------------------------------------------------15

10 Maintenance Service and Trouble shooting----------------------------------16

11 Circuit Diagram-------------------------------------------------------------------------24

12 Circuit Explanation--------------------------------------------------------------------27

13 Adjustment-------------------------------------------------------------------------------32

14 Exploded View--------------------------------------------------------------------------33

15 List of Parts------------------------------------------------------------------------------34

16 Damageable Parts List---------------------------------------------------------------49

17 Information of Resistors and Capacitors--------------------------------------50

1

Page 3

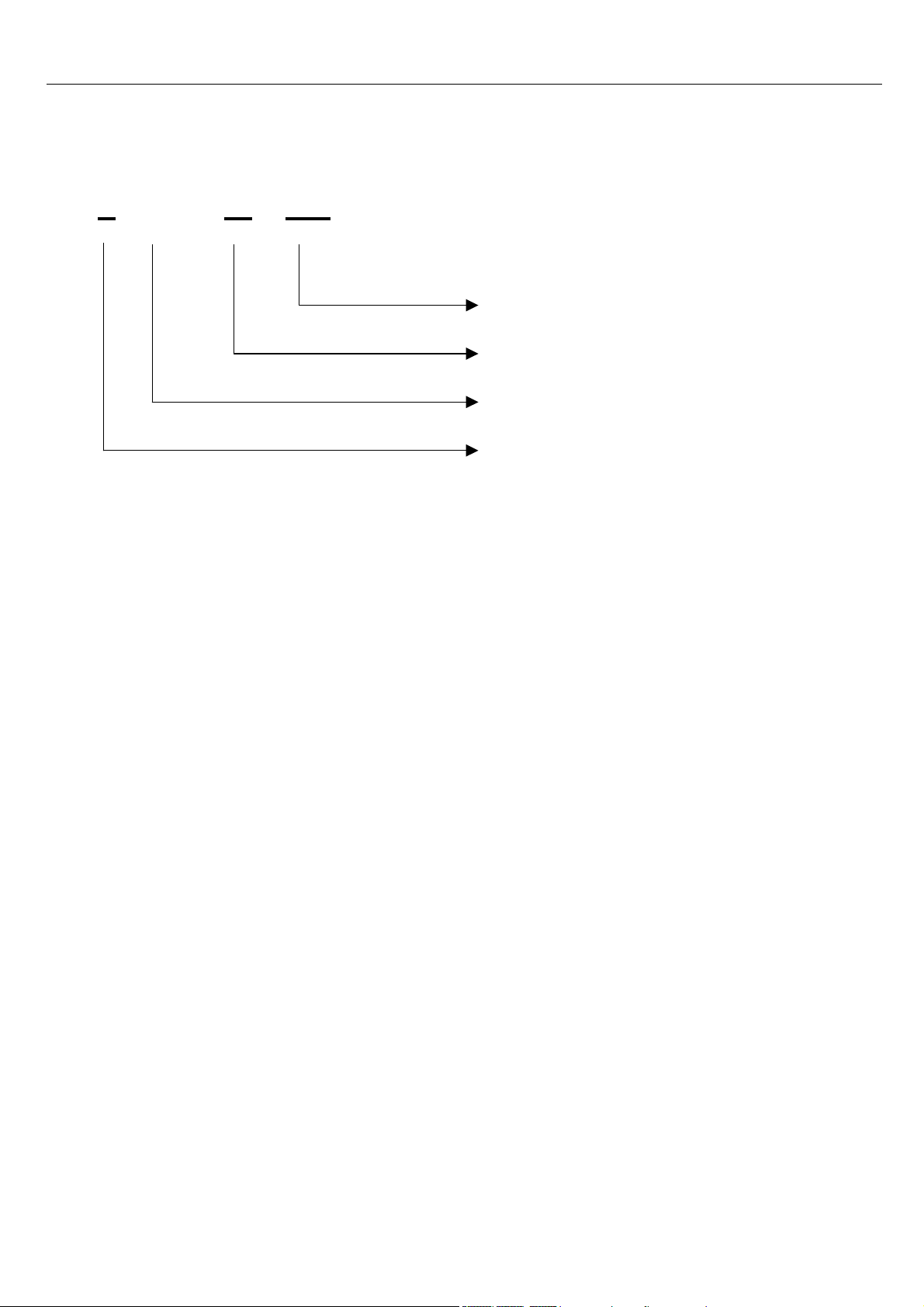

Product Code illumination and Series Introduction

2.

Product Code illumination and Series Introduction

T - 21

H

80

Color television appearance

CRT size(unit:inch)

Company of Signal processor IC TD: Toshiba

Haier

2

Page 4

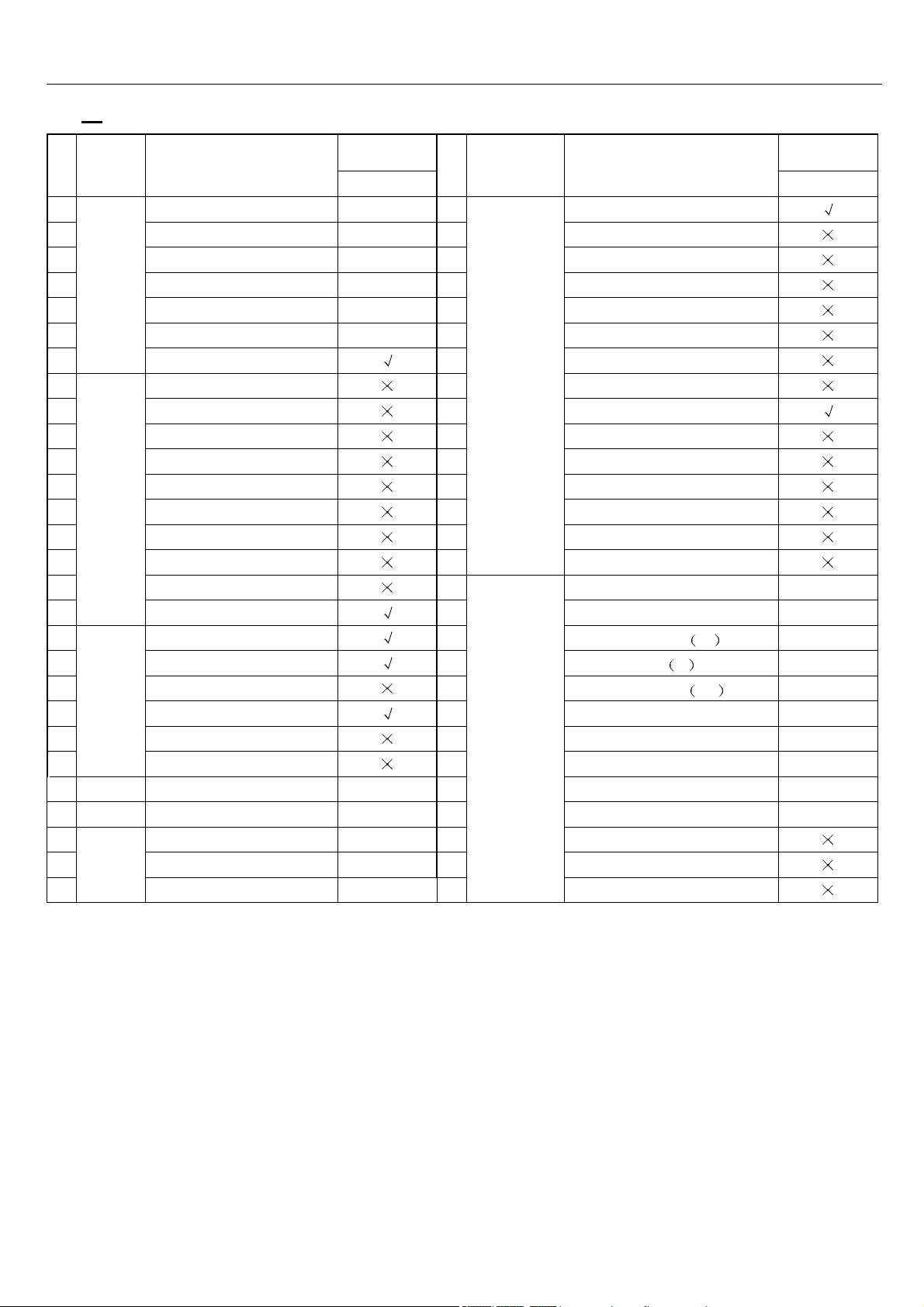

Features

3.

Features

PICTURE

1

2

3

4

5

6

7

AUDIO

8

9

10

11

12

13

14

15

16

17

JACK

18

19

20

21

22

23

ITEM

Main IC 1238

CRT

Color system

Audio system

NO.of channels

OSD language

Multi-picture modes

AV stereo

Super woofer

Surrounding sound

Treble/bass boost

Left/right balancer

NICAM

Multi-audio modes

Tone adjuster

MTS/SAP

Auto-volume leveling

AV input

AV output

DVD terminal

S-video jack

Headphone socket

SCART socket

NO.

FUNCTION

HT-2180

Flat square 25

ENGLISH 29

MODEL

NO.

24

PAL 26

B/G 27

218 28

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

ITEM

SOFTWARE

PARAMETER

FUNCTION

Digital curtain

Slow fading on & off

Semitransparent menu

Non-flashing channel changing

ZOOM

16:9 mode

Games

Calendar

Child-lock

Multi-functional lock

No-picture listening

Background light

Auto-timer on

CCD

V-CHIP

NO. of built-in speakers

Audio output power(W)

Total power input

Voltage range

Power frequency

Time of sleep timer(MINS)

Net weight(KG)

Gross weight(KG)

Net dimension(MM)

Packaged dimension(MM)

Quantity for 20' container

Quantity for 40' container

Quantiry for 40' high container

W

V

Hz

MODEL

HT-2180

2

3

70

~90-250

50/60

120

23.5

25

610×460×490

685×50×530

3

Page 5

Safety Precautions

4.Safety Precautions

SAFETY PRECAUTIONS

IMPORTANT SAFETY NOTICE

Many electrical identify these parts and mechanical parts in this chassis have special safety-related

characteristics! In the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of the manufacturer.

General Guidance

An Isolation Transformer should always be used during the servicing of a receiver whose chassis is

not isolated from the AC power line. Use a transformer of adequate power rating as this protects the

technician from accidents that might result in personal injury caused by electrical shocks.

It will also protect the receiver and it’s components from being damaged by accidental shorts of the

circuitry that might be inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown, replace it with a specified one.

When replacing a high wattage resistor (Oxide Metal Film Resistor, over 1W), keep the resistor

10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to the high vacuum and large surface area of the picture tube, extreme care should be taken in

handling the Picture Tube. Do not lift the Picture Tube by its Neck.

X-RAY Radiation

Warning:

The source of X-RAY RADIATION in this TV receiver is the High Voltage Section and the Picture

Tube.

For continued X-RAY RADIATION protection, the replacement tube must be of the same type as

specified in the Replacement Parts List.

Before returning the receiver to the customer,

Always perform an AC leakage current check on the exposed metallic parts of the cabinet, such as

antennas, terminals, etc., to make sure that the set is safe to operate without any danger of electrical

shock.

4

Page 6

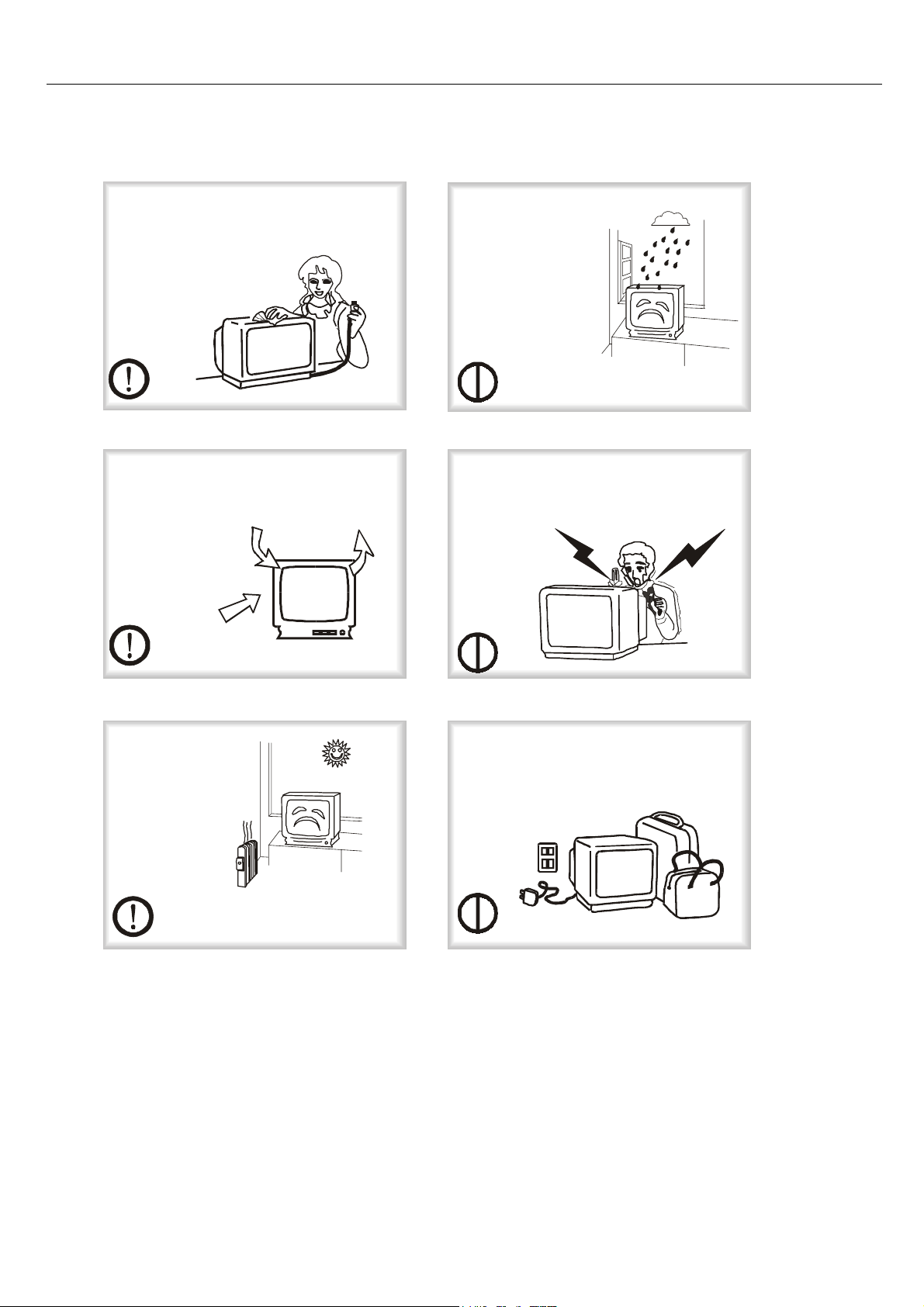

5. Warning and Cautions

g

Warning and Cautions

1. When you clean the TV set, please pull

out the power plu

clean the cabinet and the screen with

benzene, petrol and other chemicals.

2.

In order to prolong the using life of the

TV set, please place it on a ventilated

place.

from AC outlet. Don't

Warning and Cautions

4. To prevent the TV set from firing and

electric shock, don't

make the TV set rain

or moisture.

5. Don't open the back cover, otherwise it is

possible to damage the components in the

TV set and harm you.

3.

Don't place the

TV set in the

sunshine or near

heat source.

6. When the TV set isn't going to be used

for long time or it is in thunder and

lightening, please pull out the pl ug from AC

outlet and the antenna plug from the cover

of the TV set.

Explanation on the display tube

Generally, it is not needed to clean the tube surface. However, if necessary,its surface can be

cleaned with a dry cotton cloth after cutting off the power.Don't use any cleanser. If using hard

cloth, the tube surface will be damaged.

CAUTION: Before servicing receivers covered by this service manual and its supplements and

addenda, read and follow the SAFETY PRECAUTIONS.

NOTE: If unforeseen circumstances create conflict between the following servicing precautions

5

Page 7

Warning and Cautions

NOTE: If unforeseen circumstances create conflict between the following servicing precautions and

any of the safety precautions, always follow the safety precautions. Remember: Safety First.

General Servicing Precautions

1) Always unplug the receiver AC power cord from the AC power source before:

a. Removing or reinstalling any component, circuit board module or any other assembly of the

receiver.

b. Disconnecting or reconnecting any receiver electrical plug or other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic capacitor in the receiver.

CAUTION: A wrong substitution part or incorrect installation polarity of electrolytic capacitors

may result in an explosion hazard.

d. Discharging the picture tube anode.

2) Test high voltage only by measuring it with an appropriate high voltage meter or other

voltage-measuring device (DVM, FETVOM, etc.) equipped with a suitable high voltage probe. Do

not test high voltage by “drawing an arc”.

3) Discharge the picture tube anode only by (a) first connecting one end of an insulated clip lead

to the degaussing or kine aquadag grounding system shield at the point where the picture tube

socket ground lead is connected, and then (b) touch the other end of the insulated clip lead to the

picture tube anode button, using an insulating handle to avoid personal contact with high voltage.

4) Do not spray chemicals on or near this receiver or any of its assemblies.

5) Unless specified otherwise in this service manual, clean electrical contacts only by applying the

following mixture to the contacts with a pipe cleaner, cotton-tipped stick or comparable

nonabrasive applicator; 10% (by volume) Acetone and 90% (by volume) isopropyl alcohol

(90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of contacts is not required.

6) Do not defeat any plug / socket B+ voltage interlocks with which receivers covered by this

service manual might be equipped.

7) Do not apply AC power to this instrument and/or any of its electrical assemblies unless all

solid-state device heat sinks are correctly installed.

8) Always connect the test receiver ground lead to the receiver chassis ground before connecting

the test receiver positive lead.

Always remove the test receiver ground lead last.

9) Use with this receiver only the test fixtures specified in this service manual.

CAUTION: Do not connect the test fixture ground strap to any heat sink in this receiver.

Electrostatic ally Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

6

Page 8

Warning and Cautions

components are usually called Electrostatic ally Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field effect transistors and semiconductor “chip”

components. The following techniques should be used to help reduce the incidence of component

damage caused by static electricity.

1) Immediately before handling any semiconductor component or semiconductor- equipped

assembly, drain off any electrostatic charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed to prevent potential shock prior to applying power to the unit under test.

2) After removing an electrical assembly equipped with ES devices, place the assembly on a

conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of

the assembly.

3) Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4) Use only an anti-static type folder removal device. Some solder removal devices not classified

as “anti-static” can generate electrical charges sufficient to damage ES devices.

5) Do not use freon-propelled chemicals. These can generate electrical charges sufficient to

damage ES devices.

6) Do not remove a replacement ES device from its protective package until immediately before

you are ready to install it. (Most replacement ES devices are packaged with leads electrically

shorted together by conductive foam, aluminum foil or comparable conductive material).

7) Immediately before removing the protective material from the leads of a replacement ES

device, touch the protective material to the chassis or circuit assembly into which the device will

be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other safety

precautions.

8) Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise even

some normally harmless motions such as mutual brushing of your clothes’ fabric or lifting of your

foot from a carpeted floor might generate static electricity sufficient to damage an ES device.)

General Soldering Guidelines

Use a grounded-tip, low-wattage soldering iron and appropriate tip size and shape that will maintain

tip temperature within the range of 500 oF to 600 oF.

Use an appropriate gauge of RMA resin-core solder composed of 60 parts tin/40 parts lead.

Keep the soldering iron tip clean and well tinned.

Thoroughly clean the surfaces to be soldered. Use a mall wire bristle (0.5 inch, or 1.25cm) brush

with a metal handle. Do not use freon-propelled spay-on cleaners.

Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature. (500 o F to 600o F)

b. Heating the component lead until the solder melts.

7

Page 9

Warning and Cautions

Warning and Cautions

c. draw the melted solder with an anti-static, suction-type solder removal device with solder

braid.

CAUTION: Work quickly to avoid overheating the circuit board printed foil.

Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature. (500 o F to 600o F)

b. First, hold the soldering iron tip and solder the strand against the component lead until the

solder melts.

c. Quickly move the soldering iron tip to the junction of the component lead and the printed

circuit foil, and hold it there only until the solder flows onto and around both the component

lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit board printed foil.

d. Closely inspect the solder area and remove any excess or splashed solder with a small

wire-bristle brush.

Remove /Replacement

Some chassis circuit boards have slotted holes (oblong) through which the IC leads are inserted and

then bent flat against the circuit foil. When holes are of slotted type, the following technique should

be used to remove and replace the IC. When working with boards using the familiar round hole, use

the standard technique as outlined.

Removal

Desolder and straighten each IC lead in one operation by gently prying up on the lead with the

soldering iron tip as the solder melts.

Draw away the melted solder with an anti-static suction-type solder removal device (or with solder

braid) before removing the IC.

Replacement

Carefully insert the replacement IC in the circuit board.

Carefully bend each IC lead against the circuit foil pad and solder it.

Clean the soldered areas with a small wire-bristle brush. (It is not necessary to reapply acrylic

coating to the areas).

“Small-Signal” Discrete Transistor

Removal/Replacement

Remove the defective transistor by clipping its leads as close as possible to the component body.

Bend into a “U” shape the end of each of three leads remaining on the circuit board.

Bend into a “U” shape the replacement transistor leads.

Connect the replacement transistor leads to the corresponding leads extending from the circuit board

and crimp the “U” with long nose pliers to insure metal to metal contact then solder each connection.

Power Output, Transistor Device

8

Page 10

Warning and Cautions

Removal/Replacement

Heat and remove all solder from around the transistor leads.

Remove the heat sink mounting screw (if so equipped).

Carefully remove the transistor from the heat sink of the circuit board.

Insert new transistor in the circuit board.

Solder each transistor lead, and clip off excess lead.

Replace heat sink.

Diode Removal/Replacement

Remove defective diode by clipping its leads as close as possible to diode body.

Bend the two remaining leads perpendicularly to the circuit board.

Observing diode polarity, wrap each lead of the new diode round the corresponding lead on the

circuit board.

Securely crimp each connection and solder it.

Inspect (on the circuit board copper side) the solder joints of the two “original” leads. If they are not

shiny, reheat them and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1) Clip each fuse or resistor lead at top of the circuit board hollow stake.

2) Securely crimp the leads of replacement component around notch at stake top.

3) Solder the connections

CAUTION: Maintain original spacing between the replaced component and adjacent components

and the circuit board to prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit board will weaken the adhesive that

bonds foil to the circuit board causing the foil to separate from or “lift-off” the board. The following

guidelines and procedures should be followed whenever this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the following procedure to install a jumper

wire on the copper pattern side of the circuit board. (Use this technique only on IC connections).

1) Carefully remove the damaged copper pattern with a sharp knife. (Remove only as much copper

as absolutely necessary).

2) Carefully scratch away the solder resist and acrylic coating (if used) from the end of the

remaining copper pattern.

3) Bend a small “U” in one end of a small gauge jumper wire and carefully crimp it around the IC

9

Page 11

Warning and Cautions

pin. Solder the IC connection.

4) Route the jumper wire along the path of the out-away copper pattern and let it overlap the

previously scraped end of the good copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At other connections

Use the following technique to repair the defective copper pattern at connections other than IC Pins.

This technique involves the installation of a jumper wire on the component side of the circuit board.

Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to insure that a hazardous condition will not exist if the jumper

wire opens.

Trace along the copper pattern from both sides of the pattern break and locate the nearest

component that is directly connected to the affected copper pattern.

Connect insulated 20-gauge jumper wire from the lead of the nearest component on one side of the

pattern break to the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so that it does not touch components or

sharp edges.

10

Page 12

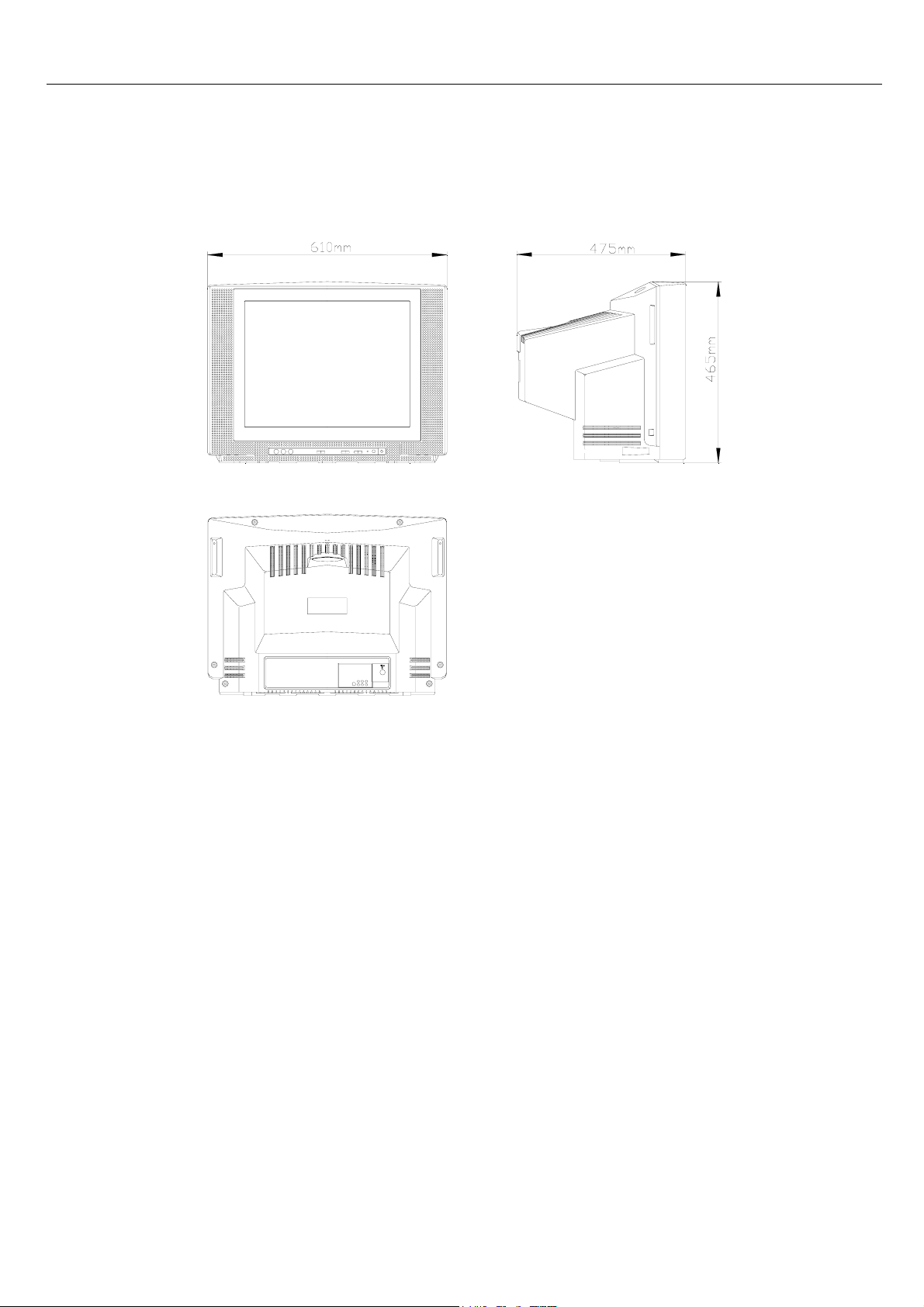

b

Net dimension

6.

Net dimension

Front view

Haier

ack-view

Side view

HT-2180

11

Page 13

g

g

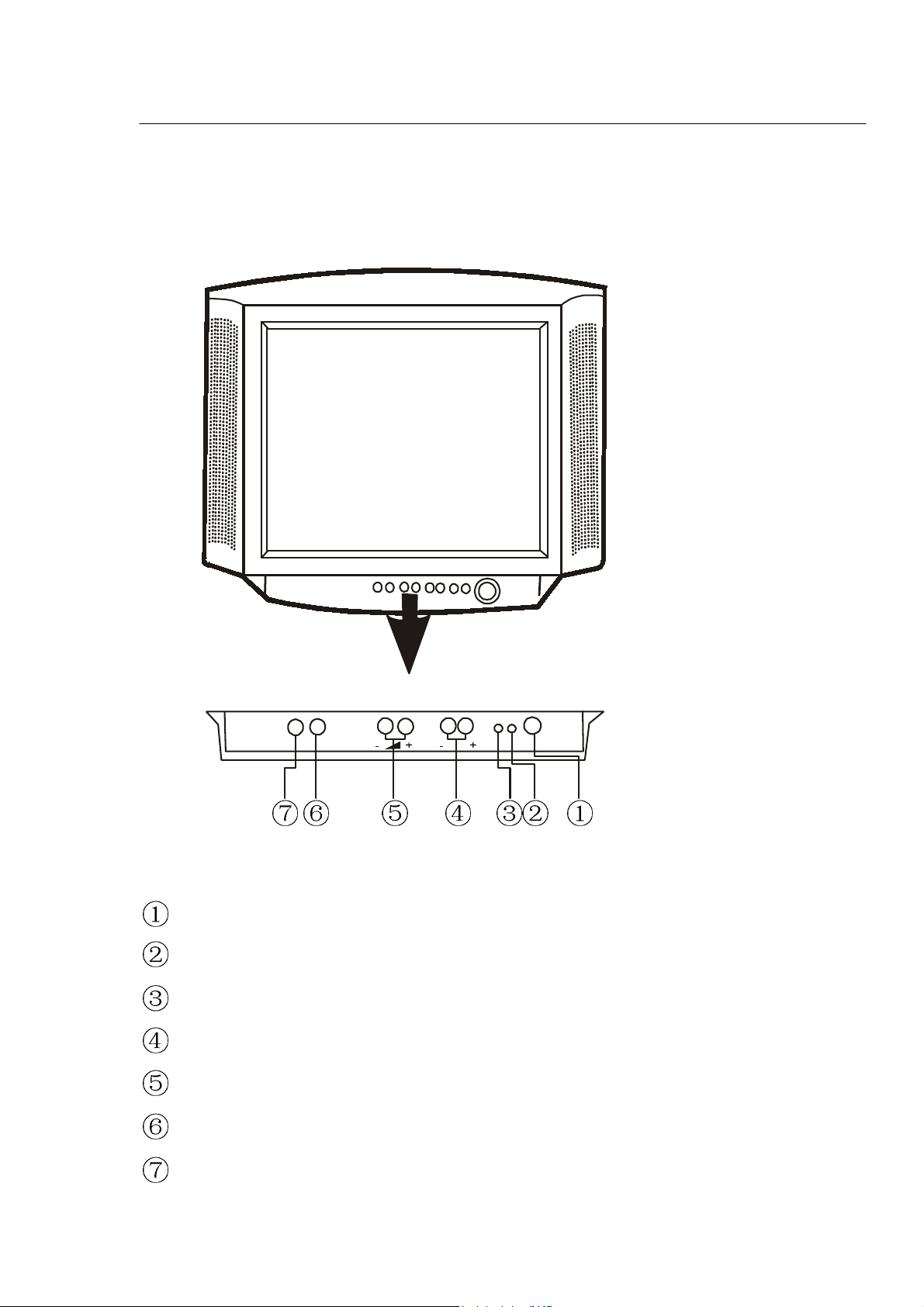

Parts and Functions

7.

Parts and Functions

V

/

A

V

T

M

E

N

U

O

P

R

Powe r switch button

Infrared sensor window

Power indicator

Pro

ramme u p/down button

Volume up/down button

TV/AV alternatin

button

Menu display but ton

12

Page 14

Parts and Functions

The sockets on the back cover

Aerial socket

Video input socket

Audio input (L) socket

Audio input (R) socket

S-Video input socket

Video output socket

Audio output (L) socket

Audio output (R) socket

S-VIDEO

RL

AV-OUT

AV-IN

VIDEOAUDIO

13

Page 15

Remote Controller Functions

Remote Controller Functions

8.

Remote Controller

1 4

Page 16

Program Diagram

9.Program Diagram

Insert the power plug into the power line socket and insert the antenna plug into the antenna socket

on the rear panel. Press down the power switch of the TV set. The red indicator light goes on. If no

picture appears, press the button on the remote controller. Follow the steps below.

A Program preset

1) Auto searching and storing program

Press MENU button on the remote controller then use the “ “ key to call up the “tune

program” menu on the screen. Then Press the menu” “ item to select it.Use the “ ” key

to select the bar “auto search program” then press the “ ” to make sure. If you want to

stop ,press the key “ ”.

2) Manual search and fine tune

Press MENU button then use the “ “ key to call up the “tune program” menu on the screen.

Then Press the menu” “ item to select it.Use the “ ” key to select the bar “Manual search

program” then press the “ ” to make sure.

3) Deleting channel number

Press Program up/down buttons to select a channel to skip. Press MENU to call Menu. then

use the “ “ key to call up the “tune program” menu on the screen. Then Press the menu”

“ item to select it.Use the “ ” key to select the bar “Cannal number” then press the “ ” to

make sure. Enter the number that you do not want to see .Then Then select “SKIP” and select

SKIP to ON. Now the program number is deleted. Repeat the above steps and select SKIP to

OFF, the deleted program number can be resumed.

B Volume tuning

Press VOLUME buttons - to increase and + to decrease the volume.

C Personal preference settings

Picture modes

Press SELC PICTURE repeatedly to change among MEMORY 1, MEMORY2,MEMORY3,to chang

the Picture Mode.

15

Page 17

Maintenance Service and Trouble shooting

10.Maintenance Service and Trouble shooting

1.Factory adjustment information

Operation method: after the appliance is switched on, make the volume value to zero. Then

press “ V- ” key on the TV set and press the DISP button on remote controller at the same time

to enter the S state. Press DISP button one times and “S” will disappear, Repeat the first step,

you will enter the D mode. Now one “D” is displayed on the TV screen.

Press PRO- and PRO+ buttons to select items for adjustment.

Press VOL- and VOL+ buttons to adjust selected items.

Press the POWER button to switch off the appliance and go back to the normal state.

Maintenance menu (Table 8)

Item Specifications Default Value

RCUT RED CUT OFF BALANCE 20 *

GCUT GREEN CUT OFF BALANCE 20 *

BCUT BLUE CUT OFF BALANCE 20 *

GDRV GREEN DRIVE BALANCE 40 *

BDRV BLUE DRIVE BALANCE 40 *

CNTX CONTRAST MAX VALUE 7F

BRTC BRIGHTNESS 48

COLC NTSC COLOUR CENTER VALUE 2E

TNTC TINT CENTER VALUE 48

COLP PAL COLOUR CENTER VALUE 20

COLS SECAM COLOUR CENTER VALUE 40

SCOL SUB SCOL TRAST 07

SCNT SUB CONTRAST 0E

CNTC SUB CONTRAST CENTER VALUE 50

CNTN SUB CONTRAST MIN VALUE 08

BRTX SUB BRIGHTNESS MAX VALUE 35

BRTN SUB BRIGHTNESS MIN VALUE 35

COLX SUB COLOUR MAX VALUE 3F

COLN SUB COLOUR MIN VALUE 00

TNTX SUB TINT MAX VALUE 28

TNTN SUB TINT MIN VALUE 28

ST3 TV-3.58 SHARPNESS 25

SV3 AV-3.58 SHARPNESS 25

ST4 TV-4.43 SHARPNESS 25

SV4 AV-4.43 SHARPNESS 25

ASSH 07

SHPX SHARPNESS MAX VALUE 38

SHPN SHARPNESS MIN VALUE 15

TXCX OSD CONTRAST MAX VALUE 1F

RGCN OSD CONTRAST MIN VALUE 1F

ABL ABL 37

DCBS 33

CLTO 0B

CLTM 4B

CLVO 4B

CLVD VCD DATUM0 4B

DEF VCD DATUM1 01

AKB 00

Variable

Mark

16

Page 18

Maintenance Service and Trouble shooting

Item

SECD 08

HPOS 50Hz HORIZONTAL POSITION 0F *

VP50

HIT 50Hz VERTICAL HEIGHT 27 *

HPS 50/60Hz HORIZONTAL POSITION 05 *

VP60 60Hz VERTICAL POSITION 00 *

HITS 50/60Hz VERTICAL HEIGHT 01 *

VLIN 50Hz VERTICAL LINEAR CORRECTION 08

VSC VERTICAL S CORRECTION 04

VLIS 50/60Hz VERTICAL LINEAR CORRECTION 00

VSS 00

DPC 50Hz PINCUSHION CORRECTION 00

DPCS 50/60Hz PINCUSHION CORRECTION 00

KEY 50Hz TRAPEZIUM CORRECTION 00

KEYS 50/60Hz TRAPEZIUM CORRECTION 00

WID 50Hz HORIZONTAL WIDTH 00

WIDS 50/60Hz HORIZONTAL WIDTH 00

VCP VERTICAL COMPENSATION 00

CNR CONNER CORRECTION 00

HCP HORIZONTAL COMPENSATION 00

SBY SECAM B-Y 08

SRY SECAM R-Y 08

RAGC RADIO FREQUENCY AGC 23

AFT AUTO FREQUENCY TRACE 15

HAFC HORIZONTAL AUTO FREQUENCY CONTROL 00

V25 25 PERCENT OF VOLUME 25

V50 50 PERCENT OF VOLUME 50

BRTS SUB BRIGHTNESS 00

VM2 SYS 24

MOD0 MODE0 41

MOD1 MODE1 17

MOD2 MODE2 DC

NO SIGNAL LEFT NO SIGNAL LEFT

NO SIGNAL RIGHT NO SIGNAL RIGHT

NO SIGNAL DTOP NO SIGNAL DTOP

NOSIGNAL DBOTTOM NO SIGNAL DBOTTOM

WAIT TIME WAIT TIME 48 *

SELF ROM DATA CHECK SELF 00

SELF VOC VCO CHECK SELF 80

SELF AGC AGC CHECK SELF 80

SELF BRTC BRIGHTNESS CENTER VALUE CHECK SELF 75

SELF CNTC CONTRAST CENTER VALUE CHECK SELF 23

SELF TNTC TINT CENTER VALUE CHECK SELF 00

SELF COL COLOUR CENTER VALUE CHECK SELF 20

OSD OSD POSITION 07

OPT OPTION 07

You can change the DATA with “*” mark when necessary.

Specifications

50Hz VERTICAL POSITION

17

Default Value

02

04 *

70 *

* *

* *

Variable

Mark

*

*

*

*

Page 19

N

N

n

r

N

Maintenance Service and Trouble shooting

ormal

Check D902 V902

and V901

1.

o raster and no sound

Check the fuse

Normal

Check VD503∼VD506 V513 C507

Normal

Check if the connector electrode

Normal

Check 12V

9V 5V

Abnormal

Check V552 or CPU

POWER control

circuit

Abnormal

There is breakdown i

horizontal circuit and N201

Abnormal

Check if all loading resistors are normal

ormal

Check switch

circuit

Normal

Replace the

rectifier diodes

powe

Abnormal

Abnormal

Check if rectifier diodes

breakdown

Abnormal

Loading has

breakdown

18

Page 20

Maintenance Service and Trouble shooting

N

n

b

d

t

r

r

f

t

d

r

t

r

Norma

N

r

b

2.

Check heater voltage

Normal

Check all

voltages of pins

at X602

ormal

No raster

Check if G2 voltage on CRT board is normal

l

Check the base electrode voltage of V444

Abnormal

ormal

The heate

resister is

broken.

Abnormal

Check the voltage betwec

ace electrode an

connector electrode of v411

Abnorma

Abnormal

Check the circui

between pin 32 at N210

and H drive grade

There is

breakdown in

CRT broad

Check the connecto

electrode voltage o

V411

V411 is rosin joint o

roken

Normal

Check circuit

between pin18

pin20 in N201

Lower

Ye s

Check if FBT T402

V411or C415 C416 are

leakage of electricity

There is breakdown in horizontal

drive grade, Check V444 T401

R437

Check if pin 28

voltage 9V a

N201 is normal

Rechange ba

components o

remedy conten

circuit.

Abnormal

Abnormal

Check the horizontal oscillation external

circuit of Z280 N201 and N201

Check 9V powe

19

Page 21

k

r

f

t

f

d

r

Maintenance Service and Trouble shootin

g

3.

Horizontal bright line

Break R908 , let multimeter preset on R 1K and red meter rod grounding, let blac

meter rod tap pin 4 at N402.see if the bright line can wide at instant.

YES

Check if R907 R448 are

There is breakdown in the vertical outpu

rosin joint and the resisto

value of R448 changes

larger.

YES

NO

grate.

YES

Check if the connector o

the deflection yoke is

Normal

Check the

external circuit o

N201 and N201.

connected well,and C433is

rosin joint or cutoff, and the

external circuit of N402 an

N402.

NO

Check 26V powe

circuit.

20

Page 22

d

f

n

Maintenance Service and Trouble shooting

4.

Picture OK, no sound

Break C700,let red meter rod ground and let black meter rod tap pin6 at N701,

the speakers has snapping.

Ye s

If power amplifier is normal ,

check N201 sound IF circuit an

N201.

Ye s

There is breakdown in sound mute

circuit, check V701, V903

Ye s

Check sound power amplifier N701

No

Break the connector electrode o

V701, let the black meter rod tap pi

6 at N701 , see if the speakers have

snapping.

No

Check if there is 19V voltage

No

Check 19V power circuit.

and

circuit , speaker.

21

Page 23

d

t

n

,

r

N

N

d

p

N

Maintenance Service and Trouble shooting

5.

NO YES

Check RAGC item of IC bus is

“

”

YES

Use the remote controller an

enter S-MODE and adjus

RAGC to near 2D

RASTER OK, NO PICTURE, NO SOUND

Whether there are noise dots?

Whether there are voltages i

every pin of tuner

O

Check picture IF channel

and V231

V212, N201

YES

Aerial system or tune

breaks down.

NO

Check the circuit between

CPU and tuner.

6.

YES

Replace V622 or joint.

O red

Check if V622 is rosin joint or break?

YES

Check V621, R621

Check the circuit between pin 18 at N201 an

in 3 at XS261

NO

Check the voltage of pin 1 at XS602

O

22

Page 24

n

Maintenance Service and Trouble shooting

7.

Check L902,C926,C925

Normal

Replace the

compartments

Abnormal

No

There is black words?

Check the circuit between pin 22pin 24

Check the circuit betwee

V922,R915,C450 and pin 5 at FBT.

23

Page 25

11

Ci

Di

.Circuit Diagram

rcuit

agram

24

Page 26

n

Circuit Block Diagram

Circuit Block Diagram

CPU

Infrared sensor

SAW

Remote co

IF.video color RGB

H.V oscillation sca

signal prossing

EPROM

AV i nput/output

Sound power amf.

CRT

H output

V output

SIF band

pass filter

unit

volume control

AU.OUT

SIF trap

unit

EXT.C.INEXT.A.IN

.

scan unit

V.OUT

IF INIF IN

H.OUT

6dB

EXT.Y.IN

6dB

Color subcarry

trap circuit

Video unit

matrix unit

band-pass/ high

-pass filter

Color unit

23

25

Page 27

26

Page 28

l

Circuit Explanation

Circuit Explanation

12.

IC function pins

1) Integrated circuits used in this model

1) TBA1238AN: picture intermediate amplification, sound intermediate amplification, video signal

processing, chrominance signal processing, RGB output circuit, horizontal and field oscillating scan

circuit.

2) TMP87CK38N: super central micro-processing unit.

3) LA7830 (LA7833): field scan circuit

4) LA4275: sound power amplifier circuit

5) LA7910: wave band change-over switch

2) IC functions and parameters

N402 LA7830 (LA7833)

No. Function Reference

1 Grounding 0 0 0

2 Output 14 0.45 1.6

3 Pump power supply output 24(26) 0.5

4 Field scanning sawtooth signal input 0.9 0.9 1

5 Field scanning sawtooth signal

forming terminal

6 Field power supply 24(26) 0.5 4.5

7 Field power supply input 1.9 0.72 30

N701 LA4275

Item Function Reference

1 Grounding 0 0 0

2 Power amplifier output 10 0.55 4.5

3 Power supply 20 0.42 2.8

4 Ripple wave filtering 10 1.2 2.4

5 Grounding 0 0 0

6 Audio Input 0.7 1.1

7 Feedback 0.2 0.72 2.0

Reference Resistance(KΩ )

Voltage(V)

0.8 0.65 1.4

Voltage(V)

27

Forward Backward

∞

Reference Resistance(KΩ )

Forward Backward

∞

Page 29

Circuit Explanation

l

N201 TB1238AN

Pin Function

1 Unweighted 5.0 5.0 800 2000

2 Audio signal output 3.5 3.5 750 2000

3 PIF circuit power supply 9.0 9.0 460 600

4 AFT output and auto-adjusting 2.1 2.1 750 600

5 PIF circuit grounding 0 0 0 0

6 IF signal input pin 2.0 2.0 680 2000

7 IF signal input pin 2.0 2.0 680 2000

8 RF AGC output 6.6 4.0 680 2000

9 IF AGC filtering 5.2 4.1 760 2000

10

Color demodulation APC filtering

11 4.43MHz crystal oscillator 3.5 3.5 820 3000

12 Y/C circuit grounding 0 0 0 0

13 Analog RGB and AKB mode

alternating

14 Analog R signal input 2.7 2.7 800 3000

15 Analog G signal input 2.7 2.7 800 3000

16 Analog B signal input 2.7 2.7 800 3000

17 RGB(image and message

circuit) power supply

18 R signal output 3.0 3.0 760 1500

19 G signal output 3.0 3.0 760 1500

20 B signal output 3.0 3.0 720 1400

21 ABCL control pin 5.6 5.6 820 2000

22 Field sawtooth wave forming 4.1 4.1 750 2000

23 Field feedback signal 5.0 5.0 820 2000

24 Field driving signal output 0.9 0.9 720 900

25 Field AGC 1.8 1.8 800 2000

26 Bus clock signal 5.0 5.0 720 15000

27 Bus data signal 5.0 5.0 720 15000

28 Deflection circuit power supply 9.0 9.0 450 600

29

PAL/NTSC identification signal

output

SECAM identification signal input

30 Line feedback pulse input 0.6 0.6 780 2000

31 Composite synchronizing pulse

signal output

32 Line driving signal 2.7 2.7 640 680

33

Deflection circuit grounding pin

34 Sandcastle pulse input 1.5 1.5 820 2000

35 Video switching signal output 3.1 3.1 750 1200

36 Digital circuit power supply 5.0 5.0 470 800

Reference Voltage(V)

Without

With signal

Reference Resistance(KΩ )

Forward(Ω) Backward(Ω)

signal

2.4 2.4 750 3000

0 0 720 650

9.0 9.0 450 600

1.5 1.5 800 2000

4.5 4.5 780 2000

0 0 0 0

28

Page 30

l

Pin Function

Reference Voltage(V)

Without

With signal

Forward(Ω) Backward(Ω)

Circuit Explanation

Reference Resistance(KΩ )

signal

37 SECAM B-Y signal input 2.4 2.4 800 2000

38 SECAM R-Y signal input 2.4 2.4 800 2000

39 Y signal input 3.1 3.1 800 3600

40 Line AFC filtering 6.6 6.6 800 2000

41 External video/Y signal input 1.6 1.6 800 2000

42 Digital circuit grounding 0 0 0 0

43

PIF composite video signal input

3.3 3.3 800 2000

44 Black level detection filtering 2.3 2.3 800 4000

45

External chrominance signal input

2.9 2.9 800 2000

46 Y/C circuit power supply 5.0 5.0 500 1200

47 PIF and SIF composite signal

3.8 3.8 680 900

output

48 Intermediate frequency locked

4.7 4.7 800 2000

phase loop filtering

49 VCO and SIF grounding 0 0 0 0

50 Intermediate frequency VCO 8.1 8.1 550 1000

51 Intermediate frequency VCO 8.1 8.1 650 1000

52 VCO and SIF power supply 9.0 9.0 450 600

53 SIF signal input and horizontal

4.5 4.5 820 2000

curve correction

54 SIF smooth filtering 5.6 5.6 800 1300

55 External audio input 4.2 4.2 800 2000

56 FM DC negative feedback 3.5 3.5 800 2000

N901 TMP87CK38N(87CM38N)

Reference Voltage(V) Reference Resistance Pin Function

Without

signal

With

signal

Forward(Ω) Backward(Ω)

1 Power supply grounding 0 0 0 0

2 Tuning voltage output * * 700 8000

3 Vacant pin 5.0 5.0 700 8000

4 Mute 5.0 0 700 8000

5 External mute 5.0 0 700 8000

6 Vacant pin 0 0 700 8000

7 Standby power supply 2.0 2.0 700 8000

8 Vacant pin 1~4.2 1~4.2 700 8000

9 Band 1 0~4.8 0~4.8 700 3500

10 Band 2 0~1.7 0~1.7 700 3000

11 Clock bus control 5.0 5.0 700 15000

12 Digit bus control 5.0 5.0 600 15000

13 AFC input 2.3 2.3 700 3000

14 Karaoke switch 0 0 600 10000

15 Keyboard matrix input 4.0 4.0 700 10000

29

Page 31

p

l

Circuit Ex

lanation

Reference Voltage(V) Reference Resistance Pin Function

Without

signal

With

signal

Forward(Ω) Backward(Ω)

16 Keyboard matrix input 4.0 4.0 680 10000

17 Vacant pin 0 0 700 10000

18 Vacant pin 0 0 700 10000

19 Vacant pin 0 0 620 10000

20 Vacant pin 0 0 620 10000

21 Grounding 0 0 0 0

22 Red primary color character

0 0 620 2200

output

30

Page 32

l

Circuit Explanation

Reference Voltage(V) Reference Resistance Pin Function

23 Green primary color

Without

signal

0 0 620 2200

With

signal

Forward(Ω) Backward(Ω)

character output

24 Blue primary color

0 0 620 2200

character output

25 Character blanking 0 0 620 2200

26 Line flyback 4.0 4.0 680 10000

27 Field flyback 4.8 4.8 680 10000

28 Character oscillating 5.0 5.0 600 10000

29 Character oscillating 5.0 5.0 0 10000

30 Grounding 0 0 0 0

31 CPU clock 2.1 2.1 700 10000

32 CPU clock 2.1 2.1 700 10000

33 CPU reset 5.0 5.0 650 40000

34 Vacant pin 5.0 5.0 700 10000

35 Infrared receiving input 5.0 5.0 700 10000

36 Line synchronizing signal

4.7 4.7 700 10000

input

37 Clock bus control 2.9 2.9 700 10000

38 Data bus control 3.2 3.2 700 10000

39 Vacant pin 0 0 700 10000

40 Vacant pin 4.6 4.6 700 10000

41 Vacant pin 0 0 700 10000

42 Power supply 5.0 5.0 420 2700

N101 LA7910

Pin Function

Reference

Voltage(V)

Reference Resistance

Without signal Forward(KΩ) Backward(KΩ)

1 Output (BU) 1.7 120 7.2

2 Output (BH) 12.6 17.5 7.5

3 Control input 4.8 6.5 8.5

4 Control input 0 6.5 9.0

5 Grounding terminal 0 0 0

6 Power input terminal 1 14.0 6.0 50

7 Output (BL) 0 1.5 1.5

8 Vacant pin 0 8.5

9 Power input terminal 2 12 0.5 0.5

31

Page 33

j

l

13.

Adjustment

The chassis of this TV set uses Toshiba IC with the latest digital bus processing technology.

The adjustment points are fewer and the adjustment is simpler. The adjustment method is as

follows:

1) +B: 109±0.3V adjustment.

A) Switch on the power and connect PAL circular signals to the tuner.

B) Adjust variable resistor RP501 until the voltage of the main power is 109±0.3V.

2) Screen voltage adjustment.

A) Switch on the power and receive PAL system circular signal. Warm up the TV set for 15

min.

B) Enter the adjustment D state. Press the “-/--” button, then a bright horizontal line appears.

Adjust screen potentiometer to let the horizontal line just appears.

Ad

ustment

3) Focus adjustment.

A) Receive electronic circular signal.

B) Set picture mode on standard mode.

C) Adjust focus potentiometer until the optimum picture is achieved.

4) White balance adjustment.

A) Set the picture mode on standard mode.

B) Enter the Factory state and adjust WPR, WPG, WPB, RED and GRN.

C) Coordinate of reference white color: (X=0.281, Y=0.311).

5) Adjustment of horizontal and vertical position and size.

A) Switch on the power and connect the signals to the tuner to receive PAL/NTSC system

circular signal.

B) Enter the Factory state. Adjust 5HSH to change the horizontal position and 5VAM to

change the vertical position. Adjust 5VSH to change the vertical size until the vertical size

is 90-92%. Horizontal size is related to the capacitor C906. Hold the horizontal size is

90-92%.

6) Adjustment of character positions

Adjust OSD for the horizontal positions of the screen menu.

32

Page 34

Exploded View

14.

Exploded View

HT-2180 EXPLODED VIEW

HT-2180 PARTS LIST

Serial Number Name Part Code Specification Quantity

1 FRONT MASK 0090200309 MTAA5013AA--- 1

2 SPEAKER 0094000221 YDT613-4W-16 2

3 SCREW 0090600023 SJ2824-87 ST4*16F 8

4 RUBBER WASHER 0090200076 1mm 4

5 CRT 0094004661 54SX503Y22-DC01 1

6 DEGAUSSING COIL CLIP 0090800171 BJZ0001------ 4

7 COMBINED NUT 0090600069 M6 4

8 CRT GROUND AS. 0090400232 JE221-02-4--- 1

9 DEGAUSSING COIL 0094500875 HXC-54 1

10 MAIN -BOARD 0094002328 BXA5096---J-- 1

11 BRACKET 0090200419 MTAC5002AC--- 1

12 SCREW 0090600075 SJ2825-87 ST3*10F 4

13 BACK COVER 0090200262 MTAA0097AC--- 1

14 SCREW 0090600014 SJ2824-87 ST4*20F 8

15 LABEL 0090202207 MTFB5223CA--- 1

16 BLOCK 0090201452 MTAH5010AA--- 1

33

Page 35

l

List of Parts

15.

List of Parts

Location

0090300076 Rubber washer 1mm φ6.5 4

0090800171 Degaussing coil tie BJZ0001-----Q 4

0090100122 Washer 1MM φ8.5 4

0090501291 plastic bag 240*160 1

0090600069 combined nut M6 (98025) 4

0094000222 CRT 54SX503Y22-DC01 1

W1002 0090400240 Wire JG4401-610--Q 1

W1004 0090400238 Wire JT2481-B0035Q 1

W1005 0090400362 Wire JA2811-B----Q 1

0094500443 Degaussing coil HXC-54 1

0090400194 CRT grounding assembly JE221-02-4--Q 1

0090202267 Back label MTFB5235CA--Q 1

0090600020 Screw SJ2825-87 ST3*12F 2

0090600014 Screw SJ2824-87 ST4*20F 8

0090200480 Mains-cord hoke MTAJ5002AG--Q 1

0090200247 Clamp TMMOA101 1

0090801724 Front mask assembly BJK5044-----Q 1

0090202269 Front mask MTAA5075AC--Q 1

0090600023 Screw SJ2824-87 ST4*16F 8

0090600034 Screw SJ2824-87 ST3*12F 5

0094000221 speaker YDT613-4W-16Ω 2

0090801684 Back cover assembly BJH5033-----Q 1

0090200262 Back cover MTAA0097AC--Q 1

0090200264 PVC cover MTAH0057AJ--Q 1

0090300079 Cloth 15*200 2

0090300080 Cloth 15*320 2

0090200265 Mains cord clamp MTAJ0015AG--Q 1

0090500102 Plastic cover 21" 1

0090501814 Carton MTED5181CA--Q 1

0090500189 Top pad MTEE0073AK--Q 1

0090500190 Bottom pad MTEE0074AK--Q 1

0090100165 Staple 65*2 8

0090500094 Accessory poke 270*180 1

0090501815 Operating instructions MTDB5330CA--Q 1

0094000299 battery 5# 2

0094000809 Remote controller HYF-30A 1

0091800099 PCB PX10086A----Q 1

0091800100 PCB PX10087A----Q 1

R444 0094101020 Resister RT13-1/6W-4.7Ω±5%------T 1

R704 0094101020 Resister RT13-1/6W-4.7Ω±5%------T 1

R279 0094100797 Resister RT13-1/6W-33Ω±5%------T 1

R602 0094100797 Resister RT13-1/6W-33Ω±5%------T 1

R612 0094100797 Resister RT13-1/6W-33Ω±5%------T 1

R622 0094100797 Resister RT13-1/6W-33Ω±5%------T 1

R218 0094100805 Resister RT13-1/6W-68Ω±5%------T 1

R106 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R201 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R203 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

Naterial Code parts Name Type Q'ty(Unit) Remark

34

Page 36

List of Parts

l

Location

R207 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R216 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R217 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R219 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R221 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R232 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R236 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R238 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R702 0094100017 Resister RT13-1/6W-100Ω±5%------T 1

R111 0094100802 Resister RT13-1/6W-150Ω±5%------T 1

R404 0094100802 Resister RT13-1/6W-150Ω±5%------T 1

R107 0094100019 Resister RT13-1/6W-220Ω±5%------T 1

R234 0094100019 Resister RT13-1/6W-220Ω±5%------T 1

R215 0094100795 Resister RT13-1/6W-270Ω±5%------T 1

R264 0094100795 Resister RT13-1/6W-270Ω±5%------T 1

R265 0094100795 Resister RT13-1/6W-270Ω±5%------T 1

R271 0094100795 Resister RT13-1/6W-270Ω±5%------T 1

R272 0094100795 Resister RT13-1/6W-270Ω±5%------T 1

R273 0094100795 Resister RT13-1/6W-270Ω±5%------T 1

R604 0094100020 Resister RT13-1/6W-470Ω±5%------T 1

R614 0094100020 Resister RT13-1/6W-470Ω±5%------T 1

R624 0094100020 Resister RT13-1/6W-470Ω±5%------T 1

R243 0094100021 Resister RT13-1/6W-560Ω±5%------T 1

R244 0094100021 Resister RT13-1/6W-560Ω±5%------T 1

R403 0094100021 Resister RT13-1/6W-560Ω±5%------T 1

R601 0094100021 Resister RT13-1/6W-560Ω±5%------T 1

R611 0094100021 Resister RT13-1/6W-560Ω±5%------T 1

R621 0094100021 Resister RT13-1/6W-560Ω±5%------T 1

R703 0094100021 Resister RT13-1/6W-560Ω±5%------T 1

R937 0094100021 Resister RT13-1/6W-560Ω±5%------T 1

R115 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R206 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R233 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R235 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R251 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R252 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R423 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R635 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R907 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R908 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R912 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R945 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R957 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R958 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R973 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R979 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R985 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R986 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R987 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

R988 0094100023 Resister RT13-1/6W-1KΩ±5%------T 1

Naterial Code parts Name Type Q'ty(Unit) Remark

35

Page 37

List of Parts

l

Location

R517 0094100753 Resister RT13-1/6W-1.2KΩ±5%------T 1

R603 0094100753 Resister RT13-1/6W-1.2KΩ±5%------T 1

R613 0094100753 Resister RT13-1/6W-1.2KΩ±5%------T 1

R623 0094100753 Resister RT13-1/6W-1.2KΩ±5%------T 1

R633 0094100753 Resister RT13-1/6W-1.2KΩ±5%------T 1

R211 0094100025 Resister RT13-1/6W-1.5kΩ±5%------T 1

R274 0094100025 Resister RT13-1/6W-1.5kΩ±5%------T 1

R275 0094100025 Resister RT13-1/6W-1.5kΩ±5%------T 1

R276 0094100025 Resister RT13-1/6W-1.5kΩ±5%------T 1

R277 0094100025 Resister RT13-1/6W-1.5kΩ±5%------T 1

R932 0094100025 Resister RT13-1/6W-1.5kΩ±5%------T 1

R934 0094100025 Resister RT13-1/6W-1.5kΩ±5%------T 1

W913 0094100025 Resister RT13-1/6W-1.5kΩ±5%------T 1

W914 0094100025 Resister RT13-1/6W-1.5kΩ±5%------T 1

R523 0094100026 Resister RT13-1/6W-2.2KΩ±5%------T 1

R637 0094100026 Resister RT13-1/6W-2.2KΩ±5%------T 1

R559 0094100028 Resister RT13-1/6W-3.3KΩ±5%------T 1

R925 0094100028 Resister RT13-1/6W-3.3KΩ±5%------T 1

R108 0094100029 Resister RT13-1/6W-4.7KΩ±5%------T 1

R202 0094100029 Resister RT13-1/6W-4.7KΩ±5%------T 1

R639 0094100029 Resister RT13-1/6W-4.7KΩ±5%------T 1

R922 0094100029 Resister RT13-1/6W-4.7KΩ±5%------T 1

R938 0094100029 Resister RT13-1/6W-4.7KΩ±5%------T 1

R989 0094100029 Resister RT13-1/6W-4.7KΩ±5%------T 1

R213 0094100721 Resister RT13-1/6W-5.6KΩ±5%------T 1

R263 0094100721 Resister RT13-1/6W-5.6KΩ±5%------T 1

R511 0094100721 Resister RT13-1/6W-5.6KΩ±5%------T 1

R905 0094100721 Resister RT13-1/6W-5.6KΩ±5%------T 1

R906 0094100721 Resister RT13-1/6W-5.6KΩ±5%------T 1

R253 0094100031 Resister RT13-1/6W-6.8KΩ±5%------T 1

R933 0094100031 Resister RT13-1/6W-6.8KΩ±5%------T 1

R208 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R214 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R258 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R292 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R293 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R562 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R705 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R902 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R917 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R926 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R927 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R931 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R935 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R951 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R952 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R955 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R956 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R976 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R977 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

Naterial Code parts Name Type Q'ty(Unit) Remark

36

Page 38

List of Parts

l

Location

R991 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R992 0094100033 Resister RT13-1/6W-10KΩ±5%------T 1

R102 0094100034 Resister RT13-1/6W-15KΩ±5%------T 1

R212 0094100034 Resister RT13-1/6W-15KΩ±5%------T 1

R294 0094100034 Resister RT13-1/6W-15KΩ±5%------T 1

R634 0094100034 Resister RT13-1/6W-15KΩ±5%------T 1

R929 0094100034 Resister RT13-1/6W-15KΩ±5%------T 1

R515 0094100779 Resister RT13-1/6W-22kΩ±5%------T 1

R551 0094100779 Resister RT13-1/6W-22kΩ±5%------T 1

R940 0094100779 Resister RT13-1/6W-22kΩ±5%------T 1

R967 0094100779 Resister RT13-1/6W-22kΩ±5%------T 1

R968 0094100779 Resister RT13-1/6W-22kΩ±5%------T 1

R969 0094100779 Resister RT13-1/6W-22kΩ±5%------T 1

R990 0094100779 Resister RT13-1/6W-22kΩ±5%------T 1

R260 0094100036 Resister RT13-1/6W-33kΩ±5%------T 1

R278 0094100036 Resister RT13-1/6W-33kΩ±5%------T 1

R447 0094100036 Resister RT13-1/6W-33kΩ±5%------T 1

R914 0094100036 Resister RT13-1/6W-33kΩ±5%------T 1

R960 0094100036 Resister RT13-1/6W-33kΩ±5%------T 1

R965 0094100036 Resister RT13-1/6W-33kΩ±5%------T 1

R974 0094100036 Resister RT13-1/6W-33kΩ±5%------T 1

R975 0094100036 Resister RT13-1/6W-33kΩ±5%------T 1

R103 0094100800 Resister RT13-1/6W-47kΩ±5%------T 1

R104 0094100800 Resister RT13-1/6W-47kΩ±5%------T 1

R256 0094100800 Resister RT13-1/6W-47kΩ±5%------T 1

R900 0094100800 Resister RT13-1/6W-47kΩ±5%------T 1

R930 0094100800 Resister RT13-1/6W-47kΩ±5%------T 1

R970 0094100800 Resister RT13-1/6W-47kΩ±5%------T 1

R981 0094100800 Resister RT13-1/6W-47kΩ±5%------T 1

R446 0094100038 Resister RT13-1/6W-56KΩ±5%------T 1

R448 0094100038 Resister RT13-1/6W-56KΩ±5%------T 1

R105 0094100039 Resister RT13-1/6W-68KΩ±5%------T 1

R443 0094101024 Resister RT13-1/6W-120KΩ±5%------T 1

R204 0094100077 Resister RT13-1/6W-100KΩ±5%------T 1

R205 0094100077 Resister RT13-1/6W-100KΩ±5%------T 1

R101 0094100917 Resister RT13-1/6W-220KΩ±5%------T 1

R262 0094100944 Resister RT13-1/6W-390KΩ±5%------T 1

R237 0094100732 Resister RT13-1/6W-820KΩ±5%------T 1

R632 0094100946 Resister RT14-1/4W-33Ω±5%------T 1

R638 0094100946 Resister RT14-1/4W-33Ω±5%------T 1

R519 0094100946 Resister RT14-1/4W-33Ω±5%------T 1

R261 0094100990 Resister RT14-1/4W-220Ω±5%------T 1

R901 0094100991 Resister RT14-1/4W-470Ω±5%------T 1

R903 0094100991 Resister RT14-1/4W-470Ω±5%------T 1

R944 0094101288 Resister RT14-1/4W-680Ω±5%------T 1

R255 0094100992 Resister RT14-1/4W-2.2KΩ±5%------T 1

R441 0094100992 Resister RT14-1/4W-2.2KΩ±5%------T 1

R526 0094101092 Resister RT14-1/4W-2.7KΩ±5%------T 1

R557 0094100993 Resister RT14-1/4W-4.7KΩ±5%------T 1

R424 0094100994 Resister RT14-1/4W-15kΩ±5%------T 1

Naterial Code parts Name Type Q'ty(Unit) Remark

37

Page 39

List of Parts

l

Location

R522 0094100994 Resister RT14-1/4W-15kΩ±5%------T 1

R566 0094100996 Resister RT14-1/4W-100KΩ±5%------T 1

R554 0094100997 Resister RT14-1/4W-150KΩ±5%------T 1

R442 0094100999 Resister RT15-1/2W-330Ω±5%------T 1

R407 0094101000 Resister RT15-1/2W-1KΩ±5%------T 1

R451 0094101001 Resister RT15-1/2W-2.7KΩ±5%------T 1

R560 0094101002 Resister RT15-1/2W-3.3KΩ±5%------T 1

R462 0094101003 Resister RT15-1/2W-6.8KΩ±5%------T 1

R552 0094100954 Resister RT15-1/2W-47KΩ±5%------T 1

R555 0094100954 Resister RT15-1/2W-47KΩ±5%------T 1

R556 0094100954 Resister RT15-1/2W-47KΩ±5%------T 1

R415 0094100956 Resister RT15-1/2W-220KΩ±5%------T 1

R501 0094100956 Resister RT15-1/2W-220KΩ±5%------T 1

R561 0094100956 Resister RT15-1/2W-220KΩ±5%------T 1

R605 0094101005 Resister RS11-1/2W-3.3KΩ±10%------T 1

R615 0094101005 Resister RS11-1/2W-3.3KΩ±10%------T 1

R625 0094101005 Resister RS11-1/2W-3.3KΩ±10%------T 1

R520 0094101301 Resister RS11-1/2W-100KΩ±10%------T 1

R521 0094101301 Resister RS11-1/2W-100KΩ±10%------T 1

R531 0094101090 Resister RS11-1/2W-12MΩ±20%------T 1

R532 0094101090 Resister RS11-1/2W-12MΩ±20%------T 1

C926 0094201349 Capacitor CC1-05-RH-63V-22pF-J------F 1

C214 0094201088 Capacitor CC1-08-CH-63V-100pF-J------F 1

C232 0094201088 Capacitor CC1-08-CH-63V-100pF-J------F 1

C236 0094201088 Capacitor CC1-08-CH-63V-100pF-J------F 1

C257 0094201088 Capacitor CC1-08-CH-63V-100pF-J------F 1

C951 0094200979 Capacitor CT1-05-2B4-63V-220pF-K------F 1

C952 0094200979 Capacitor CT1-05-2B4-63V-220pF-K------F 1

C953 0094200979 Capacitor CT1-05-2B4-63V-220pF-K------F 1

C954 0094200979 Capacitor CT1-05-2B4-63V-220pF-K------F 1

C971 0094200979 Capacitor CT1-05-2B4-63V-220pF-K------F 1

C972 0094200979 Capacitor CT1-05-2B4-63V-220pF-K------F 1

C974 0094200979 Capacitor CT1-05-2B4-63V-220pF-K------F 1

C601 0094200977 Capacitor CT1-05-2B4-63V-390PF-K------F 1

C611 0094200977 Capacitor CT1-05-2B4-63V-390PF-K------F 1

C621 0094200977 Capacitor CT1-05-2B4-63V-390PF-K------F 1

C201 0094200981 Capacitor CT1-06-2B4-63V-1000pF-K------F 1

C446 0094200981 Capacitor CT1-06-2B4-63V-1000pF-K------F 1

C934 0094200981 Capacitor CT1-06-2B4-63V-1000pF-K------F 1

C269 0094201038 Capacitor CT1-06-2B4-63V-1800PF-K------F 1

C447 0094201038 Capacitor CT1-06-2B4-63V-1800PF-K------F 1

C551 0094201038 Capacitor CT1-06-2B4-63V-1800PF-K------F 1

C112 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C113 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C114 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C202 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C217 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C221 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C237 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C251 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

Naterial Code parts Name Type Q'ty(Unit) Remark

38

Page 40

List of Parts

l

Location

C225 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C226 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C258 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C260 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C296 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C297 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C262 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C266 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C273 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C281 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C633 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C921 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C923 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C929 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C933 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C995 0094201040 Capacitor CT1-08-2F4-63V-0.01μF-Z------F 1

C402 0094201237 Capacitor CT1-10-2B4-500V-1000pF-K------F 1

C403 0094201238 Capacitor CT1-14-2B4-500V-3900pF-K------F 1

C450 0094201238 Capacitor CT1-14-2B4-500V-3900pF-K------F 1

C215 0094200008 Capacitor CD110-16V-10μF-M------F 1

C216 0094200008 Capacitor CD110-16V-10μF-M------F 1

C298 0094200008 Capacitor CD110-16V-10μF-M------F 1

C632 0094200008 Capacitor CD110-16V-10μF-M------F 1

C975 0094200008 Capacitor CD110-16V-10μF-M------F 1

C976 0094200008 Capacitor CD110-16V-10μF-M------F 1

C205 0094200476 Capacitor CD110X-16V-22μF-M------F 1

C206 0094200476 Capacitor CD110X-16V-22μF-M------F 1

C107 0094200469 Capacitor CD110X-16V-47μF-M------F 1

C203 0094200469 Capacitor CD110X-16V-47μF-M------F 1

C219 0094200469 Capacitor CD110X-16V-47μF-M------F 1

C259 0094200469 Capacitor CD110X-16V-47μF-M------F 1

C292 0094200469 Capacitor CD110X-16V-47μF-M------F 1

C282 0094200469 Capacitor CD110X-16V-47μF-M------F 1

C902 0094200469 Capacitor CD110X-16V-47μF-M------F 1

C904 0094200469 Capacitor CD110X-16V-47μF-M------F 1

C930 0094200469 Capacitor CD110X-16V-47μF-M------F 1

C935 0094200469 Capacitor CD110X-16V-47μF-M------F 1

C261 0094200433 Capacitor CD110X-16V-100μF-M------F 1

C263 0094200433 Capacitor CD110X-16V-100μF-M------F 1

C267 0094200433 Capacitor CD110X-16V-100μF-M------F 1

C299 0094200433 Capacitor CD110X-16V-100μF-M------F 1

C702 0094200433 Capacitor CD110X-16V-100μF-M------F 1

C901 0094200433 Capacitor CD110X-16V-100μF-M------F 1

C931 0094200433 Capacitor CD110X-16V-100μF-M------F 1

C994 0094200433 Capacitor CD110X-16V-100μF-M------F 1

C223 0094200862 Capacitor CD110X-16V-470μF-M------F 1

C272 0094201046 Capacitor CA42-25V-1μF-K------F 1

C279 0094201046 Capacitor CA42-25V-1μF-K------F 1

C222 0094201113 Capacitor CD110-25V-47μF-M------F 1

C704 0094200581 Capacitor CD110X-25V-100μF-M------F 1

Naterial Code parts Name Type Q'ty(Unit) Remark

39

Page 41

List of Parts

l

Location

C430 0094200990 Capacitor CD110-35V-47μF-M------F 1

C705 0094201243 Capacitor CD110X-35V-100μF-M------F 1

C449 0094201243 Capacitor CD110X-35V-100μF-M------F 1

C212 0094200042 Capacitor CD110-50V-0.22μF-M------F 1

C271 0094200016 Capacitor CD110-50V-0.47μF-M------F 1

C256 0094200043 Capacitor CD110-50V-1μF-M------F 1

C291 0094200043 Capacitor CD110-50V-1μF-M------F 1

C265 0094200043 Capacitor CD110-50V-1μF-M------F 1

C103 0094200992 Capacitor CD110-50V-4.7μF-M------F 1

C104 0094200992 Capacitor CD110-50V-4.7μF-M------F 1

C105 0094200992 Capacitor CD110-50V-4.7μF-M------F 1

C106 0094200992 Capacitor CD110-50V-4.7μF-M------F 1

C443 0094200992 Capacitor CD110-50V-4.7μF-M------F 1

C700 0094200992 Capacitor CD110-50V-4.7μF-M------F 1

C701 0094200992 Capacitor CD110-50V-4.7μF-M------F 1

C411 0094201045 Capacitor CD110-160V-4.7μF------F 1

C278 0094200825 Capacitor CL11-50V-2200PF-J------F 1

C204 0094201459 Capacitor CL11-63V-1000pF-J------F 1

C111 0094201427 Capacitor CL11-50V-0.012μF-K------F 1

C515 0094201427 Capacitor CL11-50V-0.012μF-K------F 1

C517 0094200998 Capacitor CL11-63V-0.022UF-K------F 1

C264 0094200998 Capacitor CL11-63V-0.022UF-K------F 1

C274 0094201093 Capacitor CL21X-50V-0.047μF-K------F 1

C275 0094201093 Capacitor CL21X-50V-0.047μF-K------F 1

C276 0094201093 Capacitor CL21X-50V-0.047μF-K------F 1

C238 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C252 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C253 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C254 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C255 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C444 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C991 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C992 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C413 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C707 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C514 0094200759 Capacitor CL21X-50V-0.1μF-J------F 1

C277 0094201463 Capacitor CL21X-63V-0.22μF-J------F 1

L232 0094500316 Inducer LGA0307-4.7μH-K------T 1

L101 0094500284 Inducer LGA0307-12μH±10%------T 1

L231 0094500284 Inducer LGA0307-12μH±10%------T 1

L261 0094500284 Inducer LGA0307-12μH±10%------T 1

L901 0094500284 Inducer LGA0307-12μH±10%------T 1

L251 0094500268 Inducer LGA0307-15μH±10%------T 1

L252 0094500268 Inducer LGA0307-15μH±10%------T 1

L902 0094500286 Inducer LGA0307-21μH±5%------T 1

VD514 0094400049 Diode 1N4148------T 1

VD516 0094400049 Diode 1N4148------T 1

VD518 0094400049 Diode 1N4148------T 1

VD601 0094400049 Diode 1N4148------T 1

VD611 0094400049 Diode 1N4148------T 1

Naterial Code parts Name Type Q'ty(Unit) Remark

40

Page 42

List of Parts

l

Location

VD621 0094400049 Diode 1N4148------T 1

VD630 0094400049 Diode 1N4148------T 1

VD631 0094400049 Diode 1N4148------T 1

VD902 0094400049 Diode 1N4148------T 1

VD904 0094400049 Diode 1N4148------T 1

VD924 0094400049 Diode 1N4148------T 1

VD971 0094400049 Diode 1N4148------T 1

VD972 0094400049 Diode 1N4148------T 1

R923 0094400049 Diode 1N4148------T 1

VD517 0094400328 Diode ES1------T 1

VD552 0094400328 Diode ES1------T 1

VD553 0094400329 Diode EU2Z------T 1

VD557 0094400329 Diode EU2Z------T 1

VD412 0094400329 Diode EU2Z------T 1

VD433 0094400388 Diode EM01Z------T 1

VD434 0094400388 Diode EM01Z------T 1

VD555 0094400331 Diode EU1C------T 1

VD554 0094400329 Diode EU2Z------T 1

VD556 0094401113 Diode RU3A------T 1

VD551 0094400358 Diode RD6.2EB3------T 1

VD261 0094400359 Diode RD5.1EB2------T 1

VD436 0094400359 Diode RD5.1EB2------T 1

VD922 0094400359 Diode RD5.1EB2------T 1

VD903 0094400360 Diode RD10EB1------T 1

VD921 0094400394 Diode RD3.6EL------T 1

VD901 0094400362 Diode RD5.6EB3------T 1

VD519 0094400397 Diode RD8.2EB3------T 1

V231 0094400460 Transistor 2SA1015(Y)------F 1

V251 0094400460 Transistor 2SA1015(Y)------F 1

V511 0094400460 Transistor 2SA1015(Y)------F 1

V631 0094400460 Transistor 2SA1015(Y)------F 1

V903 0094400460 Transistor 2SA1015(Y)------F 1

V925 0094400460 Transistor 2SA1015(Y)------F 1

V201 0094400461 Transistor 2SC1815(Y)------F 1

V211 0094400461 Transistor 2SC1815(Y)------F 1

V212 0094400461 Transistor 2SC1815(Y)------F 1

V551 0094400461 Transistor 2SC1815(Y)------F 1

V601 0094400461 Transistor 2SC1815(Y)------F 1

V611 0094400461 Transistor 2SC1815(Y)------F 1

V621 0094400461 Transistor 2SC1815(Y)------F 1

V922 0094400461 Transistor 2SC1815(Y)------F 1

V923 0094400461 Transistor 2SC1815(Y)------F 1

V924 0094400461 Transistor 2SC1815(Y)------F 1

V975 0094400461 Transistor 2SC1815(Y)------F 1

WC283 0094101102 Jumper φ0.6mm/5mm------B 1

W412 0094101102 Jumper φ0.6mm/5mm------B 1

W287 0094101102 Jumper φ0.6mm/5mm------B 1

V261 0094101102 Jumper φ0.6mm/5mm------B 1

V262 0094101102 Jumper φ0.6mm/5mm------B 1

V263 0094101102 Jumper φ0.6mm/5mm------B 1

Naterial Code parts Name Type Q'ty(Unit) Remark

41

Page 43

List of Parts

l

Location

WR295 0094101102 Jumper φ0.6mm/5mm------B 1

W101 0094101103 Jumper φ0.6mm/7.5mm------B 1

W102 0094101103 Jumper φ0.6mm/7.5mm------B 1

W103 0094101103 Jumper φ0.6mm/7.5mm------B 1

W104 0094101103 Jumper φ0.6mm/7.5mm------B 1

W105 0094101103 Jumper φ0.6mm/7.5mm------B 1

W106 0094101103 Jumper φ0.6mm/7.5mm------B 1

W204 0094101103 Jumper φ0.6mm/7.5mm------B 1

W205 0094101103 Jumper φ0.6mm/7.5mm------B 1

W211 0094101103 Jumper φ0.6mm/7.5mm------B 1

W212 0094101103 Jumper φ0.6mm/7.5mm------B 1

W214 0094101103 Jumper φ0.6mm/7.5mm------B 1

W218 0094101103 Jumper φ0.6mm/7.5mm------B 1

W219 0094101103 Jumper φ0.6mm/7.5mm------B 1

W232 0094101103 Jumper φ0.6mm/7.5mm------B 1

W253 0094101103 Jumper φ0.6mm/7.5mm------B 1

W254 0094101103 Jumper φ0.6mm/7.5mm------B 1

W263 0094101103 Jumper φ0.6mm/7.5mm------B 1

W264 0094101103 Jumper φ0.6mm/7.5mm------B 1

W265 0094101103 Jumper φ0.6mm/7.5mm------B 1

W268 0094101103 Jumper φ0.6mm/7.5mm------B 1

W411 0094101103 Jumper φ0.6mm/7.5mm------B 1

W267 0094101103 Jumper φ0.6mm/7.5mm------B 1

W422 0094101103 Jumper φ0.6mm/7.5mm------B 1

W432 0094101103 Jumper φ0.6mm/7.5mm------B 1

W433 0094101103 Jumper φ0.6mm/7.5mm------B 1

W435 0094101103 Jumper φ0.6mm/7.5mm------B 1

W436 0094101103 Jumper φ0.6mm/7.5mm------B 1

W437 0094101103 Jumper φ0.6mm/7.5mm------B 1

W438 0094101103 Jumper φ0.6mm/7.5mm------B 1

W463 0094101103 Jumper φ0.6mm/7.5mm------B 1

W553 0094101103 Jumper φ0.6mm/7.5mm------B 1

W554 0094101103 Jumper φ0.6mm/7.5mm------B 1

W555 0094101103 Jumper φ0.6mm/7.5mm------B 1

W558 0094101103 Jumper φ0.6mm/7.5mm------B 1

W559 0094101103 Jumper φ0.6mm/7.5mm------B 1

W562 0094101103 Jumper φ0.6mm/7.5mm------B 1

W601 0094101103 Jumper φ0.6mm/7.5mm------B 1

W602 0094101103 Jumper φ0.6mm/7.5mm------B 1

W604 0094101103 Jumper φ0.6mm/7.5mm------B 1

W605 0094101103 Jumper φ0.6mm/7.5mm------B 1

W701 0094101103 Jumper φ0.6mm/7.5mm------B 1

W905 0094101103 Jumper φ0.6mm/7.5mm------B 1

W906 0094101103 Jumper φ0.6mm/7.5mm------B 1

W916 0094101103 Jumper φ0.6mm/7.5mm------B 1

W917 0094101103 Jumper φ0.6mm/7.5mm------B 1

W918 0094101103 Jumper φ0.6mm/7.5mm------B 1

W921 0094101103 Jumper φ0.6mm/7.5mm------B 1

W929 0094101103 Jumper φ0.6mm/7.5mm------B 1

W930 0094101103 Jumper φ0.6mm/7.5mm------B 1

Naterial Code parts Name Type Q'ty(Unit) Remark

42

Page 44

List of Parts

l

Location

W931 0094101103 Jumper φ0.6mm/7.5mm------B 1

W932 0094101103 Jumper φ0.6mm/7.5mm------B 1

W933 0094101103 Jumper φ0.6mm/7.5mm------B 1

W953 0094101103 Jumper φ0.6mm/7.5mm------B 1

W954 0094101103 Jumper φ0.6mm/7.5mm------B 1

W955 0094101103 Jumper φ0.6mm/7.5mm------B 1

W956 0094101103 Jumper φ0.6mm/7.5mm------B 1

W957 0094101103 Jumper φ0.6mm/7.5mm------B 1

W958 0094101103 Jumper φ0.6mm/7.5mm------B 1

W959 0094101103 Jumper φ0.6mm/7.5mm------B 1

WC422 0094101103 Jumper φ0.6mm/7.5mm------B 1

WC416 0094101103 Jumper φ0.6mm/7.5mm------B 1

WR971 0094101103 Jumper φ0.6mm/7.5mm------B 1

WR972 0094101103 Jumper φ0.6mm/7.5mm------B 1

WL411 0094101103 Jumper φ0.6mm/7.5mm------B 1

W207 0094101104 Jumper φ0.6mm/10mm------B 1

W220 0094101104 Jumper φ0.6mm/10mm------B 1

W221 0094101104 Jumper φ0.6mm/10mm------B 1

W222 0094101104 Jumper φ0.6mm/10mm------B 1

W223 0094101104 Jumper φ0.6mm/10mm------B 1

W225 0094101104 Jumper φ0.6mm/10mm------B 1

W231 0094101104 Jumper φ0.6mm/10mm------B 1

W238 0094101104 Jumper φ0.6mm/10mm------B 1

W251 0094101104 Jumper φ0.6mm/10mm------B 1

W260 0094101104 Jumper φ0.6mm/10mm------B 1

W266 0094101104 Jumper φ0.6mm/10mm------B 1

W285 0094101104 Jumper φ0.6mm/10mm------B 1

W289 0094101104 Jumper φ0.6mm/10mm------B 1

W413 0094101104 Jumper φ0.6mm/10mm------B 1

W430 0094101104 Jumper φ0.6mm/10mm------B 1

W440 0094101104 Jumper φ0.6mm/10mm------B 1

W504 0094101104 Jumper φ0.6mm/10mm------B 1

W556 0094101104 Jumper φ0.6mm/10mm------B 1

W560 0094101104 Jumper φ0.6mm/10mm------B 1

W606 0094101104 Jumper φ0.6mm/10mm------B 1

W904 0094101104 Jumper φ0.6mm/10mm------B 1

W908 0094101104 Jumper φ0.6mm/10mm------B 1

W910 0094101104 Jumper φ0.6mm/10mm------B 1

W915 0094101104 Jumper φ0.6mm/10mm------B 1

W922 0094101104 Jumper φ0.6mm/10mm------B 1

W927 0094101104 Jumper φ0.6mm/10mm------B 1

W928 0094101104 Jumper φ0.6mm/10mm------B 1

W951 0094101104 Jumper φ0.6mm/10mm------B 1

W952 0094101104 Jumper φ0.6mm/10mm------B 1

W980 0094101104 Jumper φ0.6mm/10mm------B 1

WL201 0094101104 Jumper φ0.6mm/10mm------B 1

WL202 0094101104 Jumper φ0.6mm/10mm------B 1

WL262 0094101104 Jumper φ0.6mm/10mm------B 1

WL510 0094101104 Jumper φ0.6mm/10mm------B 1

WL601 0094101104 Jumper φ0.6mm/10mm------B 1

Naterial Code parts Name Type Q'ty(Unit) Remark

43

Page 45

List of Parts

l

Location

WL941 0094101104 Jumper φ0.6mm/10mm------B 1

WR921 0094101104 Jumper φ0.6mm/10mm------B 1

WR978 0094101104 Jumper φ0.6mm/10mm------B 1

W234 0094101105 Jumper φ0.6mm/12.5mm------B 1

W236 0094101105 Jumper φ0.6mm/12.5mm------B 1

W261 0094101105 Jumper φ0.6mm/12.5mm------B 1

W603 0094101105 Jumper φ0.6mm/12.5mm------B 1

W900 0094101105 Jumper φ0.6mm/12.5mm------B 1

W902 0094101105 Jumper φ0.6mm/12.5mm------B 1

W907 0094101105 Jumper φ0.6mm/12.5mm------B 1

W923 0094101105 Jumper φ0.6mm/12.5mm------B 1

W924 0094101105 Jumper φ0.6mm/12.5mm------B 1

W925 0094101105 Jumper φ0.6mm/12.5mm------B 1

W926 0094101105 Jumper φ0.6mm/12.5mm------B 1

W981 0094101105 Jumper φ0.6mm/12.5mm------B 1

W982 0094101105 Jumper φ0.6mm/12.5mm------B 1

W983 0094101105 Jumper φ0.6mm/12.5mm------B 1

W984 0094101105 Jumper φ0.6mm/12.5mm------B 1

WR250 0094101105 Jumper φ0.6mm/12.5mm------B 1

WR570 0094101105 Jumper φ0.6mm/12.5mm------B 1

WR916 0094101105 Jumper φ0.6mm/12.5mm------B 1

W224 0094101106 Jumper φ0.6mm/15mm------B 1

W235 0094101106 Jumper φ0.6mm/15mm------B 1

W286 0094101106 Jumper φ0.6mm/15mm------B 1

W503 0094101106 Jumper φ0.6mm/15mm------B 1

W901 0094101106 Jumper φ0.6mm/15mm------B 1

W911 0094101106 Jumper φ0.6mm/15mm------B 1

W912 0094101106 Jumper φ0.6mm/15mm------B 1

WR412 0094101106 Jumper φ0.6mm/15mm------B 1

WR569 0094101106 Jumper φ0.6mm/15mm------B 1

WR911 0094101106 Jumper φ0.6mm/15mm------B 1

WR411 0094101106 Jumper φ0.6mm/15mm------B 1

W903 0094101150 Jumper φ0.6mm/20mm------B 1

VD503(2 0090100079 Rivet φ1.6mm*3.0mm 2

VD504(2 0090100079 Rivet φ1.6mm*3.0mm 2

VD505(2 0090100079 Rivet φ1.6mm*3.0mm 2

VD506(2 0090100079 Rivet φ1.6mm*3.0mm 2

T501(6) 0090100079 Rivet φ1.6mm*3.0mm 6

T402(5) 0090100079 Rivet φ1.6mm*3.0mm 5

L414(3) 0090100079 Rivet φ1.6mm*3.0mm 3

PS501(3) 0090100079 Rivet φ1.6mm*3.0mm 3

V513(5) 0090100078 Rivet φ2.3mm*3.0mm 5

V411(5) 0090100078 Rivet φ2.3mm*3.0mm 5

C507(2) 0090100078 Rivet φ2.3mm*3.0mm 2

R502(2) 0090100078 Rivet φ2.3mm*3.0mm 2

R550 0094101006 Resister RF10-1W-1Ω±5%-15-C-A 1

R558 0094101006 Resister RF10-1W-1Ω±5%-15-C-A 1

R910 0094101290 Resister RF10-1W-1Ω±5%-17-C-A 1

R630 0094101295 Resister RF10-2W-3.9Ω±5%-20-C-A 1

R445 0094101010 Resister RY16-1W-1.8Ω±5%-15-C-A 1

Naterial Code parts Name Type Q'ty(Unit) Remark

44

Page 46

List of Parts

l

Location

R413 0094101291 Resister RY16-1W-1KΩ±5%-12-C-A 1

R525 0094100972 Resister RY17-2W-68Ω±5%-20-C-A 1

R437 0094100719 Resister RY17-2W-270Ω±5%-20-C-A 1

R939 0094100719 Resister RY17-2W-270Ω±5%-20-C-A 1

R553 0094101011 Resister RY17-2W-12KΩ±5%-20-C-A 1

R563 0094101011 Resister RY17-2W-12KΩ±5%-20-C-A 1

R606 0094101011 Resister RY17-2W-12KΩ±5%-20-C-A 1

R616 0094101011 Resister RY17-2W-12KΩ±5%-20-C-A 1

R626 0094101011 Resister RY17-2W-12KΩ±5%-20-C-A 1

R904 0094101292 Resister RY18-3W-27Ω±5%-30-C-A 1

R936 0094101012 Resister RY18-3W-27Ω±5%-25-C-A 1

R524 0094101296 Resister RX27-3A-6W-27Ω±5% 1

R502 0094101297 Resister RX27-3A-6W-1.8Ω±5% 1

R414 0094101294 Resister RX27-3A-6W-10Ω±10% 1

PS501 0094400296 Resister MZ73L18RM270 1

RP551 0094100979 Varistor W206-2AL-2kΩ 1

C925 0094201771 Capacitor CC1-06-CH-63V-22PF-05-C-A 1

C924 0094201369 Capacitor CC1-08-CH-63V-120PF-J-07-C-A 1

C213 0094201370 Capacitor CT1-05-2B4-63V-220PF-K-05-C-A 1

C915 0094201721 Capacitor CT1-05-2B4-63V-270PF-K-15-C-A 1

C448 0094201371 Capacitor CT1-06-2B4-63V-560PF-K-05-C-A 1

C270 0094201259 Capacitor CT1-08-2F4-63V-0.01μF-K-05-C-A 1

C503 0094201372 Capacitor CT81-10-2B4-1KV-1000PF-K-10-C-A 1

C504 0094201372 Capacitor CT81-10-2B4-1KV-1000PF-K-10-C-A 1

C505 0094201372 Capacitor CT81-10-2B4-1KV-1000PF-K-10-C-A 1

C506 0094201372 Capacitor CT81-10-2B4-1KV-1000PF-K-10-C-A 1

C553 0094201055 Capacitor CT81-10B-2B4-1KV-470PF-K-07-C-A 1

C554 0094201055 Capacitor CT81-10B-2B4-1KV-470PF-K-07-C-A 1

C555 0094201055 Capacitor CT81-10B-2B4-1KV-470PF-K-07-C-A 1

C560 0094201055 Capacitor CT81-10B-2B4-1KV-470PF-K-07-C-A 1

C630 0094201061 Capacitor CT81-10B-2B4-2KV-2200PF-K-10-C-A 1

C556 0094201056 Capacitor CT81-10B-2B4-2KV-220PF-K-07-C-A 1

AW414 0094201217 Capacitor CT81-10-2B4-2KV-470PF-K-07-C-A 1

C516 0094201373 Capacitor CT81-10-2B4-2KV-680PF-K-07-C-A 1

VD415 0094201722 Capacitor CT81-10-2B4-2KV-470PF-K-20-J-A 1

C534 0094200841 Capacitor DE0910B471K-KX-10-C-A 1

C535 0094200840 Capacitor DE0910E102M-KX-10-C-A 1

C207 0094202149 Capacitor CD110-16V-10μF-M-05-F-A 1

C218 0094201375 Capacitor CD110-16V-22μF-M-05-F-A 1

C235 0094201376 Capacitor CD110-16V-100μF-M-07-F-A 1

C932 0094200937 Capacitor CD265-16V-470uF-M-05-G-A 1

C706 0094201009 Capacitor CD110-25V-470μF-M-05-E-A 1

C433 0094201011 Capacitor CD110-25V-1000μF-M-05-E-A 1

C552 0094201011 Capacitor CD110-25V-1000μF-M-05-E-A 1

C557 0094201011 Capacitor CD110-25V-1000μF-M-05-E-A 1

C559 0094201065 Capacitor CD110-35V-330μF-M-05-E-A 1

C565 0094201016 Capacitor CD110-35V-1000μF-M-05-E-A 1

C231 0094201066 Capacitor CD110-50V-0.47μF-M-05-F-A 1

C973 0094201287 Capacitor CD110-50V-2.2μF-M-05-F-A 1

C421 0094201377 Capacitor CD71-50V-4.7μF-M-05-F-A 1

Naterial Code parts Name Type Q'ty(Unit) Remark

45

Page 47

List of Parts

l

Location

C101 0094201251 Capacitor CD110-50V-4.7μF-M-05-F-A 1

C563 0094201389 Capacitor CD288-160V-330μF-M-05-E-A 1

C562 0094202156 Capacitor CD287-250V-22μF-M-05-E-A 1

C507 0094201723 Capacitor CD293-450V-150μF-M-10-G-A 1

C703 0094201379 Capacitor CL11-50V-4700PF-J-05-C-A 1

C414 0094201380 Capacitor CL21X-50V-0.47μF-K-07-C-A 1

C445 0094201381 Capacitor CL21X-50V-0.047μF-K-05-C-A 1

C102 0094201104 Capacitor CL21X-50V-0.1uF-F5-K-05-C-A 1

C412 0094201665 Capacitor CBB21-400V-0.39μF-J-20-B-A 1

C501 0094201120 Capacitor CL21-AC250V-0.22μF-K-20-B-A 1

C502 0094201120 Capacitor CL21-AC250V-0.22μF-K-20-B-A 1

C415 0094201384 Capacitor CBB81-1600V-7500PF-J-20-B-A 1

L412 0094500325 Inducer ZZ0008-15-A-A 1

L414 0094500376 Inducer LX038 1

T101 0094500394 Inducer A-TL13 1

T211 0094500377 Inducer A-TX17 1

VD515 0094400036 photo coupler PC817B 1

VD503 0094400474 Diode RM11C-15-V-- 1

VD504 0094400474 Diode RM11C-15-V-- 1

VD505 0094400474 Diode RM11C-15-V-- 1

VD506 0094400474 Diode RM11C-15-V-- 1

D902 0094400636 IC CAT24C08P 1

N101 0094400314 IC LA7910 1

D901 0094400869 IC 87CM38N-3D27(V2.0) 1

N201 0094400343 IC TB1238AN 1

N202 0094400138 IC TC4052BP 1

N251 0094400757 IC TA1275AZ 1

N904 0094400437 Diode UPC574J 1

V921 0094400441 Transistor 2SB764(E)----D-A 1

V552 0094400442 Transistor 2SB892(S)----D-A 1

V101 0094400660 Transistor 2SC2216(O)------F 1

V444 0094400446 Transistor 2SC2383(O)----D-A 1

V602 0094400569 Transistor 2SC2688(K)----E-A 1

V612 0094400569 Transistor 2SC2688(K)----E-A 1